weight MAZDA PROTEGE 1992 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 81 of 1164

DISASSEMBLY Bl

23UOBl-03

05UOBX-1’ 9

23UOBl-040

03UOBl-08 5

Disassembly Note

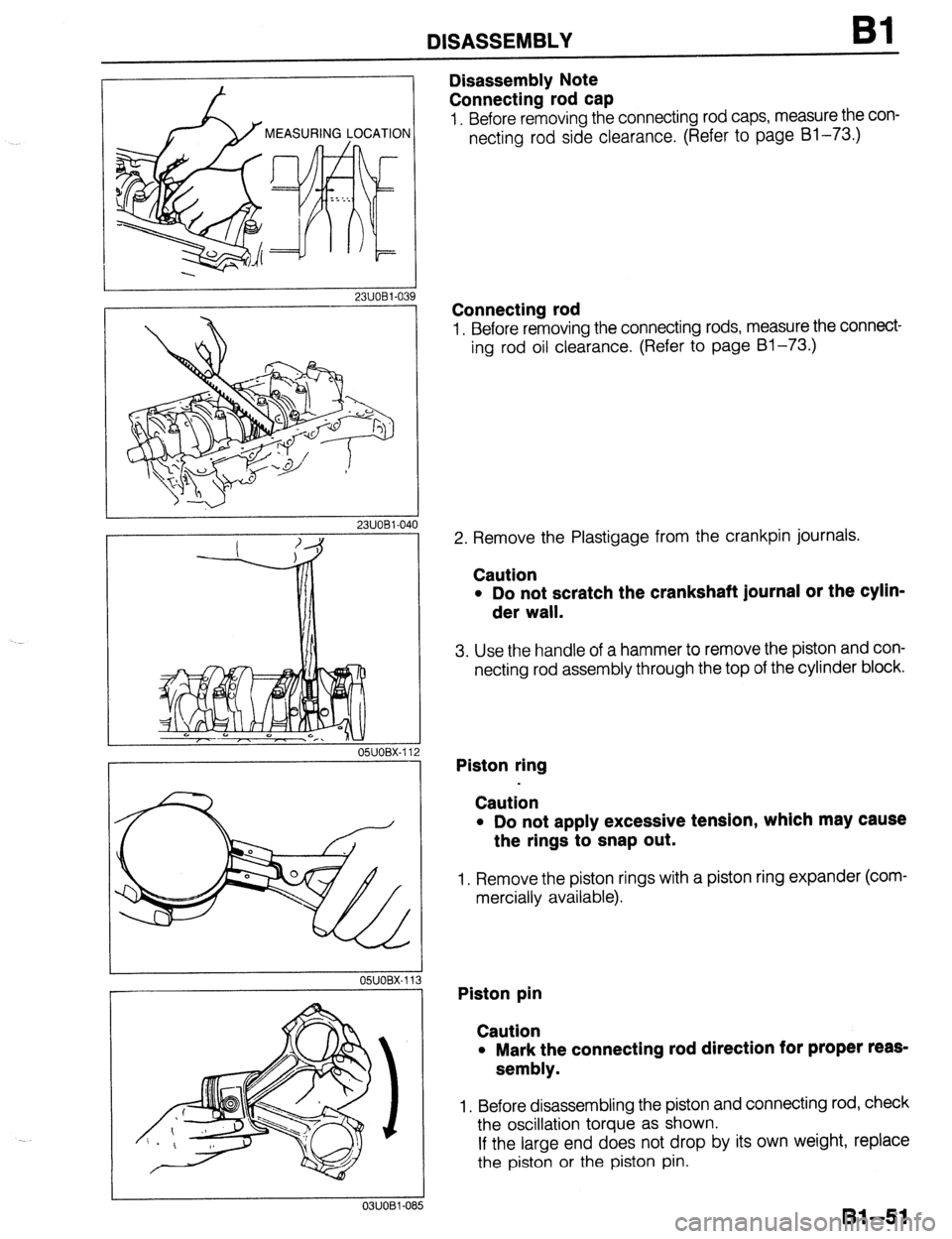

Connecting rod cap

1. Before removing the connecting rod caps, measure the con-

necting rod side clearance. (Refer to page Bl-73.)

Connecting rod

1. Before removing the connecting rods, measure the connect-

ing rod oil clearance. (Refer to page Bl-73.)

2. Remove the Plastigage from the crankpin journals.

Caution

l Do not scratch the crankshaft journal or the cylin-

der wall.

3. Use the handle of a hammer to remove the piston and con-

necting rod assembly through the top of the cylinder block.

Piston ring

Caution

l Do not apply excessive tension, which may cause

the rings to snap out.

1. Remove the piston rings with a piston ring expander (com-

mercially available).

Piston pin

Caution

l Mark the connecting rod direction for proper reas-

sembly.

1. Before disassembling the piston and connecting rod, check

the oscillation torque as shown.

If the large end does not drop by its own weight, replace

the piston or the piston pin.

81-51

Page 201 of 1164

ASSEMBLY

2311082-04

05UOBX-17

OSUOBX-17

SPACER TANG

OIL RING

SPACER ENDS

-I

a

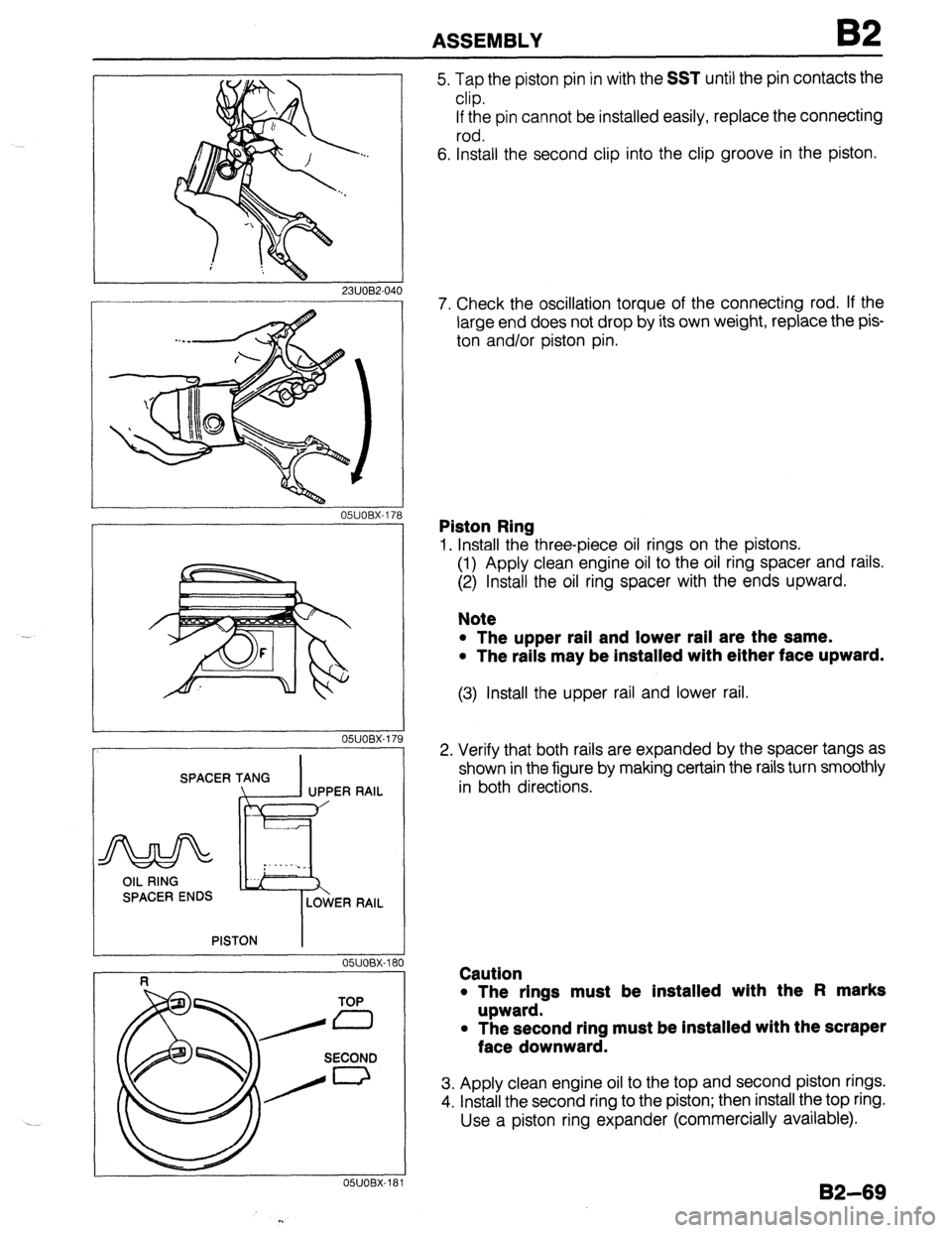

5. Tap the piston pin in with the SST until the pin contacts the

clip.

If the pin cannot be installed easily, replace the connecting

rod.

6. Install the second clip into the clip groove in the piston.

7. Check the oscillation torque of the connecting rod. If the

large end does not drop by its own weight, replace the pis-

ton and/or piston pin.

Piston Ring

1. Install the three-piece oil rings on the pistons.

(1) Apply clean engine oil to the oil ring spacer and rails.

(2) Install the oil ring spacer with the ends upward.

Note

l The upper rail and lower rail are the same.

l The rails may be installed with either face upward.

(3) Install the upper rail and lower rail.

2. Verify that both rails are expanded by the spacer tangs as

shown in the figure by making certain the rails turn smoothly

in both directions.

Caution

l The rings must be installed with the Fl marks

upward.

l The second ring must be installed with the scraper

face downward.

3. Apply clean engine oil to the top and second piston rings.

4. install the second ring to the piston; then install the top ring.

Use a piston ring expander (commercially available).

132-69

Page 706 of 1164

WHEELS AND TIRES

L 13UOQX-005

FRONT

13UOQX-006

G=a I) OUTSIDE

BALANC

WEIGHT

REMOVAL / INSTALLATION

1. The wheel-to-hub contact surfaces must be clean.

2. Tighten the lug nuts to the specified torque.

Tightening torque:

88-l 18 N-m (9-12 m-kg, 85-87 ft-lb)

Caution

l When reinstalling a wheel, retighten the lug nuts to

the specified torque after about 1,000 km (820 miles)

driving.

TIRE ROTATION

To prolong tire life and assure uniform tire wear, rotate the tires

from every 3,000 km (1,860 miles) to every 6,000 km (3,720

miles).

Caution

l Do not include “TEMPORARY USE ONLY” spare tire

in rotation.

l Use the best tires on the front axle.

l After rotating the tires, adjust each tire to the speci-

fied air pressure. (Refer to page Q-3.)

WHEEL BALANCE ADJUSTMENT

If a wheel becomes unbalanced or if a tire is replaced or

repaired, the wheel must be rebalanced to within specification.

Maximum unbalance (at rim edge)

13 inch wheel: 11 g (0.39 oz)

14 inch wheel: 10 g (0.35 or)

Caution

l Do not use more than two balance weights on the

inner or outer side of the wheel.

l If the total weight exceeds 1OOg (3.5 oz) perslde,

rebalance after moving the tire around on the rim.

l Attach the balance weights tightly on the wheel.

l Select suitable balance weights for steel or alumi-

num alloy wheels.

l Do not use an on-car balancer on automatic trans-

axle models; it may cause transaxle damage.

.__’

Q-6