ignition MAZDA PROTEGE 1992 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 3 of 1164

GENERAL INFORMATION

IMPORTANT INFORMATION ..................... GI- 2

BASIC ASSUMPTIONS ............................ GI- 2

SAFETY RISK ........................................ GI- 2

POSSIBLE LOSS OF WARRANTY ............. GI- 2

WARNING ON LUBRICANTS

AND GREASES .................................... GI- 2

HOW TO USE THIS MANUAL.. .................. GI- 3

PREPARATION ...................................... GI- 3

REPAIR PROCEDURE ............................. GI- 3

SYMBOLS ............................................. GI- 4

NOTES, CAUTIONS, AND WARNINGS.. ..... GI- 4

FUNDAMENTAL PROCEDURES.. ............... GI- 4

PROTECTION OF THE VEHICLE .............. GI- 4

A WORD

ABOUT SAFETY ....................... GI- 5

PREPARATION OF TOOLS

AND MEASURING EQUIPMENT.. ........... GI- 5

SPECIAL TOOLS .................................... GI- 5

REMOVAL OF PARTS ............................. GI- 5

DISASSEMBLY ...................................... GI- 5

REASSEMBLY ....................................... GI- 6

ADJUSTMENTS ..................................... GI- 7

RUBBER

PARTS AND TUBING ................

GI- 7

JACK AND SAFETY STAND POSITIONS.. .. GI- 6

VEHICLE LIFT (P-SUPPORT TYPE)

POSITIONS ............................................ GI- 6

TOWING .................................................. GI- 9

IDENTIFICATION NUMBER LOCATIONS ..... 61-10

UNITS ..................................................... GI-10

ABBREVIATIONS ..................................... GI-10

CAUTION ................................................ GI-1 1

INSTALLATION OF MOBILE

TWO-WAY RADIO SYSTEM .................... GI-11

REMOVAL OF IGNITION KEY ON

AUTOMATIC TRANSAXLE MODEL.. ........

GI-1 1

ELECTRICAL TROUBLESHOOTING TOOLS GI-12

CAUTION WITH ELECTRICAL PARTS ........

GI-13

03UGIX-001

Page 11 of 1164

TOWING

.-

WHEEL dOLLlES

03UGIX-00

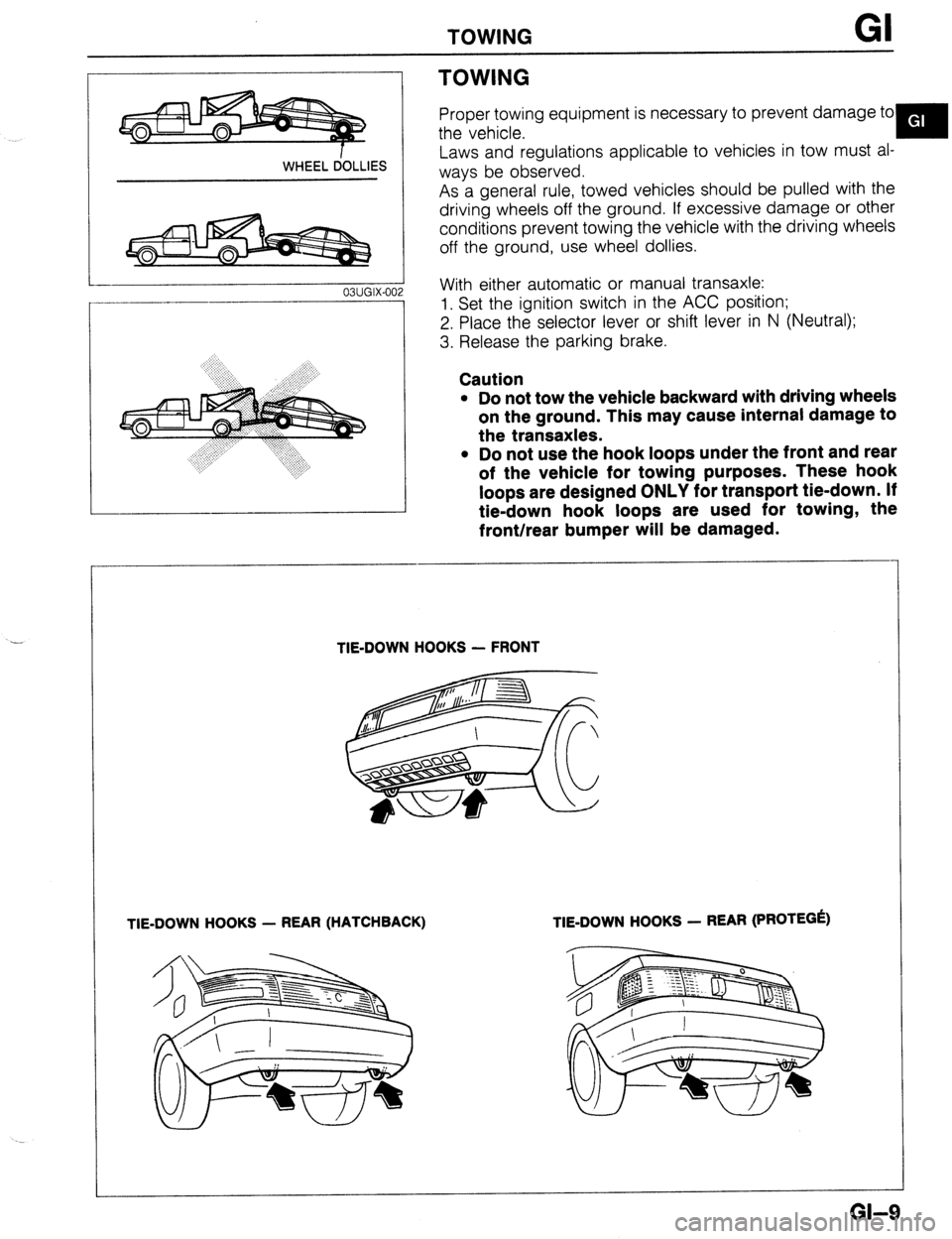

TOWING

Proper towing equipment is necessary to prevent damage to

the vehicle.

Y

Laws and regulations applicable to vehicles in tow must al-

ways be observed.

As a general rule, towed vehicles should be pulled with the

driving wheels off the ground. If excessive damage or other

conditions prevent towing the vehicle with the driving wheels

off the ground, use wheel dollies.

With either automatic or manual transaxle:

1. Set the ignition switch in the ACC position;

2. Place the selector lever or shift lever in N (Neutral);

3. Release the parking brake.

Caution

l Do not tow the vehicle backward with driving wheels

on the ground. This may cause internal damage to

the transaxles.

l Do not use the hook loops under the front and rear

of the vehicle for towing purposes. These hook

loops are designed ONLY for transport tie-down. If

tie-down hook loops are used for towing, the

front/rear bumper will be damaged.

TIE-DOWN HOOKS - FRONT

TIE-DOWN HOOKS - REAR (HATCHBACK) TIE-DOWN HOOKS - REAR (PROTEGk)

GI-9

Page 12 of 1164

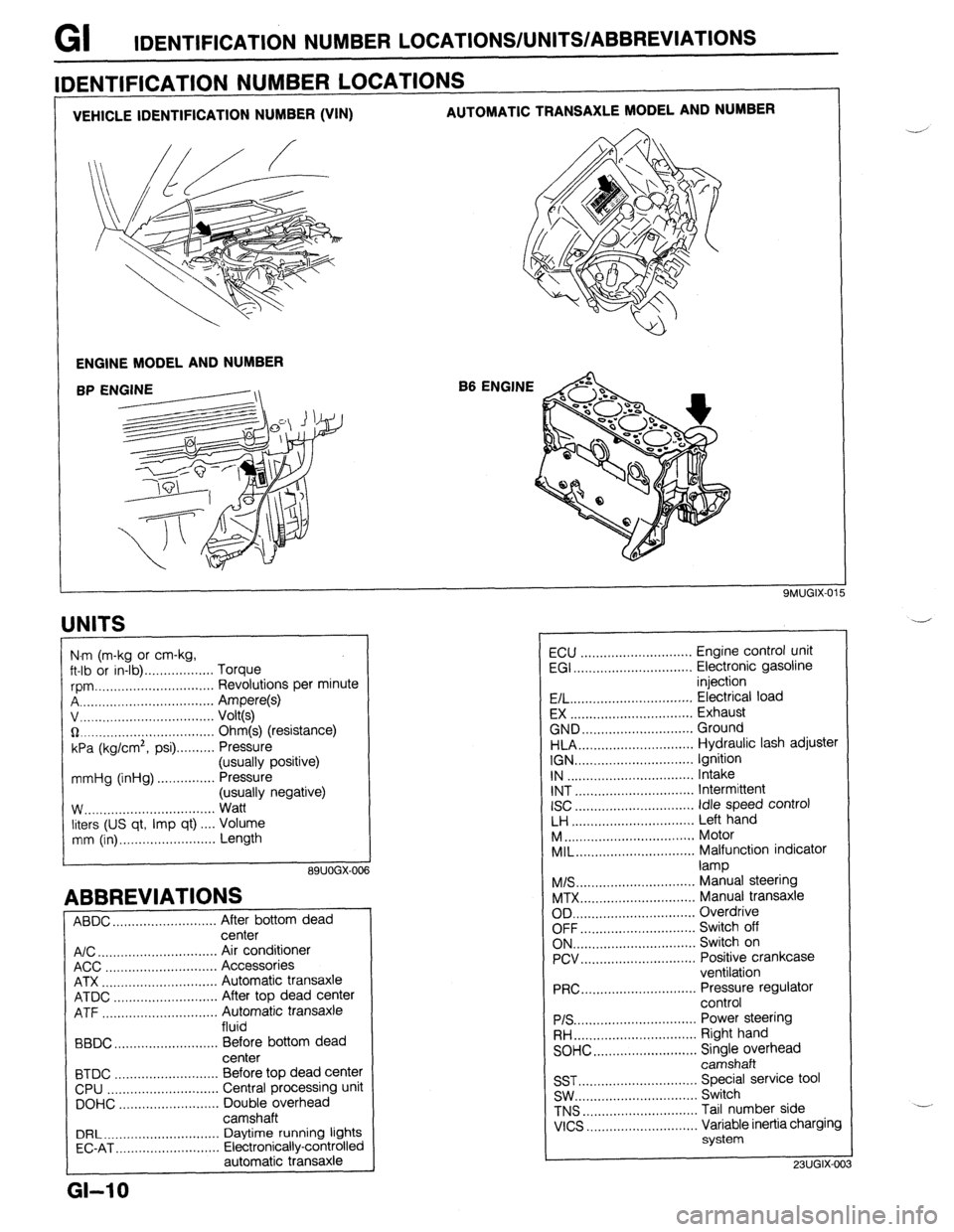

GI IDENTIFICATION NUMBER LOCATIONS/UNITS/ABBREVlATlONS

VEHICLE IDENTIFICATION NUMBER (VIN) AUTOMATIC TRANSAXLE MODEL AND NUMBER

ENGINE MODEL AND NUMBER

B6 ENGINE

IDENTIFICATION NUMBER LOCATIONS

UNITS

I

N.m (m-kg or cm-kg,

ft-lb or in-lb) . . . . . . . . . . . . . . . . . . Torque

rpm ._..,,,.............,.......... Revolutions per minute

A . . . . . . . . . . . . . . . . . Ampere(s)

v, . . . . . . . . . . . . . .

Volt(s)

$2 _....._..,......................... Ohm(s) (resistance)

kPa (kg/cm2,

psi) . . . . . . . . . . Pressure

(usually positive)

mmHg (inHg) . . . . . . . . . . . . . . . Pressure

(usually negative)

W.. . . . . . . . . . . .

Watt

liters (US qt, Imp qt) ,... Volume

mm (in) ..,......,...,........... Length

89UOGX-00

ABBREVIATIONS

ABDC . . . . . . . . . . . . . . . . . . . . .

After bottom dead

center

A/C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air conditioner

ACC ..,.,...... 3 . . . . . . . . . . . . . . . . . Accessories

ATX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Automatic transaxle

ATDC ..,,...,...,............... After top dead center

ATF . . . . . . . . . . . . . . . . . Automatic transaxle

fluid

BBDC ,,..,.......,...,......,... Before bottom dead

center

BTDC .,......,...............,.. Before top dead center

CPU ..,,.......,...,..........,.. Central processing unit

DOHC ..,...,..,............,,.. Double overhead

camshaft

DRL ____.......................... Daytime running lights

EC-AT .,_.......,............,,.. Electronically-controlled

automatic transaxle

L

GI-10

ECU ............................. Engine control unit

EGI ............................... Electronic gasoline

injection

E/L.. .............................. Electrical load

EX ................................ Exhaust

GND.. ........................... Ground

HLA.. ............................ Hydraulic lash adjuster

IGN ............................... Ignition

IN ................................. Intake

INT ............................... Intermittent

ISC

............................... idle speed control

LH ................................ Left hand

M..

................................ Motor

MIL..

............................. Malfunction indicator

lamp

M/S..

............................. Manual steering

MTX.. ............................ Manual transaxle

OD ................................ Overdrive

OFF.. ............................ Switch off

ON.. .............................. Switch on

PCV.. ............................ Positive crankcase

ventilation

PRC..

............................ Pressure regulator

control

PIS ................................ Power steering

RH..

.............................. Right hand

SOHC.. .........................

z;;kiprhead

SST ............................... Special service tool

SW.. .............................. Switch

TNS

.............................. Tail number side

VICS

............................. Variable inertia charging

system

23UGIX-00

Page 13 of 1164

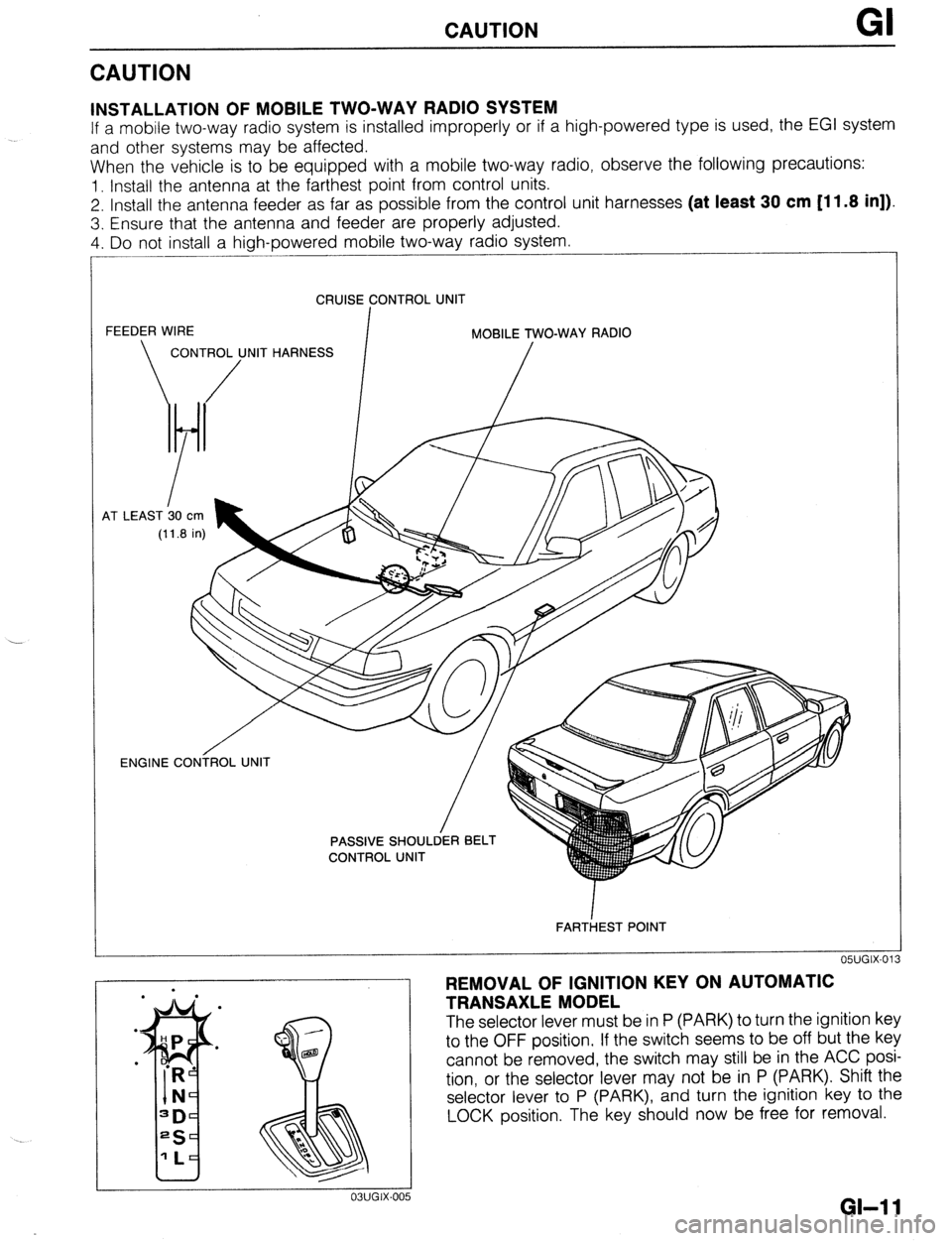

CAUTION GI

CAUTION

INSTALLATION OF MOBILE TWO-WAY RADIO SYSTEM

If a mobile two-way radio system is installed improperly or if a high-powered type is used, the EGI system

and other systems may be affected.

When the vehicle is to be equipped with a mobile two-way radio, observe the following precautions:

1. Install the antenna at the farthest point from control units.

2. Install the antenna feeder as far as possible from the control unit harnesses (at least 30 cm [11.8 in]).

3. Ensure that the antenna and feeder are properly adjusted.

4. Do not install a high-powered mobile two-way radio system.

CRUISE CONTROL UNIT

FEEDER WIRE

I MOBILE TWO-WAY RADIO

CONTROL UNIT HARNESS

/ /

4T LEAST b0

cm

(11.8 in)

OWGIX-013 ENGINE CONiROL UNIT

/

FARTiEST POINT

REMOVAL OF IGNITION KEY ON AUTOMATIC

TRANSAXLE MODEL

The selector lever must be in P (PARK) to turn the ignition key

to the OFF position. If the switch seems to be off but the key

cannot be removed, the switch may still be in the ACC posi-

tion, or the selector lever may not be in P (PARK). Shift the

selector lever to P (PARK), and turn the ignition key to the

LOCK position. The key should now be free for removal.

GI-1 1

Page 20 of 1164

PRE-DELIVERY INSPECTION

PRE-DELIVERY INSPECTION

PRE-DELIVERY INSPECTION TABLE

Following items may be done at any time prior to delivery to your customer.

INSPECT and ADJUST, if necessary, the following items to

the specifications:

0 Glass, exterior bright metal and paint for damage

Cl Wheel lug nuts, and locks (if equipped)

88-118 N.m (9-12 m-kg, 65-87 ft-lb)

q All weatherstrips for damage or detachment

0 Operation of hood release and lock

0 Operation of trunk lid, rear hatch, and fuel lid opener

Cl With trunk open, check for spare jack, tire, tools, and

fasteners securing these items in place.

Cl Door operation and alignment

Cl Headlight aim

INSTALL the following parts:

Cl Wheel caps or rings (if equipped)

q Outside rearview mirror(s)

1 UNDER HOOD-ENGINE OFF )

INSPECT and ADJUST, if necessary, the following items to

the specifications:

0 Fuel, coolant and hydraulic lines, fittings, connections and

components for leaks

Cl Engine oil level

0 Power steering fluid level

0 Brake and clutch master cylinder fluid level

El Windshield washer reservoir fluid level

Cl Radiator coolant level

Cl Tightness of battery terminals

Cl Manual transaxle oil level

riizmiq

INSTALL the following parts:

Cl Rubber stopper for inside rearview mirror

CHECK operation of the following items:

0 Seat controls (sliding and reclining) and head restraint

Cl Folding rear seat

0 Door locks, including childproof door locks (if equipped)

Seat belts and warning system

Cl Ignition switch and steering lock

0 Inhibitor switch (ATX only)

U Starter interlock switch (clutch pedal, MTX only)

Cl All lights, including warning and indicator lamps

Cl Sound warning system

Cl Horn, wipers and washers (front and rear, if equipped)

0 Audio system (if equipped) 0 Cigarette lighter and clock

0 Sunroof (if equipped)

II Remote control outside rearview mirrors (if equipped)

Cl Power windows (if equipped)

q Heater, defroster and air conditioner at various mode

selections (if equipped)

CHECK the following items:

Cl Presence of spare fuse

0 Upholstery and interior finish

CHECK and ADJUST, if necessary, the following items:

0 Pedal height and free play of brake and clutch pedal

Pedal height mm (in) Free play mm (in)

0 Parking brake

5-7 notches/98 N (10 kg, 22lb)

UNDER HOOD-ENGINE RUNNING AT

OPERATING TEMPERATURE

CHECK the following items:

q Automatic transaxle fluid level

[I

CHECK the following items:

Cl Underside fuel, coolant and hydraulic lines, fittings, con-

nections and components for leaks

0 Tires for cuts or bruises

0 Steering linkage, suspension, exhaust system and all un-

derside hardware for looseness or damage

[I

CHECK the following items:

0 Brake operation

0 Clutch operation

Cl Steering control

Cl Operation of gauges

q Squeaks, rattles or unusual noise

Cl Emergency locking retractors

0 Cruise control system (if equipped)

1 AFTER ROAD TEST (

CHECK for necessary owner information materials.

Following items must be done just before the delivery to your customer.

q Load test battery and charge if necessary

1 Volts 1 0 Install fuses for accessories

i.. _

0 Adjust tire pressure to the specification

Load test result cl Remove seat and floor mat protective covers

(Refer to door label) 0 Vacuum and clean interior of vehicle

0 Clean outside of vehicle q Inspect installation of option parts with invoice

23UOAX-002

A-2

Page 31 of 1164

Bl

ENGINE

(SOHC)

INDEX .......................................... Bl- 2

OUTLINE ...................................... Bl- 3

SPECIFICATIONS ........................

Bl- 3

TROUBLESHOOTING GUIDE ..........

Bl- 3

ENGINE TUNE-UP PROCEDURE ......

Bl- 5

PREPARATION ............................ Bl- 5

ENGINE OIL ............................... Bl- 5

ENGINE COOLANT.. ....................

Bl- 5

DRIVE BELT ............................... Bl- 5

HLA .......................................... Bl- 7

IGNITION TIMING, IDLE SPEED

..... Bl- 8

COMPRESSION ............................. Bl-10

INSPECTION ............................... 81-10

ON-VEHICLE

MAINTENANCE.. ........

Bl-1 1

PREPARATION ............................ Bl-11

TIMING BELT .............................. Bl-12

CYLINDER

HEAD GASKET ........... Bl-16

HLA .......................................... Bl-20

FRONT OIL SEAL.. ...................... 81-23

REAR OIL SEAL ..........................

Bl-25

REMOVAL ..................................... 81-28

PROCEDURE .............................. Bl-28

ENGINE STAND MOUNTING.. .........

Bl-35

PREPARATION

............................ 81-35

PROCEDURE ..............................

Bl-36

DISASSEMBLY .............................. Bl-38

PREPARATION ............................ Bl-38

AUXILIARY PARTS.. ..................... 81-40

TIMING BELT .............................. 81-41

CYLINDER HEAD.. ......................

81-43

CYLINDER BLOCK

(EXTERNAL PARTS)

................... 81-47

CYLINDER BLOCK

(INTERNAL

PARTS). ................... Bl-50 INSPECTION /

REPAIR.. .................

81-54

PREPARATION ............................ Bl-54

CYLINDER HEAD.. ...................... Bl-54

VALVE

MECHANISM.. .................. Bl-55

CAMSHAFT ................................ 81-58

HLA .......................................... Bl-60

CYLINDER BLOCK ......................

Bl-60

OIL JET ..................................... Bl-61

PISTON, PISTON RING, AND

PISTON PIN .............................. Bl-62

CONNECTING ROD.. ...................

Bl-63

CRANKSHAFT ............................ Bl-64

BEARING ................................... 81-64

TIMING BELT .............................. Bl-65

TENSIONER,

IDLER.. ................... 81-65

TENSIONER SPRING ...................

81-65

PULLEY ..................................... Bl-65

ASSEMBLY ................................... Bl-66

PREPARATION ............................ Bl-66

CYLINDER BLOCK

(INTERNAL PARTS). ................... Bl-68

CYLINDER BLOCK

(EXTERNAL PARTS) ...................

Bl-74

CYLINDER

HEAD.. ...................... 81-79

TIMING BELT .............................. Bl-86

AUXILIARY

PARTS.. ..................... Bl-89

ENGINE STAND DISMOUNTING.. .... Bl-92

PROCEDURE .............................. 81-92

INSTALLATION ............................. 81-94

PROCEDURE .............................. Bl-94

23UOBl-001

Page 33 of 1164

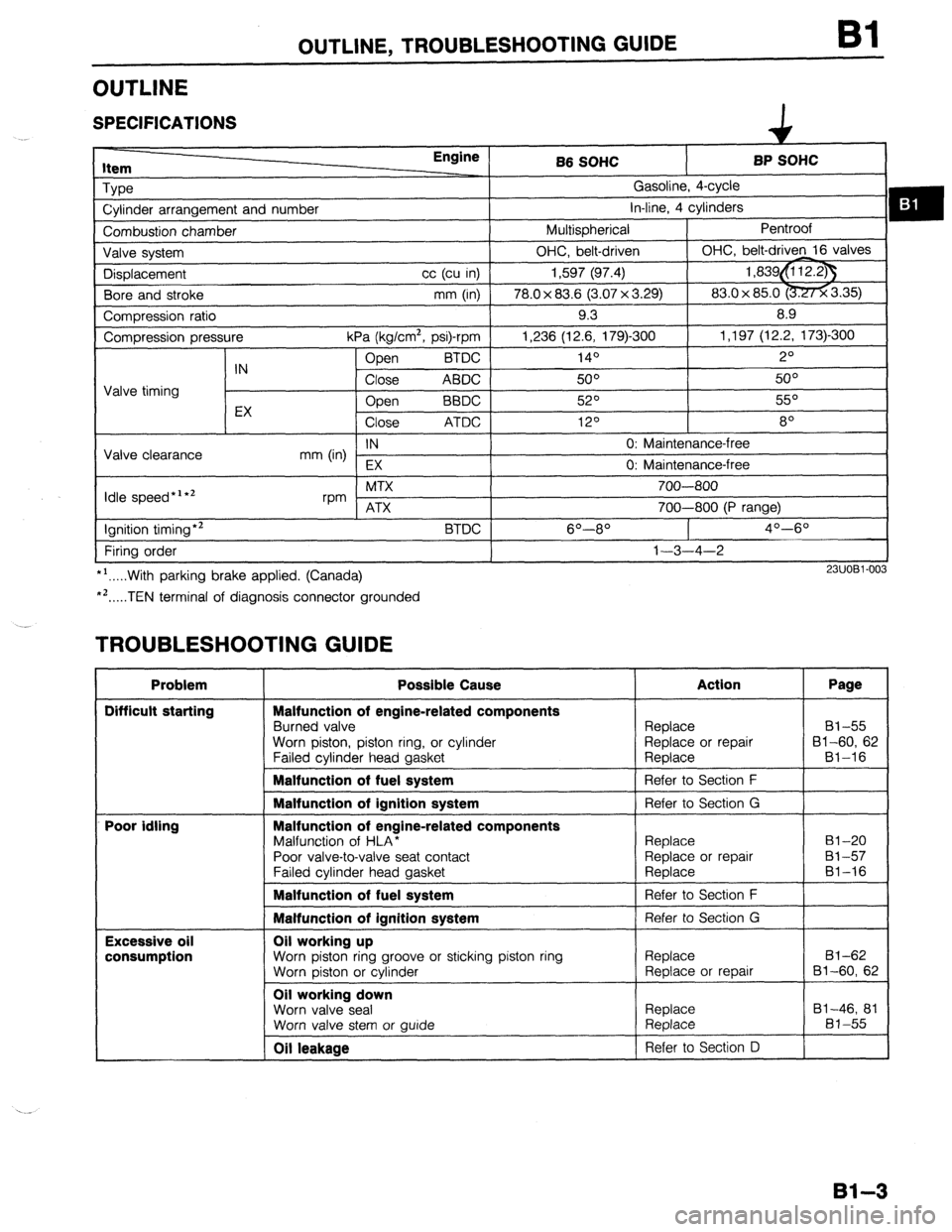

OUTLINE, TROUBLESHOOTING GUIDE Bl

OUTLINE

SPECIFICATIONS

item Engine

Type

Cylinder arrangement and number

Combustion chamber

Valve system

Displacement cc (cu in)

Bore and stroke mm (in)

Compression ratio

Compression pressure

kPa (kg/cm2, psi)-rpm

Open BTDC

IN

Close ABDC

Valve timing

EX Open

BBDC

Close ATDC

IN

Valve clearance

mm (in)

EX

Idle speed*‘*’ MTX

rpm ATX

Ignition timing*2

BTDC

Firing order

*‘.....With parking brake applied. (Canada)

*‘.....TEN terminal of diagnosis connector grounded B6 SOHC BP SOHC

Gasoline, 4-cycle

in-line, 4 cylinders

Multispherical Pentroof

OHC, belt-driven OHC, belt-driven 16 valves

1,597 (97.4) 1,839&i 12.23

78.0 x 83.6 (3.07 x 3.29) 83.0x 85.0 -3.35)

9.3 8.9

1,236 (12.6, 179)300 1,197 (12.2, 173)-300

140 2O

50° 5o”

52O 55O

120 8

0: Maintenance-free

0: Maintenance-free

700-800

700-800 (P range)

6O----8O 4O--6O

1-3-4-2

23UOBl-003

TROUBLESHOOTING GUIDE

Problem

Difficult starting

Poor idling

Excessive oil

consumption Possible Cause

Malfunction of engine-related components

Burned valve

Worn piston, piston ring, or cylinder

Failed cvlinder head aasket Action Page

Replace 81-55

Replace or repair 81-60, 62

Reolace Bl-16

Malfunction of fuel system

1 Refer to Section F

I

Malfunction of ignition system

Malfunction of engine-related components

Malfunction of HLA*

Poor valve-to-valve seat contact

Failed cvlinder head aasket Refer to Section G

Replace

Replace or repair

Reolace 81-20

81-57

81-16

Malfunction of fuel system 1 Refer to Section F

I

Malfunction of ignition system Refer to Section G

Oil working up

Worn piston ring groove or sticking piston ring

Worn piston or cylinder

Oil working down

Worn valve seal

Worn valve stem or wide Replace

Replace or repair

Replace

Replace 81-62

Bl-60, 62

81-46, 81

81-55

Oil leakage Refer to Section D

81-3

Page 34 of 1164

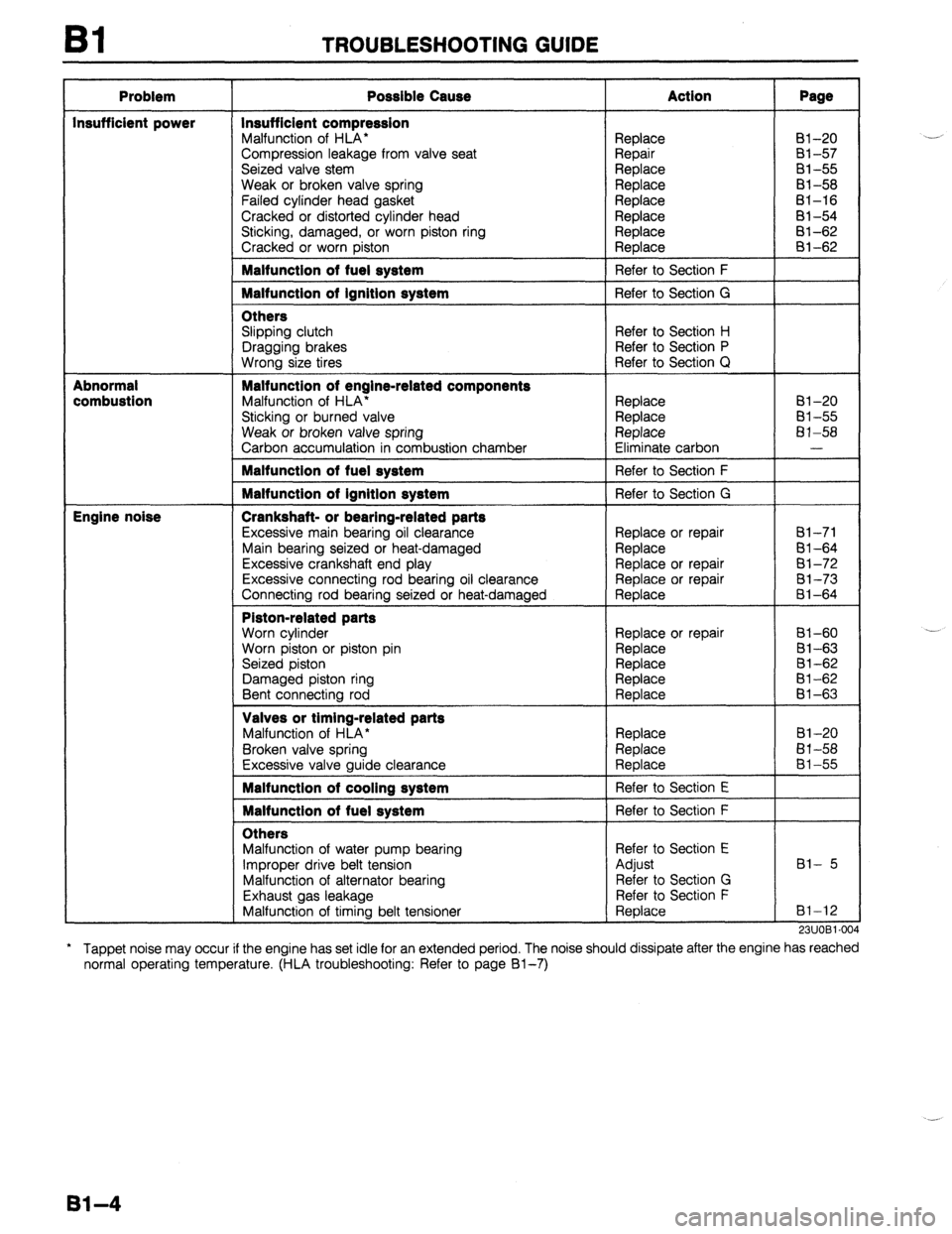

Bl TROUBLESHOOTING GUIDE

Problem

Insufficient power

Abnormal

combustion

Engine noise Possible Cause

Insufficient compression

Malfunction of HLA*

Compression leakage from valve seat

Seized valve stem

Weak or broken valve spring

Failed cylinder head gasket

Cracked or distorted cylinder head

Sticking, damaged, or worn piston ring

Cracked or worn piston Malfunction of fuel system

Malfunction of ignition system

Others

Slipping clutch

Dragging brakes

Wrong size tires Malfunction of engine-related components

Malfunction of HLA’

Sticking or burned valve

Weak or broken valve spring

Carbon accumulation in combustion chamber Malfunction of fuel system

Malfunction of ignition system

Crankshaft- or bearing-related parts

Excessive main bearing oil clearance

Main bearing seized or heat-damaged

Excessive crankshaft end play

Excessive connecting rod bearing oil clearance

Connecting rod bearing seized or heat-damaged Piston-related parts

Worn cylinder

Worn piston or piston pin

Seized piston

Damaged piston ring

Bent connecting rod Valves or timing-related parts

Malfunction of HLA*

Broken valve spring

Excessive valve guide clearance Malfunction of cooling system

Malfunction of fuel system

Others

Malfunction of water pump bearing

Improper drive belt tension

Malfunction of alternator bearing

Exhaust gas leakage

Malfunction of timing belt tensioner Action

Replace

Repair

Replace

Replace

Replace

Replace

Replace

Replace

Refer to Section F

Refer to Section G

Refer to Section H

Refer to Section P

Refer to Section Q

Replace

Replace

Replace

Eliminate carbon

Refer to Section F

Refer to Section G

Replace or repair

Replace

Replace or repair

Replace or repair

Replace

Replace or repair

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Refer to Section E

Refer to Section F

Refer to Section E

Adjust

Refer to Section G

Refer to Section F

Replace Page 81-20

Bl-57

81-55

81-58

81-16

81-54

81-62

al-62

81-20

81-55

81-58

-

61-71

Bl-64

81-72

81-73 8-i-64

Bl-60

81-63

81-62

81-62

El-63

Bl-20

El-58

81-55

Bl- 5

81-12

911 IORI .N)J LI.,“l. --

* Tappet noise may occur if the engine has set idle for an extended period. The noise should

normal operating temperature. (HLA troubleshooting: Refer to page Bl-7) dissipate after the engine has reached

81-4

Page 38 of 1164

Bl ENGINE TUNE-UP PROCEDURE

13UOBi-036

-i

OWOBX-261

13UOBl-08

LOCK BOLTS

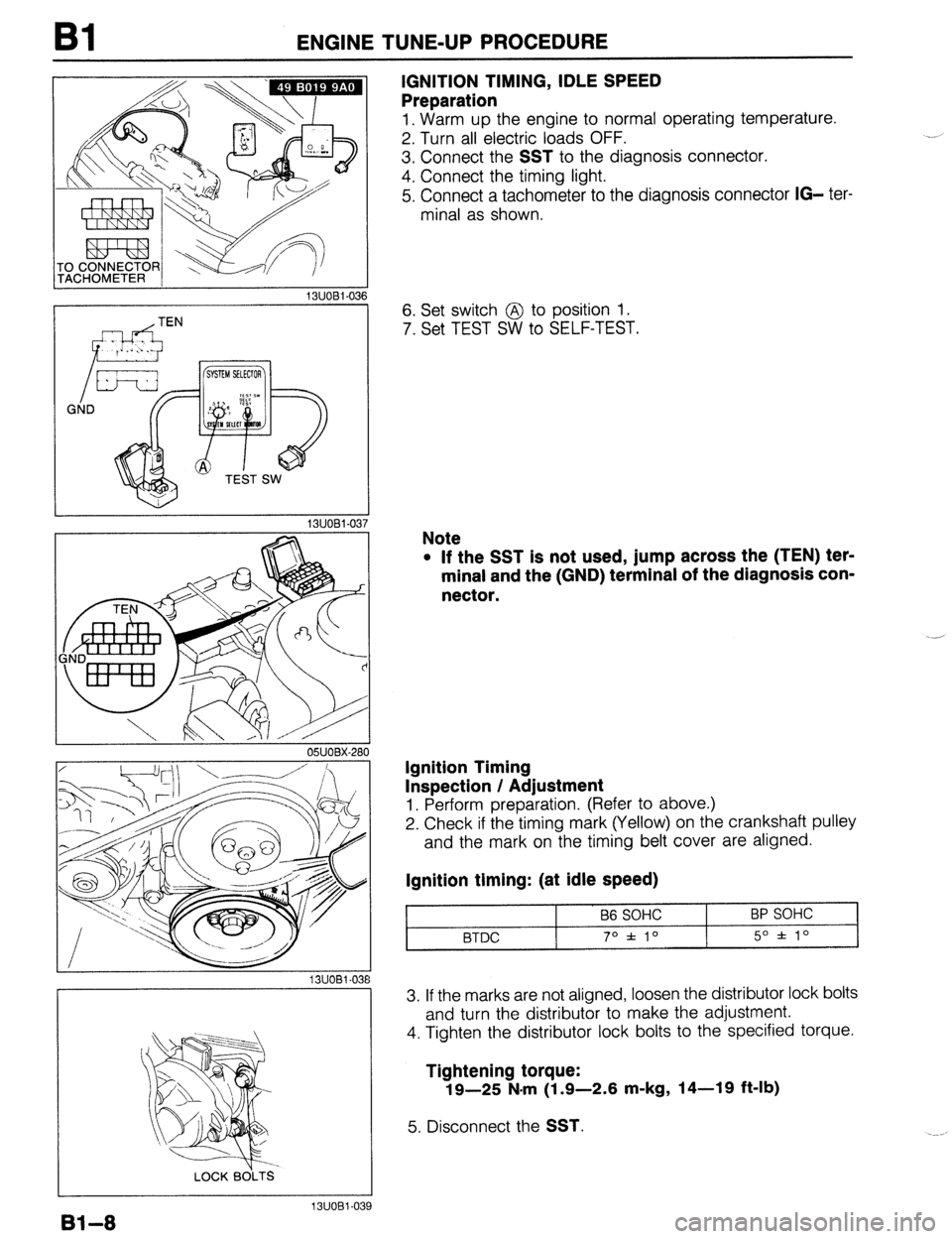

IGNITION TIMING, IDLE SPEED

Preparation

1, Warm up the engine to normal operating temperature.

2. Turn all electric loads OFF.

3. Connect the

SST to the diagnosis connector.

4. Connect the timing light.

5. Connect a tachometer to the diagnosis connector

IG- ter-

minal as shown.

6. Set switch @ to position 1.

7. Set TEST SW to SELF-TEST.

Note

l If the SST is not used, jump across the (TEN) ter-

minal and the (GND) terminal of the diagnosis con-

nector.

Ignition Timing

Inspection / Adjustment

1. Perform preparation. (Refer to above.)

2. Check if the timing mark (Yellow) on the crankshaft pulley

and the mark on the timing belt cover are aligned.

Ignition timing: (at idle speed)

B6 SOHC

BTDC 70 f 10 BP SOHC

5O f lo

3. If the marks are not aligned, loosen the distributor lock bolts

and turn the distributor to make the adjustment.

4. Tighten the distributor lock bolts to the specified torque.

Tightening torque:

19-25 N.m (1.9-2.6 m-kg, 14-19 ft-lb)

5. Disconnect the SST.

Bl-8

13UOBl-039

Page 40 of 1164

Bl COMPRESSION

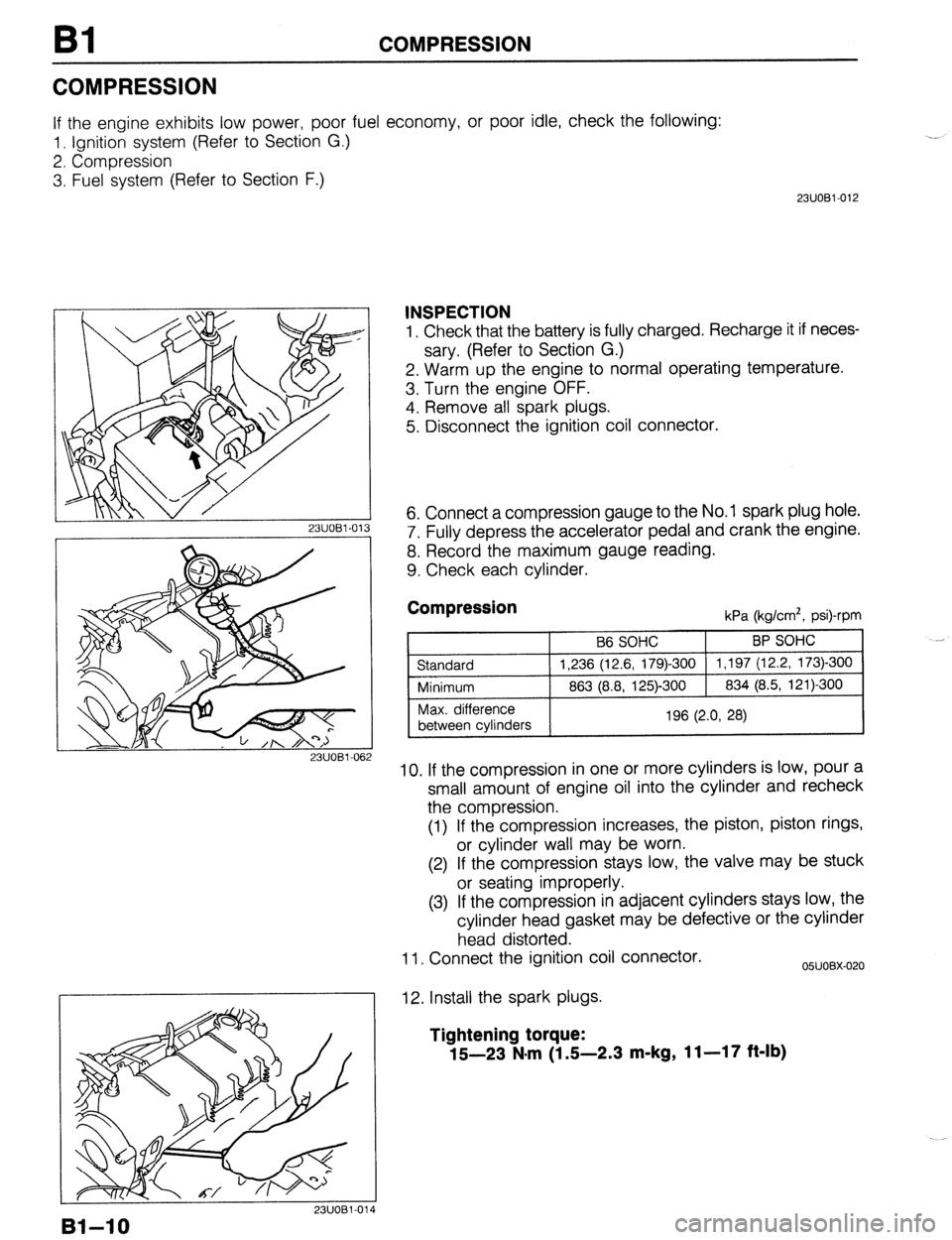

COMPRESSION

If the engine exhibits low power, poor fuel economy, or poor idle, check the following:

1. Ignition system (Refer to Section G.)

2. Compression

3. Fuel system (Refer to Section F.)

23UOBl-01

23UOBl-06

23UOBl-014 23UOBl-012

INSPECTION

1. Check that the battery is fully charged. Recharge it if neces-

sary. (Refer to Section G.)

2. Warm up the engine to normal operating temperature.

3. Turn the engine OFF.

4. Remove all spark plugs.

5. Disconnect the ignition coil connector.

6. Connect a compression gauge to the No. 1 spark plug hole.

7. Fully depress the accelerator pedal and crank the engine.

8. Record the maximum gauge reading.

9. Check each cylinder.

Compression kPa (kg/cm*, psi)-rpm

10. If the compression in one or more cylinders is low, pour a

small amount of engine oil into the cylinder and recheck

the compression.

(1) If the compression increases, the piston, piston rings,

or cylinder wall may be worn.

(2) If the compression stays low, the valve may be stuck

or seating improperly.

(3) If the compression in adjacent cylinders stays low, the

cylinder head gasket may be defective or the cylinder

head distorted.

11. Connect the ignition coil connector.

12. Install the spark plugs.

05UOBX-020

Tightening torque:

15-23 N*m (1 S-2.3 m-kg, 11-17 ft-lb)

Bl-10