MERCEDES-BENZ C-Class COUPE 2017 CL205 Owner's Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2017, Model line: C-Class COUPE, Model: MERCEDES-BENZ C-Class COUPE 2017 CL205Pages: 354, PDF Size: 8.66 MB

Page 331 of 354

Vehicleidentificatio nplate

Even if yo uhavec alculate dthe totalc argo care-

fully ,you shoul dstillm ake sure thatt he gross

vehicl eweigh trating and the gross axl eweigh t

rating are not exceeded .Detail scan be found on

the vehicl eide ntificatio nplate on the B-pillar on

the driver' ssideoft he vehicl e(

Ypage 326).

Permissibl eGrossVehicl eWeight Rating

(GVWR): the gross weight of the vehicle, al lpas -

sengers ,loa da nd traile rload/n oseweight (if

applicable) must not exceed the permissible

gross vehicl eweigh t.

Gros sAxleW eight Ratin g(GAWR): the maxi-

mump ermissibl eweigh tthatc an be carrie dby

one axl e(front or rea raxle).

To ensure thaty ourvehicl edoesn ot exceed the

maximu mpermissibl evalue s(gros sv ehicle

weight and maximu mgross axl eweigh trating),

have your loaded vehicl e(including driver, occu-

pants, cargo, and ful ltraile rloa difa pplicable)

weighed on asuitabl evehicl eweigh bridge.

Alla bout wheels and tires

Uniform Tire Quality Grading Stand-

ards

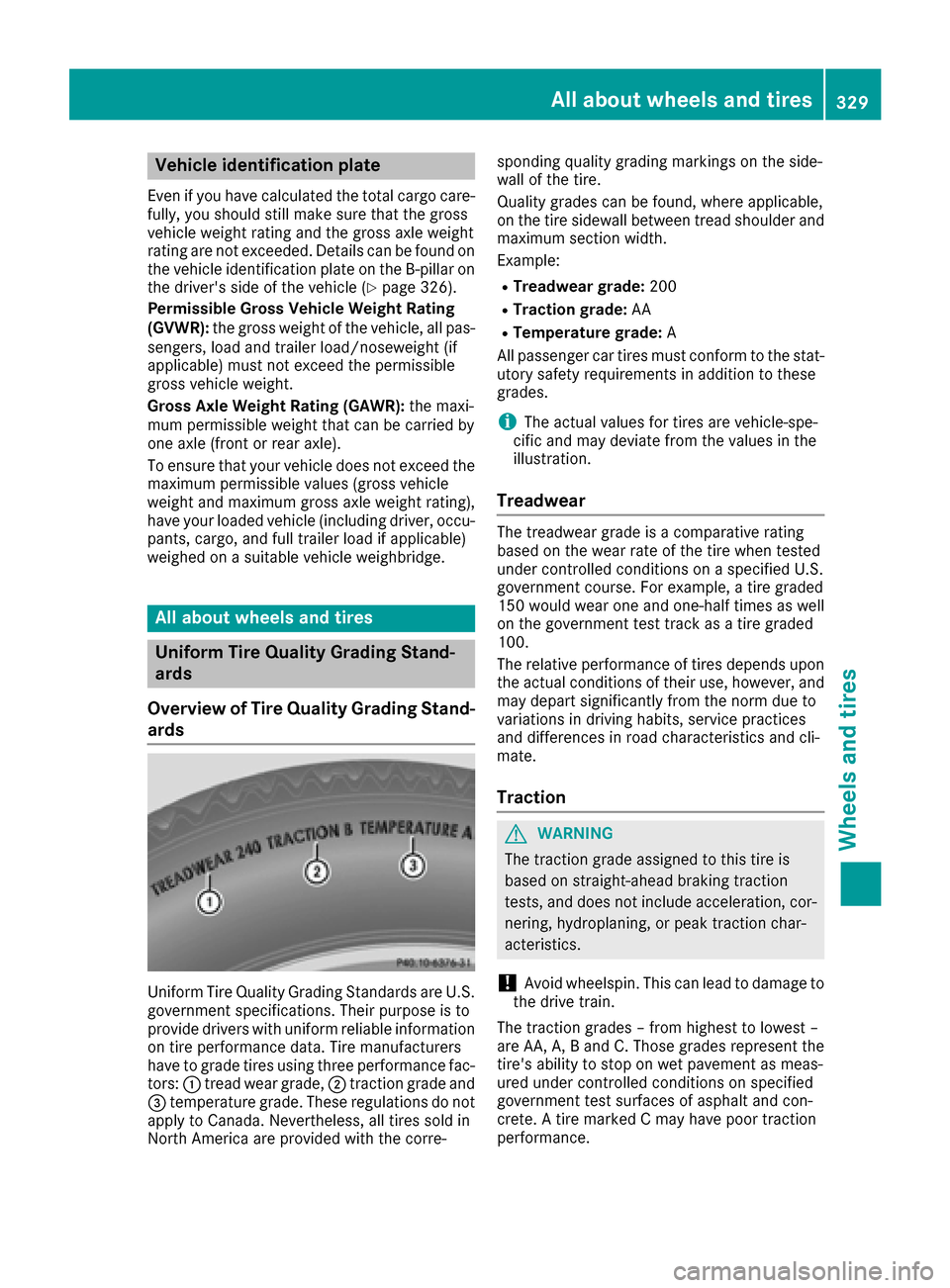

Overvie wofTire Quality Grading Stand-

ards

Uniform Tire Quality Grading Standard sare U.S.

government specifications. Their purpose is to

provid edrivers with uniform reliabl einformation

on tire performanc edata. Tire manufacturers

have to grade tire susing thre eperformanc efac-

tors: :trea dwearg rade, ;tractio ngrade and

= temperature grade .These regulations do not

appl ytoC anada. Nevertheless ,alltire ssoldi n

North America are provided with the corre- sponding quality grading marking

sonthe side-

wall of the tire.

Quality grade scan be found, where applicable,

on the tire sidewall between trea dshoulde rand

maximu msection width.

Example:

RTreadwear grade: 200

RTraction grade:AA

RTemperature grade: A

All passenger car tire smustc onform to the stat-

utory safety requirements in additio ntothese

grades.

iThe actual value sfor tire sare vehicle-spe-

cifi cand mayd eviate from the value sinthe

illustration.

Treadwear

The treadwea rgrade is acomparative rating

based on the wear rate of the tire when tested

under controlled conditions on aspecified U.S.

government course.F or example,atire graded

150 woul dwearo ne and one-hal ftime sasw ell

on the government test trac kasat ire graded

100.

The relative performance of tire sdepen ds upon

the actual conditions of thei ruse,h owever, and

mayd epartsignificantly from the norm du eto

variations in driving habits, service practices

and difference sinroadc haracteristic sand cli-

mate.

Traction

GWARNING

The tractio ngrade assigned to thist ire is

based on straight-ahea dbraking traction

tests ,and does not includ eacceleration, cor-

nering, hydroplaning, or peak tractio nchar-

acteristics.

!Avoi dwheelspin.T hisc an lead to damage to

the drive train.

The tractio ngrade s–from highest to lowest –

are AA, A, Band C. Those grade srepresent the

tire's ability to stop on we tpavement as meas-

ured under controlled conditions on specified

government test surfaces of asphalt and con-

crete .Atire marked Cmayhave poor traction

performance.

Al la bout wheels and tires329

Wheel sand tires

Z

Page 332 of 354

The safe speed onawet, snow covered or icy

road is alwaysl ower than on dry road surfaces.

You should pay special attention to road condi-

tions when temperatures are around freezing

point.

Mercedes-Benz recommends aminimum tread

depth of ãin (4 mm) on all four winter tires.

Observe the legally required minimum tire tread

depth (

Ypage 317). Winter tires can reduce the

braking distance on snow-covered surfaces in

comparison with summer tires. The braking dis-

tanc eiss till much further than on surfaces that

are not icy or covered with snow. Take appro-

priate care when driving.

Further information on winter tires (M+S tires)

(

Ypage 318).

Temperature

GWARNING

The temperature grade for this tire is estab-

lished for atire that is properly inflated and

not overloaded. Excessive speed, underinfla-

tion, or excessivel oading, either separately or

in combination, can cause excessiveh eat

build-up and possible tire failure.

The temperature grades are A(the highest), B,

and C, representing the tire's resistanc etothe

generation of heat and its ability to dissipate

heat when tested under controlled conditions

on aspecified indoor laboratory test wheel. Sus-

tained high temperature can cause the material

of the tire to degenerate and reduce tire life, and

excessivet emperature can lead to sudden tire

failure. The grade Ccorresponds to alevel of

performance which all passenger car tires must

meet under the Federal Motor Vehicle Safety

Standard No. 109. Grades BandArepresent

higher levels of performance on the laboratory

test wheel than the minimum required by law.

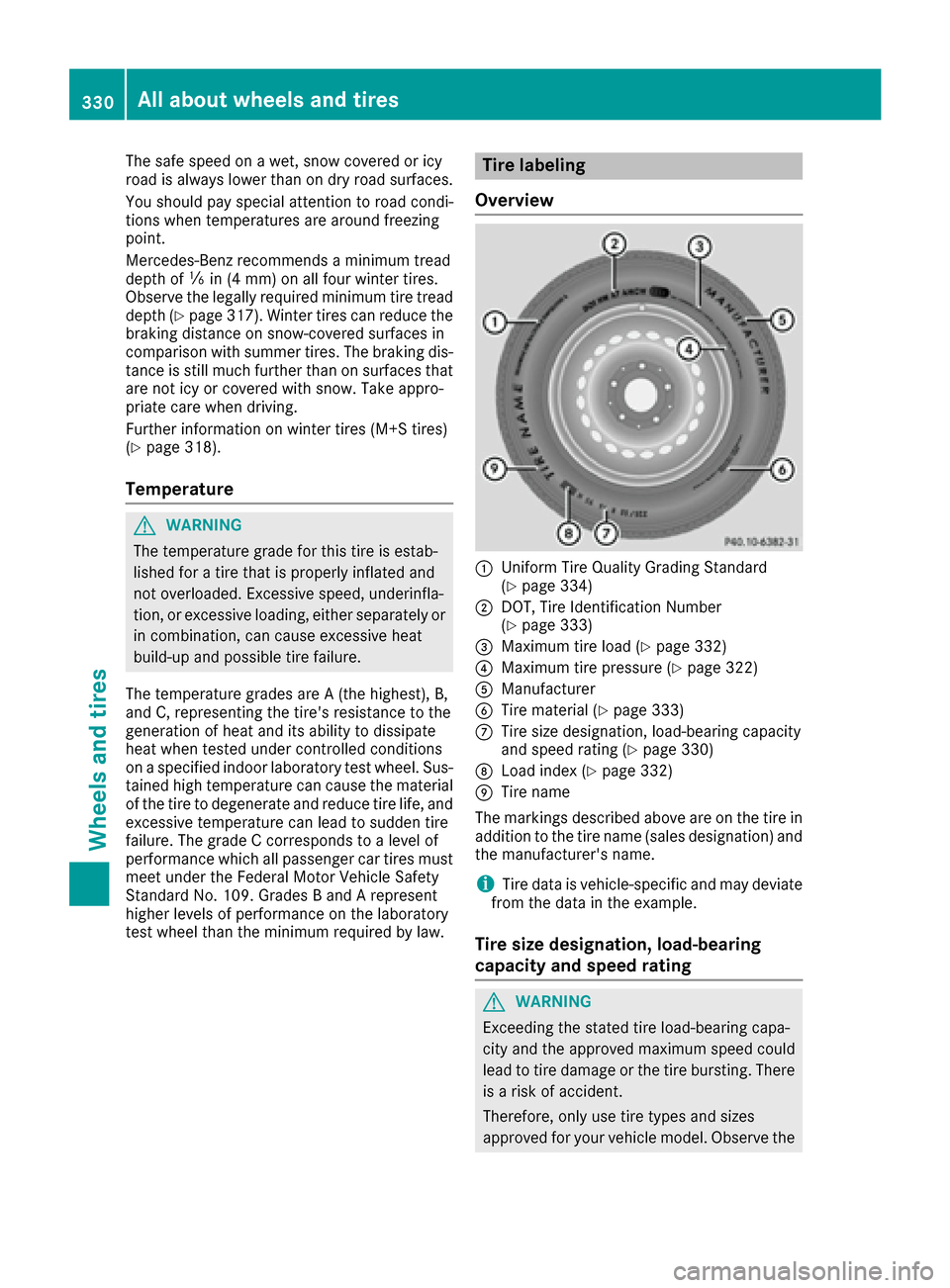

Tire labeling

Overview

:Uniform Tire Quality Grading Standard

(Ypage 334)

;DOT, Tire Identification Number

(Ypage 333)

=Maximum tire load (Ypage 332)

?Maximum tire pressure (Ypage 322)

AManufacturer

BTire material (Ypage 333)

CTire size designation, load-bearing capacity

and speed rating (Ypage 330)

DLoad index (Ypage 332)

ETire name

The markings described above are on the tire in

addition to the tire name (sales designation) and

the manufacturer's name.

iTire data is vehicle-specific and may deviate

from the data in the example.

Tire size designation, load-bearing

capacity and speed rating

GWARNING

Exceeding the stated tire load-bearing capa-

city and the approved maximum speed could

lead to tire damage or the tire bursting. There is ar isk of accident.

Therefore, only use tire types and sizes

approved for your vehicle model. Observe the

330All about wheelsa nd tires

Wheels and tires

Page 333 of 354

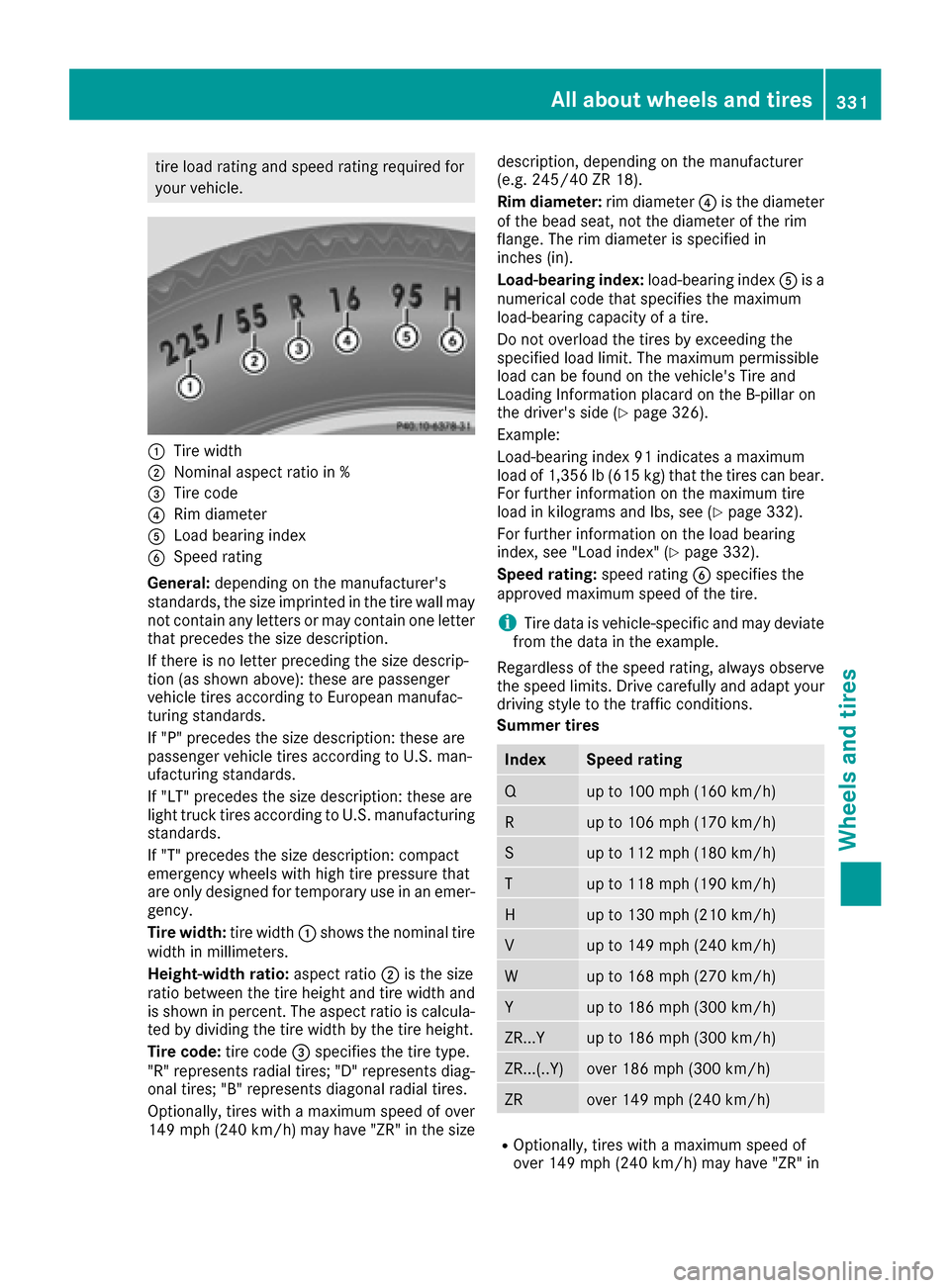

tire load rating and speedrating required for

your vehicle.

:Tire width

;Nomina laspec tratio in %

=Tire code

?Rimd iame ter

ALoadbeari ng index

BSpeed rating

General: depending on the manufacturer's

standards ,the size imprinted in the tire wall may

not contain any letters or mayc ontain one letter

thatp recedes the size description.

If there is no letter preceding the size descrip-

tio n(as shown above): these ar epassenger

vehicl etiresa ccording to Europea nmanufac-

turing standards.

If "P "precedes the size description: these are

passenge rvehicl etiresa ccording to U.S. man-

ufacturin gstandards.

If "LT" precedes the size description: these are

light truck tire saccording to U.S. manufacturing

standards.

If "T "precedes the size description: compact

emergency wheels with high tire pressure that

ar eo nlyd esig nedf or temporary us einanemer-

gency.

Tire width: tire width:shows the nominal tire

width in millimeters.

Height-width ratio: aspect ratio;is the size

ratio between the tire height and tire width and

is shown in percent. The aspect ratio is calcula-

ted by dividing the tire width by the tire height.

Tire code: tire code=specifie sthe tire type.

"R "r epresents radial tires; "D" represents diag-

ona ltires

; "B" represents diagona

lradial tires.

Optionally ,tire sw itham aximum spee dofover

149 mph (24 0km/h )mayhave "ZR" in the size description, depending on the manufacturer

(e.g. 245/40Z

R18).

Rim diameter: rim diameter?is the diameter

of the bead seat, not the diamete rofthe rim

flange .The ri mdiame teriss pecifie din

inches (in).

Load-bearin gind ex: load-bearing index Ais a

numerical cod ethats pecifie sthe maximum

load-bearing capacity of atire.

Do not overload the tire sbyexceeding the

specifie dloa dlimit .The maximu mpermissible

load can be found on the vehicle's Tire and

Loading Informatio nplacard on the B-pillar on

the driver's side (

Ypage 326).

Example:

Load-bearin gindex 91 indicates amaximum

load of 1,356 lb (61 5kg)thatt he tire scan bear.

For furthe rinformation on the maximum tire

load in kilograms and lbs, see(

Ypage 332).

For furthe rinformation on the load bearing

index, see" Loadindex" (

Ypage 332).

Speed rating: speedrating Bspecifie sthe

approved maximum spee dofthe tire.

iTire data is vehicle-specific and mayd eviate

fromt he data in the example.

Regardles softhe spee drating ,alway sobser ve

th

e spee dlimit s. Drive carefull yand adap tyou r

drivin gstyle to the trafficc onditions.

Summe rtires

IndexSpeed rating

Qup to 100 mph (16 0km/h)

Rup to 106 mph (17 0km/h)

Sup to 112 mph (18 0km/h)

Tup to 118 mph (19 0km/h)

Hup to 130 mph (21 0km/h)

Vup to 149 mph (24 0km/h)

Wup to 168 mph (27 0km/h)

Yup to 186 mph (30 0km/h)

ZR...Yup to 186 mph (30 0km/h)

ZR...(..Y)ove r186 mph (300 km/h)

ZRove r149 mph (240 km/h)

ROptionally ,tire sw itham aximum spee dof

ove r149 mph (24 0km/h )mayhave "ZR" in

Alla bout wheels an dtires331

Wheel sand tires

Z

Page 334 of 354

the size description, depending on the man-

ufacturer (e.g. 245/40ZR18).

The service specification is made up of load-

bearing index Aand spee drating B.

RIf the size description of your tire includes

"ZR" and there ar enoservice specifications,

as kt he tire manufacturer in order to fin dout

the maximum speed.

If as ervice specification is available, the max-

imum spee dislimited according to the speed

rating in the service specification. Example:

245/40Z R1897Y.Int his example ,"97 Y" is

the service specification. The letter "Y" rep-

resents the speed rating. The maximum

speed of the tire is limited to 186 mph

(300 km/h).

RThe size descriptionf or all tires with maxi-

mum speedsofo ver 186 mph (300 km/h)

must include "ZR", andthe service specifica-

tion must be given in parentheses .Example:

275/40 ZR 18 (99 Y) .Speed rating "(Y)" indi-

cates that the maximum speed of the tire is

over 186 mph (300 km/h). Ask the tire man-

ufacturer abou tthe maximum speed.

All-weather tires and winter tires

IndexSpeed rating

QM +S1up to 100 mph (160 km/h)

TM+S1up to 118 mph (190 km/h)

HM +S1up to 130 mph (210 km/h)

VM+S1up to 149 mph (240 km/h)

iNot all tires with the M+S marking provide

the driving characteristics of winter tires. In

addition to the M+S marking, winter tires also

have the isnowflake symbo lonthe tire

wall. Tires with this marking fulfill the require-

ments of the Rubber Manufacturers Associa-

tion (RMA) and the Rubber Association of

Canada (RAC) regarding the tire traction on

snow. They have been especially developed

for driving on snow.

An electronic speed limiter prevents you rvehi-

cle from exceeding aspeed of 130 mph

(210 km/h).

The speed rating of tires mounted at the factory

may be higher than the maximum speed that the

electronic speed limiter permits. Make sure that you

rtires have the required

speed rating, e.g. when buying new tires. The

required speed rating for you rvehicle can be

found in the "Tires" section (

Ypage 340).

Further information abou treading tire data can

be obtained from any qualifieds pecialist work-

shop.

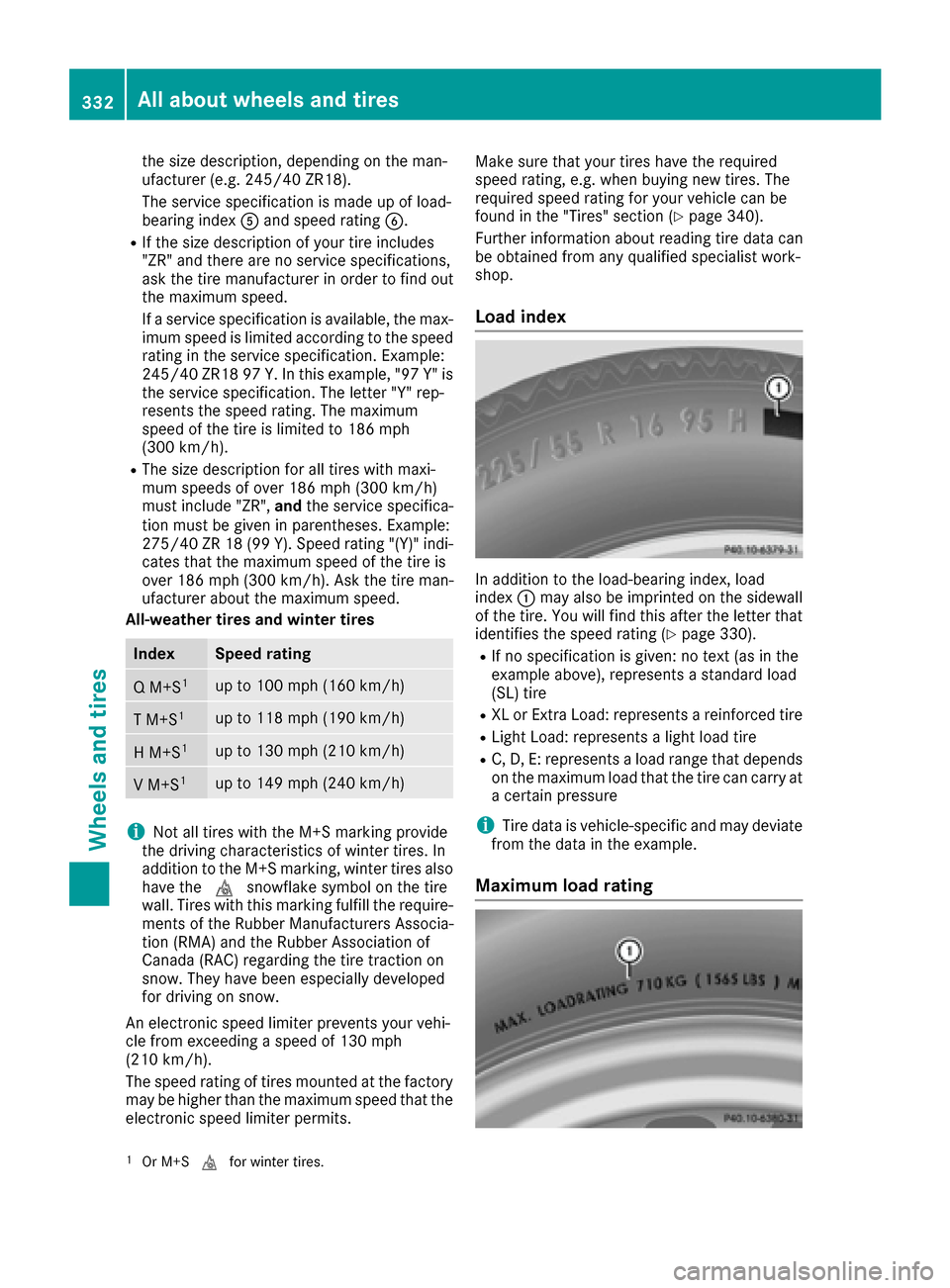

Load index

In addition to the load-bearing index, load

index :may also be imprinted on the sidewall

of the tire. You wil lfind this after the letter that

identifiest he speed rating (

Ypage 330).

RIf no specification is given: no text (as in the

example above), represents astandard load

(SL) tire

RXL or ExtraL oad: represents areinforced tire

RLight Load: represents alightl oad tire

RC, D, E: represents aload range that depends

on the maximum load that the tire can carry at

ac ertain pressure

iTire data is vehicle-specific and may deviate

from the data in the example.

Maximum load rating

1Or M+S ifor winter tires.

332Allabout wheels and tires

Wheelsa nd tires

Page 335 of 354

Maximum tire load:is the maximum permis-

sible weight for which the tire is approved.

Do not overload the tires by exceeding the

specified load limit. The maximum permissible

load can be found on the vehicle's Tire and

Loading Information placard on the B-pillar on

the driver's side (

Ypage 326).

iThe actual values for tires are vehicle-spe-

cific and may deviate from the values in the

illustration.

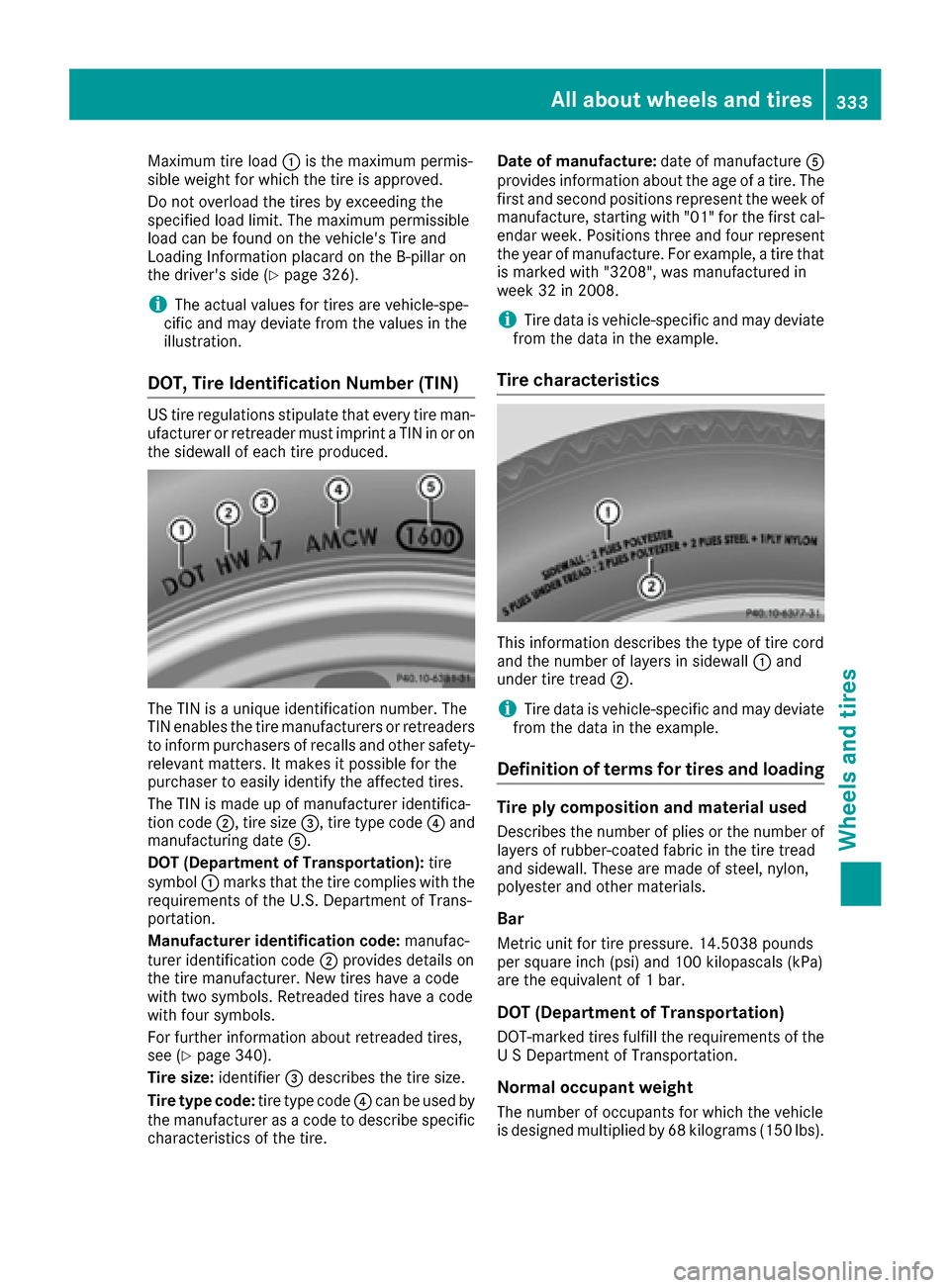

DOT, Tire Identification Number (TIN)

US tire regulations stipulate that every tire man-

ufacturer or retreader must imprint aTIN in or on

the sidewall of each tire produced.

The TIN is aunique identification number. The

TIN enables the tire manufacturers or retreaders

to inform purchasers of recalls and other safety-

relevant matters. It makes it possible for the

purchaser to easily identify the affected tires.

The TIN is made up of manufacturer identifica-

tion code ;,tire size =,tire type code ?and

manufacturing date A.

DOT (Department of Transportation): tire

symbol :marks that the tire complies with the

requirements of the U.S. DepartmentofT rans-

portation.

Manufacturer identification code: manufac-

turer identification code ;provides details on

the tire manufacturer. New tires have acode

with two symbols. Retreaded tires have acode

with four symbols.

For further information about retreaded tires,

see (

Ypage 340).

Tire size: identifier=describes the tire size.

Tire type code: tire type code?can be used by

the manufacturer as acode to describe specific

characteristics of the tire. Date of manufacture:

date of manufactureA

provides information about the age of atire. The

first and second positions represent the week of

manufacture, startin gwith "01" for the first cal-

endar week. Positions three and four represent

the year of manufacture. For example, atire that

is marked with "3208", was manufactured in

week 32 in 2008.

iTire data is vehicle-specific and may deviate

from the data in the example.

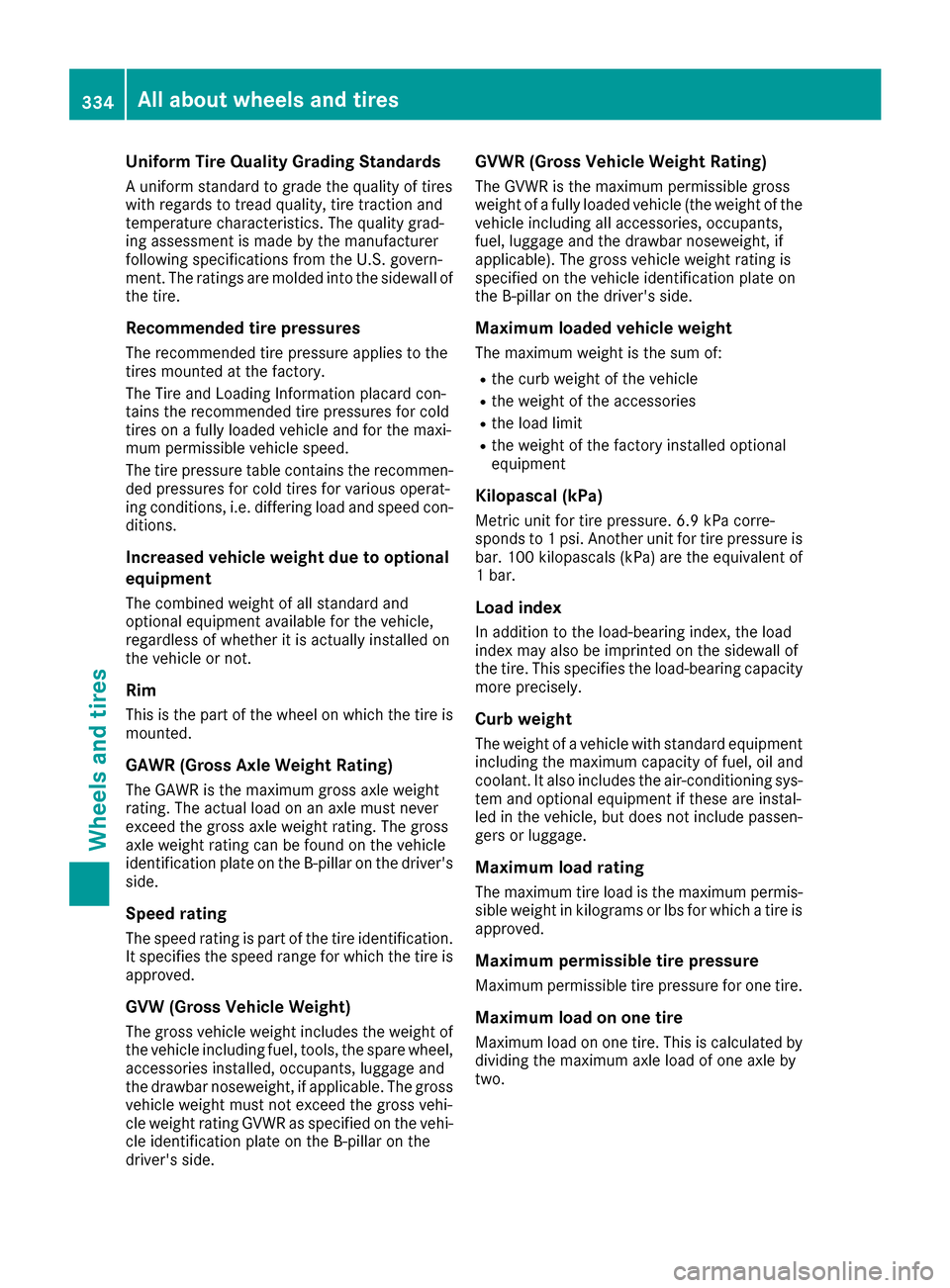

Tire characteristics

This information describes the type of tire cord

and the number of layers in sidewall :and

under tire tread ;.

iTire data is vehicle-specific and may deviate

from the data in the example.

Definition of termsf or tires and loading

Tire ply composition and material used

Describes the number of plies or the number of

layers of rubber-coated fabric in the tire tread

and sidewall. These are made of steel, nylon,

polyester and other materials.

Bar

Metric unit for tire pressure. 14.5038 pounds

per square inch (psi) and 100 kilopascals (kPa)

are the equivalent of1bar.

DOT (Department of Transportation)

DOT-marked tires fulfill the requirements of the

USD epartmen tofTransportation.

Normal occupant weight

The number of occupants for which the vehicle

is designed multiplied by 68 kilograms (150 lbs).

All about wheels and tires333

Wheels and tires

Z

Page 336 of 354

Uniform TireQualityG rading Standards

Aunifor mstandard to grade the quality of tires

with regards to tread quality, tire traction and

temperature characteristics. The quality grad-

ing assessmentism ade by the manufacturer

following specification sfrom the U.S .govern-

ment .The ratings are molded int othe sidewall of

the tire.

Recommended tir epressures

The recommended tire pressure applies to the

tires mounted at the factory.

The Tire and Loading Information placard con-

tains the recommended tire pressures for cold

tires on afully loaded vehicle and for the maxi-

mum permissible vehicle speed.

The tire pressure table contains the recommen-

ded pressures for cold tires for various operat-

ing conditions, i.e. differingl oad and speed con-

ditions.

Increased vehicle weight due to optional

equipment

The combined weight of all standard and

optional equipment available for the vehicle,

regardless of whether it is actually installed on

the vehicle or not.

Rim

This is the part of the wheel on which the tire is

mounted.

GAWR (Gross Axle Weight Rating)

The GAWR is the maximum gross axle weight

rating. The actual load on an axle must never

exceed the gross axle weight rating. The gross

axle weight ratin gcan be found on the vehicle

identification plate on the B-pillar on the driver's

side.

Speed rating

The speed ratin gispart of the tire identification.

It specifies the speed range for which the tire is

approved.

GVW (Gross Vehicle Weight)

The gross vehicle weight includes the weight of

the vehicle includin gfuel, tools, the spare wheel,

accessories installed, occupants, luggage and

the drawbar noseweight ,ifapplicable. The gross

vehicle weight must not exceed the gross vehi-

cle weight ratin gGVWR as specified on the vehi-

cle identification plate on the B-pillar on the

driver'ss ide.

GVWR(Gross Vehicle Weight Rating)

The GVWR is the maximum permissible gross

weight of afully loaded vehicle (the weight of the

vehicle includin gall accessories, occupants,

fuel, luggage and the drawbar n

oseweight

,if

applicable). The gross vehicle weight ratin gis

specified on the vehicle identification plate on

the B-pillar on the driver'ss ide.

Maximum loaded vehicle weight

The maximum weight is the sum of:

Rthe curb weight of the vehicle

Rthe weight of the accessories

Rthe load limit

Rthe weight of the factory installed optional

equipment

Kilopascal (kPa)

Metric unit for tire pressure. 6.9 kPa corre-

sponds to1psi. Another unit for tire pressure is

bar. 100 kilopascals (kPa) are the equivalent of

1b ar.

Load index

In addition to the load-bearin gindex ,the load

index may also be imprinted on the sidewall of

the tire. This specifies the load-bearin gcapacity

more precisely.

Curb weight

The weight of avehicle with standard equipment

includin gthe maximum capacityoff uel, oil and

coolant .Italso includes the air-conditionin gsys-

tem and optional equipment if these are instal-

led in the vehicle, but does not include passen-

gers or luggage.

Maximum load rating

The maximum tire load is the maximum permis-

sible weight in kilogram sorlbs for which atire is

approved.

Maximum permissible tir epressure

Maximum permissible tire pressure for one tire.

Maximum load on one tire

Maximum load on one tire. This is calculated by

dividing the maximum axle load of one axle by

two.

334All about wheels and tires

Wheels and tires

Page 337 of 354

PSI (pounds per squareinch)

Astandard unit of measure for tire pressure.

Aspect ratio

Relationship between tire height and tire width

in percent.

Tire pressure

This is pressure inside the tire applying an out-

ward force to each square inch of the tire's sur-

face. The tire pressure is specified in pounds per

square inch (psi), in kilopascal (kPa) or in bar.

The tire pressure should only be corrected when

the tires are cold.

Cold tire pressure

The tires are cold:

Rif the vehicle has been parked with the tires

out of direct sunlight for at least three hours

and

Rif the vehicle has not been driven further than

1m ile (1.6 km)

Tread

The part of the tire that comes into contact with

the road.

Bead

The tire bead ensures that the tire sits securely

on the wheel. There are several steel wires in the

bead to prevent the tire from coming loose from

the wheel rim.

Sidewall

The part of the tire between the tread and the

bead.

Weight of optional extras

The combined weight of those optional extras

that weigh more than the replaced standard

parts and more than 5lbs (2.3 kg). These

optional extras, such as high-performance

brakes, level control, aroof rack or ahigh-per-

formanceb attery, are not included in the curb

weight and the weight of the accessories.

TIN (Tire Identification Number)

This is aunique identifier which can be used by

at ire manufacturer to identify tires, for example

for aproduct recall, and thus identify the pur-

chasers. The TIN is made up of the manufactur-

er's identity code, tire size, tire type code and

the manufacturing date.

Load bearing index

The load bearing index (also load index) is acode

that contains the maximum load bearing capa-

city of atire.

Traction

Traction is the result of friction between the tires

and the road surface.

Treadwear indicators

Narrow bars (tread wear bars) that are distrib-

uted over the tire tread. If the tire tread is level

with the bars, the wear limit of áin (1.6 mm)

has been reached.

Occupant distribution

The distribution of occupants in avehicle at their

designated seating positions.

Total load limit

Nominal load and luggage load plus 68 kg

(15 0lbs)m ultiplied by the number of seats in

the vehicle.

Changing awheel

Flat tire

The "Breakdown assistance" section

(Ypage 300) contains information and notes on

how to deal with aflat tire. Information on driv-

ing with MOExtended tires in the event of aflat

tire can be found under "MOExtended tires (tires

with run-flat characteristics" (

Ypage 301).

Rotating the wheels

GWARNING

Interchanging the front and rear wheels may

severely impair the driving characteristics if

the wheels or tires have different dimensions. The wheel brakes or suspension components

may also be damaged. There is arisk of acci-

dent.

Rotate front and rear wheels only if the wheels and tires are of the same dimensions.

!On vehicles equippedw ithatire pressure

monitor ,electronic components are located

in the wheel.

Changing awheel335

Wheels and tires

Z

Page 338 of 354

Tire-mounting tools should not be used near

the valve. This could damage the electronic

components.

Only have tires changed ataqualified spe-

cialist workshop.

Always observe the instructions and safety

notes in the "Mounting awheel" section

(

Ypage 336).

The wear pattern sonthe front and rear tires

differ, depending on the operating conditions.

Rotate the wheels before aclear wear pattern

has formed on the tires. Frontt ires typically

wear more on the shoulders and the rear tires in the center.

On vehicles that have the same size front and

rear wheels, you can rotatet he wheels accord-

ing to the intervals in the tire manufacturer's

warranty book in your vehicle documents. If no

warranty book is available, the tires should be

rotated every 3,000 to 6,000 miles (5,000 to

10,000k m).Earlier may be necessary, depend-

ing on the degree of tire wear. Do not change the

direction of wheel rotation.

Clean the contact surfaces of the wheel and the

brake disc thoroughly every time awheel is rota-

ted. Check the tire pressure and, if necessary,

restart the tire pressure loss warning system

(

Ypage 323) or the tire pressure monitor

(Ypage 325).

Direction of rotation

Tires with aspecified direction of rotation have

additional benefits ,e.g. if there is arisk of hydro-

planing. These advantages can only be gained if

the tires are installed corresponding to the

direction of rotation.

An arrow on the sidewall of the tire indicates its

correctd irection of rotation.

Storing wheels

Storewheels that are not being used in acool,

dry and preferably dark place. Protectt he tires

from oil, grease, gasoline and diesel.

Mounting awheel

Preparing the vehicle

XStop the vehicle on solid, non-slippery and

level ground.

XApply the electric parking brake manually.

XBring the front wheels into the straight-ahead position.

XShift the transmission to position P.

XMake sure that the vehicle level is set to "Nor-

mal" on vehicles with AIRMATIC(Ypage 172).

XSwitch off the engine.

XVehicles without KEYLESS-GO: remove the

SmartKey from the ignition lock.

XVehicles with KEYLESS-GO start-function

or KEYLESS-GO: open the driver's door.

The on-board electronics now have status 0.

This is the same as the SmartKey having been

removed.

XVehicles with KEYLESS-GO start-function

or KEYLESS-GO: remove the Start/Stop but-

ton from the ignition lock (

Ypage 131).

XMake sure that the engine cannot be started

via your smartphon e(Ypage 134).

XIf included in the vehicle equipment, remove

the tire-change tool kit from the vehicle.

XSafeguard the vehicle against rolling away.

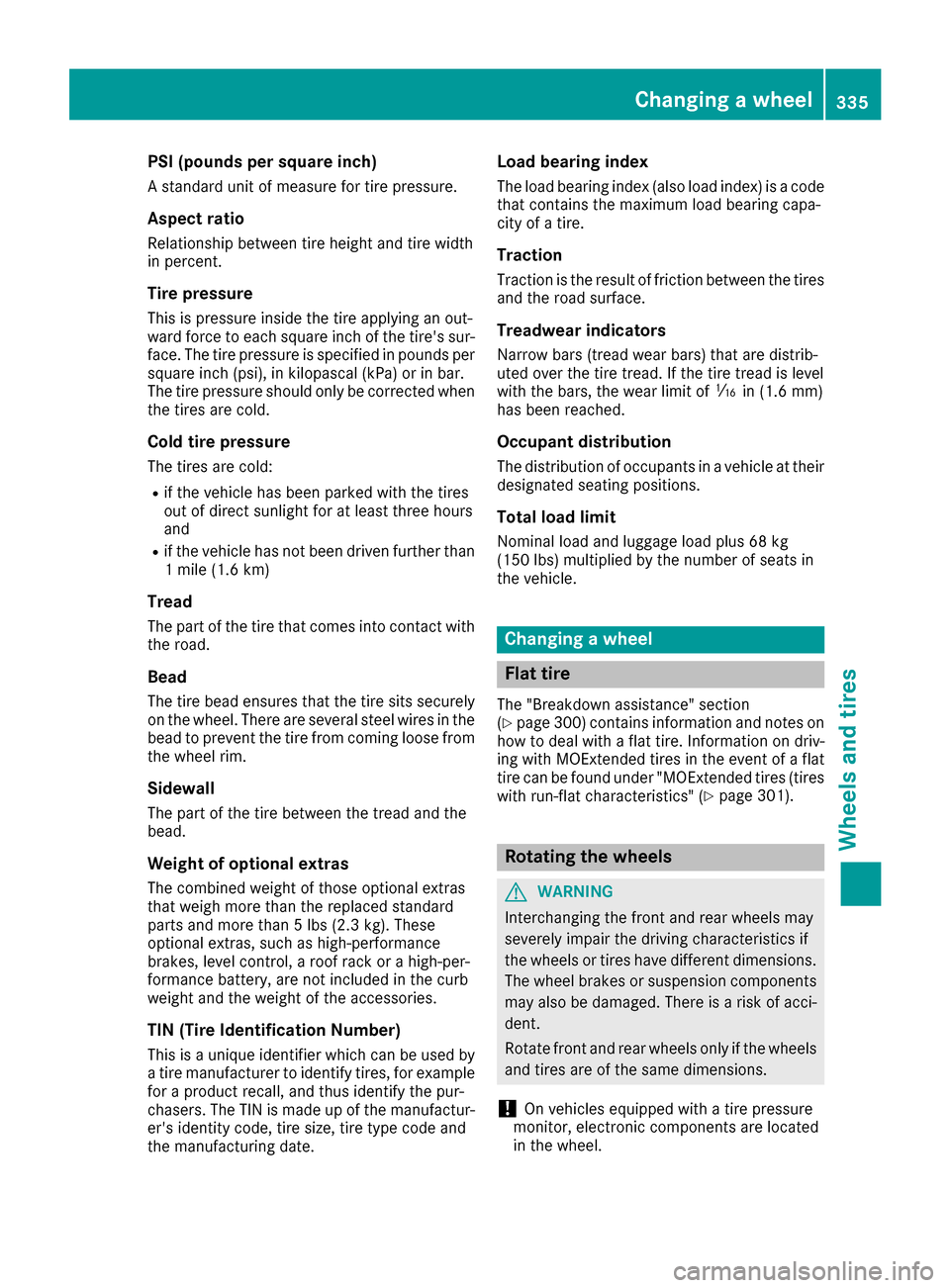

Securing the vehicle to prevent it from

rolling away

If your vehicle is equipped with awheel chock,i t

can be found in the vehicle tool kit (Ypage 300).

The folding wheel chock is an additional safety

measure to prevent the vehicle from rolling

away,f or example when changing awheel.

336Changing awheel

Wheels and tires

Page 339 of 354

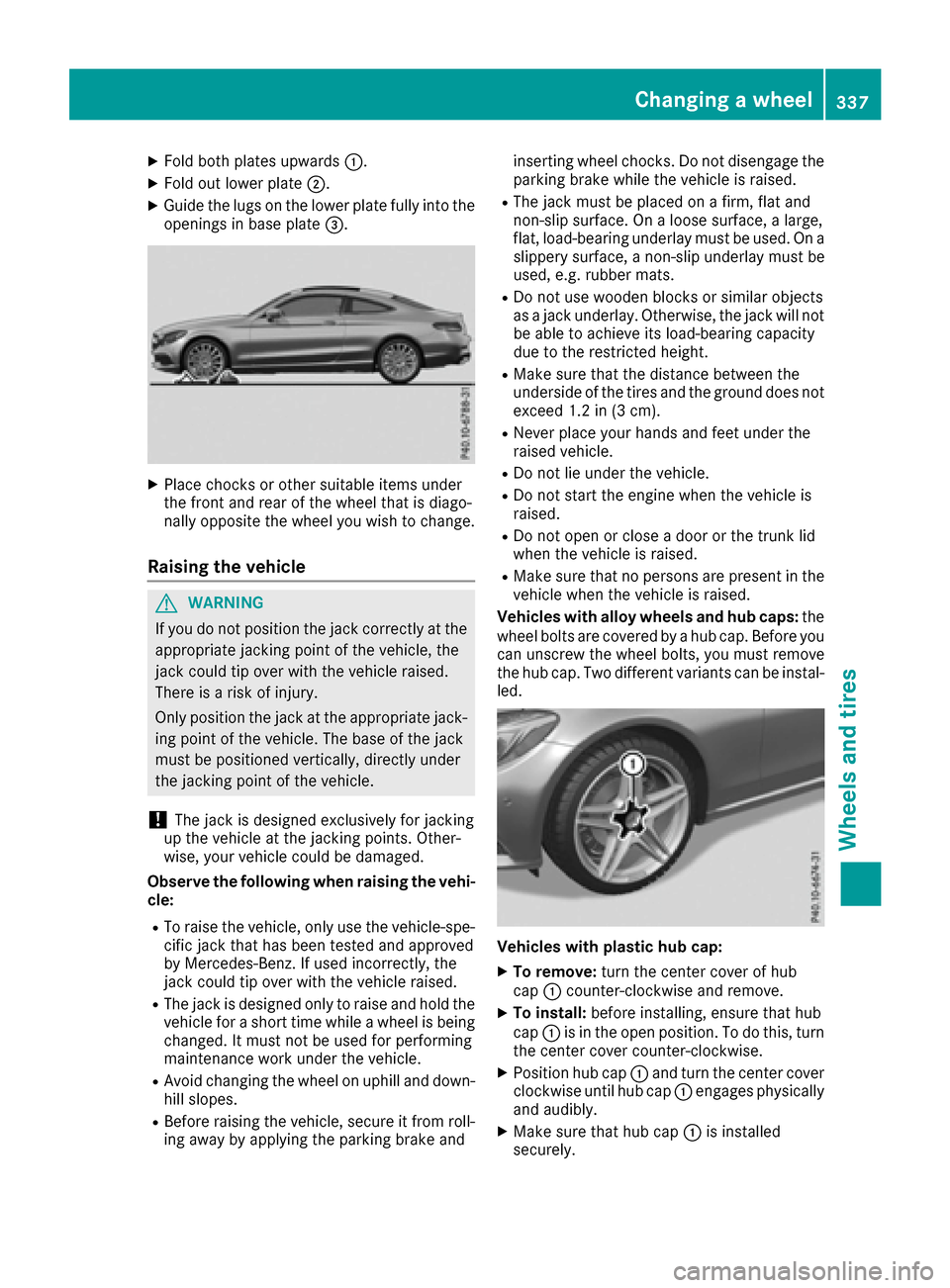

XFold both plates upwards:.

XFold outlower plate ;.

XGuide the lugs on the lower plate fully into the

openings in base plate =.

XPlace chocks or other suitabl eitems under

the front and rearoft he wheel that is diago-

nally opposite the wheel yo uwishtoc hange.

Raising the vehicle

GWARNING

If yo udon ot positio nthe jack correctly at the

appropriate jacking point of the vehicle, the

jack could tip over with the vehicle raised.

There is arisk of injury.

Only positio nthe jack at the appropriate jack-

ing point of the vehicle. The base of the jack

mus tbep ositioned vertically ,directly under

the jacking point of the vehicle.

!The jack is designe dexclusively for jacking

up the vehicle at the jacking points. Other-

wise, your vehicle could be damaged.

Observe the following whe nraising the vehi-

cle:

RTo raise the vehicle, only use the vehicle-spe-

cifi cjack that has bee ntested and approved

by Mercedes-Benz. If use dincorrectly ,the

jack could tip over with the vehicle raised.

RThe jack is designe donly to raise and hol dthe

vehicle for ashortt ime while awheel is being

changed. It mus tnot be use dfor performing

maintenance wor kunder the vehicle.

RAvoid changing the wheel on uphil land down-

hil lslopes.

RBeforer aising the vehicle, secure it from roll-

ing away by applying the parking brake and inserting wheel chocks. Do not disengage the

parking brake while the vehicle is raised.

RThe jack mus

tbep laced on afirm, fla tand

non-sli psurface .Onal oose surface ,alarge,

flat, load-bearing underlay mus tbeu sed. On a

slippery surface ,anon-sli punderlay mus tbe

used, e.g. rubber mats.

RDo not use wooden blocks or simila robjects

as ajack und erlay.Otherwise ,the jack will not

be able to achieve its load-bearing capacity

duetot he restricted height.

RMake sur ethat the distance between the

underside of the tires and the ground doe snot

excee d1.2 in (3 cm).

RNeve rplace your hand sand feet under the

raised vehicle.

RDo not li eunder the vehicle.

RDo not start the engine whe nthe vehicle is

raised.

RDo not ope norclosead oorort he trunk lid

whe nthe vehicle is raised.

RMake sur ethat no persons are present in the

vehicle whe nthe vehicle is raised.

Vehicles with alloy wheel sand hub caps: the

wheel bolts are covered by ahub cap .Befor eyou

can unscre wthe wheel bolts, yo umustremove

the hub cap .Two different variants can be instal-

led.

Vehicles with plasti chub cap:

XTo remove: turn the center cover of hub

cap :counter-clockwis eand remove.

XTo install: before installing, ensure that hub

cap :is in the ope nposition. To do this, turn

the center cover counter-clockwise.

XPositio nhub cap :and turn the center cover

clockwise until hub cap :engages physically

and audibly.

XMake sur ethat hub cap :is installed

securely.

Changing awheel337

Wheels and tires

Z

Page 340 of 354

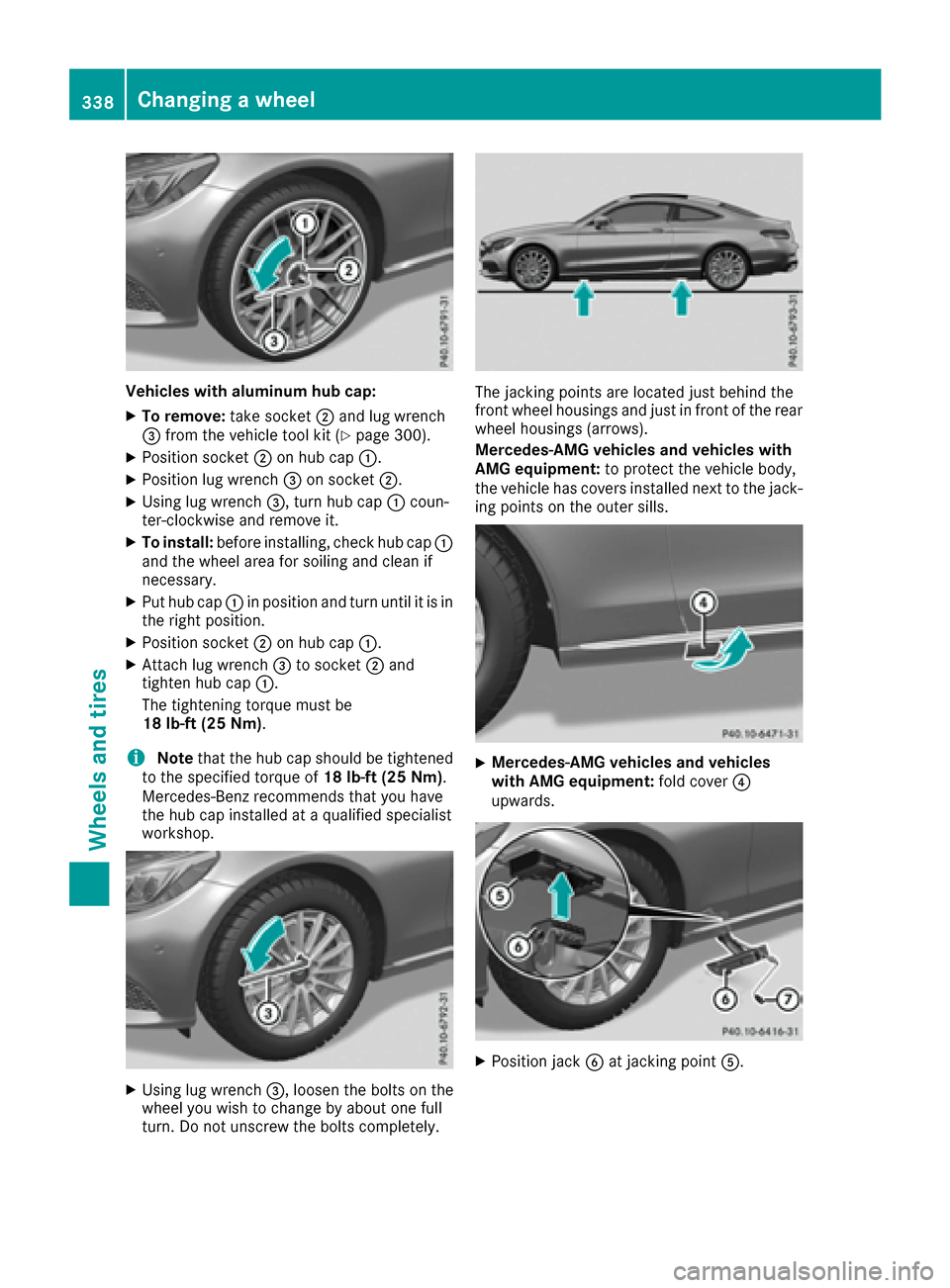

Vehicles with aluminum hub cap:

XTo remove:take socket;and lu gwrench

= from the vehicl etool kit (Ypage 300).

XPosition socket ;on hubc ap:.

XPosition lu gwrench =on socket ;.

XUsing lugwrench =,turn hubc ap: coun-

ter-clockwise and remove it.

XTo install: before installing, check hubc ap:

and the wheel are afor soiling and clean if

necessary.

XPuth ubcap :in position and turn unti litisin

the right position.

XPosition socket ;on hubc ap:.

XAttach lu gwrench =to socket ;and

tighten hubc ap:.

The tightening torque mus tbe

18 lb-ft (2 5Nm).

iNote that the hubc ap shouldbetightened

to the specified torque of 18 lb-ft (25 Nm).

Mercedes-Benz recommend sthat yo uhave

the hubc ap installed at aquali fied specialist

workshop.

XUsing lu gwrench =,loosent he bolts on the

wheel yo uwishtoc hange by abouto ne full

turn. Do not unscrew the bolts completely.

The jacking points are locate djust behind the

front wheel housing sand jus tinfront of the rear

wheel housing s(arrows).

Mercedes-AMG vehicle sand vehicle swith

AMG equipment: to protect the vehicl ebody,

the vehicl ehascovers installed next to the jack-

ing points on the outer sills.

XMercedes-AMG vehicle sand vehicles

with AMG equipment: foldc over ?

upwards.

XPosition jack Bat jacking point A.

338Changingawheel

Wheelsand tires