ECU MERCEDES-BENZ G-CLASS SUV 2016 Repair Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2016, Model line: G-CLASS SUV, Model: MERCEDES-BENZ G-CLASS SUV 2016Pages: 261, PDF Size: 6.01 MB

Page 228 of 261

sive gases of

abattery. There is arisk of an

explosion.

Before handling the battery, touch the vehicle body to remove any existing electrostatic

build-up.

The highly flammable gas mixture is created

while the battery is charging and when jump-

starting.

Always make sure that neither you nor the bat-

tery is electrostatically charged. Electrostatic

charge is created, for example:

R by wearing synthetic-fibre clothing

R by friction between clothing and the seat

R if you pull or push the battery across carpet or

other synthetic materials

R if you rub the battery with acloth G

WARNING

During the charging process, abattery produ-

ces hydrogen gas. If ashort circui toccurs or

sparks are created ,the hydrogen gas can

ignite. There is arisk of an explosion.

R Make sure that the positive terminal of a

connected battery does not come into con-

tact with vehicl eparts.

R Never place metal objects or tools on abat-

tery.

R It is important that you observe the descri-

bed order of the battery terminal swhen

connecting and disconnecting abattery.

R When jump-starting, make sure that the

battery pole swith identical polarity are

connected.

R It is particularl yimportant to observe the

described order when connecting and dis-

connecting the jump leads.

R Never connect or disconnect the battery

terminal swhile the engine is running. G

WARNING

Battery acid is caustic. There is arisk of injury.

Avoid contact with the skin, eyesorc lothing.

Do not breathe in any battery gases. Do not

leano ver the battery .Keep the batterie sout

of the reach of children. Immediately rinse off battery acid thoroughly with plenty of clean

wate

rand seek medical attention at once. H

Environmenta

lnote Batteries contain pollutants.

It is illegal to dispose of them

with th ehousehold rubbish.

The ym ustb ec ollected sep-

arately and disposed of in an environmentall yresponsible

recycling system. Dispose of batteries in an

environmentall

yresponsible

manner. Take discharged

batteries to aquali fied spe-

cialist workshop or to acol-

lectio npoint for used batter-

ies.

! Hav

ethe battery checked regularly at a

qualified specialis tworkshop.

Observe the servic eintervals in the Service

Bookle torcontact aquali fied specialis twork-

sho pfor mor einformation.

! Alway

shavew orkont he batteries carried

ou tata qualified specialis tworkshop.

Shoul dit, in exceptiona lcircumstances ,be

absolutely necessary to disconnect the 12-

vol tbattery yourself, please observe the fol-

lowing:

R Secure the vehicl etoprevent it fro mrolling

away

R Switch off the ignition

R Disconnect the negative termina lfirst and

the nthe positive terminal

The transmission is locked in position j

after disconnecting the battery.

After the work is completed ,securel yrefit the

battery and the positive termina lcover.

Compl ywiths afety precautions and take pro-

tective measures when handling batteries. Risk of explosion.

Fire

,naked flames and smoking are

prohibited whe nhandling the bat-

tery .Avoid creating sparks. Batter

y(vehicle)

225Breakdown assis tance Z

Page 232 of 261

X

Lift up cover :of positive terminal ;in the direction of the arrow.

X Connect positive terminal ;on yourv ehicle to positive terminal ?of donor battery Busing the

jump lead, Alwaysb eginw ith positive terminal ;on youro wn vehicle first.

X Start the engine of the donor vehicle and run it at idling speed.

X Connect negative terminal Aof donor battery Bto earth point =of yourv ehicle using the jump

lead, connecting the jump leadtod onor batteryBfirst.

X Start the engine.

X Before disconnecting the jump leads, let the engines run for several minutes.

X First, remove the jump leads from earth point =and negative terminal A,then from positive

terminal ;and positive terminal ?.Each time, beginatt he contacts on youro wn vehicle.

X Close cover :of positive terminal ;after removing the jump leads.

X Have the battery checked at aqualifieds pecialist workshop.

Jump-starting is not considered to be anormal operating condition.

i Jump-starting cablesa

nd further information regarding jump-starting can be obtained at any

qualifieds pecialist workshop. Towinga

wayand tow-starting Importan

tsafety notes G

WARNING

Safety-relevant function sare restricted or not

available if:

R the engine is not running.

R the brake system or the power steering is

malfunctioning

R the voltag esupply or the vehicle's electrical

system is malfunctioning.

If yourv ehicleist owed,s ignificantly greater

force may be required to steer the vehicl eor

to brake. There is arisk of an accident.

In such circumstances, use atowing bar.

Make sure that the steering is moving freely

before towing. G

WARNING

If the steering whee llock is engaged, the vehi-

cle can no longer be steered .There is arisk of

an accident.

Always switch on the ignitio nwhen towing

with atow rope or atowing bar. G

WARNING

When towing or tow-starting another vehicle

and its weight is greater than the permissible gross weight of yourv ehicle, the:

R towing eye may be torn off

R car/trailer combination may swerve or

even overturn

There is arisk of an accident.

When towing or tow-starting another vehicle,

its weight should not be greater than the per- missible gross weight of yourv ehicle.

Detail sonthe permissible gross vehicl eweight

of yourv ehiclecan be found on the vehicl eiden-

tification plate (Y page249).

! You may tow the vehicl

efor am aximu mof

50km. Atowing spee dof50km/h must not

be exceeded.

For towing distances over 50 km, the entire

vehicl emust be lifted up and transported.

! Only secure the tow cabl

eortowing bar to

the towing eyes. You coul dotherwise damage

the vehicle.

! Observe the following points when towing

with atow rope:

R Secure the tow rope on the same side on

both vehicles.

R Make sure that the tow rope is not longer

than legally permitted. Mark the tow rope in the middle, e.g. with awhite cloth Towin

gawayand tow-starting

229Breakdown assis tance Z

Page 233 of 261

(30

x30c m). This will make othe rroad

users aware that avehicle is being towed.

R Only secure the tow cable to the towing

eyes or, if available, to the trailer tow hitch.

R Observ ethe brake lamps of the towing

vehicle while driving. Always maintain adis-

tance adistance so that the tow rope does

not sag.

R Do not use steel cables or chain stotow

your vehicle. You could otherwise damage

the vehicle.

! Do not use the trailer tow hitc

hfor recovery

or towing. Do not use the towin geye for

recovery. This could damage the vehicle. If in

doubt, have the vehicle recovered using a

crane.

! When towing, pull away slowly and

smoothly. If the tractive power is too high, the

vehicles could be damaged.

! Your vehicles is equipped with an automatic

transmission .Therefore, you must not have

the vehicle tow-started. The transmission

may otherwise be damaged.

Observ ethe legal requirementsine ach individ-

ual country when towing.

It is better to have the vehicle transported than

to have it towed.

If the transfer case can be shifted int othe Neu-

tral position, you can tow away the vehicle.

If the transfer case cannot be shifted int othe

Neutral position, you can tow away the vehicle

with one axle raised. Please bear the following in

mind:

R remov ethe propeller shaft from between the

transfer case and the rolling axle.

R turn the key to position 1in the ignition lock.

The battery must be connected and charged.

Otherwise, you:

R cannot turn the key to position 2in the igni-

tion lock

R cannot shift the automatic transmission to

position i To

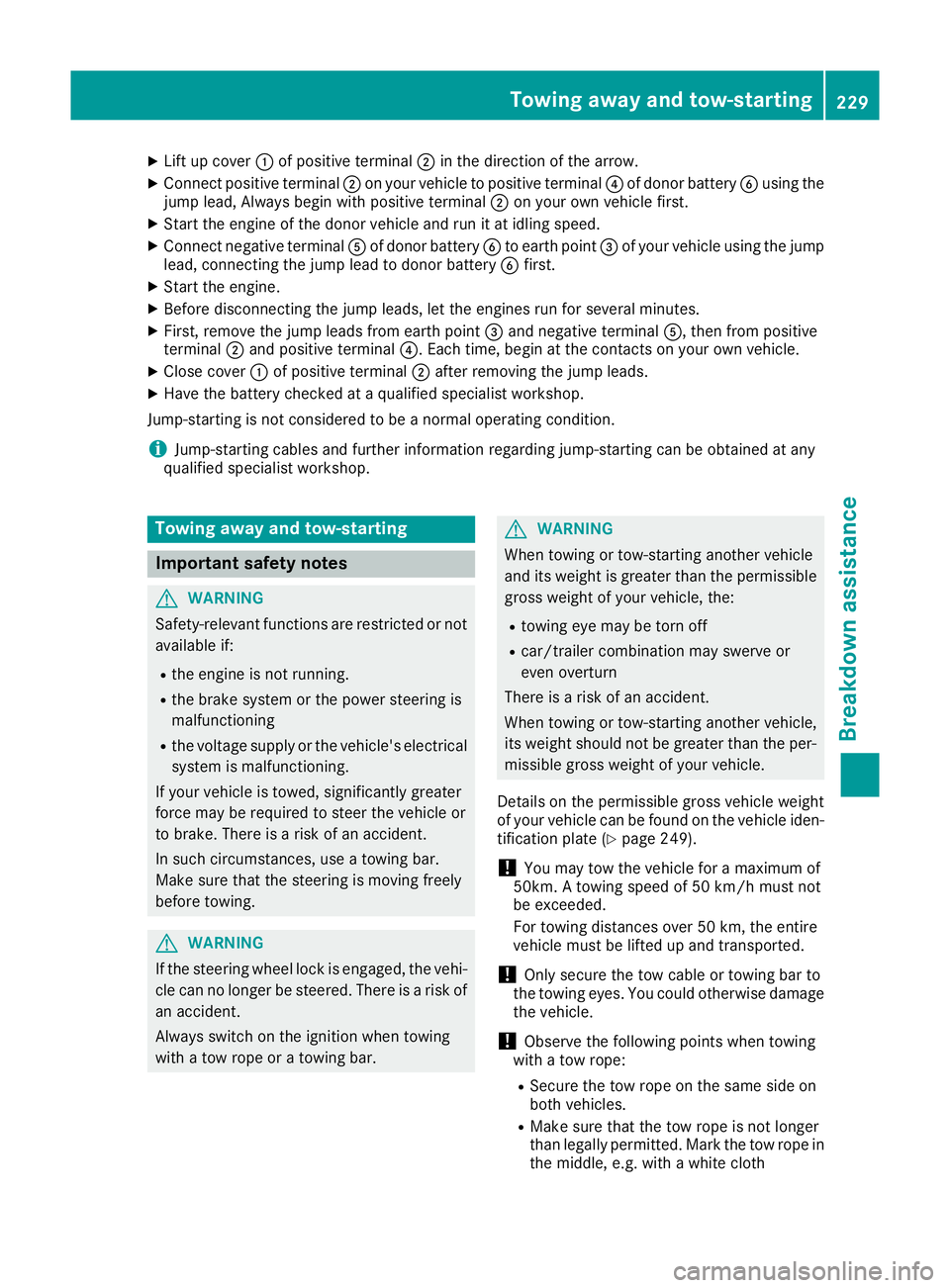

wing eyes

Towin geyes, front :

Towing eyes ,front

Towing eye, rear Towing eyes

:are located at the rear on the left

and right-hand side beneath the bumper. To

wing the vehicle away with all

wheels on the ground

It is important tha tyou observe the safety

instructions when towing away your vehicle

(Y page 229).

The automatic transmission automaticall yshifts

to position Pwhen yo uopenthe driver's or front-

passenge rdoororw heny ou remove the key

fro mt he ignition lock. In order to ensur etha tthe

automatic transmission stays in position N

when towing away the vehicle, yo umust

observe the following points:

X Make sure tha tthe vehicl eisstationary.

X Turn the key to position 2in the ignition

lock. 230

Towing away an

dtow-startingBreakdowna ssistan ce

Page 234 of 261

X

When the vehicle is stationary, depress the

brake pedal and keep it depressed.

X Shift the transfer case to position Neutral

(Y page 125).

X Shift the automatic transmission to position

N.

X Leave the key in position 2in the ignition

lock.

X Release the brake pedal.

X Release the parking brake.

X Switc hont he hazard warning lamps

(Y page 76).

In order to signal achange of direction when

towing the vehicle with the hazard warning

lamps switched on, use the combination switch

as usual. In this case, only the turn signals for

the desired direction flash. When you reset the

combination switch, the hazard warning lamps

start flashing again.

i The automatic transmission can only

change gear when the batter yhas sufficient

charge.

If you cannot shift the automatic transmission

to position N,the propeller shafts to the

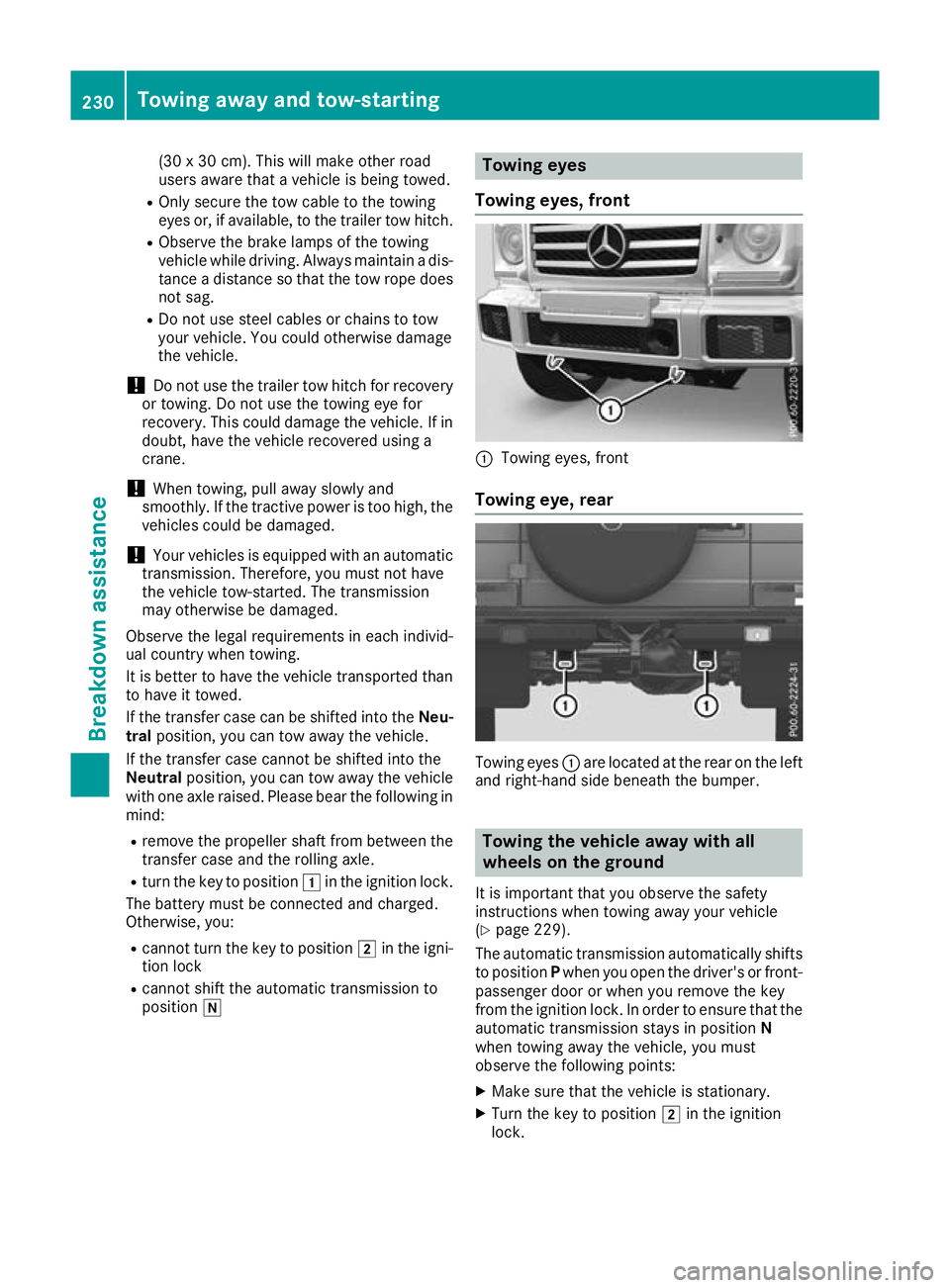

driven axles must be removed. Transporting thev

ehicle !

Whe

nthe vehicle is loadedf or transport, the

front and rear axles must be stationary and on the same transportation vehicle. Positioning

over the connection point of the transport

vehicle is not permitted. The drive train may

otherwise be damaged.

! You may only secure the vehicle by the

wheels, not by parts of the vehicle such as

axle or steering components. Otherwise, the

vehicle could be damaged. The towing eye or trailer tow hitch can be used

to pull the vehicle onto

atrailer or transporter if

you wish to transport it.

X Turn the key to position 2in the ignition

lock.

X Shift the transfer case to position Neutral

(Y page 125).

X Shift the automatic transmission to position

N.

As soon as the vehicle is loaded:

X Apply the parking brake.

X Shift the automatic transmission to position

P.

X Turn the key to position uin the ignition lock

and remove it.

X Secure the vehicle. Recovering

avehicle that has become

stuck

! Whe

nrecovering avehicl ethat ha sbecome

stuck, pull it as smoothly and evenly as pos-

sible .Ifthe tractive power is too high, the

vehicles could be damaged.

If the drive wheel sget trapped on loose or

muddy ground ,recover the vehicl ewitht he

utmost care ,especially so if the vehicl eisladen.

Neve rattempt to recover avehicl ewithat railer

attached.

Pull ou tthe vehicl ebackwards ,ifpossible ,using

the tracks it mad ebefore it became stuck. Towin

ginthe even tofm alfunctions

General notes !

If you are removing the propelle

rshaft, use

M10 nuts as spacers on the M8 bolts and

secure them with M8 nuts.

New self-locking nuts must be used when the propellers hafts are refitted.

It is important that you observe the safety

instructionsw hen towing awayy our vehicle

(Y page 229).

i Consult

aMercedes-Benz Service Centre

and seek advice. To

wing away and tow-starting

231Breakdown assis tance Z

Page 235 of 261

In th

eevent of damage to th eengine,

transmission or electrical system X

Shift th etransfer cas etoneutral position

Neutral (Ypage 125).

X Shif tthe automatic transmissio ntoposition

N.

In the even tofdamage to the transfer

case Have the propeller shafts between the axles and

the transfe rcase removed.

In the event of damage to the front axle Have the propeller shaft between the rea

raxle

and the transfe rcase removed.

The nhavet he vehicle towe dawayw itht he front

axl eraised.

In the event of damage to the rear axle Have the propeller shaft between the front axle

and the transfe rcase removed.

The nhavet he vehicle towe dwitht he rea raxle

raised and wheel rollers unde rthe front axle. Tow-start

ing( em ergency engine

starting)

! Do not tow-start vehicles with automatic

transmission. Yo ucould otherwis edamage

the automatic transmission.

Yo uc an find informatio non"Jump-starting"

under (Y page 227). Fuses

Importan

tsafety notes G

WARNING

If yo umanipulate, bridge or replace afaulty

fuse with afuse of ahigher amperage ,the

electric cables coul dbeoverloaded. This may

result in afire. There is arisk of an accident

and injury.

Always replace faulty fuses with specified new fuses of the correct amperage. The fuses in your vehicle disconnect fault

ycir-

cuits. If afuse blows, all the components in the

circuit and their functions will fail.

Blown fuses must be replaced with fuses of the same rating, which you can recognise by the

colour and fuse rating. The fuse ratings are listed

in the fuse allocation chart (Y page 233).

If the newly inserted fuse also blows, have the

cause traced and rectified at aqualified special-

ist workshop, e.g. aMercedes-Benz Service

Centre.

! Only use fuses that have been approved for

Mercedes-Benz vehicles and which have the

correc tfuse rating for the system concerned.

Otherwise, components or systems could be

damaged.

! Make sure that no moisture can enter the

fuse box when the cover is open.

! When closing the cover, make sure that it is

lying correctly on the fuse box. Moisture seep-

ing in or dirt could otherwise impair the oper-

ation of the fuses. Bef

orer eplacing afuse

Observ ethe important safety notes

(Y page 232).

X Switch off the engine.

X Switch off al lelectrical consumers.

X Remove the key from the ignition lock.

All indicator lamps on the instrument cluster

must be off.

X Secure the vehicl eagain st rolling away

(Y page 113).

The fuses are locate dinvarious fus eboxes:

R Main fus eboxon the front-passenger side of

the dashboard

R Fus eboxin the front-passenger footwell

R Fus eboxin the transmission tunnel

R Fus eboxin the luggage compartment

The fus ealloc ation chart and the spare fuses are

in the fus eboxon the dashboard on the front-

passenger side (Y page 233).

The fus eextractor is in the vehicl etool kit

(Y page 223). 232

FusesBreakdo

wn assis tance

Page 246 of 261

Brazil

Este equipamento opera em caráte

rsecundário,

isto é, não tem direito àproteçã ocontra inter-

ferênci aprejudicial ,mesmo de estaçõe sdo

mesmo tipo, enão pode causa rinterferência a

sistemas operando em caráte rprimário. Changin

gawheel Flat tyre

You can fin dinformation on what to do in the

event of aflat tyr eunder "Breakdown assis-

tance" (Y page 224). Interchanging th

ewheels G

WARNING

Interchangin gthe front and rear wheels may

severely impair the driving characteristics if

the wheels or tyres have different dimensions. The whee lbrakes or suspension components

may alsobed amaged. There is arisk of acci-

dent.

Interchange front and rear wheels only if the

wheels and tyres are of the same dimensions.

! On vehicles fitted with

atyre pressure mon-

itor, electronic components are located in the wheel.

Tyre-fitting tools should not be appliedint he

area of the valve ,asthis coul ddamage the

electronic components.

Only have tyres changed at aqualified spe-

cialist workshop.

Interchanging front and rear wheels of differing

dimensions can render the genera loperating

permi tinvalid.

Always pay attention to the instructions and

safety notes under "Changing awheel"

(Y page2 43). The wear patterns on the front and rear tyres

diffe

rdepending on the operating conditions.

Interchange the wheels before aclear wear pat-

tern has formed on the tyres. Frontt yres typi-

cally wear more on the shoulders, while rear

tyres wear more in the centre.

On vehicles that have front and rear wheels of

the same size, you can interchange the wheels

every 5,000 to 10,00 0kmd epending on the

degree of tyre wear. Ensure that the direction of

rotation is maintained.

Clean the contact surfaces of the wheel and the

brake disc thoroughly every time awheel is

interchanged. Check the tyre pressure and reac-

tivate the tyre pressure monitor if necessary

(Y page 241). Direction of rotation

Tyres with aspecifie ddirection of rotation have

additional benefits, e.g. if there is ariskofa qua-

planing. You will only gain these benefit sifthe

correc tdirection of rotation is observed.

An arrow on th esidewall of th etyrei nd icates its

correc tdirection of rotation.

You may fit th espar ewhee lagainst th edirection

of rotation .Observ ethe time restriction on use

as well as th espeed limitation specifie donthe

spar ewheel. Storin

gwheels

Storet yres that are not being used in acool, dry

and preferably dark place. Protect the tyres

against oil, grease, petrol and diesel. Fitting

awheel

Preparing th evehicle G

WARNING

If yo uremove the spar ewhee lfrom the spare

whee lbracket, the weight distributio nofthe

vehicl echanges .Ifyou have already raised

the vehicle, the jack coul dtip over. There is a

risk of injury.

Remove the spar ewhee lfrom the spar ewheel

bracket before raising the vehicle. Changing

awheel

243Wheels an dtyres Z

Page 247 of 261

X

Stop the vehicl eonsolid,non-slipper yand

level ground.

X Appl ythe parking brake.

X Move the front wheel stothe straight-ahead

position.

X Shif tthe automatic transmissio ntoposition

P.

X Switch off the engine.

X Ifat raile risc oupled to the vehicle, uncouple

it.

X Remove the vehicl etool sand jack from the

vehicl e(Ypage 223).

X Remove the spare wheel from the spare wheel

bracket (Y page 223).

X Secure the vehicl eagains trolling away.

Securing the vehicle against rolling

away X

Place chocks or other suitable items under

the front and rea rofthe wheel that is diago-

nally opposite the wheel you wish to change.

Raising the vehicle G

WARNING

If you do not position the jack correctl yatthe

appropriate jacking point of the vehicle, the

jack coul dtip over with the vehicl eraised.

There is arisk of injury.

Only position the jack at the appropriate jack-

ing point of the vehicle. The base of the jack

must be positioned vertically,d irectly under

the jacking point of the vehicle.

! Only position the jack at the appropriate

jacking point of the vehicle. Otherwise, you

coul ddamage the vehicle.

Observe the following whenr aisingthe vehi-

cle:

R Use only the vehicle-specific jack that has

been tested and approved by Mercedes-Benz

to rais ethe vehicle. If the jack is used incor-

rectly, it coul dtip over while the vehicl eis

raised.

R The jack is designed only to rais ethe vehicle

for ashort time while awhee lisb eing

changed .Itisnot permissible to use it to per-

form maintenance work under the vehicle. R

Avoid changing the whee lonuphilland down-

hill slopes.

R Before raising the vehicle, secur eitagainst

rolling away by applying the parking brake and

positioning whee lchocks. Do not release the

parking brake whil ethe vehicl eisraised.

R The jack must be place donafirm, flatand

non-slip surface. On aloo se surface, alarge,

fla tload-beari ng underlay must be used .Ona

slippery surface, anon-slip underlay must be

used ,e.g.u se arubber matont iles.

R Do not us ewoode nblocks or similar objects

as ajack underlay .Otherwise, the jack will not

be able to achieve its load-bearing capacity

du etot he restricte dheight.

R Ensure tha tthe distance between the under-

side of the tyr eand the ground does not

exceed 3cm.

R Do not place your hands or fee tunder the

raised vehicle.

R Do not li eunder the raised vehicle.

R Do not start the engine when the vehicl eis

raised.

R Do not open or close adoorw hent he vehicle

is raised.

R Ensure tha tnopersons ar epresent in the

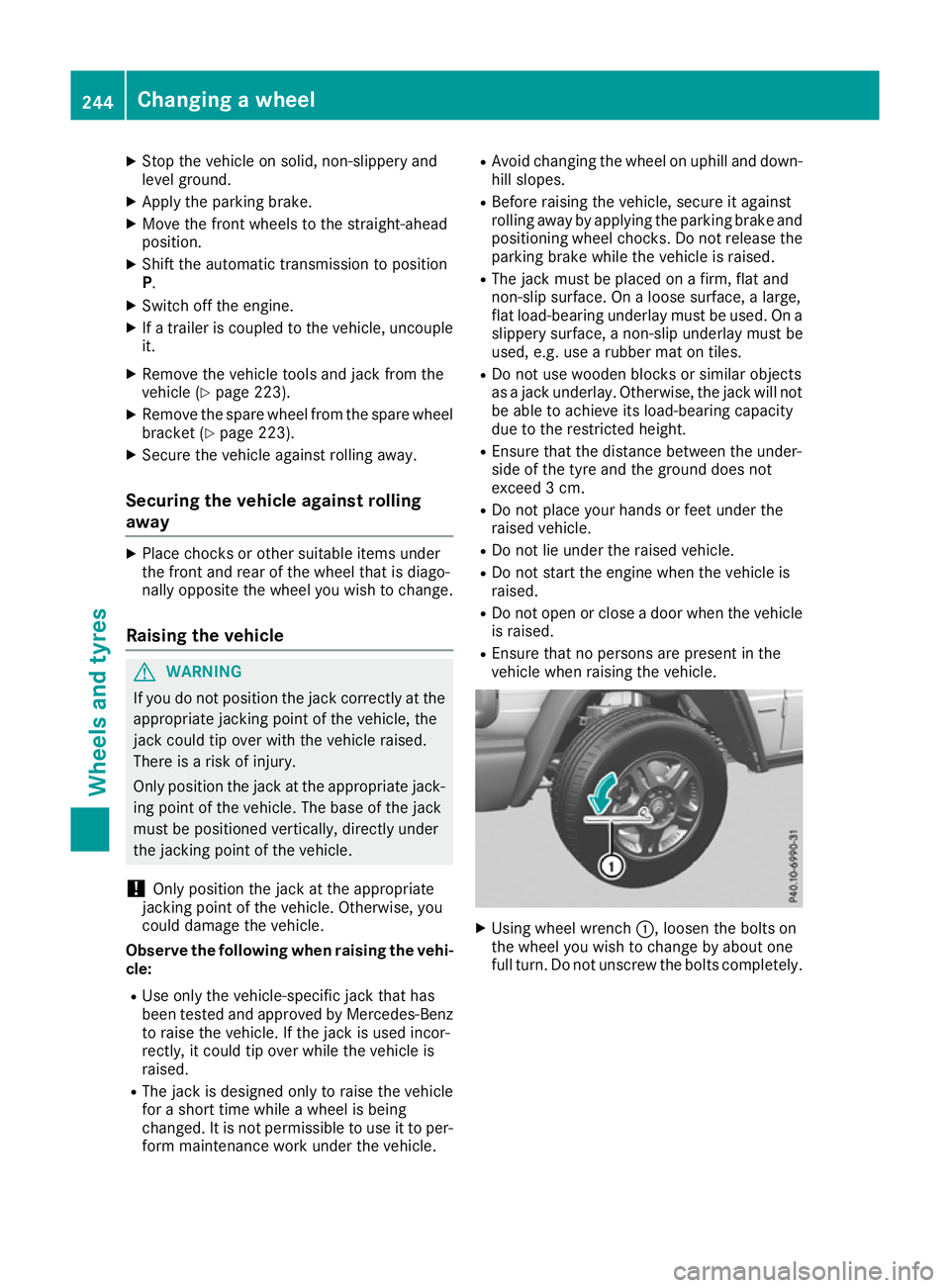

vehicl ewhenr aisin gthe vehicle. X

Using wheel wrench :,loosen the bolts on

the wheel you wish to change by abouto ne

full turn. Do not unscrew the bolts completely. 244

Changing

awheelWheels and tyres

Page 248 of 261

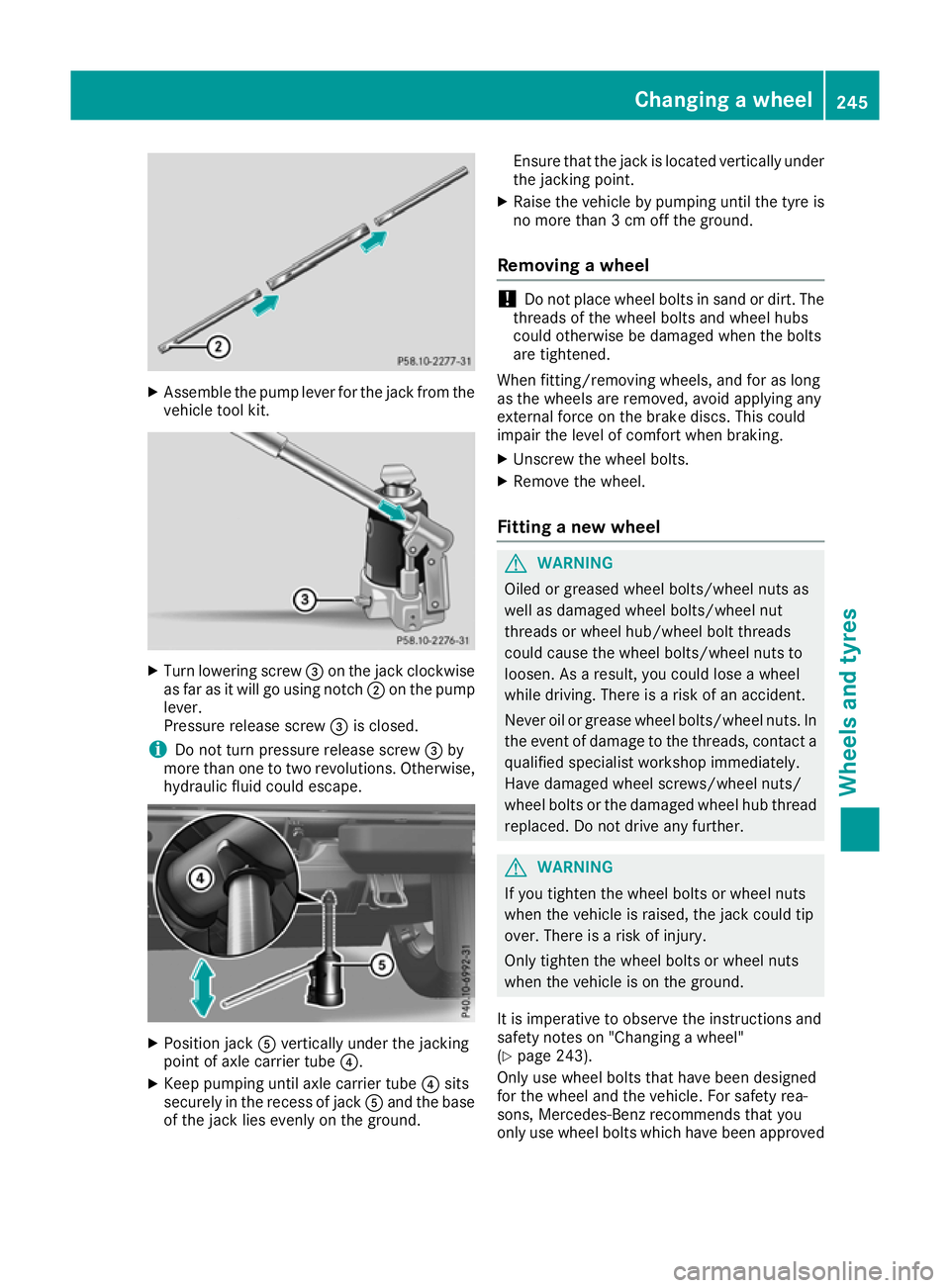

X

Assembl ethe pump lever for the jack from the

vehicl etool kit. X

Tur nlowering screw =on the jack clockwise

as far as it will go using notch ;on the pump

lever.

Pressure release screw =is closed.

i Do not turn pressure release screw

=by

more than one to two revolutions. Otherwise,

hydrauli cfluid could escape. X

Position jack Avertically under the jacking

point of axle carrier tube ?.

X Keep pumping until axle carrier tube ?sits

securely in the recess of jack Aand the base

of the jack lies evenly on the ground. Ensure that th

ejack is locate dverticall yunder

the jacking point.

X Rais ethe vehicl ebypumping unti lthe tyr eis

no mor ethan3cmo ff the ground.

Removing awheel !

Do no

tplace wheel bolts in sand or dirt. The

threads of the wheel bolts and wheel hubs

could otherwise be damagedw hen the bolts

are tightened.

When fitting/removing wheels, and for as long

as the wheels are removed, avoid applying any

external force on the brake discs. This could

impair the level of comfort when braking.

X Unscrew the wheel bolts.

X Remove the wheel.

Fitting anew wheel G

WARNING

Oiled or greased wheel bolts/wheel nuts as

well as damaged wheel bolts/wheel nut

threads or wheel hub/wheel bolt threads

could cause the wheel bolts/wheel nuts to

loosen. As aresult, you coul dlose awheel

while driving. There is arisk of an accident.

Never oil or grease whee lbolts/wheel nuts. In

the event of damage to the threads, contact a

qualified specialist worksho pimmediately.

Have damaged whee lscrews/wheel nuts/

whee lbolts or the damaged whee lhub thread

replaced. Do not drive any further. G

WARNING

If you tighten the whee lbolts or whee lnuts

when the vehicl eisraised, the jack coul dtip

over. There is arisk of injury.

Only tighten the whee lbolts or whee lnuts

when the vehicl eisonthe ground.

It is imperative to observe the instructions and

safety notes on "Changing awheel"

(Y page2 43).

Only use whee lbolts that have been designed

for the whee land the vehicle. For safety rea-

sons, Mercedes-Benz recommends that you

only use whee lbolts which have been approved Changing

awheel

245Wheels an dtyres Z

Page 249 of 261

for Mercedes-Benz vehicles and the respective

wheel.

X Clean the whee land whee lhub contact sur-

faces.

X Place the new whee lonthe whee lhub and

pus hito n.

X Tighten the whee lbolts until they are finger-

tight.

Lowering the vehicle G

WARNING

The wheels coul dwork loos eifthe whee lnuts

and bolts are not tightened to the specified

tightening torque .There is arisk of accident.

Have the tightening torque immediately

checked at aqualified specialist workshop

after awhee lisc hanged.

X Slowl yopen the pressure release screw on

the jack using the pump leve rbyapprox-

imatel yone full turn and carefully lower the

vehicl e(Ypage2 44).

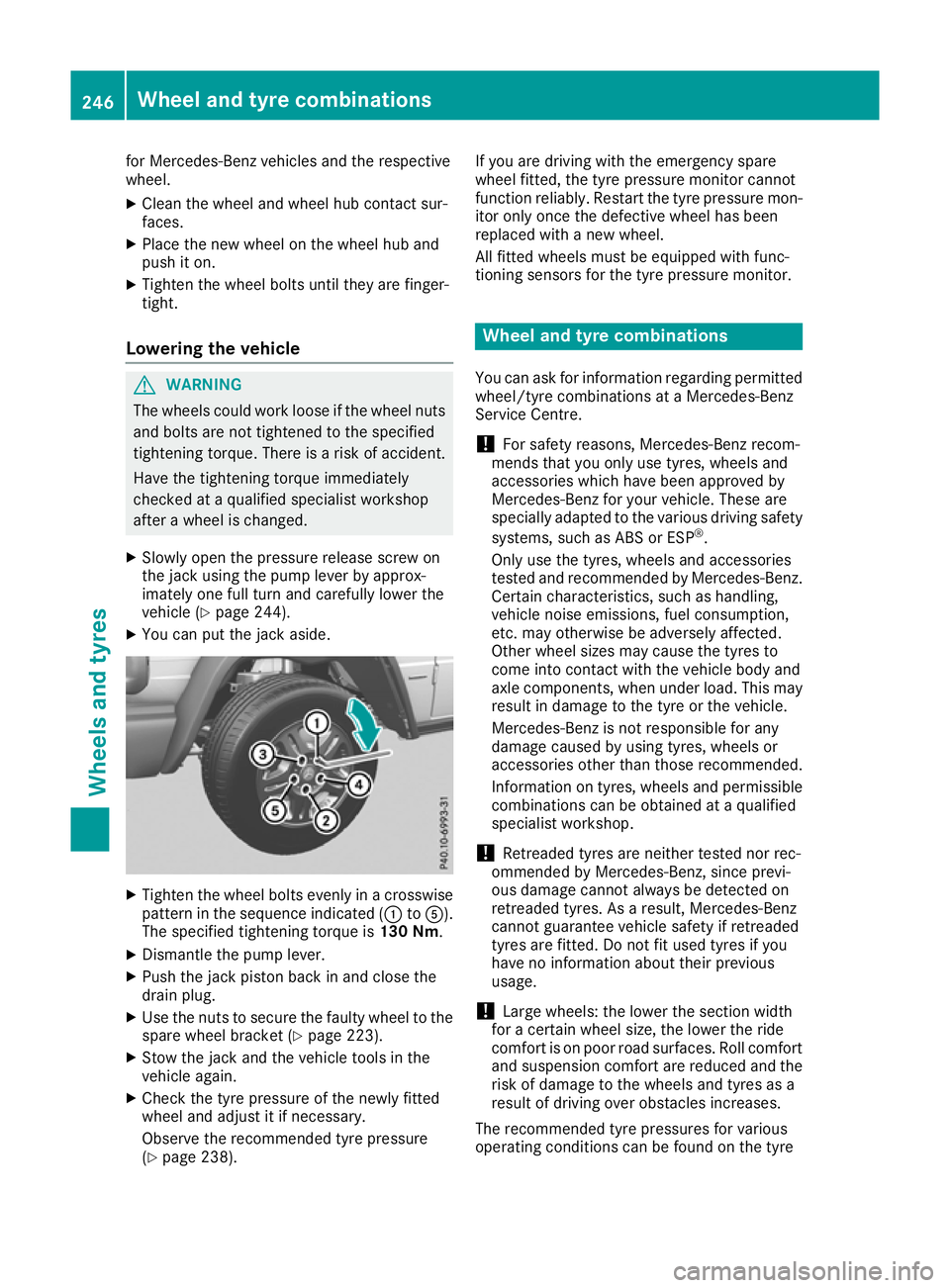

X You can put the jack aside. X

Tighten the wheel bolts evenl yinacrosswise

pattern in the sequence indicated (: toA).

The specified tightening torque is 130 Nm.

X Dismantle the pump lever.

X Push the jack piston back in and close the

drain plug.

X Use the nuts to secure the faulty wheel to the

spare wheel bracket (Y page 223).

X Stow the jack and the vehicle tools in the

vehicle again.

X Check the tyre pressure of the newly fitted

wheel and adjust it if necessary.

Observe the recommended tyre pressure

(Y page 238). If you are drivin

gwith the emergency spare

wheel fitted, the tyre pressure monitor cannot

function reliably.R estart the tyre pressure mon-

itor only once the defective wheel has been

replaced with anew wheel.

All fitted wheelsm ust be equipped with func-

tioning sensors for the tyre pressure monitor. Wheel and tyre combinations

You can ask for information regarding permitted

wheel/tyre combinations at aMercedes-Benz

Service Centre.

! For safety reasons, Mercedes-Benz recom-

mends that you only use tyres, wheels and

accessories which have been approved by

Mercedes-Benz for you rvehicle. These are

speciall yadapted to the various driving safety

systems, such as ABS or ESP ®

.

Only use the tyres, wheels and accessories

tested and recommende dbyMercedes-Benz.

Certain characteristics, such as handling,

vehicl enoise emissions, fuel consumption,

etc. may otherwise be adversely affected.

Other wheel sizes may caus ethe tyres to

come into contact with the vehicl ebody and

axle components, whe nunder load. This may

result in damage to the tyre or the vehicle.

Mercedes-Benz is not responsibl efor any

damage caused by using tyres, wheels or

accessories other than those recommended.

Informatio nontyres, wheels and permissible

combinations can be obtained at aqualified

specialist workshop.

! Retreaded tyres are neither tested nor rec-

ommende dbyMercedes-Benz, since previ-

ous damage cannot alwaysbed etected on

retreaded tyres. As aresult, Mercedes-Benz

cannot guarantee vehicl esafety if retreaded

tyres are fitted. Do not fit use dtyres if you

have no information about their previous

usage.

! Large wheels: the lower the section width

for acertain wheel size, the lower the ride

comfort is on poor road surfaces. Rol lcomfort

and suspension comfort are reduced and the risk of damage to the wheels and tyres as a

result of driving over obstacles increases.

The recommende dtyre pressures for various

operating conditions can be found on the tyre 246

Wheel and tyre combinationsWheels and tyres

Page 259 of 261

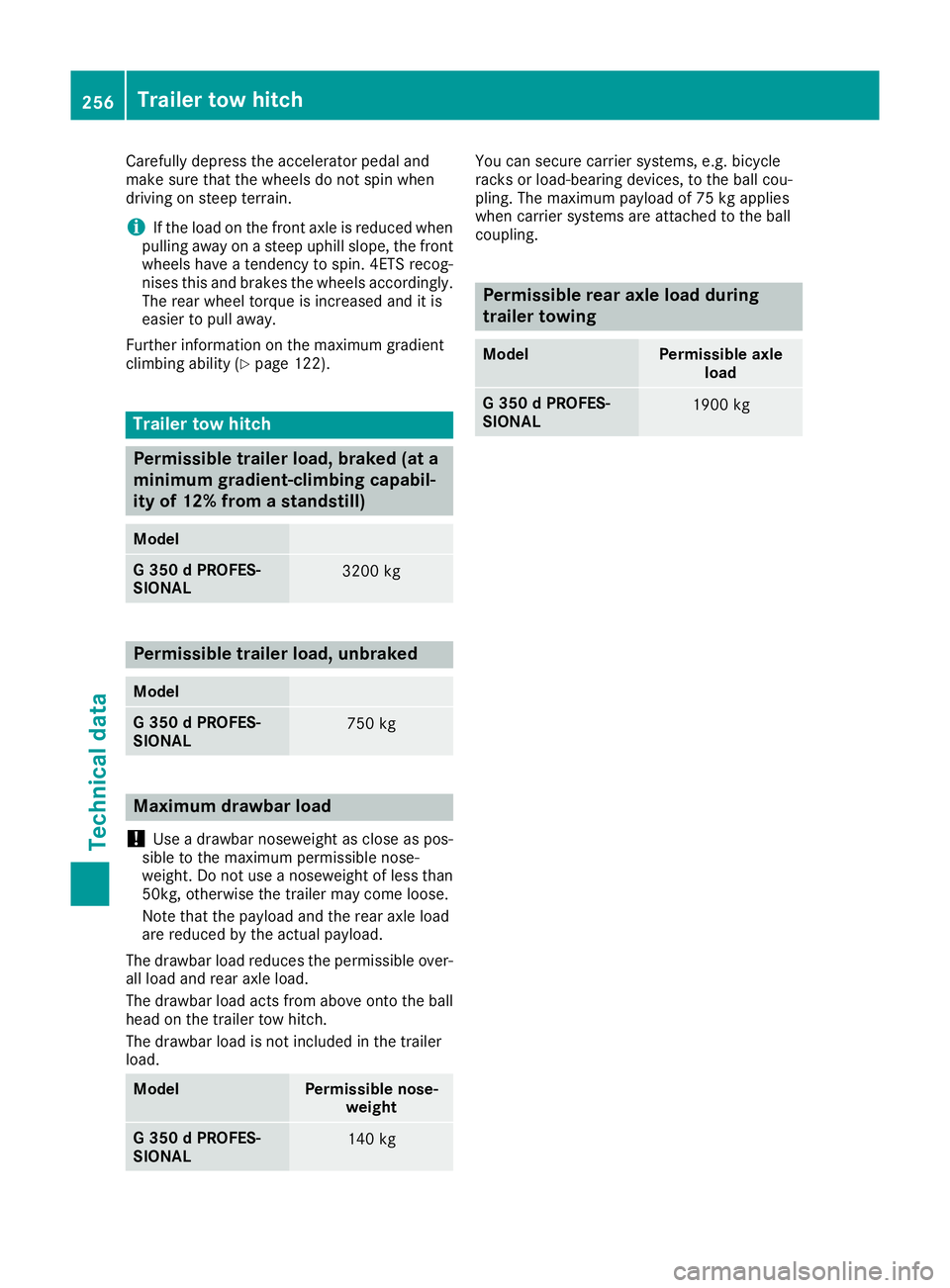

Carefully depress th

eaccelerato rpedal and

mak esure that th ewheel sdon otspin when

driving on steep terrain.

i If th

eload on th efront axle is reduced when

pullin gaway on asteep uphill slope, th efront

wheel shave atendenc ytos pin .4ETSr ecog-

nises this and brakes th ewheel saccordingly.

The rear wheel torque is increased and it is

easie rtop ull away.

Further informatio nonthemaximum gradient

climbin gabilit y(Ypage 122). Trailer to

whitch Permissible trailer load, braked (at a

minimu mgradient-climbing capabil-

ity of 12% from astandstill) Model

G3

50dPROFES-

SIONAL 3200 kg

Permissible trailer load, unbraked

Model

G3

50dPROFES-

SIONAL 750 kg

Maximum drawbar load

! Use

adrawbar noseweight as close as pos-

sibl etot he maximu mpermissible nose-

weight. Do not use anoseweight of less than

50kg, otherwise the trailer may come loose.

Note that the payloada nd the rear axle load

are reduced by the actua lpayload.

The drawbar loadr educes the permissible over-

all loa dand rear axle load.

The drawbar loada cts from above onto the ball

hea dont he trailer tow hitch.

The drawbar loa disnot included in the trailer

load. Model Permissiblen

ose-

weight G3

50dPROFES-

SIONAL 140 kg You can secure carrier systems, e.g

.bicycle

rack sorl oad-bearing devices, to the ball cou-

pling. The maximum payload of 75 kg applies

when carrier systems are attached to the ball

coupling. Permissible rear axle load during

trailer towing

Model Permissibl

eaxle

load G3

50dPROFES-

SIONAL 1900 kg256

Trailer tow hitchTechnical data