brake MERCEDES-BENZ METRIS 2020 MY20 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2020, Model line: METRIS, Model: MERCEDES-BENZ METRIS 2020Pages: 320, PDF Size: 26.38 MB

Page 276 of 320

X

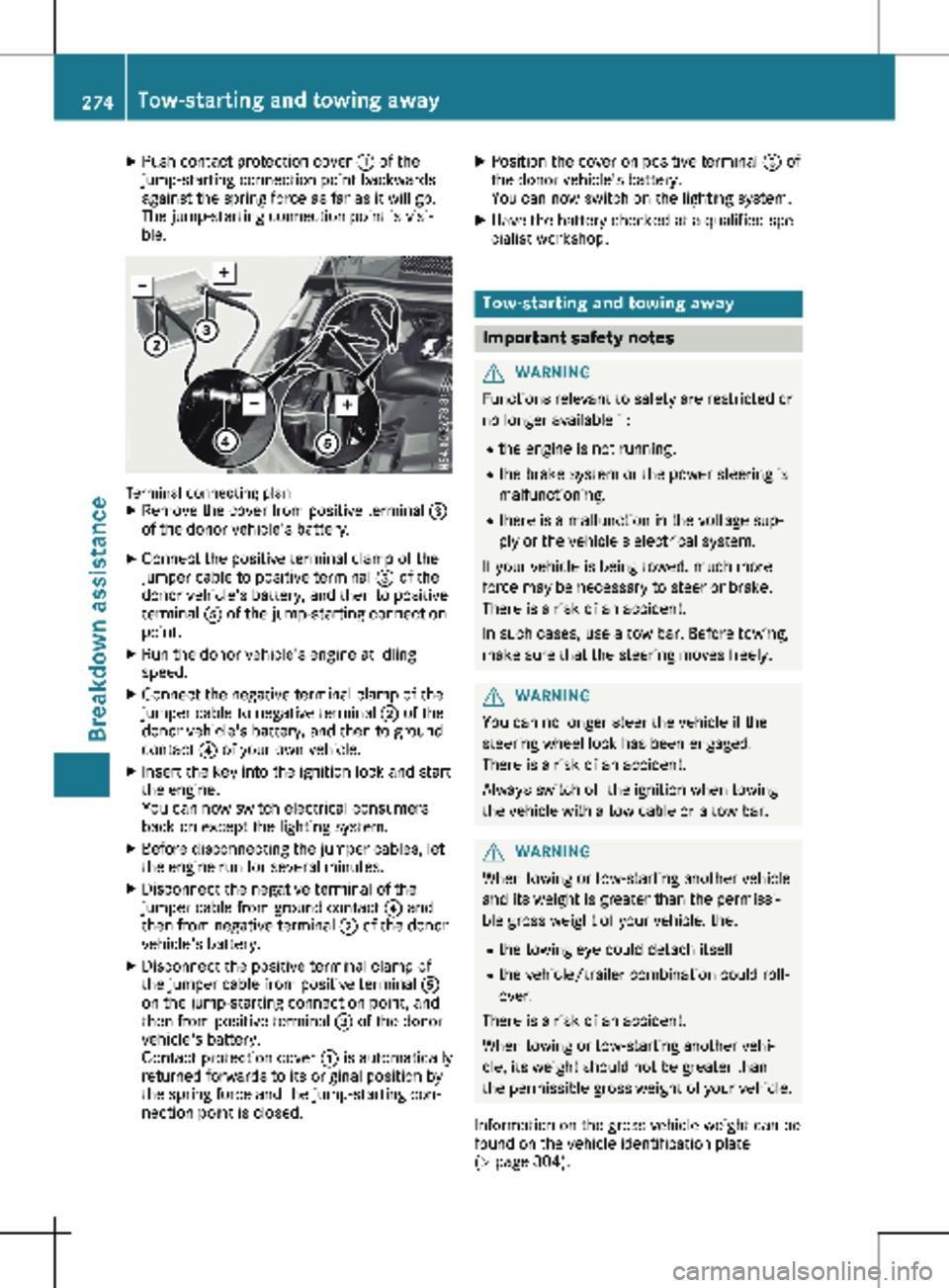

Push contact protection cover : of the

jump-starting connection point backwards

against the spring force as far as it will go.

The jump-starting connection point is visi-

ble. Terminal connecting plan

X Remove the cover from positive terminal =

of the donor vehicle's battery.

X Connect the positive terminal clamp of the

jumper cable to positive terminal = of the

donor vehicle's battery, and then to positive

terminal A of the jump-starting connection

point.

X Run the donor vehicle's engine at idling

speed.

X Connect the negative terminal clamp of the

jumper cable to negative terminal ; of the

donor vehicle's battery, and then to ground

contact ? of your own vehicle.

X Insert the key into the ignition lock and start

the engine.

You can now switch electrical consumers

back on except the lighting system.

X Before disconnecting the jumper cables, let

the engine run for several minutes.

X Disconnect the negative terminal of the

jumper cable from ground contact ? and

then from negative terminal ; of the donor

vehicle's battery.

X Disconnect the positive terminal clamp of

the jumper cable from positive terminal A

on the jump-starting connection point, and

then from positive terminal = of the donor

vehicle's battery.

Contact protection cover : is automatically

returned forwards to its original position by

the spring force and the jump-starting con-

nection point is closed. X

Position the cover on positive terminal = of

the donor vehicle's battery.

You can now switch on the lighting system.

X Have the battery checked at a qualified spe-

cialist workshop. Tow-starting and towing away

Important safety notes

G

WARNING

Functions relevant to safety are restricted or

no longer available if:

R the engine is not running.

R the brake system or the power steering is

malfunctioning.

R there is a malfunction in the voltage sup-

ply or the vehicle's electrical system.

If your vehicle is being towed, much more

force may be necessary to steer or brake.

There is a risk of an accident.

In such cases, use a tow bar. Before towing,

make sure that the steering moves freely. G

WARNING

You can no longer steer the vehicle if the

steering wheel lock has been engaged.

There is a risk of an accident.

Always switch off the ignition when towing

the vehicle with a tow cable or a tow bar. G

WARNING

When towing or tow-starting another vehicle

and its weight is greater than the permissi-

ble gross weight of your vehicle, the:

R the towing eye could detach itself

R the vehicle/trailer combination could roll-

over.

There is a risk of an accident.

When towing or tow-starting another vehi-

cle, its weight should not be greater than

the permissible gross weight of your vehicle.

Information on the gross vehicle weight can be

found on the vehicle identification plate

(Y page

304).274

Tow-starting and towing away

Breakdown assistance

Page 278 of 320

X

Unscrew the towing eye.

X Insert cover : with the lug at the top and

press it in at the bottom until it engages.

X Stow the towing eye and the screwdriver

with the vehicle tool kit (Y page

270).Towing with the rear axle raised

! Vehicles with automatic transmission must

not be towed with the rear axle raised. The

vehicle/trailer combination may otherwise

swerve or even roll over.

! The ignition must be switched off if the

vehicle is being towed with the front or rear

axle raised. Otherwise, ESP ®

may intervene

and damage the brake system.

X Switch on the hazard warning lamps

(Y page

101).

X Turn the front wheels to the straight-ahead

position.

X Release the parking brake.

X If necessary, turn the key in the ignition lock

to position g and remove the key from the

ignition lock.

X Take the key with you when leaving the vehi-

cle.

X Do not exceed the towing speed of 30 mph

(50 km/h

).

Please observe the important safety instruc-

tions when towing your vehicle with the rear

axle raised

(Y page 274). Towing the vehicle with both axles

on the ground

Important safety notes G

WARNING

You can no longer steer the vehicle if the

steering wheel lock has been engaged.

There is a risk of an accident.

Always switch off the ignition when towing

the vehicle with a tow cable or a tow bar.

! Do not exceed the towing speed of

30 mph

(50 km/h). You could otherwise

damage the transmission. Please observe the important safety notes

before towing your vehicle

(Y page 274).

Towing vehicles with automatic trans-

mission X

Turn the key to position 2 in the ignition

lock.

X Depress the brake pedal and keep it

depressed.

X Shift the automatic transmission to position

i.

X Leave the key in position 2 in the ignition

lock.

X Switch on the hazard warning lamps

(Y page

101).

X Release the parking brake.

X Release the brake pedal.

X Do not exceed the towing speed of 30 mph

(50 km/h

). Recovering a vehicle that is stuck

! When recovering a vehicle that has

become stuck, pull it as smoothly and

evenly as possible. If the tractive power is

too high, the vehicles could be damaged.

If the drive wheels get trapped on loose or

muddy ground, recover the vehicle with the

utmost care. This is especially the case if the

vehicle is laden.

Never attempt to recover a vehicle with a

trailer attached.

Pull out the vehicle backwards, if possible,

using the tracks it made when it became

stuck. Transporting the vehicle

! You may only secure the vehicle by the

wheels, not by parts of the vehicle such as

axle or steering components. Otherwise, the

vehicle could be damaged.

The towing eye or trailer tow hitch can be used

to pull the vehicle onto a trailer or transporter

if you wish to transport it. 276

Tow-starting and towing away

Breakdown assistance

Page 279 of 320

X

Turn the key to position 2 in the ignition

lock.

X Shift the transmission to position i.

X Release the parking brake.

If the vehicle is loaded: X Shift the transmission to position j.

X Turn the key to position u in the ignition

lock and remove it.

X Make sure the parking brake is applied.

X Lash down the vehicle. Tow-starting (emergency engine

starting)

General notes !

Vehicles with automatic transmission must

not be tow-started. You could otherwise

damage the automatic transmission.

You can find information on jump-starting

under "Jump-starting“

(Y page 272).Electrical fuses

The fuse allocation chart and important safety

information on the fuses can be found in the

"Fuse allocation chart" supplement. Electrical fuses

277

Breakdown assistance Z

Page 280 of 320

Useful information

This Operator's Manual describes all models

as well as standard and optional equipment of

your vehicle that were available at the time of

going to print. Country-specific variations are

possible. Note that your vehicle may not be

equipped with all of the described functions.

This also applies to systems and functions rel-

evant to safety.

Read the information on qualified specialist

workshops (Y page

32).Important safety notes

G

Warning

A flat tire severely impairs the driving, steer-

ing and braking characteristics of the vehi-

cle. There is a risk of an accident.

do not drive with a flat tire. Immediately

replace the flat tire with your spare wheel,

or consult a qualified specialist workshop. G

WARNING

If you install wheels and tires with incorrect

dimensions, the service brake or wheel sus-

pension components may be damaged.

There is a risk of an accident.

Always replace wheels and tires with ones

that comply with the specifications of the

original part.

When replacing wheels, pay attention to the:

R Designation

R Model

When replacing tires, pay attention to the:

R Designation

R Manufacturer

R Model

Accessories that are not approved for your

vehicle by Mercedes-Benz or are not being

used correctly can impair operating safety. Before purchasing and using non-approved

accessories, visit a qualified specialist work-

shop and inquire about the following points:

R

suitability

R legal stipulations

R factory recommendations

Information on the dimensions and types of

wheels and tires for your vehicle can be found

under "Wheel and tire combinations"

( Y page

301).

Information on your vehicle's tire pressures

can be found in the following locations:

R in the Tire and Loading Information placard

on the B-pillar, driver's side

R in the tire pressure table inside the fuel filler

flap ( Y page 282)

R under "Tire pressure tables" (Y page 289)

R under "Tire pressure" (Y page 282)

Modifications to the brake system or wheels

are not permitted. The use of spacers or brake

dust shields is not permitted. This invalidates

the general operating permit for the vehicle.

Further information on wheels and tires can be

obtained at any qualified specialist workshop. Operation

Information for a journey

If the vehicle is heavily laden, check the tire

pressures, and correct them, if necessary

( Y page

282).

While driving, pay attention to vibrations,

noises and unusual handling characteristics,

e.g. pulling to one side. This may indicate that

the wheels or tires are damaged. If you sus-

pect that a tire is defective, reduce your speed

immediately. Stop the vehicle as soon as pos-

sible to check the wheels and tires for dam-

age. Hidden tire damage could also be causing

the unusual handling characteristics. If you

find no signs of damage, have the tires and

wheels checked at a qualified specialist work-

shop.

When parking your vehicle, make sure that the

tires do not get deformed by the curb or other

obstacles. If it is necessary to drive over curbs,

speed humps or similar elevations, try to do so

slowly and not at a sharp angle. Otherwise, the

tires, particularly the sidewalls, can get dam-

aged. 278

Operation

Wheels and tires

Page 288 of 320

For further information on displaying the cur-

rent tire pressures, refer to "Checking the tire

pressure electronically"

(Y page 287).

Important safety notes G

WARNING

Risk of accident due to incorrect tire

pressure

Each tire, including the spare (if provided),

should be checked monthly when cold and

inflated to the inflation pressure recommen-

ded by the vehicle manufacturer on the vehi-

cle placard or tire inflation pressure label. (If

your vehicle has tires of a different size than

the size indicated on the vehicle placard or

the tire inflation pressure label, you should

determine the proper tire inflation pressure

for those tires.)

As an added safety feature, your vehicle has

been equipped with a tire pressure monitor-

ing system (TPMS) that illuminates a low tire

pressure telltale when one or more of your

tires is significantly under-inflated. Accord-

ingly, when the low tire pressure telltale illu-

minates, you should stop and check your

tires as soon as possible, and inflate them to

the proper pressure. Driving on a signifi-

cantly under-inflated tire causes the tire to

overheat and can lead to tire failure. Under-

inflation also reduces fuel efficiency and tire

tread life, and may affect the vehicle's han-

dling and stopping ability.

Please note that the TPMS is not a substi-

tute for proper tire maintenance, and it is

the driver's responsibility to maintain cor-

rect tire pressure, even if under-inflation has

not reached the level to trigger illumination

of the TPMS low tire pressure telltale.

Your vehicle has also been equipped with a

TPMS malfunction indicator to indicate

when the system is not operating properly.

The TPMS malfunction indicator is combined

with the low tire pressure telltale. When the

system detects a malfunction, the telltale

will flash for approximately one minute and

then remain continuously illuminated. This sequence will continue upon subsequent

vehicle start-ups as long as the malfunction

exists.

When the malfunction indicator is illumina-

ted, the system may not be able to detect or

signal low tire pressure as intended. TPMS

malfunctions may occur for a variety of rea-

sons, including the installation of replace-

ment or alternate tires or wheels on the

vehicle that prevent the TPMS from func-

tioning properly.

Always check the TPMS malfunction telltale

after replacing one or more tires or wheels

on your vehicle to ensure that the replace-

ment or alternate tires and wheels allow the

TPMS to continue to function properly.

It is the driver's responsibility to set the tire

pressure to the recommended cold tire pres-

sure suitable for the operating conditions

(Y page

282).

Note that the correct tire pressure for the cur-

rent operating conditions must first be pro-

gramed into the tire pressure monitor. If a sub-

stantial pressure loss occurs, the warning

threshold for the warning message is aligned

to the taught-in reference values. Restart the

tire pressure monitor after adjusting the cold

tire pressure ( Y page 288). The current pres-

sures are saved as new reference values. This

will ensure that a warning message will only

appear if the tire pressure drops significantly.

The tire pressure monitor does not warn you if

a tire pressure is incorrect. Observe the notes

on the recommended tire pressure

(Y page 282).

The tire pressure monitor is not able to warn

you of a sudden loss of pressure, e.g. following

penetration by a foreign object. In this event,

brake the vehicle until it comes to a standstill.

Avoid sudden steering movements.

The tire pressure monitor has a yellow h

warning lamp in the instrument cluster for indi-

cating pressure loss/malfunctions (USA) or

pressure loss (Canada). Depending on how the

warning lamp flashes or lights up, an underin-

flated tire or a malfunction in the tire pressure

monitor is displayed:

R if the h warning lamp is lit continuously,

the tire pressure on one or more tires is sig- 286

Tire pressure

Wheels and tires

Page 291 of 320

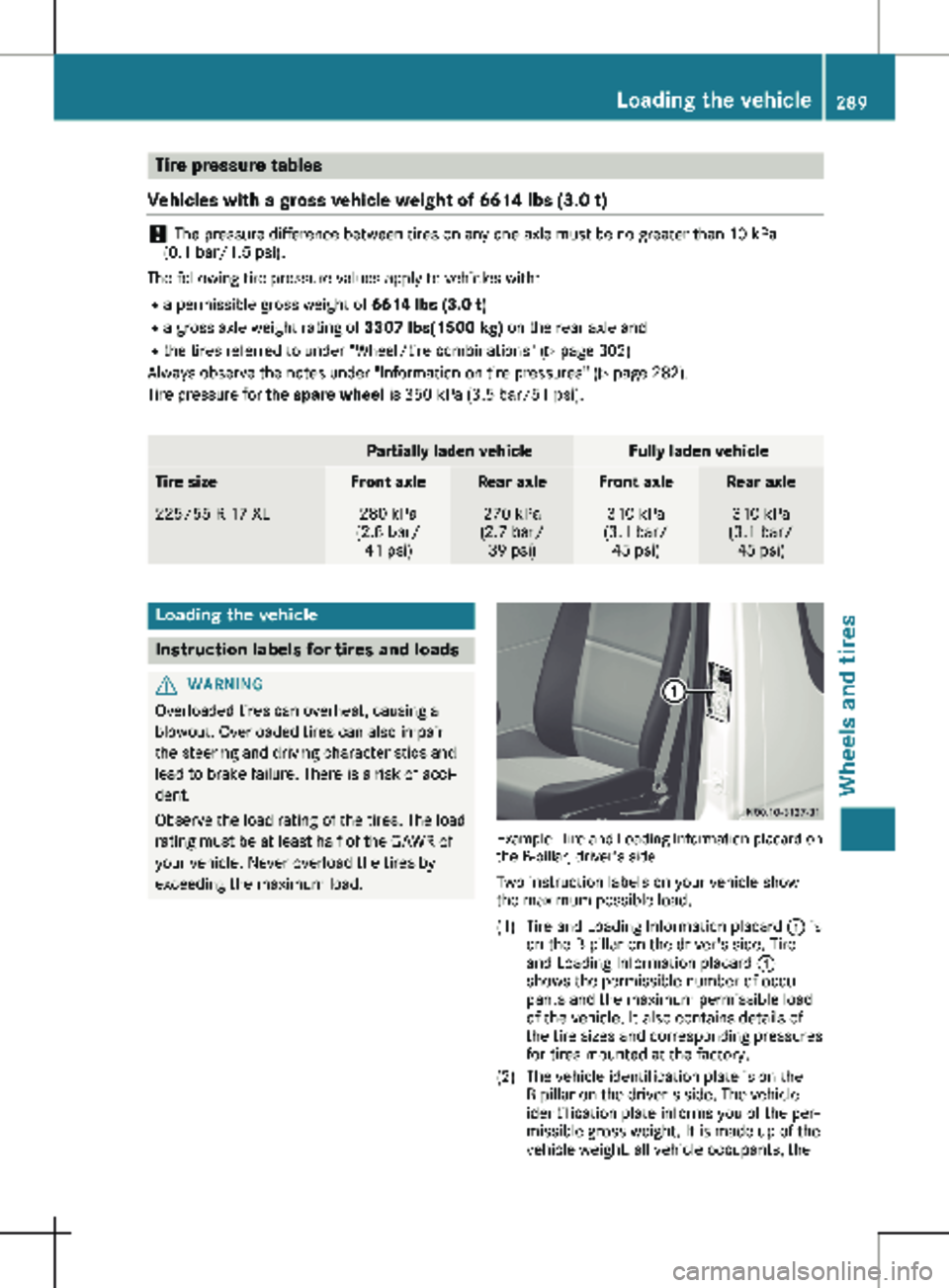

Tire pressure tables

Vehicles with a gross vehicle weight of 6614 lbs (3.0 t)!

The pressure difference between tires on any one axle must be no greater than

10 kPa

(0.1 bar/1.5 psi).

The following tire pressure values apply to vehicles with: R a permissible gross weight of 6614 lbs (3.0 t)

R a gross axle weight rating of 3307 lbs(1500 kg) on the rear axle and

R the tires referred to under "Wheel/tire combinations" (Y page 302)

Always observe the notes under "Information on tire pressures" (Y page 282).

Tire pressure for the spare wheel is 350 kPa (3.5 bar/51 psi).

Partially laden vehicle Fully laden vehicle

Tire size Front axle Rear axle Front axle Rear axle

225/55 R 17 XL 280 kPa

(2.8 bar/ 41 psi) 270 kPa

(2.7 bar/ 39 psi) 310 kPa

(3.1 bar/ 45 psi) 310 kPa

(3.1 bar/ 45 psi) Loading the vehicle

Instruction labels for tires and loads

G

WARNING

Overloaded tires can overheat, causing a

blowout. Overloaded tires can also impair

the steering and driving characteristics and

lead to brake failure. There is a risk of acci-

dent.

Observe the load rating of the tires. The load

rating must be at least half of the GAWR of

your vehicle. Never overload the tires by

exceeding the maximum load. Example: Tire and Loading Information placard on

the B-pillar, driver's side

Two instruction labels on your vehicle show

the maximum possible load.

(1) Tire and Loading Information placard : is

on the

B-pillar on the driver's side. Tire

and Loading Information placard :

shows the permissible number of occu-

pants and the maximum permissible load

of the vehicle. It also contains details of

the tire sizes and corresponding pressures

for tires mounted at the factory.

(2) The vehicle identification plate is on the B-pillar on the driver's side. The vehicle

identification plate informs you of the per-

missible gross weight. It is made up of the

vehicle weight, all vehicle occupants, the Loading the vehicle

289

Wheels and tires Z

Page 299 of 320

Tire tread

The part of the tire that comes into contact

with the road.

Tire bead

The tire bead ensures that the tire sits

securely on the wheel. There are several steel

wires in the bead to prevent the tire from com-

ing loose from the wheel rim.

SidewallThe part of the tire between the tread and the

tire bead.

Weight of optional extras The combined weight of those optional extras

that weigh more than the replaced standard

parts and more than 2.3 kg

(5 lbs). These

optional extras, such as high-performance

brakes, a roof rack or a high-performance bat-

tery, are not included in the curb weight and

the weight of the accessories.

TIN (Tire Identification Number) A unique identification number which can be

used by a tire manufacturer to identify tires,

for example for a product recall, and thus iden-

tify the purchasers. The TIN is composed of

the manufacturer identification code, tire size,

tire model code and manufacturing date.

Load bearing index

The load bearing index (also load index) is a

code that contains the maximum load bearing

capacity of a tire.

Traction

Traction is the result of friction between the

tires and the road surface.

TWR (permissible trailer drawbar load)

The TWR is the maximum permissible weight

that may act on the ball coupling of the trailer

tow hitch.

Wear indicator Narrow bars (tread wear bars) that are distrib-

uted over the tire tread. If the tire tread is level

with the bars, the wear limit of á in (1.6 mm)

has been reached. Distribution of the vehicle occupants

The distribution of vehicle occupants over des-

ignated seat positions in a vehicle.

Maximum permissible payload weightNominal load and goods/luggage load plus

68 kg (150 lbs) multiplied by the number of

seats in the vehicle. Changing wheels

Rotating the wheels

! On vehicles equipped with a tire pressure

monitor, electronic components are located

in the wheel.

Tire-mounting tools should not be used near

the valve. This could damage the electronic

components.

Only have tires changed at a qualified spe-

cialist workshop.

Always observe the instructions and safety

notes under "Mounting a wheel"

(Y page

298).

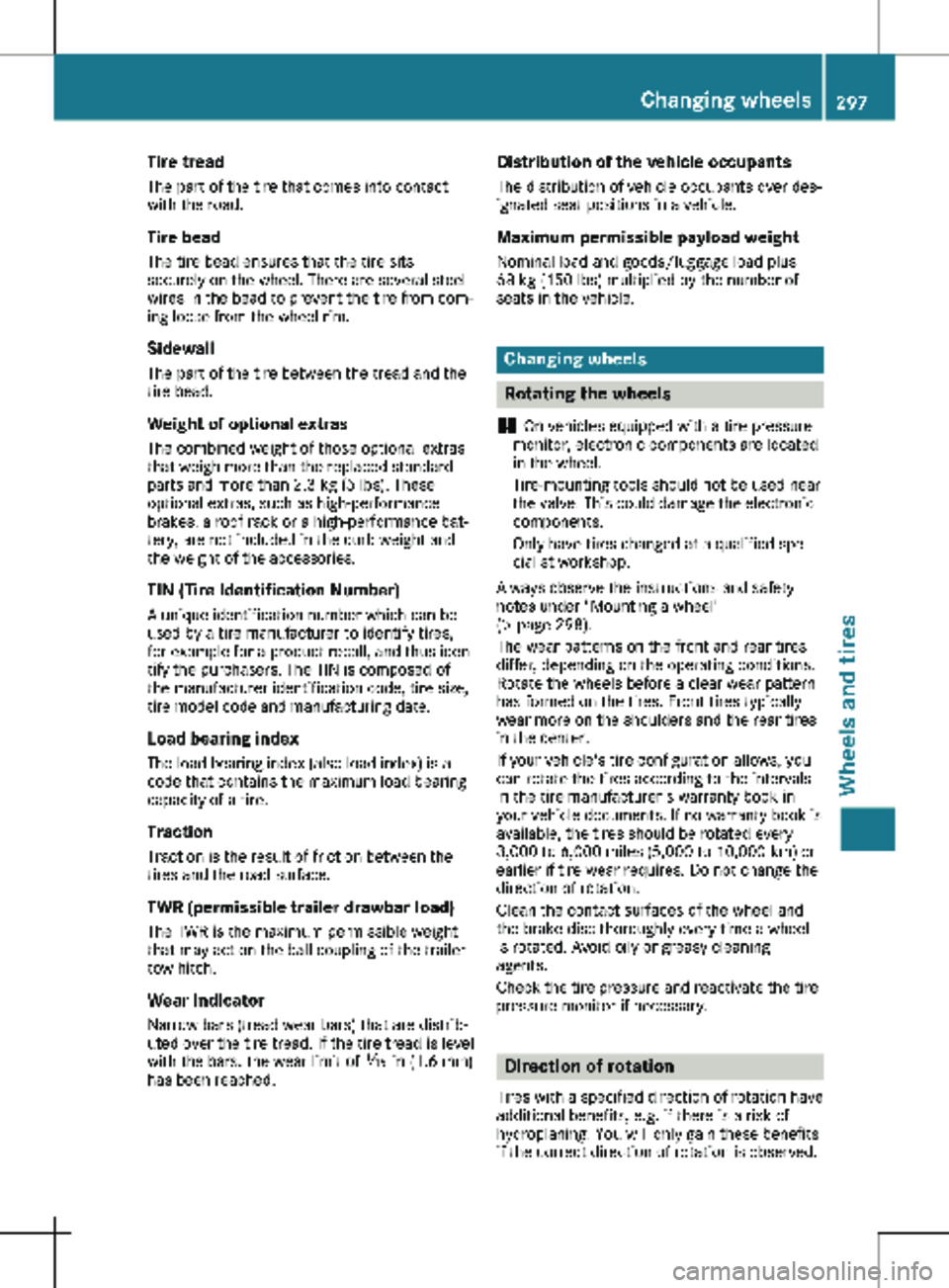

The wear patterns on the front and rear tires

differ, depending on the operating conditions.

Rotate the wheels before a clear wear pattern

has formed on the tires. Front tires typically

wear more on the shoulders and the rear tires

in the center.

If your vehicle's tire configuration allows, you

can rotate the tires according to the intervals

in the tire manufacturer's warranty book in

your vehicle documents. If no warranty book is

available, the tires should be rotated every

3,000 to 6,000 miles (5,000 to 10,000 km) or

earlier if tire wear requires. Do not change the

direction of rotation.

Clean the contact surfaces of the wheel and

the brake disc thoroughly every time a wheel

is rotated. Avoid oily or greasy cleaning

agents.

Check the tire pressure and reactivate the tire

pressure monitor if necessary. Direction of rotation

Tires with a specified direction of rotation have

additional benefits, e.g. if there is a risk of

hydroplaning. You will only gain these benefits

if the correct direction of rotation is observed. Changing wheels

297

Wheels and tires Z

Page 300 of 320

An arrow on the sidewall of the tire indicates

its correct direction of rotation.

You may mount a spare wheel against the

direction of rotation. Observe the time restric-

tion on use as well as the speed limitation

specified on the spare wheel. Storing wheels

Store wheels that are not being used in a cool,

dry and preferably dark place. Protect the tires

from contact with oil, grease and fuel. Mounting a wheel

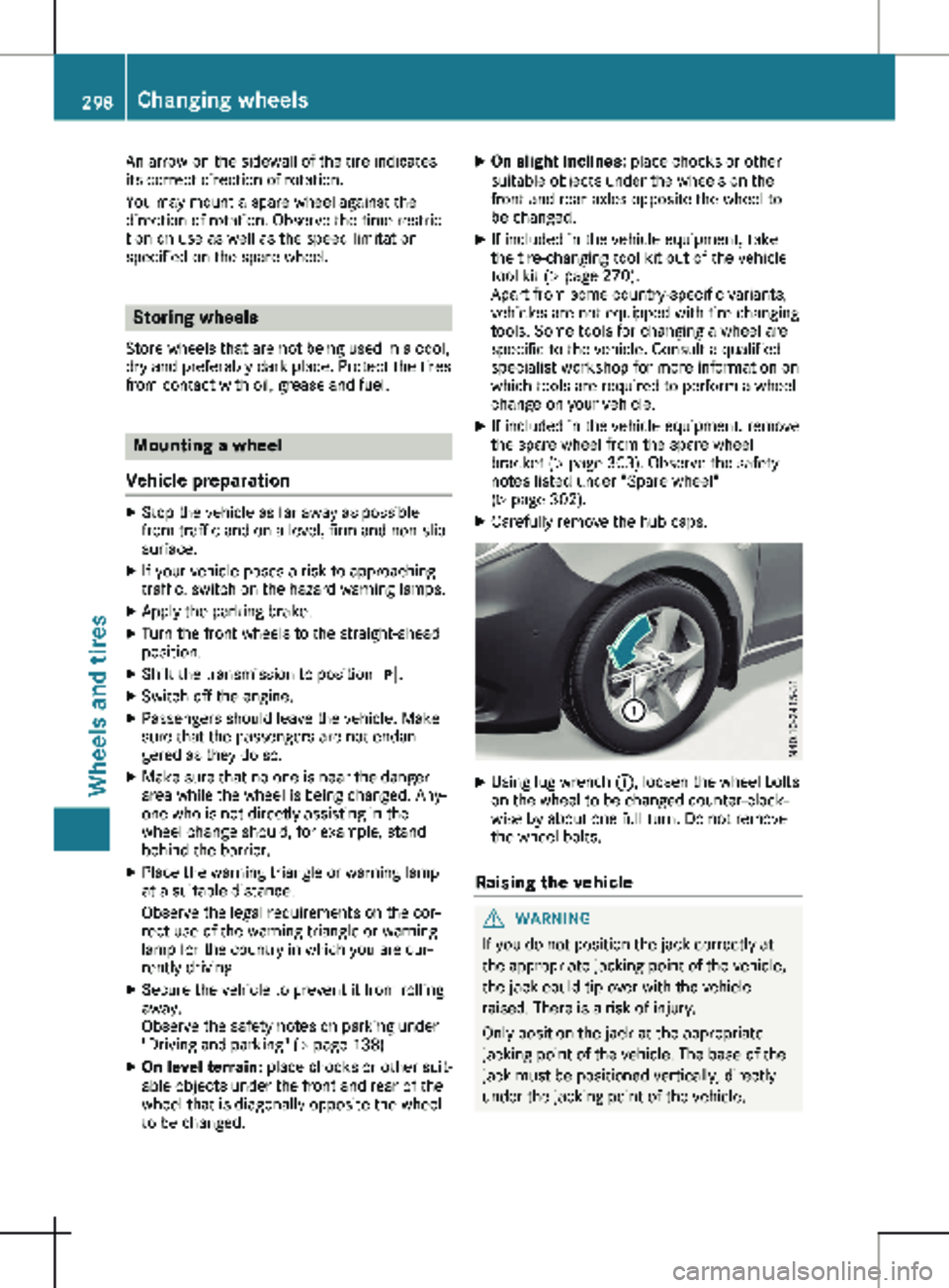

Vehicle preparation X

Stop the vehicle as far away as possible

from traffic and on a level, firm and non-slip

surface.

X If your vehicle poses a risk to approaching

traffic, switch on the hazard warning lamps.

X Apply the parking brake.

X Turn the front wheels to the straight-ahead

position.

X Shift the transmission to position j.

X Switch off the engine.

X Passengers should leave the vehicle. Make

sure that the passengers are not endan-

gered as they do so.

X Make sure that no one is near the danger

area while the wheel is being changed. Any-

one who is not directly assisting in the

wheel change should, for example, stand

behind the barrier.

X Place the warning triangle or warning lamp

at a suitable distance.

Observe the legal requirements on the cor-

rect use of the warning triangle or warning

lamp for the country in which you are cur-

rently driving

X Secure the vehicle to prevent it from rolling

away.

Observe the safety notes on parking under

"Driving and parking"

(Y page 138)

X On level terrain: place chocks or other suit-

able objects under the front and rear of the

wheel that is diagonally opposite the wheel

to be changed. X

On slight inclines: place chocks or other

suitable objects under the wheels on the

front and rear axles opposite the wheel to

be changed.

X If included in the vehicle equipment, take

the tire-changing tool kit out of the vehicle

tool kit (Y page

270).

Apart from some country-specific variants,

vehicles are not equipped with tire-changing

tools. Some tools for changing a wheel are

specific to the vehicle. Consult a qualified

specialist workshop for more information on

which tools are required to perform a wheel

change on your vehicle.

X If included in the vehicle equipment, remove

the spare wheel from the spare wheel

bracket

(Y page 303). Observe the safety

notes listed under "Spare wheel"

(Y page 302).

X Carefully remove the hub caps. X

Using lug wrench :, loosen the wheel bolts

on the wheel to be changed counter-clock-

wise by about one full turn. Do not remove

the wheel bolts.

Raising the vehicle G

WARNING

If you do not position the jack correctly at

the appropriate jacking point of the vehicle,

the jack could tip over with the vehicle

raised. There is a risk of injury.

Only position the jack at the appropriate

jacking point of the vehicle. The base of the

jack must be positioned vertically, directly

under the jacking point of the vehicle. 298

Changing wheels

Wheels and tires

Page 301 of 320

G

WARNING

On uphill and downhill slopes, the jack could

tip over with the vehicle raised. There is a

risk of injury.

Do not change wheels on uphill or downhill

gradients. Notify a qualified specialist work-

shop.

! Only position the jack on the jacking

points intended for this purpose. You could

otherwise damage the vehicle.

Observe the following when raising the vehi-

cle:

R To raise the vehicle, only use the vehicle-

specific jack that has been tested and

approved by Mercedes-Benz. If the jack is

used incorrectly, it could tip over while the

vehicle is raised.

R The vehicle's jack is intended only to raise

the vehicle for a short time when changing a

wheel. It is not suited for performing mainte-

nance work under the vehicle.

R Avoid changing the wheel on uphill and

downhill slopes.

R Before raising the vehicle, secure it from

rolling away by applying the parking brake

and inserting wheel chocks. Never disen-

gage the parking brake while the vehicle is

raised.

R The jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a large,

load-bearing underlay must be used. On a

slippery surface, a non-slip underlay must

be used, e.g. rubber mats.

R Make sure that the distance between the

underside of the tires and the ground does

not exceed

1.2 in(3 cm).

R Never place your hands or feet under the

raised vehicle.

R Never lie under the raised vehicle.

R Never start the engine when the vehicle is

raised.

R Never open or close a door or the tailgate/

door when the vehicle is raised.

R Make sure that no persons are present in

the vehicle when the vehicle is raised. Jacking points : (rubber stoppers) are loca-

ted just behind the front wheel arches and just

in front of the rear wheel arches.

X Place jack ; beneath corresponding jack-

ing points :.

X Turn handwheel = until jack plate ; sits

securely on jacking point :.

X Make sure the base of jack ; is positioned

vertically beneath jacking point :.

X Assemble adapter ? and ratchet A from

the vehicle tool kit.

X Place adapter ? and ratchet A on the hex-

agon nut of jack ; so that the lettering

AB/DOWN is visible.

X Turn ratchet A in the AUF/UP direction

until the tire is a maximum of 3 cm off the

ground.

When doing so, jack ; may move to one of

the side support surfaces.

Removing a wheel !

Do not place wheel bolts in sand or on a

dirty surface. The bolt and wheel hub

threads could otherwise be damaged when

you screw them in.

X Unscrew the wheel bolts.

X Remove the wheel. Changing wheels

299

Wheels and tires Z

Page 307 of 320

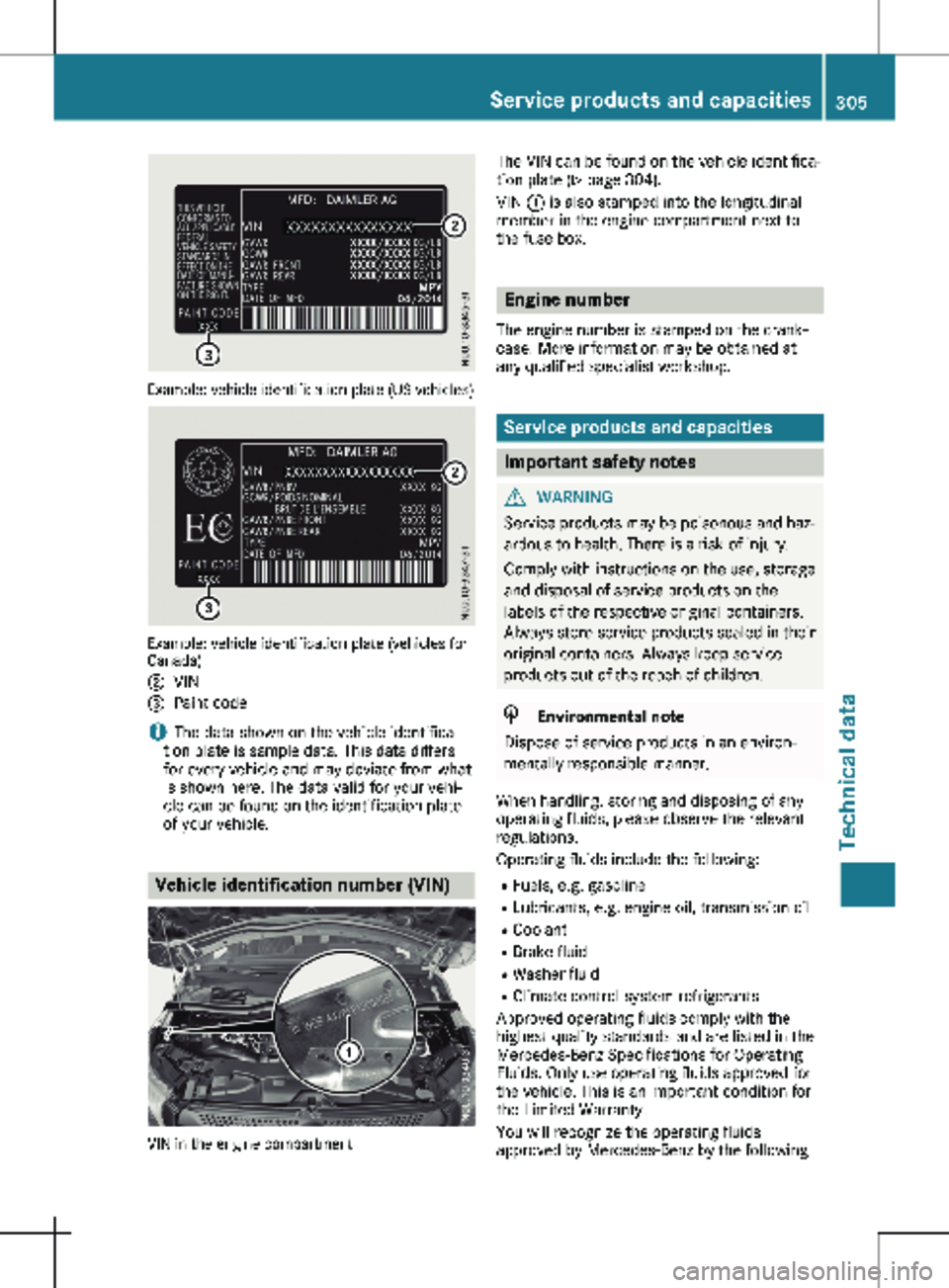

Example: vehicle identification plate (US vehicles)

Example: vehicle identification plate (vehicles for

Canada)

; VIN

= Paint code

i The data shown on the vehicle identifica-

tion plate is sample data. This data differs

for every vehicle and may deviate from what

is shown here. The data valid for your vehi-

cle can be found on the identification plate

of your vehicle. Vehicle identification number (VIN)

VIN in the engine compartment The VIN can be found on the vehicle identifica-

tion plate (Y page

304).

VIN : is also stamped into the longitudinal

member in the engine compartment next to

the fuse box. Engine number

The engine number is stamped on the crank-

case. More information may be obtained at

any qualified specialist workshop. Service products and capacities

Important safety notes

G

WARNING

Service products may be poisonous and haz-

ardous to health. There is a risk of injury.

Comply with instructions on the use, storage

and disposal of service products on the

labels of the respective original containers.

Always store service products sealed in their

original containers. Always keep service

products out of the reach of children. H

Environmental note

Dispose of service products in an environ-

mentally responsible manner.

When handling, storing and disposing of any

operating fluids, please observe the relevant

regulations.

Operating fluids include the following:

R Fuels, e.g. gasoline

R Lubricants, e.g. engine oil, transmission oil

R Coolant

R Brake fluid

R Washer fluid

R Climate control system refrigerants

Approved operating fluids comply with the

highest quality standards and are listed in the

Mercedes-Benz Specifications for Operating

Fluids. Only use operating fluids approved for

the vehicle. This is an important condition for

the Limited Warranty.

You will recognize the operating fluids

approved by Mercedes-Benz by the following Service products and capacities

305

Technical data Z