low oil pressure MERCEDES-BENZ METRIS 2020 MY20 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2020, Model line: METRIS, Model: MERCEDES-BENZ METRIS 2020Pages: 320, PDF Size: 26.38 MB

Page 245 of 320

replaced. If you use load securing aids or tie

downs which are worn out, the load may not

be sufficiently secured and could cause dam-

age to property.

In the event of an accident, have a damaged

cargo compartment floor or loading area, the

cargo tie-down rings and the tie down checked

at a specialist workshop. Otherwise, the load

may not be correctly secured the next time

anything is stowed.

Even if you follow all loading guidelines, the

load increases the risk of injury in the event of

an accident. Observe the information in the

"Securing a load"

(Y page 244) and "Load dis-

tribution" (Y page 243) sections.

You will find information about the maximum

roof load under "Cargo tie-down points and

carrier systems" (Y page 313). You will find

information about roof carriers under "Carrier

systems" (Y page 249). Before loading

! The anti-slip mats cannot be used for

securing goods and must be replaced when

they show signs of:

R Permanent deformation and crushing

R Crack formation

R Cuts

X Tire pressure: check the tire pressure and

correct if necessary

(Y page 282).

X Cargo compartment floor: clean the cargo

compartment floor.

The cargo compartment floor must be free

from oil and dust, dry and swept clean to

prevent the load from slipping.

X Place non-slip mats (anti-slip mats) on the

cargo compartment floor if necessary. During loading

X Observe the gross axle weight rating and

permissible gross vehicle weight for your

vehicle.

Take into account that your vehicle's curb

weight is increased if accessories or optional equipment are installed. The maxi-

mum payload is thus reduced.

X Observe the notes on load distribution

(Y page

243).

The overall center of gravity of the load

should always be as low as possible, cen-

tered and between the axles near the rear

axle.

X Secure the load (Y page

244).

Observe the legal requirements of the coun-

try in which you are currently driving. Checks after loading

G

DANGER

Combustion engines emit poisonous

exhaust gases, such as carbon monoxide.

Exhaust gases can enter the vehicle interior

if the tailgate/rear-end door is open when

the engine is running, especially if the vehi-

cle is in motion. There is a risk of poisoning.

Always switch off the engine before opening

the tailgate/rear-end door. Never drive the

vehicle when the tailgate/rear-end door is

open.

X Securing luggage/loads: make sure that

the luggage and/or load is secure before

every journey and at regular intervals during

a long journey, and correct it if necessary.

X Doors/tailgate: close the sliding doors and

tailgate/door.

X Tire pressure: adjust the tire pressure

according to the vehicle load

(Y page 282).

X Driving style: adapt your driving style

according to the vehicle load. Load distribution

General notes

! Excessive loads on individual points of the

cargo floor or on the load surface impair

vehicle handling characteristics and could

cause damage to the floor covering.

The overall center of gravity of the load should

always be as low as possible, centered and

between the axles near the rear axle. Load distribution

243

Transporting loads Z

Page 254 of 320

X

Hold support strut ? and lift the hood

slightly.

X Guide support strut ? towards retainer =

and apply slight pressure to make it engage.

X Lower the hood and allow it to fall with

momentum from a height of approximately

1 ft (30 cm

).

The hood locks audibly.

X Check that the hood is correctly locked.

If the hood can be raised slightly, it is not

properly engaged. If the hood is not cor-

rectly engaged, open the hood again. Let

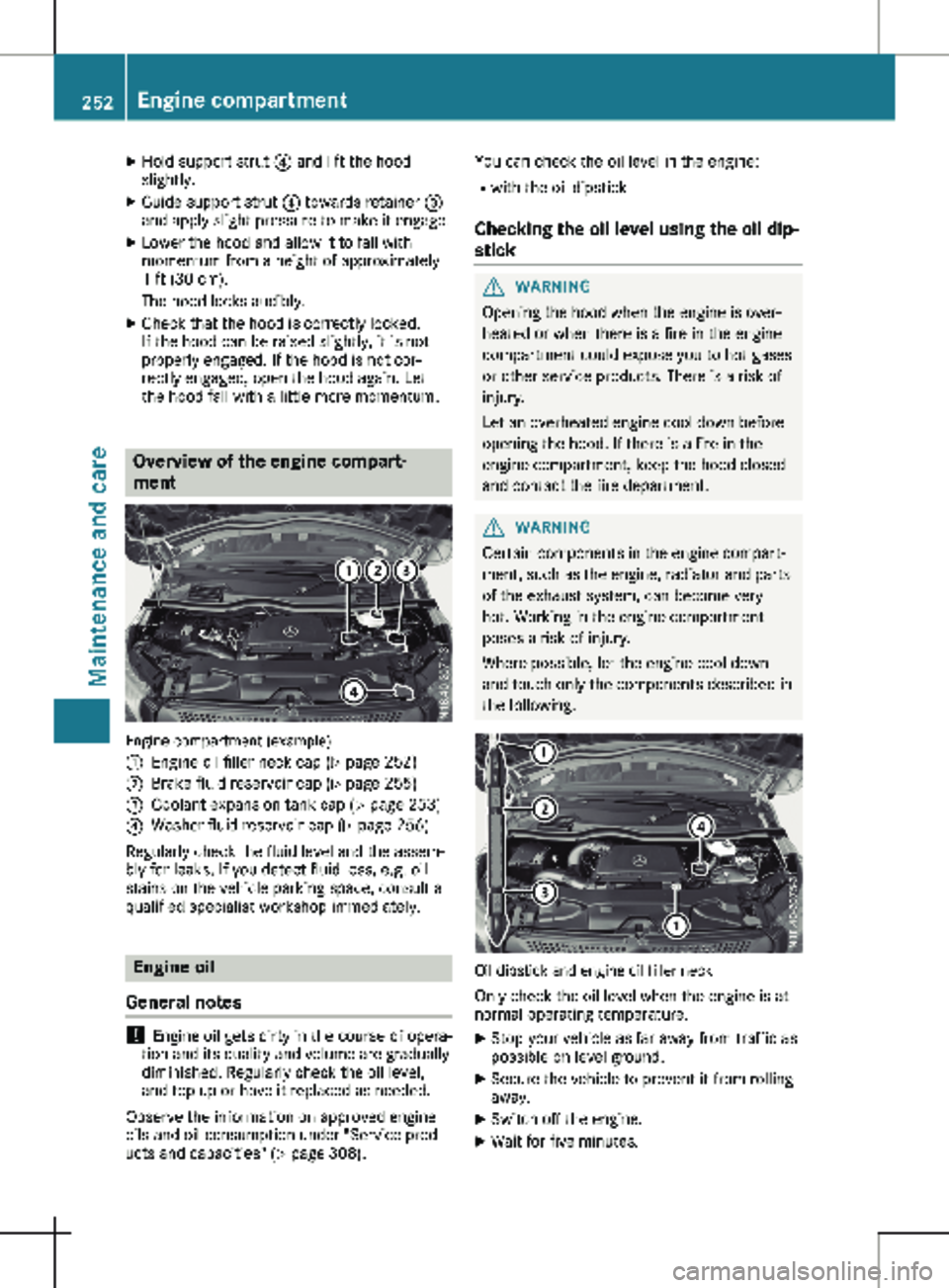

the hood fall with a little more momentum. Overview of the engine compart-

ment

Engine compartment (example)

:

Engine oil filler neck cap (Y page

252)

; Brake fluid reservoir cap (Y page

255)

= Coolant expansion tank cap ( Y page

253)

? Washer fluid reservoir cap (Y page

256)

Regularly check the fluid level and the assem-

bly for leaks. If you detect fluid loss, e.g. oil

stains on the vehicle parking space, consult a

qualified specialist workshop immediately. Engine oil

General notes !

Engine oil gets dirty in the course of opera-

tion and its quality and volume are gradually

diminished. Regularly check the oil level,

and top up or have it replaced as needed.

Observe the information on approved engine

oils and oil consumption under "Service prod-

ucts and capacities" ( Y page

308).You can check the oil level in the engine:

R with the oil dipstick

Checking the oil level using the oil dip-

stick G

WARNING

Opening the hood when the engine is over-

heated or when there is a fire in the engine

compartment could expose you to hot gases

or other service products. There is a risk of

injury.

Let an overheated engine cool down before

opening the hood. If there is a fire in the

engine compartment, keep the hood closed

and contact the fire department. G

WARNING

Certain components in the engine compart-

ment, such as the engine, radiator and parts

of the exhaust system, can become very

hot. Working in the engine compartment

poses a risk of injury.

Where possible, let the engine cool down

and touch only the components described in

the following. Oil dipstick and engine oil filler neck

Only check the oil level when the engine is at

normal operating temperature. X Stop your vehicle as far away from traffic as

possible on level ground.

X Secure the vehicle to prevent it from rolling

away.

X Switch off the engine.

X Wait for five minutes.252

Engine compartment

Maintenance and care

Page 267 of 320

X

Thoroughly hose down the vehicle with a

gentle jet of water.

X Do not point the water jet directly towards

the air inlet grilles.

X Use plenty of water and rinse out the

sponge frequently.

X Rinse the vehicle with clean water and dry

thoroughly with a chamois.

X Do not let the cleaning agents dry on the

paintwork.

When using the vehicle in winter, remove all

traces of road salt deposits carefully and as

soon as possible.

Power washers G

WARNING

The water jet from a circular jet nozzle (dirt

blasters) can cause invisible exterior dam-

age to the tires or chassis components.

Components damaged in this way may fail

unexpectedly. There is a risk of an accident.

Do not use power washers with circular jet

nozzles to clean the vehicle. Have damaged

tires or chassis components replaced imme-

diately.

! Under no circumstances use power wash-

ers in the vehicle interior. The pressurized

water and associated spray produced by the

power washer could cause extensive dam-

age to the vehicle.

! When using high-pressure cleaning equip-

ment, maintain a minimum distance of

approx. 1 ft (30 cm

) between the spray noz-

zle and the vehicle parts. Do not use a

power washer with a round-jet nozzle. You

could damage the vehicle or engine parts.

! Keep the water jet moving constantly

while cleaning. This will avoid causing dam-

age to the vehicle.

Do not point the water jet at:

R door joints

R rear view camera

R air bellows

R brake hoses

R wheel balance weights

R electrical components

R electrical connections R

seals

R drive train, especially not at the inter-

mediate bearing of the propeller shaft

Cleaning the engine !

Water must not enter intake or ventilation

openings. When cleaning with high pressure

water or steam cleaners, the spray must not

be aimed directly at electrical components

or the terminals of electrical lines.

Preserve the engine after the engine has

been cleaned. Protect the belt drive system

from exposure to the preservative agent.

Also observe the information under "Power

washers"

(Y page 265).

Cleaning the paintwork !

Do not affix:

R stickers

R films

R magnetic plates or similar items

to painted surfaces. You could otherwise

damage the paintwork.

Scratches, corrosive deposits, areas affected

by corrosion and damage caused by inade-

quate care cannot always be completely

repaired. In such cases, visit a qualified spe-

cialist workshop.

X Remove impurities immediately, where pos-

sible, whilst avoiding rubbing too hard.

X Soak insect remains with insect remover

and rinse off the treated areas afterwards.

X Soak bird droppings with water and rinse off

the treated areas afterwards.

X Remove coolant, brake fluid, tree resin, oils,

fuels and greases by rubbing gently with a

cloth soaked in petroleum ether or lighter

fluid.

X Use tar remover to remove tar stains.

X Use silicone remover to remove wax.

Cleaning the windows G

WARNING

You could become trapped by the wind-

shield wipers if they start moving while

cleaning the windshield or wiper blades.

There is a risk of injury. Care

265

Maintenance and care

Z

Page 270 of 320

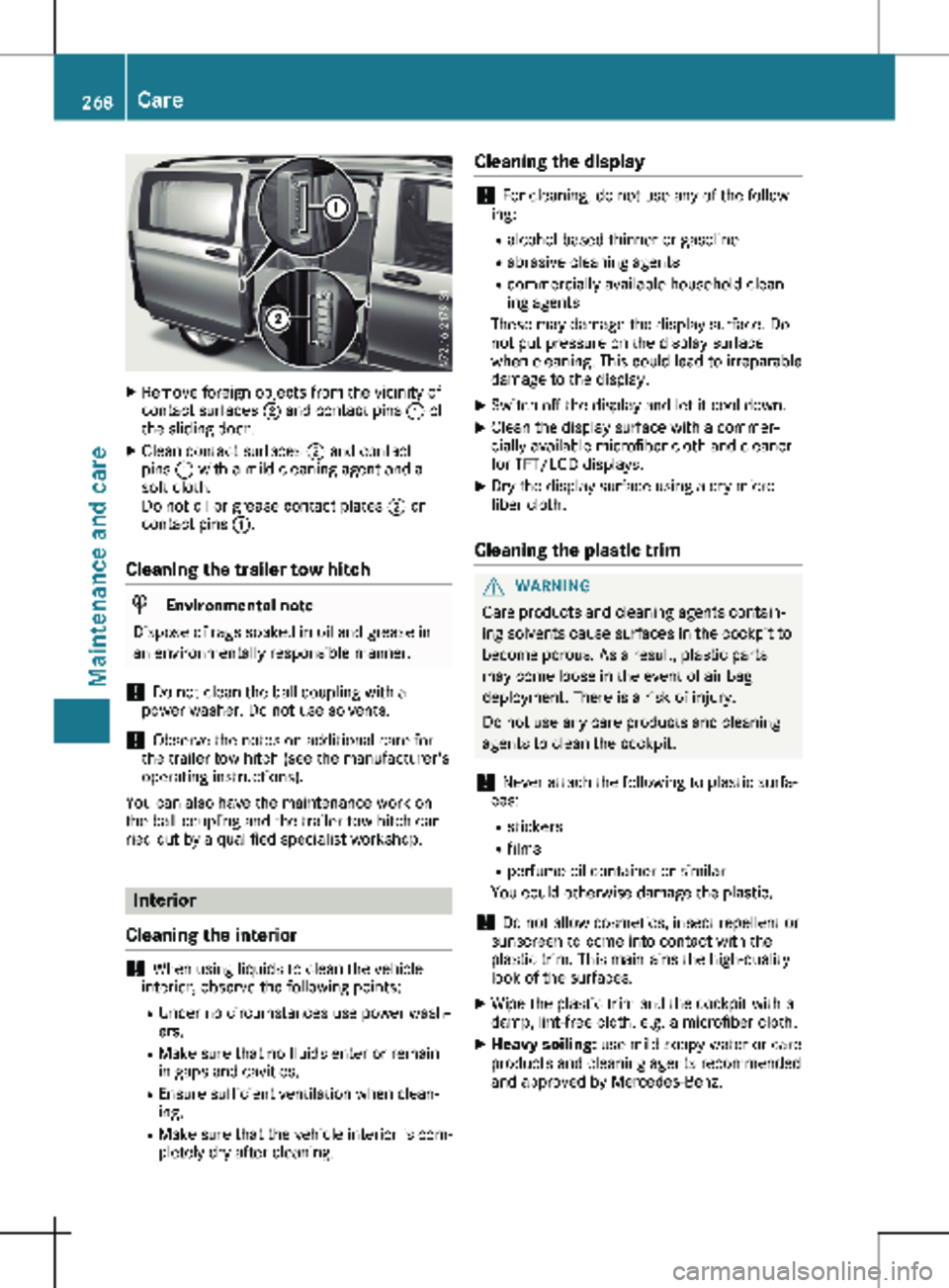

X

Remove foreign objects from the vicinity of

contact surfaces ; and contact pins : of

the sliding door.

X Clean contact surfaces ; and contact

pins : with a mild cleaning agent and a

soft cloth.

Do not oil or grease contact plates ; or

contact pins :.

Cleaning the trailer tow hitch H

Environmental note

Dispose of rags soaked in oil and grease in

an environmentally responsible manner.

! Do not clean the ball coupling with a

power washer. Do not use solvents.

! Observe the notes on additional care for

the trailer tow hitch (see the manufacturer's

operating instructions).

You can also have the maintenance work on

the ball coupling and the trailer tow hitch car-

ried out by a qualified specialist workshop. Interior

Cleaning the interior !

When using liquids to clean the vehicle

interior, observe the following points:

R Under no circumstances use power wash-

ers.

R Make sure that no fluids enter or remain

in gaps and cavities.

R Ensure sufficient ventilation when clean-

ing.

R Make sure that the vehicle interior is com-

pletely dry after cleaning. Cleaning the display !

For cleaning, do not use any of the follow-

ing:

R alcohol-based thinner or gasoline

R abrasive cleaning agents

R commercially-available household clean-

ing agents

These may damage the display surface. Do

not put pressure on the display surface

when cleaning. This could lead to irreparable

damage to the display.

X Switch off the display and let it cool down.

X Clean the display surface with a commer-

cially available microfiber cloth and cleaner

for TFT/LCD displays.

X Dry the display surface using a dry micro-

fiber cloth.

Cleaning the plastic trim G

WARNING

Care products and cleaning agents contain-

ing solvents cause surfaces in the cockpit to

become porous. As a result, plastic parts

may come loose in the event of air bag

deployment. There is a risk of injury.

Do not use any care products and cleaning

agents to clean the cockpit.

! Never attach the following to plastic surfa-

ces:

R stickers

R films

R perfume oil container or similar

You could otherwise damage the plastic.

! Do not allow cosmetics, insect repellent or

sunscreen to come into contact with the

plastic trim. This maintains the high-quality

look of the surfaces.

X Wipe the plastic trim and the cockpit with a

damp, lint-free cloth, e.g. a microfiber cloth.

X Heavy soiling: use mild soapy water or care

products and cleaning agents recommended

and approved by Mercedes-Benz. 268

CareMaintenance and care

Page 299 of 320

Tire tread

The part of the tire that comes into contact

with the road.

Tire bead

The tire bead ensures that the tire sits

securely on the wheel. There are several steel

wires in the bead to prevent the tire from com-

ing loose from the wheel rim.

SidewallThe part of the tire between the tread and the

tire bead.

Weight of optional extras The combined weight of those optional extras

that weigh more than the replaced standard

parts and more than 2.3 kg

(5 lbs). These

optional extras, such as high-performance

brakes, a roof rack or a high-performance bat-

tery, are not included in the curb weight and

the weight of the accessories.

TIN (Tire Identification Number) A unique identification number which can be

used by a tire manufacturer to identify tires,

for example for a product recall, and thus iden-

tify the purchasers. The TIN is composed of

the manufacturer identification code, tire size,

tire model code and manufacturing date.

Load bearing index

The load bearing index (also load index) is a

code that contains the maximum load bearing

capacity of a tire.

Traction

Traction is the result of friction between the

tires and the road surface.

TWR (permissible trailer drawbar load)

The TWR is the maximum permissible weight

that may act on the ball coupling of the trailer

tow hitch.

Wear indicator Narrow bars (tread wear bars) that are distrib-

uted over the tire tread. If the tire tread is level

with the bars, the wear limit of á in (1.6 mm)

has been reached. Distribution of the vehicle occupants

The distribution of vehicle occupants over des-

ignated seat positions in a vehicle.

Maximum permissible payload weightNominal load and goods/luggage load plus

68 kg (150 lbs) multiplied by the number of

seats in the vehicle. Changing wheels

Rotating the wheels

! On vehicles equipped with a tire pressure

monitor, electronic components are located

in the wheel.

Tire-mounting tools should not be used near

the valve. This could damage the electronic

components.

Only have tires changed at a qualified spe-

cialist workshop.

Always observe the instructions and safety

notes under "Mounting a wheel"

(Y page

298).

The wear patterns on the front and rear tires

differ, depending on the operating conditions.

Rotate the wheels before a clear wear pattern

has formed on the tires. Front tires typically

wear more on the shoulders and the rear tires

in the center.

If your vehicle's tire configuration allows, you

can rotate the tires according to the intervals

in the tire manufacturer's warranty book in

your vehicle documents. If no warranty book is

available, the tires should be rotated every

3,000 to 6,000 miles (5,000 to 10,000 km) or

earlier if tire wear requires. Do not change the

direction of rotation.

Clean the contact surfaces of the wheel and

the brake disc thoroughly every time a wheel

is rotated. Avoid oily or greasy cleaning

agents.

Check the tire pressure and reactivate the tire

pressure monitor if necessary. Direction of rotation

Tires with a specified direction of rotation have

additional benefits, e.g. if there is a risk of

hydroplaning. You will only gain these benefits

if the correct direction of rotation is observed. Changing wheels

297

Wheels and tires Z

Page 302 of 320

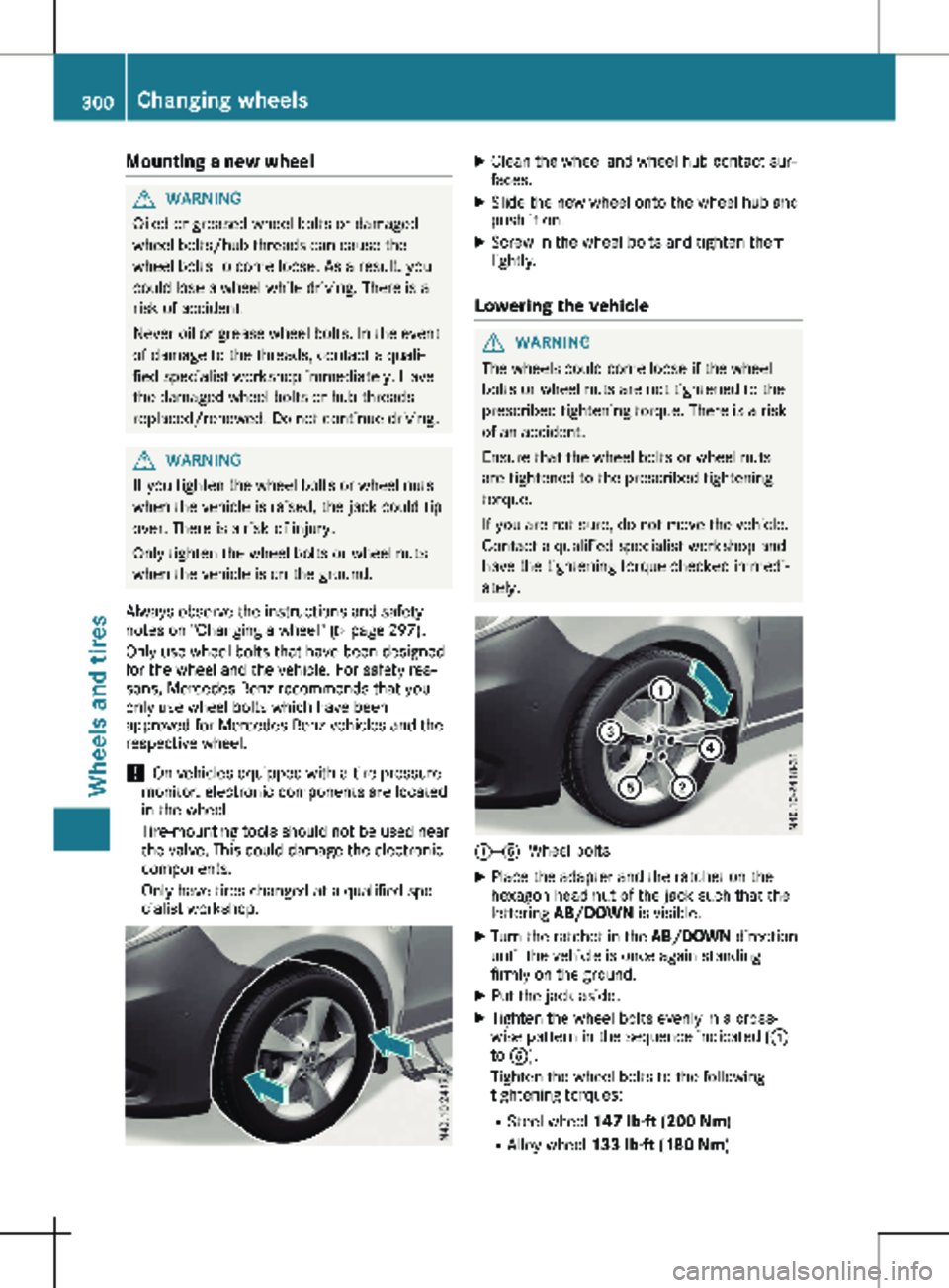

Mounting a new wheel

G

WARNING

Oiled or greased wheel bolts or damaged

wheel bolts/hub threads can cause the

wheel bolts to come loose. As a result, you

could lose a wheel while driving. There is a

risk of accident.

Never oil or grease wheel bolts. In the event

of damage to the threads, contact a quali-

fied specialist workshop immediately. Have

the damaged wheel bolts or hub threads

replaced/renewed. Do not continue driving. G

WARNING

If you tighten the wheel bolts or wheel nuts

when the vehicle is raised, the jack could tip

over. There is a risk of injury.

Only tighten the wheel bolts or wheel nuts

when the vehicle is on the ground.

Always observe the instructions and safety

notes on "Changing a wheel"

(Y page 297).

Only use wheel bolts that have been designed

for the wheel and the vehicle. For safety rea-

sons, Mercedes-Benz recommends that you

only use wheel bolts which have been

approved for Mercedes-Benz vehicles and the

respective wheel.

! On vehicles equipped with a tire pressure

monitor, electronic components are located

in the wheel.

Tire-mounting tools should not be used near

the valve. This could damage the electronic

components.

Only have tires changed at a qualified spe-

cialist workshop. X

Clean the wheel and wheel hub contact sur-

faces.

X Slide the new wheel onto the wheel hub and

push it on.

X Screw in the wheel bolts and tighten them

lightly.

Lowering the vehicle G

WARNING

The wheels could come loose if the wheel

bolts or wheel nuts are not tightened to the

prescribed tightening torque. There is a risk

of an accident.

Ensure that the wheel bolts or wheel nuts

are tightened to the prescribed tightening

torque.

If you are not sure, do not move the vehicle.

Contact a qualified specialist workshop and

have the tightening torque checked immedi-

ately. :—A

Wheel bolts

X Place the adapter and the ratchet on the

hexagon head nut of the jack such that the

lettering AB/DOWN is visible.

X Turn the ratchet in the AB/DOWN direction

until the vehicle is once again standing

firmly on the ground.

X Put the jack aside.

X Tighten the wheel bolts evenly in a cross-

wise pattern in the sequence indicated (:

to A).

Tighten the wheel bolts to the following

tightening torques:

R Steel wheel 147 lb-ft (200 Nm)

R Alloy wheel 133 lb-ft (180 Nm)300

Changing wheels

Wheels and tires

Page 310 of 320

The following components of the different

vehicle versions influence fuel consumption:

R tire sizes, tire tread, tire pressure, tire condi-

tion

R transmission ratios for the drive assemblies

R additional equipment (e.g. air-conditioning

system, auxiliary heating system)

For these reasons, the actual consumption fig-

ures for your vehicle may deviate from the

consumption figures determined according to

EU Directive

80/1268/EEC.

Details on fuel consumption can be called up

in the on-board computer:

R on vehicles without steering wheel buttons

(Y page 177)

R on vehicles with steering wheel buttons

(Y page 184) Engine oil

General notes When handling engine oil, observe the impor-

tant safety notes on operating fluids

(Y page

305).

The quality of the engine oil used is of decisive

importance for the engine's functionality and

operating life. Mercedes-Benz continually

approves engine oils based on complex experi-

ments according to the current state of the

art.

Therefore, only Mercedes-Benz approved

engine oils may be used in Mercedes-Benz

engines. Mercedes-Benz recommends having

the oil changed at a qualified specialist work-

shop. Information about engine oils approved by

Mercedes-Benz can be obtained:

R from any Mercedes-Benz Commercial Van

Center

R on the Internet at

http://bevo.mercedes-benz.com

by enter-

ing the designation, e.g. 229.5.

Mercedes-Benz approval is indicated on the oil

container by the inscription „MB-Freigabe“ or

„MB Approval“ and the corresponding designa-

tion, e.g. MB-Freigabe or MB Approval 229.5.

Designations of the approved engine oils for

your vehicle MB-Freigabe or MB

Approval

229.5,

229.62 Mercedes-Benz recommends that you only use

approved multigrade engine oils of the SAE

classes

SAE 0W-30 and SAE 0W-40 or

SAE 5W-30 and SAE 5W-40. These engine oils

ensure optimum lubrication even at very low

outside temperatures (Y page 309).

To achieve the lowest possible fuel consump-

tion, it is recommended to use the engine oil

specifications marked in the table for the low-

est SAE viscosity class. Observe possible

restrictions of the released SAE classifications.

When refilling, we recommend that you only

use engine oil of the same grade (MB-Freigabe

or MB Approvaldesignation) and SAE class as

the oil filled at the last oil change.

i If the engine oils listed in the table are not

available, you may add the following engine

oils until the next oil change:

R MB-Freigabe or MB Approval 229.1, or

ACEA A3

This must only be added once and the

amount must not be greater than 1 qt

(1.0 l).

Subsequently have the engine oil changed

at the earliest possible opportunity.

! Using engine oils of another grade quality

is not permitted.

2 Recommended for the lowest possible fuel consumption (lowest viscosity class in each case taking into

account possible restrictions of the approved SAE classifications). 308

Service products and capacities

Technical data