warning MERCEDES-BENZ METRIS 2021 MY21 Operator's Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2021, Model line: METRIS, Model: MERCEDES-BENZ METRIS 2021Pages: 290, PDF Size: 4.68 MB

Page 170 of 290

R

Movelarge and heavy loads as farasp ossible

to wa rdst he front of thev ehicle in thed irec‐

tion of tra vel, agains tthe front or rear seats.

St orel oads flush wit hthe rear or front seats.

R Additionall ysecur ethe load wit hsuitable load

securing aids or tie downs.

R The load mus tnotprotru de abo vetheu pper

edg eoft he seat backrests.

R Transpor tloads behin dseat sthat ar enot

occupied.

R Ifth er ear benc hseat is no toccupied, insert

th es eat belts crosswise int othe seat belt

buckle of theo pposit eseat belt.

Cargo compartment variants

Yo uc an vary thec argo compartmen taccording

to your transpor tatio nr equirements as follo ws:

R Byfolding thes eat backrests forw ardtot he

ta ble position

R Byremoving ther ear benc hseat

Yo uw illfind information abou trear benc hseats

in the" Seats" section (/ page66). Securing loads

Note

sonl oad securing &

WARNING Risk of accident and inju ry

due toincor rect use of thel ashing stra ps

The following can occur:

R The tie-down eyes ma ydetac hort he lash‐

ing stra pm aytear if thep ermissible load

is exc eeded

R The load cann otbe restra ined

The load can slip, tip over or be flung about,

st riking vehicle occupants. #

Alwayst ension thel ashing stra ps in the

proper manner and onl ybetwe en the

described tie-down eyes. #

Alwaysu se lashing stra ps designed spe‐

cificall yfor thel oads. *

NO

TEDama getothev ehicle if them axi‐

mum loading capacity of thec argo tie-

down point is exceeded If

yo uc ombin evarious cargo tie-down points

to secur eaload, alw ayst aket he maximum loading capacity of

thew eakes tcargo tie-

down poin tint oa ccount.

During maximum full- stop braking, forc es may

act whic hcan multipl ythe weight of thel oad. #

Alwaysu se se veralc argo tie-down

point stod istribut ethe load. #

Distribut ethe load on thec argo tie-

down points evenly. Obser

vetheO perating Instruction sorthe lashing

st ra pm anufacturer's instruction sfor theo pera‐

tion of thel ashing stra p.

Obser vethei nformation relatin gtot he maximum

loading capacity of thec argo tie-down points

(/ page234).

As thed rive r,yo ua re re sponsible fore nsuring the

fo llowing:

R The load is secured agains tslipping, tipping,

ro lling or falling off.

Ta ke usual traf ficc onditions as well as swerv‐

ing or full brak eapplication and bad roads

int oa ccount.

R The applicable requ irements and guidelines

re latin gtol oad-securing practices ar emet.

If th is is no tthe case, this ma yconstitut ea

punishable of fense, depending on local legis‐

lation and an yensuing conse quences.

Obser vecountr y-specific la ws.

Mak esuret hat thel oad is secur ebefor eevery

jou rney and at regular inter vals during along

journe y.Ad jus tthe load securing as necessar y.

Information on ho wtosecureloads cor rectly can

be obtained from them anufacturer softhe load

securing aids or tie downs forl oa ds ecuring, for

ex ample.

Als oo bse rvet he no tesonl oading guidelines

(/ page166).

Whe nsecuring loads, obser vethef ollowing:

R Fill spaces between thel oad and thec argo

compartmen twalls or wheel wells. Forthis

purpose, use rigid load securing aids, suc has

ch oc ks,w ooden fixing sorp adding.

R Attach secured and stabilized loads in all

directions.

Use thec argo tie-down points or thet ie-down

ey es and guide rails in ther ear compartment.

Only use tie downs, suc haslashin gnetsa nd

lashin gstraps, whic hhave been tested in

accordance wit hcurrent standards. Alw ays 16 8

Transporting

Page 173 of 290

#

Obser vetheO perating Instruction sorthe

manufacturer's no tesonh owtouse the

ra tche tstrap.

Re leasing thet ensioning le ver #

Press slider lock 3outwards in thed irection

of thea rrow and swin gtensioning le ver2

from de tent position 0047tothed esired posi‐

tion.

Ti ghtening ther atche tstrap #

Release and open tensioning le ver2. Threading and

tensioning #

Guid eratche tstrap 4thro ugh slotted shaft

5 from behin dasillustrated and tighten it. #

Swin gtensioning le ver2bac kand forth

until ratche tstrap 4hasw ound around slot‐

te ds haft 5and is suf ficiently tensioned. #

Swing tensioning le ver2todetent position

0047.

Re leasing ther atche tstrap Te

nsioning le verint herelease position #

Press and hold slider lock 3outwards. #

Swin gtensioning le ver2asfarasitw illgo

to release position 004Eand release slider lock

3.

Slider lock 3engages in end recess 7and

slider lock 6unloc ksslotted shaft 5. #

Pull ratche tstrap 4outoft heratchet. In

stalling and removing tie-down eyes &

WARNING Risk of inju rydue toincor‐

re ctly ins talled tie-down eyes

If th et ie-down eyes ar enotcor rectly ins tal‐

led, they can sli portear out.

This ma ycause objects, luggag eorthe load

to slip, tip overorbet hrow na bout thev ehicle

interior ,striking vehicle occupants. #

Mak esuret hat thet ie-down eyes are

cor rectl yins tal led and do no tmove. #

Obser vethen otes on loading guidelines and

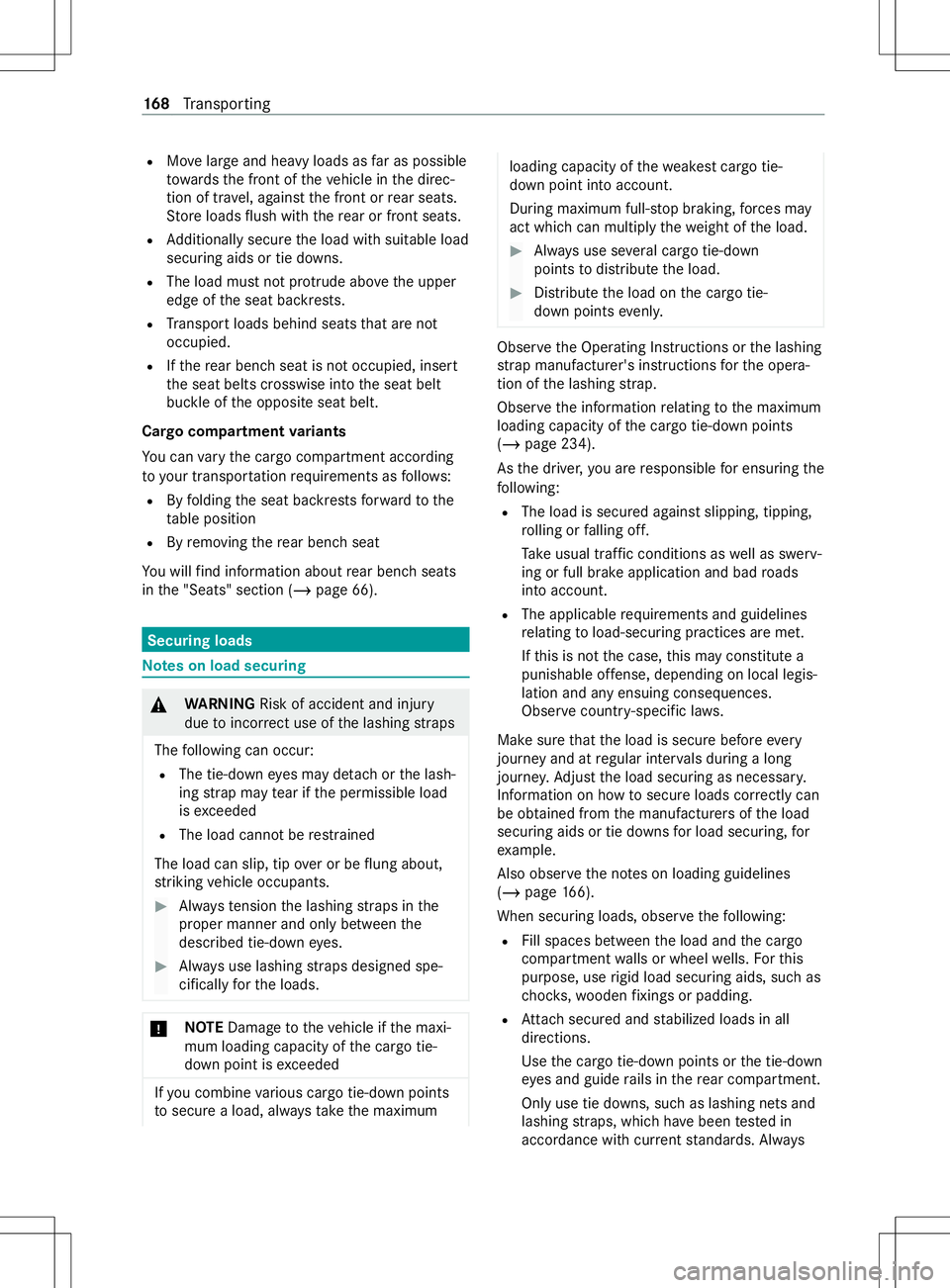

on securing loads (/ page166). Example

:guide rails Ti

e-down eyes forg uide rails Tr

ansporting 171

Page 174 of 290

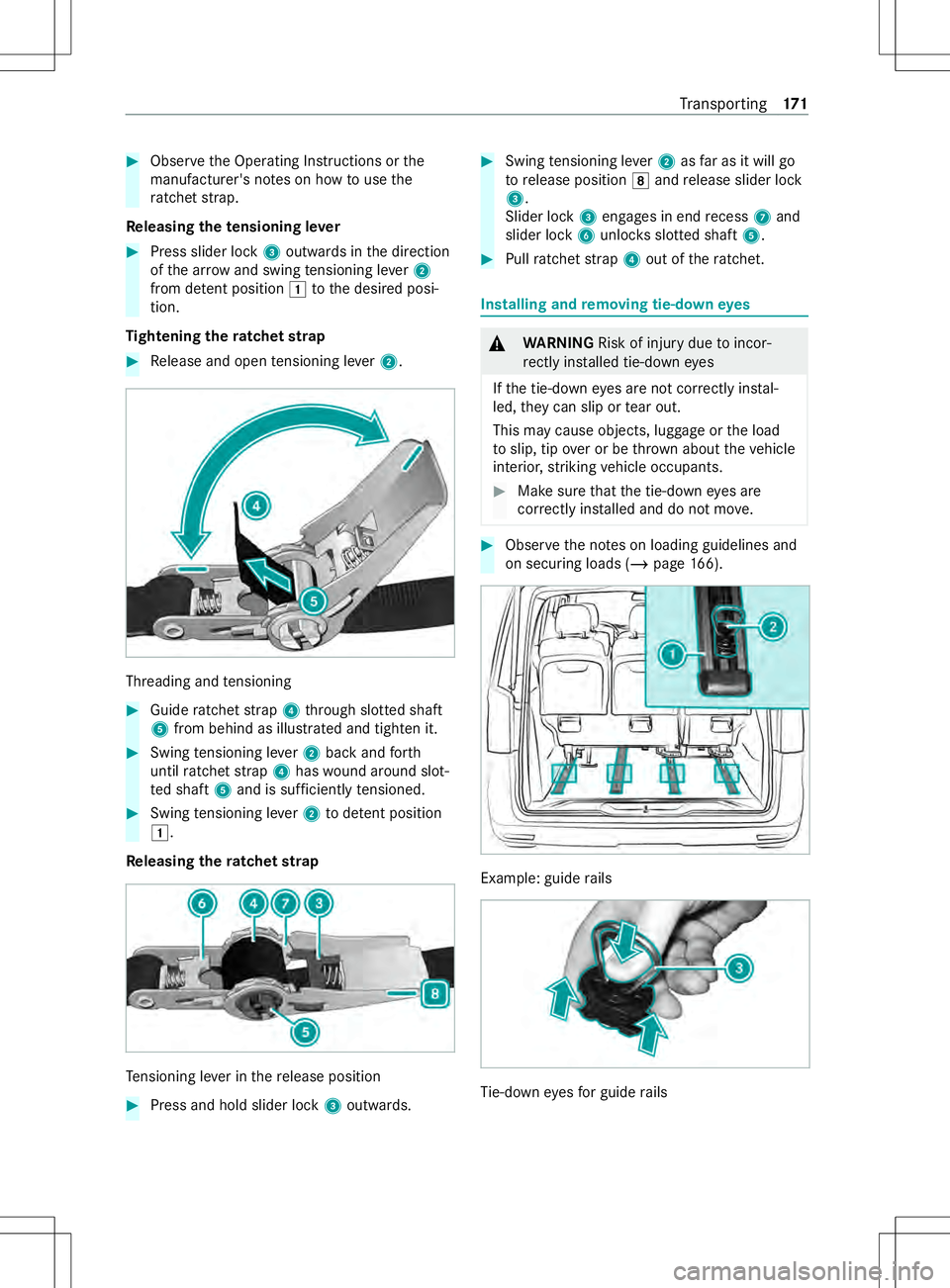

Installing

#

Turn me tal retainin gring 3sothat it is paral‐

lel tothel ong axis of tie-down eye2as illus‐

tra ted.

The locking pin can onl ybepushed down suf‐

fi ciently and allo wthe tie-down eyetobe

ins talled, mo vedorr emoved, if them etal

re tainin gring is parallel tothel ong axis of the

tie-down eye. #

Hold tie-down eye2between your fore finger

and middl efinger as illustrated, and place

yo ur thumb thro ugh me talr etainin gring 3

an dont he centra lpressur epoint. #

Use your thumb topush thel ocking pin down

as farasitw illg o. #

Push tie-down eye2near thel oad using the

notches on guid erail 1,a nd mo veit appr ox‐

imatel y0.5 in (1 2mm). #

Remo veyour thumb from thep ressur epoint

and slide tie-down eye2until it engages. #

Turn me tal retainin gring 3sothat it is per‐

pendicular tothel ong axis of tie-down eye

2 .

The locking pin cannot be pushed downfarif

th em etal retainin gring is perpendicula rto

th el ong axis of thet ie-down eye. This pre‐

ve nts thet ie-down eyef romb eing released

unin tentionally ,e.g. if thet ie-down eyeis

st epped on. #

Chec kthat tie-down eye2is seated cor‐

re ctly.

The tie-d owne yecann otbe mo ved.

Re moving #

Turn me tal retainin gring 3sothat it is paral‐

lel tothel ong axis of tie-down eye2. #

Grip tie-down eye2as described abo ve

unde rins talling and use your thumb topush

th el ocking pin down as farasitw illg o. #

Slide tie-down eye2and pull it up and out

th ro ugh then otch of guide rail1. Load securing aid

Re

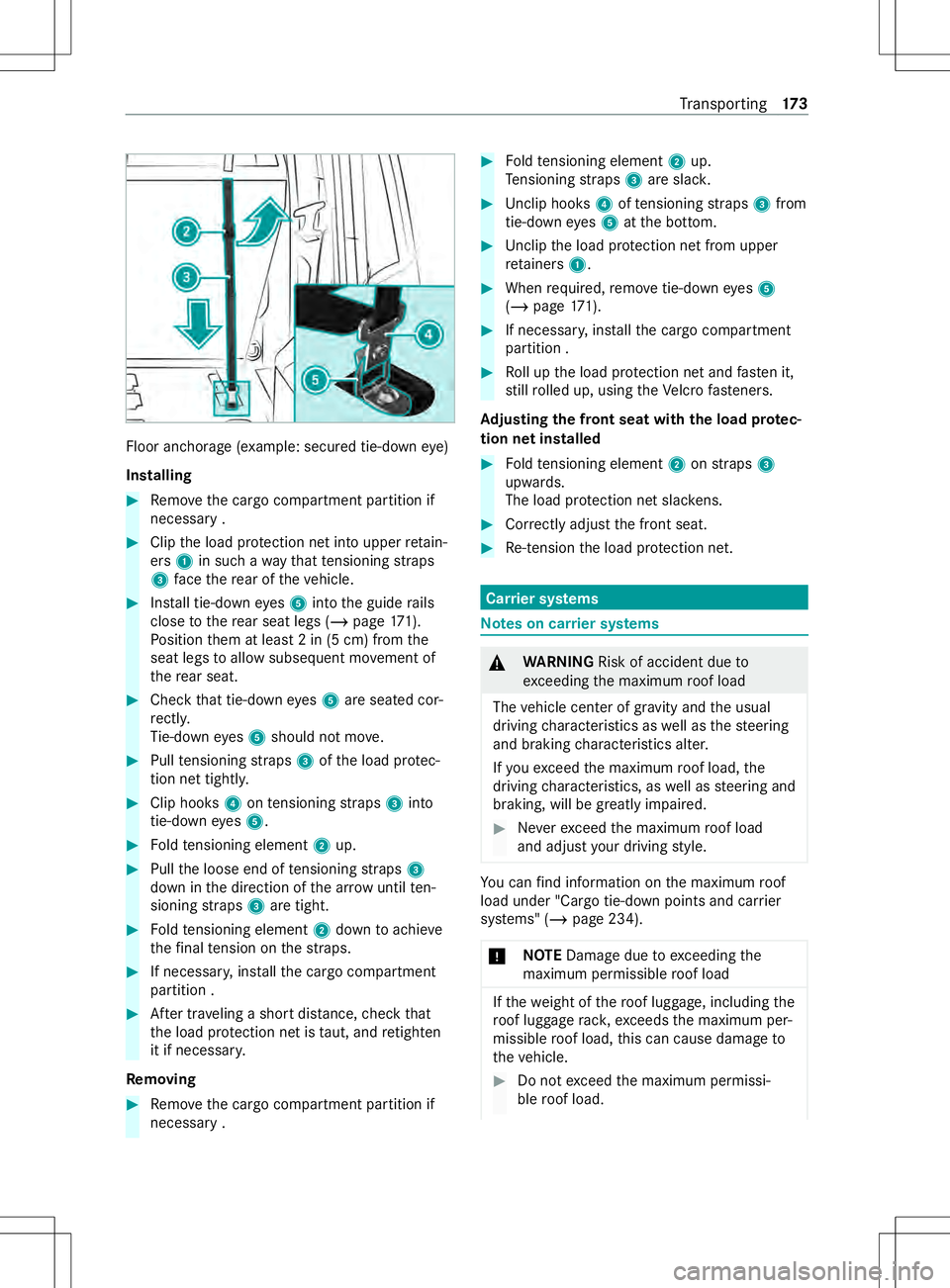

moving/installin galoadp rote ction net &

WARNING Risk of inju ryor deat hdueto

object sbeing poorly secured

The load pr otection ne talone cann otrestra in

or secur eheavy objects, luggag eorheavy

loads. Yo

uc oul dbeh itby an unsecured load during

sudden changes in direction ,brakin gorint he

eve nt of an accident. #

Alwayss towo bjectsins uchaw aythat

th ey canno tbethrow na bout thev ehi‐

cle. #

Secur eobjects, luggag eorloads against

slipping or tipping over,e.g. byusin gtie

downs ,evenw heny ou ar eusingthe

load pr otection net. &

WARNING Risk of inju rydue tositting

behind apartitioning net

Ve hicle occupants can be pressed agains tthe

partitioning net. Ther eisarisk of injur y. #

Nevera llow vehicle occupants tosit

behind thep artitioning net. The load pr

otection ne tpartition sthe cargo com‐

partment. It pr otects vehicle occupants from light

objects and/or luggag eslipping or tipping over.

Yo uc an ins tallth el oad pr otection ne tatanangle

behind thef ront seats or behind thef irst ro wof

re ar seats. #

Obse rvet he no tesons ecuring loads

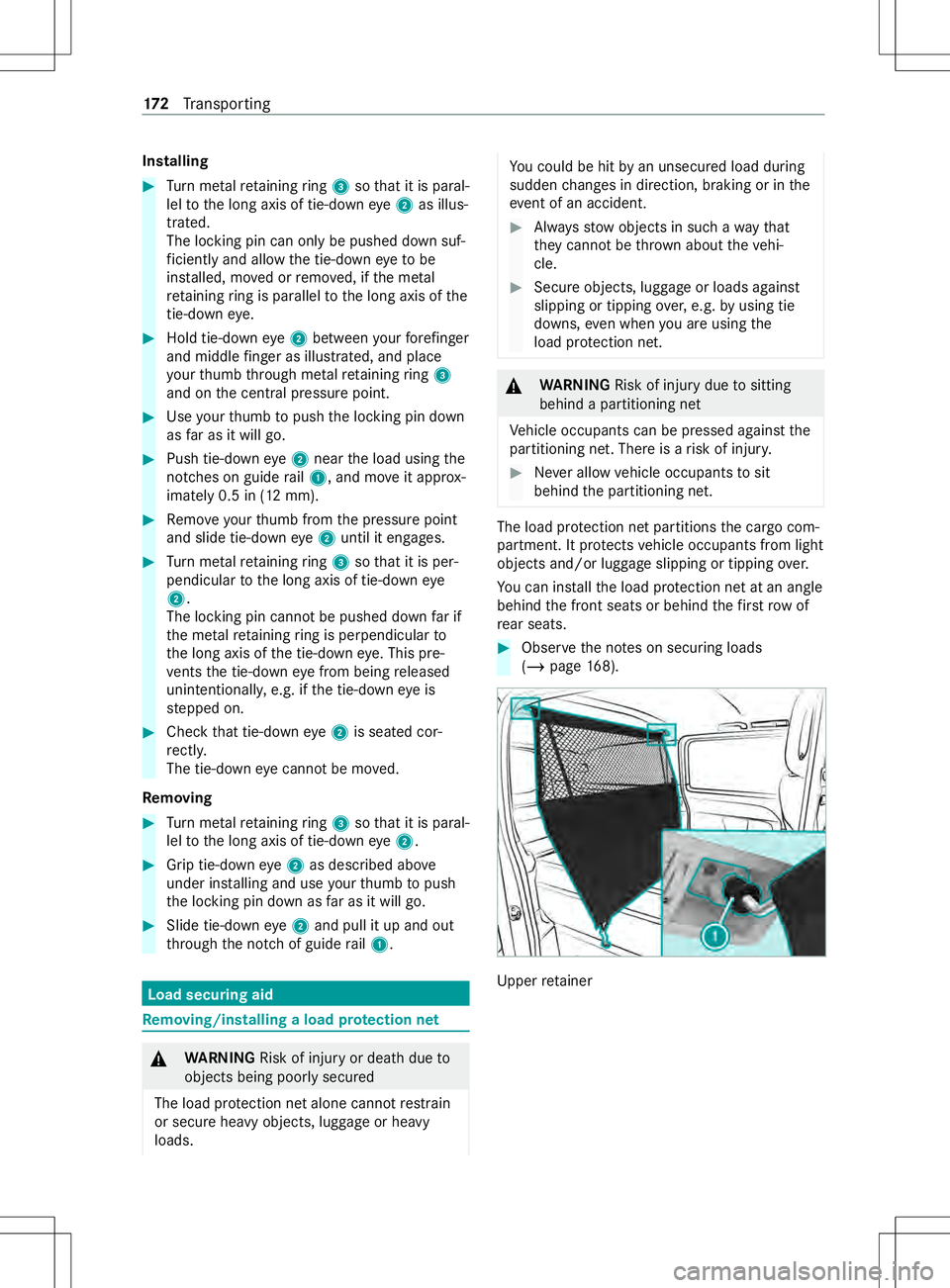

(/ page168). Up

per retainer 17 2

Transporting

Page 175 of 290

Floo

ranchorag e(example: secured tie-down eye)

Installing #

Remo vethec argo compartmen tpartition if

necessar y. #

Clip thel oad pr otection ne tint ou pper retain‐

ers 1in suc hawaythat tensioning stra ps

3 face ther ear of thev ehicle. #

Install tie-down eyes 5 intot he guide rails

close tother ear seat legs (/ page171).

Po sition them at leas t2in(5cm) fromthe

seat legs toallo wsubse quent mo vement of

th er ear seat. #

Chec kthat tie-down eyes 5 ares eated cor‐

re ctly.

Ti e-down eyes 5 should no tmove. #

Pull tensioning stra ps 3 ofthel oad pr otec‐

tion ne ttightly. #

Clip hooks 4ontensioning stra ps 3 into

tie-down eyes 5. #

Foldtensioning element 2up. #

Pull thel oose end of tensioning stra ps 3

down in thed irection of thea rrow until ten‐

sioning stra ps 3 aret ight. #

Foldtensioning element 2down toachie ve

th ef ina ltension on thes traps. #

If necessar y,ins tallth ec argo compartment

partition . #

Aftert rave ling ashor tdista nce, checkt hat

th el oad pr otection ne tistaut, and retighten

it if necessa ry.

Re moving #

Remo vethec argo compartmen tpartition if

necessar y. #

Foldtensioning element 2up.

Te nsioning stra ps 3 ares lack. #

Unc lip hooks 4oftensioning stra ps 3 from

tie-down eyes 5 attheb otto m. #

Unclip thel oad pr otection ne tfromu pper

re tainers 1. #

When requ ired, remo vetie-down eyes 5

(/ page171). #

If necessa ry,ins tallth ec argo compartment

partition . #

Roll up thel oad pr otection ne tand fast en it,

st ill rolled up, using theV elcr ofasteners.

Ad justin gthe fron tseatw itht he load pr otec‐

tion ne tinstalled #

Foldtensioning element 2onstra ps 3

upwards.

The load pr otection ne tslac kens. #

Correctl yadjus tthe front seat. #

Re-tension thel oad pr otection net. Car

rier sy stems Note

sonc arrier sy stems &

WARNING Risk of accident du eto

exc eeding them aximum roof load

The vehicle center of gr avity and theu sual

driving characteristic saswell asthes teering

and braking characteristic salter.

If yo ue xceed them aximum roof load, the

driving characteristics, as well as steering and

braking, will be greatl yimp aired. #

Nevere xceed them aximum roof load

and adjus tyour driving style. Yo

uc an find information on them aximum roof

load under "Cargo tie-down points and car rier

sy stems" (/ page234).

* NO

TEDama gedue toexc eeding the

maximu mpermissible roof load If

th ew eight of ther oof luggage, including the

ro of luggag erack, exc eeds them aximum per‐

missible roof load, this can cause damag eto

th ev ehicle. #

Do no texceed them aximum permissi‐

ble roof load. Tr

ansporting 17 3

Page 178 of 290

Information on

regular maintenance work *

NO

TEPrematur ewear thro ugh failur eto

obser veservice due dates Maintenance

workwhic hisn otcar ried out at

th er ight time or incomple tely ca nleadto

inc reased wear and damag etothevehicle. #

Adher etot he prescribed service inter‐

va ls. #

Alwaysh ave thep rescribed mainte‐

nanc eworkc arried out at aqualified

specialis tworks hop. Note

sons pecial service requ irements The prescribed service inter

valisb ased on nor‐

mal vehicle use. Maintenance workwill need to

be per form ed mor eoften than presc ribed if the

ve hicle is operated under arduous operating con‐

ditions or increased loads.

Arduous operating conditions include:

R Regular city driving wit hfrequ ent intermedi‐

at es tops

R Frequent short-dis tance driving

R Frequent operation in mountainous terrain or

on poor road sur faces

R Whe nthe engine is of tenl eftidling forl ong

periods

R Operation in particula rlyd usty conditions

and/o rifair-reci rculation mod eisfrequ ent ly

used

In these or similar operating conditions, ha vethe

air filter ,engin eoil and oil filter ,for example,

re placed mor efrequ entl y.

If th ev ehicle is subjected toinc reased loads, the

tires mu stbe checkedm oref requ ently.Yo uc an

obtain fur ther information at aqualified specialist

wo rkshop. No

n-operational times with theb attery dis‐

connected The ASS

YSTP LUSs ervice inter vald ispla ycan

onl ycalculat ethe service due dat ewhen theb at‐

te ry is connec ted. #

Displa yand no tedown thes ervice due date

on thei nstrument clus terb efor edisconnect‐

ing theb atter y. R

Displ aying thes ervice due dat einvehi‐

cles without steering wheel buttons

(/ page175).

R Displ aying thes ervice due dat einvehi‐

cles wit hsteering wheel buttons

(/ page175). Engine comp

artment Opening and closing

theh ood &

WARNING Risk of accident du etodriving

wit hthe hood unloc ked

The hood ma yopen and bloc kyour vie w. #

Neverrelease theh ood when driving. #

Befor eevery trip, ensur ethat theh ood

is loc ked. &

WARNING Risk of accident and injury

whe nopening and closing theh ood

The hood ma ysuddenl ydropi ntot he end

position.

Ther eisar isk of injur yfor an yone in the

hood's rang eofm ovement. #

Do no topen or close theh ood if ther eis

ap erson in theh ood's rang eofm ove‐

ment. &

WARNING Risk of inju ryfrom touching

component sunde rvoltage

The ignition sy stem and thef uel injection sys‐

te mw orku nde rhigh voltage. Youc ould

re ceiv eane lectric shoc k. #

Nevertouc hcomponent softhe ignition

sy stem or thef uel injection sy stem

when thei gnition is switched on. The

following ar eexamp les of liv ecomponents:

R Ignitio ncoils

R Spar kplug connec tors

R Injectors &

WARNING Risk of bu rnsf romh otcom‐

ponent parts in thee ngine compartment

Cer tainc omponent pa rtsint he engine com‐

partment can be very hot, e.g. thee ngine, the

cooler and pa rtsoft heexhaus tsystem. 176

Maintenance and care

Page 179 of 290

#

Allow thee ngine tocool down and only

to uc hc omponent parts desc ribed in the

fo llowing. *

NO

TEDama getohood or windshield

wiper swhen opening theh ood If

th ew indshield wiper shaveb een folded

bac kfromt he windshield when theh ood is

opened, thew indshield wiper sorthe hood

ma ybed amaged. #

Ensur ethat thew indshield wiper shave

no tb eenf olded bac kfromt he wind‐

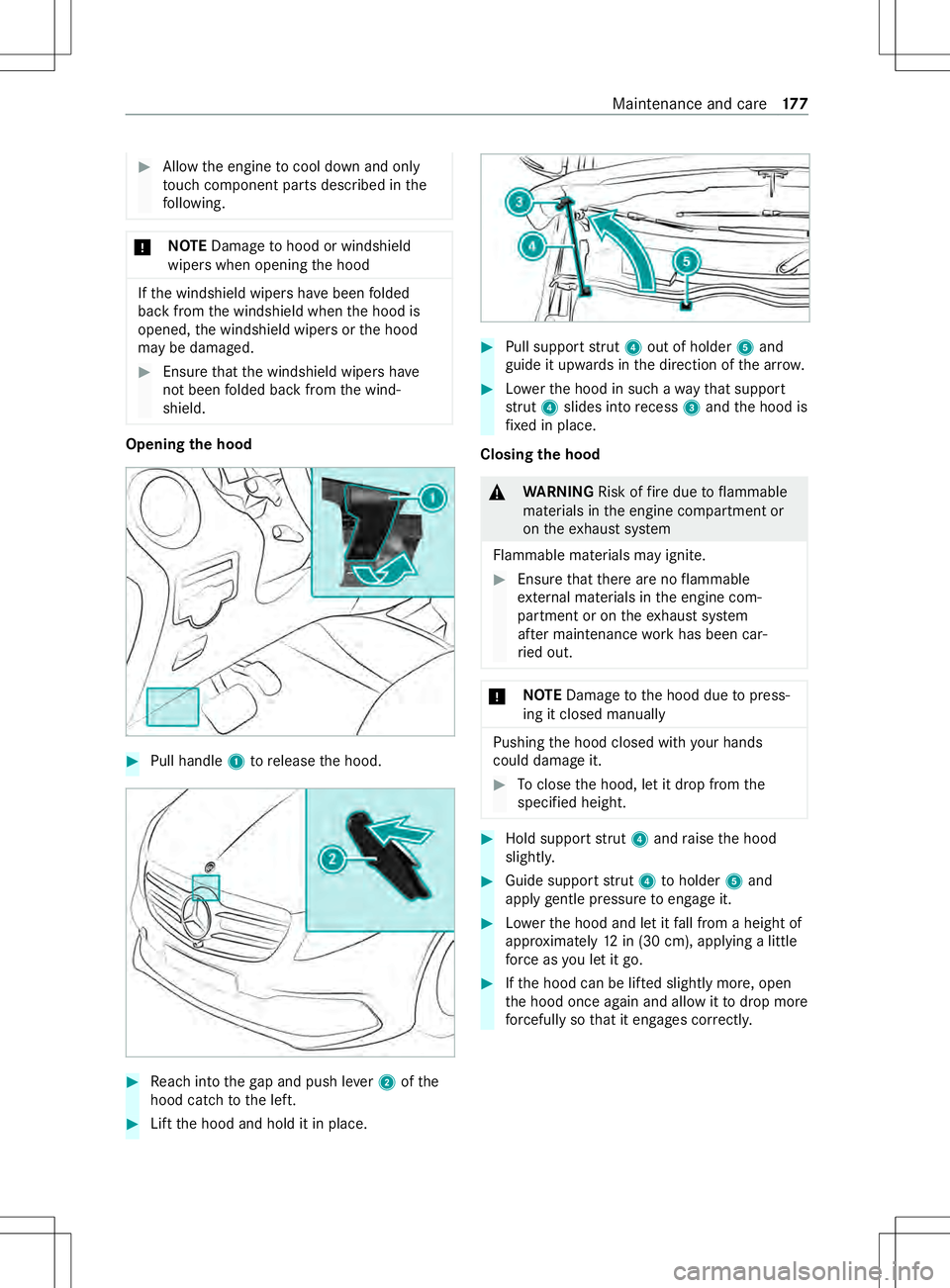

shield. Opening

theh ood #

Pull handle 1torelease theh ood. #

Reachi ntot he gapa nd push le ver2ofthe

hood catc htothe left. #

Liftthe hood and hold it in place. #

Pull suppor tstrut 4outofh older 5and

guid eitu pwards in thed irection of thea rrow. #

Lowe rthe hood in suc hawaythat support

st rut 4 slides int orecess 3and theh ood is

fi xe dinp lace.

Closing theh ood &

WARNING Risk offire due toflammable

materials in thee ngine compartmen tor

on thee xhau stsystem

Flammable materials ma yignite. #

Ensur ethat ther ea reno flammable

ex tern al materials in thee ngine com‐

partmen torontheexhaus tsyst em

af te rm aintenance workhas been car‐

ri ed out. *

NO

TEDama getotheh ood due topress‐

ing it closed manually Pushing

theh ood closed wit hyour hands

could dama geit. #

Toclos ethe hood, le titdropf romt he

specified height. #

Hold suppor tstrut 4and raise theh ood

slightl y. #

Guide suppor tstrut 4toholder 5and

apply gentle pressur etoengageit. #

Lowe rthe hood and le titfall from aheight of

appr oximately 12in (30 cm), applying alittle

fo rc easy ou letitgo. #

Ifth eh ood can be lif teds lightl ymore, open

th eh ood once again and allo wittodropm ore

fo rc efull ysot hat it engages cor rectl y. Maintenance and care

17 7

Page 181 of 290

Engine Oi

lLevel Add 1.0 l

The ba rfor displaying theo il le velont he display

is orang eand is belo w"min".

The oil le velist oo lo w. #

Add1 .1US qt (1 l) of engine oil

(/ page179).

Reduce Engine Oil Level

The bar ford isplaying theo il le velont he display

is orang eand is abo ve"max".

The oil le velist oo high. #

Siphon of fany exc ess engine oil that has

been added. Todo so, consult aqualified spe‐

cialis tworks hop.

For Engine Oil Level Ignition Must Be On #

Switc hthe ignition on tocheckt he engine oil

le ve l.

Engine Oil Level System Inoperative

The fill le vels ensor is defectiv eornotplugged in. #

Have theo il le veld ispla ychec kedataq uali‐

fi ed specialis tworks hop.

Engine Oil Level System Currently Unavail. #

Close theh ood.

% Ve

hicles wit hcold oil le veld isplay: af tert he

ve hicle has been out of use forane xtended

time ,the oil le velw ill automaticall ybeshown

on thed ispla y.If it is no tpossible tomeasu re

th ee ngine oil le vel,am essag etothat ef fect

will appea r.

Checking thee ngine oil le velw ithad ipst ick &

WARNING Risk of bu rnsf romh otcom‐

ponent parts in thee ngine compartment

Cer tainc omponent pa rtsint he engine com‐

partment can be very hot, e.g. thee ngine, the

cooler and pa rtsoft heexhaus tsystem. #

Allowthe engine tocool down and only

to uc hc omponent parts desc ribed in the

fo llowing. The engin

eoil becomes dirty during operation,

loses quality and also graduall yloses volume.

Chec kthe oil le velregularly and add oil or ha veit

ch anged if necessar y.

Re gular lych eckt he fluid le vela nd them ajor

assemblies forl ea ks.Ify ou de tect fluid loss ,for

ex ample, oil drops on thev ehicle parking space, consult

aqualified specialis tworks hop as quickly

as possible. #

Onlychec kthe oil le velw hen thee ngine is at

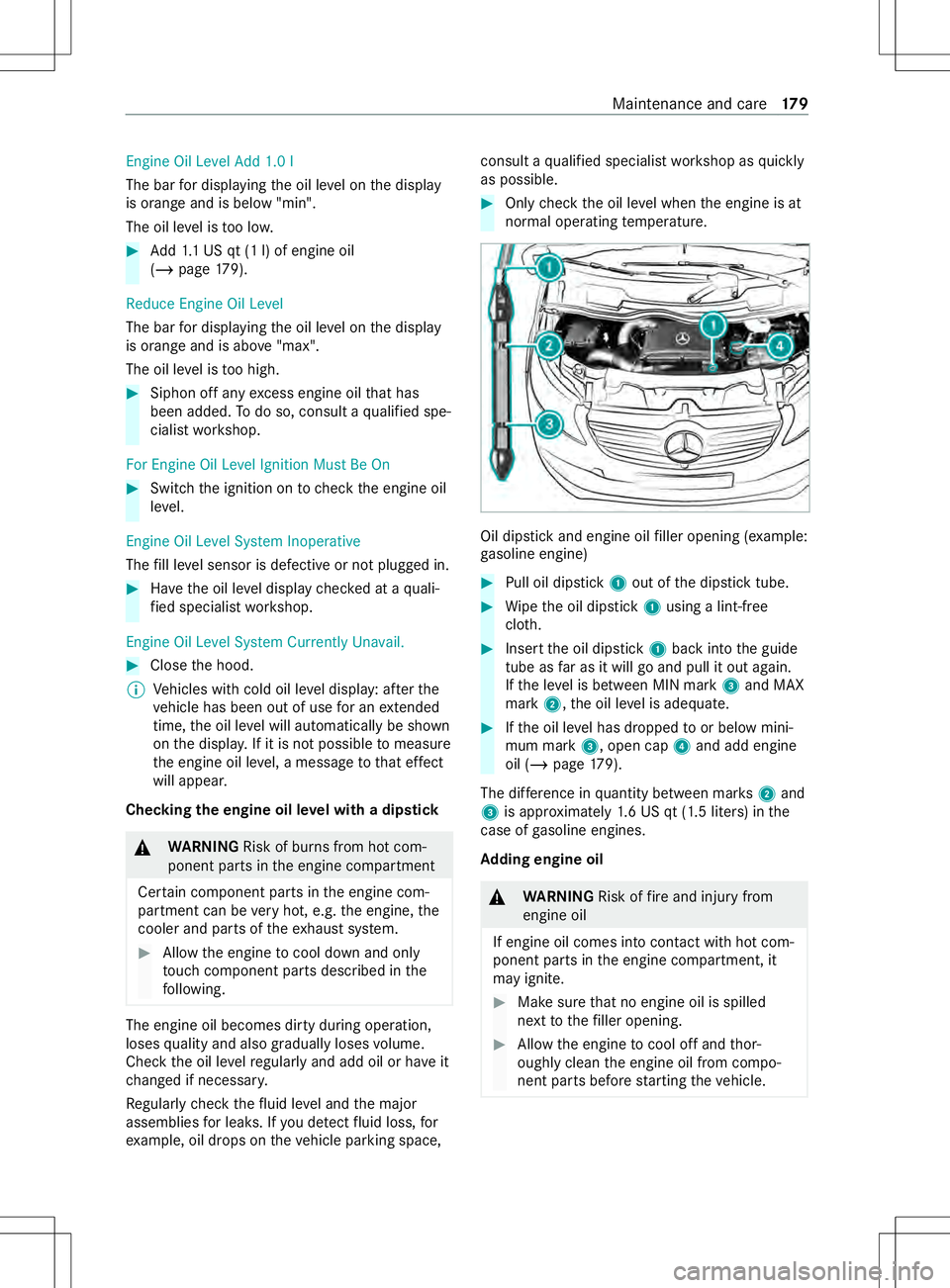

normal operating temp erature. Oil dipstic

kand engine oil filler openin g(example:

ga soline engine) #

Pull oil dipstick 1out of thed ipstic ktube. #

Wipe theo il dipstick 1using alint-free

clo th. #

Inser tthe oil dipstick 1bac kintot he guide

tube as farasitw illgoa nd pullito ut again.

If th el eve lisb etwe en MIN mark 3and MAX

mark 2,the oil le velisa dequate. #

Ifth eo il le velh as dropped toor belo wmini‐

mum mark 3,open cap 4and add engine

oil (/ page179).

The di fference in quantity between mar ks2 and

3 is appr oximatel y1.6 US qt (1.5 liters) in the

case of gasoline engines.

Ad ding engin eoil &

WARNING Risk offire and injur yfrom

engine oil

If engine oil comes int ocontact wit hhotcom‐

ponent parts in thee ngine compartment, it

ma yignite. #

Mak esuret hat no engine oil is spilled

next tothef iller opening. #

Allowthe engine tocool of fand thor‐

oughly clean thee ngine oil from compo‐

nent parts befor estartin gt he vehicle. Maintenance and care

17 9

Page 182 of 290

&

WARNING Risk of bu rnsf romh otcom‐

ponent parts in thee ngine compartment

Cer tainc omponent pa rtsint he engine com‐

partment can be very hot, e.g. thee ngine, the

cooler and pa rtsoft heexhaus tsystem. #

Allowthe engine tocool down and only

to uc hc omponent parts desc ribed in the

fo llowing. *

NO

TEDama gecaused byrefilling too

muc hengine oil To

om uche ngine oil can damag ethe engine

or thec atalytic con verter. #

Have excess engine oil remo vedata

qu alified specialis tworks hop. *

NO

TEEngine damag eduetouse of addi‐

tives in thee ngine oil The use of additional additives in

thee ngine

oil can damag ethe engine. #

Do no tuse an yadditional additives in

th ee ngine oil. +

ENVIRONMEN

TALN OTE Environmental

damag ecaused byspilling oil when refill‐

ing Damag

eiscaused tothee nvironmen tifspil‐

led oil enter sthe soil. #

When refilling oil, mak esuren oneis

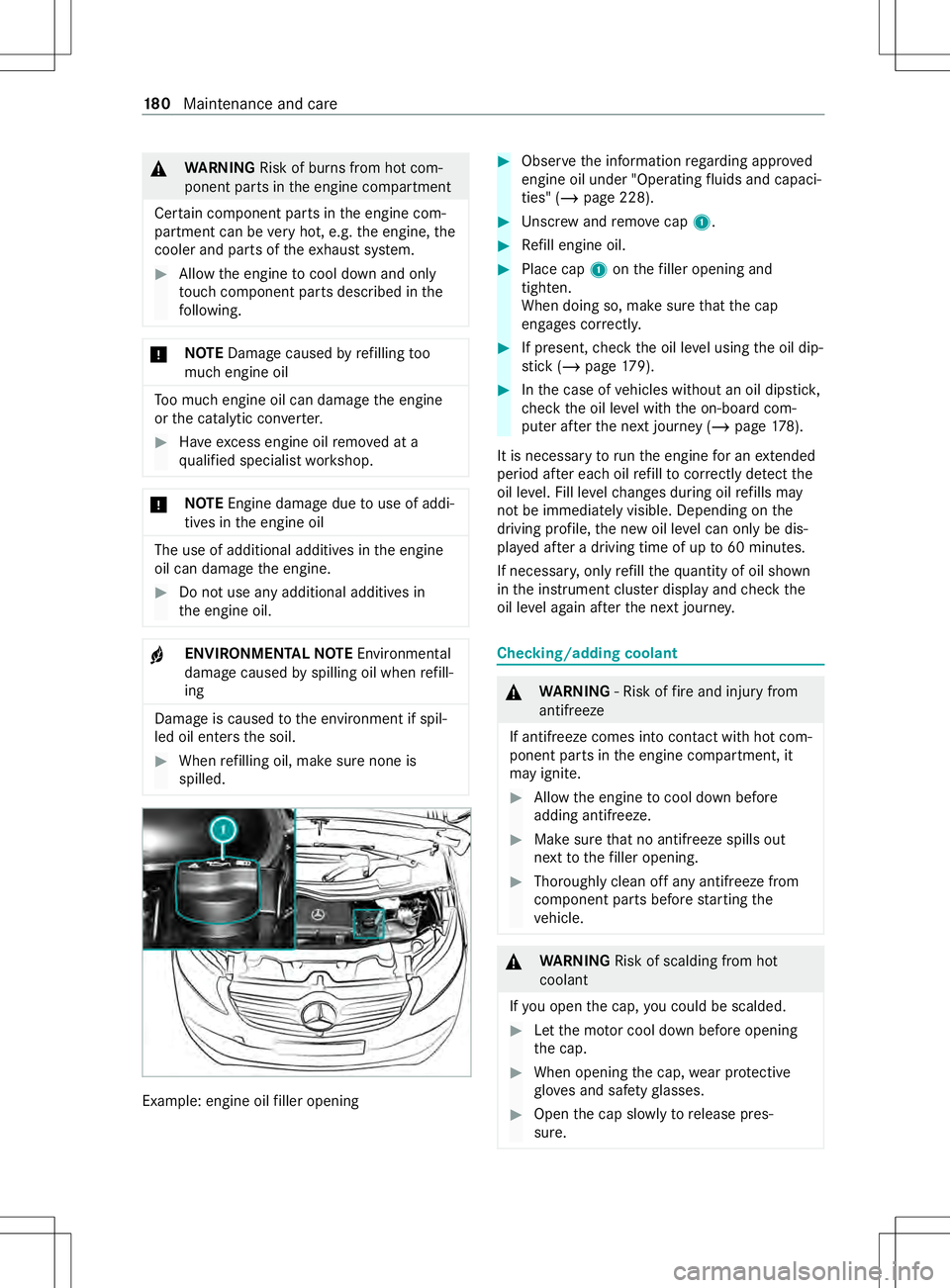

spilled. Example: engin

eoilfiller opening #

Obser vethei nformation rega rding appr oved

engine oil under "Operating fluids and capaci‐

ties" (/ page228). #

Unscr ewand remo vecap 1. #

Refill engin eoil. #

Place cap 1onthef iller openin gand

tigh ten.

Whe ndoing so, mak esuret hat thec ap

engages cor rectly. #

If present, checkt he oil le velu sing theo il dip‐

st ick( / pag e179). #

Inthec ase of vehicles without an oil dipstic k,

ch eckt he oil le velw itht he on-boar dcom‐

puter af tert he next journe y(/ pag e178).

It is necessa ryto runt he engine forane xtended

perio dafter eac hoilre fill to cor rectly de tect the

oil le vel. Fill le velc hanges during oil refills may

no tbei mmediately visible. Depending on the

driving profile, then ew oil le velc an onl ybedis‐

pla yeda fter ad riving time of up to60 minutes.

If necessa ry,o nlyr efill theq uantity of oil shown

in thei nstrument clus terd ispla yand checkt he

oil le vela ga in af tert he next journe y. Checking/adding coolant

&

WARNING ‑Riskoff irea nd injur yfrom

antifreeze

If antifreez ecomes int ocontact wi thhotc om‐

ponent parts in thee ngine compartment, it

ma yignite. #

Allowthe engine tocool down before

adding antif reeze. #

Mak esuret hat no antifreeze spills out

next tothef iller opening. #

Thoroughl yclean of fany antifreeze from

componen tparts befor estartin gt he

ve hicle. &

WARNING Risk of scalding from hot

coolant

If yo uo pen thec ap, youc oul dbes calded. #

Letthe mo torc ool down befor eopening

th ec ap. #

When opening thec ap, wear pr otective

gl ove sand saf etyg lasses. #

Open thec ap slowl ytorelease pres‐

sure. 18 0

Maintenance and care

Page 183 of 290

Only

checkt he coolant le vela nd/or fill th ec ool‐

ant if thev ehicle is stationar y,on aleve lsurface

and thee ngine has cooled down. The coolant

te mp eratur emustbeb elow1 22°F (50°C). &

WARNING Risk of bu rnsf romh otcom‐

ponent parts in thee ngine compartment

Cer tainc omponent pa rtsint he engine com‐

partment can be very hot, e.g. thee ngine, the

cooler and pa rtsoft heexhaus tsystem. #

Allowthe engine tocool down and only

to uc hc omponent parts desc ribed in the

fo llowing. #

Coolant con tains glyc ol and is therefor epoi‐

sonous. Obser vethei nformation under

"Operating fluids and capacities"

(/ page230).

* NO

TEPaint wo rkdamag eduetocoolant If coolant

getsonp ainted sur faces, thep aint‐

wo rkcan be damaged. #

Addc oolant carefully. #

Remo vespilledc oolant. Re

gular lych eckt he engine cooling sy stem and

th eh eating sy stem forl ea ks.Ift hereisal oss of

coolant ,have thec ause de term ined and rectified

in aq ualified specialis tworks hop without dela y. Example: cap and coolant

expansion reser voir

Checking thec oolant le vel #

Slowly tur ncap 1 of coolant expansion res‐

er vo ir2 half aturnc oun ter-clockwise and

allo woverpressur etoe scape. #

Turn cap 1further and remo veit. The coolan

tleve lisc orrect in thef ollowing cases:

R Uptomar kerb ar3 when thee ngine is cold

R Ifth ee ngine is warm,upto0 .6 in (1.5 cm)

ove rmarke rb ar3

Ad ding coolant

Only use coolant appr ovedfor Mercedes-Benz to

av oid damaging thee ngine cooling sy stem. #

Refe rtot he information on coolant

(/ page230). #

Refill th ec oolant up tomar kerb ar3 inthe

fi ller openin gofcoolantexpansio nreser voir

2. #

Replace cap 1and tighten in aclockwise

direction. #

Startt he engine. #

Setthe temp eratur einthevehicle interior to

th em aximum output on thec ont rolp anel of

th ec limat econt rol. #

Aftera pproxima tely five minutes, switc hoff

th ee ngine again and allo wittocool down. #

Che ckthec oolant le vela ga in and add coolant

if necessar y. Re

filling thew indshield washer sy stem &

WARNING Risk offire and injur yfrom

windshiel dwashe rconcentrate

Wi ndshield washer concentrat eishighlyflam‐

mable. #

Avoid fire ,o pen flames ,smokin gand

th ec reation of spar kswhen using wind‐

shield washer concentrate. &

WARNING Risk of bu rnsf romh otcom‐

ponent parts in thee ngine compartment

Cer tainc omponent pa rtsint he engine com‐

partment can be very hot, e.g. thee ngine, the

cooler and pa rtsoft heexhaus tsystem. #

Allowthe engine tocool down and only

to uc hc omponent parts desc ribed in the

fo llowing. *

NO

TEDama getothee xterio rlighting

due tounsuitable windshield washer fluid Uns

uitable windshield washer fluid ma ydam‐

ag et he plastic sur face of thee xterio rlighting. #

Onlyuse windshield washer fluids that

ar ea lso suitable foru se on plast ic sur‐ Maintenance and care

181

Page 184 of 290

fa

ces, e.g. MB SummerFit or MB Winter‐

Fit. Re

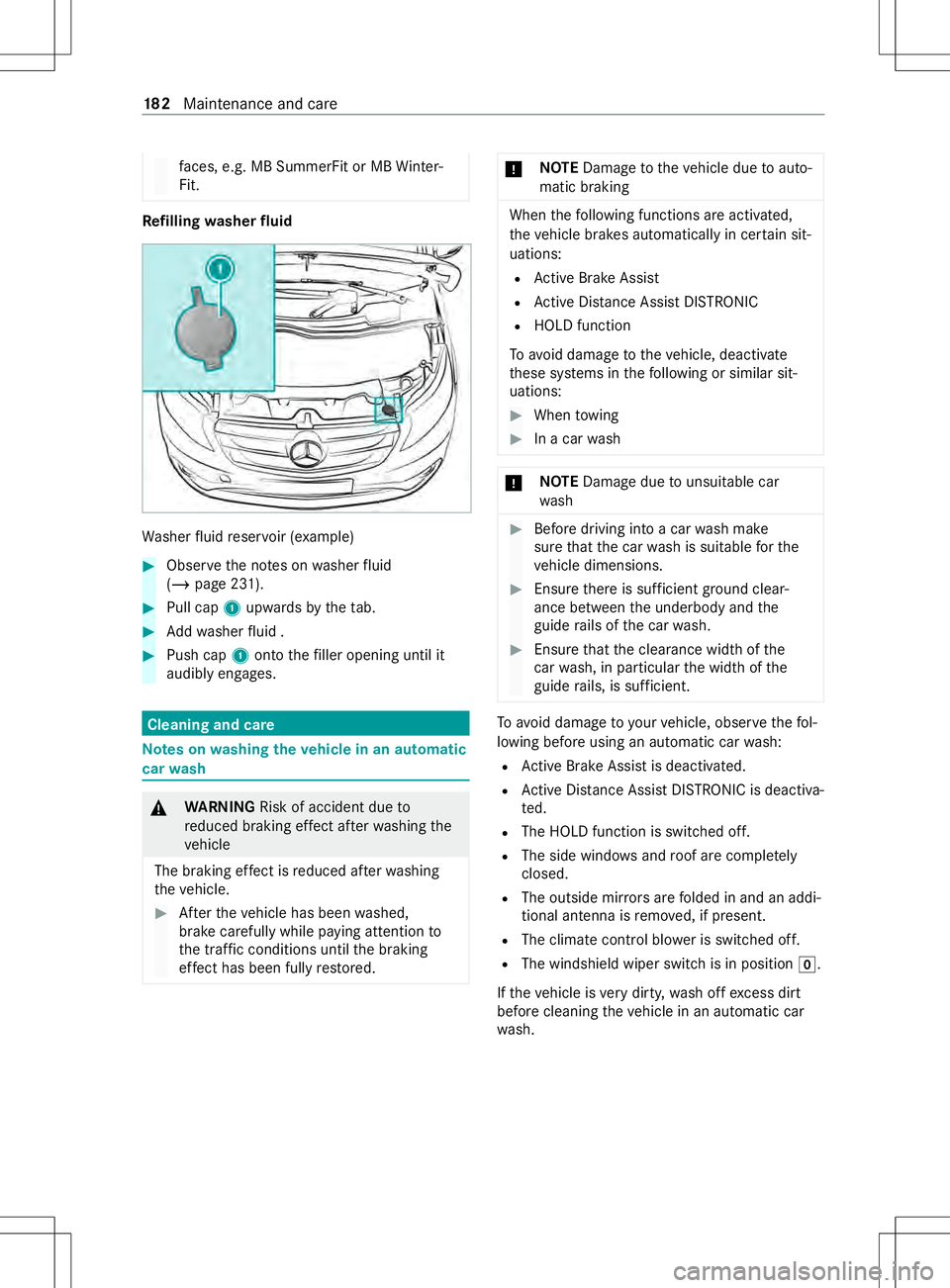

filling washer fluid Wa

sher fluid reser voir (e xamp le) #

Obser vethen otes on washer fluid

(/ page231). #

Pull cap 1upwards bythet ab. #

Addw ashe rfluid . #

Push cap 1ontothe filler openin guntil it

audibly engages. Cleaning and care

Note

sonw ashingthe vehicl einana utomatic

car wash &

WARNING Risk of accident du eto

re duced braking ef fect af terw ashing the

ve hicle

The braking ef fect is reduced af terw ashing

th ev ehicle. #

Aftert he vehicle has been washed,

brak ecarefully while paying attention to

th et raffic condition suntil theb raking

ef fect has bee nfully restored. *

NO

TEDama getothev ehicle due toauto‐

matic braking When

thef ollowing function sareactivated,

th ev ehicle brakes automatically in cer tain sit‐

uations:

R ActiveB rake Assi st

R ActiveD ista nce Assi stDISTRONIC

R HOLD function

To avo id damag etothevehicle, deactivate

th ese sy stems in thef ollowing or similars it‐

uations: #

When towing #

Inac arwa sh *

NO

TEDama gedue tounsuitable car

wa sh #

Befor edriving int oacarwa sh make

sur ethat thec arwa sh is suitable fort he

ve hicle dimensions. #

Ensur ether eiss ufficient ground clear‐

ance between theu nderbody and the

guide rails of thec arwa sh. #

Ensur ethat thec learance widt hofthe

car wash, in particular thew idthoft he

guide rails, is suf ficient. To

avo id damag etoyourvehicle, obser vethef ol‐

lowing befor eusing an automatic car wash:

R ActiveB rake Assi stis deactivated.

R ActiveD ista nce Assi stDISTRONI Cisdeacti va‐

te d.

R The HOLD function is switched off.

R The side windo wsand roof ar ecomple tely

closed.

R Theo utside mi rror sa refolded in and an addi‐

tional antenn aisremoved, if present.

R The climat econtrol blo weriss witched off.

R The windshieldw iper switchisinposition005A.

If th ev ehicle is very dirty ,wash of fexcess dirt

befor ecleaning thev ehicle in an automatic car

wa sh. 18 2

Maintenance and care