MERCEDES-BENZ ML430 1997 Complete Repair Manual

Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML430, Model: MERCEDES-BENZ ML430 1997Pages: 4133, PDF Size: 88.89 MB

Page 3941 of 4133

AR46.40-P-0200-02C

Pressing out and attaching track rod joint at

steering knuckle

k

Surface protection on track rod screw

connection to steering knuckle modified

BT46.40-P-0001-01A

Modification notes

24.3.99

Surface protection on track rod screw connection to

steering knuckle modified

Model 210

BT46.40-P-0001-01A

New tightening torques incorporated

*BA46.40-P-1002-01A

Track rod

Number

Designation

Model 210

BA46.40-P-1002-01A

Self-locking nut, track rod to steering

knuckle

yellow

Nm

60

silver or blue

Nm

70

Track rod

Number

Designation

Model 163

BA46.40-P-1001-01C

Self-locking nut, track rod to steering knuckle

Nm

55

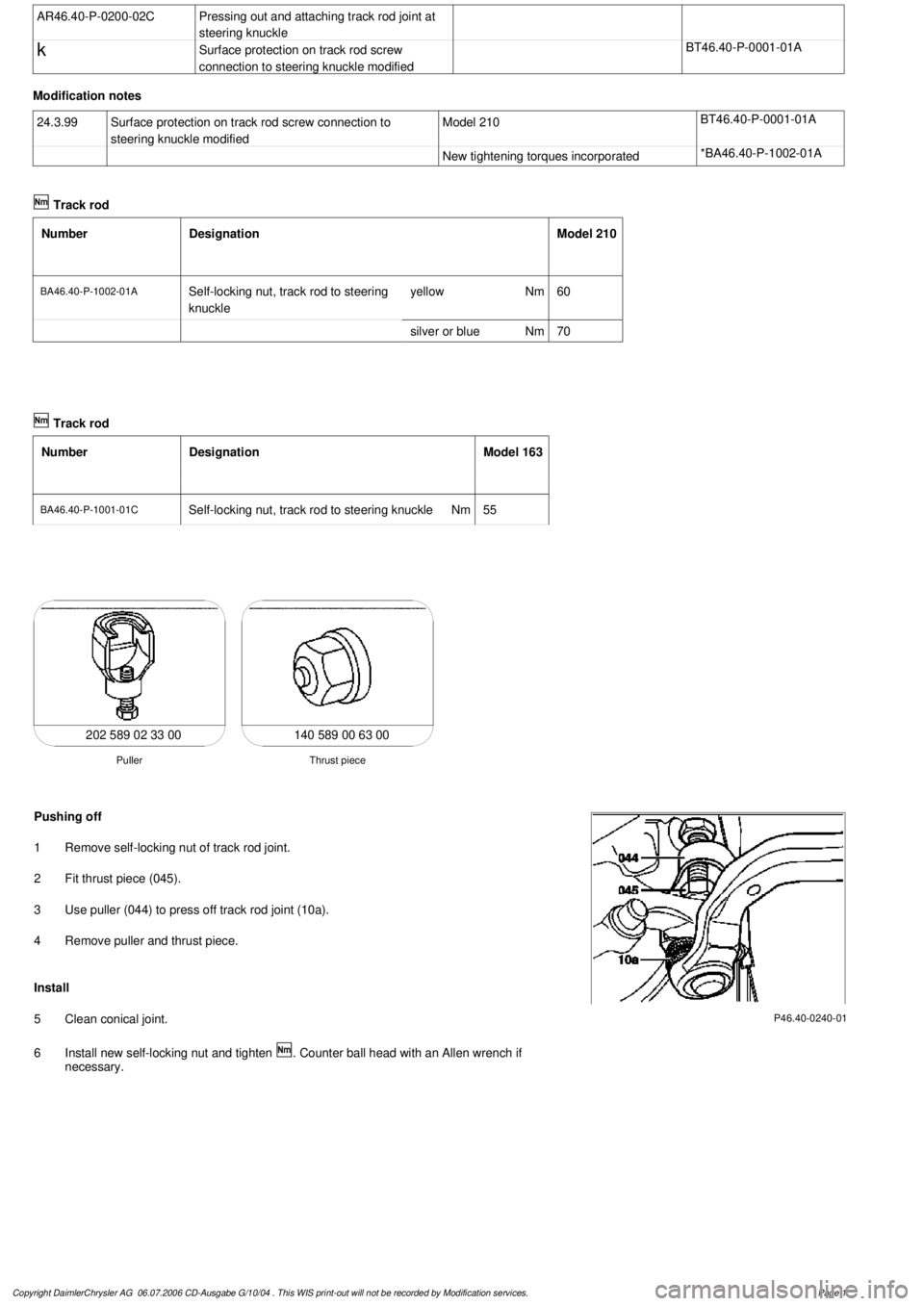

140 589 00 63 00

Thrust piece

Puller

202 589 02 33 00

P46.40-0240-01

Pushing off

1

Remove self-locking nut of track rod joint.

2

Fit thrust piece (045).

3

Use puller (044) to press off track rod joint (10a).

4

Remove puller and thrust piece.

Install

5

Clean conical joint.

6

Install new self-locking nut and tighten

. Counter ball head with an Allen wrench if

necessary.

Copyright DaimlerChrysler AG 06.07.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3942 of 4133

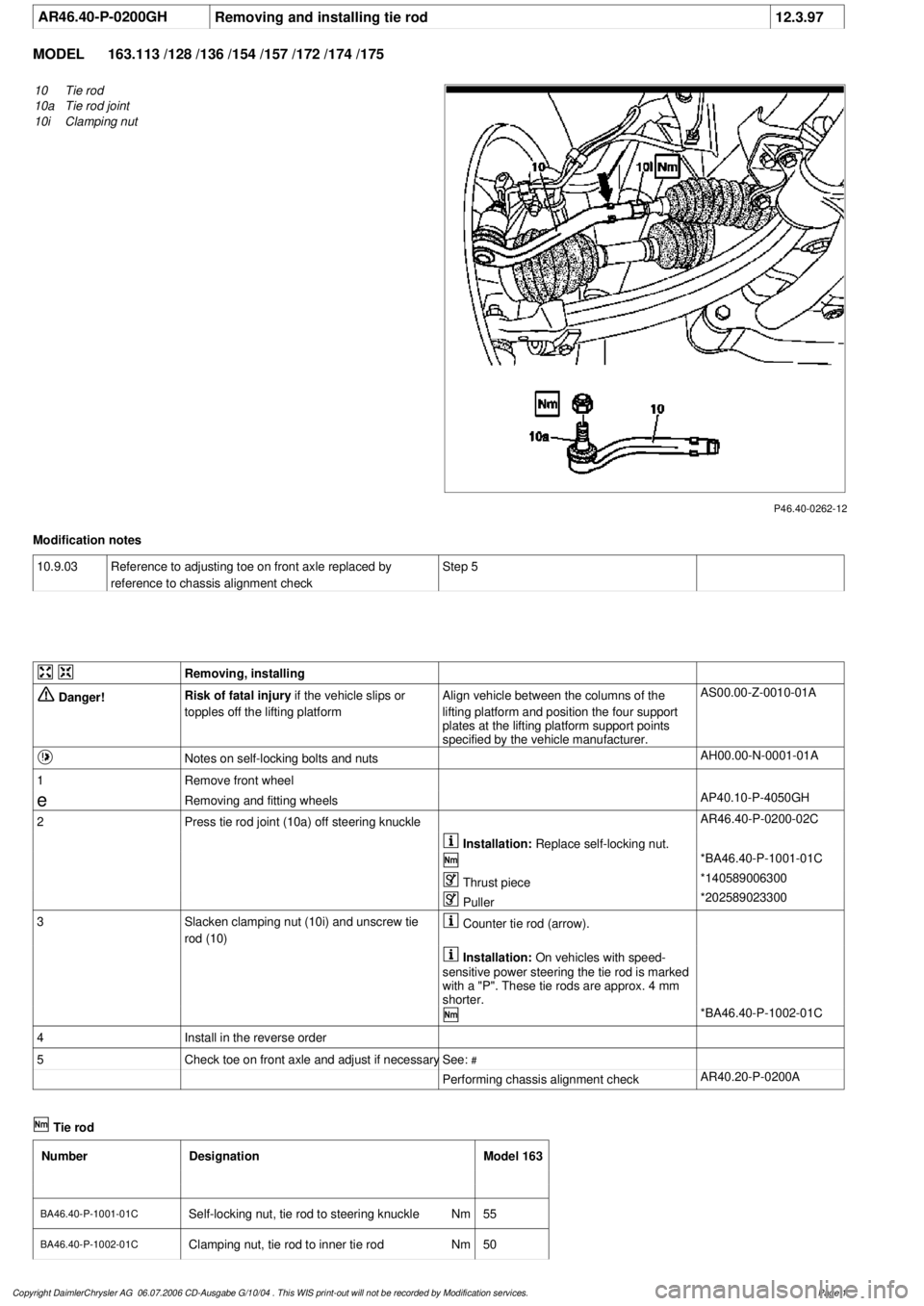

AR46.40-P-0200GH

Removing and installing tie rod

12.3.97

MODEL

163.113 /128 /136 /154 /157 /172 /174 /175

P46.40-0262-12

10

Tie rod

10a

Tie rod joint

10i

Clamping nut

Modification notes

10.9.03

Reference to adjusting toe on front axle replaced by

reference to chassis alignment check

Step 5

Removing, installing

Danger!

Risk of fatal injury

if the vehicle slips or

topples off the lifting platform

Align vehicle between the columns of the

lifting platform and position the four support

plates

at the lifting platform support points

specified by the vehicle manufacturer.

AS00.00-Z-0010-01A

Notes on self-locking bolts and nuts

AH00.00-N-0001-01A

1

Remove front wheel

e

Removing and fitting wheels

AP40.10-P-4050GH

2

Press tie rod joint (10a) off steering knuckle

AR46.40-P-0200-02C

Installation:

Replace self-locking nut.

*BA46.40-P-1001-01C

Thrust piece

*140589006300

Puller

*202589023300

3

Slacken clamping nut (10i) and unscrew tie

rod (10)

Counter tie rod (arrow).

Installation:

On vehicles with speed-

sensitive power steering the tie rod is marked

with a "P". These tie rods are approx. 4 mm

shorter.

*BA46.40-P-1002-01C

4

Install in the reverse order

5

Check toe on front axle and adjust if necessary

See:

#

Performing chassis alignment check

AR40.20-P-0200A

Tie rod

Number

Designation

Model 163

BA46.40-P-1001-01C

Self-locking nut, tie rod to steering knuckle

Nm

55

BA46.40-P-1002-01C

Clamping nut, tie rod to inner tie rod

Nm

50

Copyright DaimlerChrysler AG 06.07.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3943 of 4133

140 589 00 63 00

Thrust piece

Puller

202 589 02 33 00

Copyright DaimlerChrysler AG 06.07.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 2

Page 3944 of 4133

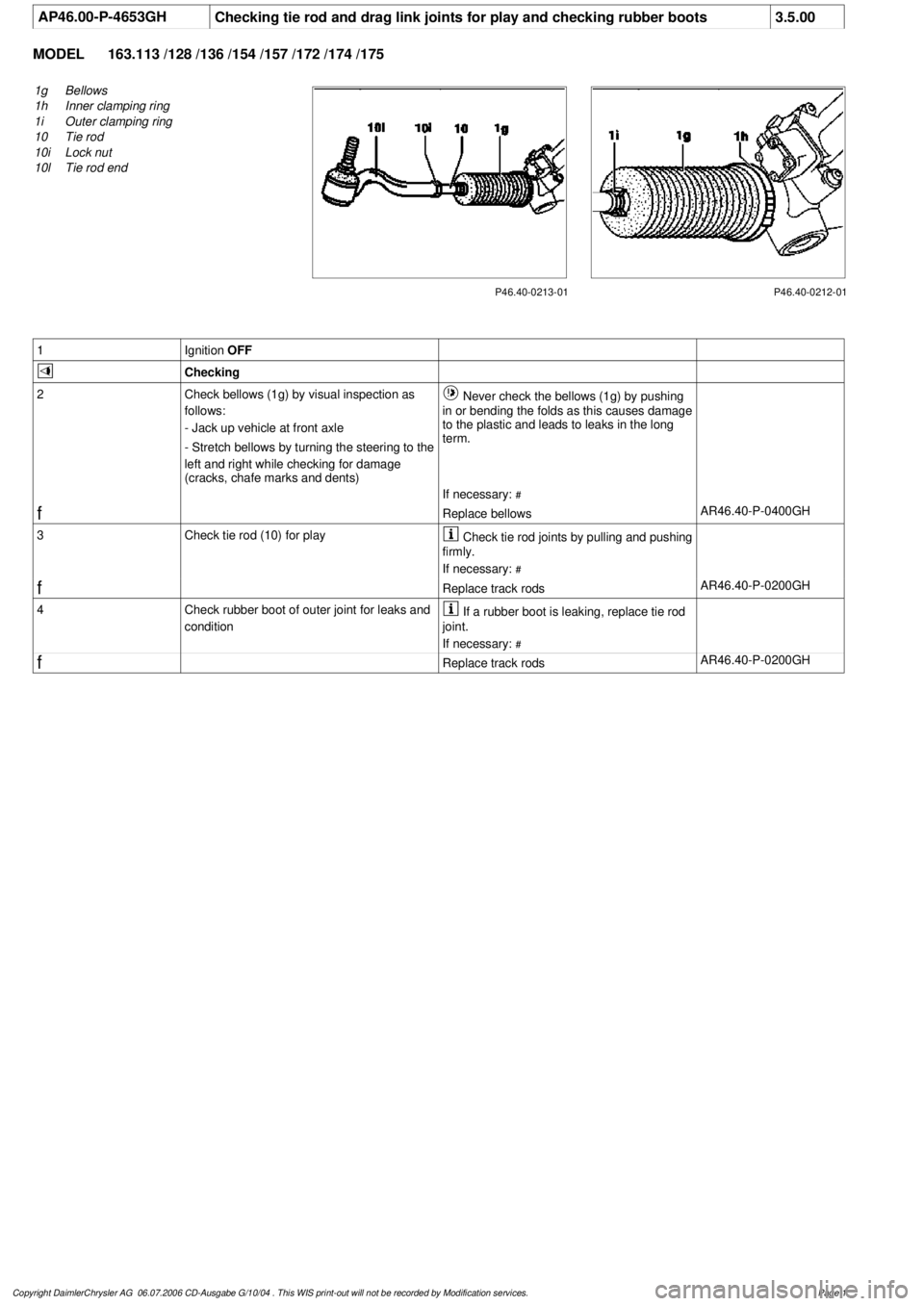

AP46.00-P-4653GH

Checking tie rod and drag link joints for play and checking rubber boots

3.5.00

MODEL

163.113 /128 /136 /154 /157 /172 /174 /175

P46.40-0213-01

1g

Bellows

1h

Inner clamping ring

1i

Outer clamping ring

10

Tie rod

10i

Lock nut

10l

Tie rod end

P46.40-0212-01

1

Ignition

OFF

Checking

2

Check bellows (1g) by visual inspection as

follows:

- Jack up vehicle at front axle

- Stretch bellows by turning the steering to the

left and right while checking for damage

(cracks, chafe marks and dents)

Never check the bellows (1g) by pushing

in or bending the folds as this causes damage

to the plastic and leads to leaks in the long

term.

If necessary:

#

f

Replace bellows

AR46.40-P-0400GH

3

Check tie rod (10) for play

Check tie rod joints by pulling and pushing

firmly.

If necessary:

#

f

Replace track rods

AR46.40-P-0200GH

4

Check rubber boot of outer joint for leaks and

condition

If a rubber boot is leaking, replace tie rod

joint.

If necessary:

#

f

Replace track rods

AR46.40-P-0200GH

Copyright DaimlerChrysler AG 06.07.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3945 of 4133

AP40.10-P-4054R

TIREFIT puncture sealing compound - check expiry date

11.6.01

MODEL

163, 168, 170

MODEL

171, 203, 209, 230, 240, 414 except CODE (669) Spare tire on steel rim

MODEL

209, 211.004 /006 /016 /023 /026 /028 /042 /043 /061 /065 /070 /080 /082 /083 /206 /216 /223 /226 /2 42 /243 /261

/265 /270 /280 /282 /283 /606 /616

except CODE (679) Spare tire in structural wheel design

except CODE (690) Compact spare tire as emergency wheel

MODEL

211.076/ 276

P40.10-2522-06

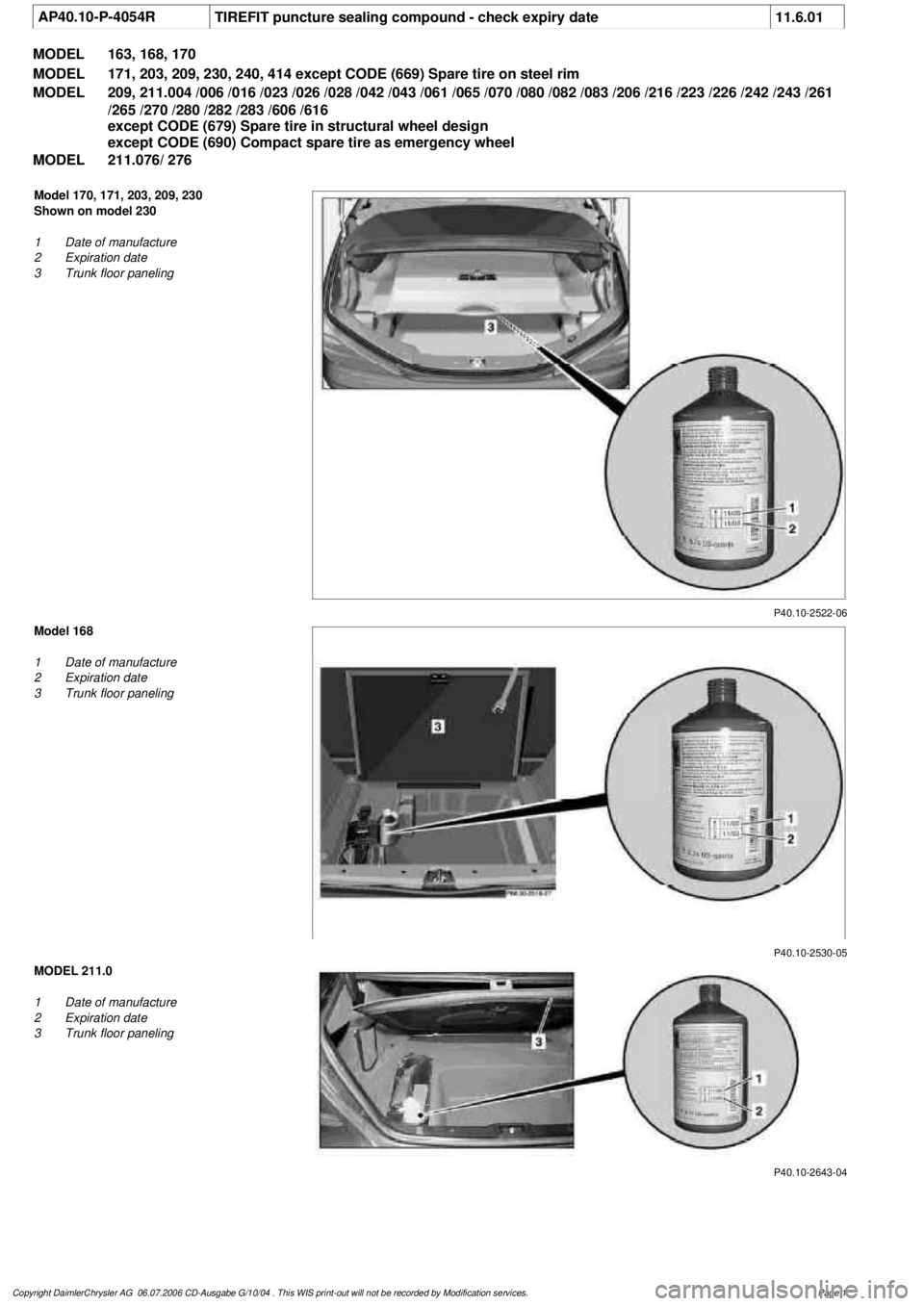

Model 170, 171, 203, 209, 230

Shown on model 230

1

Date of manufacture

2

Expiration date

3

Trunk floor paneling

P40.10-2530-05

Model 168

1

Date of manufacture

2

Expiration date

3

Trunk floor paneling

P40.10-2643-04

MODEL 211.0

1

Date of manufacture

2

Expiration date

3

Trunk floor paneling

Copyright DaimlerChrysler AG 06.07.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3946 of 4133

P40.10-3010-04

MODEL 211.2

1

Date of manufacture

2

Expiration date

5

Load compartment floor

P40.10-2803-04

Model 240

1

Date of manufacture

2

Expiration date

3

Trunk floor paneling

N42.10-2129-05

Model 163, 414

Shown on model 414

1

Date of manufacture

2

Expiration date

4

Left side paneling

Remove/Install

1.1Open luggage compartment lid

Model 170, 171, 203, 209, 211.0, 230, 240

1.2

Open tailgate

Model 163, 168, 211.2, 414

Model 211.6: The place where the

TIREFIT tire repair kit is kept can vary

depending on the vehicle body, see body

manufacturer's operating manual.

2.1

Lift trunk floor paneling (3), remove if

necessary.

Model 168, 170, 171, 203, 209, 211.0, 230, ,

240

2.2

Lift load compartment floor (5)

Model 211.2

2.3

Open left side paneling (4) in luggage

compartment

Model 163, 414

Check

3

Check expiration date (2) on the bottle.

TIREFIT tire sealant has a shelf life of 3

or 4 years depending on the version,

measured from the indicated date of

manufacture (1). The tire sealant must be

replaced after this date.

Dispose of used or old TIREFIT in a

container for paintshop waste (see Workshop

Equipment Manual, Volume 2, Chapter U,

Group 00 (22), Subject 2.3). Fire hazard! No

fire, naked flames or smoking. Avoid

formation of sparks. Do not inhale vapors.

TIREFIT tire sealant

AH40.10-P-0001-01A

4

Install in the reverse order

Copyright DaimlerChrysler AG 06.07.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 2

Page 3947 of 4133

Copyright DaimlerChrysler AG 06.07.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 3

Page 3948 of 4133

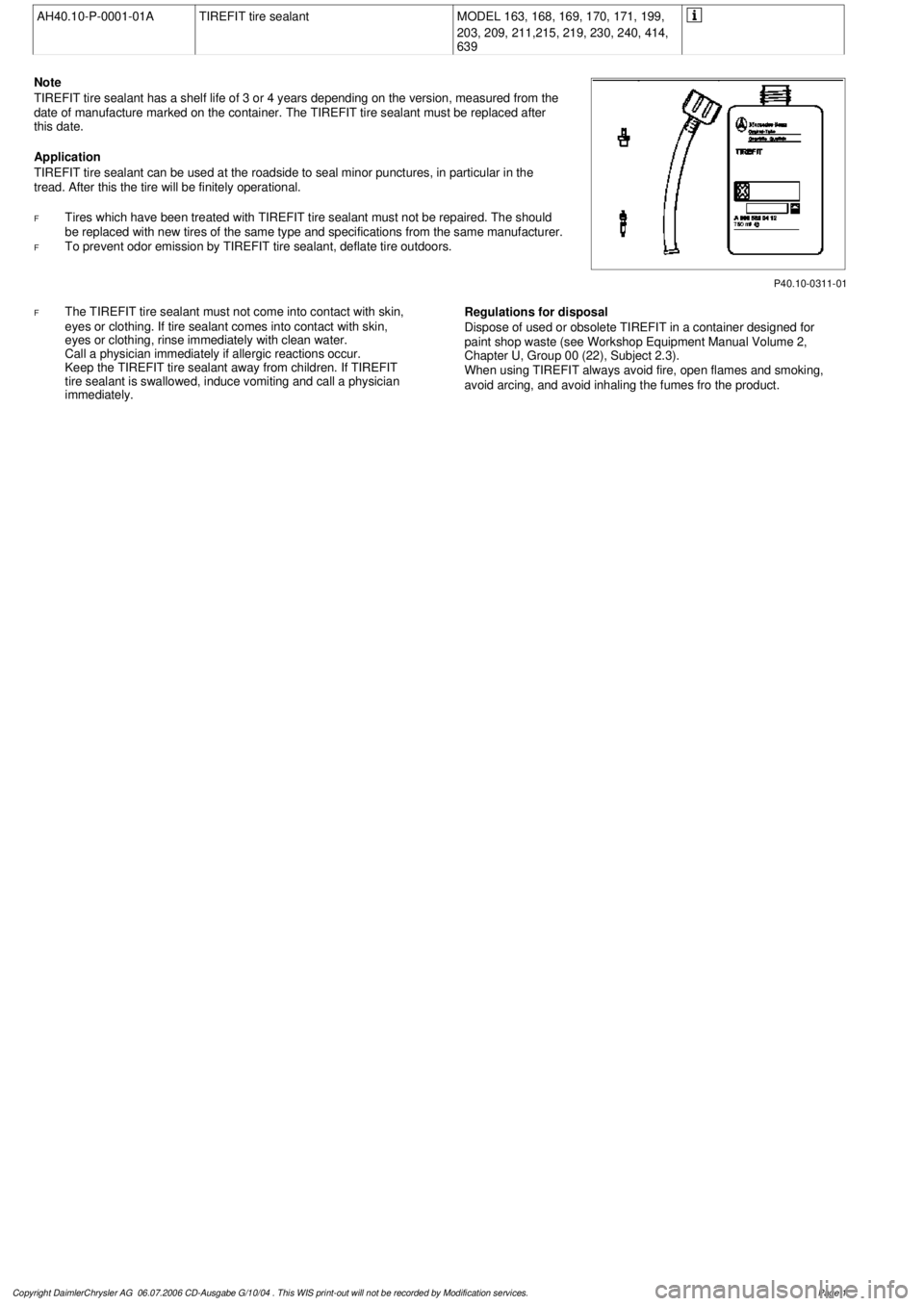

AH40.10-P-0001-01A

TIREFIT tire sealant

MODEL 163, 168, 169, 170, 171, 199,

203, 209, 211,215, 219, 230, 240, 414,

639

P40.10-0311-01

Note

TIREFIT tire sealant has a shelf life of 3 or 4 years depending on the version, measured from the

date of manufacture marked on the container. The TIREFIT tire sealant must be replaced after

this date.

Application

TIREFIT tire sealant can be used at the roadside to seal minor punctures, in particular in the

tread. After this the tire will be finitely operational.

F

Tires which have been treated with TIREFIT tire sealant must not be repaired. The should

be replaced with new tires of the same type and specifications from the same manufacturer.

F

To prevent odor emission by TIREFIT tire sealant, deflate tire outdoors.

F

The TIREFIT tire sealant must not come into contact with skin,

eyes or clothing. If tire sealant comes into contact with skin,

eyes or clothing, rinse immediately with clean water.

Call a physician immediately if allergic reactions occur.

Keep the TIREFIT tire sealant away from children. If TIREFIT

tire sealant is swallowed, induce vomiting and call a physician

immediately.

Regulations for disposal

Dispose of used or obsolete TIREFIT in a container designed for

paint shop waste (see Workshop Equipment Manual Volume 2,

Chapter U, Group 00 (22), Subject 2.3).

When using TIREFIT always avoid fire, open flames and smoking,

avoid arcing, and avoid inhaling the fumes fro the product.

Copyright DaimlerChrysler AG 06.07.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3949 of 4133

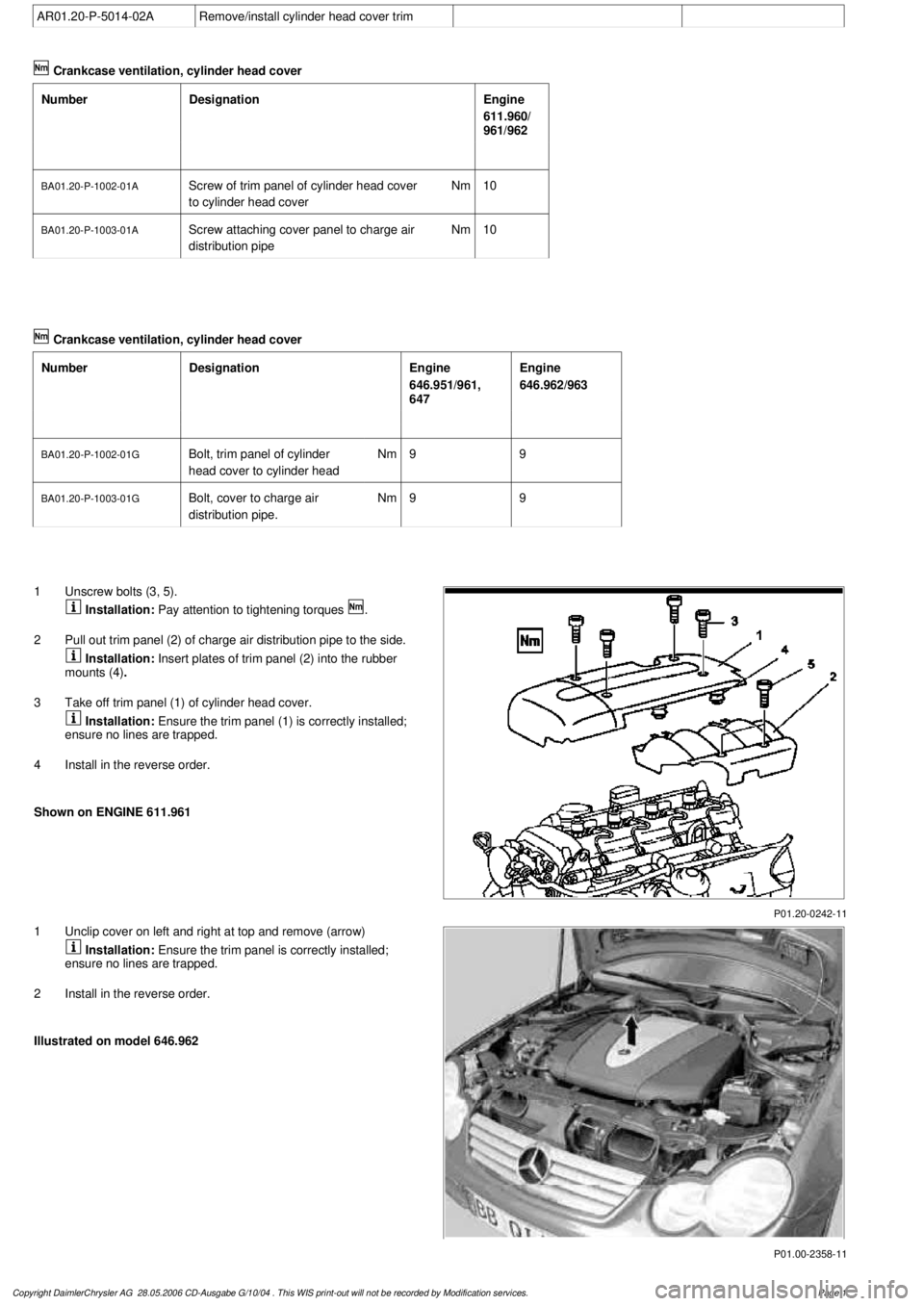

AR01.20-P-5014-02A

Remove/install cylinder head cover trim

Crankcase ventilation, cylinder head cover

Number

Designation

Engine

611.960/

961/962

BA01.20-P-1002-01A

Screw of trim panel of cylinder head cover

to cylinder head cover

Nm

10

BA01.20-P-1003-01A

Screw attaching cover panel to charge air

distribution pipe

Nm

10

Crankcase ventilation, cylinder head cover

Number

Designation

Engine

646.951/961,

647

Engine

646.962/963

BA01.20-P-1002-01G

Bolt, trim panel of cylinder

head cover to cylinder head

Nm

99

BA01.20-P-1003-01G

Bolt, cover to charge air

distribution pipe.

Nm

99

P01.20-0242-11

1

Unscrew bolts (3, 5).

Installation:

Pay attention to tightening torques

.

2

Pull out trim panel (2) of charge air distribution pipe to the side.

Installation:

Insert plates of trim panel (2) into the rubber

mounts (4)

.

3

Take off trim panel (1) of cylinder head cover.

Installation:

Ensure the trim panel (1) is correctly installed;

ensure no lines are trapped.

4

Install in the reverse order.

Shown on ENGINE 611.961

P01.00-2358-11

1

Unclip cover on left and right at top and remove (arrow)

Installation:

Ensure the trim panel is correctly installed;

ensure no lines are trapped.

2

Install in the reverse order.

Illustrated on model 646.962

Copyright DaimlerChrysler AG 28.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3950 of 4133

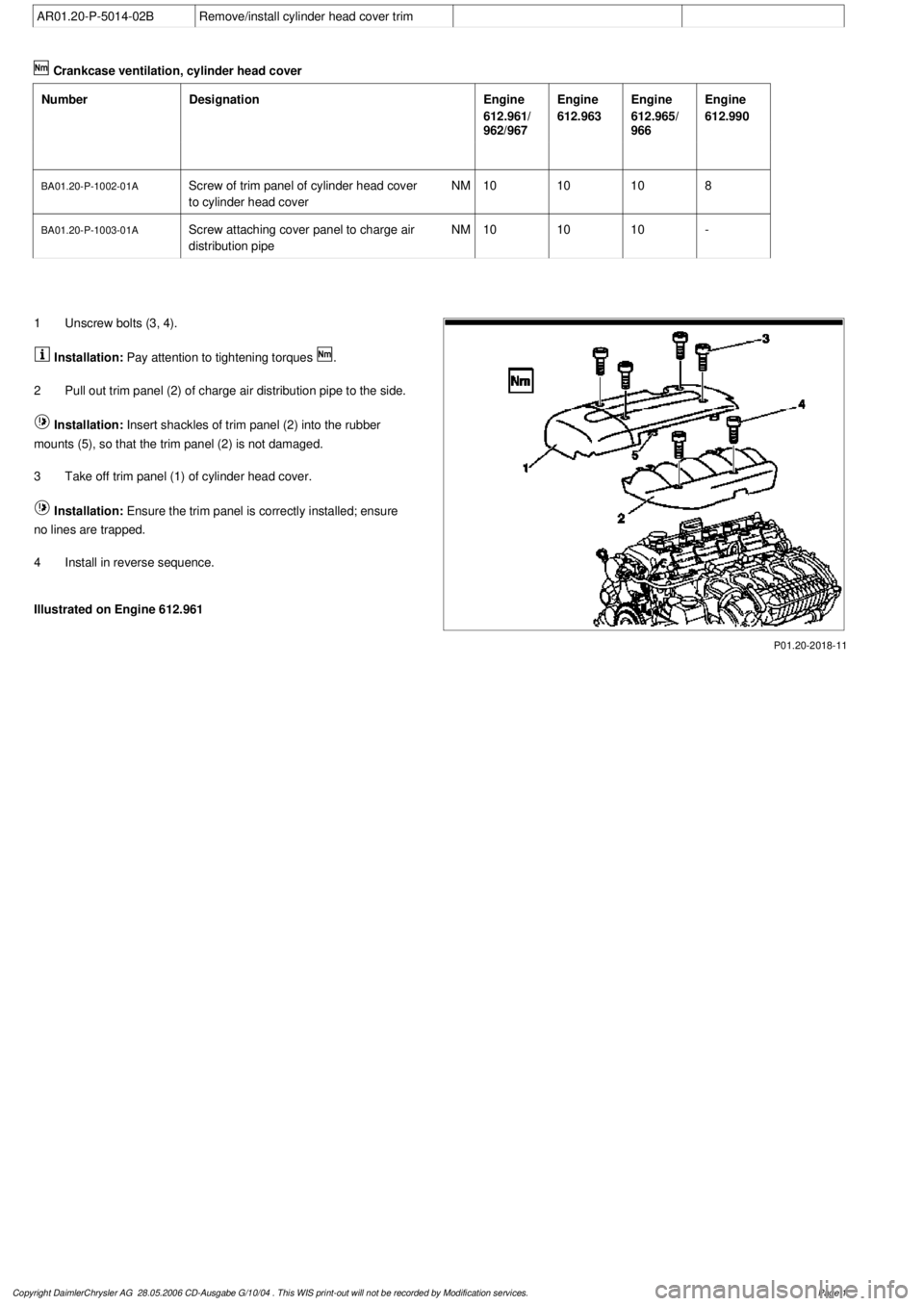

AR01.20-P-5014-02B

Remove/install cylinder head cover trim

Crankcase ventilation, cylinder head cover

Number

Designation

Engine

612.961/

962/967

Engine

612.963

Engine

612.965/

966

Engine

612.990

BA01.20-P-1002-01A

Screw of trim panel of cylinder head cover

to cylinder head cover

NM

101010

8

BA01.20-P-1003-01A

Screw attaching cover panel to charge air

distribution pipe

NM

101010

-

P01.20-2018-11

1

Unscrew bolts (3, 4).

Installation:

Pay attention to tightening torques

.

2

Pull out trim panel (2) of charge air distribution pipe to the side.

Installation:

Insert shackles of trim panel (2) into the rubber

mounts (5), so that the trim panel (2) is not damaged.

3

Take off trim panel (1) of cylinder head cover.

Installation:

Ensure the trim panel is correctly installed; ensure

no lines are trapped.

4

Install in reverse sequence.

Illustrated on Engine 612.961

Copyright DaimlerChrysler AG 28.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1