MERCEDES-BENZ SPRINTER 2005 Service Repair Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 1001 of 1232

OUTPUT SHAFT SEAL

REMOVAL

(1) Remove the propeller shaft (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/PROPELLER SHAFT/

PROPELLER SHAFT - REMOVAL). Move propeller

shaft to the right and tie up.

(2) Verify that the transmission is in PARK in

order to prepare for the removal of the output shaft

nut.

(3) Remove the nut holding the propeller shaft

flange to the output shaft and remove the flange.

(4) Remove the output shaft seal with suitable

screw and slide hammer.

INSTALLATION

(1) Position the new output shaft seal over the out-

put shaft and against the transmission case.

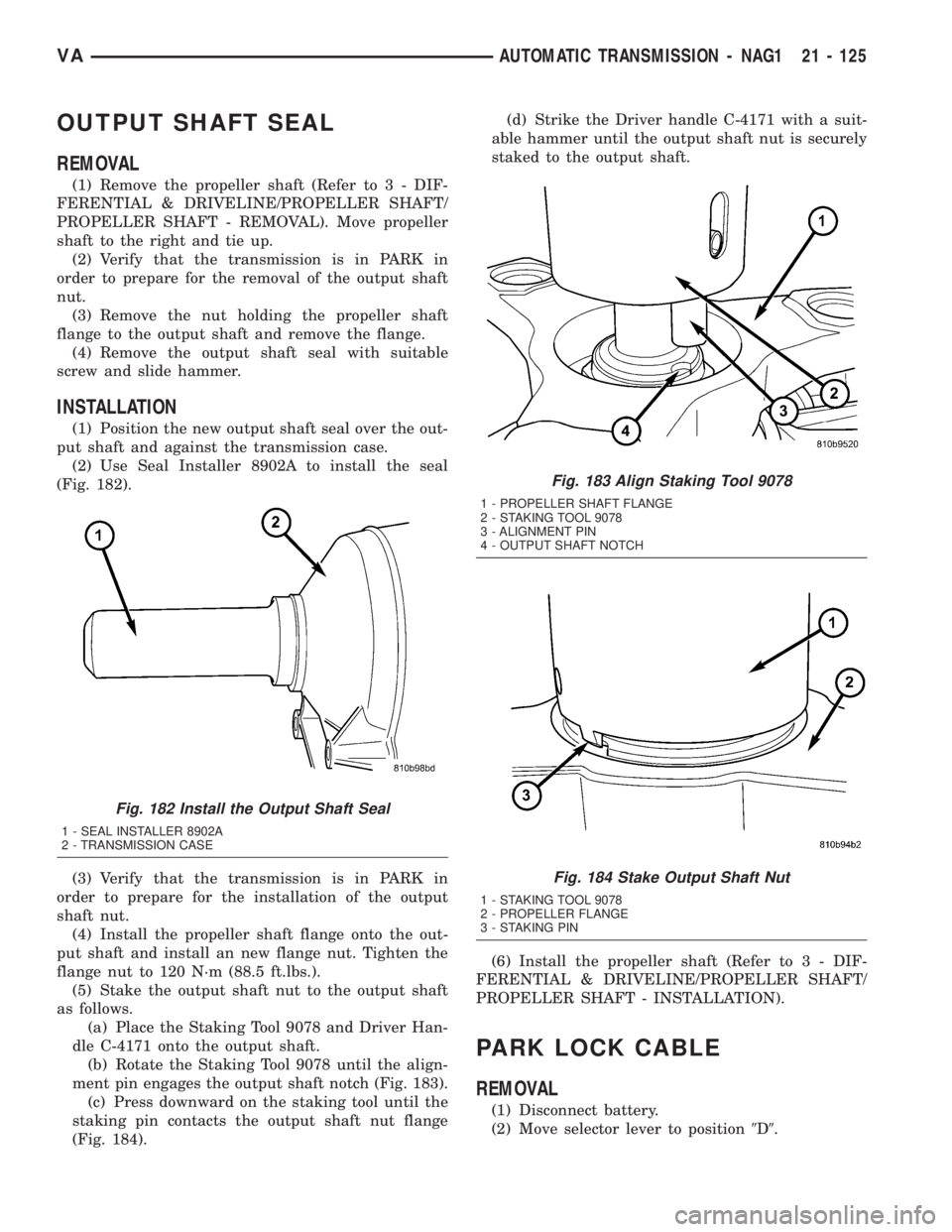

(2) Use Seal Installer 8902A to install the seal

(Fig. 182).

(3) Verify that the transmission is in PARK in

order to prepare for the installation of the output

shaft nut.

(4) Install the propeller shaft flange onto the out-

put shaft and install an new flange nut. Tighten the

flange nut to 120 N´m (88.5 ft.lbs.).

(5) Stake the output shaft nut to the output shaft

as follows.

(a) Place the Staking Tool 9078 and Driver Han-

dle C-4171 onto the output shaft.

(b) Rotate the Staking Tool 9078 until the align-

ment pin engages the output shaft notch (Fig. 183).

(c) Press downward on the staking tool until the

staking pin contacts the output shaft nut flange

(Fig. 184).(d) Strike the Driver handle C-4171 with a suit-

able hammer until the output shaft nut is securely

staked to the output shaft.

(6) Install the propeller shaft (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/PROPELLER SHAFT/

PROPELLER SHAFT - INSTALLATION).

PARK LOCK CABLE

REMOVAL

(1) Disconnect battery.

(2) Move selector lever to position9D9.

Fig. 182 Install the Output Shaft Seal

1 - SEAL INSTALLER 8902A

2 - TRANSMISSION CASE

Fig. 183 Align Staking Tool 9078

1 - PROPELLER SHAFT FLANGE

2 - STAKING TOOL 9078

3 - ALIGNMENT PIN

4 - OUTPUT SHAFT NOTCH

Fig. 184 Stake Output Shaft Nut

1 - STAKING TOOL 9078

2 - PROPELLER FLANGE

3 - STAKING PIN

VAAUTOMATIC TRANSMISSION - NAG1 21 - 125

Page 1002 of 1232

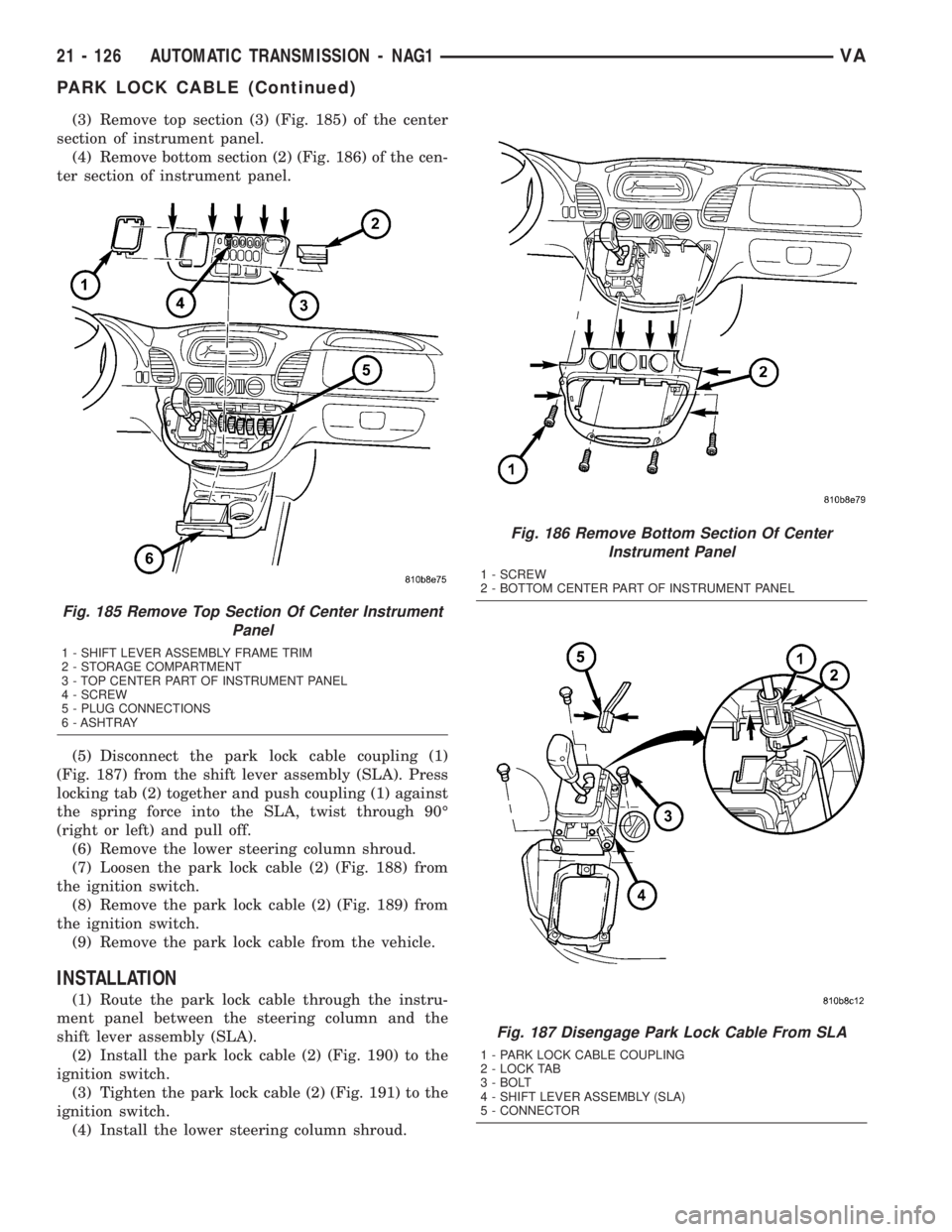

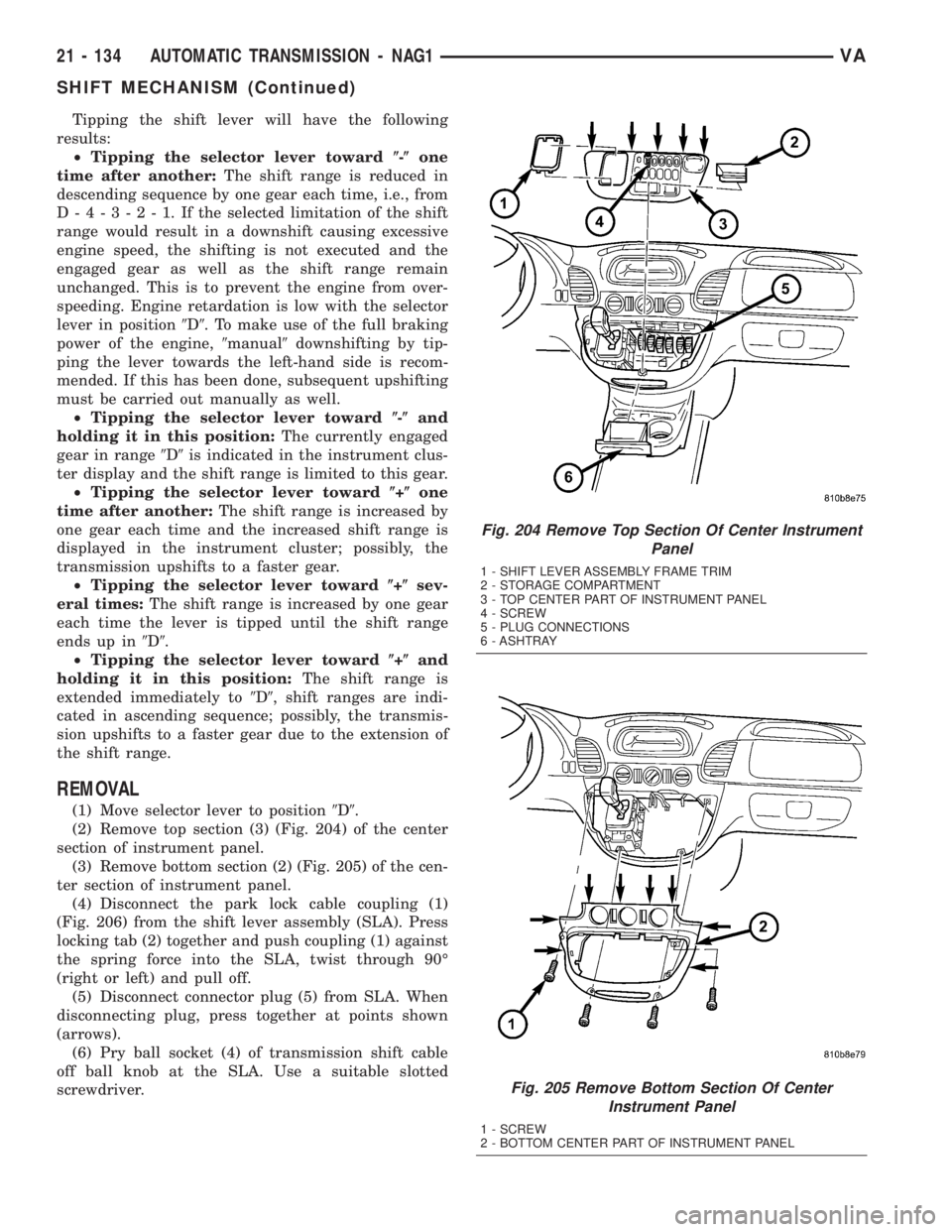

(3) Remove top section (3) (Fig. 185) of the center

section of instrument panel.

(4) Remove bottom section (2) (Fig. 186) of the cen-

ter section of instrument panel.

(5) Disconnect the park lock cable coupling (1)

(Fig. 187) from the shift lever assembly (SLA). Press

locking tab (2) together and push coupling (1) against

the spring force into the SLA, twist through 90É

(right or left) and pull off.

(6) Remove the lower steering column shroud.

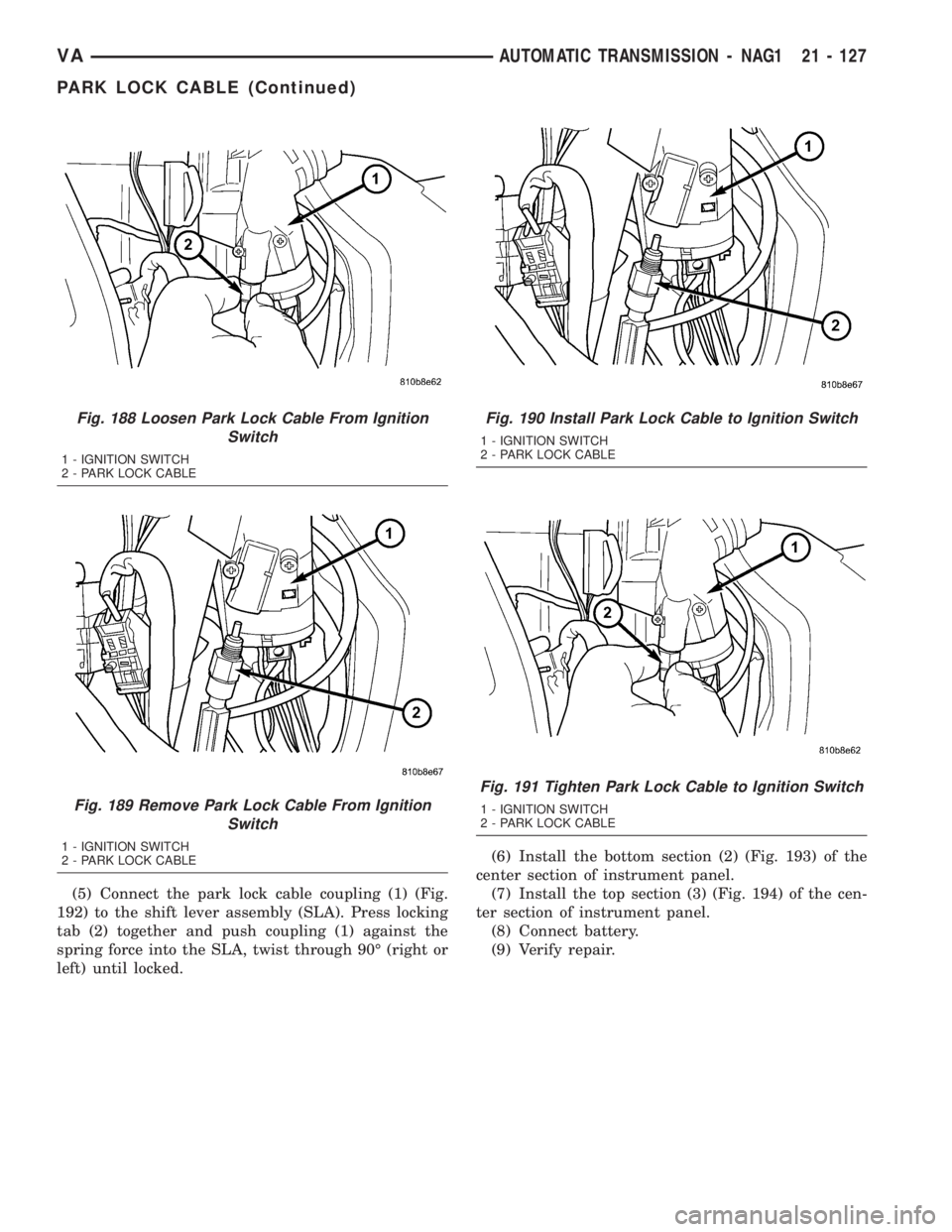

(7) Loosen the park lock cable (2) (Fig. 188) from

the ignition switch.

(8) Remove the park lock cable (2) (Fig. 189) from

the ignition switch.

(9) Remove the park lock cable from the vehicle.

INSTALLATION

(1) Route the park lock cable through the instru-

ment panel between the steering column and the

shift lever assembly (SLA).

(2) Install the park lock cable (2) (Fig. 190) to the

ignition switch.

(3) Tighten the park lock cable (2) (Fig. 191) to the

ignition switch.

(4) Install the lower steering column shroud.

Fig. 185 Remove Top Section Of Center Instrument

Panel

1 - SHIFT LEVER ASSEMBLY FRAME TRIM

2 - STORAGE COMPARTMENT

3 - TOP CENTER PART OF INSTRUMENT PANEL

4 - SCREW

5 - PLUG CONNECTIONS

6 - ASHTRAY

Fig. 186 Remove Bottom Section Of Center

Instrument Panel

1 - SCREW

2 - BOTTOM CENTER PART OF INSTRUMENT PANEL

Fig. 187 Disengage Park Lock Cable From SLA

1 - PARK LOCK CABLE COUPLING

2 - LOCK TAB

3 - BOLT

4 - SHIFT LEVER ASSEMBLY (SLA)

5 - CONNECTOR

21 - 126 AUTOMATIC TRANSMISSION - NAG1VA

PARK LOCK CABLE (Continued)

Page 1003 of 1232

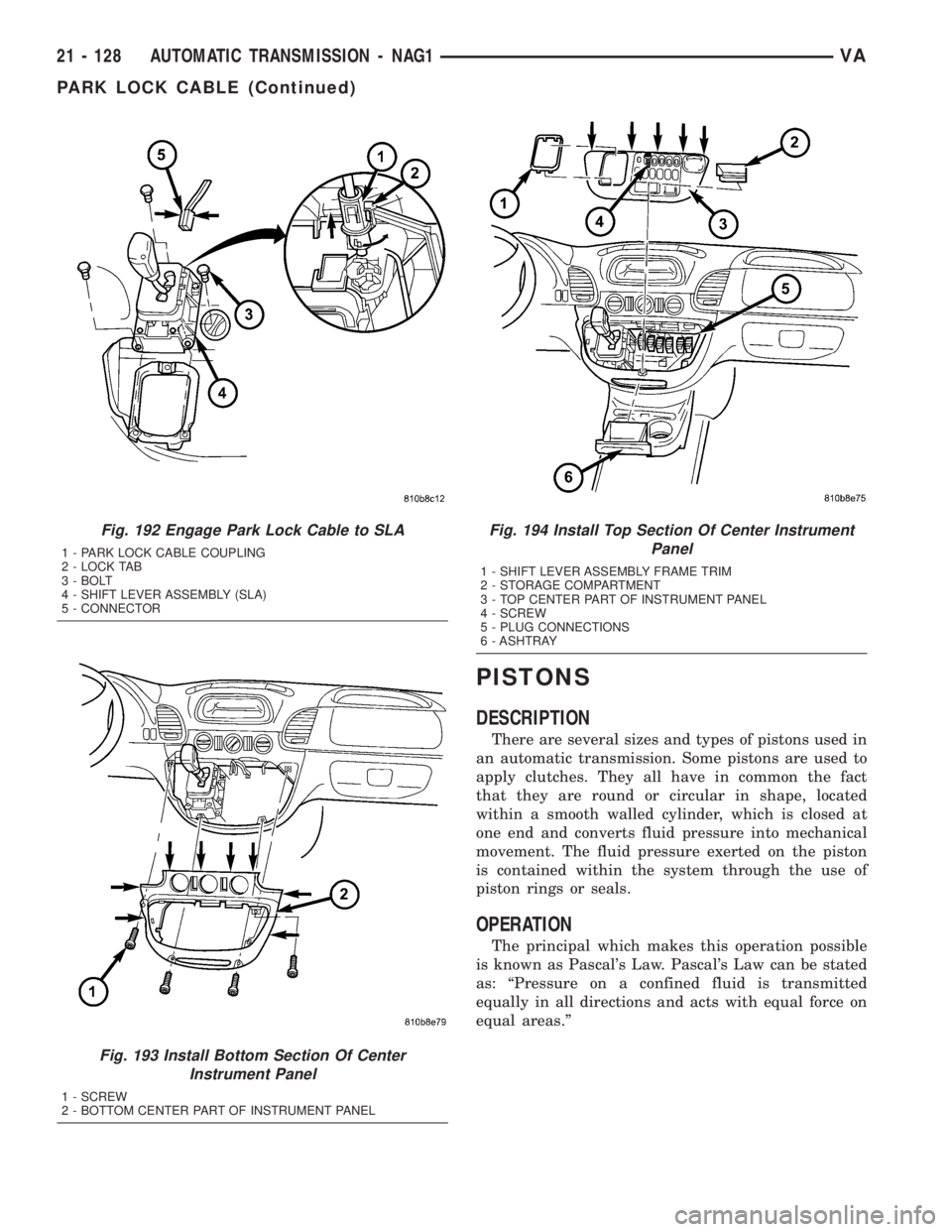

(5) Connect the park lock cable coupling (1) (Fig.

192) to the shift lever assembly (SLA). Press locking

tab (2) together and push coupling (1) against the

spring force into the SLA, twist through 90É (right or

left) until locked.(6) Install the bottom section (2) (Fig. 193) of the

center section of instrument panel.

(7) Install the top section (3) (Fig. 194) of the cen-

ter section of instrument panel.

(8) Connect battery.

(9) Verify repair.

Fig. 188 Loosen Park Lock Cable From Ignition

Switch

1 - IGNITION SWITCH

2 - PARK LOCK CABLE

Fig. 189 Remove Park Lock Cable From Ignition

Switch

1 - IGNITION SWITCH

2 - PARK LOCK CABLE

Fig. 190 Install Park Lock Cable to Ignition Switch

1 - IGNITION SWITCH

2 - PARK LOCK CABLE

Fig. 191 Tighten Park Lock Cable to Ignition Switch

1 - IGNITION SWITCH

2 - PARK LOCK CABLE

VAAUTOMATIC TRANSMISSION - NAG1 21 - 127

PARK LOCK CABLE (Continued)

Page 1004 of 1232

PISTONS

DESCRIPTION

There are several sizes and types of pistons used in

an automatic transmission. Some pistons are used to

apply clutches. They all have in common the fact

that they are round or circular in shape, located

within a smooth walled cylinder, which is closed at

one end and converts fluid pressure into mechanical

movement. The fluid pressure exerted on the piston

is contained within the system through the use of

piston rings or seals.

OPERATION

The principal which makes this operation possible

is known as Pascal's Law. Pascal's Law can be stated

as: ªPressure on a confined fluid is transmitted

equally in all directions and acts with equal force on

equal areas.º

Fig. 192 Engage Park Lock Cable to SLA

1 - PARK LOCK CABLE COUPLING

2 - LOCK TAB

3 - BOLT

4 - SHIFT LEVER ASSEMBLY (SLA)

5 - CONNECTOR

Fig. 193 Install Bottom Section Of Center

Instrument Panel

1 - SCREW

2 - BOTTOM CENTER PART OF INSTRUMENT PANEL

Fig. 194 Install Top Section Of Center Instrument

Panel

1 - SHIFT LEVER ASSEMBLY FRAME TRIM

2 - STORAGE COMPARTMENT

3 - TOP CENTER PART OF INSTRUMENT PANEL

4 - SCREW

5 - PLUG CONNECTIONS

6 - ASHTRAY

21 - 128 AUTOMATIC TRANSMISSION - NAG1VA

PARK LOCK CABLE (Continued)

Page 1005 of 1232

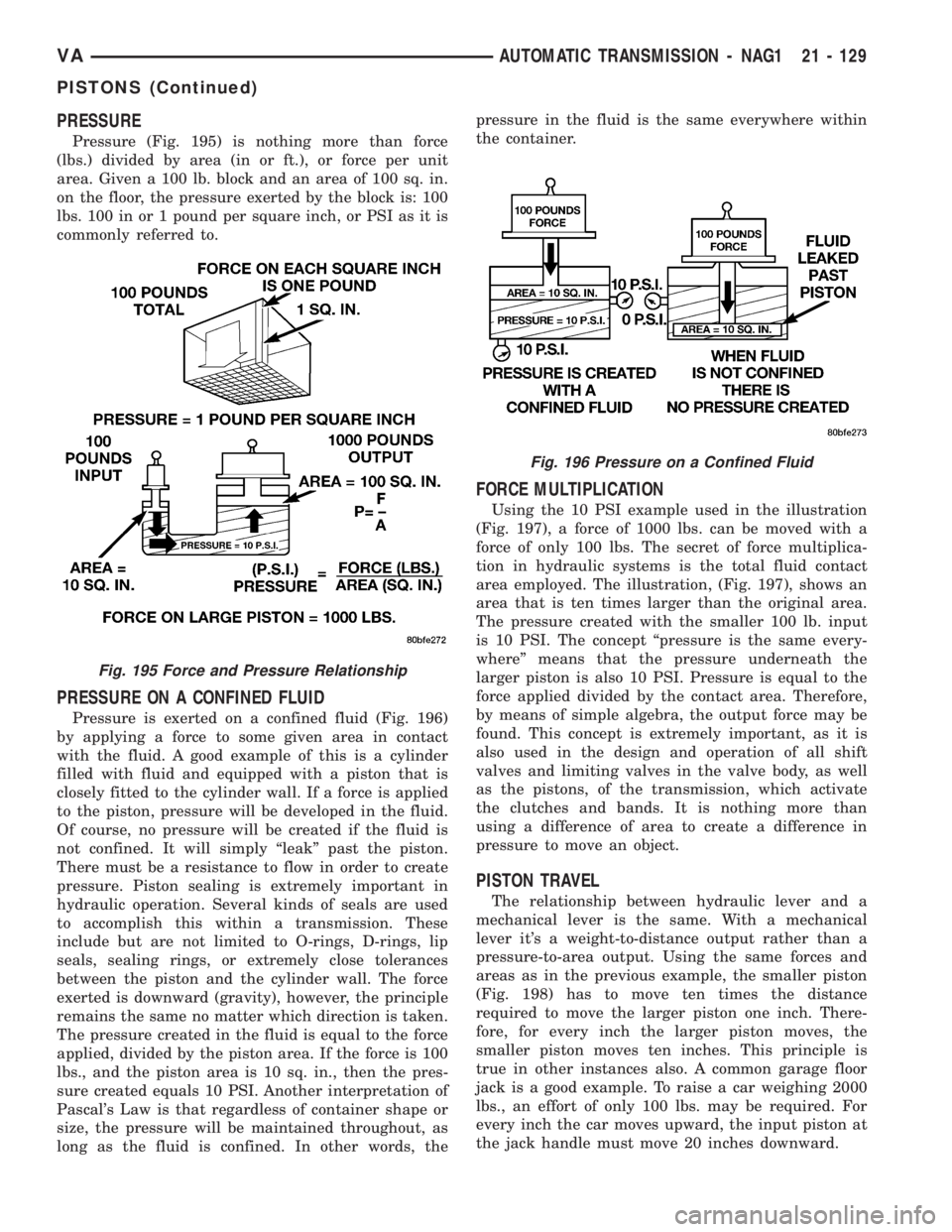

PRESSURE

Pressure (Fig. 195) is nothing more than force

(lbs.) divided by area (in or ft.), or force per unit

area. Given a 100 lb. block and an area of 100 sq. in.

on the floor, the pressure exerted by the block is: 100

lbs. 100 in or 1 pound per square inch, or PSI as it is

commonly referred to.

PRESSURE ON A CONFINED FLUID

Pressure is exerted on a confined fluid (Fig. 196)

by applying a force to some given area in contact

with the fluid. A good example of this is a cylinder

filled with fluid and equipped with a piston that is

closely fitted to the cylinder wall. If a force is applied

to the piston, pressure will be developed in the fluid.

Of course, no pressure will be created if the fluid is

not confined. It will simply ªleakº past the piston.

There must be a resistance to flow in order to create

pressure. Piston sealing is extremely important in

hydraulic operation. Several kinds of seals are used

to accomplish this within a transmission. These

include but are not limited to O-rings, D-rings, lip

seals, sealing rings, or extremely close tolerances

between the piston and the cylinder wall. The force

exerted is downward (gravity), however, the principle

remains the same no matter which direction is taken.

The pressure created in the fluid is equal to the force

applied, divided by the piston area. If the force is 100

lbs., and the piston area is 10 sq. in., then the pres-

sure created equals 10 PSI. Another interpretation of

Pascal's Law is that regardless of container shape or

size, the pressure will be maintained throughout, as

long as the fluid is confined. In other words, thepressure in the fluid is the same everywhere within

the container.

FORCE MULTIPLICATION

Using the 10 PSI example used in the illustration

(Fig. 197), a force of 1000 lbs. can be moved with a

force of only 100 lbs. The secret of force multiplica-

tion in hydraulic systems is the total fluid contact

area employed. The illustration, (Fig. 197), shows an

area that is ten times larger than the original area.

The pressure created with the smaller 100 lb. input

is 10 PSI. The concept ªpressure is the same every-

whereº means that the pressure underneath the

larger piston is also 10 PSI. Pressure is equal to the

force applied divided by the contact area. Therefore,

by means of simple algebra, the output force may be

found. This concept is extremely important, as it is

also used in the design and operation of all shift

valves and limiting valves in the valve body, as well

as the pistons, of the transmission, which activate

the clutches and bands. It is nothing more than

using a difference of area to create a difference in

pressure to move an object.

PISTON TRAVEL

The relationship between hydraulic lever and a

mechanical lever is the same. With a mechanical

lever it's a weight-to-distance output rather than a

pressure-to-area output. Using the same forces and

areas as in the previous example, the smaller piston

(Fig. 198) has to move ten times the distance

required to move the larger piston one inch. There-

fore, for every inch the larger piston moves, the

smaller piston moves ten inches. This principle is

true in other instances also. A common garage floor

jack is a good example. To raise a car weighing 2000

lbs., an effort of only 100 lbs. may be required. For

every inch the car moves upward, the input piston at

the jack handle must move 20 inches downward.

Fig. 195 Force and Pressure Relationship

Fig. 196 Pressure on a Confined Fluid

VAAUTOMATIC TRANSMISSION - NAG1 21 - 129

PISTONS (Continued)

Page 1006 of 1232

PLANETARY GEARTRAIN

DESCRIPTION

Three planetary gear sets (Fig. 199) are used to

produce the different gear ratios. These are located

in the mechanical part of the transmission as the

front, middle and rear planetary gear sets.

OPERATION

The annulus gear (1) (Fig. 200) and sun gear (3)

elements of a planetary gear system are alternately

driven and braked by the actuating elements of the

multi-plate clutch and multiple-disc brake. The plan-

etary pinion gears (2) can turn on the internal gear-

ing of the annulus gear (1) and on the external

gearing of the sun gear (3). This allows for a variety

of gear ratios and the reversal of the rotation direc-

tion without the need for moving gear wheels or shift

collars. When two components of the planetary gear

set are locked together, the planetary gear set is

locked and turns as a closed unit.

Fig. 197 Force Multiplication

Fig. 198 Piston Travel

Fig. 199 Planetary Geartrain

1 - ANNULUS GEAR

2 - PLANETARY PINION GEARS

3 - SUN GEAR

4 - PLANETARY CARRIER

Fig. 200 Planetary Geartrain

1 - ANNULUS GEAR

2 - PLANETARY PINION GEARS

3 - SUN GEAR

4 - PLANETARY CARRIER

21 - 130 AUTOMATIC TRANSMISSION - NAG1VA

PISTONS (Continued)

Page 1007 of 1232

The torque and engine speed are converted accord-

ing to the lever ratios and the ratio of the number of

teeth on the driven gears to that on the drive gears,

and is referred to as the gear ratio. The overall ratio

of a number of planetary gear sets connected in

series is obtained by multiplying the partial ratios.

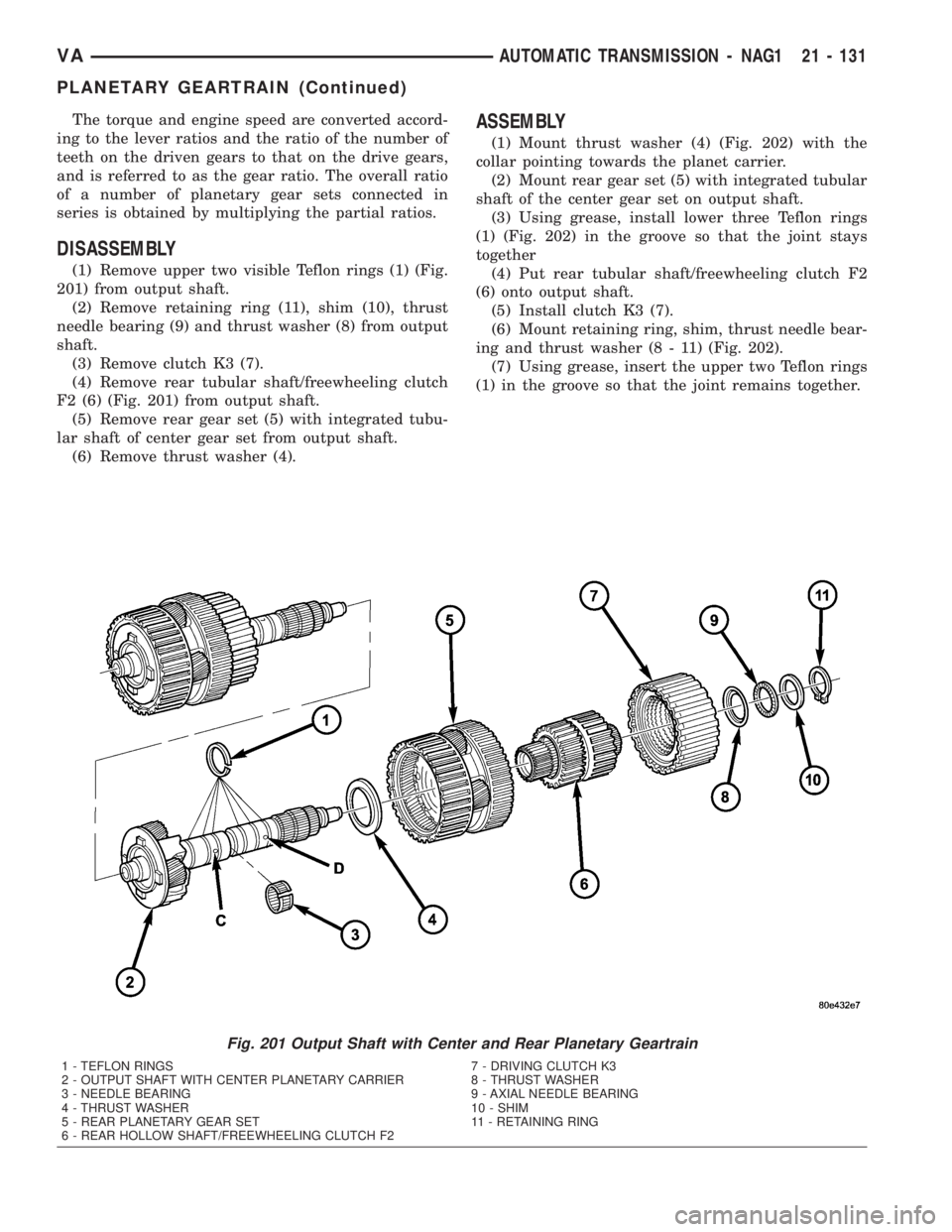

DISASSEMBLY

(1) Remove upper two visible Teflon rings (1) (Fig.

201) from output shaft.

(2) Remove retaining ring (11), shim (10), thrust

needle bearing (9) and thrust washer (8) from output

shaft.

(3) Remove clutch K3 (7).

(4) Remove rear tubular shaft/freewheeling clutch

F2 (6) (Fig. 201) from output shaft.

(5) Remove rear gear set (5) with integrated tubu-

lar shaft of center gear set from output shaft.

(6) Remove thrust washer (4).

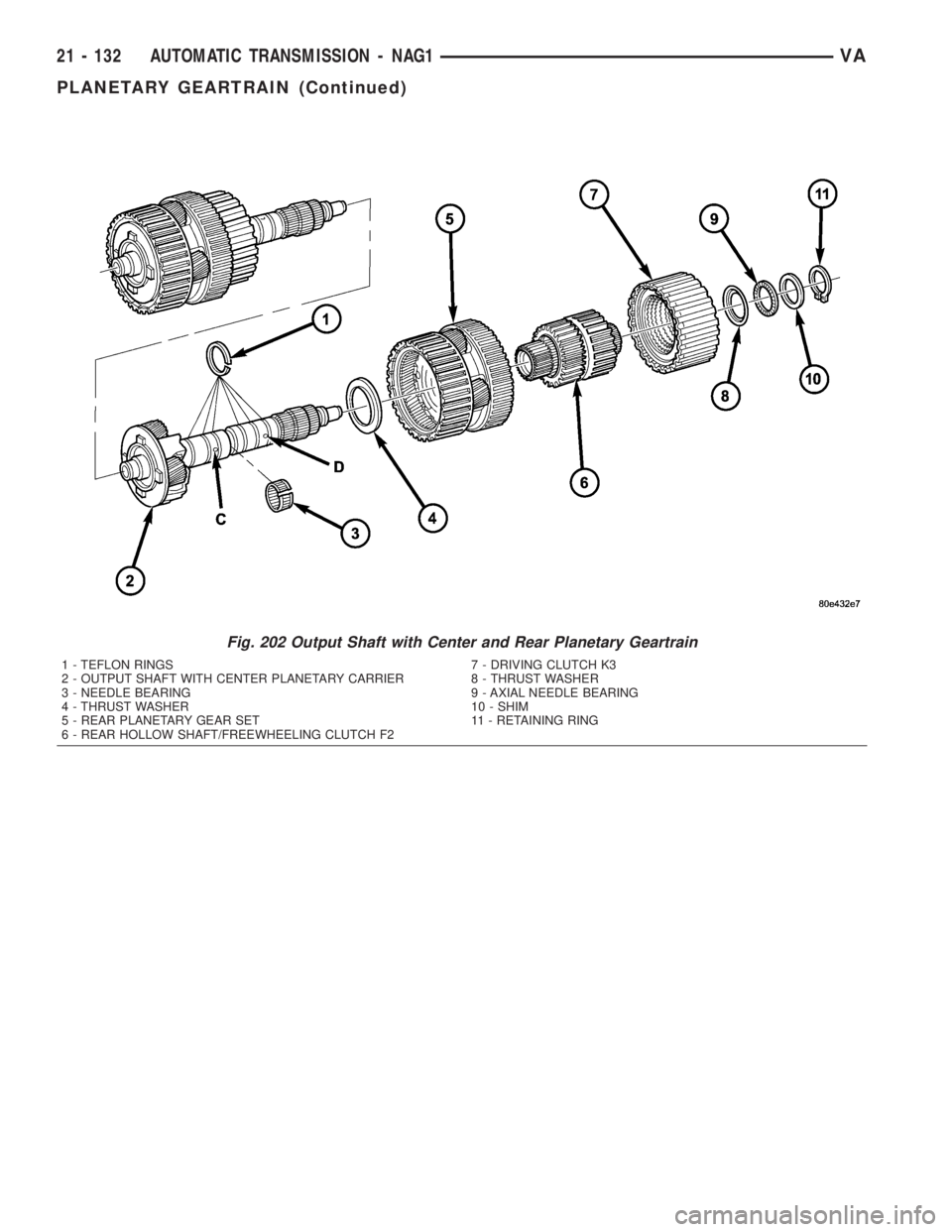

ASSEMBLY

(1) Mount thrust washer (4) (Fig. 202) with the

collar pointing towards the planet carrier.

(2) Mount rear gear set (5) with integrated tubular

shaft of the center gear set on output shaft.

(3) Using grease, install lower three Teflon rings

(1) (Fig. 202) in the groove so that the joint stays

together

(4) Put rear tubular shaft/freewheeling clutch F2

(6) onto output shaft.

(5) Install clutch K3 (7).

(6) Mount retaining ring, shim, thrust needle bear-

ing and thrust washer (8 - 11) (Fig. 202).

(7) Using grease, insert the upper two Teflon rings

(1) in the groove so that the joint remains together.

Fig. 201 Output Shaft with Center and Rear Planetary Geartrain

1 - TEFLON RINGS 7 - DRIVING CLUTCH K3

2 - OUTPUT SHAFT WITH CENTER PLANETARY CARRIER 8 - THRUST WASHER

3 - NEEDLE BEARING 9 - AXIAL NEEDLE BEARING

4 - THRUST WASHER 10 - SHIM

5 - REAR PLANETARY GEAR SET 11 - RETAINING RING

6 - REAR HOLLOW SHAFT/FREEWHEELING CLUTCH F2

VAAUTOMATIC TRANSMISSION - NAG1 21 - 131

PLANETARY GEARTRAIN (Continued)

Page 1008 of 1232

Fig. 202 Output Shaft with Center and Rear Planetary Geartrain

1 - TEFLON RINGS 7 - DRIVING CLUTCH K3

2 - OUTPUT SHAFT WITH CENTER PLANETARY CARRIER 8 - THRUST WASHER

3 - NEEDLE BEARING 9 - AXIAL NEEDLE BEARING

4 - THRUST WASHER 10 - SHIM

5 - REAR PLANETARY GEAR SET 11 - RETAINING RING

6 - REAR HOLLOW SHAFT/FREEWHEELING CLUTCH F2

21 - 132 AUTOMATIC TRANSMISSION - NAG1VA

PLANETARY GEARTRAIN (Continued)

Page 1009 of 1232

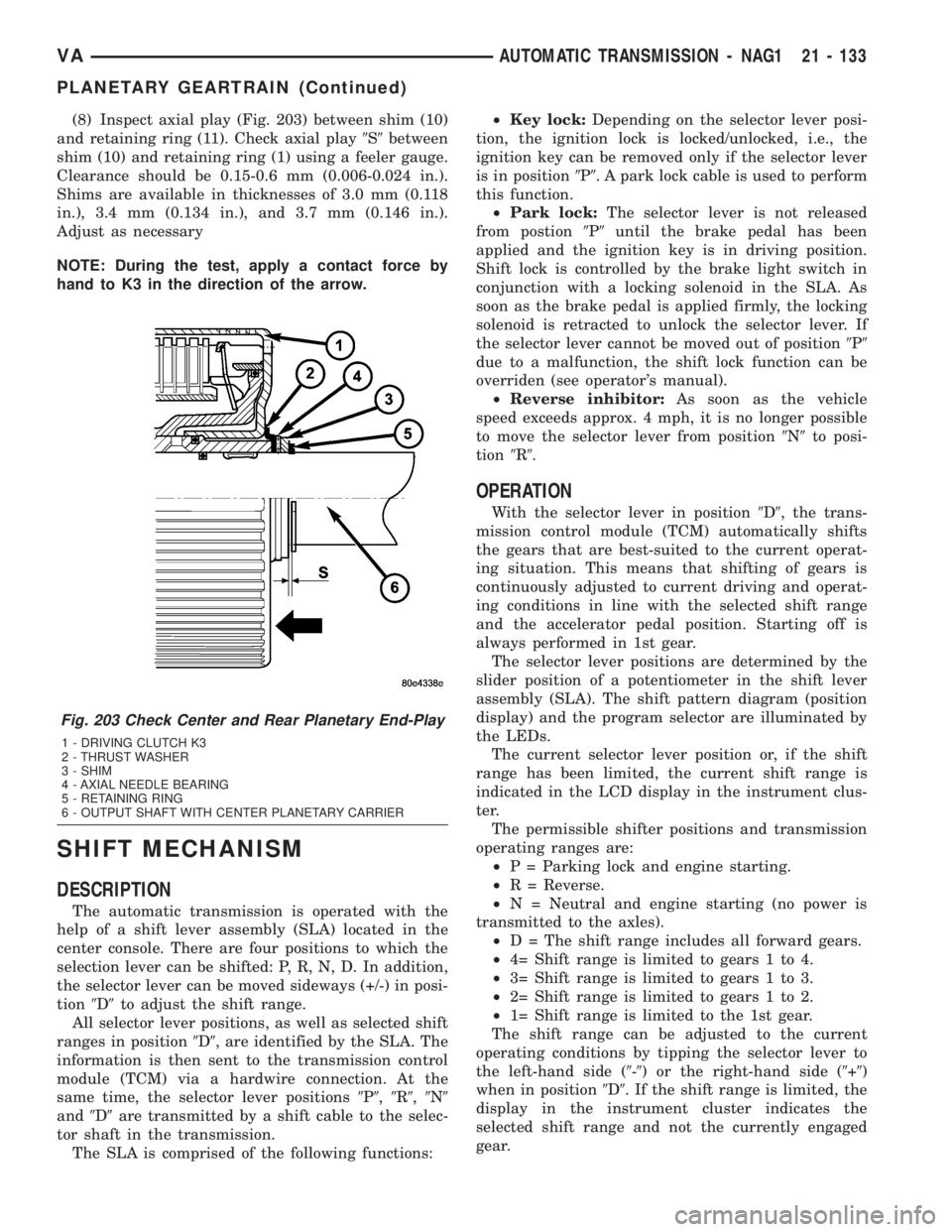

(8) Inspect axial play (Fig. 203) between shim (10)

and retaining ring (11). Check axial play9S9between

shim (10) and retaining ring (1) using a feeler gauge.

Clearance should be 0.15-0.6 mm (0.006-0.024 in.).

Shims are available in thicknesses of 3.0 mm (0.118

in.), 3.4 mm (0.134 in.), and 3.7 mm (0.146 in.).

Adjust as necessary

NOTE: During the test, apply a contact force by

hand to K3 in the direction of the arrow.

SHIFT MECHANISM

DESCRIPTION

The automatic transmission is operated with the

help of a shift lever assembly (SLA) located in the

center console. There are four positions to which the

selection lever can be shifted: P, R, N, D. In addition,

the selector lever can be moved sideways (+/-) in posi-

tion9D9to adjust the shift range.

All selector lever positions, as well as selected shift

ranges in position9D9, are identified by the SLA. The

information is then sent to the transmission control

module (TCM) via a hardwire connection. At the

same time, the selector lever positions9P9,9R9,9N9

and9D9are transmitted by a shift cable to the selec-

tor shaft in the transmission.

The SLA is comprised of the following functions:²Key lock:Depending on the selector lever posi-

tion, the ignition lock is locked/unlocked, i.e., the

ignition key can be removed only if the selector lever

is in position9P9. A park lock cable is used to perform

this function.

²Park lock:The selector lever is not released

from postion9P9until the brake pedal has been

applied and the ignition key is in driving position.

Shift lock is controlled by the brake light switch in

conjunction with a locking solenoid in the SLA. As

soon as the brake pedal is applied firmly, the locking

solenoid is retracted to unlock the selector lever. If

the selector lever cannot be moved out of position9P9

due to a malfunction, the shift lock function can be

overriden (see operator's manual).

²Reverse inhibitor:As soon as the vehicle

speed exceeds approx. 4 mph, it is no longer possible

to move the selector lever from position9N9to posi-

tion9R9.

OPERATION

With the selector lever in position9D9, the trans-

mission control module (TCM) automatically shifts

the gears that are best-suited to the current operat-

ing situation. This means that shifting of gears is

continuously adjusted to current driving and operat-

ing conditions in line with the selected shift range

and the accelerator pedal position. Starting off is

always performed in 1st gear.

The selector lever positions are determined by the

slider position of a potentiometer in the shift lever

assembly (SLA). The shift pattern diagram (position

display) and the program selector are illuminated by

the LEDs.

The current selector lever position or, if the shift

range has been limited, the current shift range is

indicated in the LCD display in the instrument clus-

ter.

The permissible shifter positions and transmission

operating ranges are:

²P = Parking lock and engine starting.

²R = Reverse.

²N = Neutral and engine starting (no power is

transmitted to the axles).

²D = The shift range includes all forward gears.

²4= Shift range is limited to gears 1 to 4.

²3= Shift range is limited to gears 1 to 3.

²2= Shift range is limited to gears 1 to 2.

²1= Shift range is limited to the 1st gear.

The shift range can be adjusted to the current

operating conditions by tipping the selector lever to

the left-hand side (9-9) or the right-hand side (9+9)

when in position9D9. If the shift range is limited, the

display in the instrument cluster indicates the

selected shift range and not the currently engaged

gear.

Fig. 203 Check Center and Rear Planetary End-Play

1 - DRIVING CLUTCH K3

2 - THRUST WASHER

3 - SHIM

4 - AXIAL NEEDLE BEARING

5 - RETAINING RING

6 - OUTPUT SHAFT WITH CENTER PLANETARY CARRIER

VAAUTOMATIC TRANSMISSION - NAG1 21 - 133

PLANETARY GEARTRAIN (Continued)

Page 1010 of 1232

Tipping the shift lever will have the following

results:

²Tipping the selector lever toward(-(one

time after another:The shift range is reduced in

descending sequence by one gear each time, i.e., from

D-4-3-2-1.Iftheselected limitation of the shift

range would result in a downshift causing excessive

engine speed, the shifting is not executed and the

engaged gear as well as the shift range remain

unchanged. This is to prevent the engine from over-

speeding. Engine retardation is low with the selector

lever in position9D9. To make use of the full braking

power of the engine,9manual9downshifting by tip-

ping the lever towards the left-hand side is recom-

mended. If this has been done, subsequent upshifting

must be carried out manually as well.

²Tipping the selector lever toward(-(and

holding it in this position:The currently engaged

gear in range9D9is indicated in the instrument clus-

ter display and the shift range is limited to this gear.

²Tipping the selector lever toward(+(one

time after another:The shift range is increased by

one gear each time and the increased shift range is

displayed in the instrument cluster; possibly, the

transmission upshifts to a faster gear.

²Tipping the selector lever toward(+(sev-

eral times:The shift range is increased by one gear

each time the lever is tipped until the shift range

ends up in9D9.

²Tipping the selector lever toward(+(and

holding it in this position:The shift range is

extended immediately to9D9, shift ranges are indi-

cated in ascending sequence; possibly, the transmis-

sion upshifts to a faster gear due to the extension of

the shift range.

REMOVAL

(1) Move selector lever to position9D9.

(2) Remove top section (3) (Fig. 204) of the center

section of instrument panel.

(3) Remove bottom section (2) (Fig. 205) of the cen-

ter section of instrument panel.

(4) Disconnect the park lock cable coupling (1)

(Fig. 206) from the shift lever assembly (SLA). Press

locking tab (2) together and push coupling (1) against

the spring force into the SLA, twist through 90É

(right or left) and pull off.

(5) Disconnect connector plug (5) from SLA. When

disconnecting plug, press together at points shown

(arrows).

(6) Pry ball socket (4) of transmission shift cable

off ball knob at the SLA. Use a suitable slotted

screwdriver.

Fig. 204 Remove Top Section Of Center Instrument

Panel

1 - SHIFT LEVER ASSEMBLY FRAME TRIM

2 - STORAGE COMPARTMENT

3 - TOP CENTER PART OF INSTRUMENT PANEL

4 - SCREW

5 - PLUG CONNECTIONS

6 - ASHTRAY

Fig. 205 Remove Bottom Section Of Center

Instrument Panel

1 - SCREW

2 - BOTTOM CENTER PART OF INSTRUMENT PANEL

21 - 134 AUTOMATIC TRANSMISSION - NAG1VA

SHIFT MECHANISM (Continued)