MERCEDES-BENZ SPRINTER 2005 Service Repair Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 231 of 1232

INSTALLATION

(1) Position the time delay relay to its vehicle wire

harness connector within the driver side seat riser.

(2) Align the time delay relay terminals with the

terminal cavities in the vehicle wire harness connec-

tor.

(3) Push firmly and evenly on the top of the time

delay relay until the terminals are fully seated in the

terminal cavities in the vehicle wire harness connec-

tor.(4) Position the cover panel onto the top of the

driver side seat riser (Fig. 12).

(5) Install and tighten the two screws that secure

the cover panel to the top of the seat riser under the

driver side front seat. Tighten the screws to 2 N´m

(18 in. lbs.).

(6) Move the driver side front seat back to its driv-

ing position.

(7) Reconnect the battery negative cable.

VALAMPS/LIGHTING - INTERIOR 8L - 33

TIME DELAY RELAY (Continued)

Page 232 of 1232

Page 233 of 1232

POWER SYSTEMS

TABLE OF CONTENTS

page page

POWER LOCKS............................ 1

POWER MIRRORS......................... 3POWER WINDOWS......................... 5

POWER LOCKS

TABLE OF CONTENTS

page page

POWER LOCKS

DESCRIPTION..........................1

DOOR LOCK MOTOR

REMOVAL.............................1

INSTALLATION..........................1

REMOTE KEYLESS ENTRY TRANSMITTER

DESCRIPTION..........................2MASTER LOCK SWITCH

DESCRIPTION..........................2

DIAGNOSIS AND TESTING - MASTER LOCK

SWITCH.............................2

REMOVAL.............................2

INSTALLATION..........................2

POWER LOCKS

DESCRIPTION

CENTRAL LOCKING

The central locking system locks all vehicle doors if

any door is locked from the inside or mechanically

locked with the key from the outside. the master door

lock switch on the instrument panel enables the

operator to lock/unlock all doors.

REMOTE KEYLESS ENTRY

The SKREEM is a combination of the Remote Key-

less Entry (RKE) module and the Sentry Key Immo-

bilizer (SKIM) module. It is located behind the

instrument cluster and has an antenna that mounts

to the A-pillar.

AUTO DOOR LOCKS

Whenever the engine is started, the CTM receivers

a message to lock all doors except the drivers door.

This is accomplished through a relay. The relay is

controlled by the Instrument Cluster which receives

a command from the ECM.

ACCIDENT RESPONSE

The CTM is hardwired to the Airbag Control Mod-

ule through the Enhanced Accident Report Driver cir-

cuit. Anytime the vehicles airbags are deployed, the

CTM will unlock all doors and a ªcrashº DTC will be

stored in memory. The door locks will be inoperative

until that code is cleared.

DOOR LOCK MOTOR

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the door trim panel.

(3) Remove the door lock.

(4) Remove the door lock motor from the door lock.

INSTALLATION

(1) Install the door lock motor to the door lock.

(2) Install the door lock.

(3) Install the door trim panel.

(4) Connect the battery negative cable.

VAPOWER SYSTEMS 8N - 1

Page 234 of 1232

REMOTE KEYLESS ENTRY

TRANSMITTER

DESCRIPTION

Pressing the unlock button on the transmitter will

unlock the drivers door, pressing it a second time

within 2.5 seconds will unlock all other doors. The

transmitter has a range of 10 meters. A key is inte-

gral to the transmitter.

When a transmitter is lost, it is necessary to dis-

able the affected transmitter so that it can no longer

be used to operate the vehicle. It will then be neces-

sary to program a new transmitter to the vehicle.

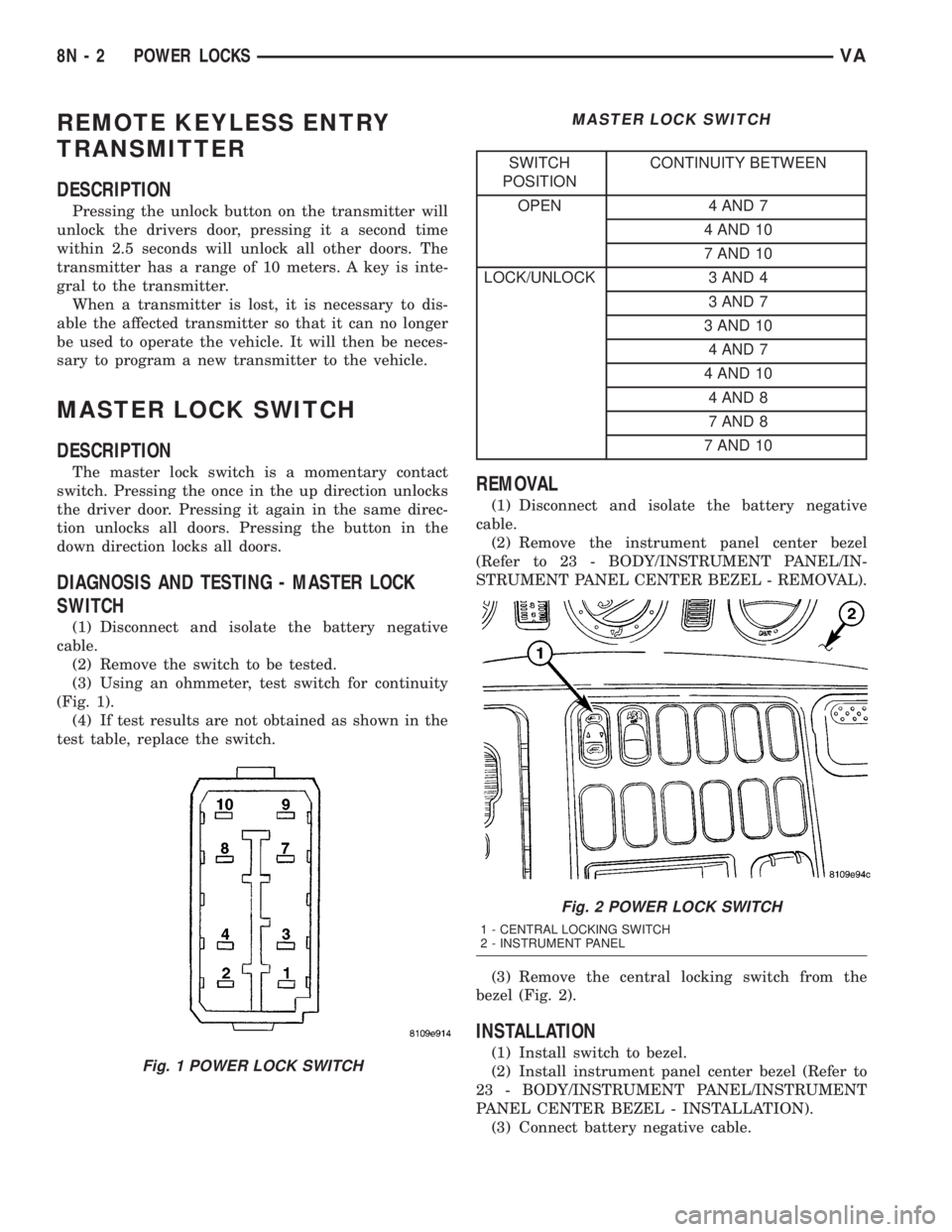

MASTER LOCK SWITCH

DESCRIPTION

The master lock switch is a momentary contact

switch. Pressing the once in the up direction unlocks

the driver door. Pressing it again in the same direc-

tion unlocks all doors. Pressing the button in the

down direction locks all doors.

DIAGNOSIS AND TESTING - MASTER LOCK

SWITCH

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the switch to be tested.

(3) Using an ohmmeter, test switch for continuity

(Fig. 1).

(4) If test results are not obtained as shown in the

test table, replace the switch.

MASTER LOCK SWITCH

SWITCH

POSITIONCONTINUITY BETWEEN

OPEN 4 AND 7

4 AND 10

7 AND 10

LOCK/UNLOCK 3 AND 4

3 AND 7

3 AND 10

4 AND 7

4 AND 10

4 AND 8

7 AND 8

7 AND 10

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument panel center bezel

(Refer to 23 - BODY/INSTRUMENT PANEL/IN-

STRUMENT PANEL CENTER BEZEL - REMOVAL).

(3) Remove the central locking switch from the

bezel (Fig. 2).

INSTALLATION

(1) Install switch to bezel.

(2) Install instrument panel center bezel (Refer to

23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL CENTER BEZEL - INSTALLATION).

(3) Connect battery negative cable.Fig. 1 POWER LOCK SWITCH

Fig. 2 POWER LOCK SWITCH

1 - CENTRAL LOCKING SWITCH

2 - INSTRUMENT PANEL

8N - 2 POWER LOCKSVA

Page 235 of 1232

POWER MIRRORS

TABLE OF CONTENTS

page page

POWER MIRRORS

DESCRIPTION..........................3

POWER MIRROR SWITCH

DIAGNOSIS AND TESTING - POWER MIRROR

SWITCH.............................3REMOVAL.............................3

INSTALLATION..........................4

POWER MIRRORS

DESCRIPTION

The power operated outside rear view mirrors

allow the driver to adjust both outside mirrors elec-

trically from the driver side front seat position by

operating a switch on the driver side front door trim

panel. The power mirrors receive a non-switched bat-

tery feed through a fuse so that the system will

remain operational, regardless of the ignition switch

position.

POWER MIRROR SWITCH

DIAGNOSIS AND TESTING - POWER MIRROR

SWITCH

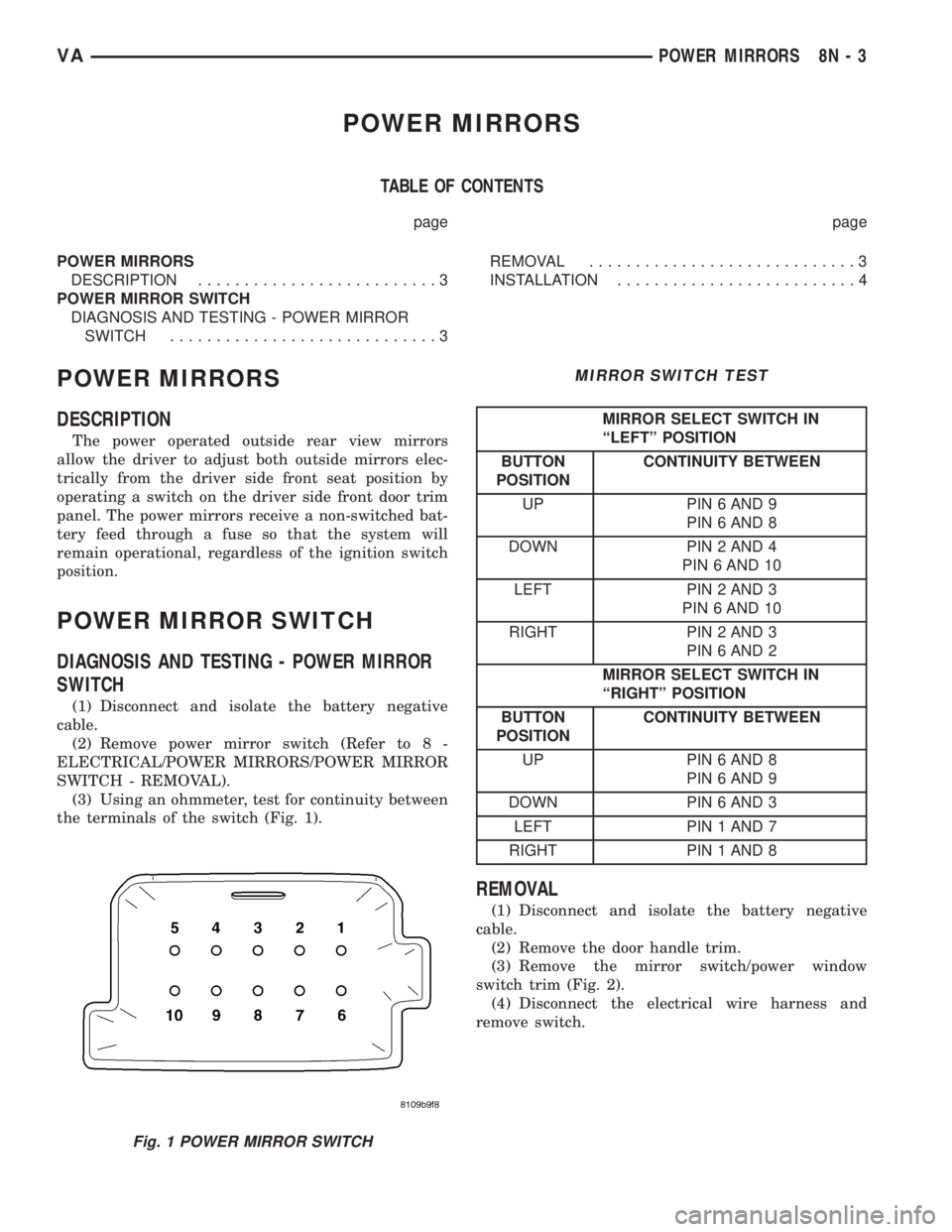

(1) Disconnect and isolate the battery negative

cable.

(2) Remove power mirror switch (Refer to 8 -

ELECTRICAL/POWER MIRRORS/POWER MIRROR

SWITCH - REMOVAL).

(3) Using an ohmmeter, test for continuity between

the terminals of the switch (Fig. 1).

MIRROR SWITCH TEST

MIRROR SELECT SWITCH IN

ªLEFTº POSITION

BUTTON

POSITIONCONTINUITY BETWEEN

UP PIN 6 AND 9

PIN 6 AND 8

DOWN PIN 2 AND 4

PIN 6 AND 10

LEFT PIN 2 AND 3

PIN 6 AND 10

RIGHT PIN 2 AND 3

PIN 6 AND 2

MIRROR SELECT SWITCH IN

ªRIGHTº POSITION

BUTTON

POSITIONCONTINUITY BETWEEN

UP PIN 6 AND 8

PIN 6 AND 9

DOWN PIN 6 AND 3

LEFT PIN 1 AND 7

RIGHT PIN 1 AND 8

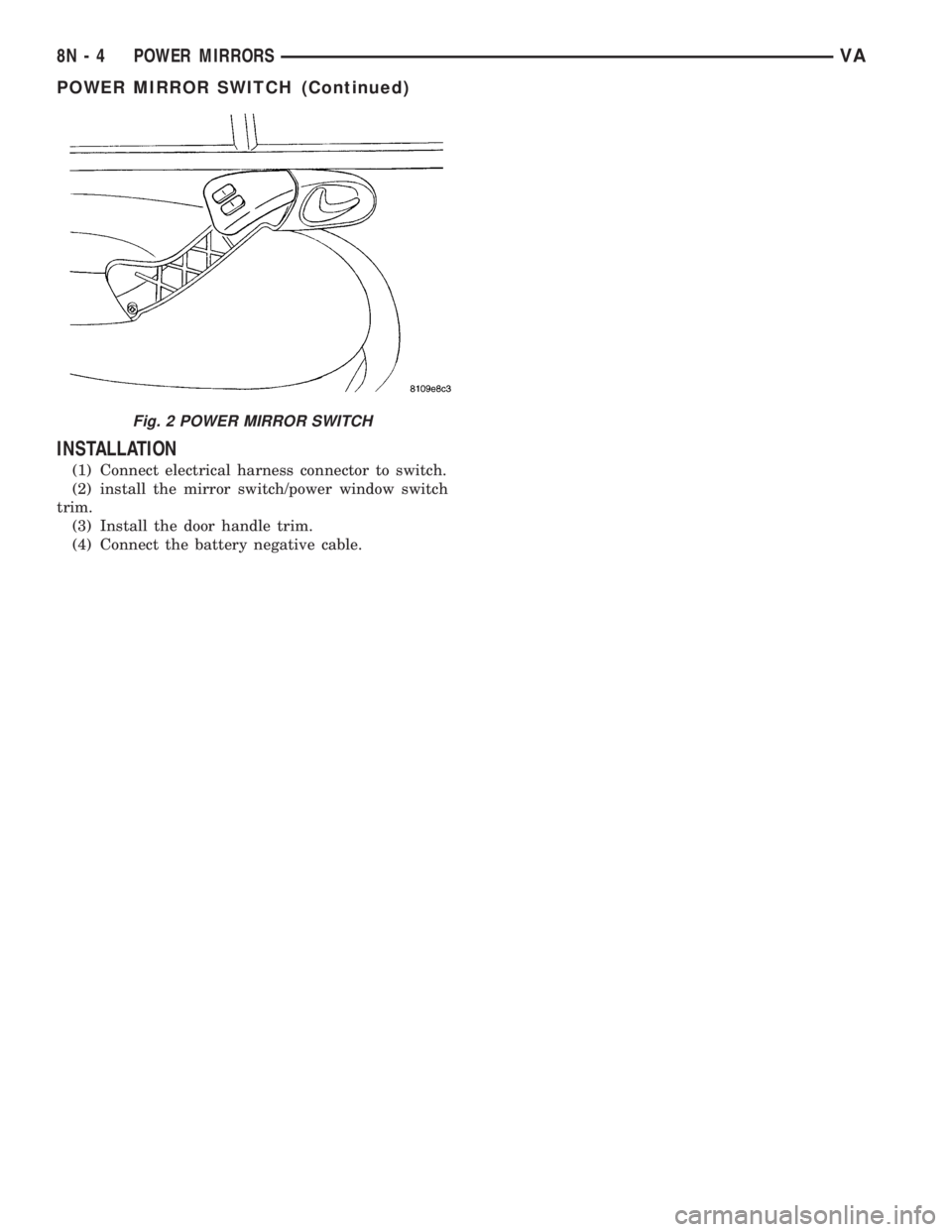

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the door handle trim.

(3) Remove the mirror switch/power window

switch trim (Fig. 2).

(4) Disconnect the electrical wire harness and

remove switch.

Fig. 1 POWER MIRROR SWITCH

VAPOWER MIRRORS 8N - 3

Page 236 of 1232

INSTALLATION

(1) Connect electrical harness connector to switch.

(2) install the mirror switch/power window switch

trim.

(3) Install the door handle trim.

(4) Connect the battery negative cable.

Fig. 2 POWER MIRROR SWITCH

8N - 4 POWER MIRRORSVA

POWER MIRROR SWITCH (Continued)

Page 237 of 1232

POWER WINDOWS

TABLE OF CONTENTS

page page

POWER WINDOWS

DESCRIPTION..........................5

OPERATION............................5

WINDOW MOTOR

REMOVAL.............................5POWER WINDOW SWITCH

DIAGNOSIS AND TESTING - POWER

WINDOW SWITCH......................5

REMOVAL.............................6

INSTALLATION..........................6

POWER WINDOWS

DESCRIPTION

The power window system allows each of the door

windows to be raised and lowered electrically by

actuating a switch on each door panel. A master

switch on the drivers door allows the driver to raise

or lower each door window. The power window sys-

tem operates only when the ignition switch is in the

RUN or ACCESSORY position.

OPERATION

WINDOW SWITCH

The power window switches control the battery

and ground feeds to the power window motors. The

passenger door power window switches receive their

battery and ground feeds through the circuitry of the

drivers window switch.

WINDOW MOTOR

Window motors use permanent type magnets. The

B+ and ground applied at the motor terminal pins

will cause the motor to rotate in one direction.

Reversing current through the motor terminals will

cause the motor to rotate in the opposite direction.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

WINDOW MOTOR

REMOVAL

The window motor is serviced with the window

regulator.

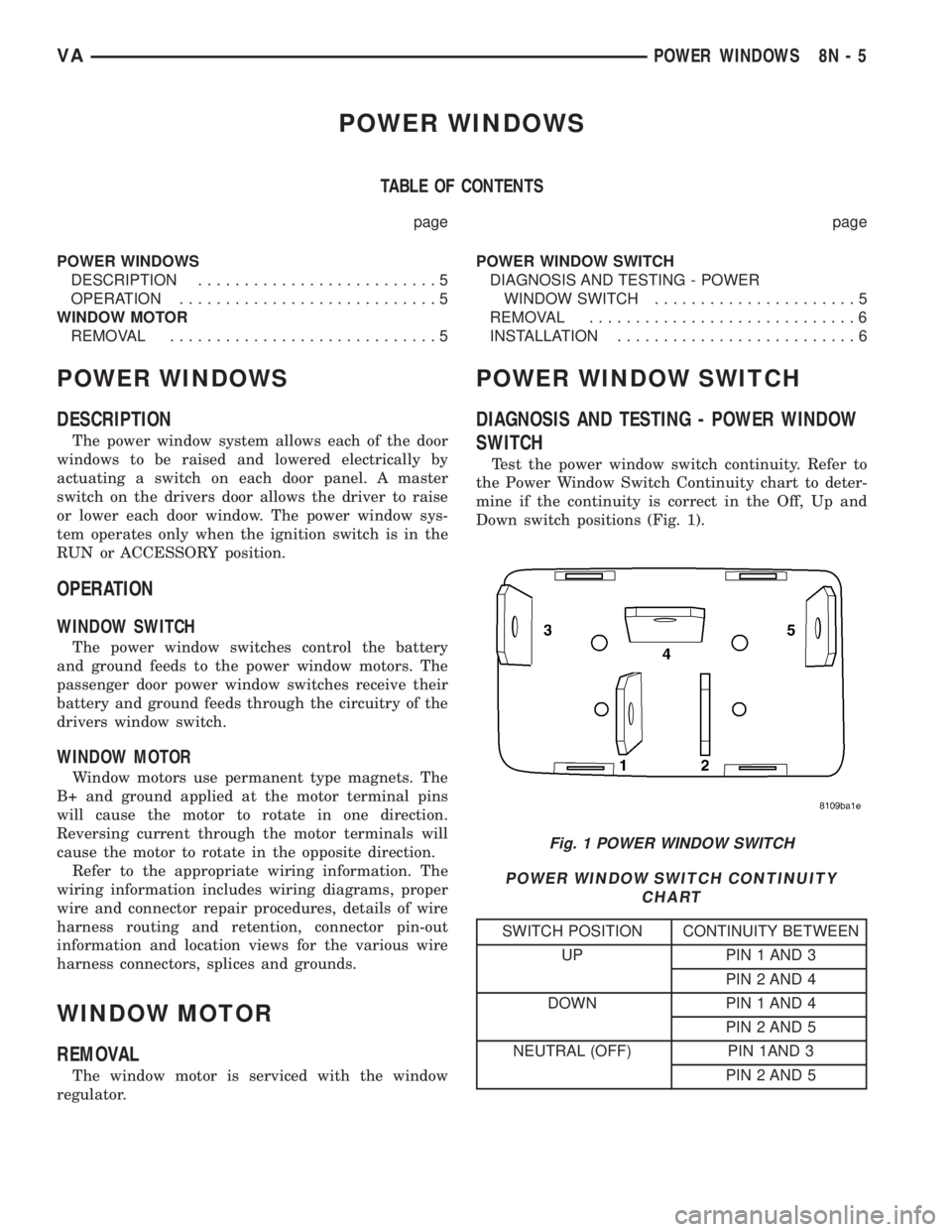

POWER WINDOW SWITCH

DIAGNOSIS AND TESTING - POWER WINDOW

SWITCH

Test the power window switch continuity. Refer to

the Power Window Switch Continuity chart to deter-

mine if the continuity is correct in the Off, Up and

Down switch positions (Fig. 1).

POWER WINDOW SWITCH CONTINUITY

CHART

SWITCH POSITION CONTINUITY BETWEEN

UP PIN 1 AND 3

PIN 2 AND 4

DOWN PIN 1 AND 4

PIN 2 AND 5

NEUTRAL (OFF) PIN 1AND 3

PIN 2 AND 5

Fig. 1 POWER WINDOW SWITCH

VAPOWER WINDOWS 8N - 5

Page 238 of 1232

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove door handle cover.

(3) Remove power window switch trim from door

trim panel.

(4) disconnect wire harness connectors from

switches.

(5) Remove power window switch from trim.

INSTALLATION

(1) Install switch to trim.

(2) Connect wire harness connectors to switches.

(3) Install power window switch trim to door trim

panel.

(4) Install door handle cover.

(5) Connect battery negative cable.

8N - 6 POWER WINDOWSVA

POWER WINDOW SWITCH (Continued)

Page 239 of 1232

RESTRAINTS

TABLE OF CONTENTS

page page

RESTRAINTS

DESCRIPTION..........................2

OPERATION............................4

WARNING

WARNINGS - RESTRAINT SYSTEM........5

DIAGNOSIS AND TESTING - SUPPLEMENTAL

RESTRAINT SYSTEM...................5

STANDARD PROCEDURE

STANDARD PROCEDURE - HANDLING

NON-DEPLOYED SUPPLEMENTAL

RESTRAINTS.........................6

STANDARD PROCEDURE - SERVICE

AFTER A SUPPLEMENTAL RESTRAINT

DEPLOYMENT.........................6

STANDARD PROCEDURE - VERIFICATION

TEST................................7

AIRBAG CONTROL MODULE

DESCRIPTION..........................8

OPERATION............................9

REMOVAL.............................10

INSTALLATION.........................11

CLOCKSPRING

DESCRIPTION.........................12

OPERATION...........................13

STANDARD PROCEDURE - CLOCKSPRING

CENTERING.........................13

REMOVAL.............................14

INSTALLATION.........................15

DRIVER AIRBAG

DESCRIPTION.........................16

OPERATION...........................17

REMOVAL.............................17

INSTALLATION.........................18FRONT SEAT BELT & RETRACTOR

REMOVAL.............................19

INSTALLATION.........................21

FRONT SEAT BELT BUCKLE

REMOVAL.............................22

INSTALLATION.........................23

PASSENGER AIRBAG

DESCRIPTION.........................23

OPERATION...........................24

REMOVAL.............................24

INSTALLATION.........................26

PASSENGER AIRBAG BRACKET

REMOVAL.............................27

INSTALLATION.........................27

REAR SEAT BELT & RETRACTOR

REMOVAL.............................27

INSTALLATION.........................29

REAR SEAT BELT BUCKLE

REMOVAL

REMOVAL - INBOARD..................29

REMOVAL - OUTBOARD................30

INSTALLATION

INSTALLATION - INBOARD..............30

INSTALLATION - OUTBOARD............31

SEAT BELT SWITCH

DESCRIPTION.........................31

OPERATION...........................31

SEAT BELT TENSIONER

DESCRIPTION.........................31

OPERATION...........................32

SEAT BELT TURNING LOOP ADJUSTER

REMOVAL.............................33

INSTALLATION.........................34

VARESTRAINTS 8O - 1

Page 240 of 1232

RESTRAINTS

DESCRIPTION

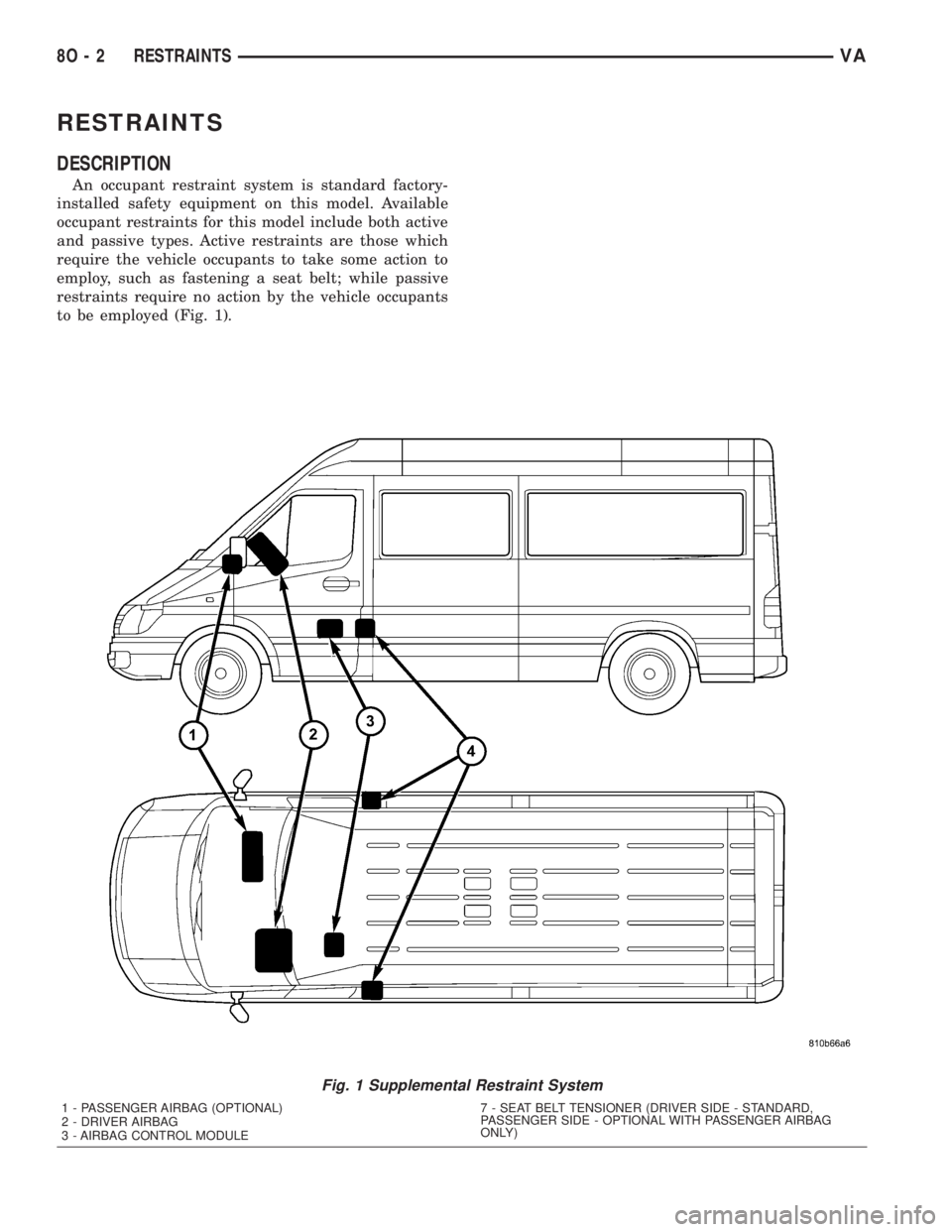

An occupant restraint system is standard factory-

installed safety equipment on this model. Available

occupant restraints for this model include both active

and passive types. Active restraints are those which

require the vehicle occupants to take some action to

employ, such as fastening a seat belt; while passive

restraints require no action by the vehicle occupants

to be employed (Fig. 1).

Fig. 1 Supplemental Restraint System

1 - PASSENGER AIRBAG (OPTIONAL)

2 - DRIVER AIRBAG

3 - AIRBAG CONTROL MODULE7 - SEAT BELT TENSIONER (DRIVER SIDE - STANDARD,

PASSENGER SIDE - OPTIONAL WITH PASSENGER AIRBAG

ONLY)

8O - 2 RESTRAINTSVA