check engine MERCEDES-BENZ SPRINTER 2005 Service Owner's Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 107 of 1232

Operate tester pump to apply 103.4 kPa (15 psi)

pressure to system. If hoses enlarge excessively or

bulges while testing, replace as necessary. Observe

gauge pointer and determine condition of cooling sys-

tem according to following criteria:

Holds Steady:If pointer remains steady for two

minutes, serious coolant leaks are not present in sys-

tem. However, there could be an internal leak that

does not appear with normal system test pressure. If

it is certain that coolant is being lost and leaks can-

not be detected, inspect for interior leakage or per-

form Internal Leakage Test.

Drops Slowly:Indicates a small leak or seepage

is occurring. Examine all connections for seepage or

slight leakage with a flashlight. Inspect radiator,

hoses, gasket edges and heater. Seal small leak holes

with a Sealer Lubricant (or equivalent). Repair leak

holes and inspect system again with pressure

applied.

Drops Quickly:Indicates that serious leakage is

occurring. Examine system for external leakage. If

leaks are not visible, inspect for internal leakage.

Large radiator leak holes should be repaired by a

reputable radiator repair shop.

INTERNAL LEAKAGE INSPECTION

Remove engine oil pan drain plug and drain a

small amount of engine oil. If coolant is present in

the pan, it will drain first because it is heavier than

oil. An alternative method is to operate engine for a

short period to churn the oil. After this is done,

remove engine dipstick and inspect for water glob-

ules. Also inspect transmission dipstick for water

globules and transmission fluid cooler for leakage.

WARNING: WITH RADIATOR PRESSURE TESTER

TOOL INSTALLED ON RADIATOR, DO NOT ALLOW

PRESSURE TO EXCEED 110 KPA (20 PSI). PRES-

SURE WILL BUILD UP QUICKLY IF A COMBUSTION

LEAK IS PRESENT. TO RELEASE PRESSURE,

ROCK TESTER FROM SIDE TO SIDE. WHEN

REMOVING TESTER, DO NOT TURN TESTER MORE

THAN 1/2 TURN IF SYSTEM IS UNDER PRESSURE.

Operate engine without pressure cap on coolant

container until thermostat opens. Attach a Pressure

Tester to container. If pressure builds up quickly it

indicates a combustion leak exists. This is usually

the result of a cylinder head gasket leak or crack in

engine. Repair as necessary.

If there is not an immediate pressure increase,

pump the Pressure Tester. Do this until indicated

pressure is within system range of 110 kPa (16 psi).

Fluctuation of gauge pointer indicates compression or

combustion leakage into cooling system.Because the vehicle is equipped with a catalytic

converter,do notremove spark plug cables or short

out cylinders to isolate compression leak.

If the needle on dial of pressure tester does not

fluctuate, race engine a few times to check for an

abnormal amount of coolant or steam. This would be

emitting from exhaust pipe. Coolant or steam from

exhaust pipe may indicate a faulty cylinder head gas-

ket, cracked engine cylinder block or cylinder head.

A convenient check for exhaust gas leakage into

cooling system is provided by a commercially avail-

able Block Leak Check tool. Follow manufacturers

instructions when using this product.

COMBUSTION LEAKAGE TEST - WITHOUT

PRESSURE TESTER

DO NOT WASTE reusable coolant. If solution is

clean, drain coolant into a clean and suitably marked

container for reuse.

WARNING: DO NOT REMOVE CYLINDER BLOCK

DRAIN PLUGS OR LOOSEN RADIATOR DRAIN

WITH SYSTEM HOT AND UNDER PRESSURE. SERI-

OUS BURNS FROM COOLANT CAN OCCUR.

Drain sufficient coolant to allow thermostat removal.

Remove accessory drive belt.

Add coolant to pressure container to bring level to

within 6.3 mm (1/4 in) of top of thermostat housing.

CAUTION: Avoid overheating. Do not operate

engine for an excessive period of time. Open drain-

cock immediately after test to eliminate boil over.

Start engine and accelerate rapidly three times, to

approximately 3000 rpm while observing coolant. If

internal engine combustion gases are leaking into

cooling system, bubbles will appear in coolant. If bub-

bles do not appear, internal combustion gas leakage

is not present.

STANDARD PROCEDURE

STANDARD PROCEDURE - ADDING

ADDITIONAL COOLANT

The use of aluminum cylinder blocks, cylinder

heads and water pumps requires special corrosion

protection. Only MopartAntifreeze/Coolant, 5

Year/100,000 Mile Formula (glycol base coolant with

corrosion inhibitors called HOAT, for Hybrid Organic

Additive Technology) is recommended. This coolant

offers the best engine cooling without corrosion when

mixed with 50% distilled water to obtain to obtain a

freeze point of -37ÉC (-35ÉF). If it loses color or

becomes contaminated, drain, flush, and replace with

fresh properly mixed coolant solution.

VAENGINE 7 - 11

COOLANT (Continued)

Page 114 of 1232

(16) Install A/C condenser.

(17) Install front bumper.

(18) Install front end cross member.

(19) Refill power steering to proper level.

(20) Refill transmission to proper level.

(21) Close radiator drain plug and refill the cooling

system to the correct level with the appropriate cool-

ant mixture.

(22) Recharge air conditioning.

(23) Run engine until warm and check for leaks.

RADIATOR PRESSURE CAP

DESCRIPTION

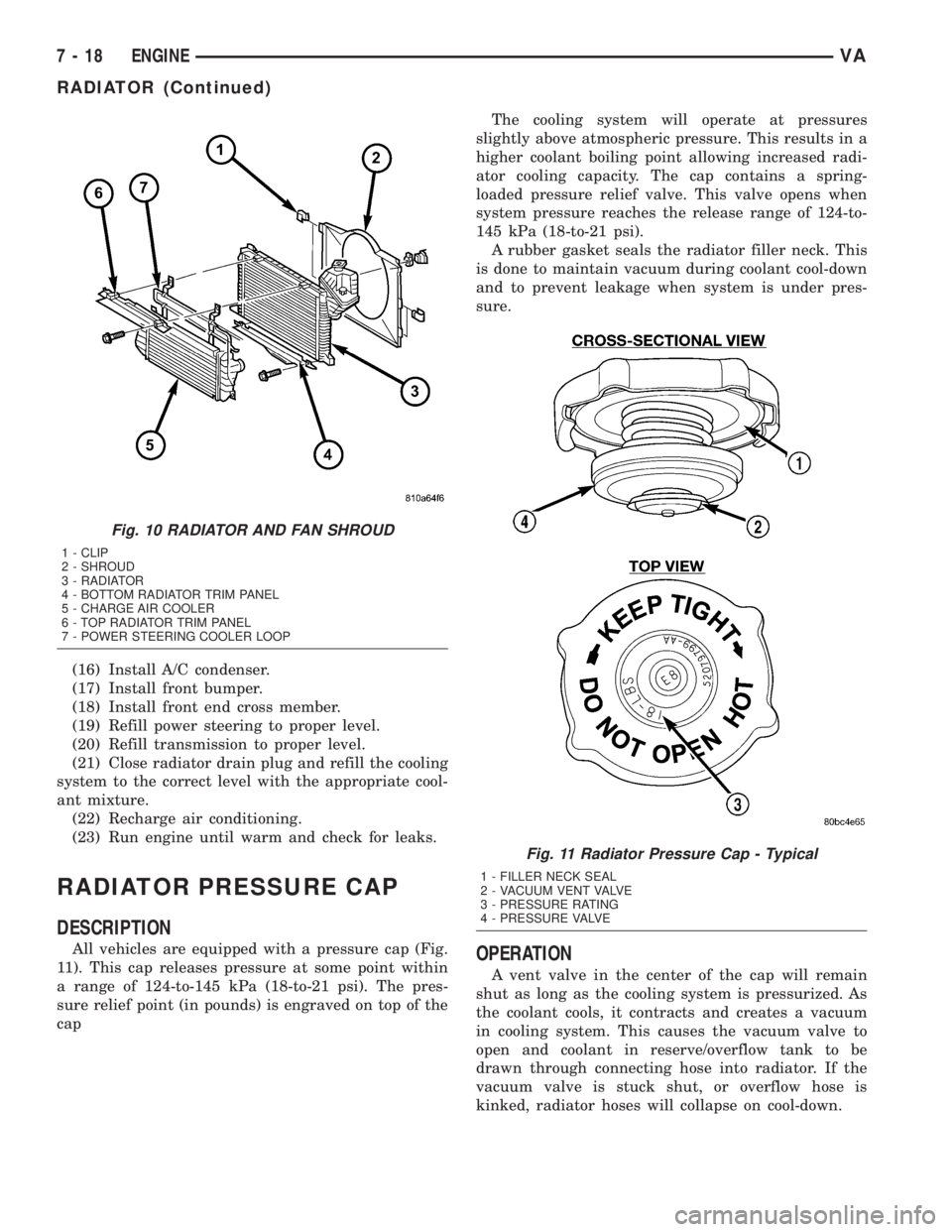

All vehicles are equipped with a pressure cap (Fig.

11). This cap releases pressure at some point within

a range of 124-to-145 kPa (18-to-21 psi). The pres-

sure relief point (in pounds) is engraved on top of the

capThe cooling system will operate at pressures

slightly above atmospheric pressure. This results in a

higher coolant boiling point allowing increased radi-

ator cooling capacity. The cap contains a spring-

loaded pressure relief valve. This valve opens when

system pressure reaches the release range of 124-to-

145 kPa (18-to-21 psi).

A rubber gasket seals the radiator filler neck. This

is done to maintain vacuum during coolant cool-down

and to prevent leakage when system is under pres-

sure.OPERATION

A vent valve in the center of the cap will remain

shut as long as the cooling system is pressurized. As

the coolant cools, it contracts and creates a vacuum

in cooling system. This causes the vacuum valve to

open and coolant in reserve/overflow tank to be

drawn through connecting hose into radiator. If the

vacuum valve is stuck shut, or overflow hose is

kinked, radiator hoses will collapse on cool-down.

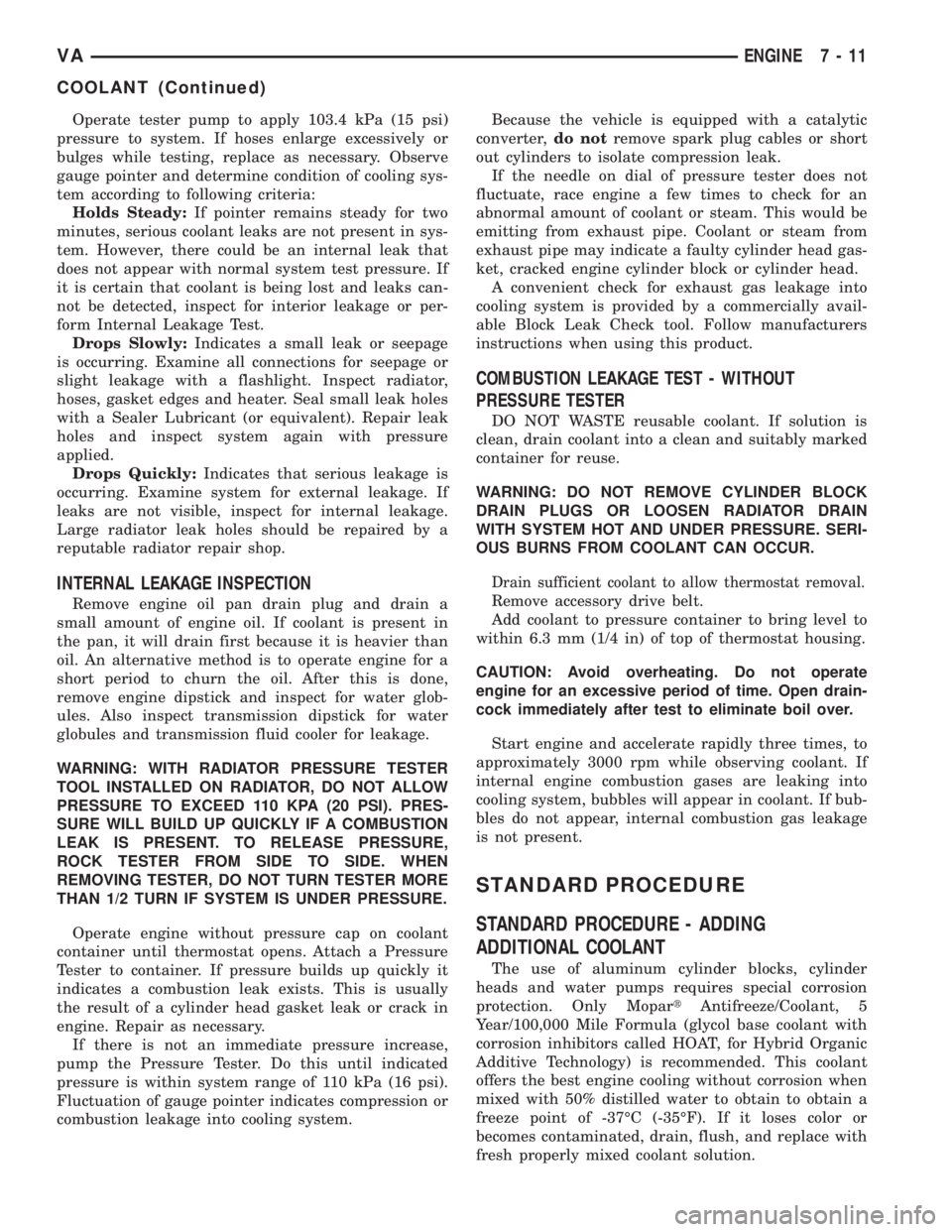

Fig. 10 RADIATOR AND FAN SHROUD

1 - CLIP

2 - SHROUD

3 - RADIATOR

4 - BOTTOM RADIATOR TRIM PANEL

5 - CHARGE AIR COOLER

6 - TOP RADIATOR TRIM PANEL

7 - POWER STEERING COOLER LOOP

Fig. 11 Radiator Pressure Cap - Typical

1 - FILLER NECK SEAL

2 - VACUUM VENT VALVE

3 - PRESSURE RATING

4 - PRESSURE VALVE

7 - 18 ENGINEVA

RADIATOR (Continued)

Page 115 of 1232

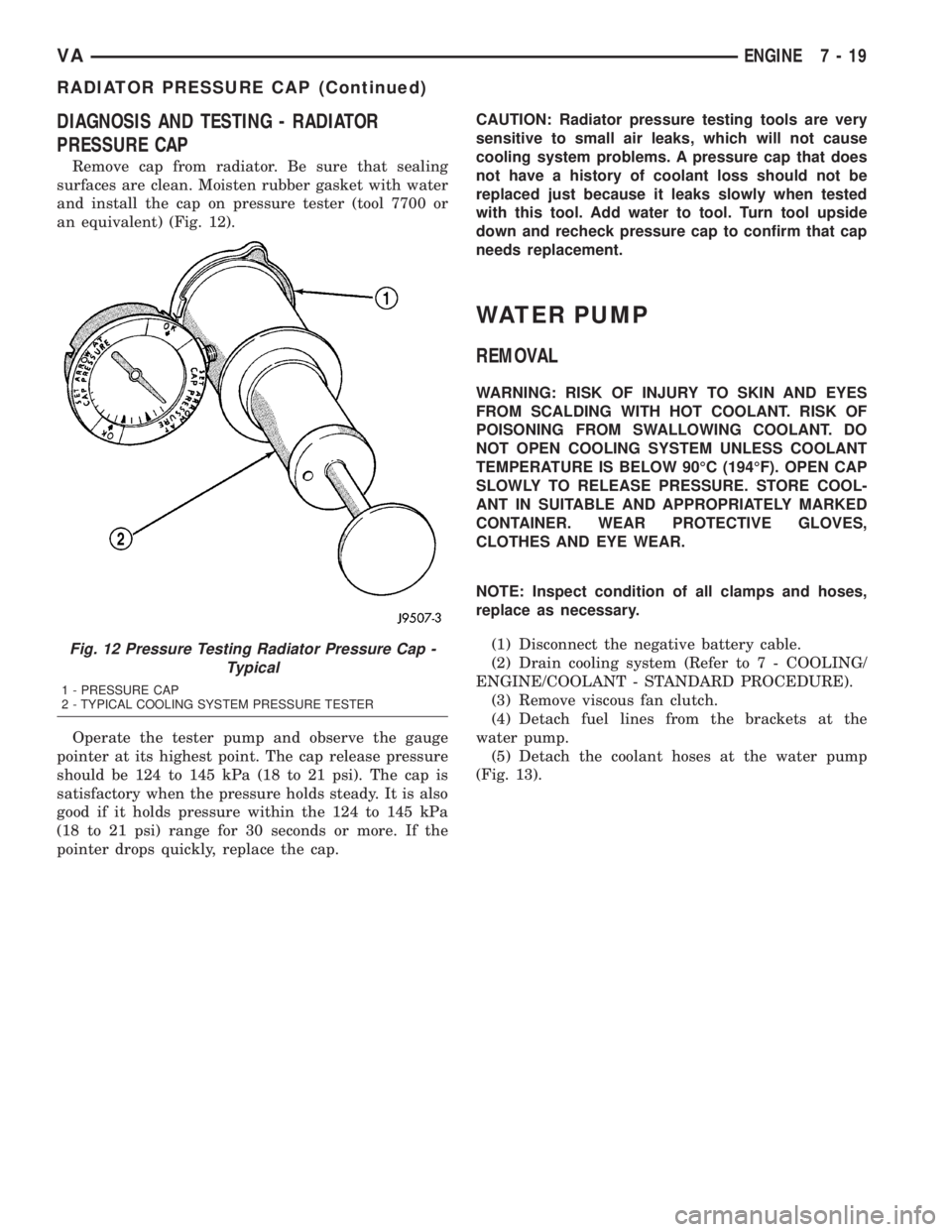

DIAGNOSIS AND TESTING - RADIATOR

PRESSURE CAP

Remove cap from radiator. Be sure that sealing

surfaces are clean. Moisten rubber gasket with water

and install the cap on pressure tester (tool 7700 or

an equivalent) (Fig. 12).

Operate the tester pump and observe the gauge

pointer at its highest point. The cap release pressure

should be 124 to 145 kPa (18 to 21 psi). The cap is

satisfactory when the pressure holds steady. It is also

good if it holds pressure within the 124 to 145 kPa

(18 to 21 psi) range for 30 seconds or more. If the

pointer drops quickly, replace the cap.CAUTION: Radiator pressure testing tools are very

sensitive to small air leaks, which will not cause

cooling system problems. A pressure cap that does

not have a history of coolant loss should not be

replaced just because it leaks slowly when tested

with this tool. Add water to tool. Turn tool upside

down and recheck pressure cap to confirm that cap

needs replacement.

WATER PUMP

REMOVAL

WARNING: RISK OF INJURY TO SKIN AND EYES

FROM SCALDING WITH HOT COOLANT. RISK OF

POISONING FROM SWALLOWING COOLANT. DO

NOT OPEN COOLING SYSTEM UNLESS COOLANT

TEMPERATURE IS BELOW 90ÉC (194ÉF). OPEN CAP

SLOWLY TO RELEASE PRESSURE. STORE COOL-

ANT IN SUITABLE AND APPROPRIATELY MARKED

CONTAINER. WEAR PROTECTIVE GLOVES,

CLOTHES AND EYE WEAR.

NOTE: Inspect condition of all clamps and hoses,

replace as necessary.

(1) Disconnect the negative battery cable.

(2) Drain cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(3) Remove viscous fan clutch.

(4) Detach fuel lines from the brackets at the

water pump.

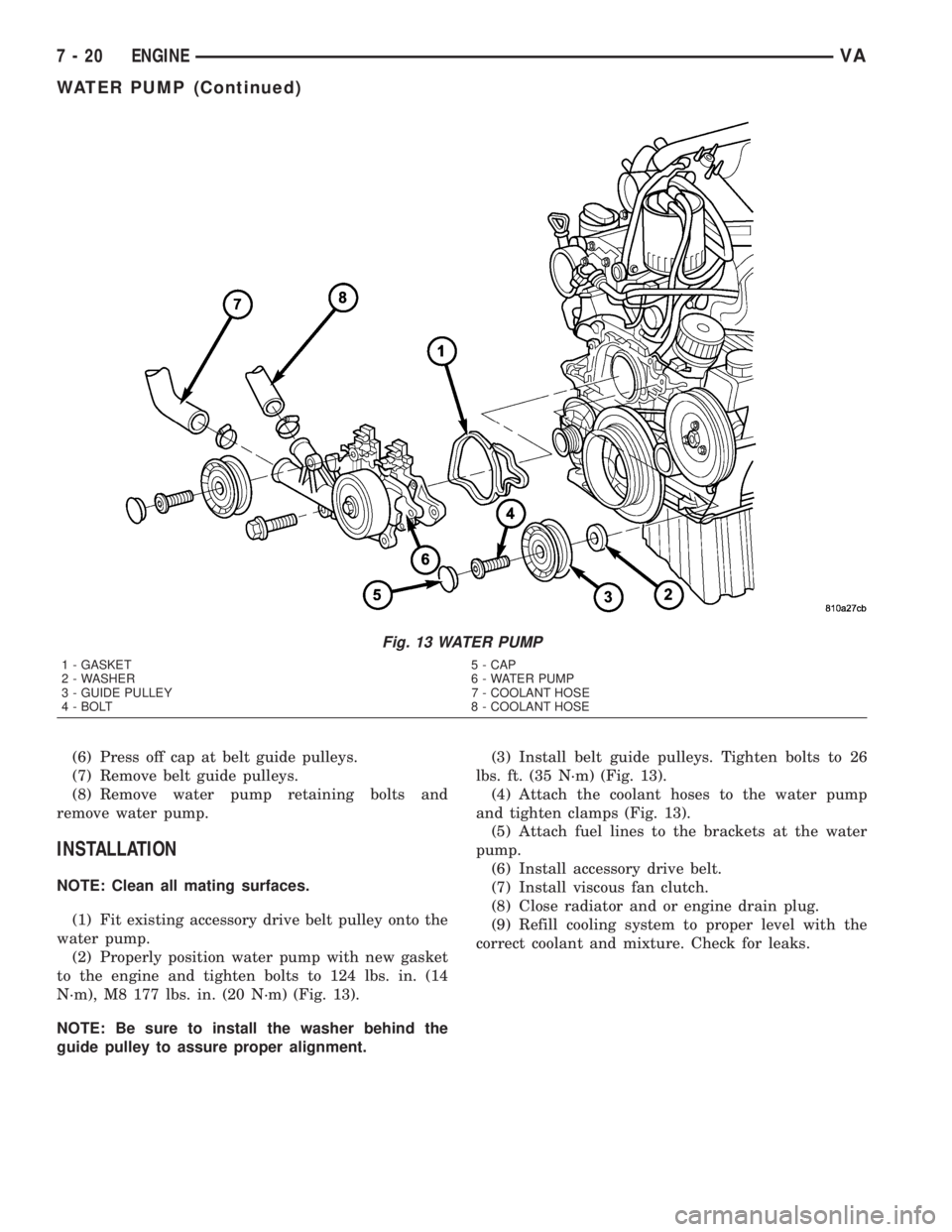

(5) Detach the coolant hoses at the water pump

(Fig. 13).

Fig. 12 Pressure Testing Radiator Pressure Cap -

Typical

1 - PRESSURE CAP

2 - TYPICAL COOLING SYSTEM PRESSURE TESTER

VAENGINE 7 - 19

RADIATOR PRESSURE CAP (Continued)

Page 116 of 1232

(6) Press off cap at belt guide pulleys.

(7) Remove belt guide pulleys.

(8) Remove water pump retaining bolts and

remove water pump.

INSTALLATION

NOTE: Clean all mating surfaces.

(1) Fit existing accessory drive belt pulley onto the

water pump.

(2) Properly position water pump with new gasket

to the engine and tighten bolts to 124 lbs. in. (14

N´m), M8 177 lbs. in. (20 N´m) (Fig. 13).

NOTE: Be sure to install the washer behind the

guide pulley to assure proper alignment.(3) Install belt guide pulleys. Tighten bolts to 26

lbs. ft. (35 N´m) (Fig. 13).

(4) Attach the coolant hoses to the water pump

and tighten clamps (Fig. 13).

(5) Attach fuel lines to the brackets at the water

pump.

(6) Install accessory drive belt.

(7) Install viscous fan clutch.

(8) Close radiator and or engine drain plug.

(9) Refill cooling system to proper level with the

correct coolant and mixture. Check for leaks.

Fig. 13 WATER PUMP

1 - GASKET 5 - CAP

2 - WASHER 6 - WATER PUMP

3 - GUIDE PULLEY 7 - COOLANT HOSE

4 - BOLT 8 - COOLANT HOSE

7 - 20 ENGINEVA

WATER PUMP (Continued)

Page 122 of 1232

OPERATION

The central timer module (CTM) monitors many

hard wired switch and sensor inputs as well as those

resources it shares with other modules in the vehicle

through its communication over the programmable

communications interface (PCI) data bus network.

The internal programming and all of these inputs

allow the CTM to determine the tasks it needs to

perform and their priorities, as well as both the stan-

dard and optional features that it should provide.

The CTM then performs those tasks and provides

those features through both PCI data bus communi-

cation with other modules and hard wired outputs

through a number of driver circuits, relays, and

actuators.These outputs allow the CTM the ability to

control numerous accessory systems in the vehicle.

The CTM monitors its own internal circuitry as

well as many of its input and output circuits, and

will store a Diagnostic Trouble Code (DTC) in elec-

tronic memory for any failure it detects. These DTCs

can be retrieved and diagnosed using a DRBIIItscan

tool. Refer to the appropriate diagnostic information.

HARD WIRED INPUTS

The hard wired inputs to the CTM include the fol-

lowing:

²Fused B(+)

²Fused ignition switch output (run-acc)

²Fused ignition switch output (run-start)

²Ground

²Key-in ignition switch sense

²Sliding door switch sense

²Passenger door switch sense

²Driver door switch sense

²PCI bus circuit

HARD WIRED OUTPUTS

The hard wired outputs of the CTM include the fol-

lowing:

²Door lock relay output

²Door unlock relay output

²VTSS indicator driver

MESSAGING

The CTM uses the following messages received

from other electronic modules over the PCI data bus:

²Airbag Deploy (ACM)

²Beep request (CMTC)

²Charging System Failure (PCM)

²Chime request (EMIC)

²Engine RPM (PCM)

²OK to Arm VTSS (PCM)

²Security indicator request (SKIM)

²System Voltage (PCM)

²Valid/Invalid Key (SKIM)

²Vehicle Distance (PCM)²Vehicle Speed (PCM)DIAGNOSIS AND TESTING - CENTRAL TIMER

MODULE

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

The hard wired inputs to and outputs from the

central timer module (CTM) may be diagnosed and

tested using conventional diagnostic tools and meth-

ods. Refer to the appropriate wiring information.

However, conventional diagnostic methods may not

prove conclusive in the diagnosis of the CTM. In

order to obtain conclusive testing of the CTM, the

programmable communications interface (PCI) data

bus network and all of the modules that provide

inputs to or receive outputs from the CTM must also

be checked. The most reliable, efficient, and accurate

means to diagnose the CTM, the PCI data bus net-

work, and the modules that provide inputs to, or

receive outputs from, the CTM requires the use of a

DRBIIItscan tool. Refer to the appropriate diagnos-

tic information.

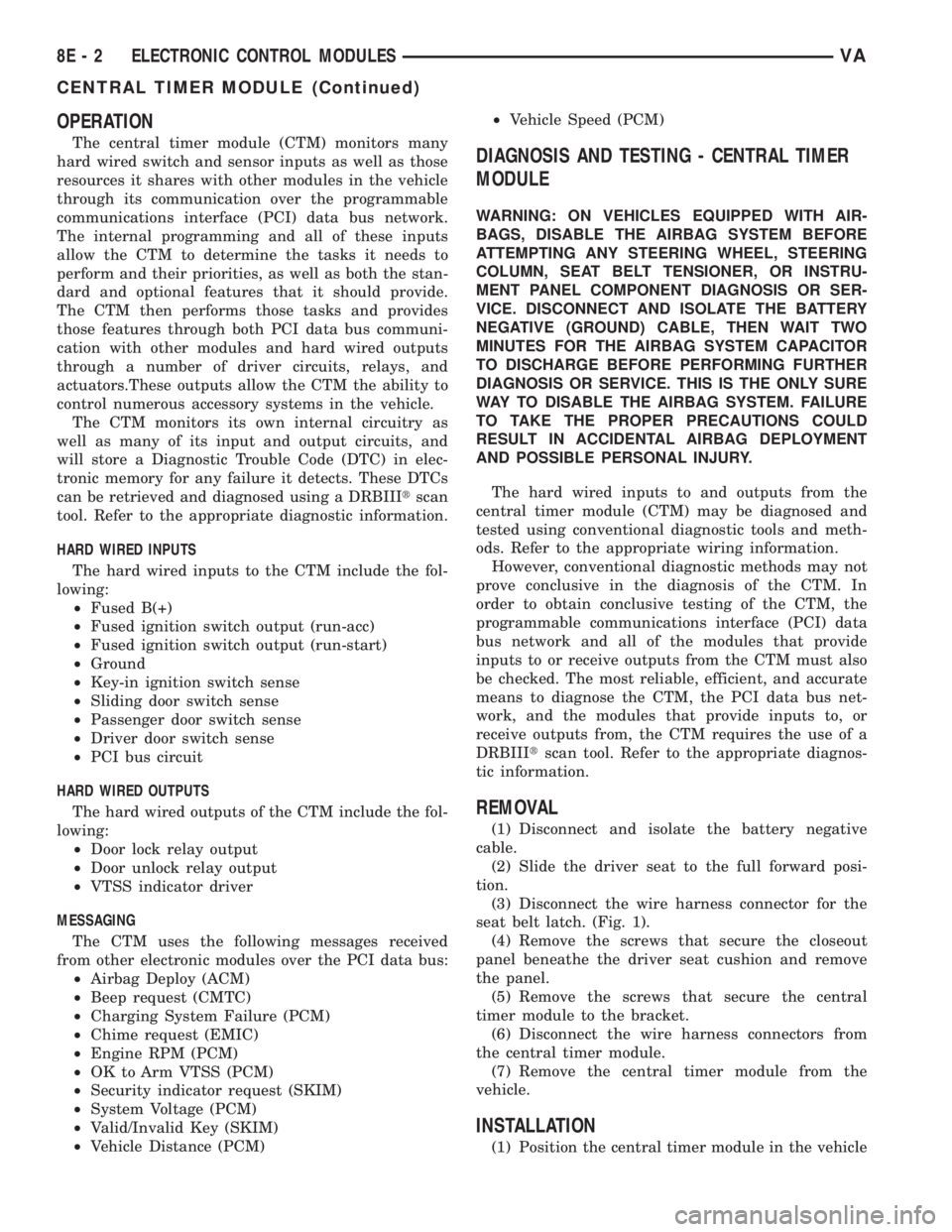

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Slide the driver seat to the full forward posi-

tion.

(3) Disconnect the wire harness connector for the

seat belt latch. (Fig. 1).

(4) Remove the screws that secure the closeout

panel beneathe the driver seat cushion and remove

the panel.

(5) Remove the screws that secure the central

timer module to the bracket.

(6) Disconnect the wire harness connectors from

the central timer module.

(7) Remove the central timer module from the

vehicle.

INSTALLATION

(1) Position the central timer module in the vehicle

8E - 2 ELECTRONIC CONTROL MODULESVA

CENTRAL TIMER MODULE (Continued)

Page 123 of 1232

(2) Connect the wire harness connectors to the

central timer module.

(3) Install the screws that secure the central timer

module. Tighten the screws securely.

(4) Route the seat belt latch wire lead through the

hole in the closeout panel and position the panel

beneath the driver seat cushion

(5) Install the screws that secure the closeout

panel beneath the driver seat cushion. Tighten the

screws securely.

(6) Connect the wire harness connector to the seat

belt latch connector.

(7) Slide the driver seat to back to its original posi-

tion.

(8) Reconnect the negative battery cable.

CONTROLLER ANTILOCK

BRAKE

DESCRIPTION

The Controler Antilock Brake (CAB) is mounted to

the Hydraulic Control Unit (HCU) and operates the

ABS system.

REMOVAL

(1) Remove the negative battery cable from the

battery.

(2) Pull up on the CAB harness connector release

and remove connector.

(3) Remove the CAB mounting bolts.

(4) Remove the CAB from the HCU.

INSTALLATION

(1) Install CAB to the HCU.

(2) Install mounting bolts. Tighten to 2 N´m (16 in.

lbs.).

(3) Install the wiring harness connector to the

CAB and push down on the release to secure the con-

nector.

(4) Install negative battery cable to the battery.

ENGINE CONTROL MODULE

DESCRIPTION

The electronic control module (ECM) is mounted to

the left lower dash panel and consists of an electronic

printed circuit board which is designed as a multi-

layer board assembly fitted on both sides. The rout-

ing of the five wiring harness connectors at the ECM

connectors are split into interfering cables and sensi-

tive cables in order to achieve improved electromag-

netic compatibility. The ECM stores engine specific

data, monitors the connected sensor and analyzes

their measurement (Fig. 2).

Its task consists in controlling the following sys-

tems in line with the analysis of the input signals:

²Fuel Supply System

²Injected Quantity Control

²Emission Control System

²Charge Pressure Control

²Cruise Control

²A/C Compressor Shut-Off

²Pre-Heating Output Relay for the Glow Plugs

²Vehicle Theft

²Air Bag

²Monitors inputs/outputs, checks plausibility and

stores faults

²Share information with other control modules

²Diagnosis

If a sensor should fail, provided the fault is not

serious, the ECM will continue to operate the engine

in Limp-Home Mode (emergency mode) using a

default value for the missing signal. The ECM

ensures that continuing to operate the engine will

not cause damage or effect safety,otherwise a Engine

shut-off process will be carried out.Fig. 1 Central Timer Module

1 - DRIVER SEAT

2 - WIRE HARNESS CONNECTOR

3 - SCREW (2)

4 - CLOSEOUT PANEL

5 - CENTRAL TIMER MODULE

6 - WIRE HARNESS CONNECTOR (2)

7 - SCREW (2)

VAELECTRONIC CONTROL MODULES 8E - 3

CENTRAL TIMER MODULE (Continued)

Page 126 of 1232

The TCM continuously checks for electrical prob-

lems, mechanical problems, and some hydraulic prob-

lems. When a problem is sensed, the TCM stores a

diagnostic trouble code (DTC). Some of these codes

cause the transmission to go into9Limp-In9or

9default9mode. Some DTCs cause permanent

Limp-In and others cause temporary Limp-In. The

NAG1 defaults in the current gear position if a DTC

is detected, then after a key cycle the transmission

will go into Limp-in, which is mechanical 2nd gear.

Some DTCs may allow the transmission to resume

normal operation (recover) if the detected problem

goes away. A permanent Limp-In DTC will recover

when the key is cycled, but if the same DTC is

detected for three key cycles the system will not

recover and the DTC must be cleared from the TCM

with the DRBIIItscan tool.

TCM SIGNALS

The TCM registers one part of the input signals by

direct inputs, the other part by CAN C bus. In addi-

tion to the direct control of the actuators, the TCM

sends various output signals by CAN C bus to other

control modules.

Selector Lever Position

The TCM monitors the SLA for all shift lever posi-

tions via the CAN bus.

ATF Temperature Sensor

The ATF temperature sensor is a positive temper-

ature co-efficient (PTC) thermistor. It measures the

temperature of the transmission fluid and is a direct

input signal for the TCM. The temperature of the

ATF has an influence on the shifttime and resulting

shift quality. As the temperature rises, resistance

rises, and therefore, the probing voltage is decreas-

ing. Because of its registration, the shifting process

can be optimized in all temperature ranges.

The ATF temperature sensor is wired in series

with the park/neutral contact. The temperature sig-

nal is transmitted to the TCM only when the reed

contact of the park/neutral contact is closed because

the TCM only reads ATF temperature while in any

forward gear, or REVERSE. When the transmission

is in PARK or NEUTRAL, the TCM will substitute

the engine temperature for the ATF temperature.

Starter Interlock

The TCM monitors a contact switch wired in series

with the transmission temperature sensor to deter-

mine PARK and NEUTRAL positions. The contact

switch is open in PARK and NEUTRAL. The TCM

senses transmission temperature as high (switch

supply voltage), confirming switch status as open.

The TCM then broadcasts a message over CAN bus

to confirm switch status. The PCM receives thisinformation and allows operation of the starter cir-

cuit.

N2 and N3 Speed Sensors

The N2 and N3 Input Speed Sensors are two Hall-

effect speed sensors that are mounted internally in

the transmission and are used by the TCM to calcu-

late the transmission's input speed. Since the input

speed cannot be measured directly, two of the drive

elements are measured. Two input speed sensors

were required because both drive elements are not

active in all gears.

CAN C Bus Indirect Input Signals

A 2.5-volt bias (operating voltage) is present on the

CAN C bus any time the ignition switch is in the

RUN position. Both the TCM and the ABS apply this

bias. On this vehicle, the CAN C bus is used for mod-

ule data exchange only. The indirect inputs used on

the NAG1 electronic control system are:

²Wheel Speed Sensors.

²Brake Switch.

²Engine RPM.

²Engine Temperature.

²Cruise Control Status.

²Gear Limit Request.

²Throttle Position - 0% at idle, 100% at WOT. If

open, TCM assumes idle (0% throttle opening).

²Odometer Mileage

²Maximum Effective Torque.

²Engine in Limp-In Mode/Mileage Where DTC

Was Set.

BRAKE TRANSMISSION SHIFT INTERLOCK (BTSI)

The BTSI solenoid prevents shifting out of the

PARK position until the ignition key is in the RUN

position and the brake pedal is pressed. The TCM

controls the ground while the ignition switch supplies

power to the BTSI solenoid. The PCM monitors the

brake switch and broadcasts brake switch status

messages over the CAN C bus. If the park brake is

depressed and there is power (Run/Start) to SLA, the

BTSI solenoid deactivates.

SHIFT SCHEDULES

The basic shift schedule includes up and down-

shifts for all five gears. The TCM adapts the shift

program according to driving style, accelerator pedal

position and deviation of vehicle speed. Influencing

factors are:

²Road Conditions.

²Incline, Decline and Altitude.

²Trailer Operation, Loading.

²Engine Coolant Temperature.

²Cruise Control Operation.

²Sporty Driving Style.

8E - 6 ELECTRONIC CONTROL MODULESVA

TRANSMISSION CONTROL MODULE (Continued)

Page 129 of 1232

ENGINE SYSTEMS

TABLE OF CONTENTS

page page

BATTERY SYSTEM......................... 1

CHARGING SYSTEM....................... 17STARTING SYSTEM....................... 24

BATTERY SYSTEM

TABLE OF CONTENTS

page page

BATTERY SYSTEM

DESCRIPTION..........................1

OPERATION............................2

DIAGNOSIS AND TESTING - BATTERY

SYSTEM.............................2

CLEANING.............................5

INSPECTION...........................6

SPECIAL TOOLS

BATTERY SYSTEM SPECIAL TOOLS.......6

BATTERY

DESCRIPTION..........................6

OPERATION............................7

DIAGNOSIS AND TESTING - BATTERY.......7

STANDARD PROCEDURE

STANDARD PROCEDURE - BATTERY

CHARGING...........................8

STANDARD PROCEDURE - OPEN-CIRCUIT

VOLTAGE TEST.......................10

STANDARD PROCEDURE - IGNITION-OFF

DRAW TEST.........................10

STANDARD PROCEDURE - USING MICRO

420 BATTERY TESTER.................11

STANDARD PROCEDURE - CHECKING

BATTERY ELECTROLYTE LEVEL.........12REMOVAL

UNDER HOOD BATTERY REMOVAL.......12

AUXILIARY BATTERY REMOVAL..........13

INSTALLATION

UNDER HOOD BATTERY INSTALLATION . . . 13

AUXILIARY BATTERY INSTALLATION......13

BATTERY HOLDDOWN

DESCRIPTION.........................14

REMOVAL.............................14

INSTALLATION.........................14

BATTERY CABLES

DESCRIPTION.........................14

OPERATION...........................14

DIAGNOSIS AND TESTING - BATTERY

CABLES............................14

REMOVAL.............................16

INSTALLATION.........................16

BATTERY TRAY

DESCRIPTION.........................16

OPERATION...........................16

REMOVAL.............................16

INSTALLATION.........................16

BATTERY SYSTEM

DESCRIPTION

A single 12-volt battery is standard factory-in-

stalled equipment on this model. Some vehicles are

equipped with a second auxiliary battery for running

additional electrical equipment. The standard battery

is located in the engine compartment, while the aux-

iliary battery (if equipped) is located under the pas-

sengers front seat. The battery system for thisvehicle covers the following related components,

which are covered in further detail later in this sec-

tion of the service manual:

²Battery- The 12v storage battery(s) provides a

reliable means of storing a renewable source of elec-

trical energy within the vehicle.

²Battery Cables- The battery cables connect

the battery terminal posts to the vehicle electrical

system.

VAENGINE SYSTEMS 8F - 1

Page 134 of 1232

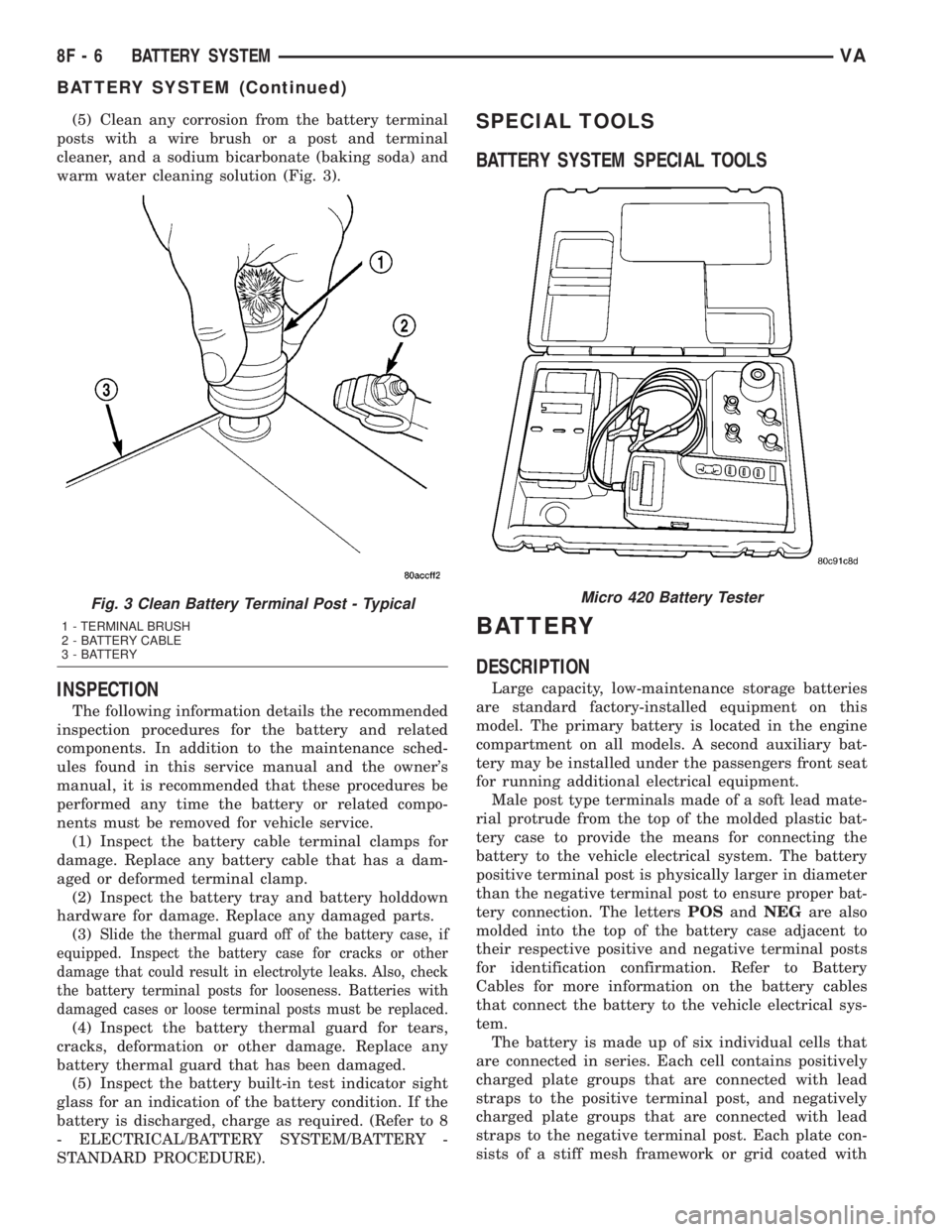

(5) Clean any corrosion from the battery terminal

posts with a wire brush or a post and terminal

cleaner, and a sodium bicarbonate (baking soda) and

warm water cleaning solution (Fig. 3).

INSPECTION

The following information details the recommended

inspection procedures for the battery and related

components. In addition to the maintenance sched-

ules found in this service manual and the owner's

manual, it is recommended that these procedures be

performed any time the battery or related compo-

nents must be removed for vehicle service.

(1) Inspect the battery cable terminal clamps for

damage. Replace any battery cable that has a dam-

aged or deformed terminal clamp.

(2) Inspect the battery tray and battery holddown

hardware for damage. Replace any damaged parts.

(3)

Slide the thermal guard off of the battery case, if

equipped. Inspect the battery case for cracks or other

damage that could result in electrolyte leaks. Also, check

the battery terminal posts for looseness. Batteries with

damaged cases or loose terminal posts must be replaced.

(4) Inspect the battery thermal guard for tears,

cracks, deformation or other damage. Replace any

battery thermal guard that has been damaged.

(5) Inspect the battery built-in test indicator sight

glass for an indication of the battery condition. If the

battery is discharged, charge as required. (Refer to 8

- ELECTRICAL/BATTERY SYSTEM/BATTERY -

STANDARD PROCEDURE).

SPECIAL TOOLS

BATTERY SYSTEM SPECIAL TOOLS

BATTERY

DESCRIPTION

Large capacity, low-maintenance storage batteries

are standard factory-installed equipment on this

model. The primary battery is located in the engine

compartment on all models. A second auxiliary bat-

tery may be installed under the passengers front seat

for running additional electrical equipment.

Male post type terminals made of a soft lead mate-

rial protrude from the top of the molded plastic bat-

tery case to provide the means for connecting the

battery to the vehicle electrical system. The battery

positive terminal post is physically larger in diameter

than the negative terminal post to ensure proper bat-

tery connection. The lettersPOSandNEGare also

molded into the top of the battery case adjacent to

their respective positive and negative terminal posts

for identification confirmation. Refer to Battery

Cables for more information on the battery cables

that connect the battery to the vehicle electrical sys-

tem.

The battery is made up of six individual cells that

are connected in series. Each cell contains positively

charged plate groups that are connected with lead

straps to the positive terminal post, and negatively

charged plate groups that are connected with lead

straps to the negative terminal post. Each plate con-

sists of a stiff mesh framework or grid coated with

Fig. 3 Clean Battery Terminal Post - Typical

1 - TERMINAL BRUSH

2 - BATTERY CABLE

3 - BATTERY

Micro 420 Battery Tester

8F - 6 BATTERY SYSTEMVA

BATTERY SYSTEM (Continued)

Page 146 of 1232

GENERATOR

DESCRIPTION

The generator is belt-driven by the engine using a

serpentine-type drive belt. It is serviced only as a

complete assembly. If the generator fails for any rea-

son, the entire assembly must be replaced.

On certain engines, the decoupler pulley may be

replaced separately.

OPERATION

As the energized rotor begins to rotate within the

generator, the spinning magnetic field induces a cur-

rent into the windings of the stator coil. Once the

generator begins producing sufficient current, it also

provides the current needed to energize the rotor.

The stator winding connections deliver the induced

AC current to 3 positive and 3 negative diodes for

rectification. From the diodes, rectified DC current is

delivered to the vehicle electrical system through the

generator battery terminal.

Although the generators appear the same exter-

nally, different generators with different output rat-

ings are used on this vehicle. Be certain that the

replacement generator has the same output rating

and part number as the original unit. Refer to Spec-

ifications and see Generator Ratings for amperage

ratings and part numbers.

Noise emitting from the generator may be caused

by: worn, loose or defective bearings; a loose or defec-

tive drive pulley (decoupler pulley); incorrect, worn,

damaged or misadjusted fan drive belt; loose mount-

ing bolts; a misaligned drive pulley or a defective sta-

tor or diode.

An instrument panel mounted, battery charge indi-

cator lamp is used. When the key is in the on posi-

tion, the lamp will be illuminated. This is done as a

bulb check. If this lamp remains illuminated while

the engine is running, a Diagnostic Trouble Code

(DTC) has been detected for the charging system.

REMOVAL

CAUTION: DISCONNECT NEGATIVE CABLE FROM

BATTERY BEFORE REMOVING BATTERY OUTPUT

WIRE FROM GENERATOR. FAILURE TO DO SO

CAN RESULT IN INJURY.

CAUTION: Never force a belt over a pulley rim

using a screwdriver. The synthetic fiber of the belt

can be damaged.

CAUTION: When installing a serpentine accessory

drive belt, the belt MUST be routed correctly. The

water pump will be rotating in the wrong direction ifthe belt is installed incorrectly, causing the engine

to overheat. Refer to belt routing label in engine

compartment, or refer to Belt Schematics in Cooling

System.

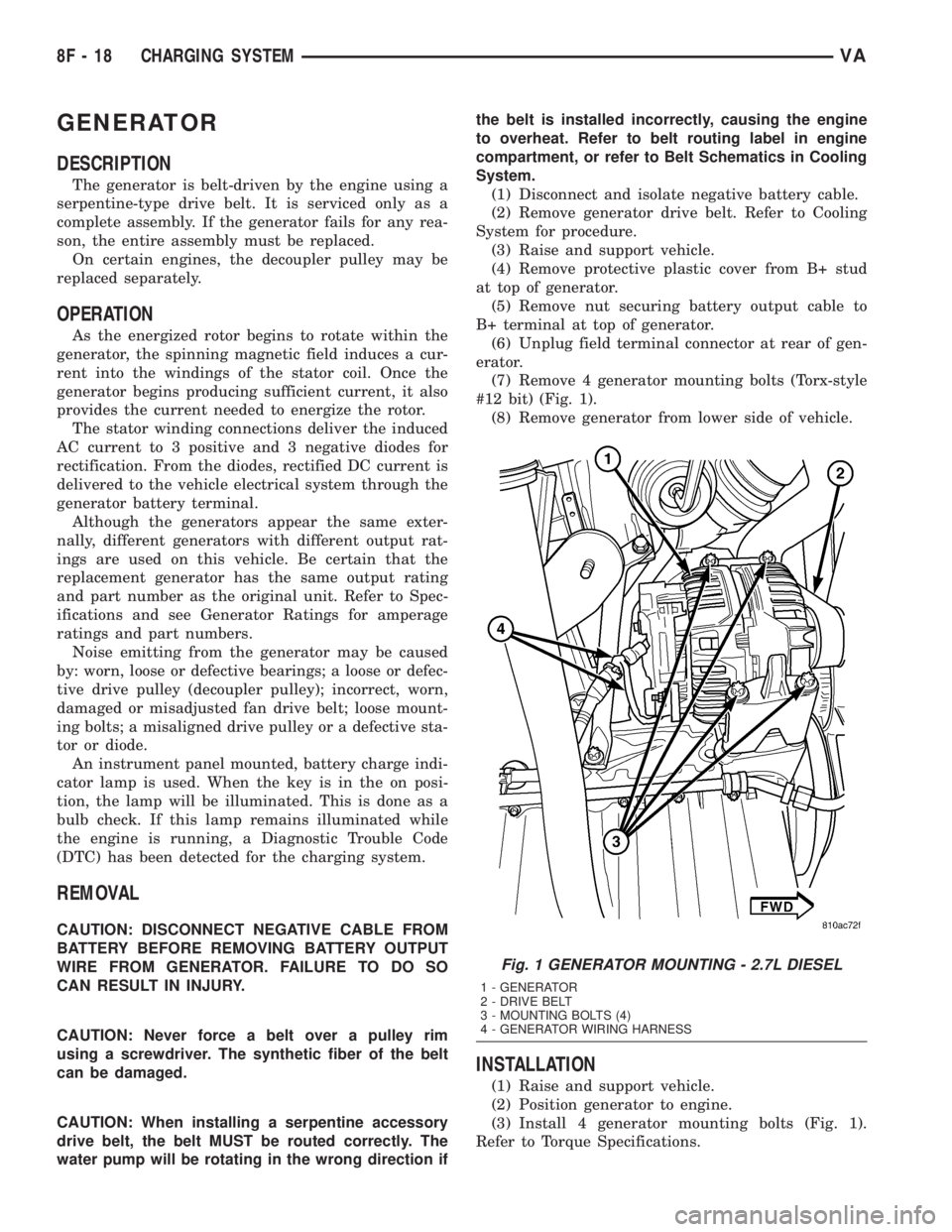

(1) Disconnect and isolate negative battery cable.

(2) Remove generator drive belt. Refer to Cooling

System for procedure.

(3) Raise and support vehicle.

(4) Remove protective plastic cover from B+ stud

at top of generator.

(5) Remove nut securing battery output cable to

B+ terminal at top of generator.

(6) Unplug field terminal connector at rear of gen-

erator.

(7) Remove 4 generator mounting bolts (Torx-style

#12 bit) (Fig. 1).

(8) Remove generator from lower side of vehicle.

INSTALLATION

(1) Raise and support vehicle.

(2) Position generator to engine.

(3) Install 4 generator mounting bolts (Fig. 1).

Refer to Torque Specifications.

Fig. 1 GENERATOR MOUNTING - 2.7L DIESEL

1 - GENERATOR

2 - DRIVE BELT

3 - MOUNTING BOLTS (4)

4 - GENERATOR WIRING HARNESS

8F - 18 CHARGING SYSTEMVA