check engine MERCEDES-BENZ SPRINTER 2005 Service Owner's Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 147 of 1232

(4) Connect field terminal connector at rear of gen-

erator.

(5) Install battery output cable and nut to B+ ter-

minal at top of generator. Refer to Torque Specifica-

tions.

(6) Install protective plastic cover to B+ stud at

top of generator.

(7) Lower vehicle.

CAUTION: Never force a belt over a pulley rim

using a screwdriver. The synthetic fiber of the belt

can be damaged.

CAUTION: When installing a serpentine accessory

drive belt, the belt MUST be routed correctly. The

water pump will be rotating in the wrong direction if

the belt is installed incorrectly, causing the engine

to overheat. Refer to belt routing label in engine

compartment, or refer to Belt Schematics in Cooling

System.

(8) Install generator drive belt. Refer to Cooling

System for procedure.

(9) Connect negative battery cable.

(10) Check charging system for proper operation.

GENERATOR DECOUPLER

PULLEY

DESCRIPTION

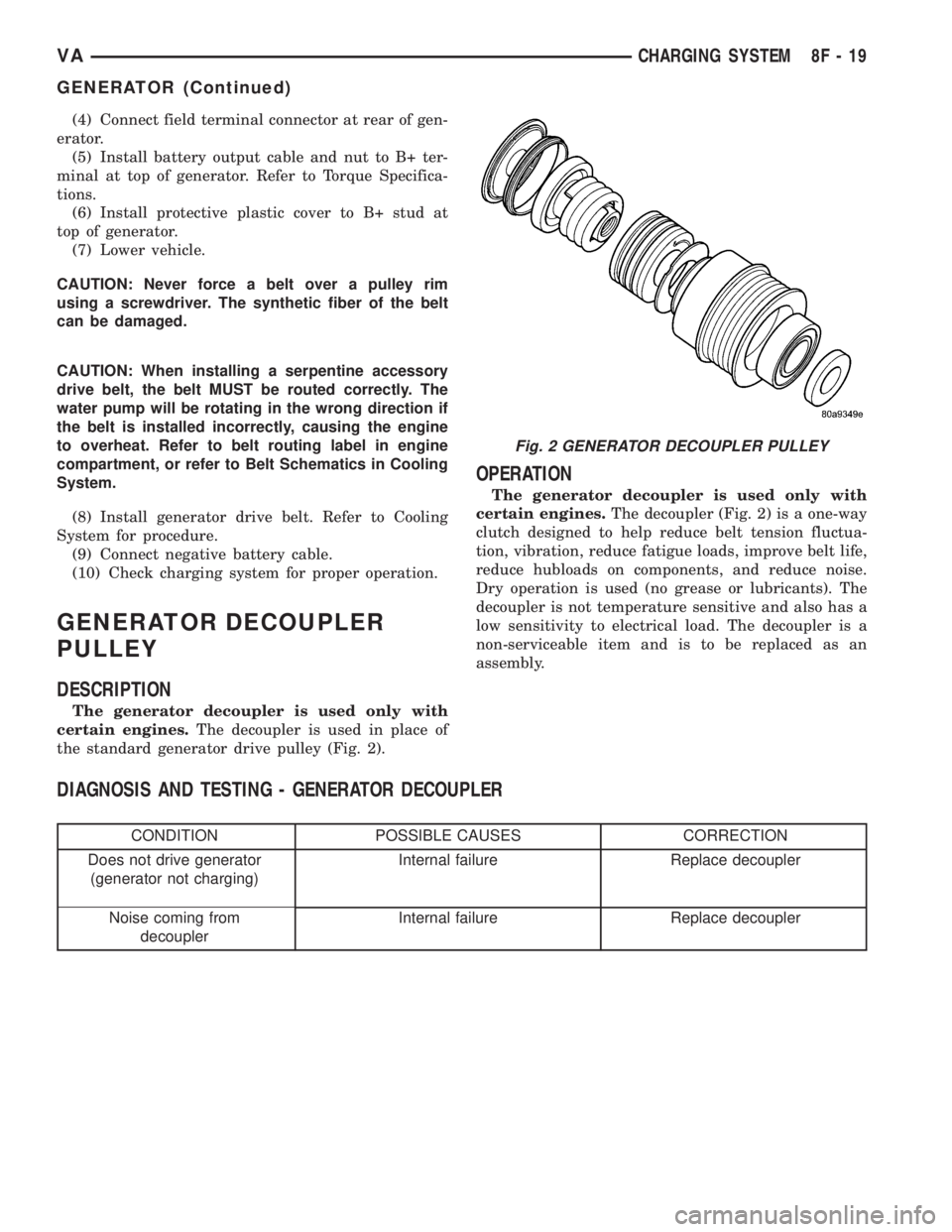

The generator decoupler is used only with

certain engines.The decoupler is used in place of

the standard generator drive pulley (Fig. 2).

OPERATION

The generator decoupler is used only with

certain engines.The decoupler (Fig. 2) is a one-way

clutch designed to help reduce belt tension fluctua-

tion, vibration, reduce fatigue loads, improve belt life,

reduce hubloads on components, and reduce noise.

Dry operation is used (no grease or lubricants). The

decoupler is not temperature sensitive and also has a

low sensitivity to electrical load. The decoupler is a

non-serviceable item and is to be replaced as an

assembly.

DIAGNOSIS AND TESTING - GENERATOR DECOUPLER

CONDITION POSSIBLE CAUSES CORRECTION

Does not drive generator

(generator not charging)Internal failure Replace decoupler

Noise coming from

decouplerInternal failure Replace decoupler

Fig. 2 GENERATOR DECOUPLER PULLEY

VACHARGING SYSTEM 8F - 19

GENERATOR (Continued)

Page 158 of 1232

STARTER SOLENOID

This test can only be performed with starter motor

removed from vehicle.

(1) Remove starter motor from vehicle. Refer to

Starter Motor Removal and Installation.

(2)

Disconnect wire from solenoid field coil terminal.

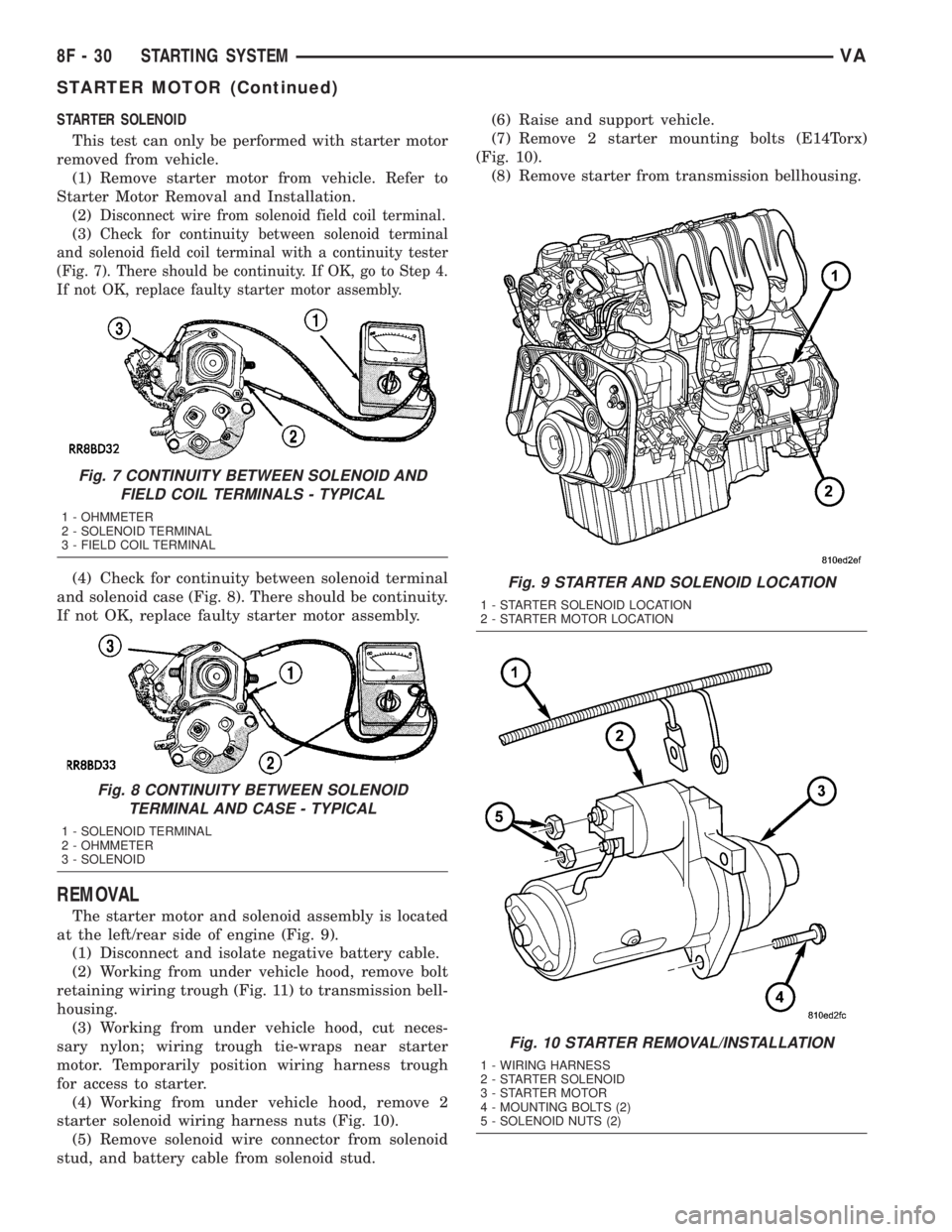

(3)Check for continuity between solenoid terminal

and solenoid field coil terminal with a continuity tester

(Fig. 7). There should be continuity. If OK, go to Step 4.

If not OK, replace faulty starter motor assembly.

(4) Check for continuity between solenoid terminal

and solenoid case (Fig. 8). There should be continuity.

If not OK, replace faulty starter motor assembly.

REMOVAL

The starter motor and solenoid assembly is located

at the left/rear side of engine (Fig. 9).

(1) Disconnect and isolate negative battery cable.

(2) Working from under vehicle hood, remove bolt

retaining wiring trough (Fig. 11) to transmission bell-

housing.

(3) Working from under vehicle hood, cut neces-

sary nylon; wiring trough tie-wraps near starter

motor. Temporarily position wiring harness trough

for access to starter.

(4) Working from under vehicle hood, remove 2

starter solenoid wiring harness nuts (Fig. 10).

(5) Remove solenoid wire connector from solenoid

stud, and battery cable from solenoid stud.(6) Raise and support vehicle.

(7) Remove 2 starter mounting bolts (E14Torx)

(Fig. 10).

(8) Remove starter from transmission bellhousing.

Fig. 7 CONTINUITY BETWEEN SOLENOID AND

FIELD COIL TERMINALS - TYPICAL

1 - OHMMETER

2 - SOLENOID TERMINAL

3 - FIELD COIL TERMINAL

Fig. 8 CONTINUITY BETWEEN SOLENOID

TERMINAL AND CASE - TYPICAL

1 - SOLENOID TERMINAL

2 - OHMMETER

3 - SOLENOID

Fig. 9 STARTER AND SOLENOID LOCATION

1 - STARTER SOLENOID LOCATION

2 - STARTER MOTOR LOCATION

Fig. 10 STARTER REMOVAL/INSTALLATION

1 - WIRING HARNESS

2 - STARTER SOLENOID

3 - STARTER MOTOR

4 - MOUNTING BOLTS (2)

5 - SOLENOID NUTS (2)

8F - 30 STARTING SYSTEMVA

STARTER MOTOR (Continued)

Page 162 of 1232

OPERATION

The heated seat system is designed to provide indi-

vidually controlled, supplemental heat to the seat

cushion and seat back surfaces of both front seats.

Because this system converts electrical current to

heat, the heated seat system can provide a measure

of warm comfort almost immediately upon entering a

cold vehicle, rather than having to wait for the

engine coolant to reach sufficient temperature to

deliver heat through the conventional heater system.

This system allows each front seat occupant to indi-

vidually select one of two comfort levels, Hi or Lo, or

to turn the heater for their seat off.

The heated seat system components operate on

battery current received through a fuse in the Fuse

Block on a fused ignition switch output (run-acc) cir-

cuit so that the system will only operate when theignition switch is in the On or Accessory positions.

The heated seat system will be turned Off automati-

cally whenever the ignition switch is turned to any

position except On or Accessory. Also, the heated seat

system will not operate when the surface tempera-

ture of the seat cushion cover at either heated seat

sensor is above the designed temperature set points

of the system.

DIAGNOSIS AND TESTING - HEATED SEATS

Refer toWiringfor the appropriate wiring infor-

mation. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

further details on wire harness routing and reten-

tion, as well as pin-out and location views for the

various wire harness connectors, splices and grounds.

HEATED SEAT SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

NO HEATED SEAT SWITCH

ILLUMINATION WITH

IGNITION ON1. Faulty fuse. 1. Check heated seat fuse in Fuse Block.

Replace fuse, if required.

2. Wiring faulty. 2. Check fused ignition switch output (run-acc)

circuit from heated seat switch connector to

ignition switch. Repair, if required.

3. Ground faulty. 3. Check for ground at heated seat switch

connector. Repair, if required.

4. Faulty switch. 4. Refer to Heated Seat Switch for the proper

switch diagnosis and testing procedures.

DRIVER HEATED SEAT

SWITCH

DESCRIPTION

The heated seat switches are located on the instru-

ment panel, in the accessory switch bezel. The two,

momentary rocker type switches provide a signal to

the Heated Seat Relay through separate hard wired

circuits. Each switch contains two light emitting

diodes (LED), one for each High and Low setting to

let the occupant know that the seat heater system is

on.

The heated seat switches and their LED's cannot

be repaired. If either switch is faulty or damaged the

entire switch must be replaced.

OPERATION

There are three modes that can be selected with

each of the heated seat switches: Off, Low, and High.

When the top of the switch rocker is depressed, the

low mode is selected and the low mode LED indicator

illuminates. Depressing the top of the switch rocker asecond time will turn the heated seat to Off. This

same process is repeated for High heat setting. The

heated seats will automatically return to the Off

mode anytime the vehicle ignition switch is turned

Off.

Both switches provide separate hard wire inputs to

the Heated Seat Relay to indicate the selected mode.

The Heated Seat Relay responds to the heated seat

switch messages by controlling the output to the seat

heater elements of the selected seat.

DIAGNOSIS AND TESTING - DRIVER HEATED

SEAT SWITCH

For circuit description and diagrams, refer toWir-

ing.

(1) Inspect the Heated Seat Switches for apparent

damage or sticking/binding and replace if required.

Refer to Heated Seat Switch Removal and Installa-

tion in this section.

(2) Replace the heated seat switch with a known

good unit and retest the heated seat system.

8G - 2 HEATED SYSTEMSVA

HEATED SEATS (Continued)

Page 210 of 1232

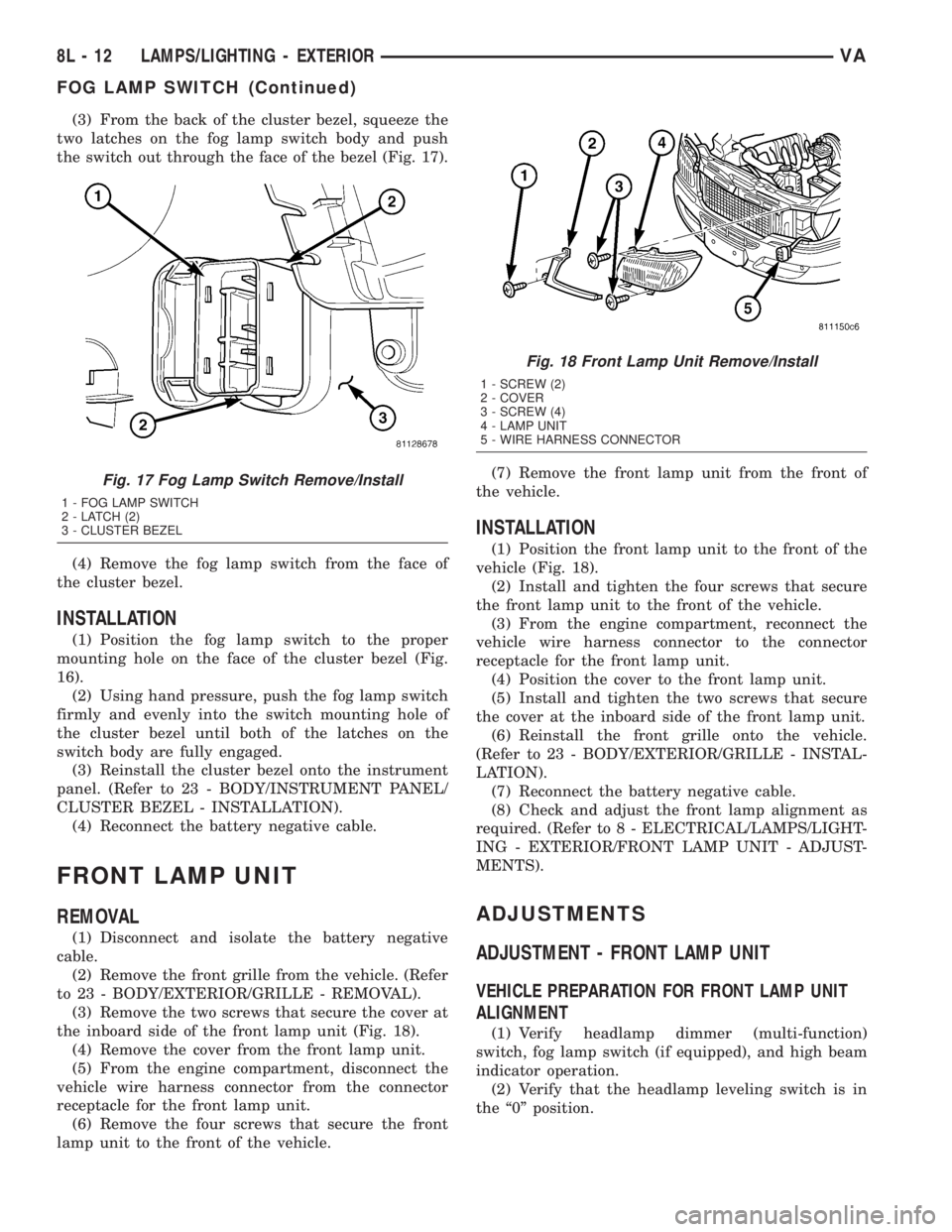

(3) From the back of the cluster bezel, squeeze the

two latches on the fog lamp switch body and push

the switch out through the face of the bezel (Fig. 17).

(4) Remove the fog lamp switch from the face of

the cluster bezel.

INSTALLATION

(1) Position the fog lamp switch to the proper

mounting hole on the face of the cluster bezel (Fig.

16).

(2) Using hand pressure, push the fog lamp switch

firmly and evenly into the switch mounting hole of

the cluster bezel until both of the latches on the

switch body are fully engaged.

(3) Reinstall the cluster bezel onto the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

CLUSTER BEZEL - INSTALLATION).

(4) Reconnect the battery negative cable.

FRONT LAMP UNIT

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the front grille from the vehicle. (Refer

to 23 - BODY/EXTERIOR/GRILLE - REMOVAL).

(3) Remove the two screws that secure the cover at

the inboard side of the front lamp unit (Fig. 18).

(4) Remove the cover from the front lamp unit.

(5) From the engine compartment, disconnect the

vehicle wire harness connector from the connector

receptacle for the front lamp unit.

(6) Remove the four screws that secure the front

lamp unit to the front of the vehicle.(7) Remove the front lamp unit from the front of

the vehicle.

INSTALLATION

(1) Position the front lamp unit to the front of the

vehicle (Fig. 18).

(2) Install and tighten the four screws that secure

the front lamp unit to the front of the vehicle.

(3) From the engine compartment, reconnect the

vehicle wire harness connector to the connector

receptacle for the front lamp unit.

(4) Position the cover to the front lamp unit.

(5) Install and tighten the two screws that secure

the cover at the inboard side of the front lamp unit.

(6) Reinstall the front grille onto the vehicle.

(Refer to 23 - BODY/EXTERIOR/GRILLE - INSTAL-

LATION).

(7) Reconnect the battery negative cable.

(8) Check and adjust the front lamp alignment as

required. (Refer to 8 - ELECTRICAL/LAMPS/LIGHT-

ING - EXTERIOR/FRONT LAMP UNIT - ADJUST-

MENTS).

ADJUSTMENTS

ADJUSTMENT - FRONT LAMP UNIT

VEHICLE PREPARATION FOR FRONT LAMP UNIT

ALIGNMENT

(1) Verify headlamp dimmer (multi-function)

switch, fog lamp switch (if equipped), and high beam

indicator operation.

(2) Verify that the headlamp leveling switch is in

the ª0º position.

Fig. 17 Fog Lamp Switch Remove/Install

1 - FOG LAMP SWITCH

2 - LATCH (2)

3 - CLUSTER BEZEL

Fig. 18 Front Lamp Unit Remove/Install

1 - SCREW (2)

2 - COVER

3 - SCREW (4)

4 - LAMP UNIT

5 - WIRE HARNESS CONNECTOR

8L - 12 LAMPS/LIGHTING - EXTERIORVA

FOG LAMP SWITCH (Continued)

Page 283 of 1232

WIPERS/WASHERS

TABLE OF CONTENTS

page page

WIPERS/WASHERS

DESCRIPTION..........................1

OPERATION............................3

DIAGNOSIS AND TESTING - WIPER &

WASHER SYSTEM.....................5

CLEANING - WIPER & WASHER SYSTEM.....5

INSPECTION - WIPER & WASHER SYSTEM . . . 6

CHECK VALVE

DESCRIPTION..........................7

OPERATION............................7

REMOVAL.............................7

INSTALLATION..........................7

WASHER FLUID LEVEL SWITCH

DESCRIPTION..........................7

OPERATION............................8

WASHER HOSES/TUBES

DESCRIPTION..........................8

OPERATION............................9

WASHER NOZZLE

DESCRIPTION..........................9

OPERATION............................9

REMOVAL.............................9

INSTALLATION..........................9

WASHER PUMP/MOTOR

DESCRIPTION..........................9

OPERATION...........................10

REMOVAL.............................10

INSTALLATION.........................10

WASHER RESERVOIR

DESCRIPTION.........................11OPERATION...........................11

REMOVAL.............................11

INSTALLATION.........................12

WIPER ARM

DESCRIPTION.........................13

OPERATION...........................14

REMOVAL.............................14

INSTALLATION.........................14

WIPER BLADE

DESCRIPTION.........................15

OPERATION...........................15

REMOVAL.............................16

INSTALLATION.........................16

WIPER LINKAGE

DESCRIPTION.........................17

OPERATION...........................17

REMOVAL.............................17

INSTALLATION.........................18

WIPER MOTOR

DESCRIPTION.........................19

OPERATION...........................19

REMOVAL.............................19

INSTALLATION.........................19

WIPER RELAY

DESCRIPTION.........................20

OPERATION...........................21

REMOVAL.............................22

INSTALLATION.........................22

WIPERS/WASHERS

DESCRIPTION

An electrically operated intermittent wiper and

washer system is standard factory-installed safety

equipment on this model (Fig. 1). The wiper and

washer system includes the following major compo-

nents, which are described in further detail else-

where in this service information:

²Check Valve- The washer system check valve

is integral to the plumbing fitting located in the

washer plumbing between the cowl plenum washer

hose and the two washer nozzle hoses, and is located

beneath the cowl top panel at the base of the wind-

shield in the engine compartment.

²Multi-Function Switch- The multi-function

switch is secured to the top of the steering column,just below the steering wheel. Only the left (lighting),

right (wiper) control stalks and the hazard warning

switch button for the multi-function switch are visi-

ble, the remainder of the switch is concealed beneath

the steering column shrouds. The multi-function

switch contains all of the switches for both the wiper

and washer systems.(Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/MULTI-FUNC-

TION SWITCH - DESCRIPTION)

²Washer Fluid Level Switch- The optional

washer fluid level switch is integral to a unique ver-

sion of the washer pump/motor unit, which is located

in a dedicated hole on the top of the sump area near

the back of the windshield washer reservoir on the

right front fender wheel house in the engine com-

partment.

²Washer Nozzle- A single washer nozzle with

three separate orifices is secured with integral snap

VAWIPERS/WASHERS 8R - 1

Page 289 of 1232

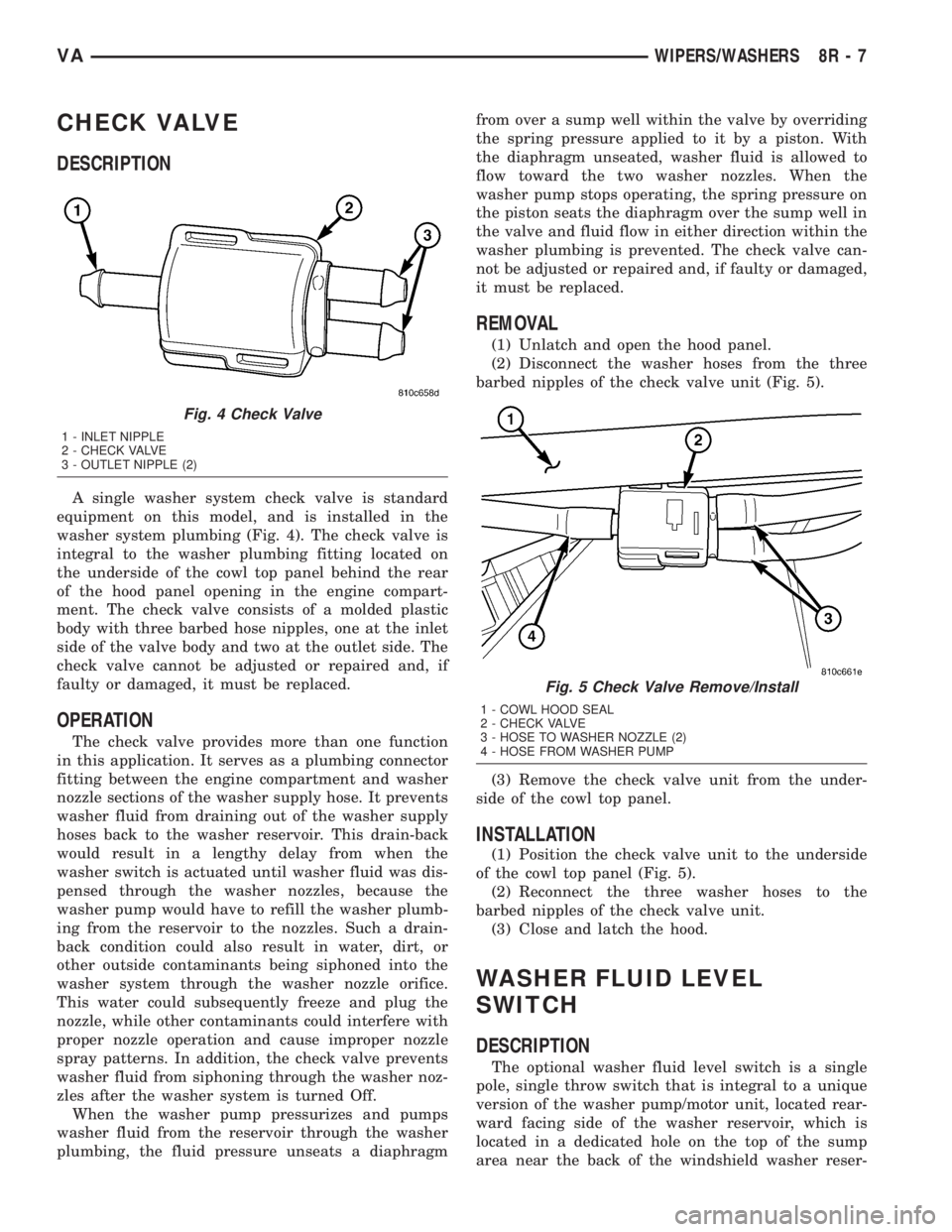

CHECK VALVE

DESCRIPTION

A single washer system check valve is standard

equipment on this model, and is installed in the

washer system plumbing (Fig. 4). The check valve is

integral to the washer plumbing fitting located on

the underside of the cowl top panel behind the rear

of the hood panel opening in the engine compart-

ment. The check valve consists of a molded plastic

body with three barbed hose nipples, one at the inlet

side of the valve body and two at the outlet side. The

check valve cannot be adjusted or repaired and, if

faulty or damaged, it must be replaced.

OPERATION

The check valve provides more than one function

in this application. It serves as a plumbing connector

fitting between the engine compartment and washer

nozzle sections of the washer supply hose. It prevents

washer fluid from draining out of the washer supply

hoses back to the washer reservoir. This drain-back

would result in a lengthy delay from when the

washer switch is actuated until washer fluid was dis-

pensed through the washer nozzles, because the

washer pump would have to refill the washer plumb-

ing from the reservoir to the nozzles. Such a drain-

back condition could also result in water, dirt, or

other outside contaminants being siphoned into the

washer system through the washer nozzle orifice.

This water could subsequently freeze and plug the

nozzle, while other contaminants could interfere with

proper nozzle operation and cause improper nozzle

spray patterns. In addition, the check valve prevents

washer fluid from siphoning through the washer noz-

zles after the washer system is turned Off.

When the washer pump pressurizes and pumps

washer fluid from the reservoir through the washer

plumbing, the fluid pressure unseats a diaphragmfrom over a sump well within the valve by overriding

the spring pressure applied to it by a piston. With

the diaphragm unseated, washer fluid is allowed to

flow toward the two washer nozzles. When the

washer pump stops operating, the spring pressure on

the piston seats the diaphragm over the sump well in

the valve and fluid flow in either direction within the

washer plumbing is prevented. The check valve can-

not be adjusted or repaired and, if faulty or damaged,

it must be replaced.

REMOVAL

(1) Unlatch and open the hood panel.

(2) Disconnect the washer hoses from the three

barbed nipples of the check valve unit (Fig. 5).

(3) Remove the check valve unit from the under-

side of the cowl top panel.

INSTALLATION

(1) Position the check valve unit to the underside

of the cowl top panel (Fig. 5).

(2) Reconnect the three washer hoses to the

barbed nipples of the check valve unit.

(3) Close and latch the hood.

WASHER FLUID LEVEL

SWITCH

DESCRIPTION

The optional washer fluid level switch is a single

pole, single throw switch that is integral to a unique

version of the washer pump/motor unit, located rear-

ward facing side of the washer reservoir, which is

located in a dedicated hole on the top of the sump

area near the back of the windshield washer reser-

Fig. 4 Check Valve

1 - INLET NIPPLE

2 - CHECK VALVE

3 - OUTLET NIPPLE (2)

Fig. 5 Check Valve Remove/Install

1 - COWL HOOD SEAL

2 - CHECK VALVE

3 - HOSE TO WASHER NOZZLE (2)

4 - HOSE FROM WASHER PUMP

VAWIPERS/WASHERS 8R - 7

Page 290 of 1232

voir on the right front fender wheel house in the

engine compartment. Only a molded plastic nipple

with a clear vent tube are visible near the top of the

washer pump/motor unit that is equipped with the

optional fluid level switch when it is installed in the

reservoir. The vent tube is routed to and retained in

an integral clip located behind the reservoir filler cap

near the top of the reservoir. This version of the

washer pump/motor unit also has a third terminal

pin in its integral connector receptacle. The washer

fluid level switch cannot be adjusted or repaired. If

faulty or damaged, the entire washer pump/motor

unit must be replaced.

OPERATION

The washer fluid level switch monitors the level of

the washer fluid in the washer reservoir. When the

fluid level in the washer reservoir is at or above the

predetermined minimum, the switch contacts are

open. When the fluid level in the washer reservoir

falls below the predetermined minimum, the switch

contacts of the normally open switch close. The

washer fluid level switch is connected to the vehicle

electrical system through the washer pump/motor

unit take out and connector of the vehicle wire har-

ness. The switch receives a path to ground at all

times through another take out of the vehicle wire

harness with a single eyelet terminal connector that

is secured under a ground screw located near the

right headlamp in the engine compartment.The switch is connected in series between ground

and the washer fluid switch sense input to the Elec-

troMechanical Instrument Cluster (EMIC). When the

switch closes, the EMIC senses the ground on the

washer fluid switch sense circuit. The EMIC is pro-

grammed to respond to this input by illuminating the

washer fluid indicator. The washer fluid level switch

input to the EMIC may be diagnosed using conven-

tional diagnostic tools and methods.

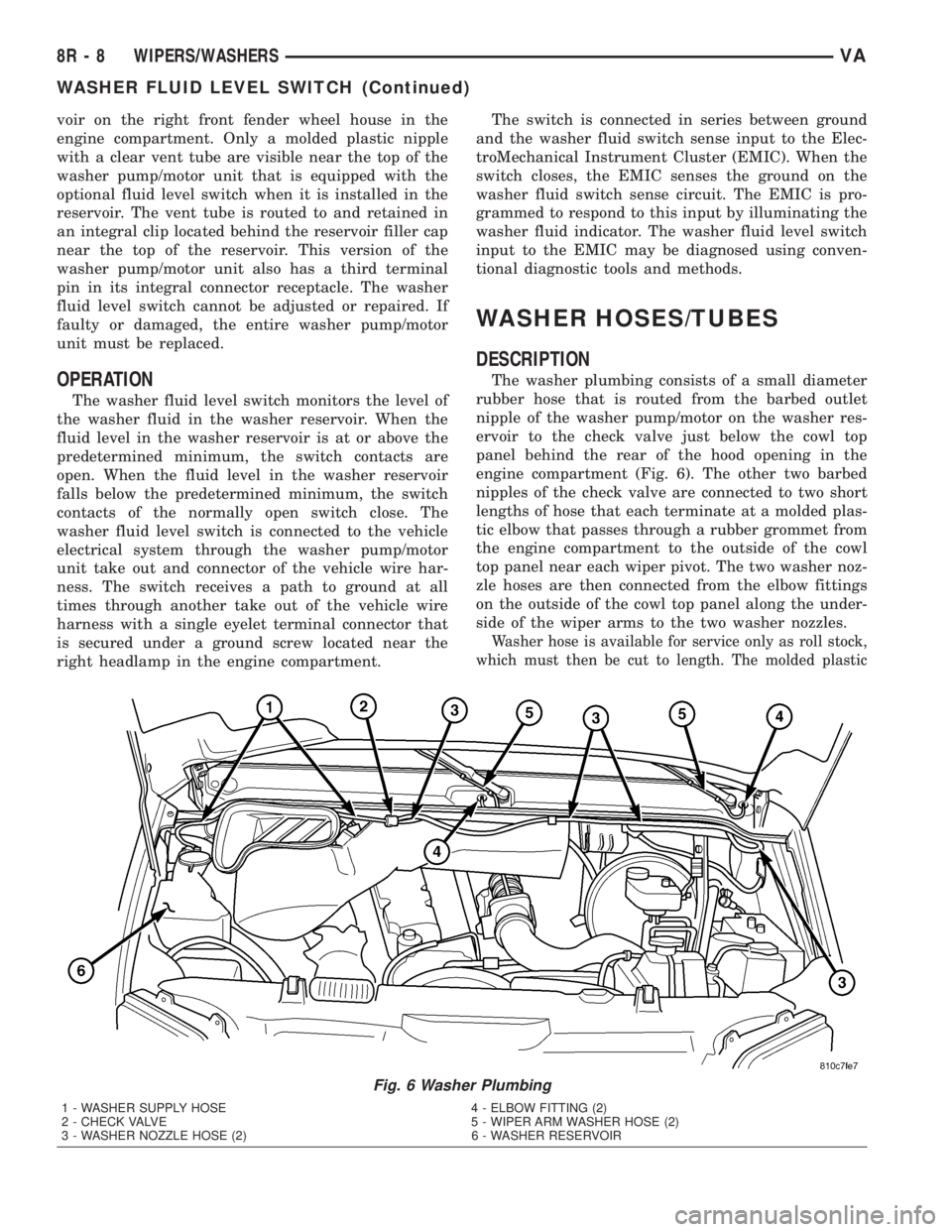

WASHER HOSES/TUBES

DESCRIPTION

The washer plumbing consists of a small diameter

rubber hose that is routed from the barbed outlet

nipple of the washer pump/motor on the washer res-

ervoir to the check valve just below the cowl top

panel behind the rear of the hood opening in the

engine compartment (Fig. 6). The other two barbed

nipples of the check valve are connected to two short

lengths of hose that each terminate at a molded plas-

tic elbow that passes through a rubber grommet from

the engine compartment to the outside of the cowl

top panel near each wiper pivot. The two washer noz-

zle hoses are then connected from the elbow fittings

on the outside of the cowl top panel along the under-

side of the wiper arms to the two washer nozzles.

Washer hose is available for service only as roll stock,

which must then be cut to length. The molded plastic

Fig. 6 Washer Plumbing

1 - WASHER SUPPLY HOSE 4 - ELBOW FITTING (2)

2 - CHECK VALVE 5 - WIPER ARM WASHER HOSE (2)

3 - WASHER NOZZLE HOSE (2) 6 - WASHER RESERVOIR

8R - 8 WIPERS/WASHERSVA

WASHER FLUID LEVEL SWITCH (Continued)

Page 311 of 1232

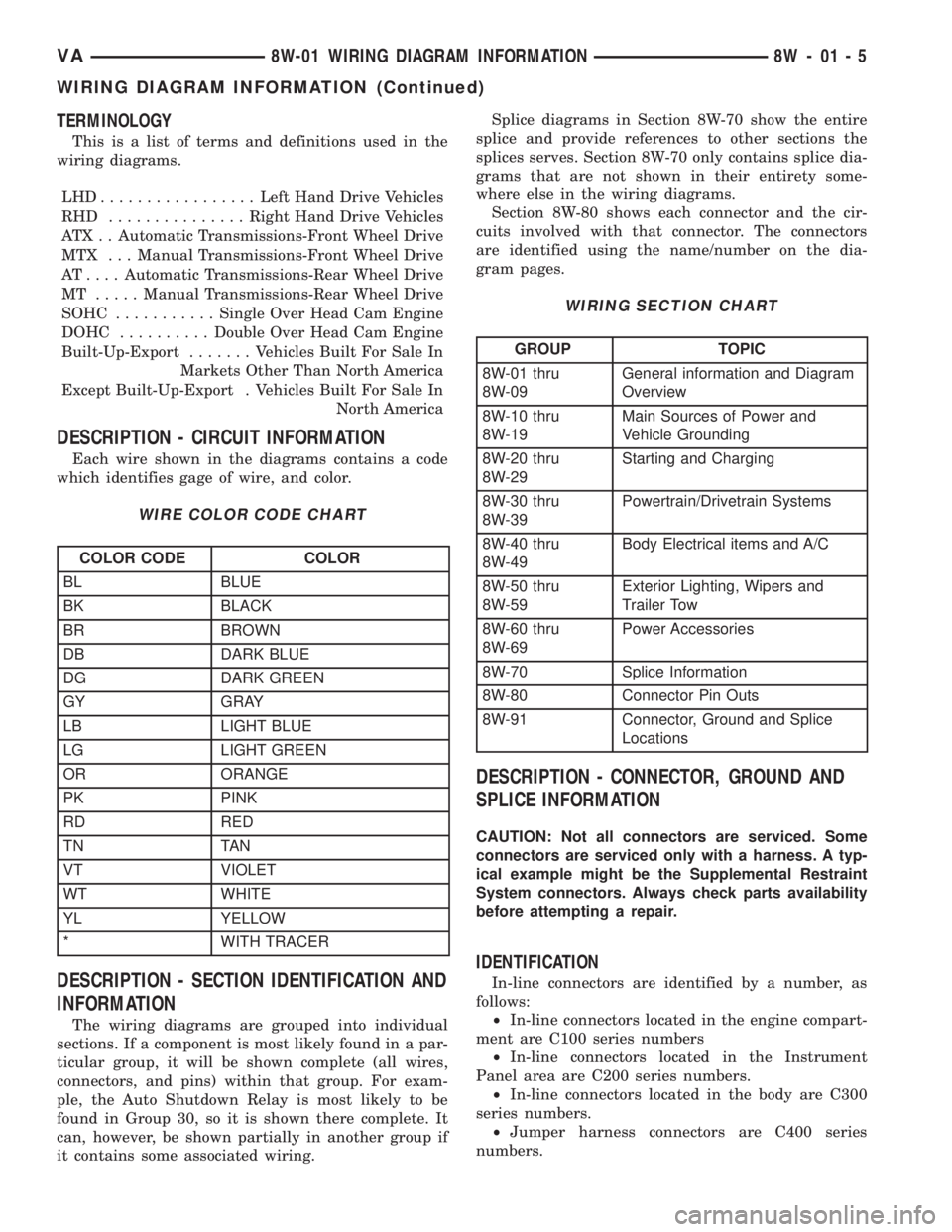

TERMINOLOGY

This is a list of terms and definitions used in the

wiring diagrams.

LHD.................Left Hand Drive Vehicles

RHD ...............Right Hand Drive Vehicles

ATX . . Automatic Transmissions-Front Wheel Drive

MTX . . . Manual Transmissions-Front Wheel Drive

AT....Automatic Transmissions-Rear Wheel Drive

MT .....Manual Transmissions-Rear Wheel Drive

SOHC...........Single Over Head Cam Engine

DOHC..........Double Over Head Cam Engine

Built-Up-Export....... Vehicles Built For Sale In

Markets Other Than North America

Except Built-Up-Export . Vehicles Built For Sale In

North America

DESCRIPTION - CIRCUIT INFORMATION

Each wire shown in the diagrams contains a code

which identifies gage of wire, and color.

WIRE COLOR CODE CHART

COLOR CODE COLOR

BL BLUE

BK BLACK

BR BROWN

DB DARK BLUE

DG DARK GREEN

GY GRAY

LB LIGHT BLUE

LG LIGHT GREEN

OR ORANGE

PK PINK

RD RED

TN TAN

VT VIOLET

WT WHITE

YL YELLOW

* WITH TRACER

DESCRIPTION - SECTION IDENTIFICATION AND

INFORMATION

The wiring diagrams are grouped into individual

sections. If a component is most likely found in a par-

ticular group, it will be shown complete (all wires,

connectors, and pins) within that group. For exam-

ple, the Auto Shutdown Relay is most likely to be

found in Group 30, so it is shown there complete. It

can, however, be shown partially in another group if

it contains some associated wiring.Splice diagrams in Section 8W-70 show the entire

splice and provide references to other sections the

splices serves. Section 8W-70 only contains splice dia-

grams that are not shown in their entirety some-

where else in the wiring diagrams.

Section 8W-80 shows each connector and the cir-

cuits involved with that connector. The connectors

are identified using the name/number on the dia-

gram pages.

WIRING SECTION CHART

GROUP TOPIC

8W-01 thru

8W-09General information and Diagram

Overview

8W-10 thru

8W-19Main Sources of Power and

Vehicle Grounding

8W-20 thru

8W-29Starting and Charging

8W-30 thru

8W-39Powertrain/Drivetrain Systems

8W-40 thru

8W-49Body Electrical items and A/C

8W-50 thru

8W-59Exterior Lighting, Wipers and

Trailer Tow

8W-60 thru

8W-69Power Accessories

8W-70 Splice Information

8W-80 Connector Pin Outs

8W-91 Connector, Ground and Splice

Locations

DESCRIPTION - CONNECTOR, GROUND AND

SPLICE INFORMATION

CAUTION: Not all connectors are serviced. Some

connectors are serviced only with a harness. A typ-

ical example might be the Supplemental Restraint

System connectors. Always check parts availability

before attempting a repair.

IDENTIFICATION

In-line connectors are identified by a number, as

follows:

²In-line connectors located in the engine compart-

ment are C100 series numbers

²In-line connectors located in the Instrument

Panel area are C200 series numbers.

²In-line connectors located in the body are C300

series numbers.

²Jumper harness connectors are C400 series

numbers.

VA8W-01 WIRING DIAGRAM INFORMATION 8W - 01 - 5

WIRING DIAGRAM INFORMATION (Continued)

Page 312 of 1232

²Grounds and ground connectors are identified

with a ªGº and follow the same series numbering as

the in-line connectors.

²Splices are identified with an ªSº and follow the

same series numbering as the in-line connectors.

²Component connectors are identified by the com-

ponent name instead of a number. Multiple connec-

tors on a component use a C1, C2, etc. identifier.

LOCATIONS

Section 8W-91 contains connector/ground/splice

location illustrations. The illustrations contain the

connector name (or number)/ground number/splice

number and component identification. Connector/

ground/splice location charts in section 8W-91 refer-

ence the figure numbers of the illustrations.

The abbreviation T/O is used in the component

location section to indicate a point in which the wir-

ing harness branches out to a component. The abbre-

viation N/S means Not Shown in the illustrations

WARNING

WARNINGS - GENERAL

WARNINGSprovide information to prevent per-

sonal injury and vehicle damage. Below is a list of

general warnings that should be followed any time a

vehicle is being serviced.

WARNING: ALWAYS WEAR SAFETY GLASSES FOR

EYE PROTECTION.

WARNING: USE SAFETY STANDS ANYTIME A PRO-

CEDURE REQUIRES BEING UNDER A VEHICLE.

WARNING: BE SURE THAT THE IGNITION SWITCH

ALWAYS IS IN THE OFF POSITION, UNLESS THE

PROCEDURE REQUIRES IT TO BE ON.

WARNING: SET THE PARKING BRAKE WHEN

WORKING ON ANY VEHICLE. AN AUTOMATIC

TRANSMISSION SHOULD BE IN PARK. A MANUAL

TRANSMISSION SHOULD BE IN NEUTRAL.

WARNING: OPERATE THE ENGINE ONLY IN A

WELL-VENTILATED AREA.

WARNING: KEEP AWAY FROM MOVING PARTS

WHEN THE ENGINE IS RUNNING, ESPECIALLY THE

FAN AND BELTS.WARNING: TO PREVENT SERIOUS BURNS, AVOID

CONTACT WITH HOT PARTS SUCH AS THE RADIA-

TOR, EXHAUST MANIFOLD(S), TAIL PIPE, CATA-

LYTIC CONVERTER AND MUFFLER.

WARNING: DO NOT ALLOW FLAME OR SPARKS

NEAR THE BATTERY. GASES ARE ALWAYS

PRESENT IN AND AROUND THE BATTERY.

WARNING: ALWAYS REMOVE RINGS, WATCHES,

LOOSE HANGING JEWELRY AND AVOID LOOSE

CLOTHING.

DIAGNOSIS AND TESTING - WIRING HARNESS

TROUBLESHOOTING TOOLS

When diagnosing a problem in an electrical circuit

there are several common tools necessary. These tools

are listed and explained below.

²Jumper Wire - This is a test wire used to con-

nect two points of a circuit. It can be used to bypass

an open in a circuit.

WARNING: NEVER USE A JUMPER WIRE ACROSS

A LOAD, SUCH AS A MOTOR, CONNECTED

BETWEEN A BATTERY FEED AND GROUND.

²Voltmeter - Used to check for voltage on a cir-

cuit. Always connect the black lead to a known good

ground and the red lead to the positive side of the

circuit.

CAUTION: Most of the electrical components used

in today's vehicles are Solid State. When checking

voltages in these circuits, use a meter with a 10 -

megohm or greater impedance rating.

²Ohmmeter - Used to check the resistance

between two points of a circuit. Low or no resistance

in a circuit means good continuity.

CAUTION: Most of the electrical components used

in today's vehicles are Solid State. When checking

resistance in these circuits use a meter with a 10 -

megohm or greater impedance rating. In addition,

make sure the power is disconnected from the cir-

cuit. Circuits that are powered up by the vehicle's

electrical system can cause damage to the equip-

ment and provide false readings.

8W - 01 - 6 8W-01 WIRING DIAGRAM INFORMATIONVA

WIRING DIAGRAM INFORMATION (Continued)

Page 739 of 1232

ENGINE

TABLE OF CONTENTS

page page

ENGINE

DESCRIPTION..........................2

STANDARD PROCEDURE

STANDARD PROCEDURE - COMPRESSION

TESTING ENGINE......................3

STANDARD PROCEDURE - CYLINDER

LEAK DOWN TEST.....................3

STANDARD PROCEDURE - DETERMINING

CYLINDER PRESSURE LOSS.............4

REMOVAL

REMOVAL - ENGINE COVER.............4

REMOVAL............................4

INSTALLATION

INSTALLATION - ENGINE COVER..........7

INSTALLATION........................7

SPECIFICATIONS - TORQUE

SPECIFICATIONS......................8

SPECIAL TOOLS.......................14

AIR CLEANER ELEMENT

REMOVAL.............................20

INSTALLATION.........................20

AIR CLEANER HOUSING

REMOVAL.............................20

INSTALLATION.........................20

CYLINDER HEAD

STANDARD PROCEDURE

STANDARD PROCEDURE - CYLINDER

HEAD BOLT INSPECTION...............21

STANDARD PROCEDURE - MEASURE

CYLINDER HEAD SURFACE.............21

REMOVAL

REMOVAL - CYLINDER HEAD............22

REMOVAL - CYLINDER HEAD FRONT

COVER.............................23

REMOVAL - CYLINDER HEAD GUIDE RAIL . . 24

INSTALLATION

INSTALLATION - CYLINDER HEAD........25

INSTALLATION - CYLINDER HEAD FRONT

COVER.............................26

INSTALLATION - CYLINDER HEAD GUIDE

RAIL...............................26

CAMSHAFT(S)

STANDARD PROCEDURE - CHECKING

CAMSHAFT POSITION.................27

REMOVAL.............................28

INSTALLATION.........................29

CYLINDER HEAD COVER(S)

REMOVAL.............................30

INSTALLATION.........................30VALVE SPRINGS

REMOVAL

REMOVAL - VALVE SPRINGS............31

REMOVAL - VALVES...................31

INSTALLATION

INSTALLATION - VALVE SPRINGS........32

INSTALLATION - VALVES...............33

ENGINE BLOCK

STANDARD PROCEDURE

STANDARD PROCEDURE - REPLACING

ENGINE CORE AND OIL GALLERY PLUGS . . 34

STANDARD PROCEDURE - MEASURING

CYLINDER BORES....................34

CRANKSHAFT

STANDARD PROCEDURE - MEASURE

CRANKSHAFT AND BLOCK JOURNALS....35

REMOVAL.............................35

INSTALLATION.........................36

CRANKSHAFT OIL SEAL - REAR

REMOVAL.............................37

INSTALLATION.........................37

CRANKSHAFT OIL SEAL - FRONT

REMOVAL.............................38

INSTALLATION.........................38

FLYWHEEL

REMOVAL.............................39

INSTALLATION

INSTALLATION.......................39

INSTALLATION.......................39

PISTON & CONNECTING ROD

DESCRIPTION.........................40

STANDARD PROCEDURE

STANDARD PROCEDURE - CHECKING AND

REPAIRING CONNECTING RODS.........40

STANDARD PROCEDURE - MEASURING

PISTON PROTRUSION.................42

REMOVAL.............................42

INSTALLATION.........................43

PISTON RINGS

STANDARD PROCEDURE - PISTON RING

FITTING.............................46

VIBRATION DAMPER

REMOVAL.............................47

INSTALLATION.........................48

VACUUM PUMP

DESCRIPTION.........................48

OPERATION...........................48

REMOVAL.............................48

INSTALLATION.........................49

VAENGINE 9 - 1