engine MERCEDES-BENZ SPRINTER 2005 Service Repair Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 1160 of 1232

(2) If servicing the driver side air outlets, remove

the instrument cluster bezel (Refer to 23 - BODY/IN-

STRUMENT PANEL/CLUSTER BEZEL - REMOV-

AL).

(3) If servicing the passenger side air outlets,

remove the passenger side airbag (Refer to 8 - ELEC-

TRICAL/RESTRAINTS/PASSENGER AIRBAG -

REMOVAL).

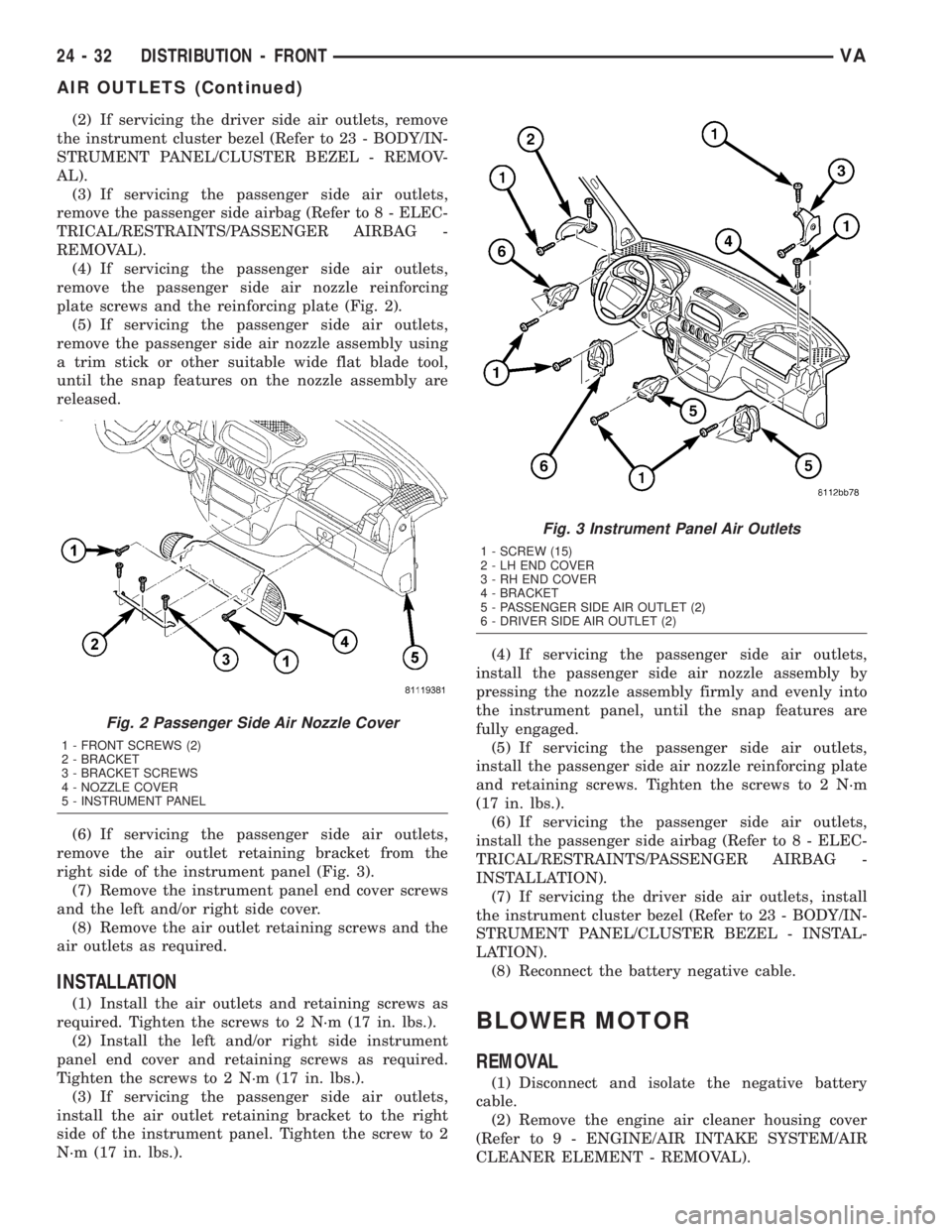

(4) If servicing the passenger side air outlets,

remove the passenger side air nozzle reinforcing

plate screws and the reinforcing plate (Fig. 2).

(5) If servicing the passenger side air outlets,

remove the passenger side air nozzle assembly using

a trim stick or other suitable wide flat blade tool,

until the snap features on the nozzle assembly are

released.

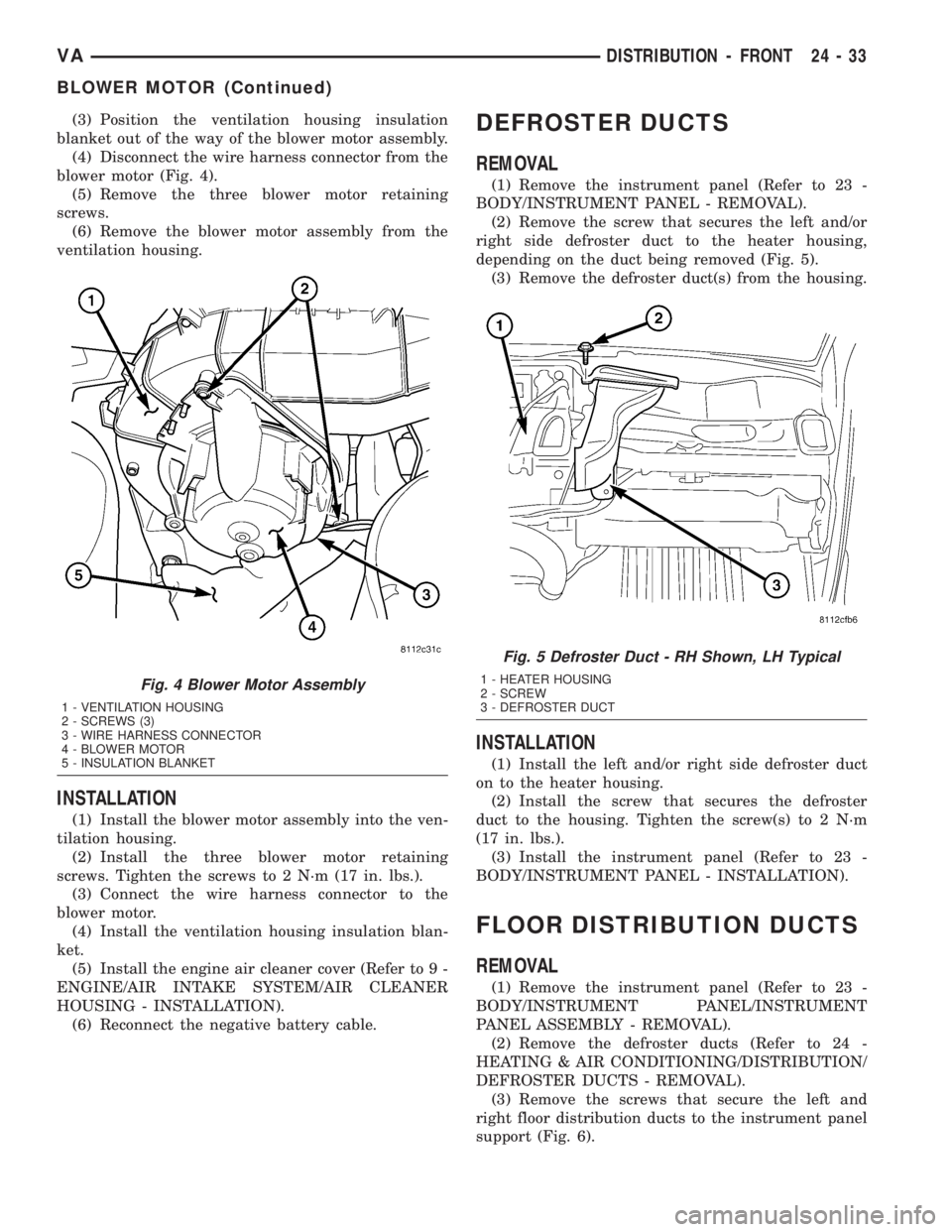

(6) If servicing the passenger side air outlets,

remove the air outlet retaining bracket from the

right side of the instrument panel (Fig. 3).

(7) Remove the instrument panel end cover screws

and the left and/or right side cover.

(8) Remove the air outlet retaining screws and the

air outlets as required.

INSTALLATION

(1) Install the air outlets and retaining screws as

required. Tighten the screws to 2 N´m (17 in. lbs.).

(2) Install the left and/or right side instrument

panel end cover and retaining screws as required.

Tighten the screws to 2 N´m (17 in. lbs.).

(3) If servicing the passenger side air outlets,

install the air outlet retaining bracket to the right

side of the instrument panel. Tighten the screw to 2

N´m (17 in. lbs.).(4) If servicing the passenger side air outlets,

install the passenger side air nozzle assembly by

pressing the nozzle assembly firmly and evenly into

the instrument panel, until the snap features are

fully engaged.

(5) If servicing the passenger side air outlets,

install the passenger side air nozzle reinforcing plate

and retaining screws. Tighten the screws to 2 N´m

(17 in. lbs.).

(6) If servicing the passenger side air outlets,

install the passenger side airbag (Refer to 8 - ELEC-

TRICAL/RESTRAINTS/PASSENGER AIRBAG -

INSTALLATION).

(7) If servicing the driver side air outlets, install

the instrument cluster bezel (Refer to 23 - BODY/IN-

STRUMENT PANEL/CLUSTER BEZEL - INSTAL-

LATION).

(8) Reconnect the battery negative cable.

BLOWER MOTOR

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the engine air cleaner housing cover

(Refer to 9 - ENGINE/AIR INTAKE SYSTEM/AIR

CLEANER ELEMENT - REMOVAL).

Fig. 2 Passenger Side Air Nozzle Cover

1 - FRONT SCREWS (2)

2 - BRACKET

3 - BRACKET SCREWS

4 - NOZZLE COVER

5 - INSTRUMENT PANEL

Fig. 3 Instrument Panel Air Outlets

1 - SCREW (15)

2 - LH END COVER

3 - RH END COVER

4 - BRACKET

5 - PASSENGER SIDE AIR OUTLET (2)

6 - DRIVER SIDE AIR OUTLET (2)

24 - 32 DISTRIBUTION - FRONTVA

AIR OUTLETS (Continued)

Page 1161 of 1232

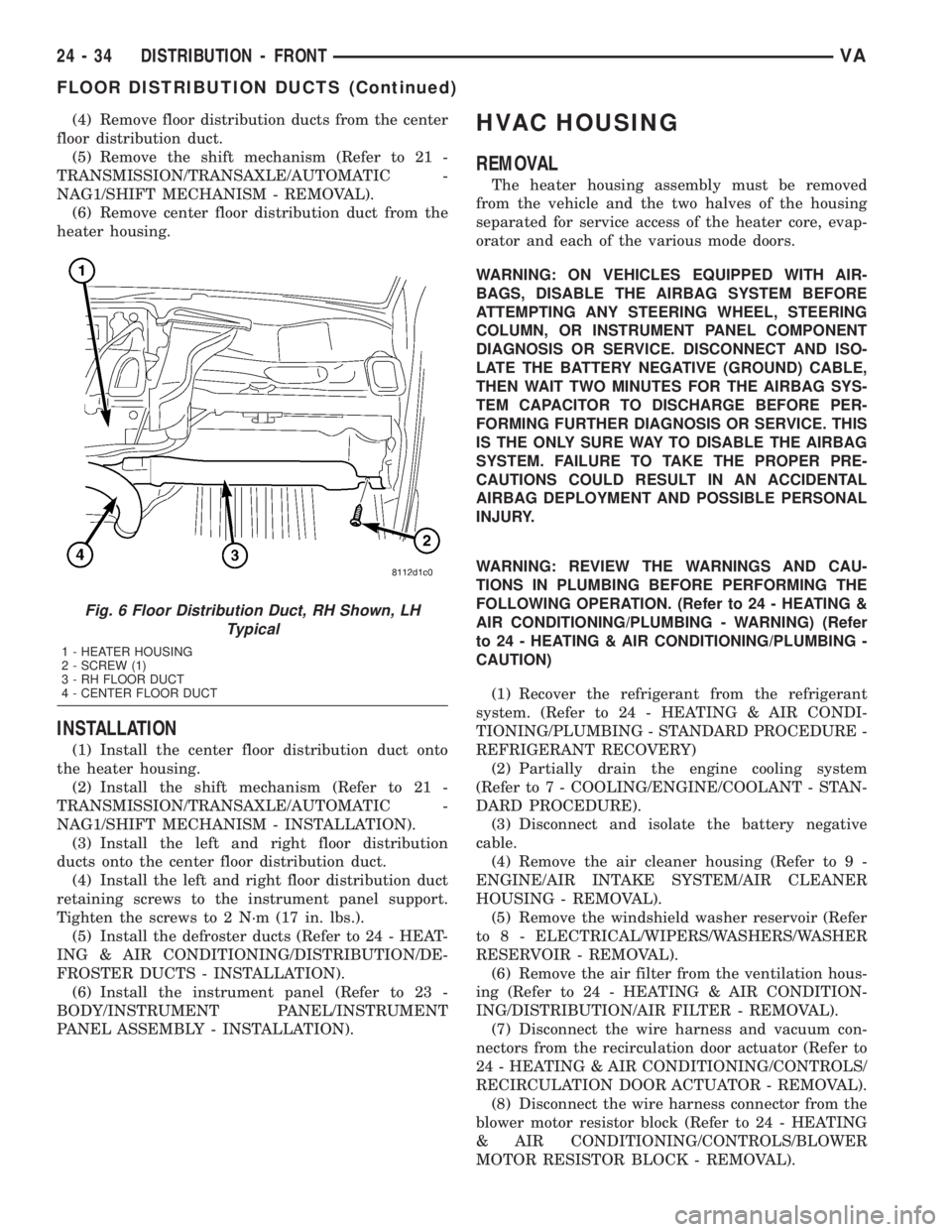

(3) Position the ventilation housing insulation

blanket out of the way of the blower motor assembly.

(4) Disconnect the wire harness connector from the

blower motor (Fig. 4).

(5) Remove the three blower motor retaining

screws.

(6) Remove the blower motor assembly from the

ventilation housing.

INSTALLATION

(1) Install the blower motor assembly into the ven-

tilation housing.

(2) Install the three blower motor retaining

screws. Tighten the screws to 2 N´m (17 in. lbs.).

(3) Connect the wire harness connector to the

blower motor.

(4) Install the ventilation housing insulation blan-

ket.

(5) Install the engine air cleaner cover (Refer to 9 -

ENGINE/AIR INTAKE SYSTEM/AIR CLEANER

HOUSING - INSTALLATION).

(6) Reconnect the negative battery cable.

DEFROSTER DUCTS

REMOVAL

(1) Remove the instrument panel (Refer to 23 -

BODY/INSTRUMENT PANEL - REMOVAL).

(2) Remove the screw that secures the left and/or

right side defroster duct to the heater housing,

depending on the duct being removed (Fig. 5).

(3) Remove the defroster duct(s) from the housing.

INSTALLATION

(1) Install the left and/or right side defroster duct

on to the heater housing.

(2) Install the screw that secures the defroster

duct to the housing. Tighten the screw(s) to 2 N´m

(17 in. lbs.).

(3) Install the instrument panel (Refer to 23 -

BODY/INSTRUMENT PANEL - INSTALLATION).

FLOOR DISTRIBUTION DUCTS

REMOVAL

(1) Remove the instrument panel (Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL ASSEMBLY - REMOVAL).

(2) Remove the defroster ducts (Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

DEFROSTER DUCTS - REMOVAL).

(3) Remove the screws that secure the left and

right floor distribution ducts to the instrument panel

support (Fig. 6).

Fig. 4 Blower Motor Assembly

1 - VENTILATION HOUSING

2 - SCREWS (3)

3 - WIRE HARNESS CONNECTOR

4 - BLOWER MOTOR

5 - INSULATION BLANKET

Fig. 5 Defroster Duct - RH Shown, LH Typical

1 - HEATER HOUSING

2 - SCREW

3 - DEFROSTER DUCT

VADISTRIBUTION - FRONT 24 - 33

BLOWER MOTOR (Continued)

Page 1162 of 1232

(4) Remove floor distribution ducts from the center

floor distribution duct.

(5) Remove the shift mechanism (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC -

NAG1/SHIFT MECHANISM - REMOVAL).

(6) Remove center floor distribution duct from the

heater housing.

INSTALLATION

(1) Install the center floor distribution duct onto

the heater housing.

(2) Install the shift mechanism (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC -

NAG1/SHIFT MECHANISM - INSTALLATION).

(3) Install the left and right floor distribution

ducts onto the center floor distribution duct.

(4) Install the left and right floor distribution duct

retaining screws to the instrument panel support.

Tighten the screws to 2 N´m (17 in. lbs.).

(5) Install the defroster ducts (Refer to 24 - HEAT-

ING & AIR CONDITIONING/DISTRIBUTION/DE-

FROSTER DUCTS - INSTALLATION).

(6) Install the instrument panel (Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL ASSEMBLY - INSTALLATION).

HVAC HOUSING

REMOVAL

The heater housing assembly must be removed

from the vehicle and the two halves of the housing

separated for service access of the heater core, evap-

orator and each of the various mode doors.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN PLUMBING BEFORE PERFORMING THE

FOLLOWING OPERATION. (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - WARNING) (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

CAUTION)

(1) Recover the refrigerant from the refrigerant

system. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY)

(2) Partially drain the engine cooling system

(Refer to 7 - COOLING/ENGINE/COOLANT - STAN-

DARD PROCEDURE).

(3) Disconnect and isolate the battery negative

cable.

(4) Remove the air cleaner housing (Refer to 9 -

ENGINE/AIR INTAKE SYSTEM/AIR CLEANER

HOUSING - REMOVAL).

(5) Remove the windshield washer reservoir (Refer

to 8 - ELECTRICAL/WIPERS/WASHERS/WASHER

RESERVOIR - REMOVAL).

(6) Remove the air filter from the ventilation hous-

ing (Refer to 24 - HEATING & AIR CONDITION-

ING/DISTRIBUTION/AIR FILTER - REMOVAL).

(7) Disconnect the wire harness and vacuum con-

nectors from the recirculation door actuator (Refer to

24 - HEATING & AIR CONDITIONING/CONTROLS/

RECIRCULATION DOOR ACTUATOR - REMOVAL).

(8) Disconnect the wire harness connector from the

blower motor resistor block (Refer to 24 - HEATING

& AIR CONDITIONING/CONTROLS/BLOWER

MOTOR RESISTOR BLOCK - REMOVAL).

Fig. 6 Floor Distribution Duct, RH Shown, LH

Typical

1 - HEATER HOUSING

2 - SCREW (1)

3 - RH FLOOR DUCT

4 - CENTER FLOOR DUCT

24 - 34 DISTRIBUTION - FRONTVA

FLOOR DISTRIBUTION DUCTS (Continued)

Page 1164 of 1232

DISASSEMBLY

(1) Remove the heater and ventilation housings

from the vehicle (Refer to 24 - HEATING & AIR

CONDITIONING/DISTRIBUTION/HVAC HOUSING

- REMOVAL).

(2) Place the heater housing in the upright posi-

tion on a work bench, making allowance for leakage

of fluids.

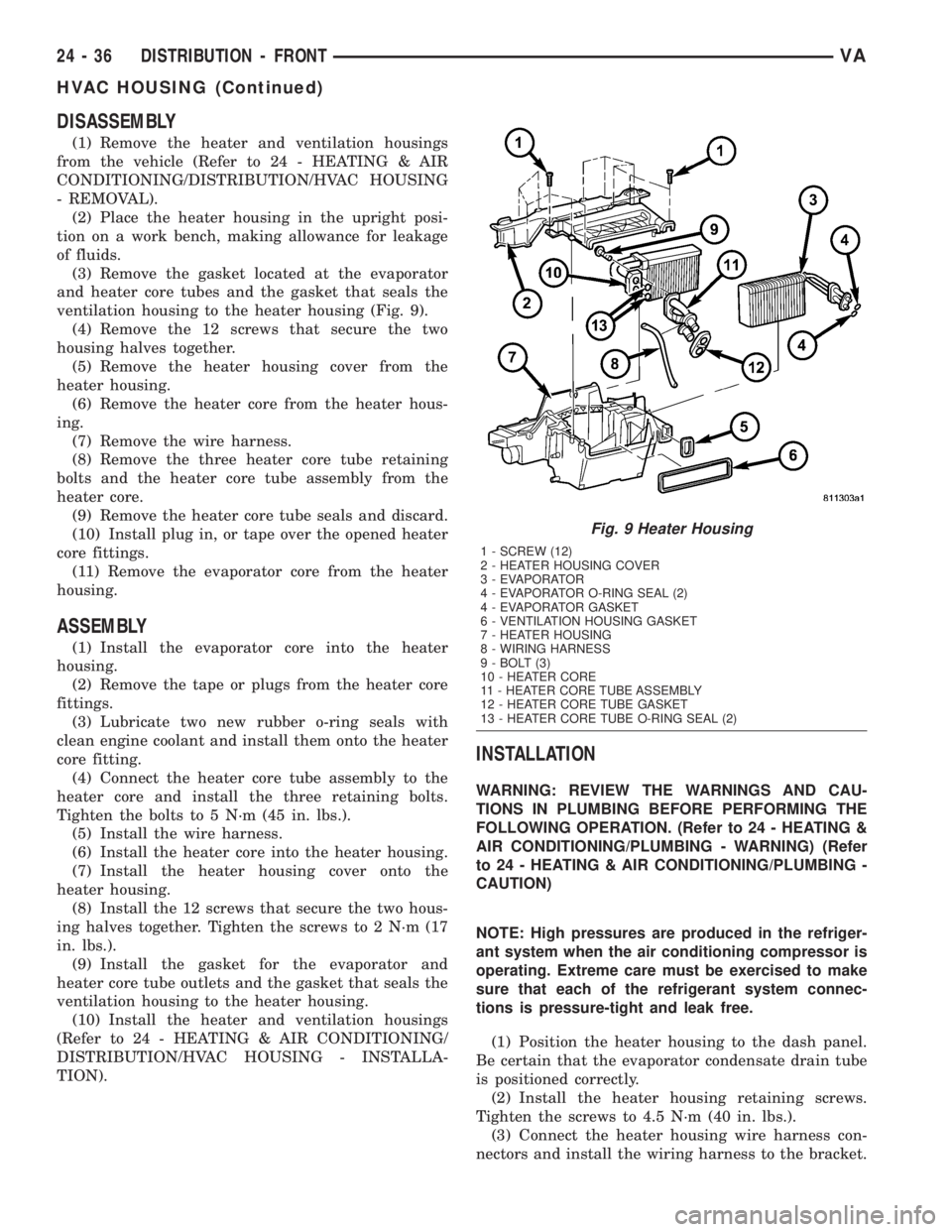

(3) Remove the gasket located at the evaporator

and heater core tubes and the gasket that seals the

ventilation housing to the heater housing (Fig. 9).

(4) Remove the 12 screws that secure the two

housing halves together.

(5) Remove the heater housing cover from the

heater housing.

(6) Remove the heater core from the heater hous-

ing.

(7) Remove the wire harness.

(8) Remove the three heater core tube retaining

bolts and the heater core tube assembly from the

heater core.

(9) Remove the heater core tube seals and discard.

(10) Install plug in, or tape over the opened heater

core fittings.

(11) Remove the evaporator core from the heater

housing.

ASSEMBLY

(1) Install the evaporator core into the heater

housing.

(2) Remove the tape or plugs from the heater core

fittings.

(3) Lubricate two new rubber o-ring seals with

clean engine coolant and install them onto the heater

core fitting.

(4) Connect the heater core tube assembly to the

heater core and install the three retaining bolts.

Tighten the bolts to 5 N´m (45 in. lbs.).

(5) Install the wire harness.

(6) Install the heater core into the heater housing.

(7) Install the heater housing cover onto the

heater housing.

(8) Install the 12 screws that secure the two hous-

ing halves together. Tighten the screws to 2 N´m (17

in. lbs.).

(9) Install the gasket for the evaporator and

heater core tube outlets and the gasket that seals the

ventilation housing to the heater housing.

(10) Install the heater and ventilation housings

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - INSTALLA-

TION).

INSTALLATION

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN PLUMBING BEFORE PERFORMING THE

FOLLOWING OPERATION. (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - WARNING) (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

CAUTION)

NOTE: High pressures are produced in the refriger-

ant system when the air conditioning compressor is

operating. Extreme care must be exercised to make

sure that each of the refrigerant system connec-

tions is pressure-tight and leak free.

(1) Position the heater housing to the dash panel.

Be certain that the evaporator condensate drain tube

is positioned correctly.

(2) Install the heater housing retaining screws.

Tighten the screws to 4.5 N´m (40 in. lbs.).

(3) Connect the heater housing wire harness con-

nectors and install the wiring harness to the bracket.

Fig. 9 Heater Housing

1 - SCREW (12)

2 - HEATER HOUSING COVER

3 - EVAPORATOR

4 - EVAPORATOR O-RING SEAL (2)

4 - EVAPORATOR GASKET

6 - VENTILATION HOUSING GASKET

7 - HEATER HOUSING

8 - WIRING HARNESS

9 - BOLT (3)

10 - HEATER CORE

11 - HEATER CORE TUBE ASSEMBLY

12 - HEATER CORE TUBE GASKET

13 - HEATER CORE TUBE O-RING SEAL (2)

24 - 36 DISTRIBUTION - FRONTVA

HVAC HOUSING (Continued)

Page 1165 of 1232

(4) Connect the heater-A/C control cables to the

mode door levers (Refer to 24 - HEATING & AIR

CONDITIONING/CONTROLS/MODE DOOR CABLE

- INSTALLATION).

(5) Reinstall the passenger airbag bracket (Refer

to 8 - ELECTRICAL/RESTRAINTS/PASSENGER

AIRBAG - INSTALLATION).

(6) Reconnect the two bulkhead ground connection

near the instrument cluster area.

(7) Reinstall the defroster, floor distribution and

instrument panel ducts.

(8) Reinstall the instrument panel (Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL ASSEMBLY - INSTALLATION).

(9) Unplug or remove the tape from the opened

refrigerant line fittings.

(10) Lubricate two new rubber o-ring seals with

clean refrigerant oil and install them onto the evap-

orator core fittings.

(11) Connect the refrigerant line terminal block to

the evaporator tubes.

(12) Install the two bolts that secure the refriger-

ant line terminal block to the evaporator. Tighten the

bolts to 5 N´m (45 in. lbs.).

(13) Unplug or remove the tape from the heater

core hoses and tubes.

(14) Connect the heater hoses to the heater core

tubes and install the heater hose clamps.

(15) Install the ventilation housing to the dash

panel.

(16) Install the nuts and washers that secure the

ventilation housing to the dash panel. Tighten the

nuts to 5 N´m (45 in. lbs.).

(17) Connect the wire harness connectors to the

blower motor, blower motor resistor block and the

recirculation door actuator.

(18) Connect the vacuum harness connector to the

recirculation door actuator.

(19) Install the air filter into the ventilation hous-

ing (Refer to 24 - HEATING & AIR CONDITION-

ING/DISTRIBUTION/AIR FILTER -

INSTALLATION).

(20) Install the windshield washer reservoir (Refer

to 8 - ELECTRICAL/WIPERS/WASHERS/WASHER

RESERVOIR - INSTALLATION).

(21) Install the air cleaner housing (Refer to 9 -

ENGINE/AIR INTAKE SYSTEM/AIR CLEANER

HOUSING - INSTALLATION).

(22) Reconnect the battery negative cable.

(23) Refill the engine cooling system (Refer to 7 -

COOLING/ENGINE/COOLANT - STANDARD PRO-

CEDURE).

(24) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE).(25) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE).

(26) Start the engine and check for proper opera-

tion of the heating and air conditioning systems.

INSTRUMENT PANEL DUCTS

REMOVAL

(1) Remove the instrument panel (Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL ASSEMBLY - REMOVAL).

(2) Remove the defroster ducts (Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

DEFROSTER DUCTS - REMOVAL).

(3) Remove the floor distribution ducts (Refer to 24

- HEATING & AIR CONDITIONING/DISTRIBU-

TION/FLOOR DISTRIBUTION DUCTS - REMOV-

AL).

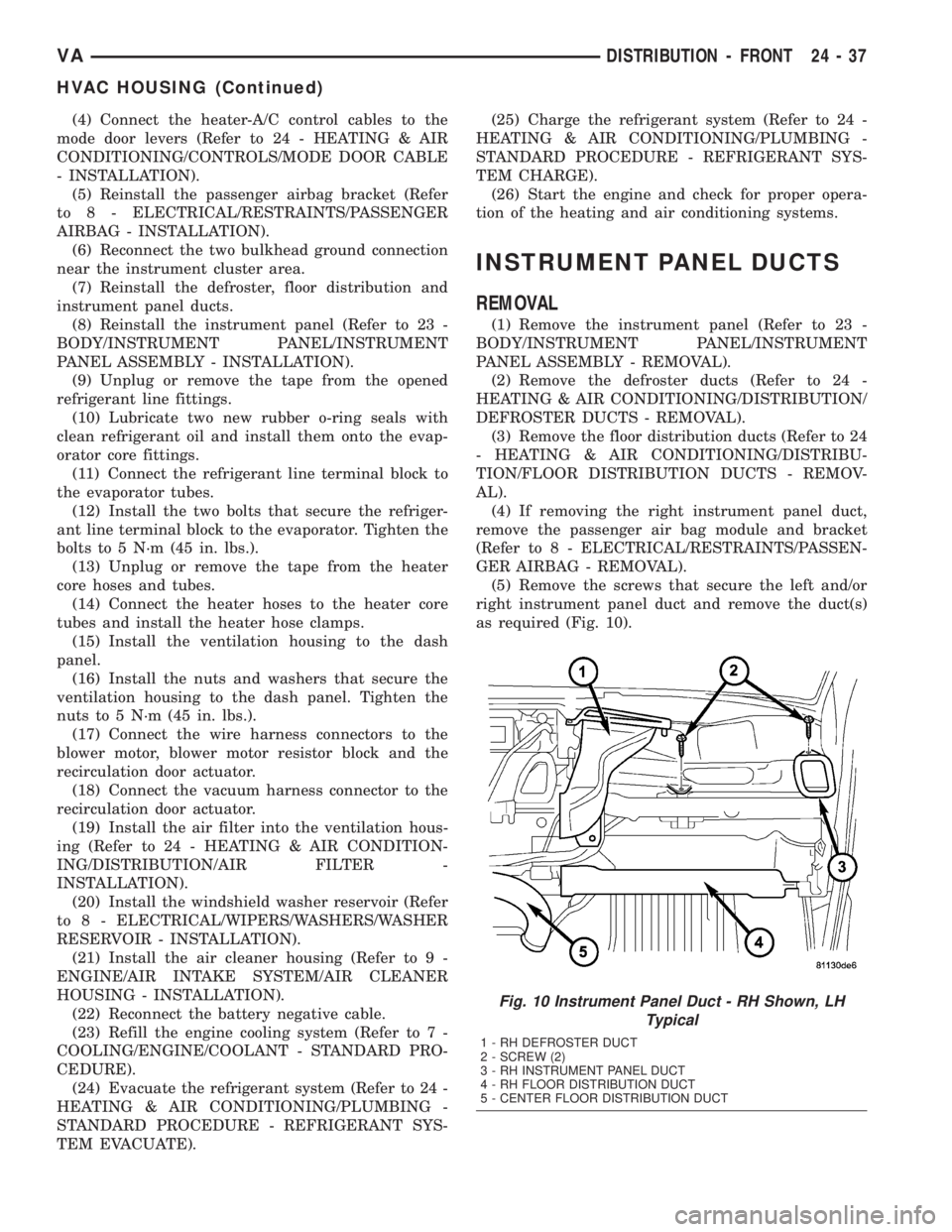

(4) If removing the right instrument panel duct,

remove the passenger air bag module and bracket

(Refer to 8 - ELECTRICAL/RESTRAINTS/PASSEN-

GER AIRBAG - REMOVAL).

(5) Remove the screws that secure the left and/or

right instrument panel duct and remove the duct(s)

as required (Fig. 10).

Fig. 10 Instrument Panel Duct - RH Shown, LH

Typical

1 - RH DEFROSTER DUCT

2 - SCREW (2)

3 - RH INSTRUMENT PANEL DUCT

4 - RH FLOOR DISTRIBUTION DUCT

5 - CENTER FLOOR DISTRIBUTION DUCT

VADISTRIBUTION - FRONT 24 - 37

HVAC HOUSING (Continued)

Page 1174 of 1232

When it is necessary to open the refrigerant sys-

tem, have everything needed to service the system

ready. The refrigerant system should not be left open

to the atmosphere any longer than necessary. Cap or

plug all lines and fittings as soon as they are opened

to prevent the entrance of dirt and moisture. All lines

and components in parts stock should be capped or

sealed until they are to be installed.

All tools, including the refrigerant recycling equip-

ment, the manifold gauge set, and test hoses should

be kept clean and dry. All tools and equipment must

be designed for R-134a refrigerant.

DIAGNOSIS AND TESTING - REFRIGERANT

SYSTEM LEAKS

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

If the air conditioning system is not cooling prop-

erly, determine if the refrigerant system is fully-

charged. (Refer to 24 - HEATING & AIR

CONDITIONING - DIAGNOSIS AND TESTING -

A/C PERFORMANCE)

An electronic leak detector designed for R-134a

refrigerant is recommended for locating and confirm-

ing refrigerant system leaks. Refer to the operating

instructions supplied by the equipment manufacturer

for proper care and use of this equipment.

An oily residue on or near refrigerant system lines,

connector fittings, components, or component seals

can indicate the general location of a possible refrig-

erant leak. However, the exact leak location should

be confirmed with an electronic leak detector prior to

component repair or replacement.

To detect a leak in the refrigerant system, perform

one of the following procedures:

SYSTEM EMPTY

(1) Evacuate the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE)

(2) Connect and dispense 0.283 kilograms (0.625

pounds or 10 ounces) of R-134a refrigerant into the

evacuated refrigerant system. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - STAN-

DARD PROCEDURE - REFRIGERANT SYSTEM

CHARGE)

(3) Position the vehicle in a wind-free work area.

This will aid in detecting small leaks.(4) With the engine not running, use a electronic

R-134a leak detector and search for leaks. Because

R-134a refrigerant is heavier than air, the leak detec-

tor probe should be moved slowly along the bottom

side of all refrigerant lines, connector fittings and

components.

(5) To inspect the evaporator coil for leaks, insert

the electronic leak detector probe into the center

instrument panel outlet. Set the blower motor switch

to the lowest speed position, the A/C button in the

On position, and select the Recirculation Mode.

SYSTEM LOW

(1) Position the vehicle in a wind-free work area.

This will aid in detecting small leaks.

(2) Bring the refrigerant system up to operating

temperature and pressure. This is done by allowing

the engine to run with the air conditioning system

turned on for five minutes.

(3) With the engine not running, use a electronic

R-134a leak detector and search for leaks. Because

R-134a refrigerant is heavier than air, the leak detec-

tor probe should be moved slowly along the bottom

side of all refrigerant lines, connector fittings and

components.

(4) To inspect the evaporator coil for leaks, insert

the electronic leak detector probe into the center

instrument panel outlet. Set the blower motor switch

to the lowest speed position, the A/C button in the

On position, and select the Recirculation Mode.

STANDARD PROCEDURE

STANDARD PROCEDURE - REFRIGERANT

SYSTEM SERVICE EQUIPMENT

WARNING: EYE PROTECTION MUST BE WORN

WHEN SERVICING AN AIR CONDITIONING REFRIG-

ERANT SYSTEM. TURN OFF (ROTATE CLOCKWISE)

ALL VALVES ON THE EQUIPMENT BEING USED,

BEFORE CONNECTING TO OR DISCONNECTING

FROM THE REFRIGERANT SYSTEM. FAILURE TO

OBSERVE THESE WARNINGS MAY RESULT IN PER-

SONAL INJURY.

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

24 - 46 PLUMBINGVA

PLUMBING (Continued)

Page 1176 of 1232

(2) Open the low and high side valves and start

the charging station vacuum pump. When the suc-

tion gauge reads 88 kPa (26 in. Hg.) vacuum or

greater, close all of the valves and turn off the vac-

uum pump.

(a) If the refrigerant system fails to reach the

specified vacuum, the system has a leak that must

be corrected. (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - DIAGNOSIS AND

TESTING - REFRIGERANT SYSTEM LEAKS)

(b) If the refrigerant system maintains the spec-

ified vacuum for five minutes, restart the vacuum

pump, open the suction and discharge valves and

evacuate the system for an additional ten minutes.

(3) Close all of the valves, and turn off the charg-

ing station vacuum pump.

(4) The refrigerant system is now ready to be

charged with R-134a refrigerant. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE)

STANDARD PROCEDURE - REFRIGERANT

SYSTEM CHARGE

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

CAUTION: A small amount of refrigerant oil is

removed from the A/C system each time the refrig-

erant system is recovered and evacuated. Before

charging the A/C system, you MUST replenish any

oil lost during the recovery process. Refer the

equipment manufacturer instructions for more infor-

mation.

After the refrigerant system has been tested for

leaks and evacuated, a refrigerant charge can be

injected into the system. (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - SPECIFICA-

TIONS - CHARGE CAPACITY)

A R-134a refrigerant recovery/recycling/charging

station that meets SAE Standard J2210 must be

used to charge the refrigerant system with R-134a

refrigerant. Refer to the operating instructions sup-

plied by the equipment manufacturer for proper care

and use of this equipment.

PARTIAL CHARGE METHOD

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

The partial charge method is used to add a partial

charge to a refrigerant system that is low on refrig-

erant. To perform this procedure the evaporator inlet

and outlet tube temperatures are measured. The

temperature difference is measured with a tempera-

ture meter with one or two clamp-on thermocouple

probes. The difference between the evaporator inlet

and outlet tube temperatures will determine the

amount of refrigerant needed.

Before adding a partial refrigerant charge, check

for refrigerant system leaks. (Refer to 24 - HEATING

& AIR CONDITIONING/PLUMBING - DIAGNOSIS

AND TESTING - REFRIGERANT SYSTEM LEAKS)

If a leak is found, make the necessary repairs before

attempting a full or partial refrigerant charge.

(1) Attach a manifold gauge set to the refrigerant

system service ports.

(2) Attach the two clamp-on thermocouple probes

to the inlet and outlet tubes of the evaporator coil.

²If a single thermocouple probe is used, attach

the probe to the evaporator inlet tube just before the

collar of the refrigerant line connector fitting. The

probe must make contact with the bottom surface of

the evaporator inlet tube.

²If dual thermocouple probes are used, attach

probe 1 to the evaporator inlet tube, and probe 2 to

the evaporator outlet tube. Attach both probes to the

evaporator tubes just before the collar of the refrig-

erant line connector fittings. The probes must make

contact with the bottom surfaces of the evaporator

inlet and outlet tubes.

(3) Open all of the windows or doors of the passen-

ger compartment.

(4) Set the A/C button on the A/C Heater controls

to the on position, the temperature control knob in

the full cool position, select Recirculation Mode, and

place the blower motor switch in the highest speed

position.

(5) Start the engine and hold the engine idle speed

at 1,000 rpm. Allow the engine to warm up to normal

operating temperature.

(6) The compressor clutch may cycle, depending

upon ambient temperature, humidity, and the refrig-

erant system charge level.

(7) Hold the engine idle speed at 1,000 rpm.

(8) Allow three to five minutes for the refrigerant

system to stabilize, then record the temperatures of

the evaporator inlet and outlet tubes.

24 - 48 PLUMBINGVA

PLUMBING (Continued)

Page 1177 of 1232

²If a single probe is used, record the temperature

of the evaporator inlet tube. Then remove the probe

from the inlet tube and attach it to the evaporator

outlet tube just before the collar of the refrigerant

line connector fitting. The probe must make contact

with the bottom surface of the evaporator outlet tube.

Allow the thermocouple and meter time to stabilize,

then record the temperature of the evaporator outlet

tube. Subtract the inlet tube temperature reading

from the outlet tube temperature reading.

²If dual probes are used, record the temperatures

of both the evaporator inlet and outlet tubes. Then

subtract the inlet tube temperature reading from the

outlet tube temperature reading.(9) If the measured temperature differential is

higher than 22É C to 26É C (40É F to 47É F), add 0.4

kilograms (14 ounces) of refrigerant.

(10) Allow three to five minutes for the refrigerant

system to stabilize, then take a second set of thermo-

couple measurements. Record the temperature differ-

ence to determine if an additional charge is required.

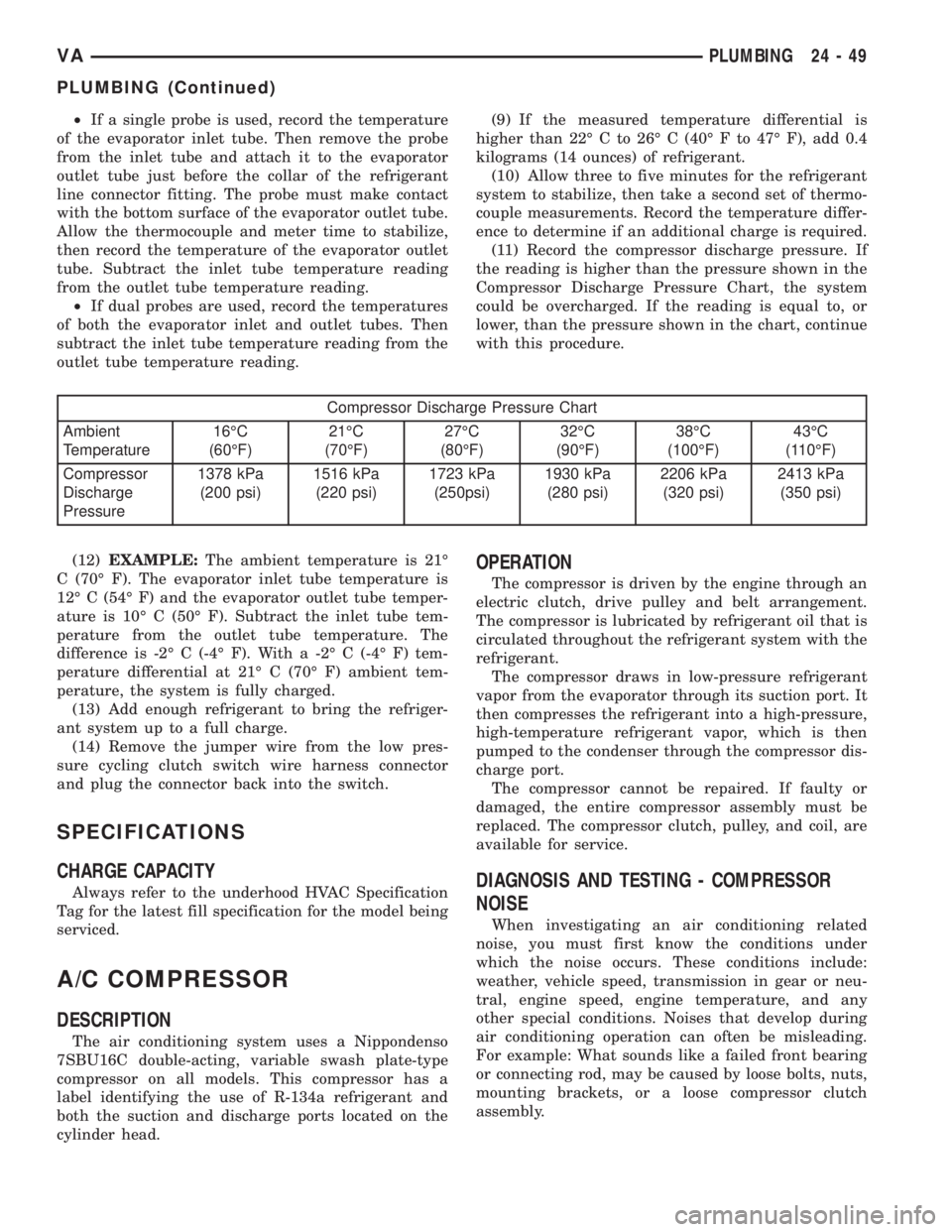

(11) Record the compressor discharge pressure. If

the reading is higher than the pressure shown in the

Compressor Discharge Pressure Chart, the system

could be overcharged. If the reading is equal to, or

lower, than the pressure shown in the chart, continue

with this procedure.

Compressor Discharge Pressure Chart

Ambient

Temperature16ÉC

(60ÉF)21ÉC

(70ÉF)27ÉC

(80ÉF)32ÉC

(90ÉF)38ÉC

(100ÉF)43ÉC

(110ÉF)

Compressor

Discharge

Pressure1378 kPa

(200 psi)1516 kPa

(220 psi)1723 kPa

(250psi)1930 kPa

(280 psi)2206 kPa

(320 psi)2413 kPa

(350 psi)

(12)EXAMPLE:The ambient temperature is 21É

C (70É F). The evaporator inlet tube temperature is

12É C (54É F) and the evaporator outlet tube temper-

ature is 10É C (50É F). Subtract the inlet tube tem-

perature from the outlet tube temperature. The

difference is -2É C (-4É F). With a -2É C (-4É F) tem-

perature differential at 21É C (70É F) ambient tem-

perature, the system is fully charged.

(13) Add enough refrigerant to bring the refriger-

ant system up to a full charge.

(14) Remove the jumper wire from the low pres-

sure cycling clutch switch wire harness connector

and plug the connector back into the switch.

SPECIFICATIONS

CHARGE CAPACITY

Always refer to the underhood HVAC Specification

Tag for the latest fill specification for the model being

serviced.

A/C COMPRESSOR

DESCRIPTION

The air conditioning system uses a Nippondenso

7SBU16C double-acting, variable swash plate-type

compressor on all models. This compressor has a

label identifying the use of R-134a refrigerant and

both the suction and discharge ports located on the

cylinder head.

OPERATION

The compressor is driven by the engine through an

electric clutch, drive pulley and belt arrangement.

The compressor is lubricated by refrigerant oil that is

circulated throughout the refrigerant system with the

refrigerant.

The compressor draws in low-pressure refrigerant

vapor from the evaporator through its suction port. It

then compresses the refrigerant into a high-pressure,

high-temperature refrigerant vapor, which is then

pumped to the condenser through the compressor dis-

charge port.

The compressor cannot be repaired. If faulty or

damaged, the entire compressor assembly must be

replaced. The compressor clutch, pulley, and coil, are

available for service.

DIAGNOSIS AND TESTING - COMPRESSOR

NOISE

When investigating an air conditioning related

noise, you must first know the conditions under

which the noise occurs. These conditions include:

weather, vehicle speed, transmission in gear or neu-

tral, engine speed, engine temperature, and any

other special conditions. Noises that develop during

air conditioning operation can often be misleading.

For example: What sounds like a failed front bearing

or connecting rod, may be caused by loose bolts, nuts,

mounting brackets, or a loose compressor clutch

assembly.

VAPLUMBING 24 - 49

PLUMBING (Continued)

Page 1178 of 1232

Drive belts are speed sensitive. At different engine

speeds and depending upon belt tension, belts can

develop noises that are mistaken for a compressor

noise. Improper belt tension can cause a misleading

noise when the compressor clutch is engaged, which

may not occur when the compressor clutch is disen-

gaged. Check the serpentine drive belt condition and

tension as described in Cooling before beginning this

procedure.

(1) Select a quiet area for testing. Duplicate the

complaint conditions as much as possible. Switch the

compressor on and off several times to clearly iden-

tify the compressor noise. Listen to the compressor

while the clutch is engaged and disengaged. Probe

the compressor with an engine stethoscope or a long

screwdriver with the handle held to your ear to bet-

ter localize the source of the noise.

(2) Loosen all of the compressor mounting hard-

ware and retighten. Tighten the compressor clutch

mounting nut. Be certain that the clutch coil is

mounted securely to the compressor, and that the

clutch plate and pulley are properly aligned and have

the correct air gap. (Refer to 24 - HEATING & AIR

CONDITIONING/CONTROLS/A/C COMPRESSOR

CLUTCH - INSTALLATION)

(3) To duplicate a high-ambient temperature condi-

tion (high head pressure), restrict the air flow

through the condenser. Install a manifold gauge set

to be certain that the discharge pressure does not

exceed 2760 kPa (400 psi).

(4) Check the refrigerant system plumbing for

incorrect routing, rubbing or interference, which can

cause unusual noises. Also check the refrigerant lines

for kinks or sharp bends that will restrict refrigerant

flow, which can cause noises. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - CAU-

TION - REFRIGERANT HOSES/LINES/TUBES

PRECAUTIONS)

(5) If the noise is from opening and closing of the

high pressure relief valve, reclaim, evacuate, and

recharge the refrigerant system. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - STAN-

DARD PROCEDURE - REFRIGERANT RECOVERY)

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - STANDARD PROCEDURE - REFRIG-

ERANT SYSTEM EVACUATE) (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE)If the high pressure relief valve still

does not seat properly, replace the a/c compressor.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/A/C COMPRESSOR - REMOVAL)

(6) If the noise is from liquid slugging on the suc-

tion line, check the refrigerant oil level and the

refrigerant system charge. (Refer to 24 - HEATING

& AIR CONDITIONING/PLUMBING/REFRIGER-ANT OIL - STANDARD PROCEDURE) (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

SPECIFICATIONS - CHARGE CAPACITY).

(7) If the noise continues, replace the compressor

and repeat Step 1.

REMOVAL

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING) and (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - CAUTION).

(1) Disconnect the negative battery cable.

(2) Recover the refrigerant from the refrigerant

system (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY).

(3) Remove the accessory drive belt from the com-

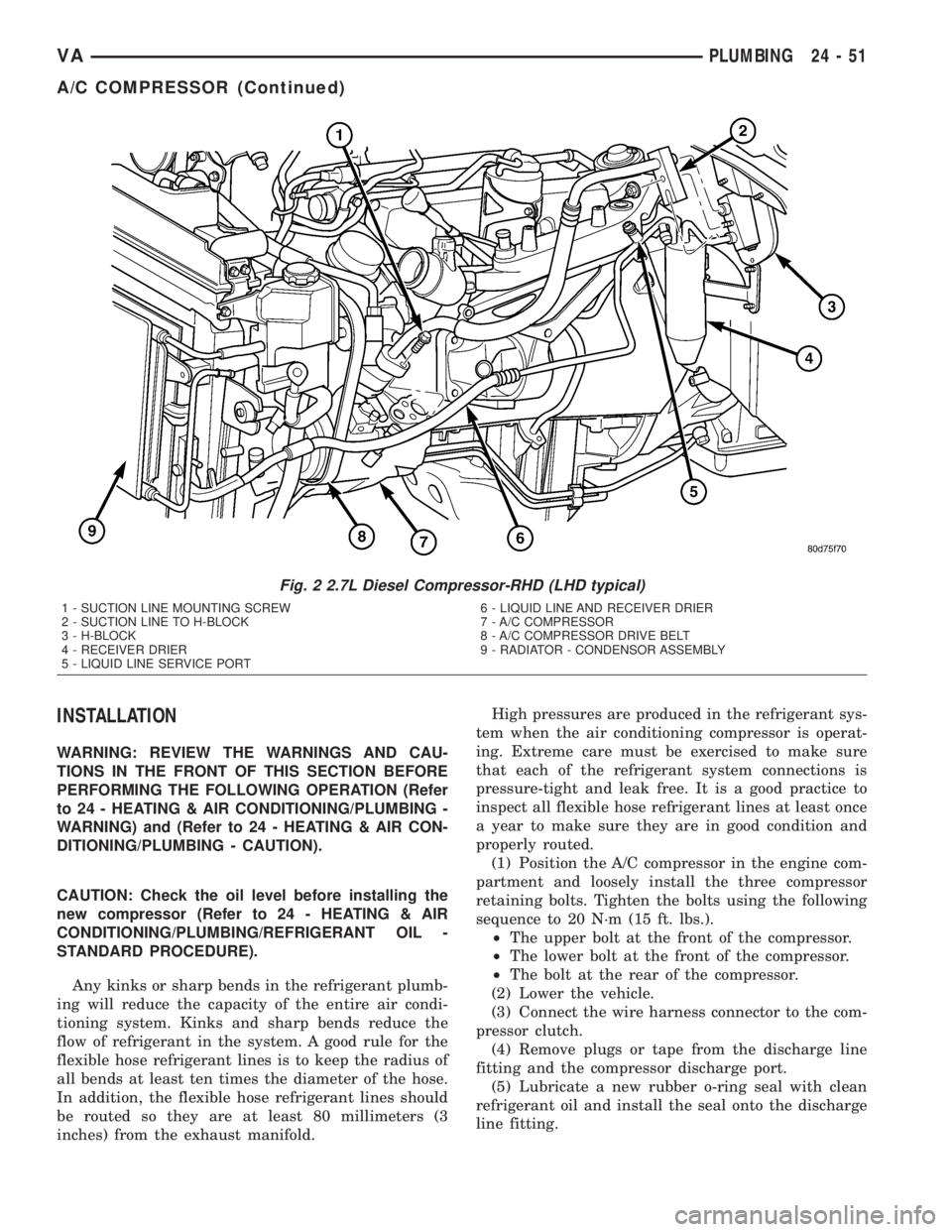

pressor clutch (Fig. 2).

(4) Remove the bolt that secures the suction line

fitting to the top of the compressor.

(5) Disconnect the suction line fitting from the

compressor suction port.

(6) Remove the seal from the suction line fitting

and discard.

(7) Install plugs in, or tape over the opened suc-

tion line fitting and the compressor suction port.

(8) Remove the bolt that secures the discharge line

fitting to the top of the compressor.

(9) Disconnect the discharge line fitting from the

compressor discharge port.

(10) Remove the seal from the discharge line fit-

ting and discard.

(11) Install plugs in, or tape over the opened dis-

charge line fitting and the compressor discharge port.

(12) Disconnect the engine wire harness connector

for the compressor clutch coil from the coil pigtail

wire connector on the top of the compressor.

(13) Raise the vehicle on a hoist.

(14) Support the compressor and remove the three

compressor mounting bolts.

(15) Remove the compressor from the engine com-

partment.

NOTE: If a replacement compressor is being

installed, be certain to drain and measure the refrig-

erant oil contained in the removed compressor.

This will determine how much oil the replacement

compressor must contain before it is installed

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/REFRIGERANT OIL - STANDARD PRO-

CEDURE).

24 - 50 PLUMBINGVA

A/C COMPRESSOR (Continued)

Page 1179 of 1232

INSTALLATION

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING) and (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - CAUTION).

CAUTION: Check the oil level before installing the

new compressor (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING/REFRIGERANT OIL -

STANDARD PROCEDURE).

Any kinks or sharp bends in the refrigerant plumb-

ing will reduce the capacity of the entire air condi-

tioning system. Kinks and sharp bends reduce the

flow of refrigerant in the system. A good rule for the

flexible hose refrigerant lines is to keep the radius of

all bends at least ten times the diameter of the hose.

In addition, the flexible hose refrigerant lines should

be routed so they are at least 80 millimeters (3

inches) from the exhaust manifold.High pressures are produced in the refrigerant sys-

tem when the air conditioning compressor is operat-

ing. Extreme care must be exercised to make sure

that each of the refrigerant system connections is

pressure-tight and leak free. It is a good practice to

inspect all flexible hose refrigerant lines at least once

a year to make sure they are in good condition and

properly routed.

(1) Position the A/C compressor in the engine com-

partment and loosely install the three compressor

retaining bolts. Tighten the bolts using the following

sequence to 20 N´m (15 ft. lbs.).

²The upper bolt at the front of the compressor.

²The lower bolt at the front of the compressor.

²The bolt at the rear of the compressor.

(2) Lower the vehicle.

(3) Connect the wire harness connector to the com-

pressor clutch.

(4) Remove plugs or tape from the discharge line

fitting and the compressor discharge port.

(5) Lubricate a new rubber o-ring seal with clean

refrigerant oil and install the seal onto the discharge

line fitting.

Fig. 2 2.7L Diesel Compressor-RHD (LHD typical)

1 - SUCTION LINE MOUNTING SCREW

2 - SUCTION LINE TO H-BLOCK

3 - H-BLOCK

4 - RECEIVER DRIER

5 - LIQUID LINE SERVICE PORT6 - LIQUID LINE AND RECEIVER DRIER

7 - A/C COMPRESSOR

8 - A/C COMPRESSOR DRIVE BELT

9 - RADIATOR - CONDENSOR ASSEMBLY

VAPLUMBING 24 - 51

A/C COMPRESSOR (Continued)