engine MERCEDES-BENZ SPRINTER 2005 Service Repair Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 980 of 1232

(a) If only fluid and filter were changed, add5.0

L (10.6 pts.)of transmission fluid to transmission.

(b) If transmission was completely overhauled,

torque converter was replaced or drained, and

cooler was flushed, add7.7 L (16.3 pts.)of trans-

mission fluid to transmission.

(5) Check the transmission fluid (Refer to 21 -

TRANSMISSION/AUTOMATIC - NAG1/FLUID -

STANDARD PROCEDURE) and adjust as required.

STANDARD PROCEDURE - FLUID/FILTER

SERVICE

(1) Run the engine until the transmission oil

reaches operating temperature.

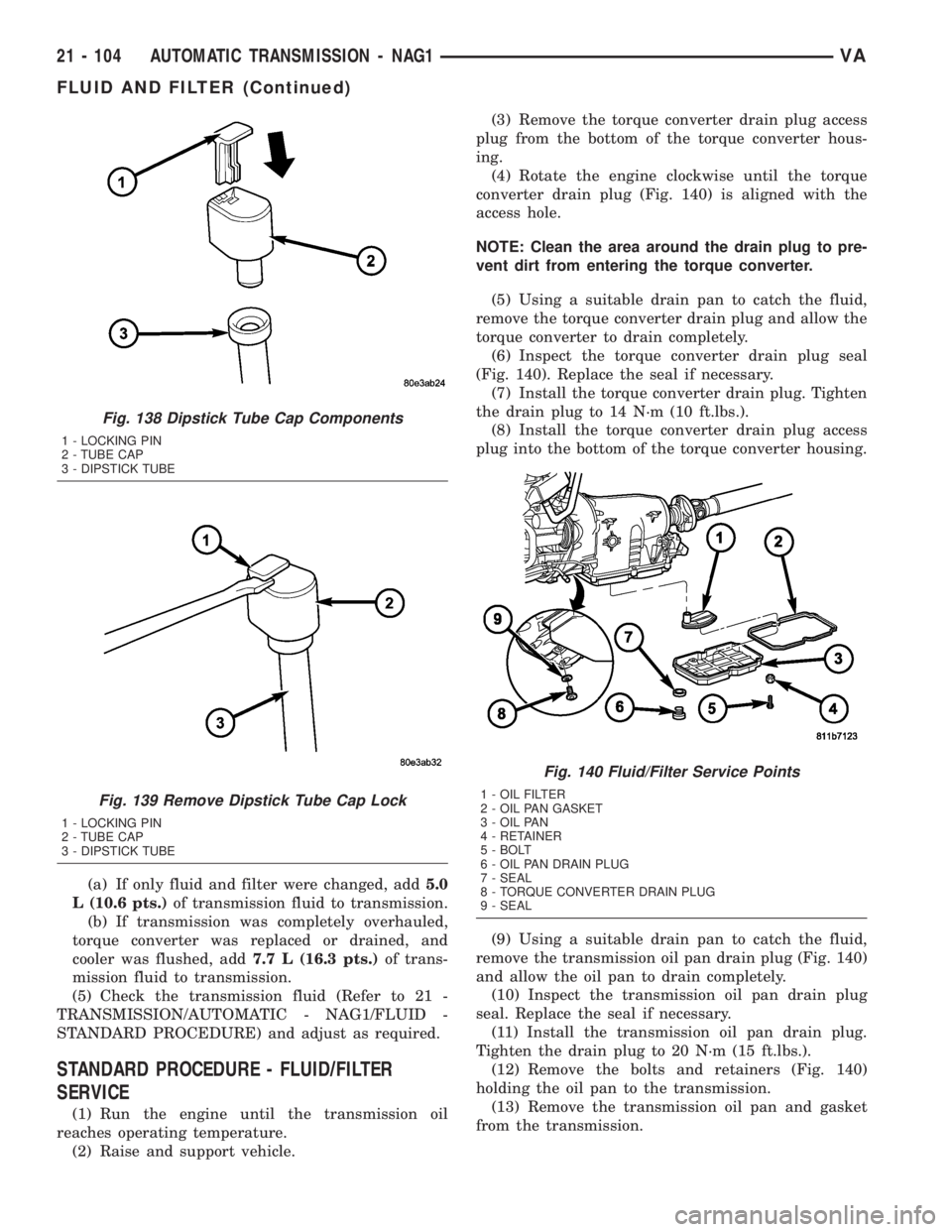

(2) Raise and support vehicle.(3) Remove the torque converter drain plug access

plug from the bottom of the torque converter hous-

ing.

(4) Rotate the engine clockwise until the torque

converter drain plug (Fig. 140) is aligned with the

access hole.

NOTE: Clean the area around the drain plug to pre-

vent dirt from entering the torque converter.

(5) Using a suitable drain pan to catch the fluid,

remove the torque converter drain plug and allow the

torque converter to drain completely.

(6) Inspect the torque converter drain plug seal

(Fig. 140). Replace the seal if necessary.

(7) Install the torque converter drain plug. Tighten

the drain plug to 14 N´m (10 ft.lbs.).

(8) Install the torque converter drain plug access

plug into the bottom of the torque converter housing.

(9) Using a suitable drain pan to catch the fluid,

remove the transmission oil pan drain plug (Fig. 140)

and allow the oil pan to drain completely.

(10) Inspect the transmission oil pan drain plug

seal. Replace the seal if necessary.

(11) Install the transmission oil pan drain plug.

Tighten the drain plug to 20 N´m (15 ft.lbs.).

(12) Remove the bolts and retainers (Fig. 140)

holding the oil pan to the transmission.

(13) Remove the transmission oil pan and gasket

from the transmission.

Fig. 138 Dipstick Tube Cap Components

1 - LOCKING PIN

2 - TUBE CAP

3 - DIPSTICK TUBE

Fig. 139 Remove Dipstick Tube Cap Lock

1 - LOCKING PIN

2 - TUBE CAP

3 - DIPSTICK TUBE

Fig. 140 Fluid/Filter Service Points

1 - OIL FILTER

2 - OIL PAN GASKET

3 - OIL PAN

4 - RETAINER

5 - BOLT

6 - OIL PAN DRAIN PLUG

7 - SEAL

8 - TORQUE CONVERTER DRAIN PLUG

9 - SEAL

21 - 104 AUTOMATIC TRANSMISSION - NAG1VA

FLUID AND FILTER (Continued)

Page 985 of 1232

GEARSHIFT CABLE

DIAGNOSIS AND TESTING - GEARSHIFT

CABLE

(1) The floor shifter lever and gate positions

should be in alignment with all transmission PARK,

NEUTRAL, and gear detent positions.

(2) Engine starts must be possible with floor shift

lever in PARK or NEUTRAL gate positions only.

Engine starts must not be possible in any other gear

position.

(3) With floor shift lever handle push-button not

depressed and lever in:

(a) PARK position - Apply forward force on cen-

ter of handle and remove pressure. Engine starts

must be possible.

(b) PARK position - Apply rearward force on cen-

ter of handle and remove pressure. Engine starts

must be possible.

(c) NEUTRAL position - Normal position. Engine

starts must be possible.

(d) NEUTRAL position - Engine running and

brakes applied, apply forward force on center of

shift handle. Transmission shall not be able to shift

from NEUTRAL to REVERSE.

REMOVAL

(1) Move selector lever to position9D9.

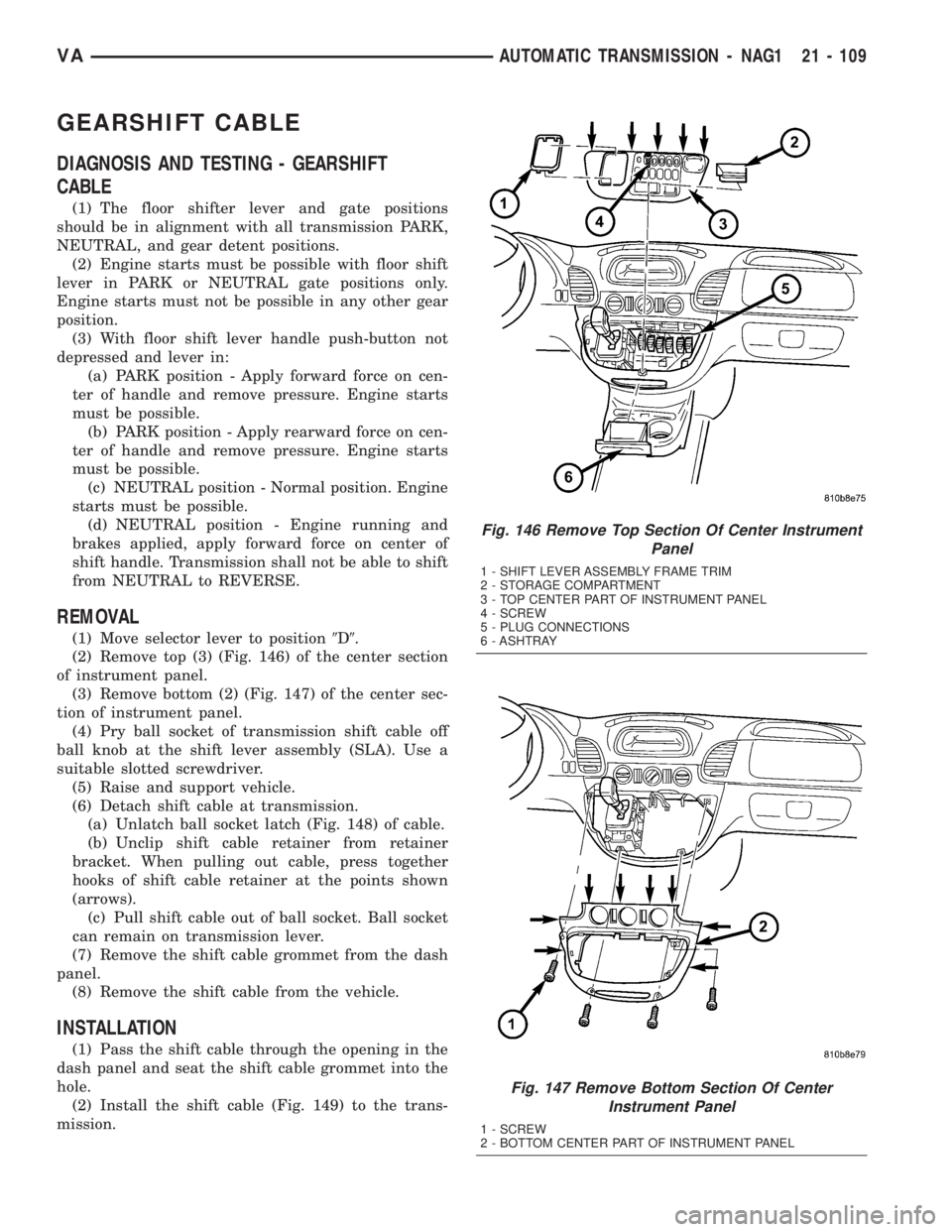

(2) Remove top (3) (Fig. 146) of the center section

of instrument panel.

(3) Remove bottom (2) (Fig. 147) of the center sec-

tion of instrument panel.

(4) Pry ball socket of transmission shift cable off

ball knob at the shift lever assembly (SLA). Use a

suitable slotted screwdriver.

(5) Raise and support vehicle.

(6) Detach shift cable at transmission.

(a) Unlatch ball socket latch (Fig. 148) of cable.

(b) Unclip shift cable retainer from retainer

bracket. When pulling out cable, press together

hooks of shift cable retainer at the points shown

(arrows).

(c) Pull shift cable out of ball socket. Ball socket

can remain on transmission lever.

(7) Remove the shift cable grommet from the dash

panel.

(8) Remove the shift cable from the vehicle.

INSTALLATION

(1) Pass the shift cable through the opening in the

dash panel and seat the shift cable grommet into the

hole.

(2) Install the shift cable (Fig. 149) to the trans-

mission.

Fig. 146 Remove Top Section Of Center Instrument

Panel

1 - SHIFT LEVER ASSEMBLY FRAME TRIM

2 - STORAGE COMPARTMENT

3 - TOP CENTER PART OF INSTRUMENT PANEL

4 - SCREW

5 - PLUG CONNECTIONS

6 - ASHTRAY

Fig. 147 Remove Bottom Section Of Center

Instrument Panel

1 - SCREW

2 - BOTTOM CENTER PART OF INSTRUMENT PANEL

VAAUTOMATIC TRANSMISSION - NAG1 21 - 109

Page 995 of 1232

INPUT SPEED SENSORS

DESCRIPTION

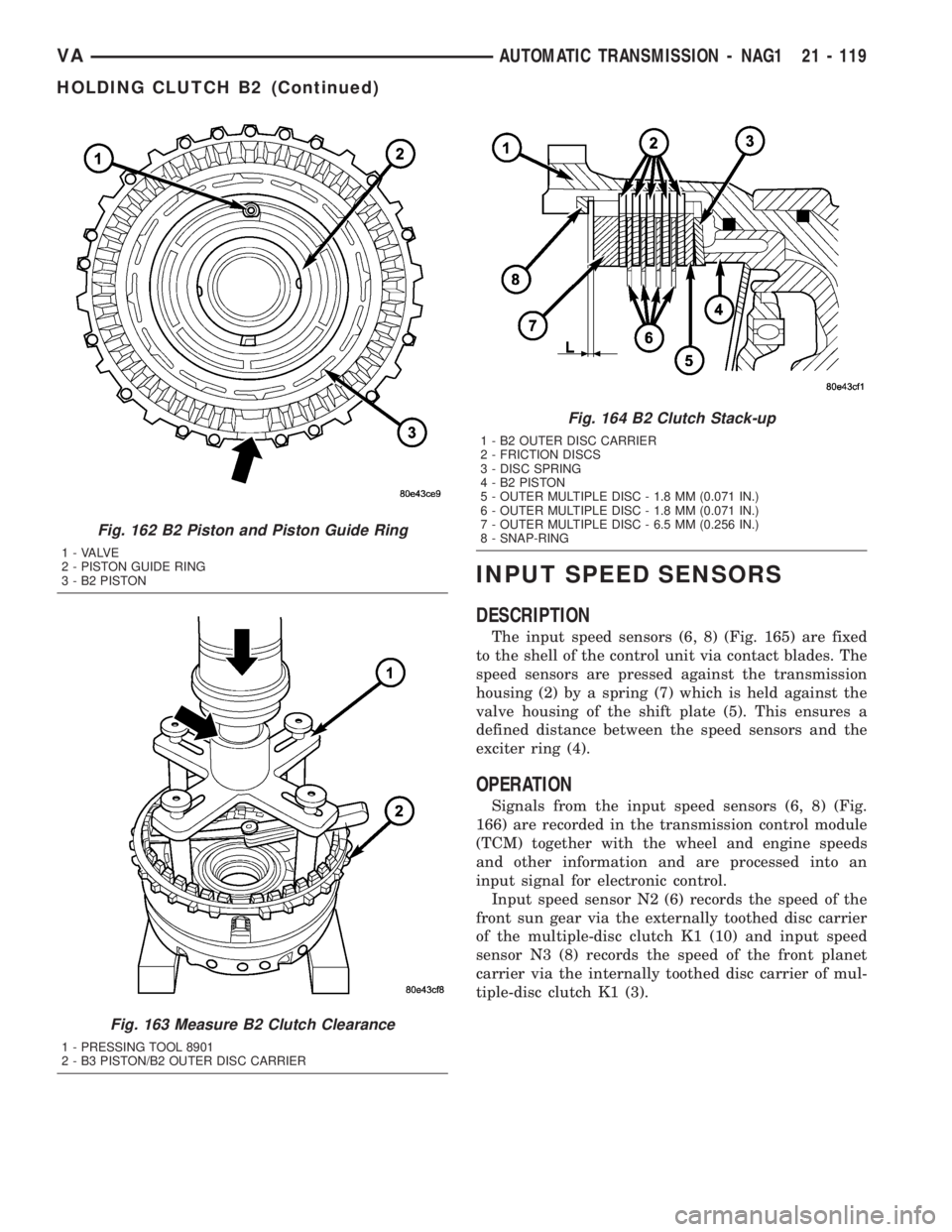

The input speed sensors (6, 8) (Fig. 165) are fixed

to the shell of the control unit via contact blades. The

speed sensors are pressed against the transmission

housing (2) by a spring (7) which is held against the

valve housing of the shift plate (5). This ensures a

defined distance between the speed sensors and the

exciter ring (4).

OPERATION

Signals from the input speed sensors (6, 8) (Fig.

166) are recorded in the transmission control module

(TCM) together with the wheel and engine speeds

and other information and are processed into an

input signal for electronic control.

Input speed sensor N2 (6) records the speed of the

front sun gear via the externally toothed disc carrier

of the multiple-disc clutch K1 (10) and input speed

sensor N3 (8) records the speed of the front planet

carrier via the internally toothed disc carrier of mul-

tiple-disc clutch K1 (3).

Fig. 162 B2 Piston and Piston Guide Ring

1 - VALVE

2 - PISTON GUIDE RING

3 - B2 PISTON

Fig. 163 Measure B2 Clutch Clearance

1 - PRESSING TOOL 8901

2 - B3 PISTON/B2 OUTER DISC CARRIER

Fig. 164 B2 Clutch Stack-up

1 - B2 OUTER DISC CARRIER

2 - FRICTION DISCS

3 - DISC SPRING

4 - B2 PISTON

5 - OUTER MULTIPLE DISC - 1.8 MM (0.071 IN.)

6 - OUTER MULTIPLE DISC - 1.8 MM (0.071 IN.)

7 - OUTER MULTIPLE DISC - 6.5 MM (0.256 IN.)

8 - SNAP-RING

VAAUTOMATIC TRANSMISSION - NAG1 21 - 119

HOLDING CLUTCH B2 (Continued)

Page 996 of 1232

OIL PUMP

DESCRIPTION

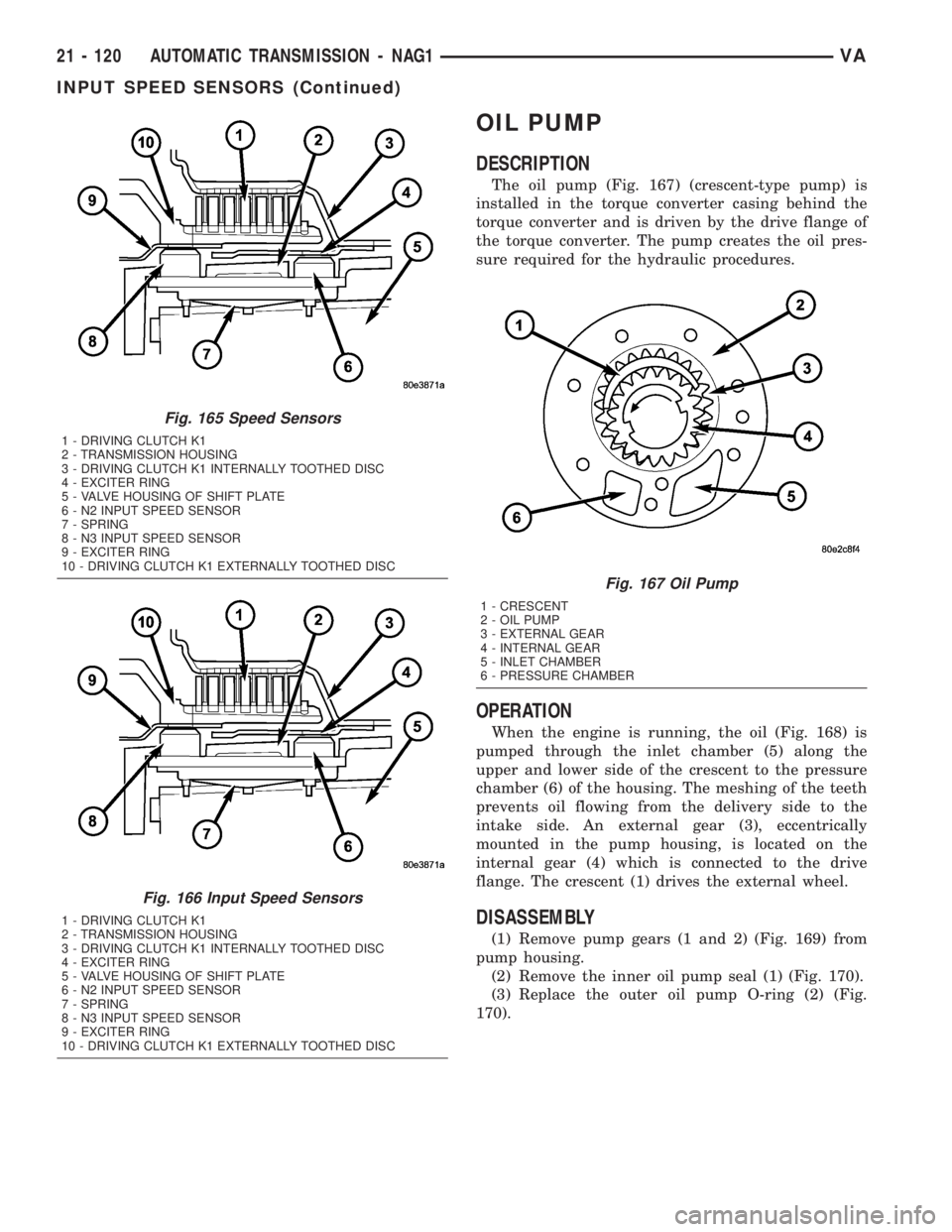

The oil pump (Fig. 167) (crescent-type pump) is

installed in the torque converter casing behind the

torque converter and is driven by the drive flange of

the torque converter. The pump creates the oil pres-

sure required for the hydraulic procedures.

OPERATION

When the engine is running, the oil (Fig. 168) is

pumped through the inlet chamber (5) along the

upper and lower side of the crescent to the pressure

chamber (6) of the housing. The meshing of the teeth

prevents oil flowing from the delivery side to the

intake side. An external gear (3), eccentrically

mounted in the pump housing, is located on the

internal gear (4) which is connected to the drive

flange. The crescent (1) drives the external wheel.

DISASSEMBLY

(1) Remove pump gears (1 and 2) (Fig. 169) from

pump housing.

(2) Remove the inner oil pump seal (1) (Fig. 170).

(3) Replace the outer oil pump O-ring (2) (Fig.

170).

Fig. 165 Speed Sensors

1 - DRIVING CLUTCH K1

2 - TRANSMISSION HOUSING

3 - DRIVING CLUTCH K1 INTERNALLY TOOTHED DISC

4 - EXCITER RING

5 - VALVE HOUSING OF SHIFT PLATE

6 - N2 INPUT SPEED SENSOR

7 - SPRING

8 - N3 INPUT SPEED SENSOR

9 - EXCITER RING

10 - DRIVING CLUTCH K1 EXTERNALLY TOOTHED DISC

Fig. 166 Input Speed Sensors

1 - DRIVING CLUTCH K1

2 - TRANSMISSION HOUSING

3 - DRIVING CLUTCH K1 INTERNALLY TOOTHED DISC

4 - EXCITER RING

5 - VALVE HOUSING OF SHIFT PLATE

6 - N2 INPUT SPEED SENSOR

7 - SPRING

8 - N3 INPUT SPEED SENSOR

9 - EXCITER RING

10 - DRIVING CLUTCH K1 EXTERNALLY TOOTHED DISC

Fig. 167 Oil Pump

1 - CRESCENT

2 - OIL PUMP

3 - EXTERNAL GEAR

4 - INTERNAL GEAR

5 - INLET CHAMBER

6 - PRESSURE CHAMBER

21 - 120 AUTOMATIC TRANSMISSION - NAG1VA

INPUT SPEED SENSORS (Continued)

Page 1007 of 1232

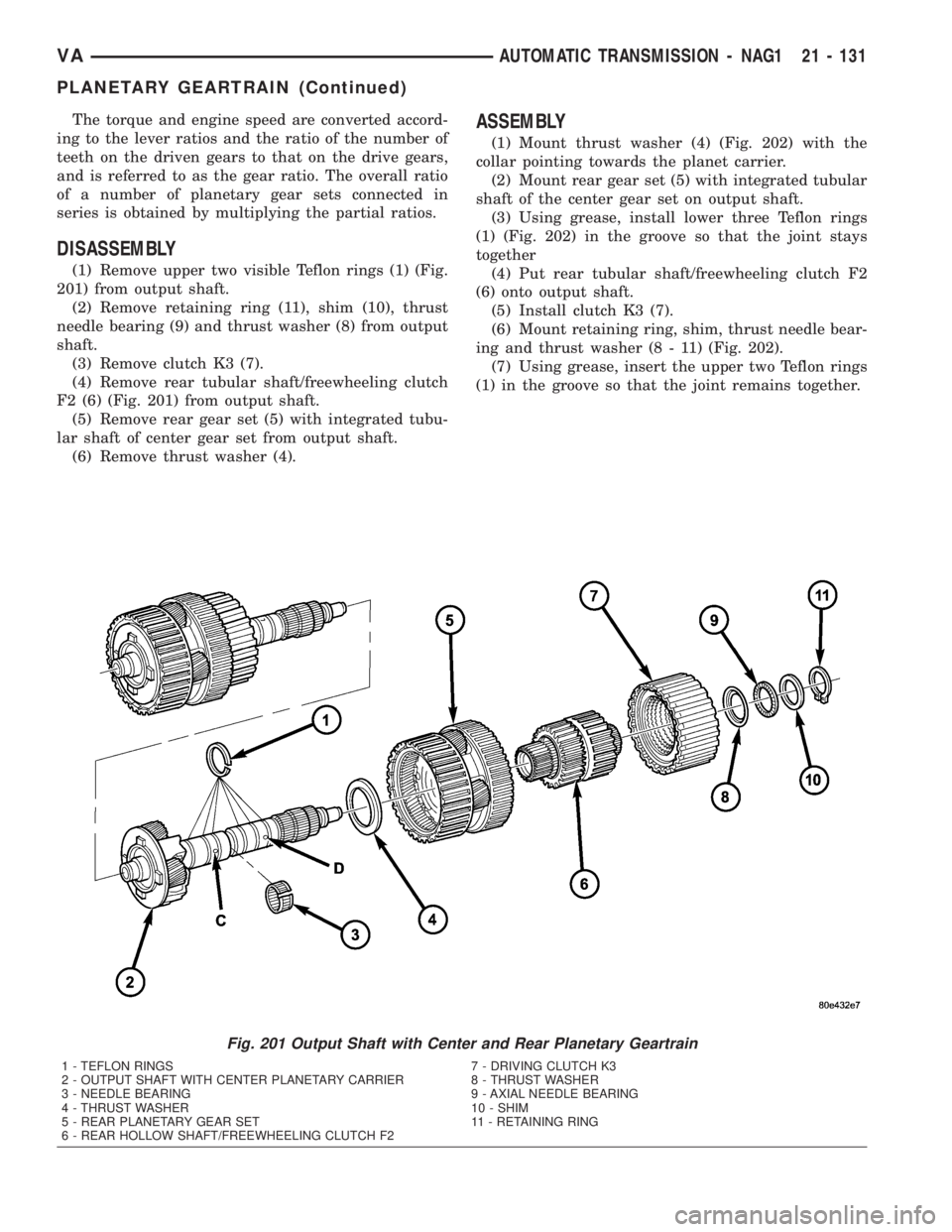

The torque and engine speed are converted accord-

ing to the lever ratios and the ratio of the number of

teeth on the driven gears to that on the drive gears,

and is referred to as the gear ratio. The overall ratio

of a number of planetary gear sets connected in

series is obtained by multiplying the partial ratios.

DISASSEMBLY

(1) Remove upper two visible Teflon rings (1) (Fig.

201) from output shaft.

(2) Remove retaining ring (11), shim (10), thrust

needle bearing (9) and thrust washer (8) from output

shaft.

(3) Remove clutch K3 (7).

(4) Remove rear tubular shaft/freewheeling clutch

F2 (6) (Fig. 201) from output shaft.

(5) Remove rear gear set (5) with integrated tubu-

lar shaft of center gear set from output shaft.

(6) Remove thrust washer (4).

ASSEMBLY

(1) Mount thrust washer (4) (Fig. 202) with the

collar pointing towards the planet carrier.

(2) Mount rear gear set (5) with integrated tubular

shaft of the center gear set on output shaft.

(3) Using grease, install lower three Teflon rings

(1) (Fig. 202) in the groove so that the joint stays

together

(4) Put rear tubular shaft/freewheeling clutch F2

(6) onto output shaft.

(5) Install clutch K3 (7).

(6) Mount retaining ring, shim, thrust needle bear-

ing and thrust washer (8 - 11) (Fig. 202).

(7) Using grease, insert the upper two Teflon rings

(1) in the groove so that the joint remains together.

Fig. 201 Output Shaft with Center and Rear Planetary Geartrain

1 - TEFLON RINGS 7 - DRIVING CLUTCH K3

2 - OUTPUT SHAFT WITH CENTER PLANETARY CARRIER 8 - THRUST WASHER

3 - NEEDLE BEARING 9 - AXIAL NEEDLE BEARING

4 - THRUST WASHER 10 - SHIM

5 - REAR PLANETARY GEAR SET 11 - RETAINING RING

6 - REAR HOLLOW SHAFT/FREEWHEELING CLUTCH F2

VAAUTOMATIC TRANSMISSION - NAG1 21 - 131

PLANETARY GEARTRAIN (Continued)

Page 1009 of 1232

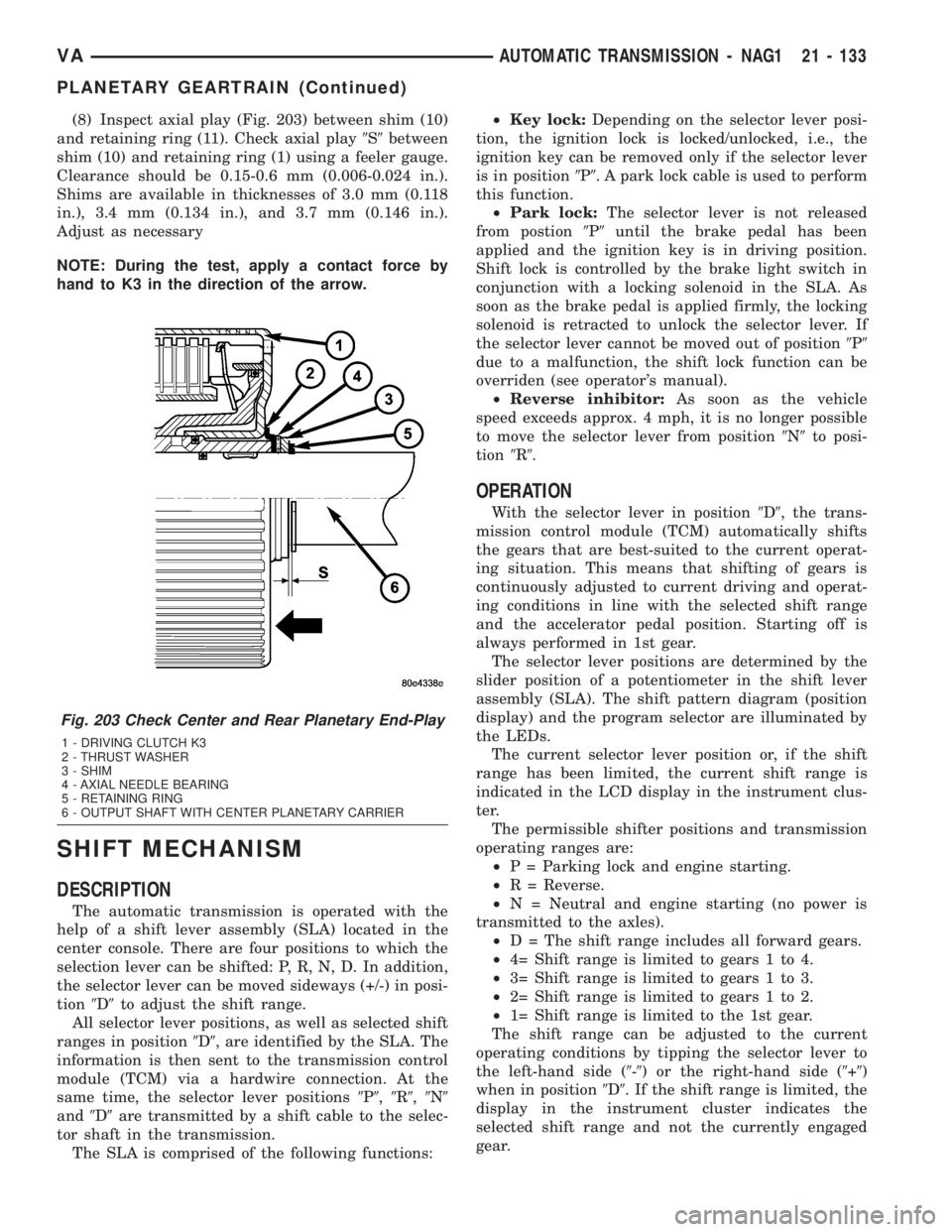

(8) Inspect axial play (Fig. 203) between shim (10)

and retaining ring (11). Check axial play9S9between

shim (10) and retaining ring (1) using a feeler gauge.

Clearance should be 0.15-0.6 mm (0.006-0.024 in.).

Shims are available in thicknesses of 3.0 mm (0.118

in.), 3.4 mm (0.134 in.), and 3.7 mm (0.146 in.).

Adjust as necessary

NOTE: During the test, apply a contact force by

hand to K3 in the direction of the arrow.

SHIFT MECHANISM

DESCRIPTION

The automatic transmission is operated with the

help of a shift lever assembly (SLA) located in the

center console. There are four positions to which the

selection lever can be shifted: P, R, N, D. In addition,

the selector lever can be moved sideways (+/-) in posi-

tion9D9to adjust the shift range.

All selector lever positions, as well as selected shift

ranges in position9D9, are identified by the SLA. The

information is then sent to the transmission control

module (TCM) via a hardwire connection. At the

same time, the selector lever positions9P9,9R9,9N9

and9D9are transmitted by a shift cable to the selec-

tor shaft in the transmission.

The SLA is comprised of the following functions:²Key lock:Depending on the selector lever posi-

tion, the ignition lock is locked/unlocked, i.e., the

ignition key can be removed only if the selector lever

is in position9P9. A park lock cable is used to perform

this function.

²Park lock:The selector lever is not released

from postion9P9until the brake pedal has been

applied and the ignition key is in driving position.

Shift lock is controlled by the brake light switch in

conjunction with a locking solenoid in the SLA. As

soon as the brake pedal is applied firmly, the locking

solenoid is retracted to unlock the selector lever. If

the selector lever cannot be moved out of position9P9

due to a malfunction, the shift lock function can be

overriden (see operator's manual).

²Reverse inhibitor:As soon as the vehicle

speed exceeds approx. 4 mph, it is no longer possible

to move the selector lever from position9N9to posi-

tion9R9.

OPERATION

With the selector lever in position9D9, the trans-

mission control module (TCM) automatically shifts

the gears that are best-suited to the current operat-

ing situation. This means that shifting of gears is

continuously adjusted to current driving and operat-

ing conditions in line with the selected shift range

and the accelerator pedal position. Starting off is

always performed in 1st gear.

The selector lever positions are determined by the

slider position of a potentiometer in the shift lever

assembly (SLA). The shift pattern diagram (position

display) and the program selector are illuminated by

the LEDs.

The current selector lever position or, if the shift

range has been limited, the current shift range is

indicated in the LCD display in the instrument clus-

ter.

The permissible shifter positions and transmission

operating ranges are:

²P = Parking lock and engine starting.

²R = Reverse.

²N = Neutral and engine starting (no power is

transmitted to the axles).

²D = The shift range includes all forward gears.

²4= Shift range is limited to gears 1 to 4.

²3= Shift range is limited to gears 1 to 3.

²2= Shift range is limited to gears 1 to 2.

²1= Shift range is limited to the 1st gear.

The shift range can be adjusted to the current

operating conditions by tipping the selector lever to

the left-hand side (9-9) or the right-hand side (9+9)

when in position9D9. If the shift range is limited, the

display in the instrument cluster indicates the

selected shift range and not the currently engaged

gear.

Fig. 203 Check Center and Rear Planetary End-Play

1 - DRIVING CLUTCH K3

2 - THRUST WASHER

3 - SHIM

4 - AXIAL NEEDLE BEARING

5 - RETAINING RING

6 - OUTPUT SHAFT WITH CENTER PLANETARY CARRIER

VAAUTOMATIC TRANSMISSION - NAG1 21 - 133

PLANETARY GEARTRAIN (Continued)

Page 1010 of 1232

Tipping the shift lever will have the following

results:

²Tipping the selector lever toward(-(one

time after another:The shift range is reduced in

descending sequence by one gear each time, i.e., from

D-4-3-2-1.Iftheselected limitation of the shift

range would result in a downshift causing excessive

engine speed, the shifting is not executed and the

engaged gear as well as the shift range remain

unchanged. This is to prevent the engine from over-

speeding. Engine retardation is low with the selector

lever in position9D9. To make use of the full braking

power of the engine,9manual9downshifting by tip-

ping the lever towards the left-hand side is recom-

mended. If this has been done, subsequent upshifting

must be carried out manually as well.

²Tipping the selector lever toward(-(and

holding it in this position:The currently engaged

gear in range9D9is indicated in the instrument clus-

ter display and the shift range is limited to this gear.

²Tipping the selector lever toward(+(one

time after another:The shift range is increased by

one gear each time and the increased shift range is

displayed in the instrument cluster; possibly, the

transmission upshifts to a faster gear.

²Tipping the selector lever toward(+(sev-

eral times:The shift range is increased by one gear

each time the lever is tipped until the shift range

ends up in9D9.

²Tipping the selector lever toward(+(and

holding it in this position:The shift range is

extended immediately to9D9, shift ranges are indi-

cated in ascending sequence; possibly, the transmis-

sion upshifts to a faster gear due to the extension of

the shift range.

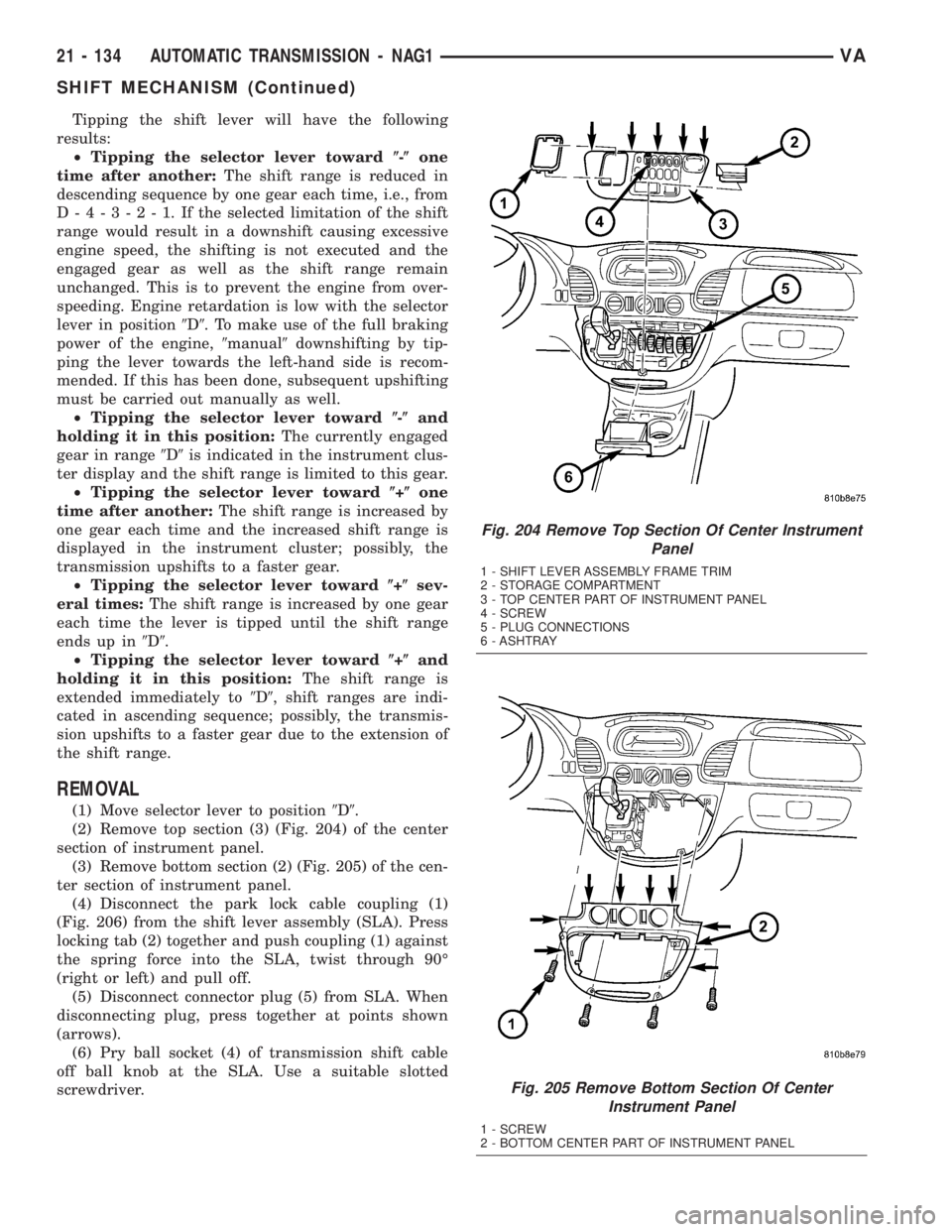

REMOVAL

(1) Move selector lever to position9D9.

(2) Remove top section (3) (Fig. 204) of the center

section of instrument panel.

(3) Remove bottom section (2) (Fig. 205) of the cen-

ter section of instrument panel.

(4) Disconnect the park lock cable coupling (1)

(Fig. 206) from the shift lever assembly (SLA). Press

locking tab (2) together and push coupling (1) against

the spring force into the SLA, twist through 90É

(right or left) and pull off.

(5) Disconnect connector plug (5) from SLA. When

disconnecting plug, press together at points shown

(arrows).

(6) Pry ball socket (4) of transmission shift cable

off ball knob at the SLA. Use a suitable slotted

screwdriver.

Fig. 204 Remove Top Section Of Center Instrument

Panel

1 - SHIFT LEVER ASSEMBLY FRAME TRIM

2 - STORAGE COMPARTMENT

3 - TOP CENTER PART OF INSTRUMENT PANEL

4 - SCREW

5 - PLUG CONNECTIONS

6 - ASHTRAY

Fig. 205 Remove Bottom Section Of Center

Instrument Panel

1 - SCREW

2 - BOTTOM CENTER PART OF INSTRUMENT PANEL

21 - 134 AUTOMATIC TRANSMISSION - NAG1VA

SHIFT MECHANISM (Continued)

Page 1017 of 1232

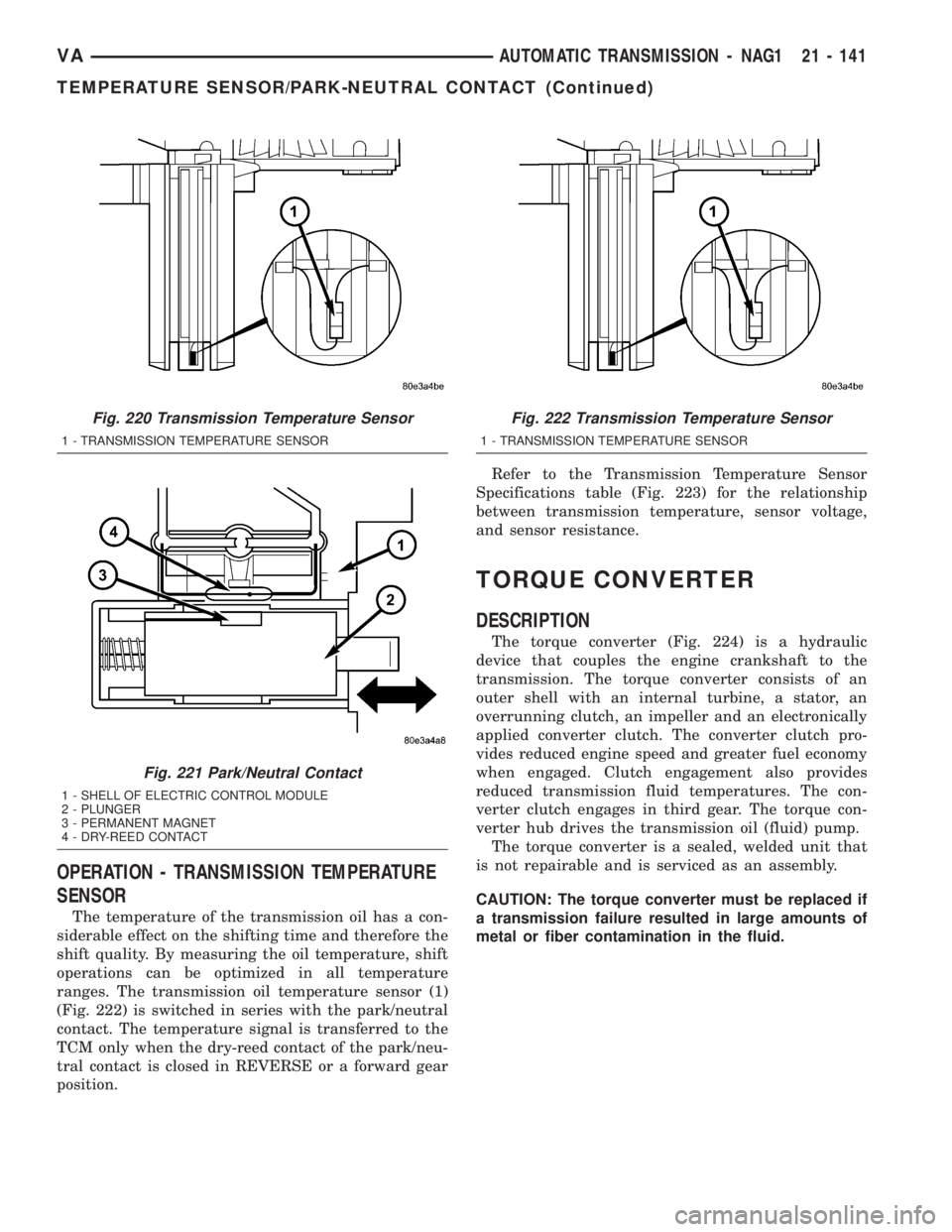

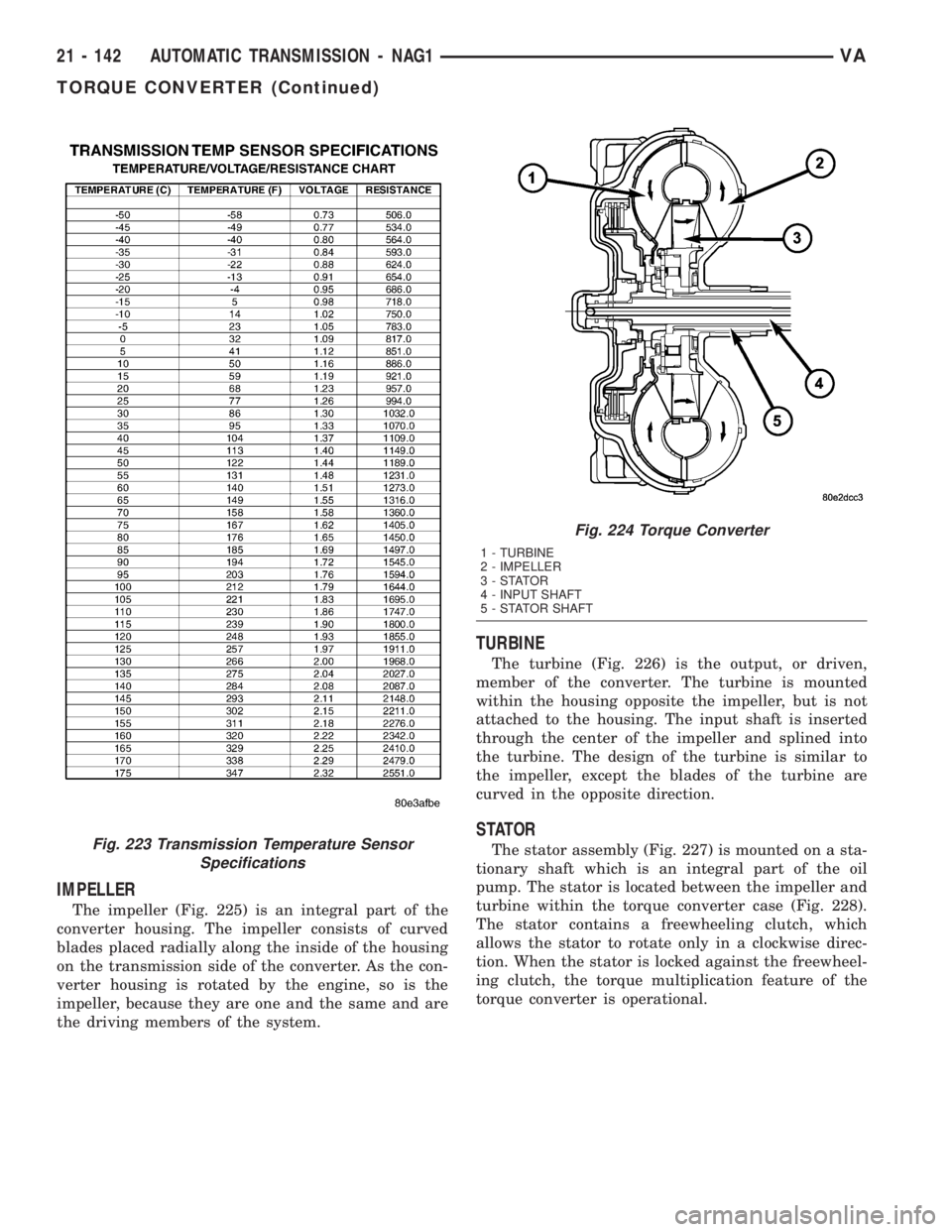

OPERATION - TRANSMISSION TEMPERATURE

SENSOR

The temperature of the transmission oil has a con-

siderable effect on the shifting time and therefore the

shift quality. By measuring the oil temperature, shift

operations can be optimized in all temperature

ranges. The transmission oil temperature sensor (1)

(Fig. 222) is switched in series with the park/neutral

contact. The temperature signal is transferred to the

TCM only when the dry-reed contact of the park/neu-

tral contact is closed in REVERSE or a forward gear

position.Refer to the Transmission Temperature Sensor

Specifications table (Fig. 223) for the relationship

between transmission temperature, sensor voltage,

and sensor resistance.

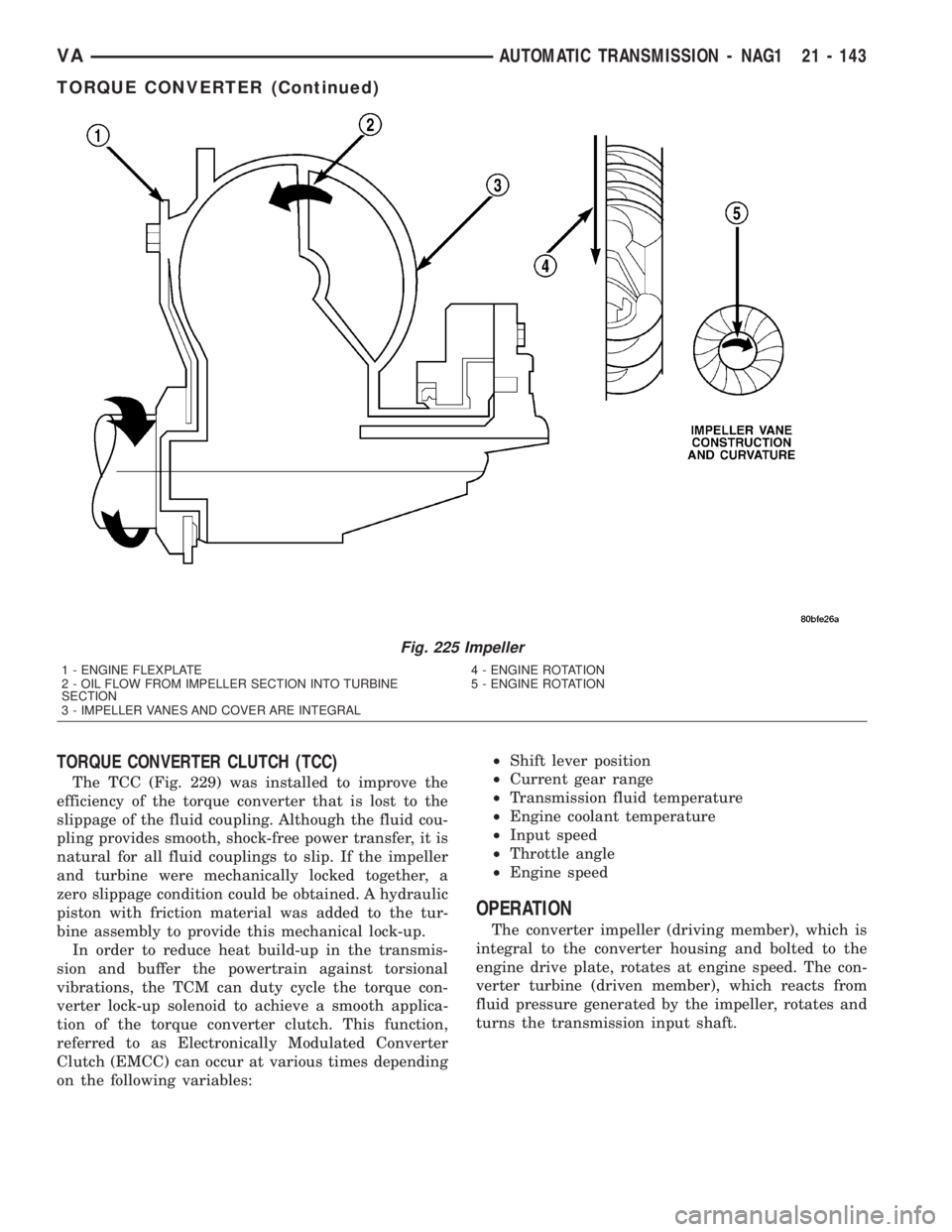

TORQUE CONVERTER

DESCRIPTION

The torque converter (Fig. 224) is a hydraulic

device that couples the engine crankshaft to the

transmission. The torque converter consists of an

outer shell with an internal turbine, a stator, an

overrunning clutch, an impeller and an electronically

applied converter clutch. The converter clutch pro-

vides reduced engine speed and greater fuel economy

when engaged. Clutch engagement also provides

reduced transmission fluid temperatures. The con-

verter clutch engages in third gear. The torque con-

verter hub drives the transmission oil (fluid) pump.

The torque converter is a sealed, welded unit that

is not repairable and is serviced as an assembly.

CAUTION: The torque converter must be replaced if

a transmission failure resulted in large amounts of

metal or fiber contamination in the fluid.

Fig. 220 Transmission Temperature Sensor

1 - TRANSMISSION TEMPERATURE SENSOR

Fig. 221 Park/Neutral Contact

1 - SHELL OF ELECTRIC CONTROL MODULE

2 - PLUNGER

3 - PERMANENT MAGNET

4 - DRY-REED CONTACT

Fig. 222 Transmission Temperature Sensor

1 - TRANSMISSION TEMPERATURE SENSOR

VAAUTOMATIC TRANSMISSION - NAG1 21 - 141

TEMPERATURE SENSOR/PARK-NEUTRAL CONTACT (Continued)

Page 1018 of 1232

IMPELLER

The impeller (Fig. 225) is an integral part of the

converter housing. The impeller consists of curved

blades placed radially along the inside of the housing

on the transmission side of the converter. As the con-

verter housing is rotated by the engine, so is the

impeller, because they are one and the same and are

the driving members of the system.

TURBINE

The turbine (Fig. 226) is the output, or driven,

member of the converter. The turbine is mounted

within the housing opposite the impeller, but is not

attached to the housing. The input shaft is inserted

through the center of the impeller and splined into

the turbine. The design of the turbine is similar to

the impeller, except the blades of the turbine are

curved in the opposite direction.

STATOR

The stator assembly (Fig. 227) is mounted on a sta-

tionary shaft which is an integral part of the oil

pump. The stator is located between the impeller and

turbine within the torque converter case (Fig. 228).

The stator contains a freewheeling clutch, which

allows the stator to rotate only in a clockwise direc-

tion. When the stator is locked against the freewheel-

ing clutch, the torque multiplication feature of the

torque converter is operational.Fig. 223 Transmission Temperature Sensor

Specifications

Fig. 224 Torque Converter

1 - TURBINE

2 - IMPELLER

3-STATOR

4 - INPUT SHAFT

5 - STATOR SHAFT

21 - 142 AUTOMATIC TRANSMISSION - NAG1VA

TORQUE CONVERTER (Continued)

Page 1019 of 1232

TORQUE CONVERTER CLUTCH (TCC)

The TCC (Fig. 229) was installed to improve the

efficiency of the torque converter that is lost to the

slippage of the fluid coupling. Although the fluid cou-

pling provides smooth, shock-free power transfer, it is

natural for all fluid couplings to slip. If the impeller

and turbine were mechanically locked together, a

zero slippage condition could be obtained. A hydraulic

piston with friction material was added to the tur-

bine assembly to provide this mechanical lock-up.

In order to reduce heat build-up in the transmis-

sion and buffer the powertrain against torsional

vibrations, the TCM can duty cycle the torque con-

verter lock-up solenoid to achieve a smooth applica-

tion of the torque converter clutch. This function,

referred to as Electronically Modulated Converter

Clutch (EMCC) can occur at various times depending

on the following variables:²Shift lever position

²Current gear range

²Transmission fluid temperature

²Engine coolant temperature

²Input speed

²Throttle angle

²Engine speed

OPERATION

The converter impeller (driving member), which is

integral to the converter housing and bolted to the

engine drive plate, rotates at engine speed. The con-

verter turbine (driven member), which reacts from

fluid pressure generated by the impeller, rotates and

turns the transmission input shaft.

Fig. 225 Impeller

1 - ENGINE FLEXPLATE 4 - ENGINE ROTATION

2 - OIL FLOW FROM IMPELLER SECTION INTO TURBINE

SECTION5 - ENGINE ROTATION

3 - IMPELLER VANES AND COVER ARE INTEGRAL

VAAUTOMATIC TRANSMISSION - NAG1 21 - 143

TORQUE CONVERTER (Continued)