engine MERCEDES-BENZ SPRINTER 2005 Service Repair Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 904 of 1232

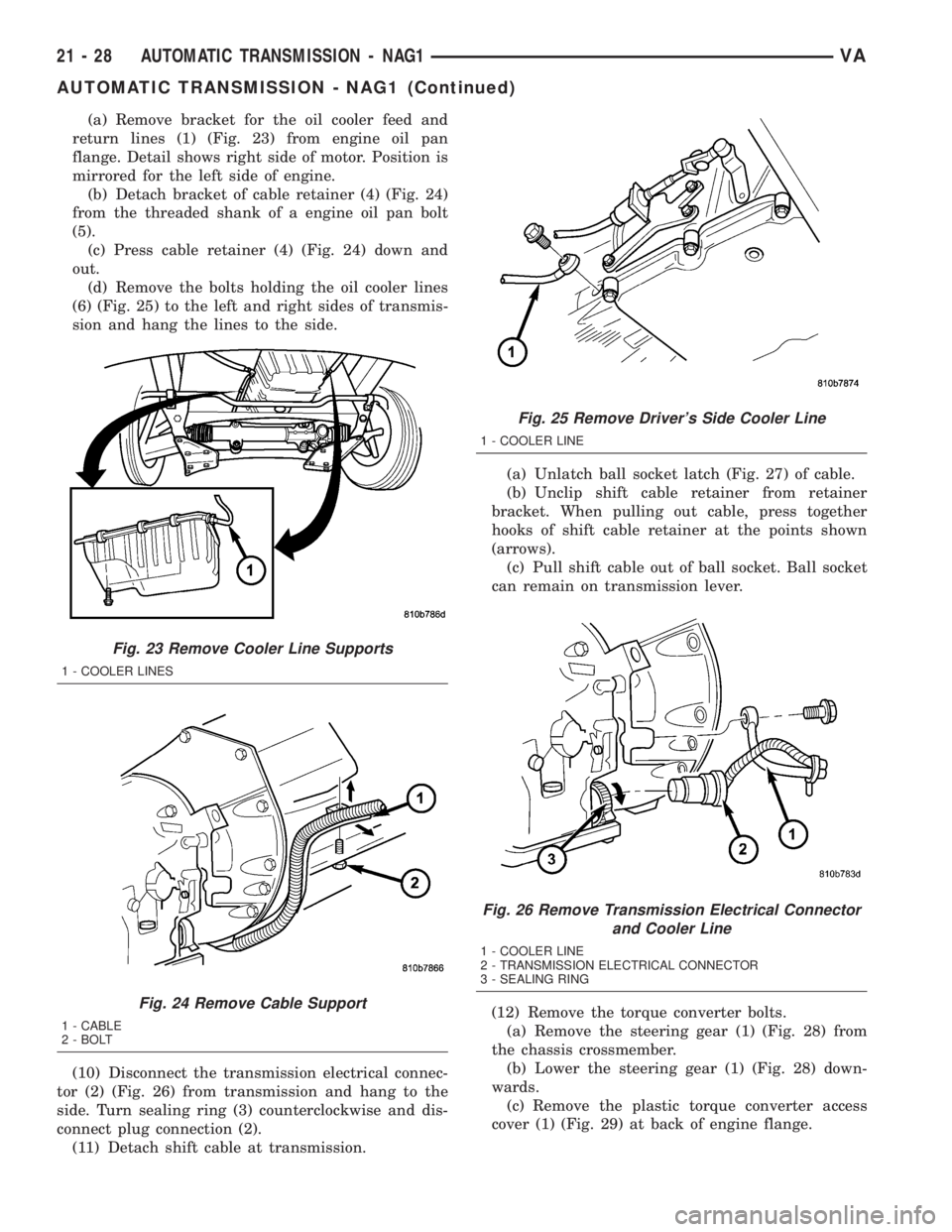

(a) Remove bracket for the oil cooler feed and

return lines (1) (Fig. 23) from engine oil pan

flange. Detail shows right side of motor. Position is

mirrored for the left side of engine.

(b) Detach bracket of cable retainer (4) (Fig. 24)

from the threaded shank of a engine oil pan bolt

(5).

(c) Press cable retainer (4) (Fig. 24) down and

out.

(d) Remove the bolts holding the oil cooler lines

(6) (Fig. 25) to the left and right sides of transmis-

sion and hang the lines to the side.

(10) Disconnect the transmission electrical connec-

tor (2) (Fig. 26) from transmission and hang to the

side. Turn sealing ring (3) counterclockwise and dis-

connect plug connection (2).

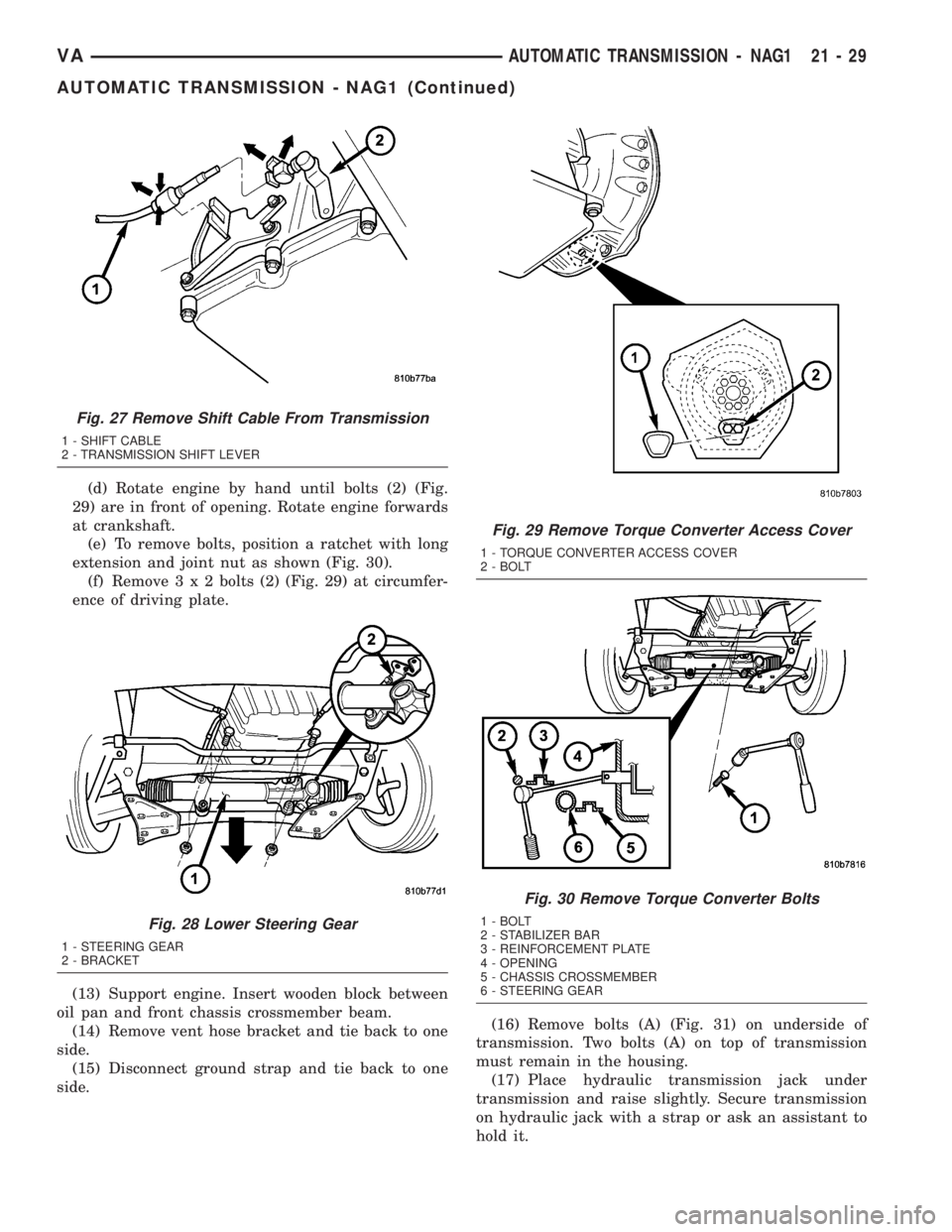

(11) Detach shift cable at transmission.(a) Unlatch ball socket latch (Fig. 27) of cable.

(b) Unclip shift cable retainer from retainer

bracket. When pulling out cable, press together

hooks of shift cable retainer at the points shown

(arrows).

(c) Pull shift cable out of ball socket. Ball socket

can remain on transmission lever.

(12) Remove the torque converter bolts.

(a) Remove the steering gear (1) (Fig. 28) from

the chassis crossmember.

(b) Lower the steering gear (1) (Fig. 28) down-

wards.

(c) Remove the plastic torque converter access

cover (1) (Fig. 29) at back of engine flange.

Fig. 23 Remove Cooler Line Supports

1 - COOLER LINES

Fig. 24 Remove Cable Support

1 - CABLE

2 - BOLT

Fig. 25 Remove Driver's Side Cooler Line

1 - COOLER LINE

Fig. 26 Remove Transmission Electrical Connector

and Cooler Line

1 - COOLER LINE

2 - TRANSMISSION ELECTRICAL CONNECTOR

3 - SEALING RING

21 - 28 AUTOMATIC TRANSMISSION - NAG1VA

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 905 of 1232

(d) Rotate engine by hand until bolts (2) (Fig.

29) are in front of opening. Rotate engine forwards

at crankshaft.

(e) To remove bolts, position a ratchet with long

extension and joint nut as shown (Fig. 30).

(f) Remove3x2bolts (2) (Fig. 29) at circumfer-

ence of driving plate.

(13) Support engine. Insert wooden block between

oil pan and front chassis crossmember beam.

(14) Remove vent hose bracket and tie back to one

side.

(15) Disconnect ground strap and tie back to one

side.(16) Remove bolts (A) (Fig. 31) on underside of

transmission. Two bolts (A) on top of transmission

must remain in the housing.

(17) Place hydraulic transmission jack under

transmission and raise slightly. Secure transmission

on hydraulic jack with a strap or ask an assistant to

hold it.

Fig. 27 Remove Shift Cable From Transmission

1 - SHIFT CABLE

2 - TRANSMISSION SHIFT LEVER

Fig. 28 Lower Steering Gear

1 - STEERING GEAR

2 - BRACKET

Fig. 29 Remove Torque Converter Access Cover

1 - TORQUE CONVERTER ACCESS COVER

2 - BOLT

Fig. 30 Remove Torque Converter Bolts

1 - BOLT

2 - STABILIZER BAR

3 - REINFORCEMENT PLATE

4 - OPENING

5 - CHASSIS CROSSMEMBER

6 - STEERING GEAR

VAAUTOMATIC TRANSMISSION - NAG1 21 - 29

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 906 of 1232

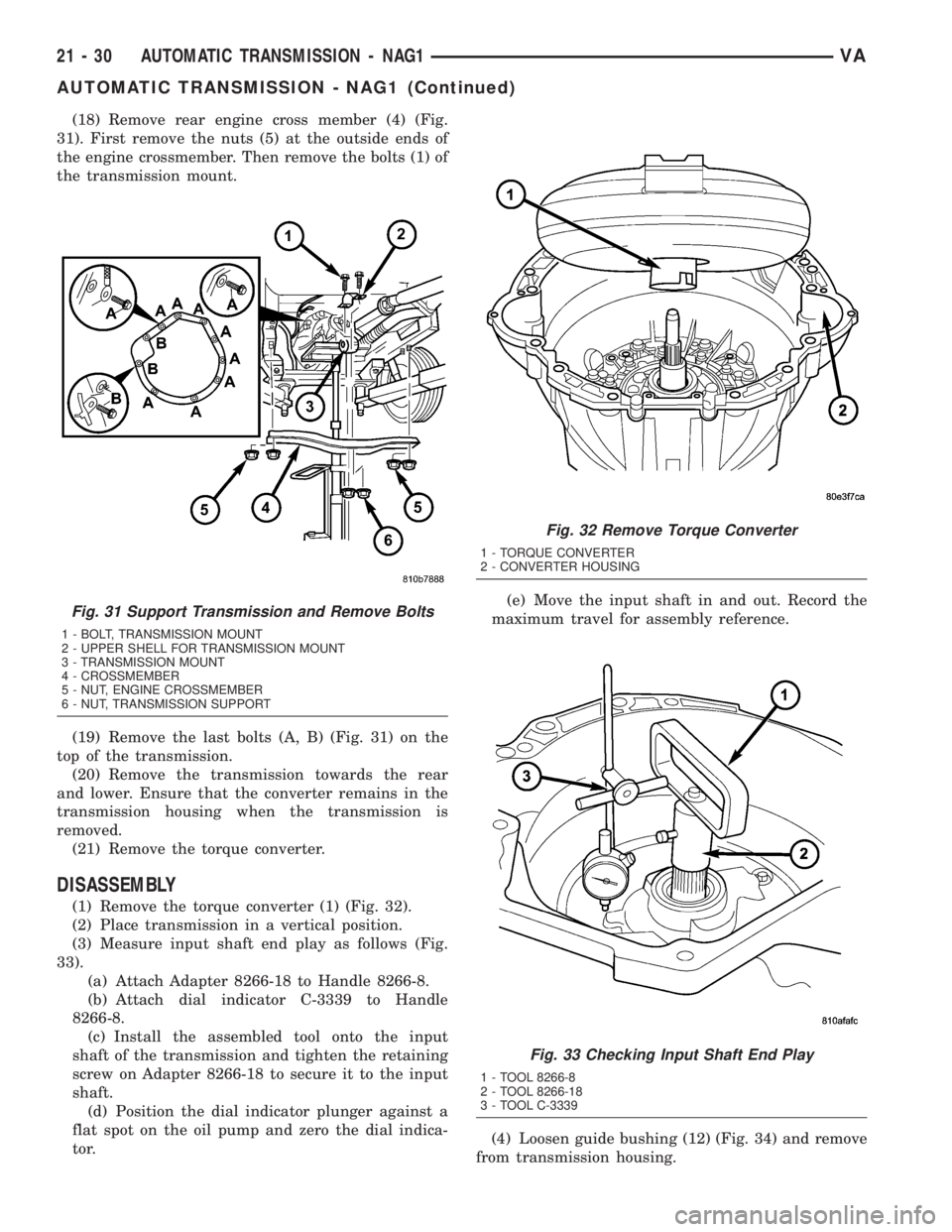

(18) Remove rear engine cross member (4) (Fig.

31). First remove the nuts (5) at the outside ends of

the engine crossmember. Then remove the bolts (1) of

the transmission mount.

(19) Remove the last bolts (A, B) (Fig. 31) on the

top of the transmission.

(20) Remove the transmission towards the rear

and lower. Ensure that the converter remains in the

transmission housing when the transmission is

removed.

(21) Remove the torque converter.

DISASSEMBLY

(1) Remove the torque converter (1) (Fig. 32).

(2) Place transmission in a vertical position.

(3) Measure input shaft end play as follows (Fig.

33).

(a) Attach Adapter 8266-18 to Handle 8266-8.

(b) Attach dial indicator C-3339 to Handle

8266-8.

(c) Install the assembled tool onto the input

shaft of the transmission and tighten the retaining

screw on Adapter 8266-18 to secure it to the input

shaft.

(d) Position the dial indicator plunger against a

flat spot on the oil pump and zero the dial indica-

tor.(e) Move the input shaft in and out. Record the

maximum travel for assembly reference.

(4) Loosen guide bushing (12) (Fig. 34) and remove

from transmission housing.

Fig. 31 Support Transmission and Remove Bolts

1 - BOLT, TRANSMISSION MOUNT

2 - UPPER SHELL FOR TRANSMISSION MOUNT

3 - TRANSMISSION MOUNT

4 - CROSSMEMBER

5 - NUT, ENGINE CROSSMEMBER

6 - NUT, TRANSMISSION SUPPORT

Fig. 32 Remove Torque Converter

1 - TORQUE CONVERTER

2 - CONVERTER HOUSING

Fig. 33 Checking Input Shaft End Play

1 - TOOL 8266-8

2 - TOOL 8266-18

3 - TOOL C-3339

21 - 30 AUTOMATIC TRANSMISSION - NAG1VA

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 918 of 1232

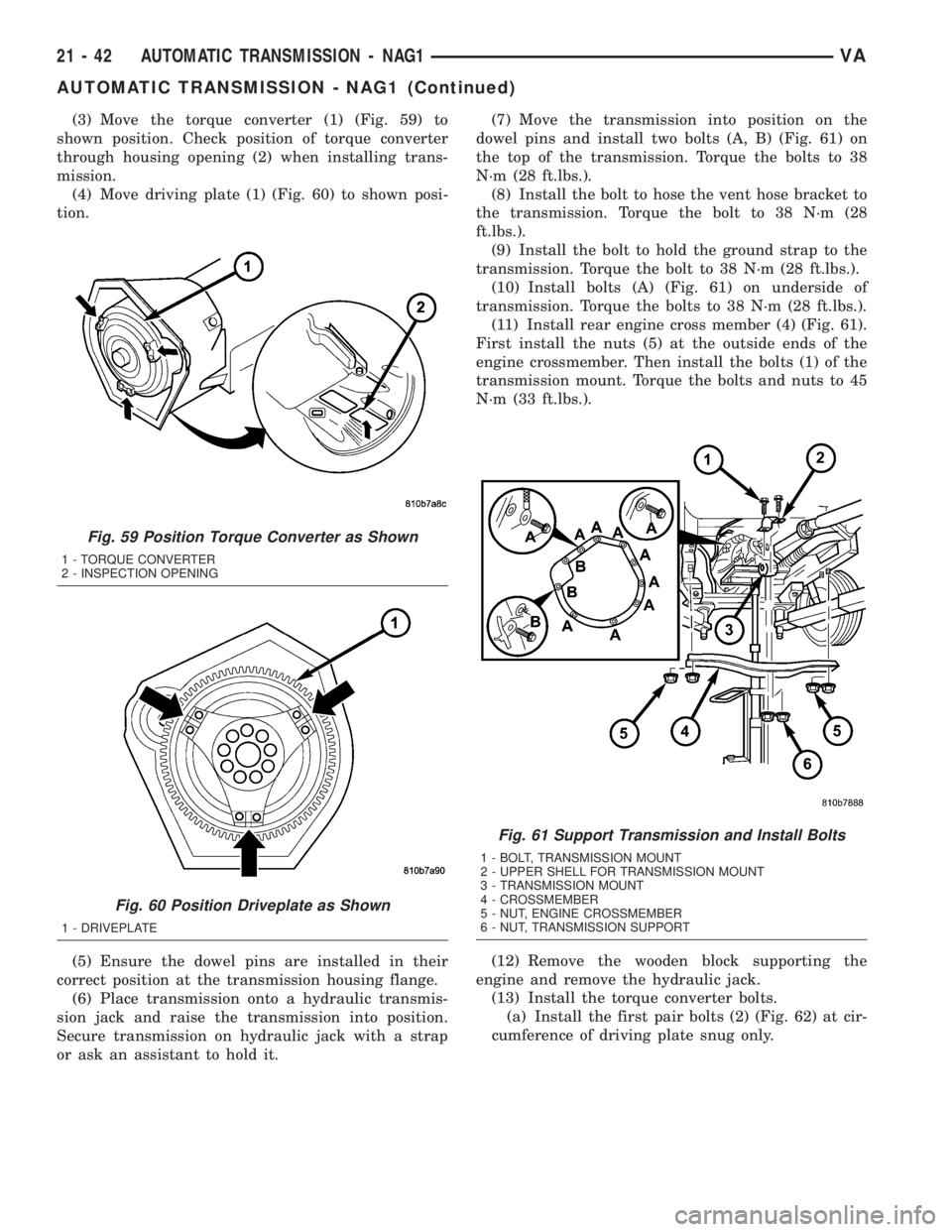

(3) Move the torque converter (1) (Fig. 59) to

shown position. Check position of torque converter

through housing opening (2) when installing trans-

mission.

(4) Move driving plate (1) (Fig. 60) to shown posi-

tion.

(5) Ensure the dowel pins are installed in their

correct position at the transmission housing flange.

(6) Place transmission onto a hydraulic transmis-

sion jack and raise the transmission into position.

Secure transmission on hydraulic jack with a strap

or ask an assistant to hold it.(7) Move the transmission into position on the

dowel pins and install two bolts (A, B) (Fig. 61) on

the top of the transmission. Torque the bolts to 38

N´m (28 ft.lbs.).

(8) Install the bolt to hose the vent hose bracket to

the transmission. Torque the bolt to 38 N´m (28

ft.lbs.).

(9) Install the bolt to hold the ground strap to the

transmission. Torque the bolt to 38 N´m (28 ft.lbs.).

(10) Install bolts (A) (Fig. 61) on underside of

transmission. Torque the bolts to 38 N´m (28 ft.lbs.).

(11) Install rear engine cross member (4) (Fig. 61).

First install the nuts (5) at the outside ends of the

engine crossmember. Then install the bolts (1) of the

transmission mount. Torque the bolts and nuts to 45

N´m (33 ft.lbs.).

(12) Remove the wooden block supporting the

engine and remove the hydraulic jack.

(13) Install the torque converter bolts.

(a) Install the first pair bolts (2) (Fig. 62) at cir-

cumference of driving plate snug only.

Fig. 59 Position Torque Converter as Shown

1 - TORQUE CONVERTER

2 - INSPECTION OPENING

Fig. 60 Position Driveplate as Shown

1 - DRIVEPLATE

Fig. 61 Support Transmission and Install Bolts

1 - BOLT, TRANSMISSION MOUNT

2 - UPPER SHELL FOR TRANSMISSION MOUNT

3 - TRANSMISSION MOUNT

4 - CROSSMEMBER

5 - NUT, ENGINE CROSSMEMBER

6 - NUT, TRANSMISSION SUPPORT

21 - 42 AUTOMATIC TRANSMISSION - NAG1VA

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 919 of 1232

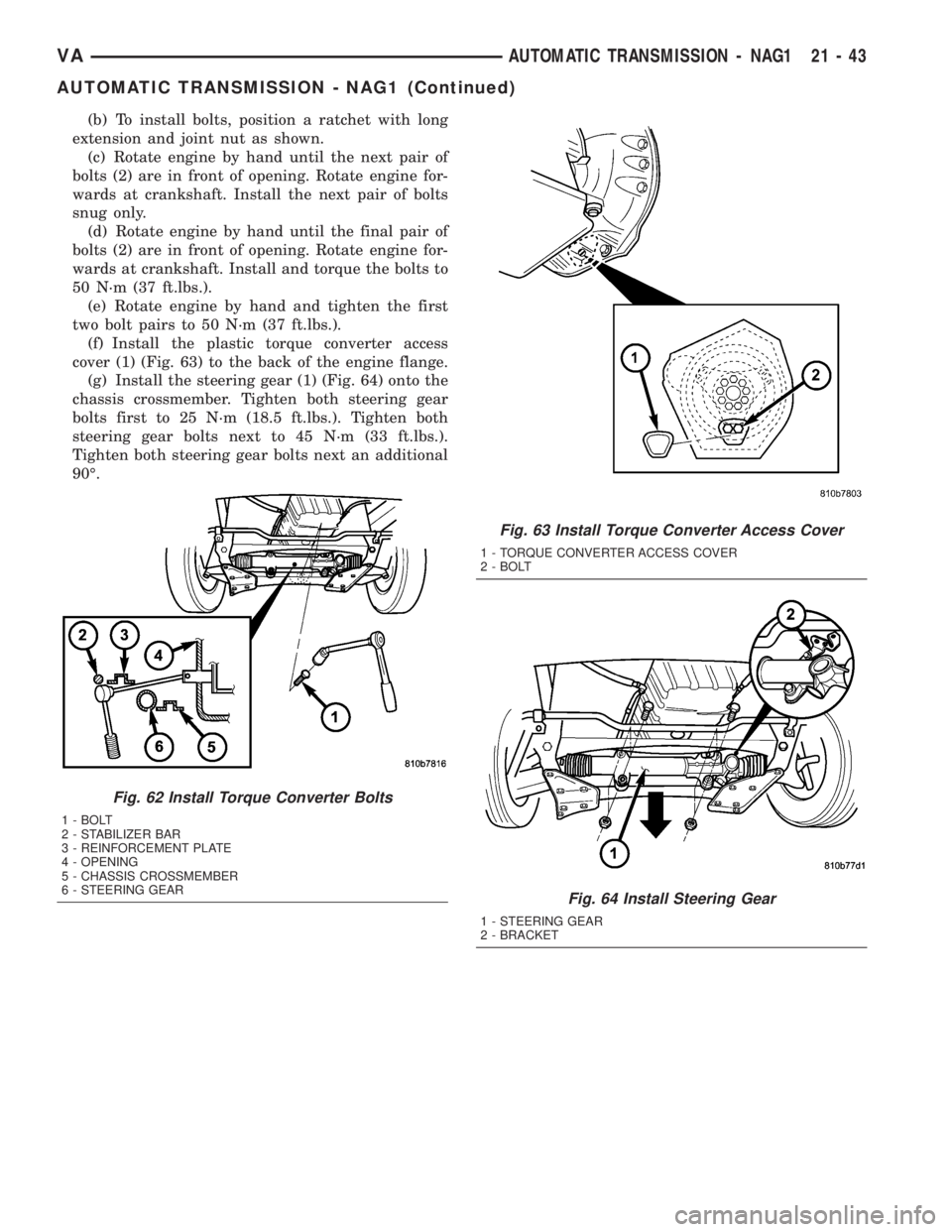

(b) To install bolts, position a ratchet with long

extension and joint nut as shown.

(c) Rotate engine by hand until the next pair of

bolts (2) are in front of opening. Rotate engine for-

wards at crankshaft. Install the next pair of bolts

snug only.

(d) Rotate engine by hand until the final pair of

bolts (2) are in front of opening. Rotate engine for-

wards at crankshaft. Install and torque the bolts to

50 N´m (37 ft.lbs.).

(e) Rotate engine by hand and tighten the first

two bolt pairs to 50 N´m (37 ft.lbs.).

(f) Install the plastic torque converter access

cover (1) (Fig. 63) to the back of the engine flange.

(g) Install the steering gear (1) (Fig. 64) onto the

chassis crossmember. Tighten both steering gear

bolts first to 25 N´m (18.5 ft.lbs.). Tighten both

steering gear bolts next to 45 N´m (33 ft.lbs.).

Tighten both steering gear bolts next an additional

90É.

Fig. 62 Install Torque Converter Bolts

1 - BOLT

2 - STABILIZER BAR

3 - REINFORCEMENT PLATE

4 - OPENING

5 - CHASSIS CROSSMEMBER

6 - STEERING GEAR

Fig. 63 Install Torque Converter Access Cover

1 - TORQUE CONVERTER ACCESS COVER

2 - BOLT

Fig. 64 Install Steering Gear

1 - STEERING GEAR

2 - BRACKET

VAAUTOMATIC TRANSMISSION - NAG1 21 - 43

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 920 of 1232

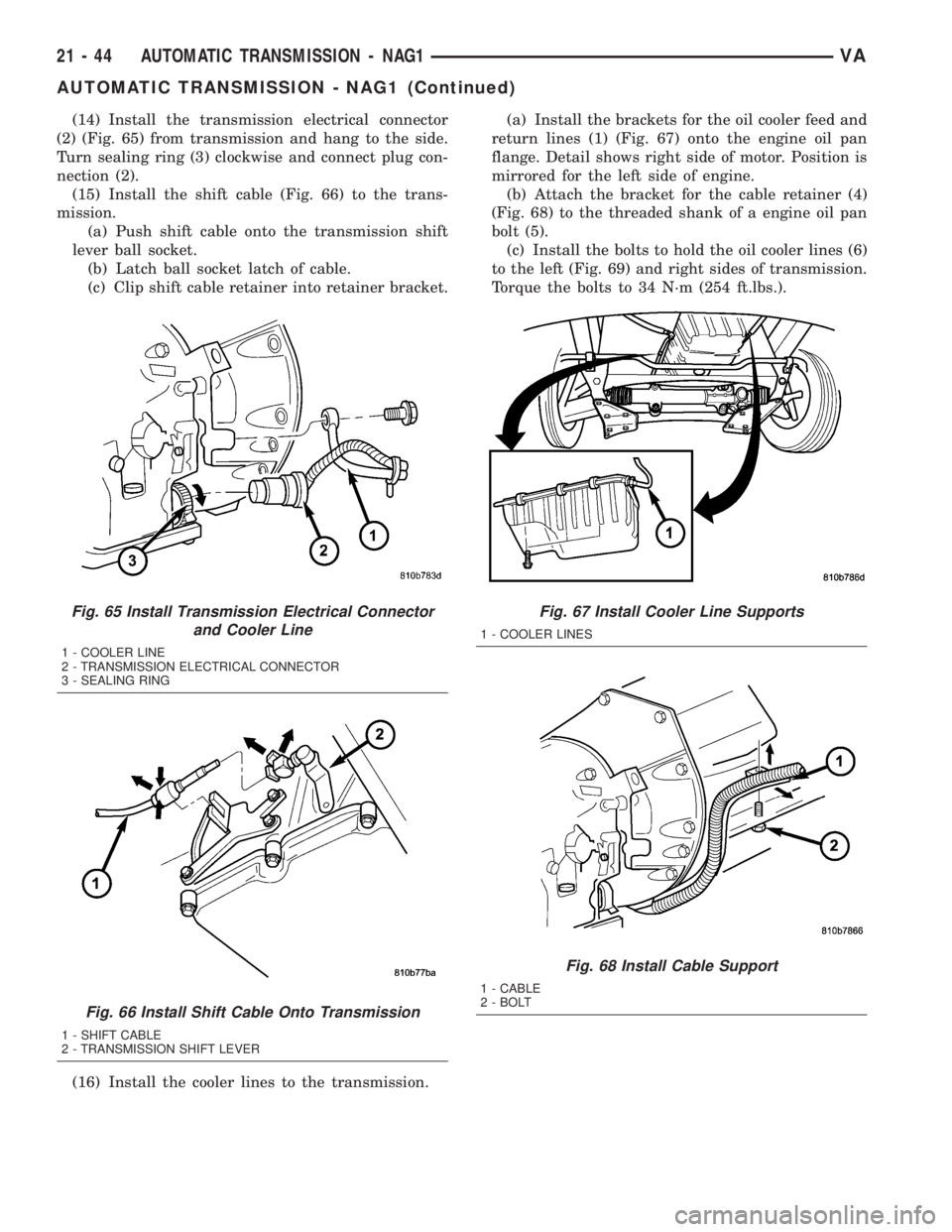

(14) Install the transmission electrical connector

(2) (Fig. 65) from transmission and hang to the side.

Turn sealing ring (3) clockwise and connect plug con-

nection (2).

(15) Install the shift cable (Fig. 66) to the trans-

mission.

(a) Push shift cable onto the transmission shift

lever ball socket.

(b) Latch ball socket latch of cable.

(c) Clip shift cable retainer into retainer bracket.

(16) Install the cooler lines to the transmission.(a) Install the brackets for the oil cooler feed and

return lines (1) (Fig. 67) onto the engine oil pan

flange. Detail shows right side of motor. Position is

mirrored for the left side of engine.

(b) Attach the bracket for the cable retainer (4)

(Fig. 68) to the threaded shank of a engine oil pan

bolt (5).

(c) Install the bolts to hold the oil cooler lines (6)

to the left (Fig. 69) and right sides of transmission.

Torque the bolts to 34 N´m (254 ft.lbs.).

Fig. 65 Install Transmission Electrical Connector

and Cooler Line

1 - COOLER LINE

2 - TRANSMISSION ELECTRICAL CONNECTOR

3 - SEALING RING

Fig. 66 Install Shift Cable Onto Transmission

1 - SHIFT CABLE

2 - TRANSMISSION SHIFT LEVER

Fig. 67 Install Cooler Line Supports

1 - COOLER LINES

Fig. 68 Install Cable Support

1 - CABLE

2 - BOLT

21 - 44 AUTOMATIC TRANSMISSION - NAG1VA

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 959 of 1232

Shift Pressure (p-S)

The shift pressure is determined by the shift pres-

sure regulating solenoid valve and the shift pressure

regulating valve. The shift pressure:

²Regulates the pressure in the activating shift

element during the shift phase.

²Determines together with the modulating pres-

sure the pressure reduction at the deactivating shift

element as regulated by the overlap regulating valve.

²Initializes 2nd gear in limp-home mode.

Modulating Pressure (p-Mod)

The modulating pressure influences the size of the

working pressure and determines together with the

shift pressure the pressure regulated at the overlap

regulating valve. The modulating pressure is regu-

lated at the modulating pressure regulating solenoid

valve, which is under regulating valve pressure. The

modulating pressure is variable and relative to the

engine load.Regulating Valve Pressure (p-RV)

The regulating valve pressure is regulated at the

regulating valve pressure regulating valve in relation

to the working pressure (p-A) up to a maximum pres-

sure of 8 bar (116 psi). It supplies the modulating

pressure regulating solenoid valve, the shift pressure

regulating solenoid valve and the shift valve pressure

regulating valve.

Shift Valve Pressure (p-SV)

The shift valve pressure (p-SV) is derived from the

regulating valve pressure (p-RV), is regulated at the

shift valve pressure regulating valve and is then

present at the:

²1-2 and 4-5 shift solenoid valve.

²3-4 shift solenoid valve.

²2-3 shift solenoid valve.

²Torque converter lockup solenoid valve.

²3-4 and 2-3 shift pressure shift valve.

The shift valve pressure (p-SV) controls the com-

mand valves via the upshift/downshift solenoid

valves.

Overlap Pressure (p-š)

The overlap pressure controls the shift component

pressure reduction during a shift phase. The pres-

sure in a shift element as it disengages is controlled

during the shift phase depending on engine load

(modulating pressure) and the pressure in the shift

element as it engages. The adjusted pressure is

inversely proportional to the transmission capability

of the shift element being engaged (controlled over-

lap).

Working Pressure Regulating Valve (Operating Pressure)

The working pressure regulating valve (Fig. 89) is

located in the valve housing of the shift plate. It reg-

ulates the primary pressure of the hydraulic system.

Torque Converter Lockup Clutch Regulating Valve

The torque converter lock-up clutch regulating

valve (Fig. 90) is located in the valve housing of the

electrohydraulic control module. The valve is respon-

sible for the hydraulic control of the torque converter

lockup clutch and distribution of the lubricating oil.

Overlap Regulating Valve

Each shift group is assigned one overlap regulating

valve (Fig. 91). The 1-2 / 4-5 overlap regulating valve

is installed in the shift valve housing; the 2-3 and 3-4

overlap regulating valves are installed in the valve

housing. The overlap regulating valve regulates the

pressure reduction during a shift phase.

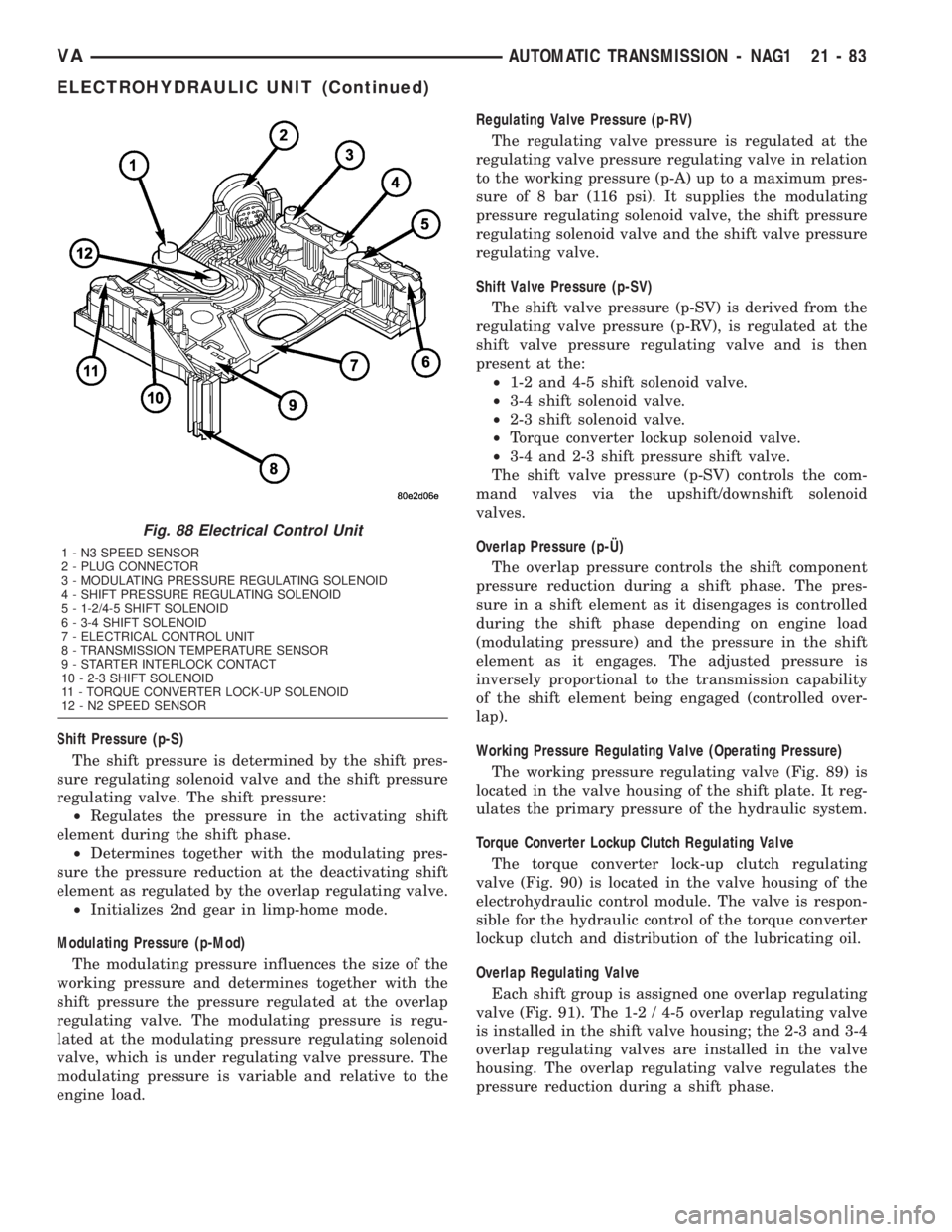

Fig. 88 Electrical Control Unit

1 - N3 SPEED SENSOR

2 - PLUG CONNECTOR

3 - MODULATING PRESSURE REGULATING SOLENOID

4 - SHIFT PRESSURE REGULATING SOLENOID

5 - 1-2/4-5 SHIFT SOLENOID

6 - 3-4 SHIFT SOLENOID

7 - ELECTRICAL CONTROL UNIT

8 - TRANSMISSION TEMPERATURE SENSOR

9 - STARTER INTERLOCK CONTACT

10 - 2-3 SHIFT SOLENOID

11 - TORQUE CONVERTER LOCK-UP SOLENOID

12 - N2 SPEED SENSOR

VAAUTOMATIC TRANSMISSION - NAG1 21 - 83

ELECTROHYDRAULIC UNIT (Continued)

Page 965 of 1232

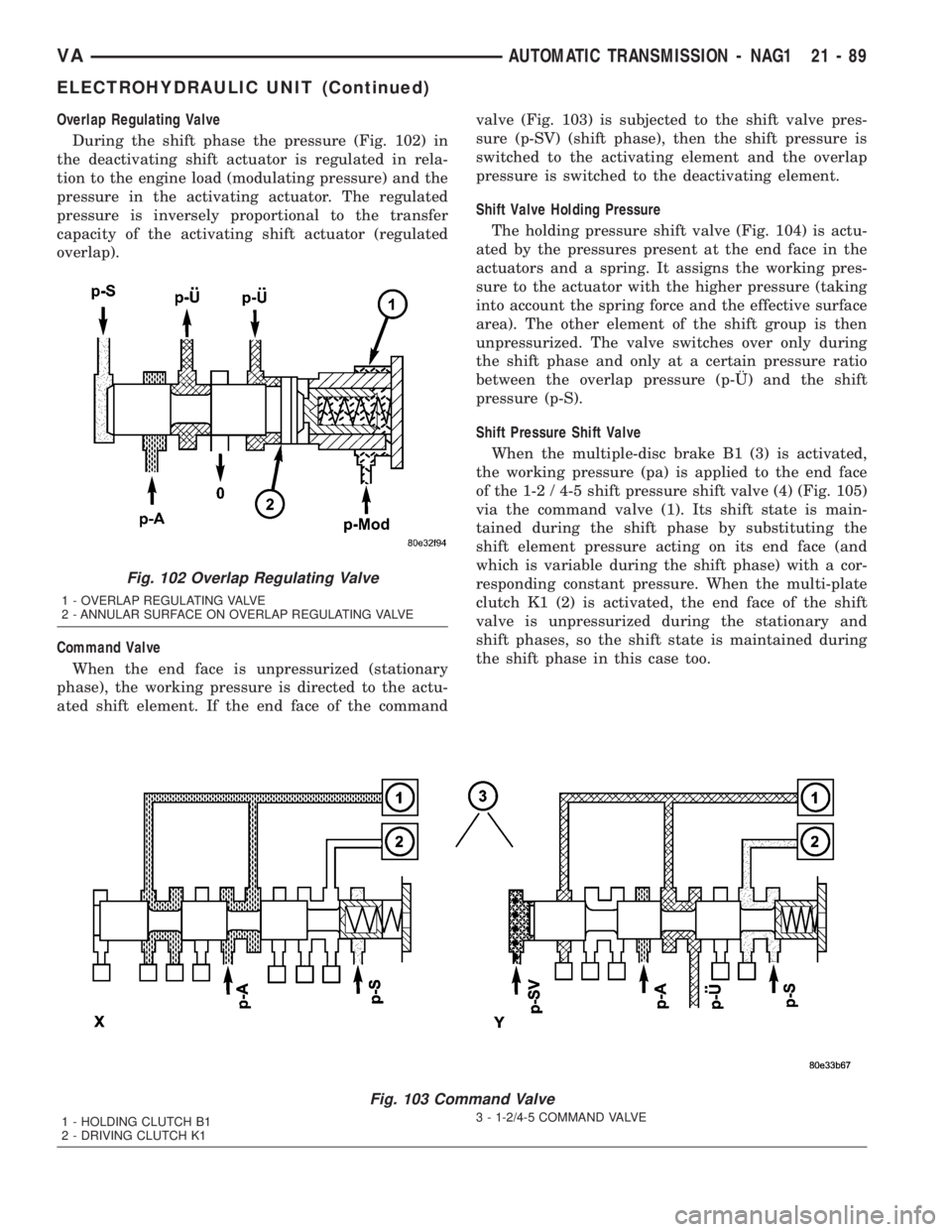

Overlap Regulating Valve

During the shift phase the pressure (Fig. 102) in

the deactivating shift actuator is regulated in rela-

tion to the engine load (modulating pressure) and the

pressure in the activating actuator. The regulated

pressure is inversely proportional to the transfer

capacity of the activating shift actuator (regulated

overlap).

Command Valve

When the end face is unpressurized (stationary

phase), the working pressure is directed to the actu-

ated shift element. If the end face of the commandvalve (Fig. 103) is subjected to the shift valve pres-

sure (p-SV) (shift phase), then the shift pressure is

switched to the activating element and the overlap

pressure is switched to the deactivating element.

Shift Valve Holding Pressure

The holding pressure shift valve (Fig. 104) is actu-

ated by the pressures present at the end face in the

actuators and a spring. It assigns the working pres-

sure to the actuator with the higher pressure (taking

into account the spring force and the effective surface

area). The other element of the shift group is then

unpressurized. The valve switches over only during

the shift phase and only at a certain pressure ratio

between the overlap pressure (p-š) and the shift

pressure (p-S).

Shift Pressure Shift Valve

When the multiple-disc brake B1 (3) is activated,

the working pressure (pa) is applied to the end face

of the 1-2 / 4-5 shift pressure shift valve (4) (Fig. 105)

via the command valve (1). Its shift state is main-

tained during the shift phase by substituting the

shift element pressure acting on its end face (and

which is variable during the shift phase) with a cor-

responding constant pressure. When the multi-plate

clutch K1 (2) is activated, the end face of the shift

valve is unpressurized during the stationary and

shift phases, so the shift state is maintained during

the shift phase in this case too.

Fig. 103 Command Valve

1 - HOLDING CLUTCH B1

2 - DRIVING CLUTCH K13 - 1-2/4-5 COMMAND VALVE

Fig. 102 Overlap Regulating Valve

1 - OVERLAP REGULATING VALVE

2 - ANNULAR SURFACE ON OVERLAP REGULATING VALVE

VAAUTOMATIC TRANSMISSION - NAG1 21 - 89

ELECTROHYDRAULIC UNIT (Continued)

Page 978 of 1232

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - EFFECTS OF

INCORRECT FLUID LEVEL

A low fluid level allows the pump to take in air

along with the fluid. Air in the fluid will cause fluid

pressures to be low and develop slower than normal.

If the transmission is overfilled, the gears churn the

fluid into foam. This aerates the fluid and causing

the same conditions occurring with a low level. In

either case, air bubbles cause fluid overheating, oxi-

dation and varnish buildup which interferes with

valve and clutch operation. Foaming also causes fluid

expansion which can result in fluid overflow from the

transmission vent or fill tube. Fluid overflow can eas-

ily be mistaken for a leak if inspection is not careful.

DIAGNOSIS AND TESTING - CAUSES OF

BURNT FLUID

Burnt, discolored fluid is a result of overheating

which has three primary causes.

(1) Internal clutch slippage, usually caused by low

line pressure, inadequate clutch apply pressure, or

clutch seal failure.

(2) A result of restricted fluid flow through the

main and/or auxiliary cooler. This condition is usu-

ally the result of a faulty or improperly installed

drainback valve, a damaged main cooler, or severe

restrictions in the coolers and lines caused by debris

or kinked lines.

(3) Heavy duty operation with a vehicle not prop-

erly equipped for this type of operation. Trailer tow-

ing or similar high load operation will overheat the

transmission fluid if the vehicle is improperly

equipped. Such vehicles should have an auxiliary

transmission fluid cooler, a heavy duty cooling sys-

tem, and the engine/axle ratio combination needed to

handle heavy loads.

DIAGNOSIS AND TESTING - FLUID

CONTAMINATION

Transmission fluid contamination is generally a

result of:

²adding incorrect fluid

²failure to clean dipstick and fill tube when

checking level

²engine coolant entering the fluid

²internal failure that generates debris

²overheat that generates sludge (fluid break-

down)

²failure to replace contaminated converter after

repair

The use of non-recommended fluids can result in

transmission failure. The usual results are erratic

shifts, slippage, abnormal wear and eventual failuredue to fluid breakdown and sludge formation. Avoid

this condition by using recommended fluids only.

The dipstick cap and fill tube should be wiped

clean before checking fluid level. Dirt, grease and

other foreign material on the cap and tube could fall

into the tube if not removed beforehand. Take the

time to wipe the cap and tube clean before withdraw-

ing the dipstick.

Engine coolant in the transmission fluid is gener-

ally caused by a cooler malfunction. The only remedy

is to replace the radiator as the cooler in the radiator

is not a serviceable part. If coolant has circulated

through the transmission, an overhaul is necessary.

The torque converter should be replaced whenever

a failure generates sludge and debris. This is neces-

sary because normal converter flushing procedures

will not remove all contaminants.

STANDARD PROCEDURE

STANDARD PROCEDURE - CHECK OIL LEVEL

(1) Verify that the vehicle is parked on a level sur-

face.

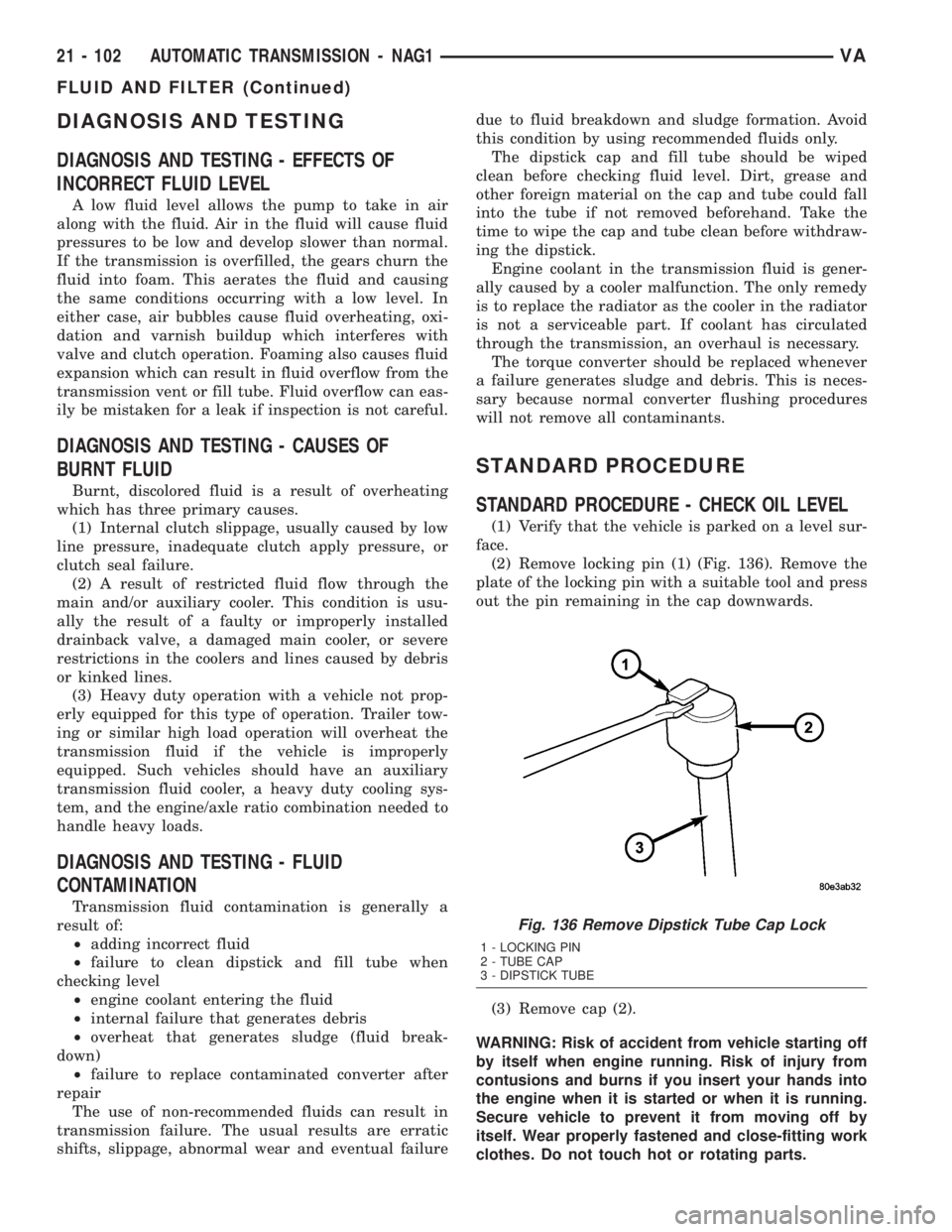

(2) Remove locking pin (1) (Fig. 136). Remove the

plate of the locking pin with a suitable tool and press

out the pin remaining in the cap downwards.

(3) Remove cap (2).

WARNING: Risk of accident from vehicle starting off

by itself when engine running. Risk of injury from

contusions and burns if you insert your hands into

the engine when it is started or when it is running.

Secure vehicle to prevent it from moving off by

itself. Wear properly fastened and close-fitting work

clothes. Do not touch hot or rotating parts.

Fig. 136 Remove Dipstick Tube Cap Lock

1 - LOCKING PIN

2 - TUBE CAP

3 - DIPSTICK TUBE

21 - 102 AUTOMATIC TRANSMISSION - NAG1VA

FLUID AND FILTER (Continued)

Page 979 of 1232

(4) Actuate the service brake. Start engine and let

it run at idle speed in selector lever position9P9.

(5) Shift through the transmission modes several

times with the vehicle stationary and the engine

idling

(6) Warm up the transmission, wait at least 2 min-

utes and check the oil level with the engine running.

Push the Oil Dipstick 8863A in up to the stop on the

electrohydraulic unit and pull out again, read off oil

level, repeat if necessary.

NOTE: The dipstick will protrude from the fill tube

approximately 75mm (3 inches) when installed.

(7) Check transmission oil temperature.

NOTE: The true transmission oil temperature can

only be read by a scan tool in REVERSE or any for-

ward gear position. (Refer to 21 - AUTOMATIC

TRANSMISSION- NAG1/TRANSMISSION TEMPERA-

TURE SENSOR/PARK-NEUTRAL SWITCH - OPERA-

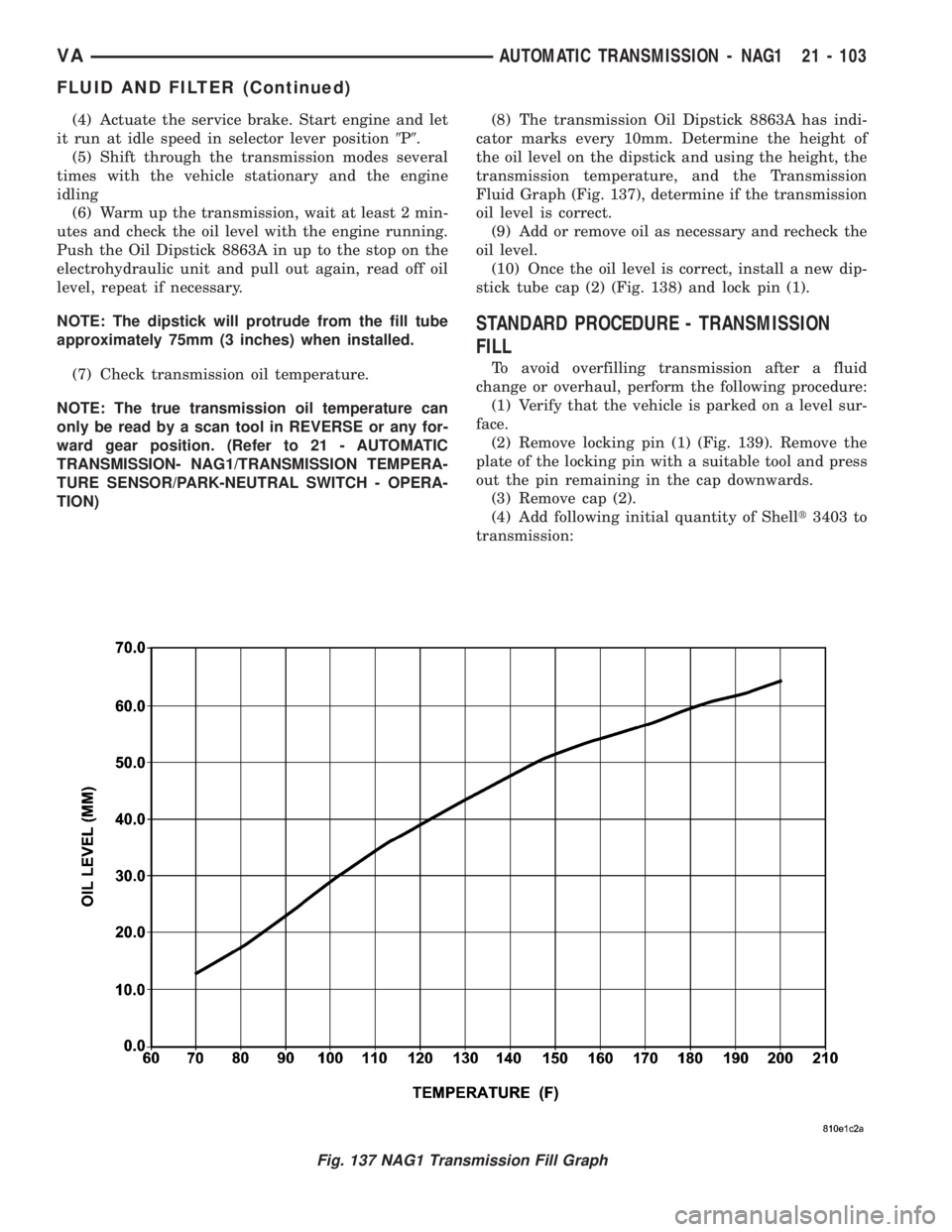

TION)(8) The transmission Oil Dipstick 8863A has indi-

cator marks every 10mm. Determine the height of

the oil level on the dipstick and using the height, the

transmission temperature, and the Transmission

Fluid Graph (Fig. 137), determine if the transmission

oil level is correct.

(9) Add or remove oil as necessary and recheck the

oil level.

(10) Once the oil level is correct, install a new dip-

stick tube cap (2) (Fig. 138) and lock pin (1).

STANDARD PROCEDURE - TRANSMISSION

FILL

To avoid overfilling transmission after a fluid

change or overhaul, perform the following procedure:

(1) Verify that the vehicle is parked on a level sur-

face.

(2) Remove locking pin (1) (Fig. 139). Remove the

plate of the locking pin with a suitable tool and press

out the pin remaining in the cap downwards.

(3) Remove cap (2).

(4) Add following initial quantity of Shellt3403 to

transmission:

Fig. 137 NAG1 Transmission Fill Graph

VAAUTOMATIC TRANSMISSION - NAG1 21 - 103

FLUID AND FILTER (Continued)