MERCEDES-BENZ SPRINTER 2005 Service Repair Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 901 of 1232

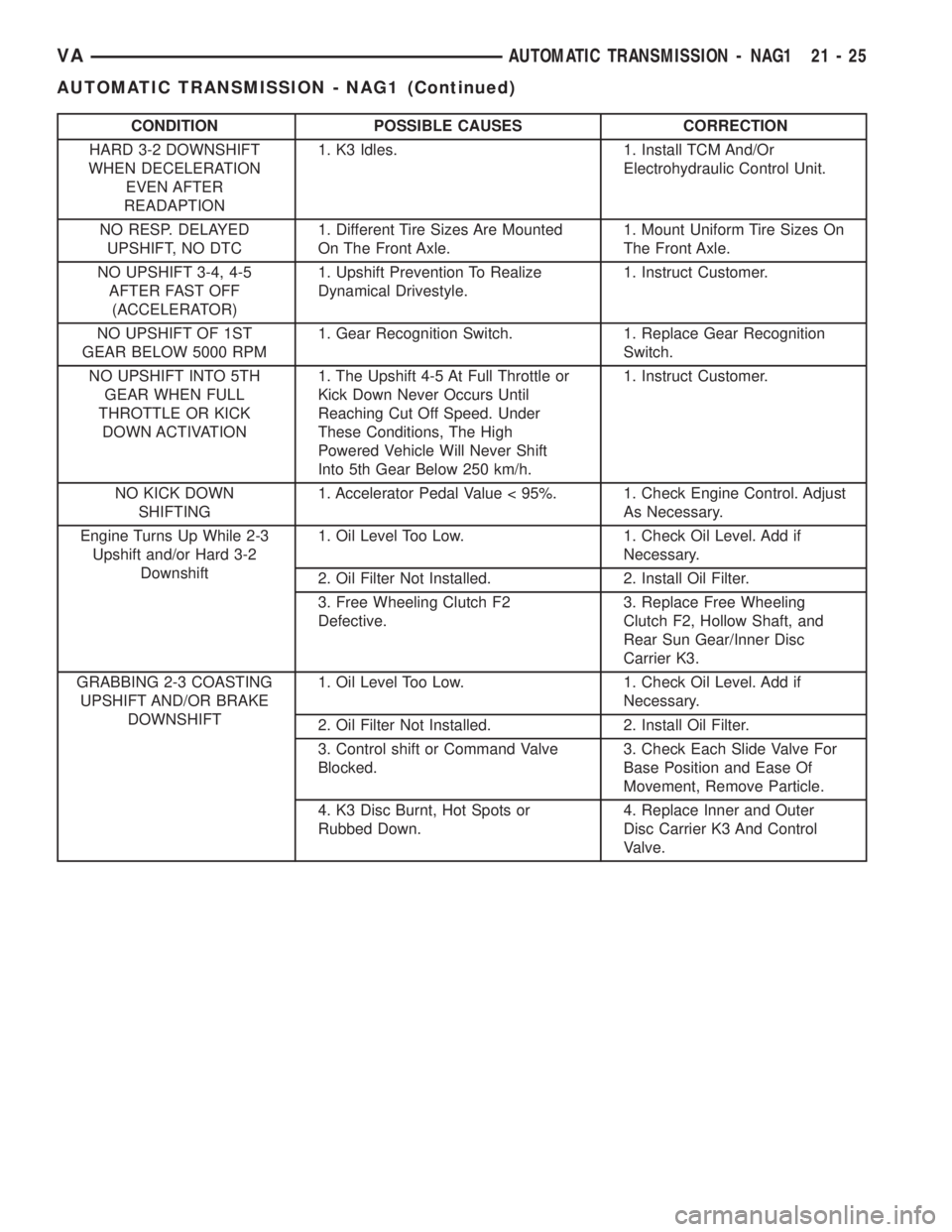

CONDITION POSSIBLE CAUSES CORRECTION

HARD 3-2 DOWNSHIFT

WHEN DECELERATION

EVEN AFTER

READAPTION1. K3 Idles. 1. Install TCM And/Or

Electrohydraulic Control Unit.

NO RESP. DELAYED

UPSHIFT, NO DTC1. Different Tire Sizes Are Mounted

On The Front Axle.1. Mount Uniform Tire Sizes On

The Front Axle.

NO UPSHIFT 3-4, 4-5

AFTER FAST OFF

(ACCELERATOR)1. Upshift Prevention To Realize

Dynamical Drivestyle.1. Instruct Customer.

NO UPSHIFT OF 1ST

GEAR BELOW 5000 RPM1. Gear Recognition Switch. 1. Replace Gear Recognition

Switch.

NO UPSHIFT INTO 5TH

GEAR WHEN FULL

THROTTLE OR KICK

DOWN ACTIVATION1. The Upshift 4-5 At Full Throttle or

Kick Down Never Occurs Until

Reaching Cut Off Speed. Under

These Conditions, The High

Powered Vehicle Will Never Shift

Into 5th Gear Below 250 km/h.1. Instruct Customer.

NO KICK DOWN

SHIFTING1. Accelerator Pedal Value < 95%. 1. Check Engine Control. Adjust

As Necessary.

Engine Turns Up While 2-3

Upshift and/or Hard 3-2

Downshift1. Oil Level Too Low. 1. Check Oil Level. Add if

Necessary.

2. Oil Filter Not Installed. 2. Install Oil Filter.

3. Free Wheeling Clutch F2

Defective.3. Replace Free Wheeling

Clutch F2, Hollow Shaft, and

Rear Sun Gear/Inner Disc

Carrier K3.

GRABBING 2-3 COASTING

UPSHIFT AND/OR BRAKE

DOWNSHIFT1. Oil Level Too Low. 1. Check Oil Level. Add if

Necessary.

2. Oil Filter Not Installed. 2. Install Oil Filter.

3. Control shift or Command Valve

Blocked.3. Check Each Slide Valve For

Base Position and Ease Of

Movement, Remove Particle.

4. K3 Disc Burnt, Hot Spots or

Rubbed Down.4. Replace Inner and Outer

Disc Carrier K3 And Control

Valve.

VAAUTOMATIC TRANSMISSION - NAG1 21 - 25

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 902 of 1232

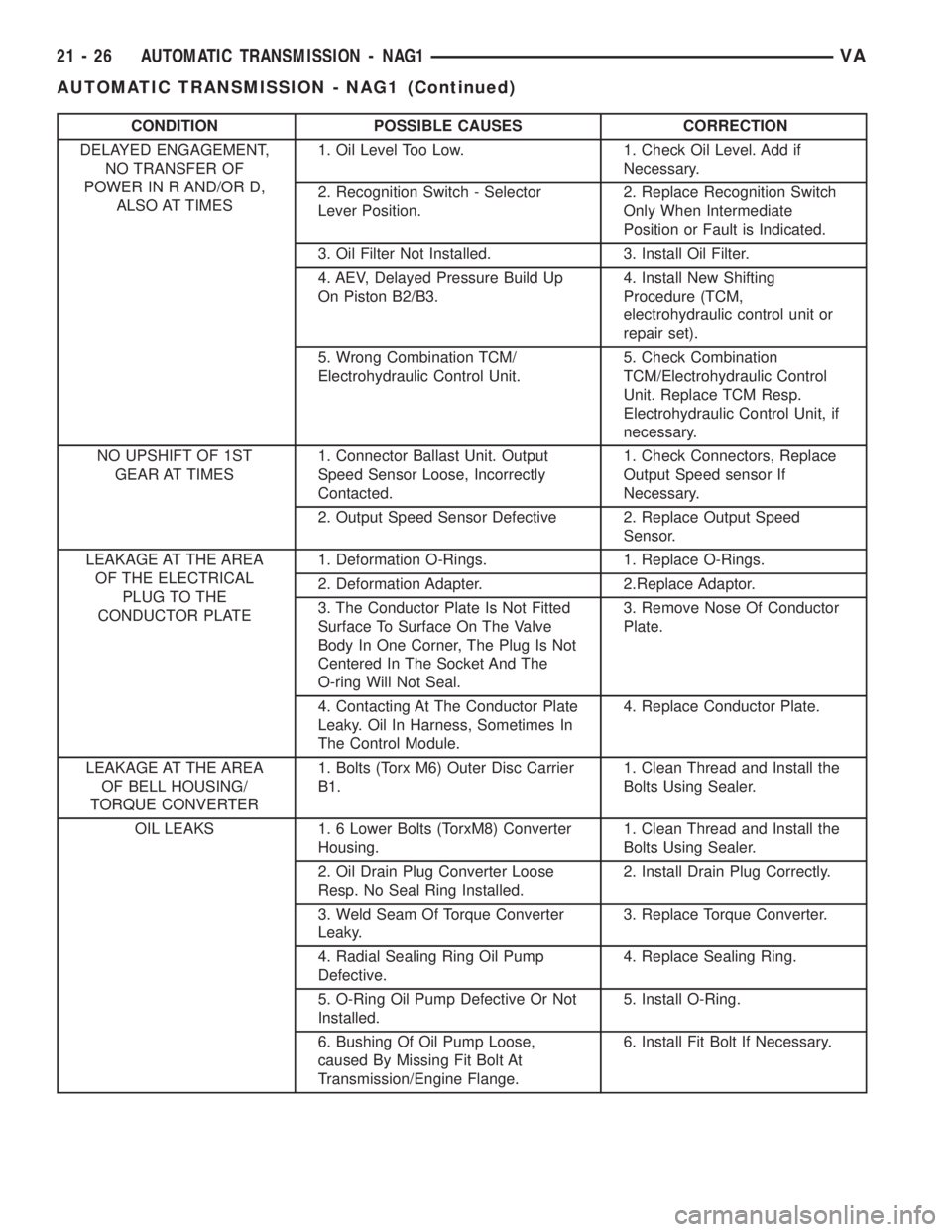

CONDITION POSSIBLE CAUSES CORRECTION

DELAYED ENGAGEMENT,

NO TRANSFER OF

POWER IN R AND/OR D,

ALSO AT TIMES1. Oil Level Too Low. 1. Check Oil Level. Add if

Necessary.

2. Recognition Switch - Selector

Lever Position.2. Replace Recognition Switch

Only When Intermediate

Position or Fault is Indicated.

3. Oil Filter Not Installed. 3. Install Oil Filter.

4. AEV, Delayed Pressure Build Up

On Piston B2/B3.4. Install New Shifting

Procedure (TCM,

electrohydraulic control unit or

repair set).

5. Wrong Combination TCM/

Electrohydraulic Control Unit.5. Check Combination

TCM/Electrohydraulic Control

Unit. Replace TCM Resp.

Electrohydraulic Control Unit, if

necessary.

NO UPSHIFT OF 1ST

GEAR AT TIMES1. Connector Ballast Unit. Output

Speed Sensor Loose, Incorrectly

Contacted.1. Check Connectors, Replace

Output Speed sensor If

Necessary.

2. Output Speed Sensor Defective 2. Replace Output Speed

Sensor.

LEAKAGE AT THE AREA

OF THE ELECTRICAL

PLUG TO THE

CONDUCTOR PLATE1. Deformation O-Rings. 1. Replace O-Rings.

2. Deformation Adapter. 2.Replace Adaptor.

3. The Conductor Plate Is Not Fitted

Surface To Surface On The Valve

Body In One Corner, The Plug Is Not

Centered In The Socket And The

O-ring Will Not Seal.3. Remove Nose Of Conductor

Plate.

4. Contacting At The Conductor Plate

Leaky. Oil In Harness, Sometimes In

The Control Module.4. Replace Conductor Plate.

LEAKAGE AT THE AREA

OF BELL HOUSING/

TORQUE CONVERTER1. Bolts (Torx M6) Outer Disc Carrier

B1.1. Clean Thread and Install the

Bolts Using Sealer.

OIL LEAKS 1. 6 Lower Bolts (TorxM8) Converter

Housing.1. Clean Thread and Install the

Bolts Using Sealer.

2. Oil Drain Plug Converter Loose

Resp. No Seal Ring Installed.2. Install Drain Plug Correctly.

3. Weld Seam Of Torque Converter

Leaky.3. Replace Torque Converter.

4. Radial Sealing Ring Oil Pump

Defective.4. Replace Sealing Ring.

5. O-Ring Oil Pump Defective Or Not

Installed.5. Install O-Ring.

6. Bushing Of Oil Pump Loose,

caused By Missing Fit Bolt At

Transmission/Engine Flange.6. Install Fit Bolt If Necessary.

21 - 26 AUTOMATIC TRANSMISSION - NAG1VA

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 903 of 1232

STANDARD PROCEDURE - ALUMINUM

THREAD REPAIR

Damaged or worn threads in the aluminum trans-

mission case and valve body can be repaired by the

use of Heli-CoilsŸ, or equivalent. This repair con-

sists of drilling out the worn-out damaged threads.

Then tap the hole with a special Heli-CoilŸ tap, or

equivalent, and installing a Heli-CoilŸ insert, or

equivalent, into the hole. This brings the hole back to

its original thread size.

Heli-CoilŸ, or equivalent, tools and inserts are

readily available from most automotive parts suppli-

ers.

REMOVAL

(1) Disconnect the negative (ground) battery cable.

CAUTION: Isolate ground lead to prevent accidental

contact.

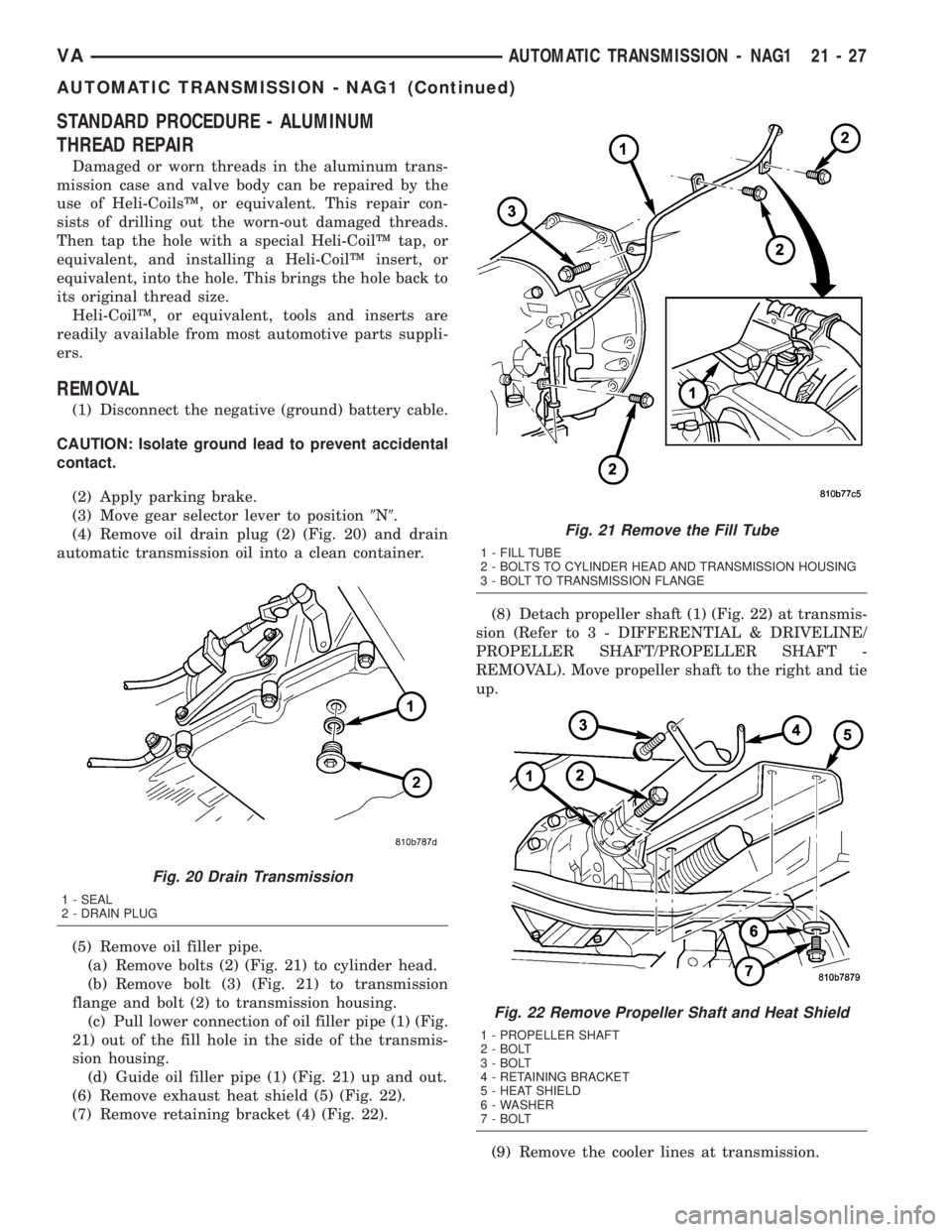

(2) Apply parking brake.

(3) Move gear selector lever to position9N9.

(4) Remove oil drain plug (2) (Fig. 20) and drain

automatic transmission oil into a clean container.

(5) Remove oil filler pipe.

(a) Remove bolts (2) (Fig. 21) to cylinder head.

(b) Remove bolt (3) (Fig. 21) to transmission

flange and bolt (2) to transmission housing.

(c) Pull lower connection of oil filler pipe (1) (Fig.

21) out of the fill hole in the side of the transmis-

sion housing.

(d) Guide oil filler pipe (1) (Fig. 21) up and out.

(6) Remove exhaust heat shield (5) (Fig. 22).

(7) Remove retaining bracket (4) (Fig. 22).(8) Detach propeller shaft (1) (Fig. 22) at transmis-

sion (Refer to 3 - DIFFERENTIAL & DRIVELINE/

PROPELLER SHAFT/PROPELLER SHAFT -

REMOVAL). Move propeller shaft to the right and tie

up.

(9) Remove the cooler lines at transmission.

Fig. 20 Drain Transmission

1 - SEAL

2 - DRAIN PLUG

Fig. 21 Remove the Fill Tube

1 - FILL TUBE

2 - BOLTS TO CYLINDER HEAD AND TRANSMISSION HOUSING

3 - BOLT TO TRANSMISSION FLANGE

Fig. 22 Remove Propeller Shaft and Heat Shield

1 - PROPELLER SHAFT

2 - BOLT

3 - BOLT

4 - RETAINING BRACKET

5 - HEAT SHIELD

6 - WASHER

7 - BOLT

VAAUTOMATIC TRANSMISSION - NAG1 21 - 27

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 904 of 1232

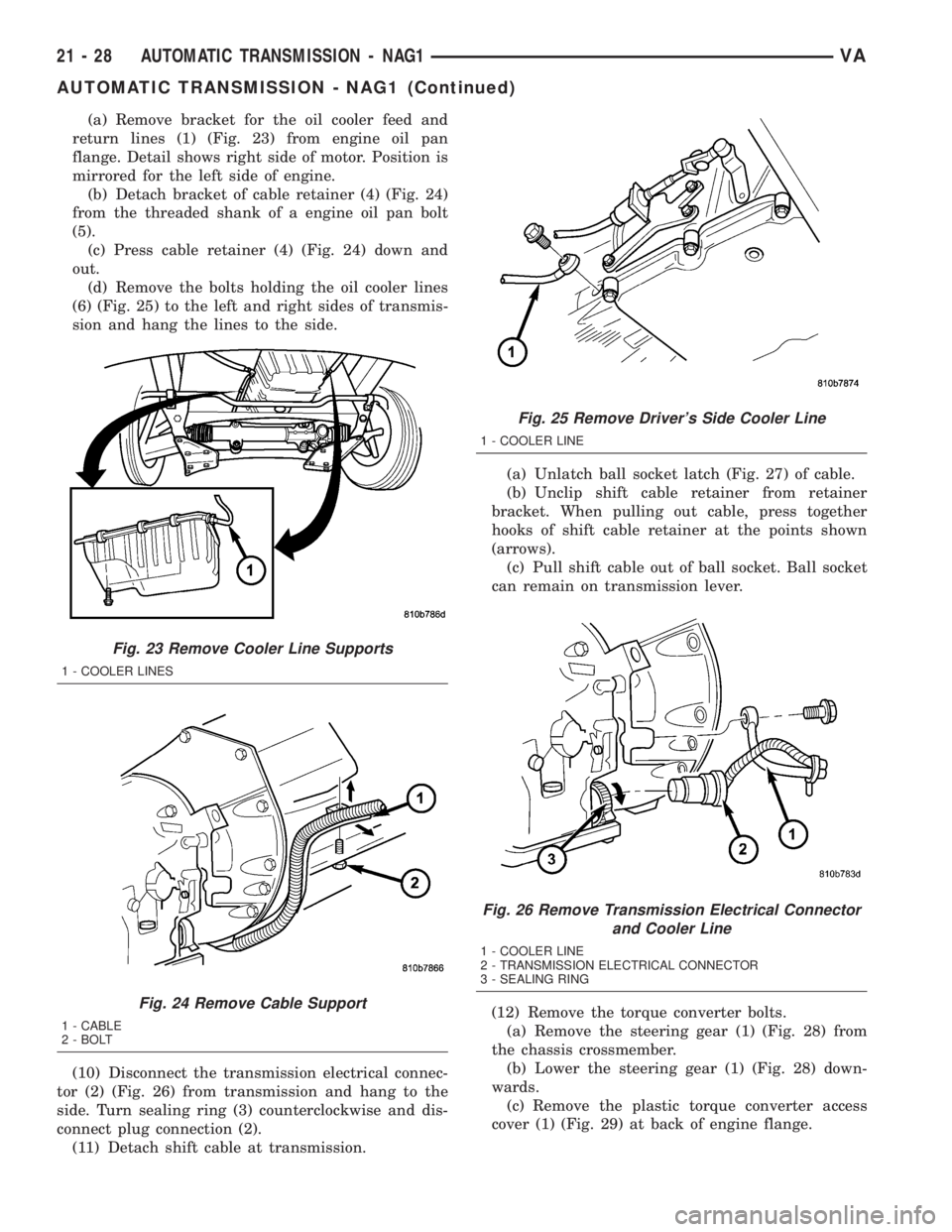

(a) Remove bracket for the oil cooler feed and

return lines (1) (Fig. 23) from engine oil pan

flange. Detail shows right side of motor. Position is

mirrored for the left side of engine.

(b) Detach bracket of cable retainer (4) (Fig. 24)

from the threaded shank of a engine oil pan bolt

(5).

(c) Press cable retainer (4) (Fig. 24) down and

out.

(d) Remove the bolts holding the oil cooler lines

(6) (Fig. 25) to the left and right sides of transmis-

sion and hang the lines to the side.

(10) Disconnect the transmission electrical connec-

tor (2) (Fig. 26) from transmission and hang to the

side. Turn sealing ring (3) counterclockwise and dis-

connect plug connection (2).

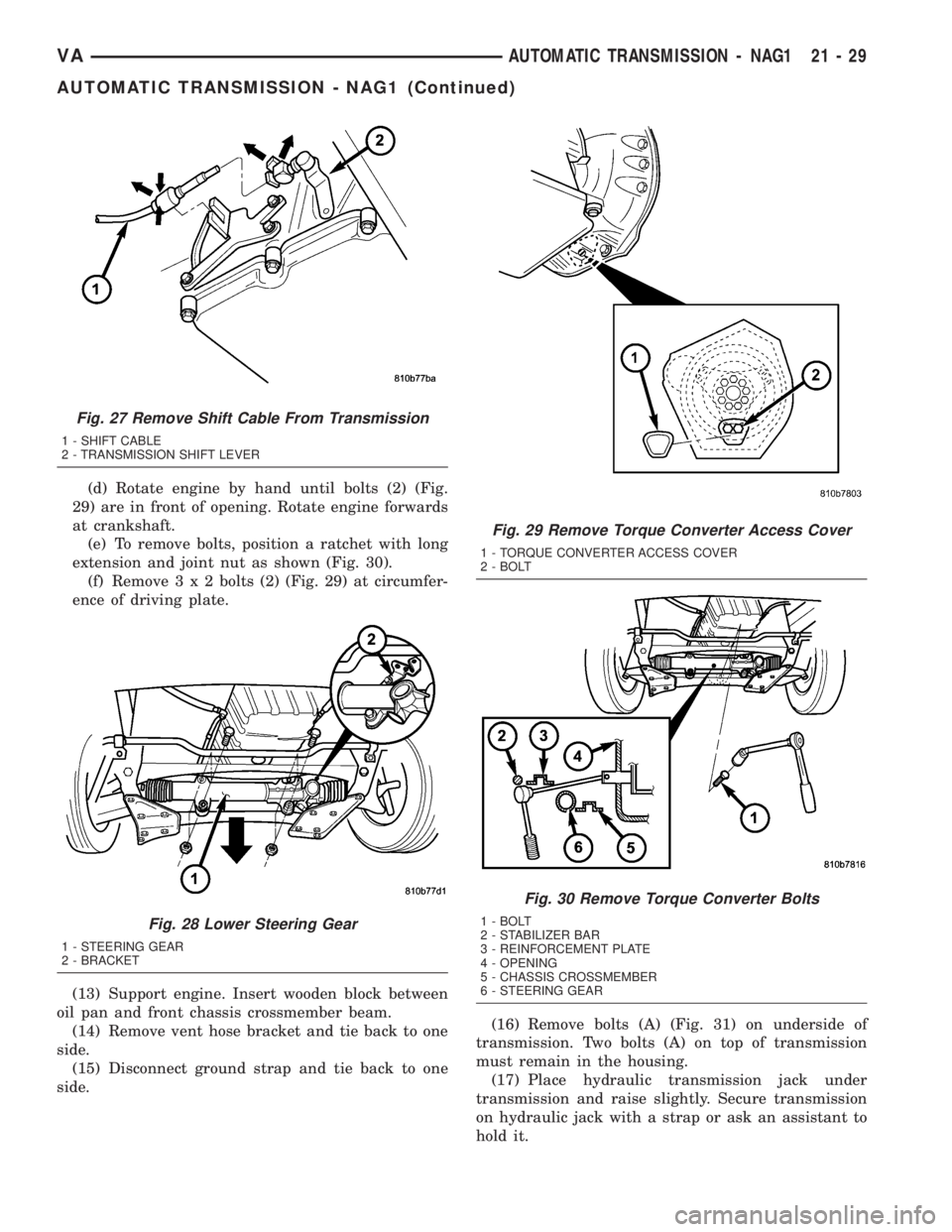

(11) Detach shift cable at transmission.(a) Unlatch ball socket latch (Fig. 27) of cable.

(b) Unclip shift cable retainer from retainer

bracket. When pulling out cable, press together

hooks of shift cable retainer at the points shown

(arrows).

(c) Pull shift cable out of ball socket. Ball socket

can remain on transmission lever.

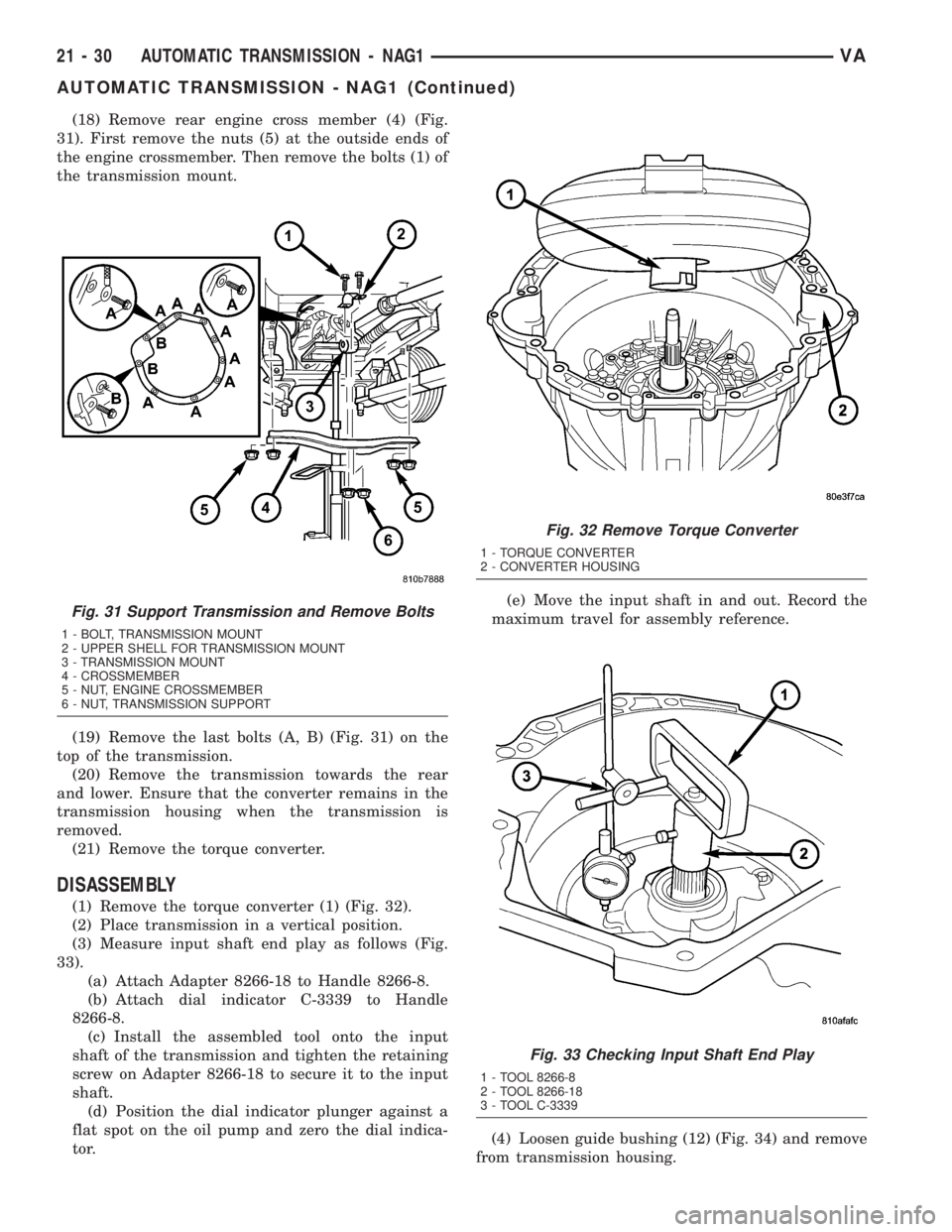

(12) Remove the torque converter bolts.

(a) Remove the steering gear (1) (Fig. 28) from

the chassis crossmember.

(b) Lower the steering gear (1) (Fig. 28) down-

wards.

(c) Remove the plastic torque converter access

cover (1) (Fig. 29) at back of engine flange.

Fig. 23 Remove Cooler Line Supports

1 - COOLER LINES

Fig. 24 Remove Cable Support

1 - CABLE

2 - BOLT

Fig. 25 Remove Driver's Side Cooler Line

1 - COOLER LINE

Fig. 26 Remove Transmission Electrical Connector

and Cooler Line

1 - COOLER LINE

2 - TRANSMISSION ELECTRICAL CONNECTOR

3 - SEALING RING

21 - 28 AUTOMATIC TRANSMISSION - NAG1VA

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 905 of 1232

(d) Rotate engine by hand until bolts (2) (Fig.

29) are in front of opening. Rotate engine forwards

at crankshaft.

(e) To remove bolts, position a ratchet with long

extension and joint nut as shown (Fig. 30).

(f) Remove3x2bolts (2) (Fig. 29) at circumfer-

ence of driving plate.

(13) Support engine. Insert wooden block between

oil pan and front chassis crossmember beam.

(14) Remove vent hose bracket and tie back to one

side.

(15) Disconnect ground strap and tie back to one

side.(16) Remove bolts (A) (Fig. 31) on underside of

transmission. Two bolts (A) on top of transmission

must remain in the housing.

(17) Place hydraulic transmission jack under

transmission and raise slightly. Secure transmission

on hydraulic jack with a strap or ask an assistant to

hold it.

Fig. 27 Remove Shift Cable From Transmission

1 - SHIFT CABLE

2 - TRANSMISSION SHIFT LEVER

Fig. 28 Lower Steering Gear

1 - STEERING GEAR

2 - BRACKET

Fig. 29 Remove Torque Converter Access Cover

1 - TORQUE CONVERTER ACCESS COVER

2 - BOLT

Fig. 30 Remove Torque Converter Bolts

1 - BOLT

2 - STABILIZER BAR

3 - REINFORCEMENT PLATE

4 - OPENING

5 - CHASSIS CROSSMEMBER

6 - STEERING GEAR

VAAUTOMATIC TRANSMISSION - NAG1 21 - 29

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 906 of 1232

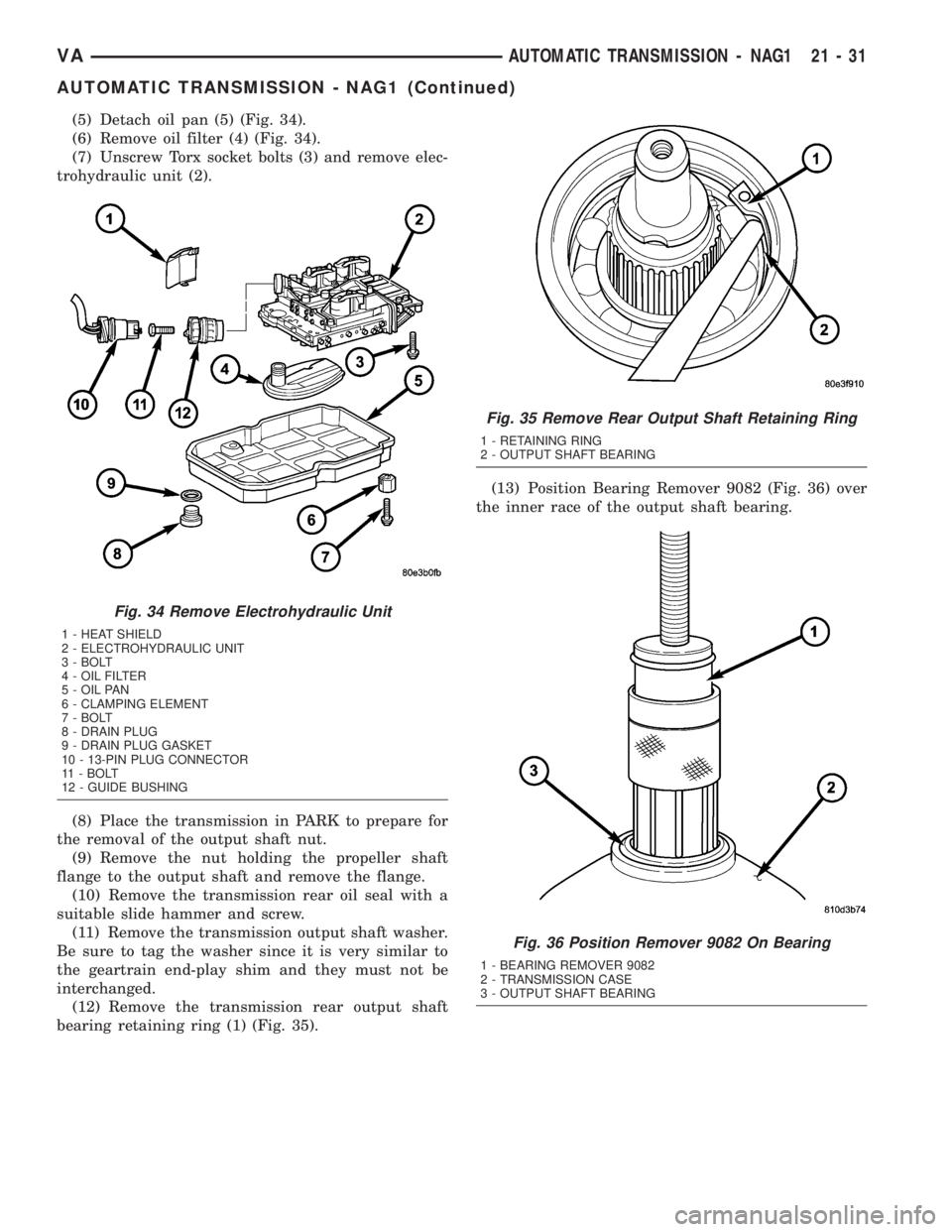

(18) Remove rear engine cross member (4) (Fig.

31). First remove the nuts (5) at the outside ends of

the engine crossmember. Then remove the bolts (1) of

the transmission mount.

(19) Remove the last bolts (A, B) (Fig. 31) on the

top of the transmission.

(20) Remove the transmission towards the rear

and lower. Ensure that the converter remains in the

transmission housing when the transmission is

removed.

(21) Remove the torque converter.

DISASSEMBLY

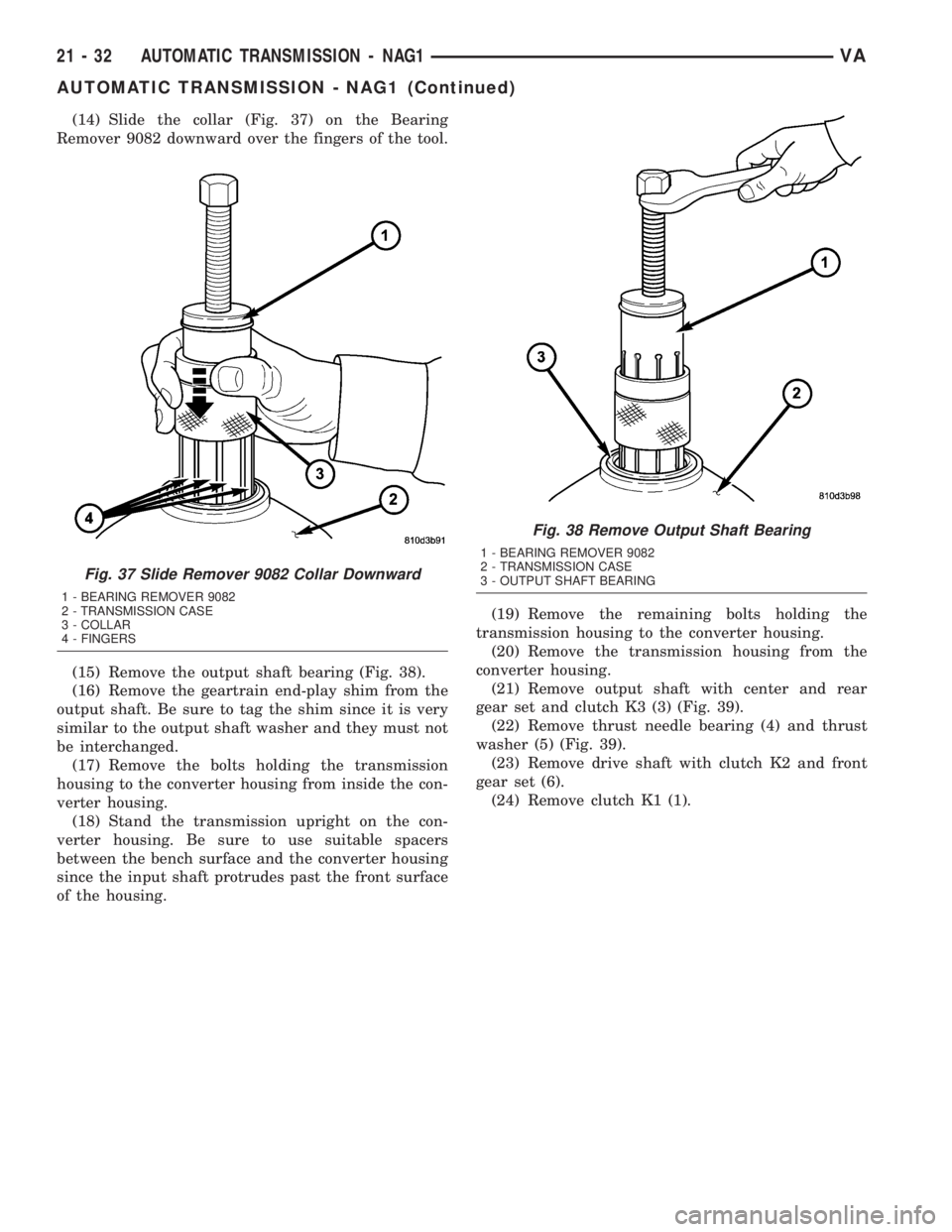

(1) Remove the torque converter (1) (Fig. 32).

(2) Place transmission in a vertical position.

(3) Measure input shaft end play as follows (Fig.

33).

(a) Attach Adapter 8266-18 to Handle 8266-8.

(b) Attach dial indicator C-3339 to Handle

8266-8.

(c) Install the assembled tool onto the input

shaft of the transmission and tighten the retaining

screw on Adapter 8266-18 to secure it to the input

shaft.

(d) Position the dial indicator plunger against a

flat spot on the oil pump and zero the dial indica-

tor.(e) Move the input shaft in and out. Record the

maximum travel for assembly reference.

(4) Loosen guide bushing (12) (Fig. 34) and remove

from transmission housing.

Fig. 31 Support Transmission and Remove Bolts

1 - BOLT, TRANSMISSION MOUNT

2 - UPPER SHELL FOR TRANSMISSION MOUNT

3 - TRANSMISSION MOUNT

4 - CROSSMEMBER

5 - NUT, ENGINE CROSSMEMBER

6 - NUT, TRANSMISSION SUPPORT

Fig. 32 Remove Torque Converter

1 - TORQUE CONVERTER

2 - CONVERTER HOUSING

Fig. 33 Checking Input Shaft End Play

1 - TOOL 8266-8

2 - TOOL 8266-18

3 - TOOL C-3339

21 - 30 AUTOMATIC TRANSMISSION - NAG1VA

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 907 of 1232

(5) Detach oil pan (5) (Fig. 34).

(6) Remove oil filter (4) (Fig. 34).

(7) Unscrew Torx socket bolts (3) and remove elec-

trohydraulic unit (2).

(8) Place the transmission in PARK to prepare for

the removal of the output shaft nut.

(9) Remove the nut holding the propeller shaft

flange to the output shaft and remove the flange.

(10) Remove the transmission rear oil seal with a

suitable slide hammer and screw.

(11) Remove the transmission output shaft washer.

Be sure to tag the washer since it is very similar to

the geartrain end-play shim and they must not be

interchanged.

(12) Remove the transmission rear output shaft

bearing retaining ring (1) (Fig. 35).(13) Position Bearing Remover 9082 (Fig. 36) over

the inner race of the output shaft bearing.

Fig. 34 Remove Electrohydraulic Unit

1 - HEAT SHIELD

2 - ELECTROHYDRAULIC UNIT

3 - BOLT

4 - OIL FILTER

5 - OIL PAN

6 - CLAMPING ELEMENT

7 - BOLT

8 - DRAIN PLUG

9 - DRAIN PLUG GASKET

10 - 13-PIN PLUG CONNECTOR

11 - BOLT

12 - GUIDE BUSHING

Fig. 35 Remove Rear Output Shaft Retaining Ring

1 - RETAINING RING

2 - OUTPUT SHAFT BEARING

Fig. 36 Position Remover 9082 On Bearing

1 - BEARING REMOVER 9082

2 - TRANSMISSION CASE

3 - OUTPUT SHAFT BEARING

VAAUTOMATIC TRANSMISSION - NAG1 21 - 31

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 908 of 1232

(14) Slide the collar (Fig. 37) on the Bearing

Remover 9082 downward over the fingers of the tool.

(15) Remove the output shaft bearing (Fig. 38).

(16) Remove the geartrain end-play shim from the

output shaft. Be sure to tag the shim since it is very

similar to the output shaft washer and they must not

be interchanged.

(17) Remove the bolts holding the transmission

housing to the converter housing from inside the con-

verter housing.

(18) Stand the transmission upright on the con-

verter housing. Be sure to use suitable spacers

between the bench surface and the converter housing

since the input shaft protrudes past the front surface

of the housing.(19) Remove the remaining bolts holding the

transmission housing to the converter housing.

(20) Remove the transmission housing from the

converter housing.

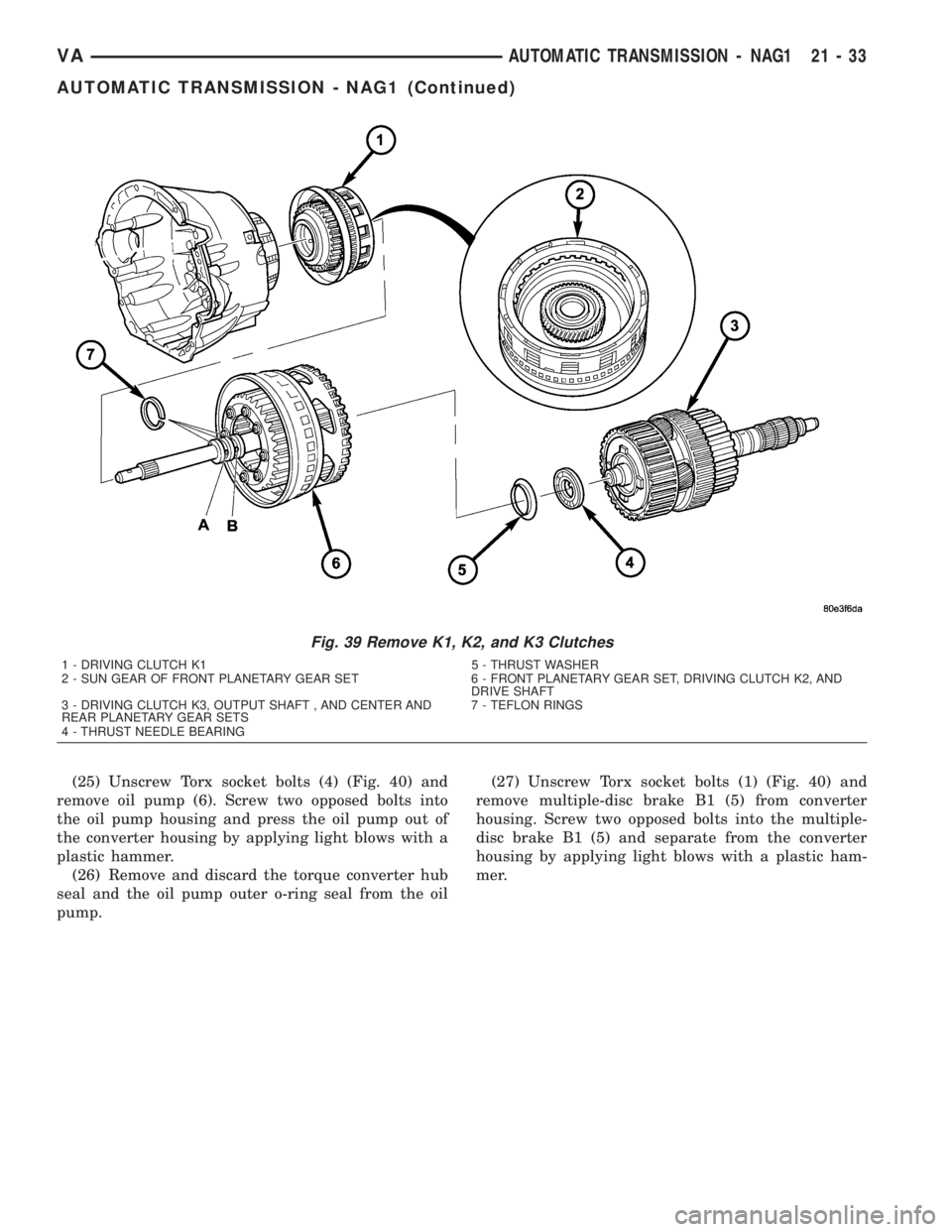

(21) Remove output shaft with center and rear

gear set and clutch K3 (3) (Fig. 39).

(22) Remove thrust needle bearing (4) and thrust

washer (5) (Fig. 39).

(23) Remove drive shaft with clutch K2 and front

gear set (6).

(24) Remove clutch K1 (1).

Fig. 37 Slide Remover 9082 Collar Downward

1 - BEARING REMOVER 9082

2 - TRANSMISSION CASE

3 - COLLAR

4 - FINGERS

Fig. 38 Remove Output Shaft Bearing

1 - BEARING REMOVER 9082

2 - TRANSMISSION CASE

3 - OUTPUT SHAFT BEARING

21 - 32 AUTOMATIC TRANSMISSION - NAG1VA

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 909 of 1232

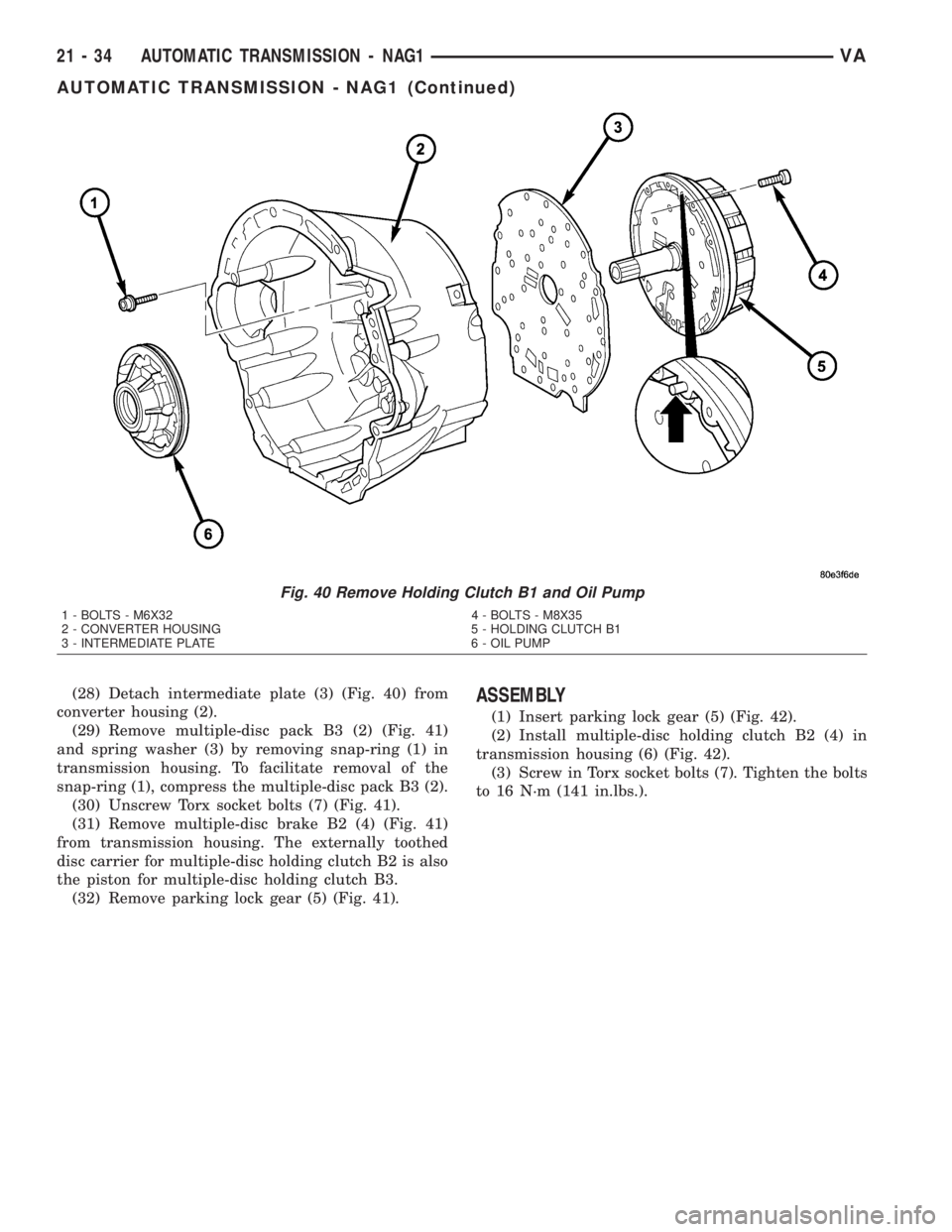

(25) Unscrew Torx socket bolts (4) (Fig. 40) and

remove oil pump (6). Screw two opposed bolts into

the oil pump housing and press the oil pump out of

the converter housing by applying light blows with a

plastic hammer.

(26) Remove and discard the torque converter hub

seal and the oil pump outer o-ring seal from the oil

pump.(27) Unscrew Torx socket bolts (1) (Fig. 40) and

remove multiple-disc brake B1 (5) from converter

housing. Screw two opposed bolts into the multiple-

disc brake B1 (5) and separate from the converter

housing by applying light blows with a plastic ham-

mer.

Fig. 39 Remove K1, K2, and K3 Clutches

1 - DRIVING CLUTCH K1 5 - THRUST WASHER

2 - SUN GEAR OF FRONT PLANETARY GEAR SET 6 - FRONT PLANETARY GEAR SET, DRIVING CLUTCH K2, AND

DRIVE SHAFT

3 - DRIVING CLUTCH K3, OUTPUT SHAFT , AND CENTER AND

REAR PLANETARY GEAR SETS7 - TEFLON RINGS

4 - THRUST NEEDLE BEARING

VAAUTOMATIC TRANSMISSION - NAG1 21 - 33

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 910 of 1232

(28) Detach intermediate plate (3) (Fig. 40) from

converter housing (2).

(29) Remove multiple-disc pack B3 (2) (Fig. 41)

and spring washer (3) by removing snap-ring (1) in

transmission housing. To facilitate removal of the

snap-ring (1), compress the multiple-disc pack B3 (2).

(30) Unscrew Torx socket bolts (7) (Fig. 41).

(31) Remove multiple-disc brake B2 (4) (Fig. 41)

from transmission housing. The externally toothed

disc carrier for multiple-disc holding clutch B2 is also

the piston for multiple-disc holding clutch B3.

(32) Remove parking lock gear (5) (Fig. 41).ASSEMBLY

(1) Insert parking lock gear (5) (Fig. 42).

(2) Install multiple-disc holding clutch B2 (4) in

transmission housing (6) (Fig. 42).

(3) Screw in Torx socket bolts (7). Tighten the bolts

to 16 N´m (141 in.lbs.).

Fig. 40 Remove Holding Clutch B1 and Oil Pump

1 - BOLTS - M6X32 4 - BOLTS - M8X35

2 - CONVERTER HOUSING 5 - HOLDING CLUTCH B1

3 - INTERMEDIATE PLATE 6 - OIL PUMP

21 - 34 AUTOMATIC TRANSMISSION - NAG1VA

AUTOMATIC TRANSMISSION - NAG1 (Continued)