MERCEDES-BENZ SPRINTER 2005 Service Repair Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 911 of 1232

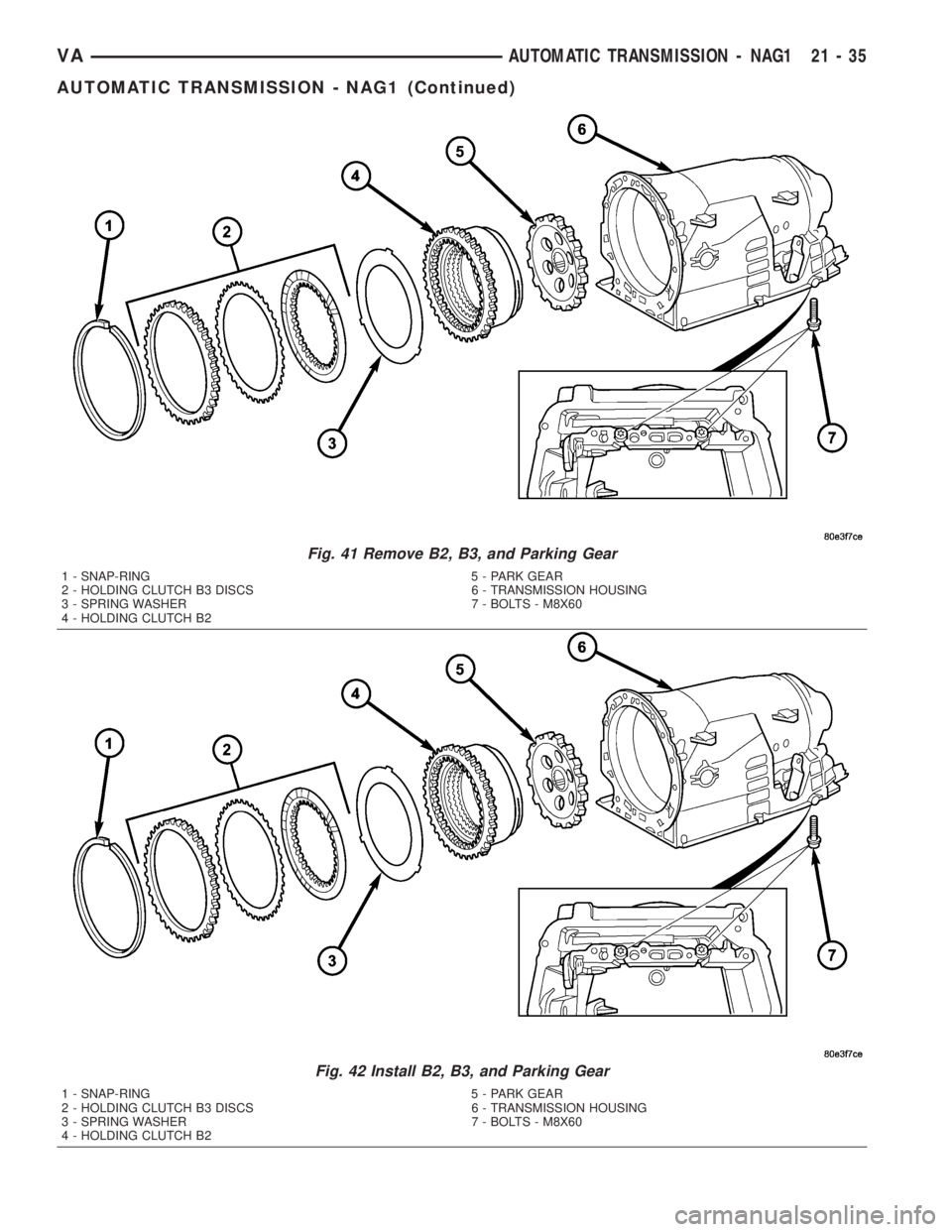

Fig. 41 Remove B2, B3, and Parking Gear

1 - SNAP-RING 5 - PARK GEAR

2 - HOLDING CLUTCH B3 DISCS 6 - TRANSMISSION HOUSING

3 - SPRING WASHER 7 - BOLTS - M8X60

4 - HOLDING CLUTCH B2

Fig. 42 Install B2, B3, and Parking Gear

1 - SNAP-RING 5 - PARK GEAR

2 - HOLDING CLUTCH B3 DISCS 6 - TRANSMISSION HOUSING

3 - SPRING WASHER 7 - BOLTS - M8X60

4 - HOLDING CLUTCH B2

VAAUTOMATIC TRANSMISSION - NAG1 21 - 35

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 912 of 1232

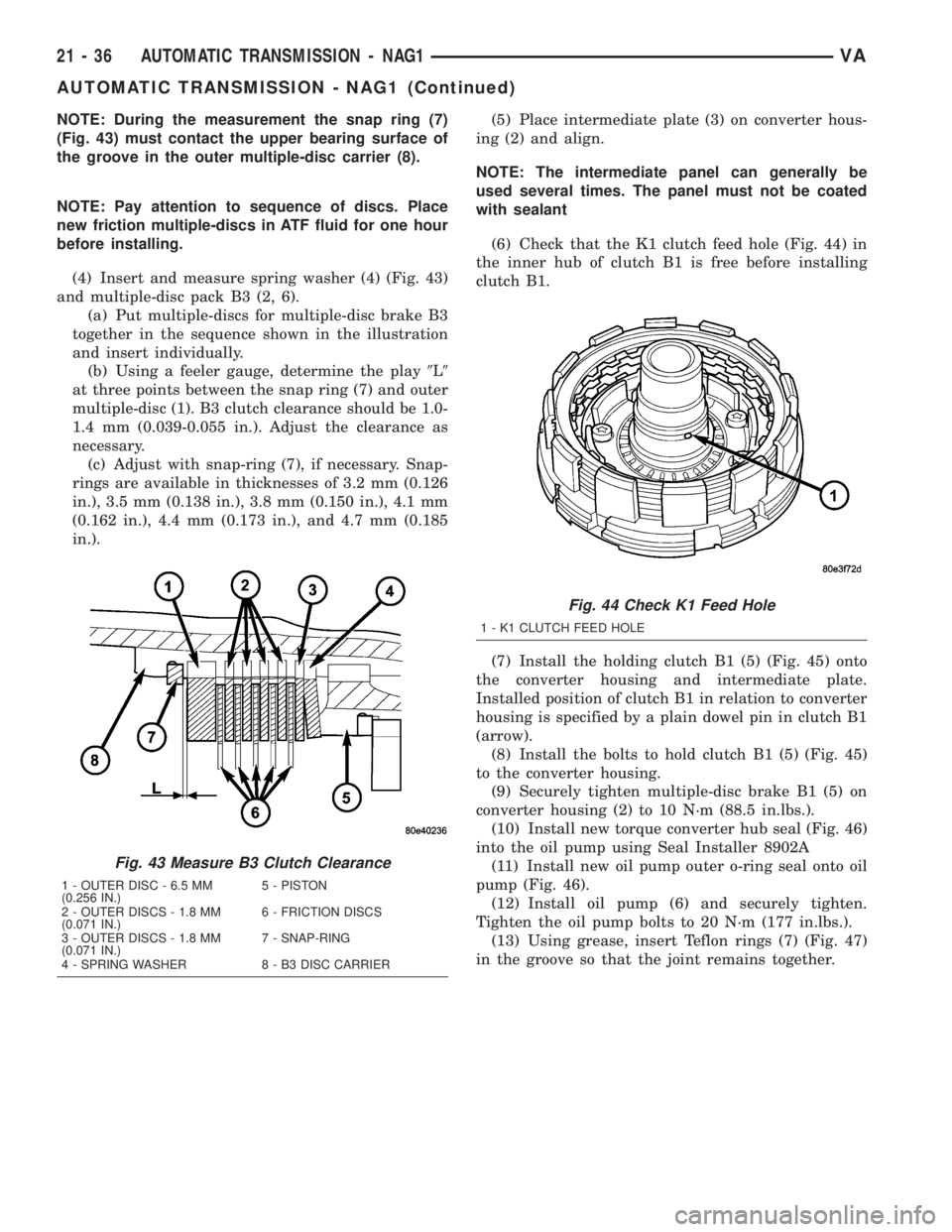

NOTE: During the measurement the snap ring (7)

(Fig. 43) must contact the upper bearing surface of

the groove in the outer multiple-disc carrier (8).

NOTE: Pay attention to sequence of discs. Place

new friction multiple-discs in ATF fluid for one hour

before installing.

(4) Insert and measure spring washer (4) (Fig. 43)

and multiple-disc pack B3 (2, 6).

(a) Put multiple-discs for multiple-disc brake B3

together in the sequence shown in the illustration

and insert individually.

(b) Using a feeler gauge, determine the play9L9

at three points between the snap ring (7) and outer

multiple-disc (1). B3 clutch clearance should be 1.0-

1.4 mm (0.039-0.055 in.). Adjust the clearance as

necessary.

(c) Adjust with snap-ring (7), if necessary. Snap-

rings are available in thicknesses of 3.2 mm (0.126

in.), 3.5 mm (0.138 in.), 3.8 mm (0.150 in.), 4.1 mm

(0.162 in.), 4.4 mm (0.173 in.), and 4.7 mm (0.185

in.).(5) Place intermediate plate (3) on converter hous-

ing (2) and align.

NOTE: The intermediate panel can generally be

used several times. The panel must not be coated

with sealant

(6) Check that the K1 clutch feed hole (Fig. 44) in

the inner hub of clutch B1 is free before installing

clutch B1.

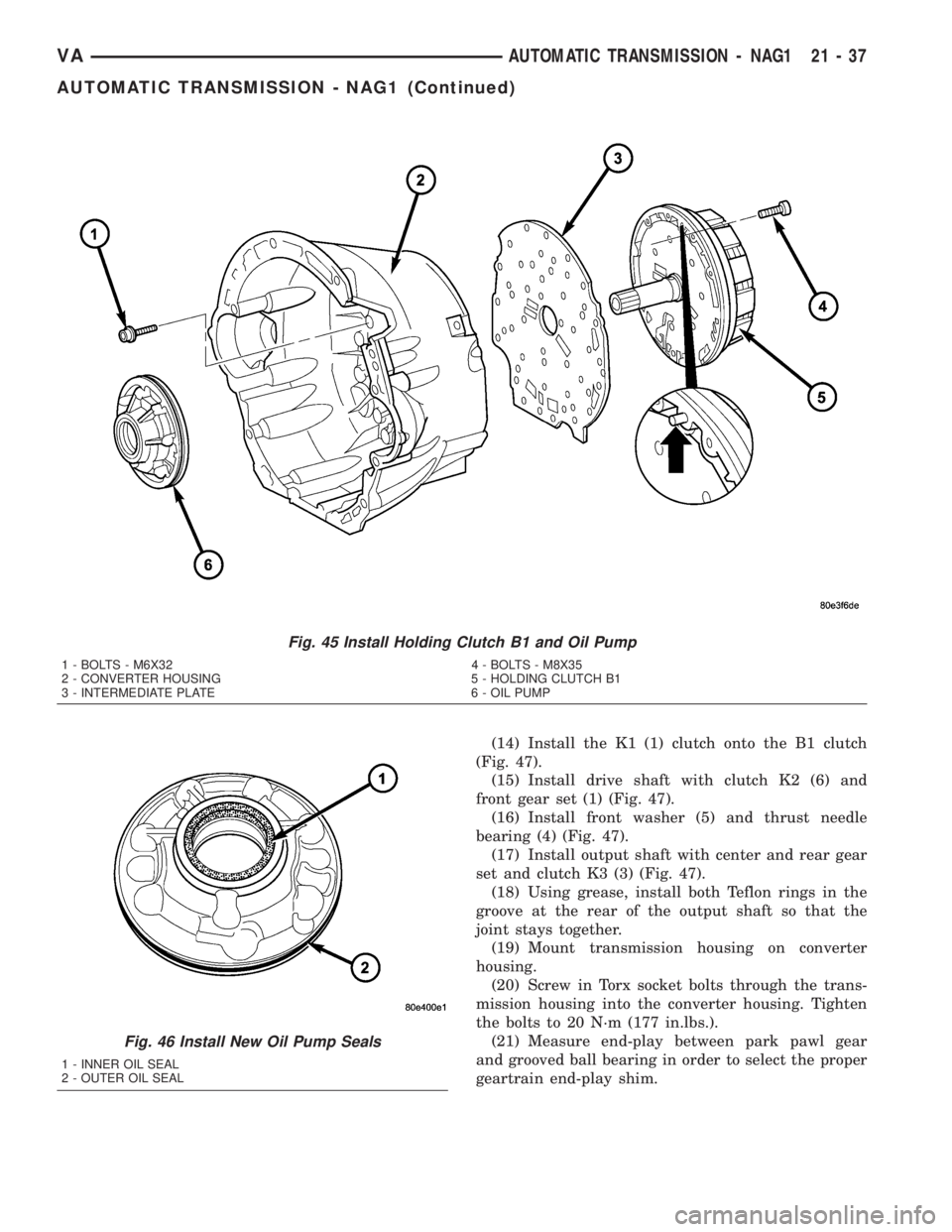

(7) Install the holding clutch B1 (5) (Fig. 45) onto

the converter housing and intermediate plate.

Installed position of clutch B1 in relation to converter

housing is specified by a plain dowel pin in clutch B1

(arrow).

(8) Install the bolts to hold clutch B1 (5) (Fig. 45)

to the converter housing.

(9) Securely tighten multiple-disc brake B1 (5) on

converter housing (2) to 10 N´m (88.5 in.lbs.).

(10) Install new torque converter hub seal (Fig. 46)

into the oil pump using Seal Installer 8902A

(11) Install new oil pump outer o-ring seal onto oil

pump (Fig. 46).

(12) Install oil pump (6) and securely tighten.

Tighten the oil pump bolts to 20 N´m (177 in.lbs.).

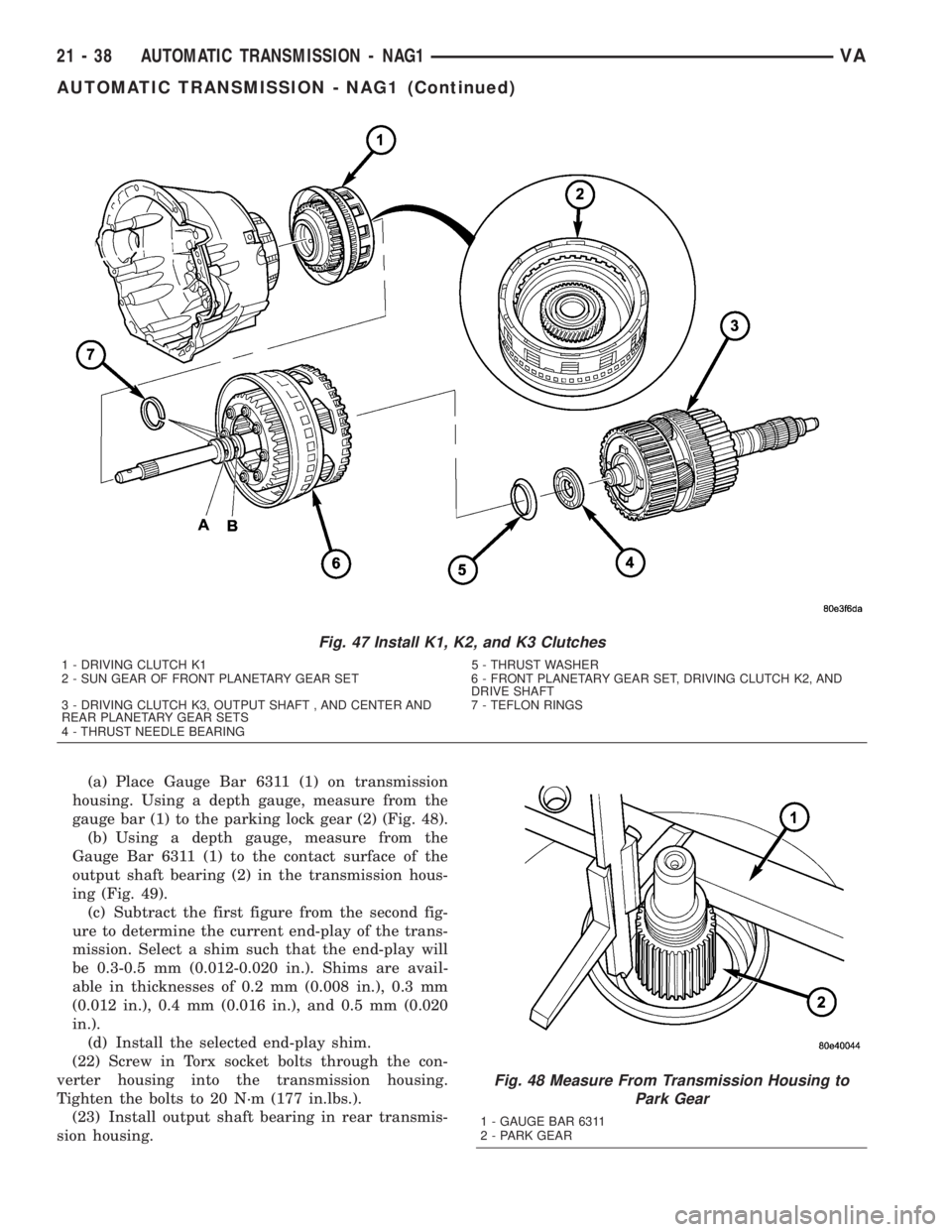

(13) Using grease, insert Teflon rings (7) (Fig. 47)

in the groove so that the joint remains together.

Fig. 43 Measure B3 Clutch Clearance

1 - OUTER DISC - 6.5 MM

(0.256 IN.)5 - PISTON

2 - OUTER DISCS - 1.8 MM

(0.071 IN.)6 - FRICTION DISCS

3 - OUTER DISCS - 1.8 MM

(0.071 IN.)7 - SNAP-RING

4 - SPRING WASHER 8 - B3 DISC CARRIER

Fig. 44 Check K1 Feed Hole

1 - K1 CLUTCH FEED HOLE

21 - 36 AUTOMATIC TRANSMISSION - NAG1VA

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 913 of 1232

(14) Install the K1 (1) clutch onto the B1 clutch

(Fig. 47).

(15) Install drive shaft with clutch K2 (6) and

front gear set (1) (Fig. 47).

(16) Install front washer (5) and thrust needle

bearing (4) (Fig. 47).

(17) Install output shaft with center and rear gear

set and clutch K3 (3) (Fig. 47).

(18) Using grease, install both Teflon rings in the

groove at the rear of the output shaft so that the

joint stays together.

(19) Mount transmission housing on converter

housing.

(20) Screw in Torx socket bolts through the trans-

mission housing into the converter housing. Tighten

the bolts to 20 N´m (177 in.lbs.).

(21) Measure end-play between park pawl gear

and grooved ball bearing in order to select the proper

geartrain end-play shim.

Fig. 45 Install Holding Clutch B1 and Oil Pump

1 - BOLTS - M6X32 4 - BOLTS - M8X35

2 - CONVERTER HOUSING 5 - HOLDING CLUTCH B1

3 - INTERMEDIATE PLATE 6 - OIL PUMP

Fig. 46 Install New Oil Pump Seals

1 - INNER OIL SEAL

2 - OUTER OIL SEAL

VAAUTOMATIC TRANSMISSION - NAG1 21 - 37

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 914 of 1232

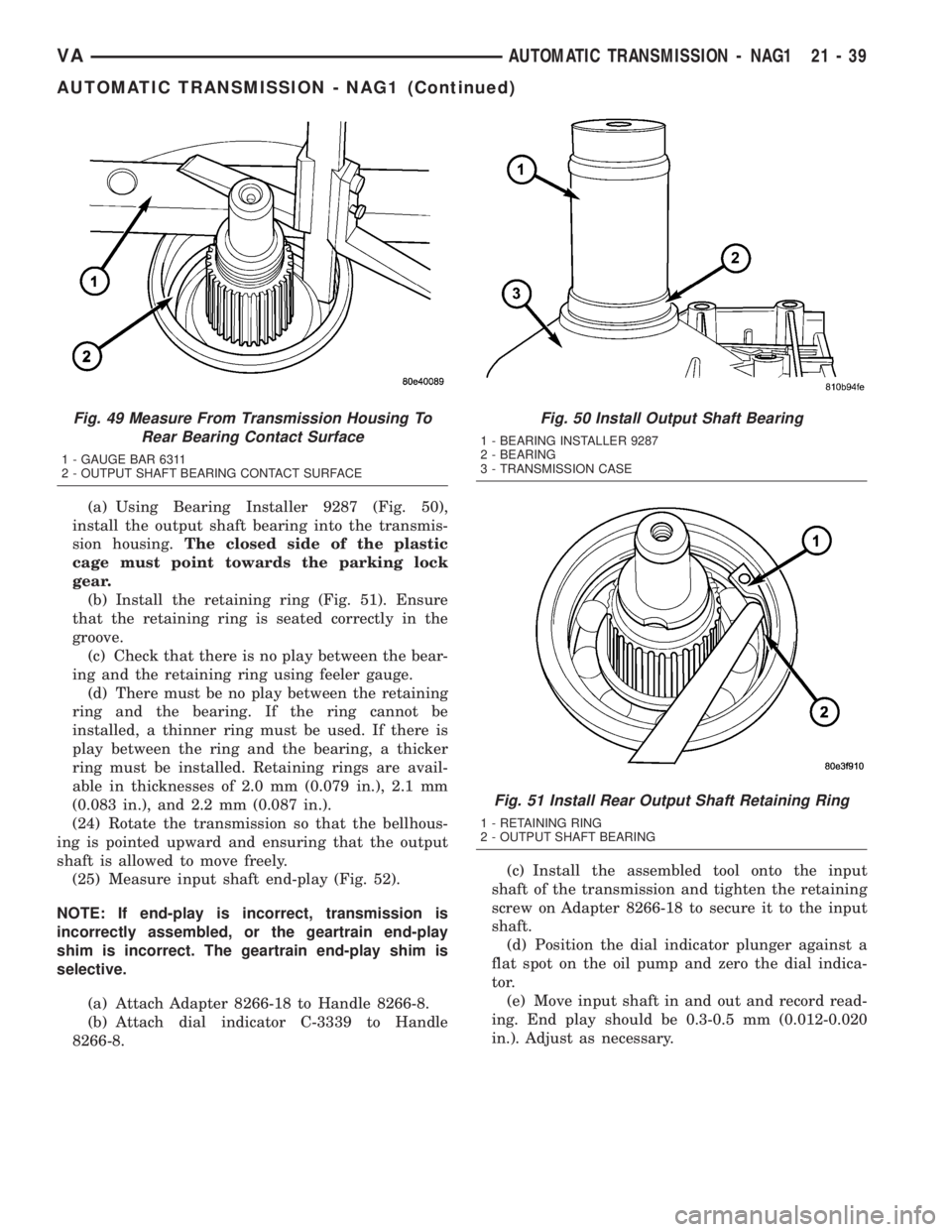

(a) Place Gauge Bar 6311 (1) on transmission

housing. Using a depth gauge, measure from the

gauge bar (1) to the parking lock gear (2) (Fig. 48).

(b) Using a depth gauge, measure from the

Gauge Bar 6311 (1) to the contact surface of the

output shaft bearing (2) in the transmission hous-

ing (Fig. 49).

(c) Subtract the first figure from the second fig-

ure to determine the current end-play of the trans-

mission. Select a shim such that the end-play will

be 0.3-0.5 mm (0.012-0.020 in.). Shims are avail-

able in thicknesses of 0.2 mm (0.008 in.), 0.3 mm

(0.012 in.), 0.4 mm (0.016 in.), and 0.5 mm (0.020

in.).

(d) Install the selected end-play shim.

(22) Screw in Torx socket bolts through the con-

verter housing into the transmission housing.

Tighten the bolts to 20 N´m (177 in.lbs.).

(23) Install output shaft bearing in rear transmis-

sion housing.

Fig. 47 Install K1, K2, and K3 Clutches

1 - DRIVING CLUTCH K1 5 - THRUST WASHER

2 - SUN GEAR OF FRONT PLANETARY GEAR SET 6 - FRONT PLANETARY GEAR SET, DRIVING CLUTCH K2, AND

DRIVE SHAFT

3 - DRIVING CLUTCH K3, OUTPUT SHAFT , AND CENTER AND

REAR PLANETARY GEAR SETS7 - TEFLON RINGS

4 - THRUST NEEDLE BEARING

Fig. 48 Measure From Transmission Housing to

Park Gear

1 - GAUGE BAR 6311

2 - PARK GEAR

21 - 38 AUTOMATIC TRANSMISSION - NAG1VA

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 915 of 1232

(a) Using Bearing Installer 9287 (Fig. 50),

install the output shaft bearing into the transmis-

sion housing.The closed side of the plastic

cage must point towards the parking lock

gear.

(b) Install the retaining ring (Fig. 51). Ensure

that the retaining ring is seated correctly in the

groove.

(c) Check that there is no play between the bear-

ing and the retaining ring using feeler gauge.

(d) There must be no play between the retaining

ring and the bearing. If the ring cannot be

installed, a thinner ring must be used. If there is

play between the ring and the bearing, a thicker

ring must be installed. Retaining rings are avail-

able in thicknesses of 2.0 mm (0.079 in.), 2.1 mm

(0.083 in.), and 2.2 mm (0.087 in.).

(24) Rotate the transmission so that the bellhous-

ing is pointed upward and ensuring that the output

shaft is allowed to move freely.

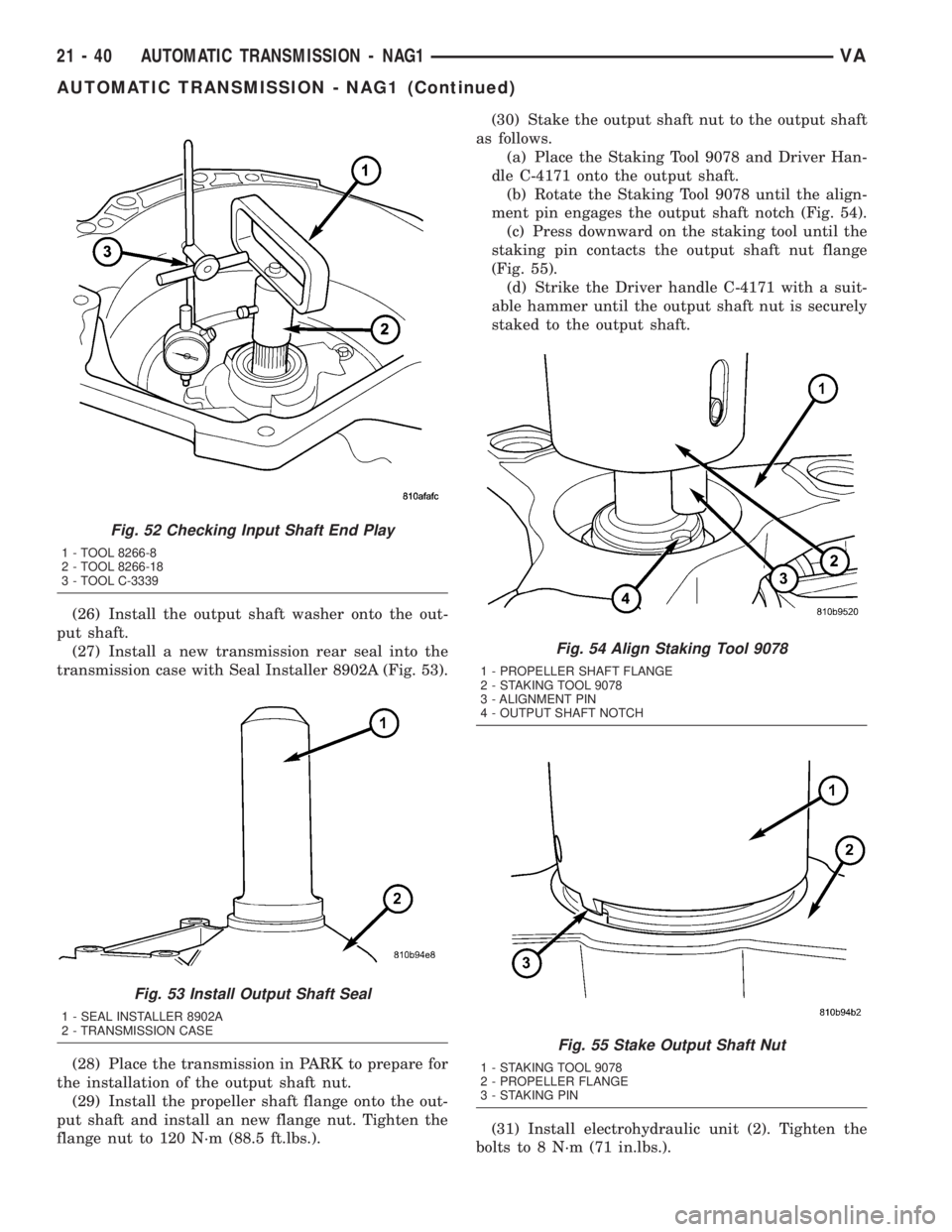

(25) Measure input shaft end-play (Fig. 52).

NOTE: If end-play is incorrect, transmission is

incorrectly assembled, or the geartrain end-play

shim is incorrect. The geartrain end-play shim is

selective.

(a) Attach Adapter 8266-18 to Handle 8266-8.

(b) Attach dial indicator C-3339 to Handle

8266-8.(c) Install the assembled tool onto the input

shaft of the transmission and tighten the retaining

screw on Adapter 8266-18 to secure it to the input

shaft.

(d) Position the dial indicator plunger against a

flat spot on the oil pump and zero the dial indica-

tor.

(e) Move input shaft in and out and record read-

ing. End play should be 0.3-0.5 mm (0.012-0.020

in.). Adjust as necessary.

Fig. 49 Measure From Transmission Housing To

Rear Bearing Contact Surface

1 - GAUGE BAR 6311

2 - OUTPUT SHAFT BEARING CONTACT SURFACE

Fig. 50 Install Output Shaft Bearing

1 - BEARING INSTALLER 9287

2 - BEARING

3 - TRANSMISSION CASE

Fig. 51 Install Rear Output Shaft Retaining Ring

1 - RETAINING RING

2 - OUTPUT SHAFT BEARING

VAAUTOMATIC TRANSMISSION - NAG1 21 - 39

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 916 of 1232

(26) Install the output shaft washer onto the out-

put shaft.

(27) Install a new transmission rear seal into the

transmission case with Seal Installer 8902A (Fig. 53).

(28) Place the transmission in PARK to prepare for

the installation of the output shaft nut.

(29) Install the propeller shaft flange onto the out-

put shaft and install an new flange nut. Tighten the

flange nut to 120 N´m (88.5 ft.lbs.).(30) Stake the output shaft nut to the output shaft

as follows.

(a) Place the Staking Tool 9078 and Driver Han-

dle C-4171 onto the output shaft.

(b) Rotate the Staking Tool 9078 until the align-

ment pin engages the output shaft notch (Fig. 54).

(c) Press downward on the staking tool until the

staking pin contacts the output shaft nut flange

(Fig. 55).

(d) Strike the Driver handle C-4171 with a suit-

able hammer until the output shaft nut is securely

staked to the output shaft.

(31) Install electrohydraulic unit (2). Tighten the

bolts to 8 N´m (71 in.lbs.).

Fig. 52 Checking Input Shaft End Play

1 - TOOL 8266-8

2 - TOOL 8266-18

3 - TOOL C-3339

Fig. 53 Install Output Shaft Seal

1 - SEAL INSTALLER 8902A

2 - TRANSMISSION CASE

Fig. 54 Align Staking Tool 9078

1 - PROPELLER SHAFT FLANGE

2 - STAKING TOOL 9078

3 - ALIGNMENT PIN

4 - OUTPUT SHAFT NOTCH

Fig. 55 Stake Output Shaft Nut

1 - STAKING TOOL 9078

2 - PROPELLER FLANGE

3 - STAKING PIN

21 - 40 AUTOMATIC TRANSMISSION - NAG1VA

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 917 of 1232

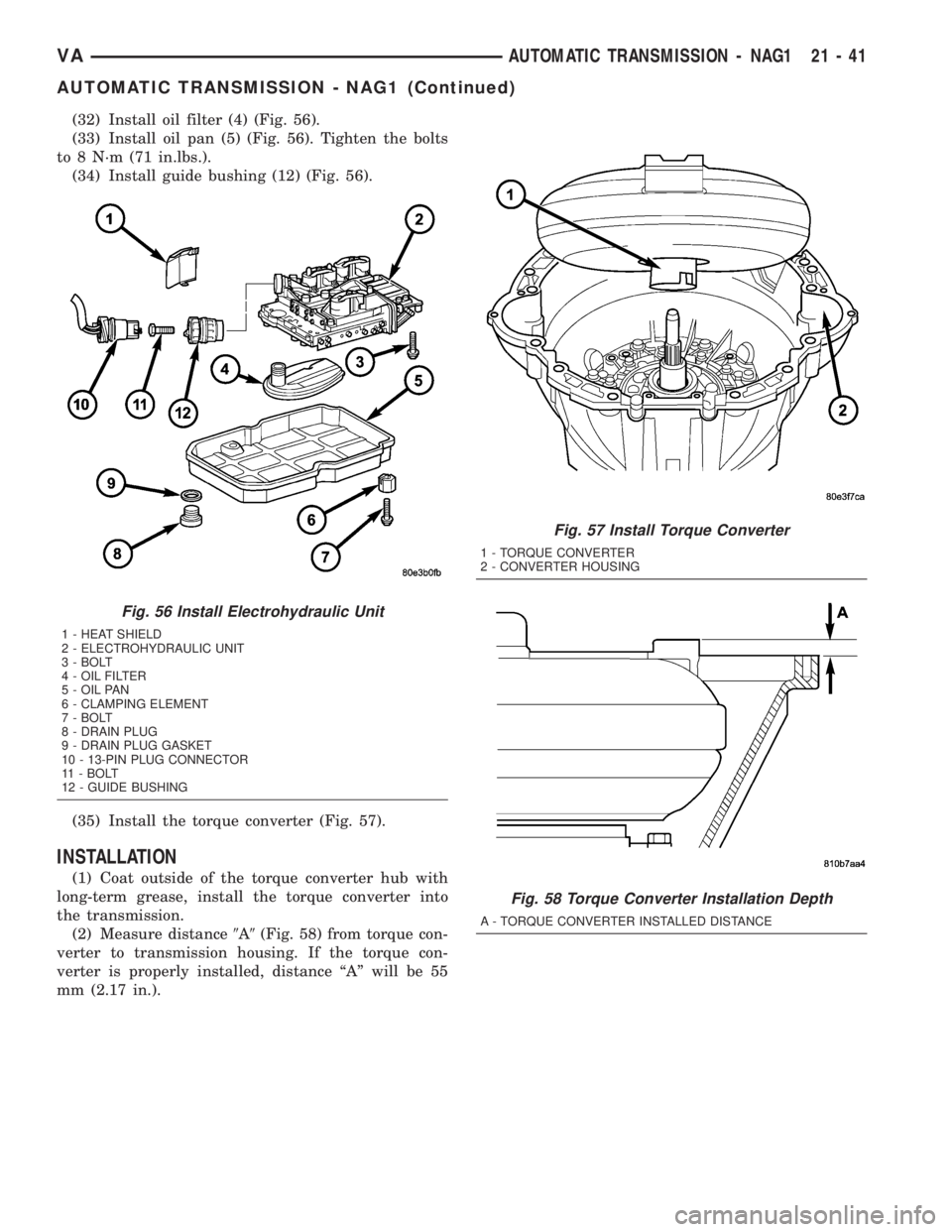

(32) Install oil filter (4) (Fig. 56).

(33) Install oil pan (5) (Fig. 56). Tighten the bolts

to 8 N´m (71 in.lbs.).

(34) Install guide bushing (12) (Fig. 56).

(35) Install the torque converter (Fig. 57).

INSTALLATION

(1) Coat outside of the torque converter hub with

long-term grease, install the torque converter into

the transmission.

(2) Measure distance9A9(Fig. 58) from torque con-

verter to transmission housing. If the torque con-

verter is properly installed, distance ªAº will be 55

mm (2.17 in.).

Fig. 56 Install Electrohydraulic Unit

1 - HEAT SHIELD

2 - ELECTROHYDRAULIC UNIT

3 - BOLT

4 - OIL FILTER

5 - OIL PAN

6 - CLAMPING ELEMENT

7 - BOLT

8 - DRAIN PLUG

9 - DRAIN PLUG GASKET

10 - 13-PIN PLUG CONNECTOR

11 - BOLT

12 - GUIDE BUSHING

Fig. 57 Install Torque Converter

1 - TORQUE CONVERTER

2 - CONVERTER HOUSING

Fig. 58 Torque Converter Installation Depth

A - TORQUE CONVERTER INSTALLED DISTANCE

VAAUTOMATIC TRANSMISSION - NAG1 21 - 41

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 918 of 1232

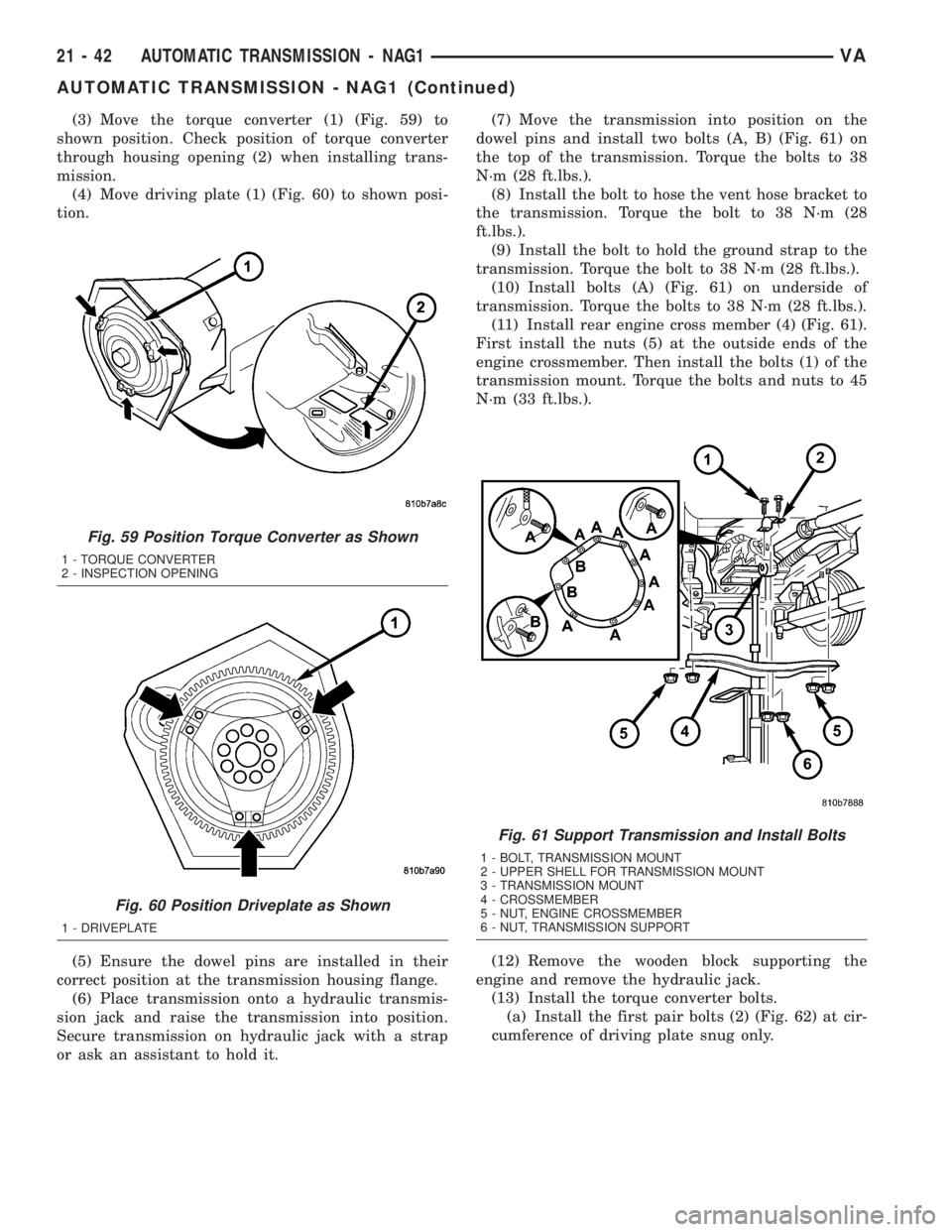

(3) Move the torque converter (1) (Fig. 59) to

shown position. Check position of torque converter

through housing opening (2) when installing trans-

mission.

(4) Move driving plate (1) (Fig. 60) to shown posi-

tion.

(5) Ensure the dowel pins are installed in their

correct position at the transmission housing flange.

(6) Place transmission onto a hydraulic transmis-

sion jack and raise the transmission into position.

Secure transmission on hydraulic jack with a strap

or ask an assistant to hold it.(7) Move the transmission into position on the

dowel pins and install two bolts (A, B) (Fig. 61) on

the top of the transmission. Torque the bolts to 38

N´m (28 ft.lbs.).

(8) Install the bolt to hose the vent hose bracket to

the transmission. Torque the bolt to 38 N´m (28

ft.lbs.).

(9) Install the bolt to hold the ground strap to the

transmission. Torque the bolt to 38 N´m (28 ft.lbs.).

(10) Install bolts (A) (Fig. 61) on underside of

transmission. Torque the bolts to 38 N´m (28 ft.lbs.).

(11) Install rear engine cross member (4) (Fig. 61).

First install the nuts (5) at the outside ends of the

engine crossmember. Then install the bolts (1) of the

transmission mount. Torque the bolts and nuts to 45

N´m (33 ft.lbs.).

(12) Remove the wooden block supporting the

engine and remove the hydraulic jack.

(13) Install the torque converter bolts.

(a) Install the first pair bolts (2) (Fig. 62) at cir-

cumference of driving plate snug only.

Fig. 59 Position Torque Converter as Shown

1 - TORQUE CONVERTER

2 - INSPECTION OPENING

Fig. 60 Position Driveplate as Shown

1 - DRIVEPLATE

Fig. 61 Support Transmission and Install Bolts

1 - BOLT, TRANSMISSION MOUNT

2 - UPPER SHELL FOR TRANSMISSION MOUNT

3 - TRANSMISSION MOUNT

4 - CROSSMEMBER

5 - NUT, ENGINE CROSSMEMBER

6 - NUT, TRANSMISSION SUPPORT

21 - 42 AUTOMATIC TRANSMISSION - NAG1VA

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 919 of 1232

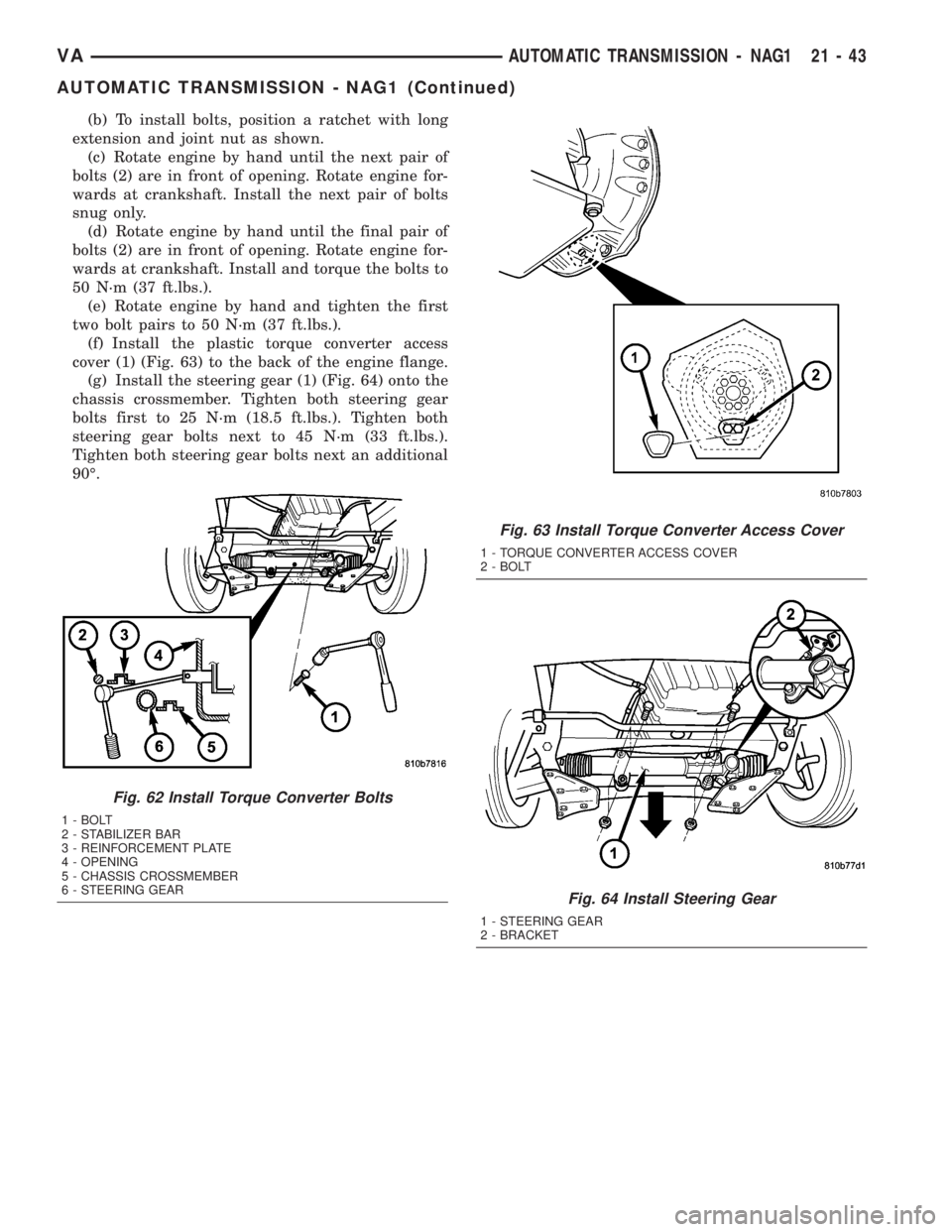

(b) To install bolts, position a ratchet with long

extension and joint nut as shown.

(c) Rotate engine by hand until the next pair of

bolts (2) are in front of opening. Rotate engine for-

wards at crankshaft. Install the next pair of bolts

snug only.

(d) Rotate engine by hand until the final pair of

bolts (2) are in front of opening. Rotate engine for-

wards at crankshaft. Install and torque the bolts to

50 N´m (37 ft.lbs.).

(e) Rotate engine by hand and tighten the first

two bolt pairs to 50 N´m (37 ft.lbs.).

(f) Install the plastic torque converter access

cover (1) (Fig. 63) to the back of the engine flange.

(g) Install the steering gear (1) (Fig. 64) onto the

chassis crossmember. Tighten both steering gear

bolts first to 25 N´m (18.5 ft.lbs.). Tighten both

steering gear bolts next to 45 N´m (33 ft.lbs.).

Tighten both steering gear bolts next an additional

90É.

Fig. 62 Install Torque Converter Bolts

1 - BOLT

2 - STABILIZER BAR

3 - REINFORCEMENT PLATE

4 - OPENING

5 - CHASSIS CROSSMEMBER

6 - STEERING GEAR

Fig. 63 Install Torque Converter Access Cover

1 - TORQUE CONVERTER ACCESS COVER

2 - BOLT

Fig. 64 Install Steering Gear

1 - STEERING GEAR

2 - BRACKET

VAAUTOMATIC TRANSMISSION - NAG1 21 - 43

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 920 of 1232

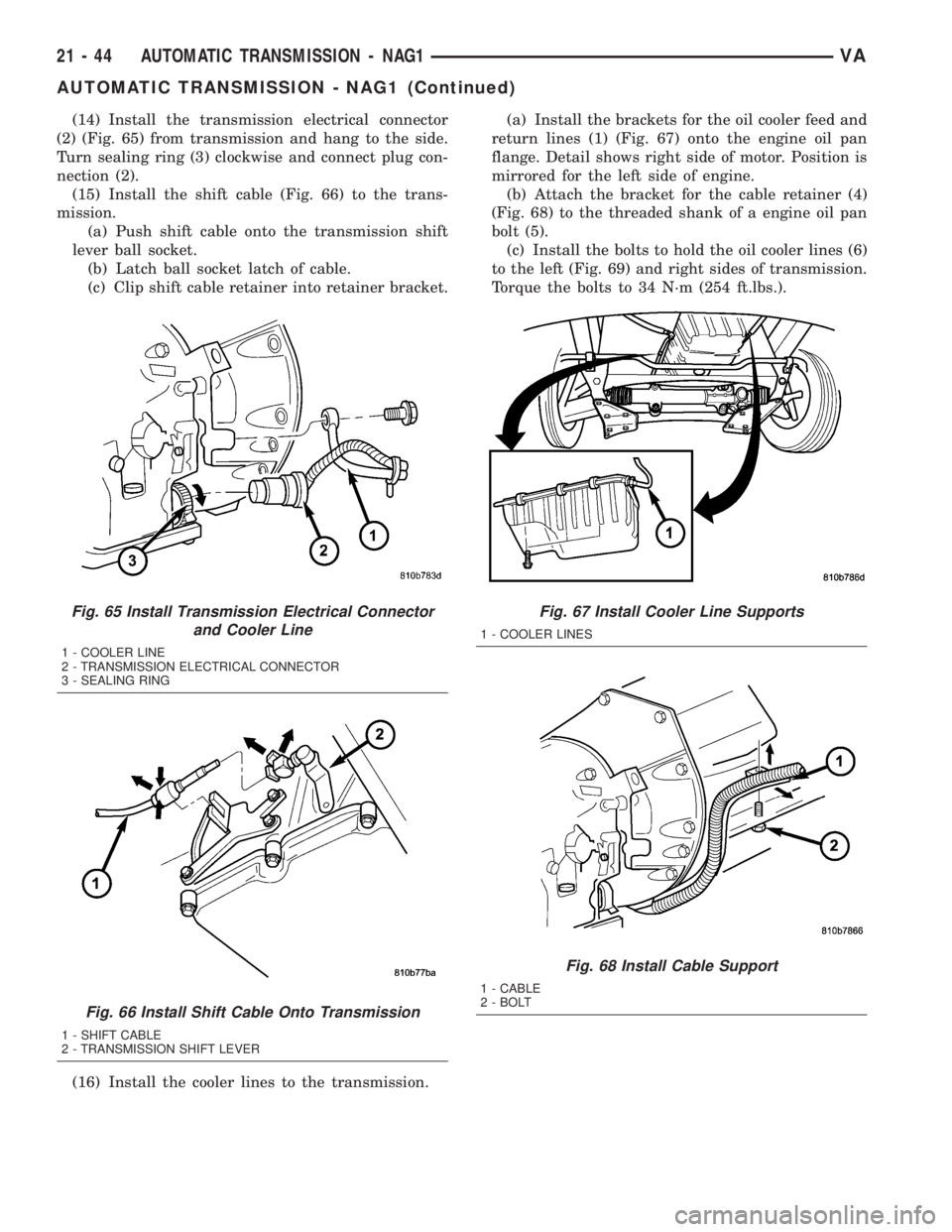

(14) Install the transmission electrical connector

(2) (Fig. 65) from transmission and hang to the side.

Turn sealing ring (3) clockwise and connect plug con-

nection (2).

(15) Install the shift cable (Fig. 66) to the trans-

mission.

(a) Push shift cable onto the transmission shift

lever ball socket.

(b) Latch ball socket latch of cable.

(c) Clip shift cable retainer into retainer bracket.

(16) Install the cooler lines to the transmission.(a) Install the brackets for the oil cooler feed and

return lines (1) (Fig. 67) onto the engine oil pan

flange. Detail shows right side of motor. Position is

mirrored for the left side of engine.

(b) Attach the bracket for the cable retainer (4)

(Fig. 68) to the threaded shank of a engine oil pan

bolt (5).

(c) Install the bolts to hold the oil cooler lines (6)

to the left (Fig. 69) and right sides of transmission.

Torque the bolts to 34 N´m (254 ft.lbs.).

Fig. 65 Install Transmission Electrical Connector

and Cooler Line

1 - COOLER LINE

2 - TRANSMISSION ELECTRICAL CONNECTOR

3 - SEALING RING

Fig. 66 Install Shift Cable Onto Transmission

1 - SHIFT CABLE

2 - TRANSMISSION SHIFT LEVER

Fig. 67 Install Cooler Line Supports

1 - COOLER LINES

Fig. 68 Install Cable Support

1 - CABLE

2 - BOLT

21 - 44 AUTOMATIC TRANSMISSION - NAG1VA

AUTOMATIC TRANSMISSION - NAG1 (Continued)