MERCEDES-BENZ SPRINTER 2005 Service Repair Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 891 of 1232

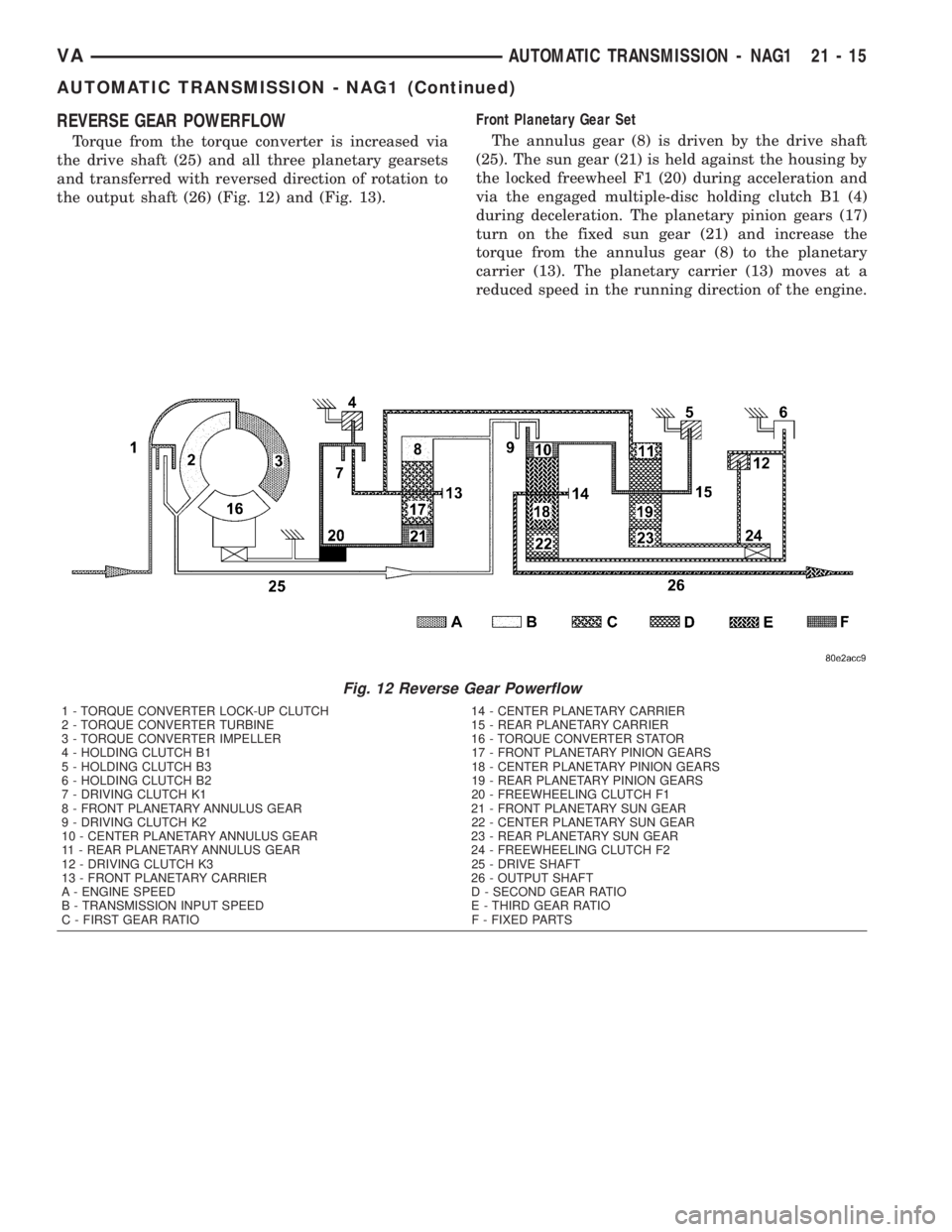

REVERSE GEAR POWERFLOW

Torque from the torque converter is increased via

the drive shaft (25) and all three planetary gearsets

and transferred with reversed direction of rotation to

the output shaft (26) (Fig. 12) and (Fig. 13).Front Planetary Gear Set

The annulus gear (8) is driven by the drive shaft

(25). The sun gear (21) is held against the housing by

the locked freewheel F1 (20) during acceleration and

via the engaged multiple-disc holding clutch B1 (4)

during deceleration. The planetary pinion gears (17)

turn on the fixed sun gear (21) and increase the

torque from the annulus gear (8) to the planetary

carrier (13). The planetary carrier (13) moves at a

reduced speed in the running direction of the engine.

Fig. 12 Reverse Gear Powerflow

1 - TORQUE CONVERTER LOCK-UP CLUTCH 14 - CENTER PLANETARY CARRIER

2 - TORQUE CONVERTER TURBINE 15 - REAR PLANETARY CARRIER

3 - TORQUE CONVERTER IMPELLER 16 - TORQUE CONVERTER STATOR

4 - HOLDING CLUTCH B1 17 - FRONT PLANETARY PINION GEARS

5 - HOLDING CLUTCH B3 18 - CENTER PLANETARY PINION GEARS

6 - HOLDING CLUTCH B2 19 - REAR PLANETARY PINION GEARS

7 - DRIVING CLUTCH K1 20 - FREEWHEELING CLUTCH F1

8 - FRONT PLANETARY ANNULUS GEAR 21 - FRONT PLANETARY SUN GEAR

9 - DRIVING CLUTCH K2 22 - CENTER PLANETARY SUN GEAR

10 - CENTER PLANETARY ANNULUS GEAR 23 - REAR PLANETARY SUN GEAR

11 - REAR PLANETARY ANNULUS GEAR 24 - FREEWHEELING CLUTCH F2

12 - DRIVING CLUTCH K3 25 - DRIVE SHAFT

13 - FRONT PLANETARY CARRIER 26 - OUTPUT SHAFT

A - ENGINE SPEED D - SECOND GEAR RATIO

B - TRANSMISSION INPUT SPEED E - THIRD GEAR RATIO

C - FIRST GEAR RATIO F - FIXED PARTS

VAAUTOMATIC TRANSMISSION - NAG1 21 - 15

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 892 of 1232

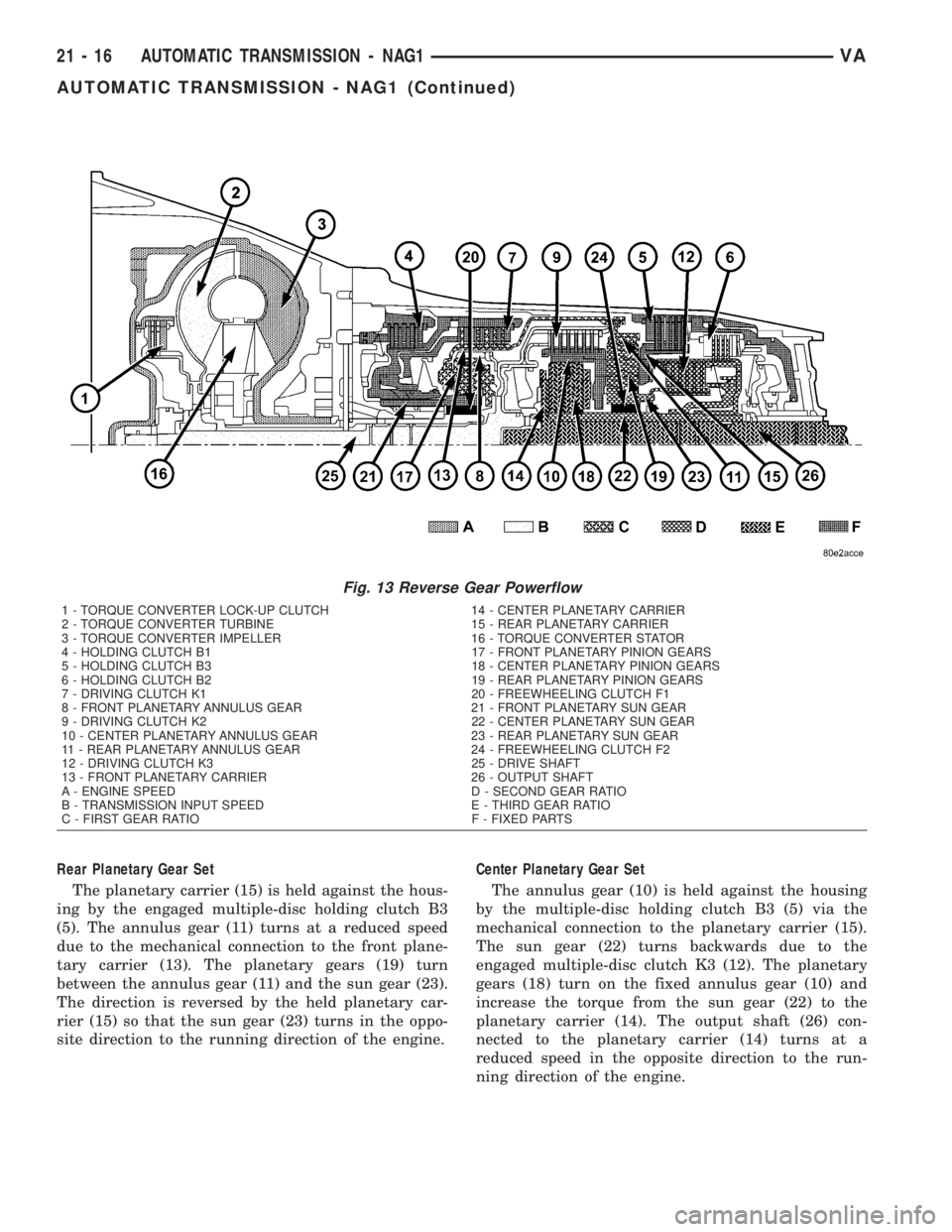

Rear Planetary Gear Set

The planetary carrier (15) is held against the hous-

ing by the engaged multiple-disc holding clutch B3

(5). The annulus gear (11) turns at a reduced speed

due to the mechanical connection to the front plane-

tary carrier (13). The planetary gears (19) turn

between the annulus gear (11) and the sun gear (23).

The direction is reversed by the held planetary car-

rier (15) so that the sun gear (23) turns in the oppo-

site direction to the running direction of the engine.Center Planetary Gear Set

The annulus gear (10) is held against the housing

by the multiple-disc holding clutch B3 (5) via the

mechanical connection to the planetary carrier (15).

The sun gear (22) turns backwards due to the

engaged multiple-disc clutch K3 (12). The planetary

gears (18) turn on the fixed annulus gear (10) and

increase the torque from the sun gear (22) to the

planetary carrier (14). The output shaft (26) con-

nected to the planetary carrier (14) turns at a

reduced speed in the opposite direction to the run-

ning direction of the engine.

Fig. 13 Reverse Gear Powerflow

1 - TORQUE CONVERTER LOCK-UP CLUTCH 14 - CENTER PLANETARY CARRIER

2 - TORQUE CONVERTER TURBINE 15 - REAR PLANETARY CARRIER

3 - TORQUE CONVERTER IMPELLER 16 - TORQUE CONVERTER STATOR

4 - HOLDING CLUTCH B1 17 - FRONT PLANETARY PINION GEARS

5 - HOLDING CLUTCH B3 18 - CENTER PLANETARY PINION GEARS

6 - HOLDING CLUTCH B2 19 - REAR PLANETARY PINION GEARS

7 - DRIVING CLUTCH K1 20 - FREEWHEELING CLUTCH F1

8 - FRONT PLANETARY ANNULUS GEAR 21 - FRONT PLANETARY SUN GEAR

9 - DRIVING CLUTCH K2 22 - CENTER PLANETARY SUN GEAR

10 - CENTER PLANETARY ANNULUS GEAR 23 - REAR PLANETARY SUN GEAR

11 - REAR PLANETARY ANNULUS GEAR 24 - FREEWHEELING CLUTCH F2

12 - DRIVING CLUTCH K3 25 - DRIVE SHAFT

13 - FRONT PLANETARY CARRIER 26 - OUTPUT SHAFT

A - ENGINE SPEED D - SECOND GEAR RATIO

B - TRANSMISSION INPUT SPEED E - THIRD GEAR RATIO

C - FIRST GEAR RATIO F - FIXED PARTS

21 - 16 AUTOMATIC TRANSMISSION - NAG1VA

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 893 of 1232

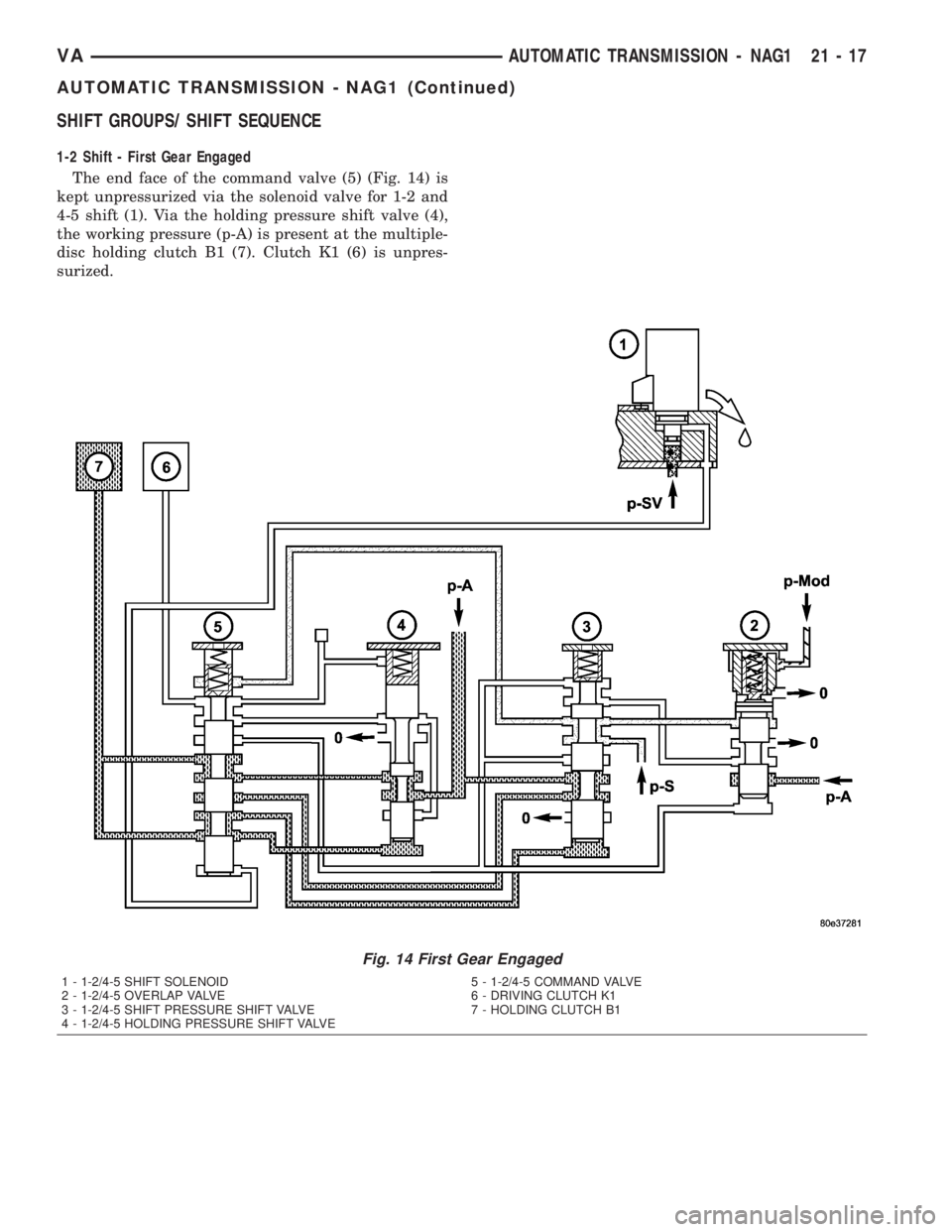

SHIFT GROUPS/ SHIFT SEQUENCE

1-2 Shift - First Gear Engaged

The end face of the command valve (5) (Fig. 14) is

kept unpressurized via the solenoid valve for 1-2 and

4-5 shift (1). Via the holding pressure shift valve (4),

the working pressure (p-A) is present at the multiple-

disc holding clutch B1 (7). Clutch K1 (6) is unpres-

surized.

Fig. 14 First Gear Engaged

1 - 1-2/4-5 SHIFT SOLENOID 5 - 1-2/4-5 COMMAND VALVE

2 - 1-2/4-5 OVERLAP VALVE 6 - DRIVING CLUTCH K1

3 - 1-2/4-5 SHIFT PRESSURE SHIFT VALVE 7 - HOLDING CLUTCH B1

4 - 1-2/4-5 HOLDING PRESSURE SHIFT VALVE

VAAUTOMATIC TRANSMISSION - NAG1 21 - 17

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 894 of 1232

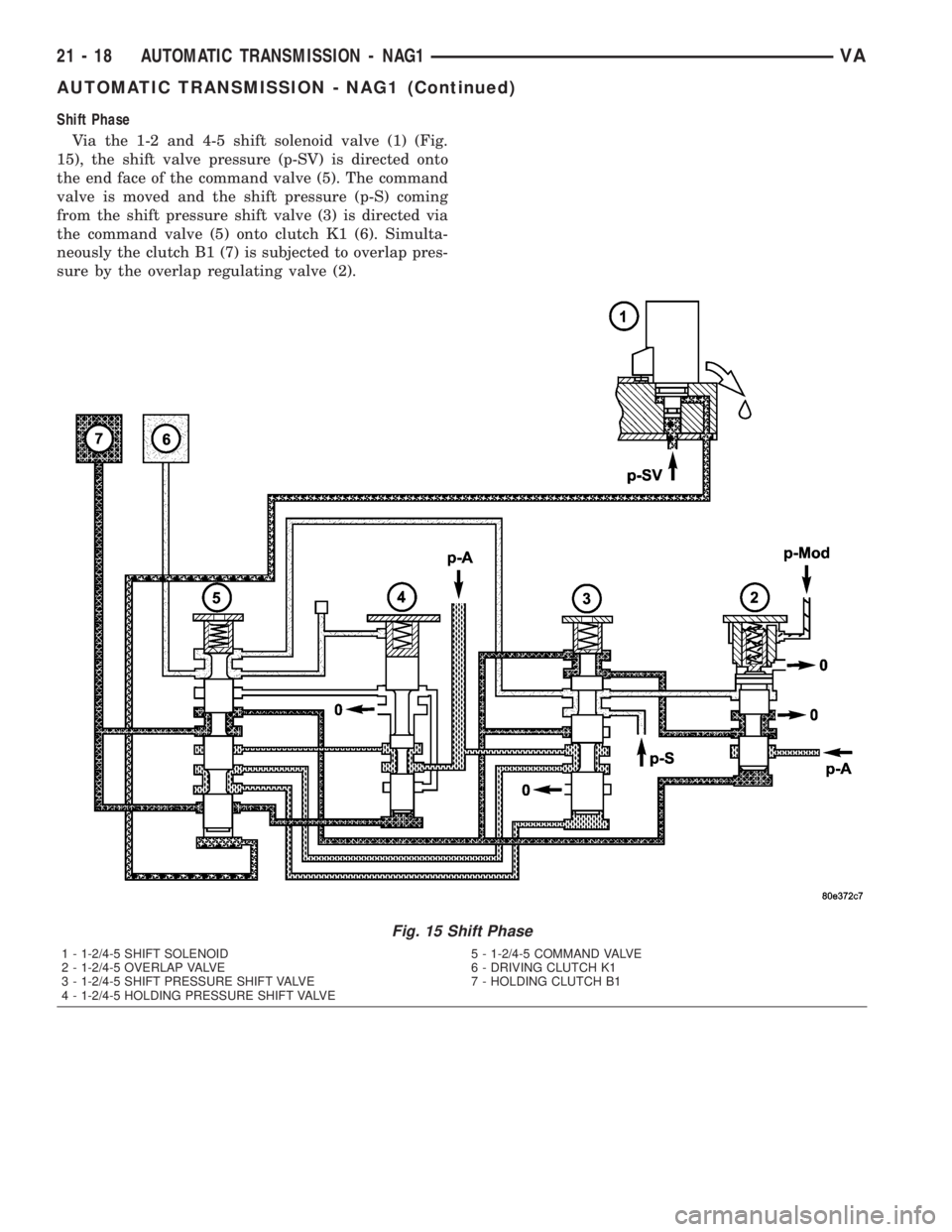

Shift Phase

Via the 1-2 and 4-5 shift solenoid valve (1) (Fig.

15), the shift valve pressure (p-SV) is directed onto

the end face of the command valve (5). The command

valve is moved and the shift pressure (p-S) coming

from the shift pressure shift valve (3) is directed via

the command valve (5) onto clutch K1 (6). Simulta-

neously the clutch B1 (7) is subjected to overlap pres-

sure by the overlap regulating valve (2).

Fig. 15 Shift Phase

1 - 1-2/4-5 SHIFT SOLENOID 5 - 1-2/4-5 COMMAND VALVE

2 - 1-2/4-5 OVERLAP VALVE 6 - DRIVING CLUTCH K1

3 - 1-2/4-5 SHIFT PRESSURE SHIFT VALVE 7 - HOLDING CLUTCH B1

4 - 1-2/4-5 HOLDING PRESSURE SHIFT VALVE

21 - 18 AUTOMATIC TRANSMISSION - NAG1VA

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 895 of 1232

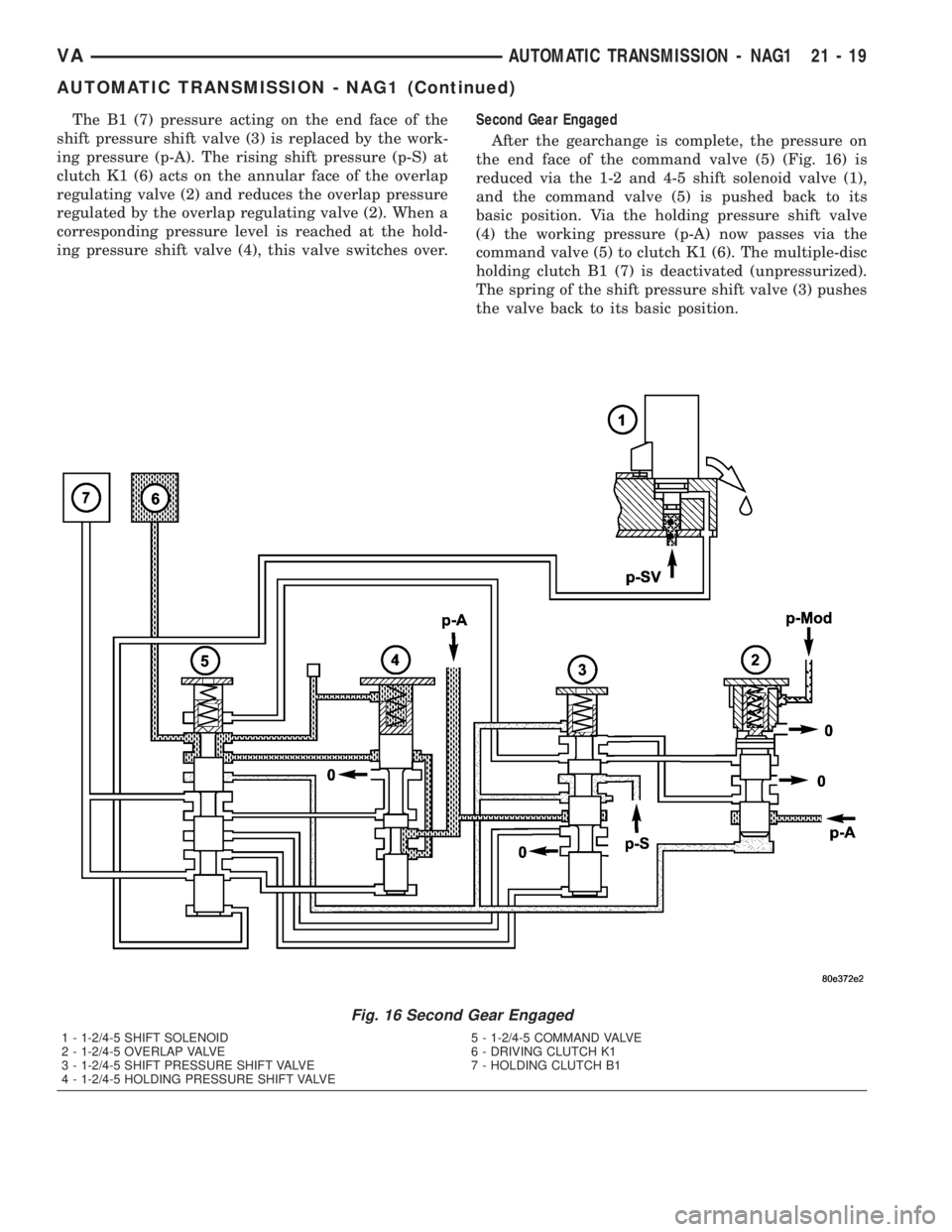

The B1 (7) pressure acting on the end face of the

shift pressure shift valve (3) is replaced by the work-

ing pressure (p-A). The rising shift pressure (p-S) at

clutch K1 (6) acts on the annular face of the overlap

regulating valve (2) and reduces the overlap pressure

regulated by the overlap regulating valve (2). When a

corresponding pressure level is reached at the hold-

ing pressure shift valve (4), this valve switches over.Second Gear Engaged

After the gearchange is complete, the pressure on

the end face of the command valve (5) (Fig. 16) is

reduced via the 1-2 and 4-5 shift solenoid valve (1),

and the command valve (5) is pushed back to its

basic position. Via the holding pressure shift valve

(4) the working pressure (p-A) now passes via the

command valve (5) to clutch K1 (6). The multiple-disc

holding clutch B1 (7) is deactivated (unpressurized).

The spring of the shift pressure shift valve (3) pushes

the valve back to its basic position.

Fig. 16 Second Gear Engaged

1 - 1-2/4-5 SHIFT SOLENOID 5 - 1-2/4-5 COMMAND VALVE

2 - 1-2/4-5 OVERLAP VALVE 6 - DRIVING CLUTCH K1

3 - 1-2/4-5 SHIFT PRESSURE SHIFT VALVE 7 - HOLDING CLUTCH B1

4 - 1-2/4-5 HOLDING PRESSURE SHIFT VALVE

VAAUTOMATIC TRANSMISSION - NAG1 21 - 19

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 896 of 1232

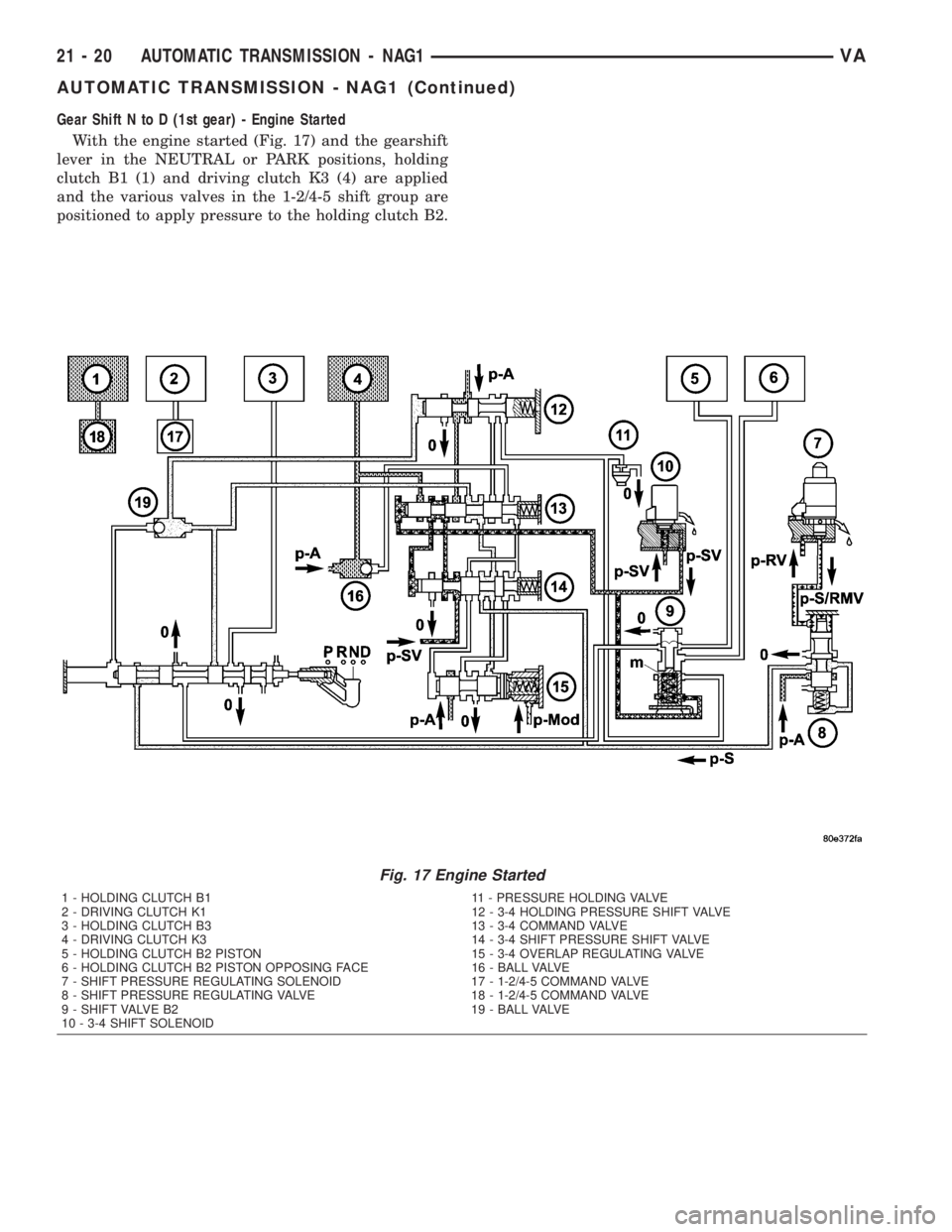

Gear Shift N to D (1st gear) - Engine Started

With the engine started (Fig. 17) and the gearshift

lever in the NEUTRAL or PARK positions, holding

clutch B1 (1) and driving clutch K3 (4) are applied

and the various valves in the 1-2/4-5 shift group are

positioned to apply pressure to the holding clutch B2.

Fig. 17 Engine Started

1 - HOLDING CLUTCH B1 11 - PRESSURE HOLDING VALVE

2 - DRIVING CLUTCH K1 12 - 3-4 HOLDING PRESSURE SHIFT VALVE

3 - HOLDING CLUTCH B3 13 - 3-4 COMMAND VALVE

4 - DRIVING CLUTCH K3 14 - 3-4 SHIFT PRESSURE SHIFT VALVE

5 - HOLDING CLUTCH B2 PISTON 15 - 3-4 OVERLAP REGULATING VALVE

6 - HOLDING CLUTCH B2 PISTON OPPOSING FACE 16 - BALL VALVE

7 - SHIFT PRESSURE REGULATING SOLENOID 17 - 1-2/4-5 COMMAND VALVE

8 - SHIFT PRESSURE REGULATING VALVE 18 - 1-2/4-5 COMMAND VALVE

9 - SHIFT VALVE B2 19 - BALL VALVE

10 - 3-4 SHIFT SOLENOID

21 - 20 AUTOMATIC TRANSMISSION - NAG1VA

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 897 of 1232

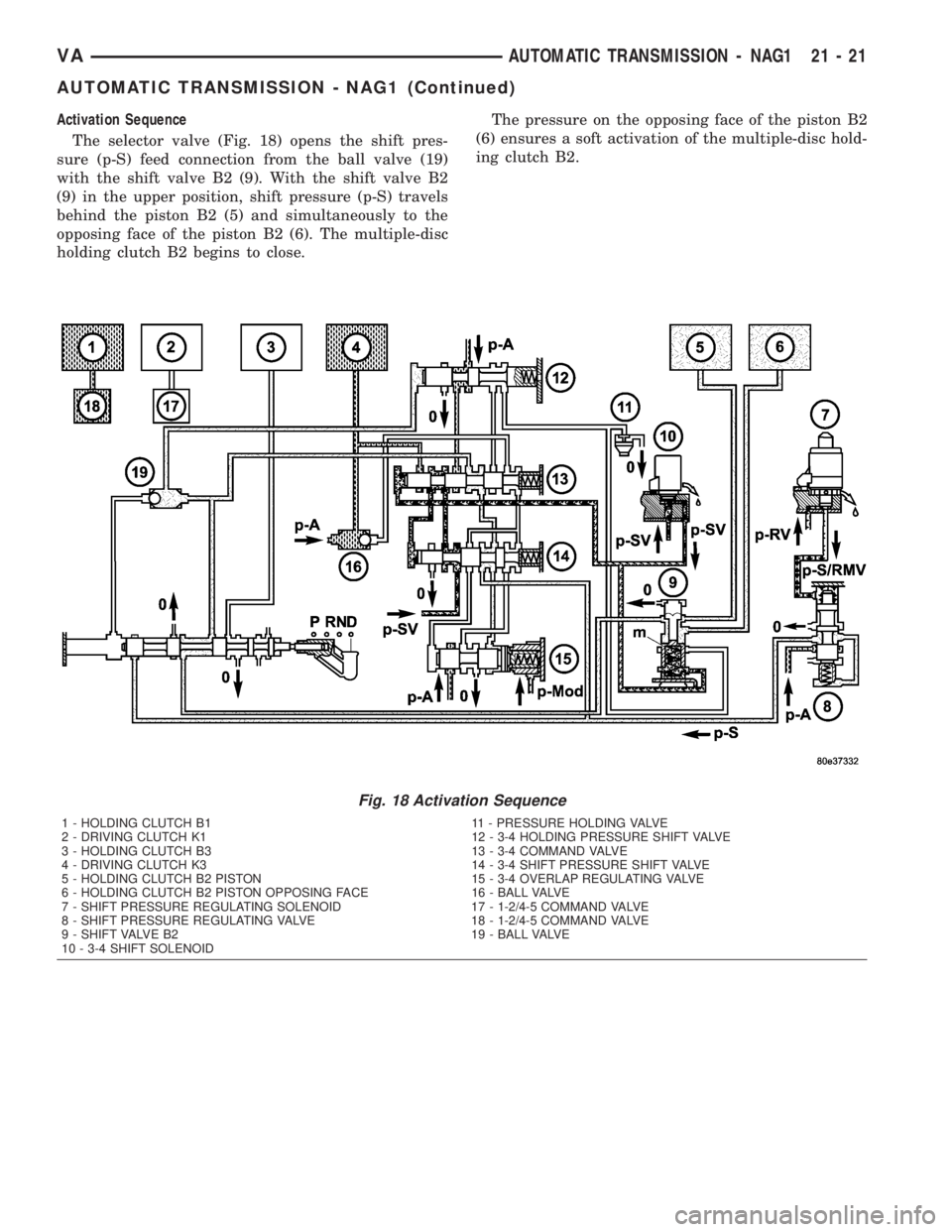

Activation Sequence

The selector valve (Fig. 18) opens the shift pres-

sure (p-S) feed connection from the ball valve (19)

with the shift valve B2 (9). With the shift valve B2

(9) in the upper position, shift pressure (p-S) travels

behind the piston B2 (5) and simultaneously to the

opposing face of the piston B2 (6). The multiple-disc

holding clutch B2 begins to close.The pressure on the opposing face of the piston B2

(6) ensures a soft activation of the multiple-disc hold-

ing clutch B2.

Fig. 18 Activation Sequence

1 - HOLDING CLUTCH B1 11 - PRESSURE HOLDING VALVE

2 - DRIVING CLUTCH K1 12 - 3-4 HOLDING PRESSURE SHIFT VALVE

3 - HOLDING CLUTCH B3 13 - 3-4 COMMAND VALVE

4 - DRIVING CLUTCH K3 14 - 3-4 SHIFT PRESSURE SHIFT VALVE

5 - HOLDING CLUTCH B2 PISTON 15 - 3-4 OVERLAP REGULATING VALVE

6 - HOLDING CLUTCH B2 PISTON OPPOSING FACE 16 - BALL VALVE

7 - SHIFT PRESSURE REGULATING SOLENOID 17 - 1-2/4-5 COMMAND VALVE

8 - SHIFT PRESSURE REGULATING VALVE 18 - 1-2/4-5 COMMAND VALVE

9 - SHIFT VALVE B2 19 - BALL VALVE

10 - 3-4 SHIFT SOLENOID

VAAUTOMATIC TRANSMISSION - NAG1 21 - 21

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 898 of 1232

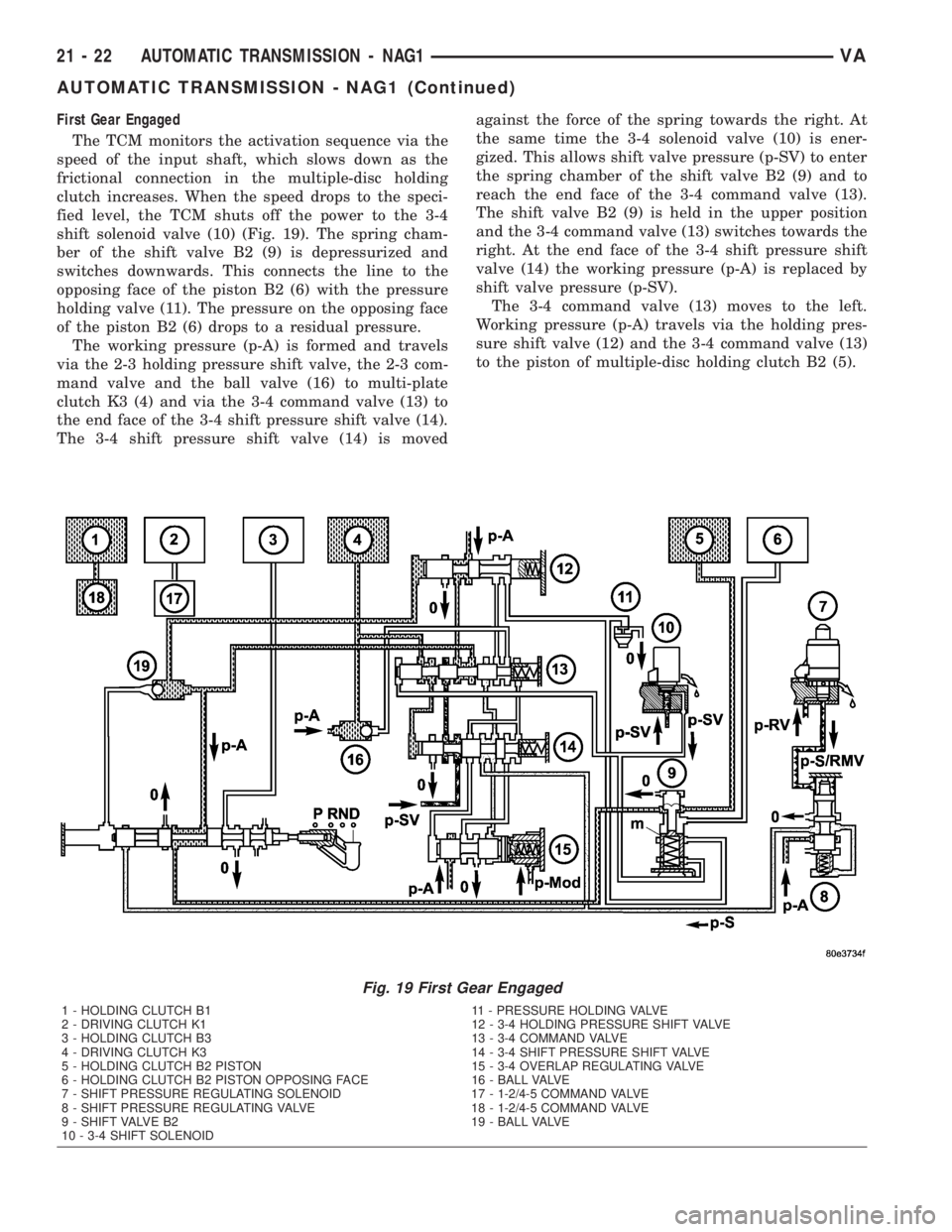

First Gear Engaged

The TCM monitors the activation sequence via the

speed of the input shaft, which slows down as the

frictional connection in the multiple-disc holding

clutch increases. When the speed drops to the speci-

fied level, the TCM shuts off the power to the 3-4

shift solenoid valve (10) (Fig. 19). The spring cham-

ber of the shift valve B2 (9) is depressurized and

switches downwards. This connects the line to the

opposing face of the piston B2 (6) with the pressure

holding valve (11). The pressure on the opposing face

of the piston B2 (6) drops to a residual pressure.

The working pressure (p-A) is formed and travels

via the 2-3 holding pressure shift valve, the 2-3 com-

mand valve and the ball valve (16) to multi-plate

clutch K3 (4) and via the 3-4 command valve (13) to

the end face of the 3-4 shift pressure shift valve (14).

The 3-4 shift pressure shift valve (14) is movedagainst the force of the spring towards the right. At

the same time the 3-4 solenoid valve (10) is ener-

gized. This allows shift valve pressure (p-SV) to enter

the spring chamber of the shift valve B2 (9) and to

reach the end face of the 3-4 command valve (13).

The shift valve B2 (9) is held in the upper position

and the 3-4 command valve (13) switches towards the

right. At the end face of the 3-4 shift pressure shift

valve (14) the working pressure (p-A) is replaced by

shift valve pressure (p-SV).

The 3-4 command valve (13) moves to the left.

Working pressure (p-A) travels via the holding pres-

sure shift valve (12) and the 3-4 command valve (13)

to the piston of multiple-disc holding clutch B2 (5).

Fig. 19 First Gear Engaged

1 - HOLDING CLUTCH B1 11 - PRESSURE HOLDING VALVE

2 - DRIVING CLUTCH K1 12 - 3-4 HOLDING PRESSURE SHIFT VALVE

3 - HOLDING CLUTCH B3 13 - 3-4 COMMAND VALVE

4 - DRIVING CLUTCH K3 14 - 3-4 SHIFT PRESSURE SHIFT VALVE

5 - HOLDING CLUTCH B2 PISTON 15 - 3-4 OVERLAP REGULATING VALVE

6 - HOLDING CLUTCH B2 PISTON OPPOSING FACE 16 - BALL VALVE

7 - SHIFT PRESSURE REGULATING SOLENOID 17 - 1-2/4-5 COMMAND VALVE

8 - SHIFT PRESSURE REGULATING VALVE 18 - 1-2/4-5 COMMAND VALVE

9 - SHIFT VALVE B2 19 - BALL VALVE

10 - 3-4 SHIFT SOLENOID

21 - 22 AUTOMATIC TRANSMISSION - NAG1VA

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 899 of 1232

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AUTOMATIC

TRANSMISSION

CAUTION: Before attempting any repair on a NAG1

automatic transmission, check for Diagnostic Trou-

ble Codes with the DRBTscan tool.

Transmission malfunctions may be caused by these

general conditions:

²Poor engine performance.

²Improper adjustments.

²Hydraulic malfunctions.

²Mechanical malfunctions.

²Electronic malfunctions.

²Transfer case performance.

Diagnosis of these problems should always begin

by checking the easily accessible variables: fluid level

and condition, gearshift cable adjustment. Then per-

form a road test to determine if the problem has been

corrected or if more diagnosis is necessary.

DIAGNOSIS AND TESTING - PRELIMINARY

Two basic procedures are required. One procedure

for vehicles that are drivable and an alternate proce-

dure for disabled vehicles (will not back up or move

forward).

VEHICLE IS DRIVABLE

(1) Check for transmission fault codes using DRBt

scan tool.

(2) Check fluid level and condition.

(3) Adjust gearshift cable if complaint was based

on delayed, erratic, or harsh shifts.

(4) Road test and note how transmission upshifts,

downshifts, and engages.

VEHICLE IS DISABLED

(1) Check fluid level and condition.(2) Check for broken or disconnected gearshift

cable.

(3) Check for cracked, leaking cooler lines, or loose

or missing pressure-port plugs.

(4) Raise and support vehicle on safety stands,

start engine, shift transmission into gear, and note

following:

(a) If propeller shaft turns but wheels do not,

problem is with differential or axle shafts.

(b) If propeller shaft does not turn and transmis-

sion is noisy, stop engine. Remove oil pan, and

check for debris. If pan is clear, remove transmis-

sion and check for damaged driveplate, converter,

oil pump, or input shaft.

(c) If propeller shaft does not turn and transmis-

sion is not noisy, perform hydraulic-pressure test to

determine if problem is hydraulic or mechanical.

DIAGNOSIS AND TESTING - ROAD TESTING

Before road testing, be sure the fluid level and con-

trol cable adjustments have been checked and

adjusted if necessary. Verify that all diagnostic trou-

ble codes have been resolved.

Observe engine performance during the road test.

A poorly tuned engine will not allow accurate analy-

sis of transmission operation.

Operate the transmission in all gear ranges. Check

for shift variations and engine flare which indicates

slippage. Note if shifts are harsh, spongy, delayed,

early, or if part throttle downshifts are sensitive.

Slippage indicated by engine flare, usually means

clutch, overrunning clutch, or line pressure problems.

A slipping clutch can often be determined by com-

paring which internal units are applied in the vari-

ous gear ranges. The Clutch Application chart

CLUTCH APPLICATION provides a basis for analyz-

ing road test results.

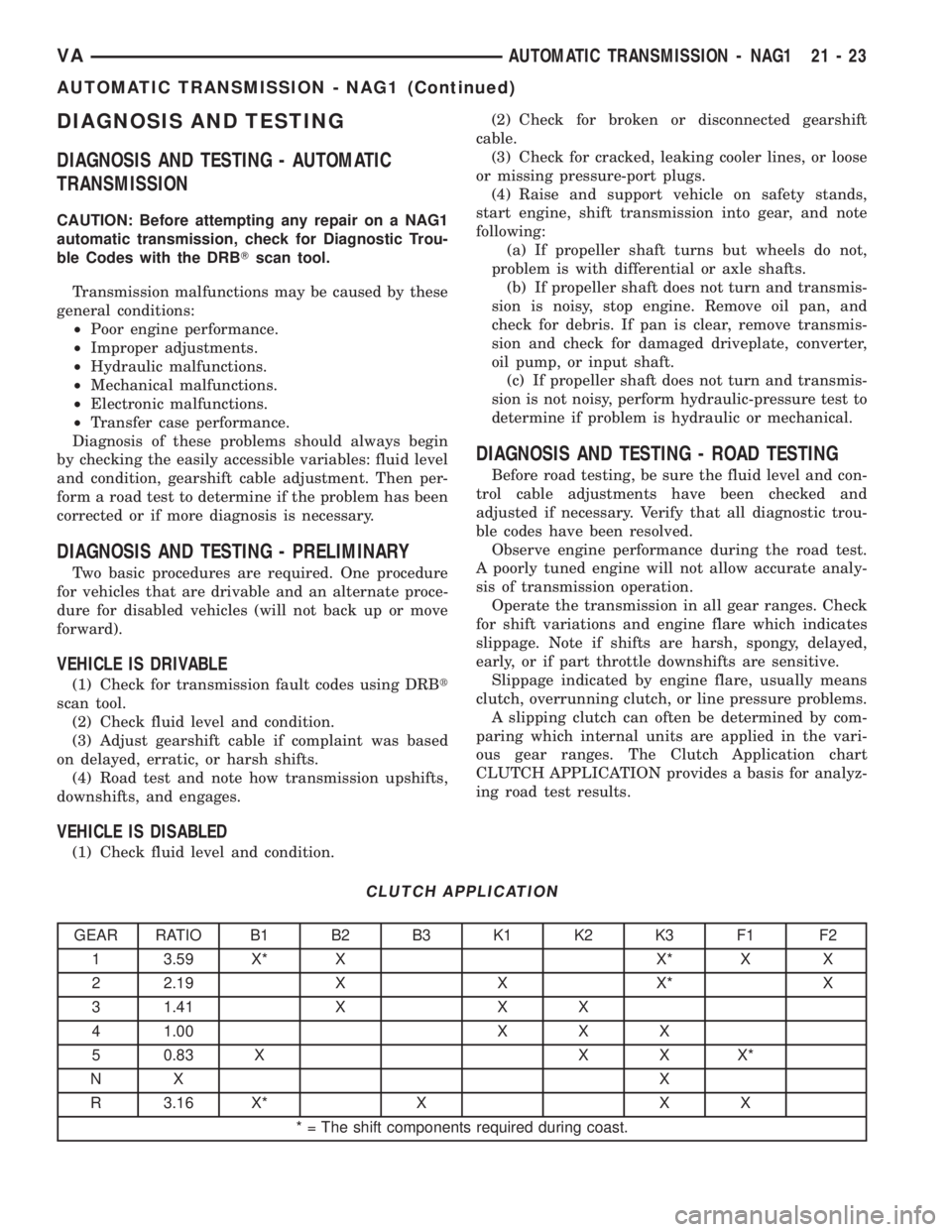

CLUTCH APPLICATION

GEAR RATIO B1 B2 B3 K1 K2 K3 F1 F2

1 3.59 X* X X* X X

2 2.19 X X X* X

3 1.41 X X X

4 1.00 X X X

5 0.83 X X X X*

NX X

R 3.16 X* X X X

* = The shift components required during coast.

VAAUTOMATIC TRANSMISSION - NAG1 21 - 23

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 900 of 1232

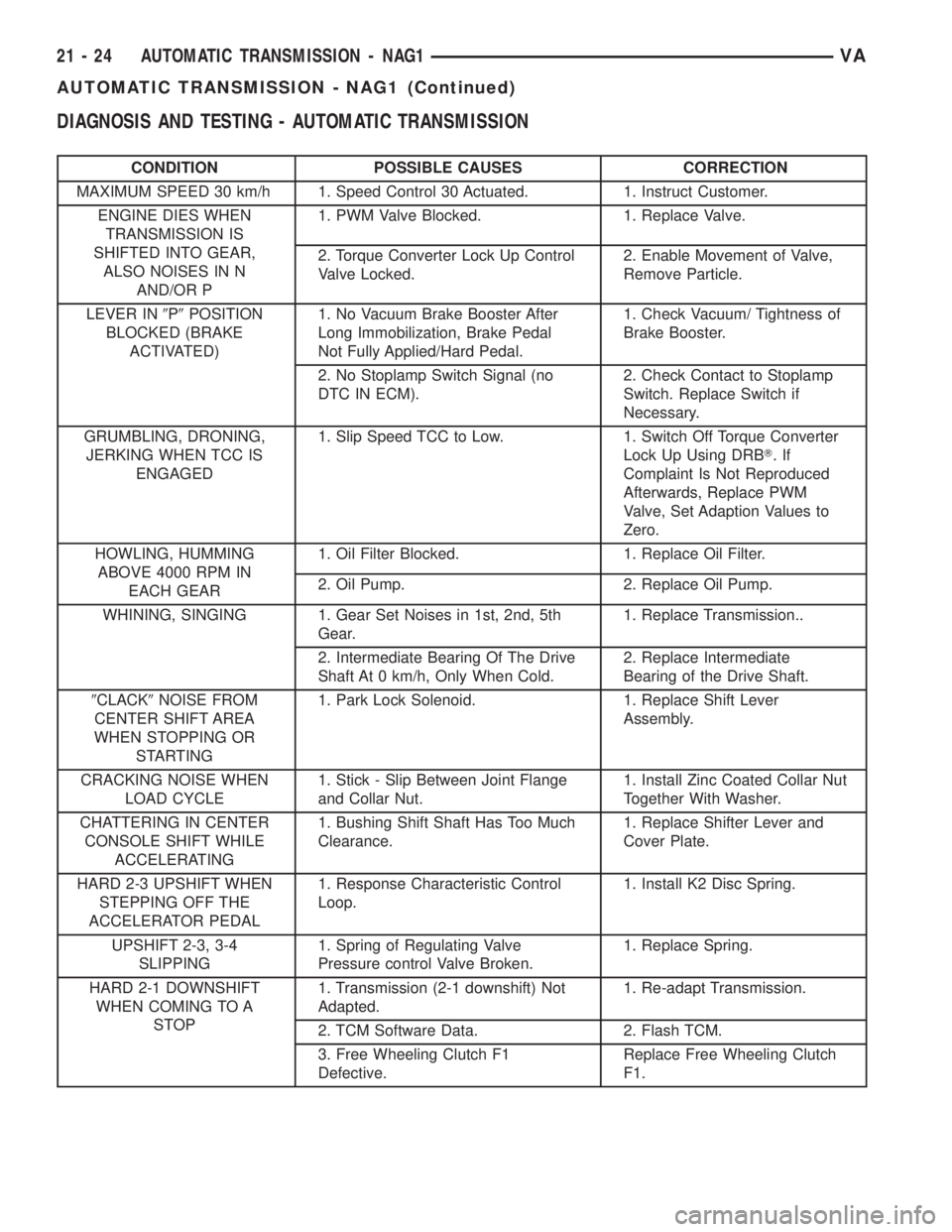

DIAGNOSIS AND TESTING - AUTOMATIC TRANSMISSION

CONDITION POSSIBLE CAUSES CORRECTION

MAXIMUM SPEED 30 km/h 1. Speed Control 30 Actuated. 1. Instruct Customer.

ENGINE DIES WHEN

TRANSMISSION IS

SHIFTED INTO GEAR,

ALSO NOISES IN N

AND/OR P1. PWM Valve Blocked. 1. Replace Valve.

2. Torque Converter Lock Up Control

Valve Locked.2. Enable Movement of Valve,

Remove Particle.

LEVER IN9P9POSITION

BLOCKED (BRAKE

ACTIVATED)1. No Vacuum Brake Booster After

Long Immobilization, Brake Pedal

Not Fully Applied/Hard Pedal.1. Check Vacuum/ Tightness of

Brake Booster.

2. No Stoplamp Switch Signal (no

DTC IN ECM).2. Check Contact to Stoplamp

Switch. Replace Switch if

Necessary.

GRUMBLING, DRONING,

JERKING WHEN TCC IS

ENGAGED1. Slip Speed TCC to Low. 1. Switch Off Torque Converter

Lock Up Using DRBT.If

Complaint Is Not Reproduced

Afterwards, Replace PWM

Valve, Set Adaption Values to

Zero.

HOWLING, HUMMING

ABOVE 4000 RPM IN

EACH GEAR1. Oil Filter Blocked. 1. Replace Oil Filter.

2. Oil Pump. 2. Replace Oil Pump.

WHINING, SINGING 1. Gear Set Noises in 1st, 2nd, 5th

Gear.1. Replace Transmission..

2. Intermediate Bearing Of The Drive

Shaft At 0 km/h, Only When Cold.2. Replace Intermediate

Bearing of the Drive Shaft.

9CLACK9NOISE FROM

CENTER SHIFT AREA

WHEN STOPPING OR

STARTING1. Park Lock Solenoid. 1. Replace Shift Lever

Assembly.

CRACKING NOISE WHEN

LOAD CYCLE1. Stick - Slip Between Joint Flange

and Collar Nut.1. Install Zinc Coated Collar Nut

Together With Washer.

CHATTERING IN CENTER

CONSOLE SHIFT WHILE

ACCELERATING1. Bushing Shift Shaft Has Too Much

Clearance.1. Replace Shifter Lever and

Cover Plate.

HARD 2-3 UPSHIFT WHEN

STEPPING OFF THE

ACCELERATOR PEDAL1. Response Characteristic Control

Loop.1. Install K2 Disc Spring.

UPSHIFT 2-3, 3-4

SLIPPING1. Spring of Regulating Valve

Pressure control Valve Broken.1. Replace Spring.

HARD 2-1 DOWNSHIFT

WHEN COMING TO A

STOP1. Transmission (2-1 downshift) Not

Adapted.1. Re-adapt Transmission.

2. TCM Software Data. 2. Flash TCM.

3. Free Wheeling Clutch F1

Defective.Replace Free Wheeling Clutch

F1.

21 - 24 AUTOMATIC TRANSMISSION - NAG1VA

AUTOMATIC TRANSMISSION - NAG1 (Continued)