MERCEDES-BENZ SPRINTER 2005 Service Repair Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 951 of 1232

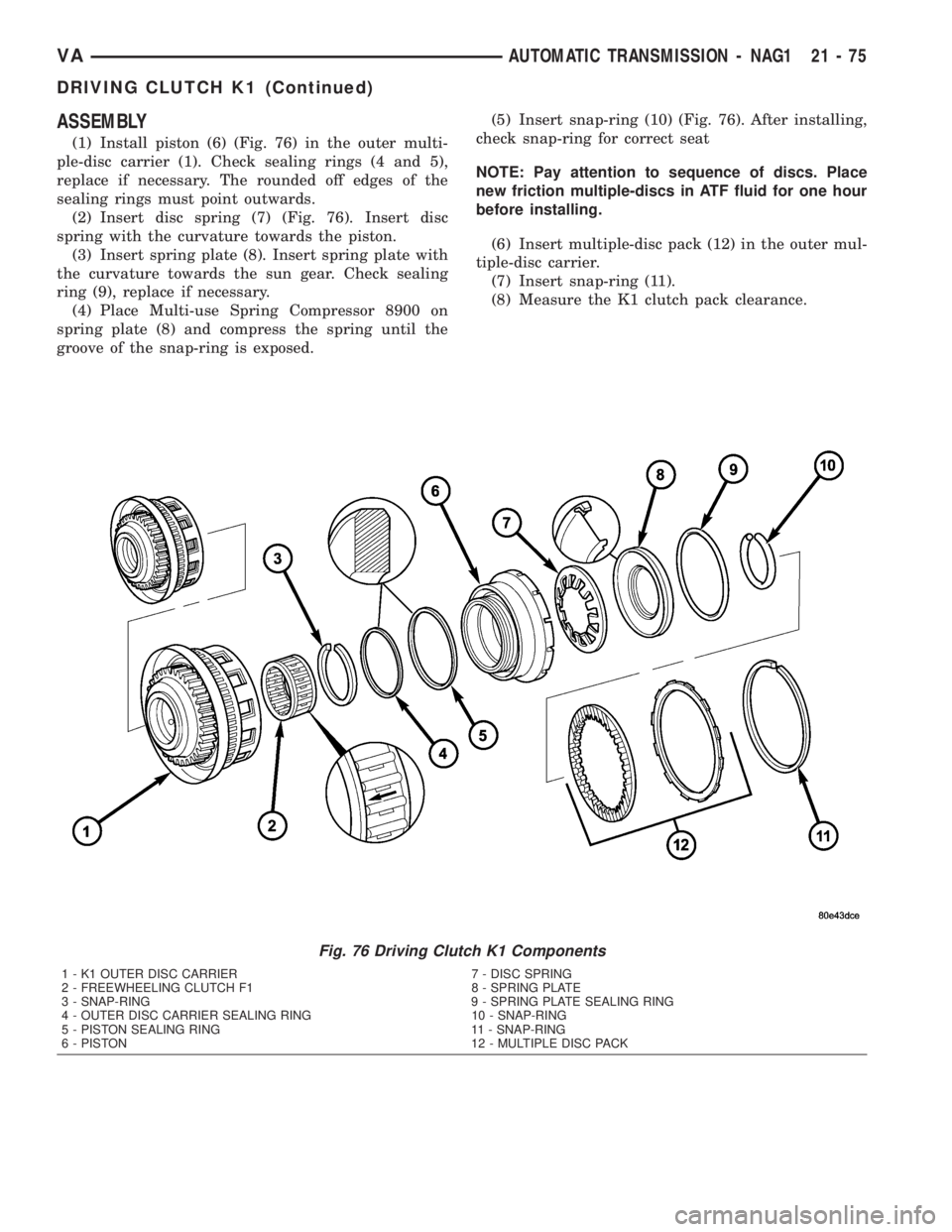

ASSEMBLY

(1) Install piston (6) (Fig. 76) in the outer multi-

ple-disc carrier (1). Check sealing rings (4 and 5),

replace if necessary. The rounded off edges of the

sealing rings must point outwards.

(2) Insert disc spring (7) (Fig. 76). Insert disc

spring with the curvature towards the piston.

(3) Insert spring plate (8). Insert spring plate with

the curvature towards the sun gear. Check sealing

ring (9), replace if necessary.

(4) Place Multi-use Spring Compressor 8900 on

spring plate (8) and compress the spring until the

groove of the snap-ring is exposed.(5) Insert snap-ring (10) (Fig. 76). After installing,

check snap-ring for correct seat

NOTE: Pay attention to sequence of discs. Place

new friction multiple-discs in ATF fluid for one hour

before installing.

(6) Insert multiple-disc pack (12) in the outer mul-

tiple-disc carrier.

(7) Insert snap-ring (11).

(8) Measure the K1 clutch pack clearance.

Fig. 76 Driving Clutch K1 Components

1 - K1 OUTER DISC CARRIER 7 - DISC SPRING

2 - FREEWHEELING CLUTCH F1 8 - SPRING PLATE

3 - SNAP-RING 9 - SPRING PLATE SEALING RING

4 - OUTER DISC CARRIER SEALING RING 10 - SNAP-RING

5 - PISTON SEALING RING 11 - SNAP-RING

6 - PISTON 12 - MULTIPLE DISC PACK

VAAUTOMATIC TRANSMISSION - NAG1 21 - 75

DRIVING CLUTCH K1 (Continued)

Page 952 of 1232

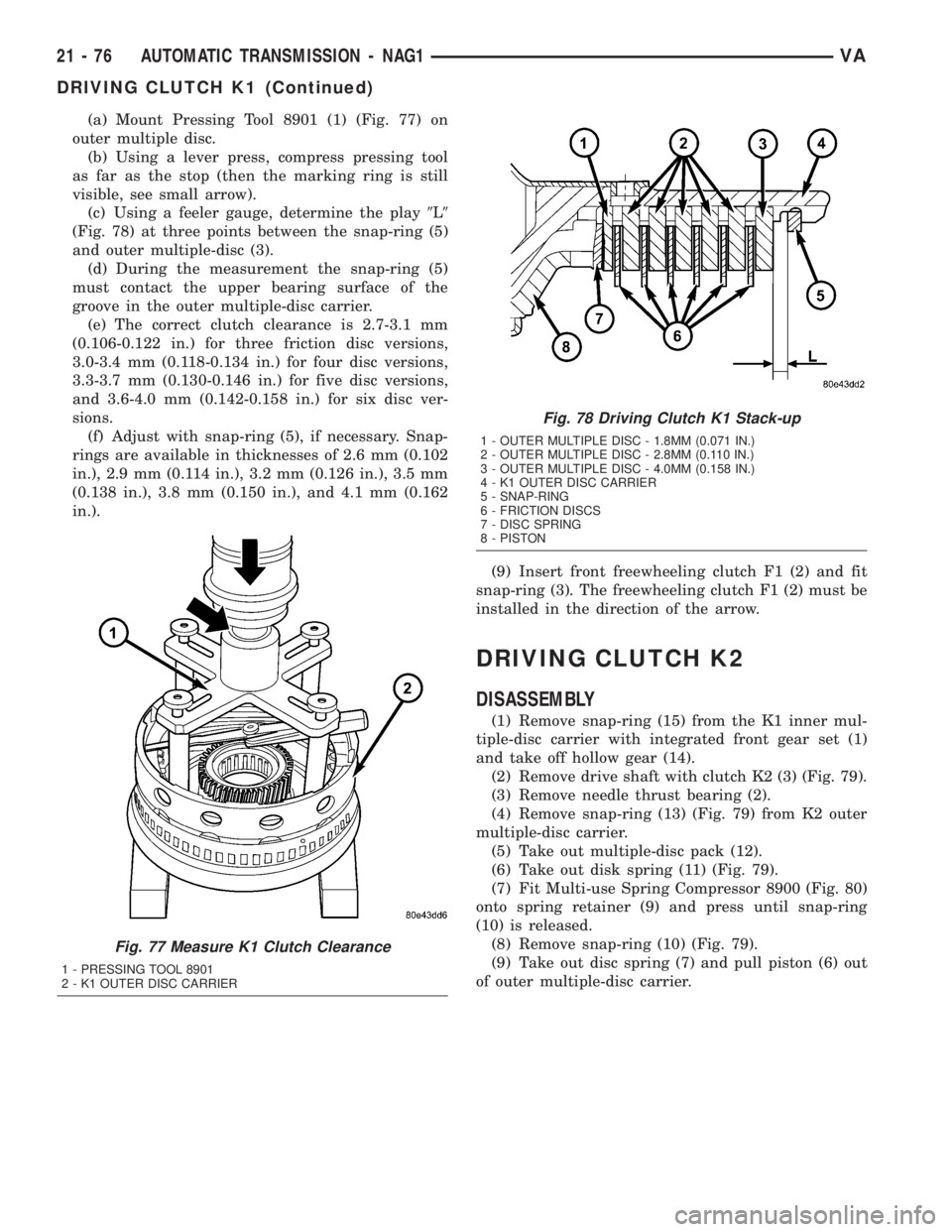

(a) Mount Pressing Tool 8901 (1) (Fig. 77) on

outer multiple disc.

(b) Using a lever press, compress pressing tool

as far as the stop (then the marking ring is still

visible, see small arrow).

(c) Using a feeler gauge, determine the play9L9

(Fig. 78) at three points between the snap-ring (5)

and outer multiple-disc (3).

(d) During the measurement the snap-ring (5)

must contact the upper bearing surface of the

groove in the outer multiple-disc carrier.

(e) The correct clutch clearance is 2.7-3.1 mm

(0.106-0.122 in.) for three friction disc versions,

3.0-3.4 mm (0.118-0.134 in.) for four disc versions,

3.3-3.7 mm (0.130-0.146 in.) for five disc versions,

and 3.6-4.0 mm (0.142-0.158 in.) for six disc ver-

sions.

(f) Adjust with snap-ring (5), if necessary. Snap-

rings are available in thicknesses of 2.6 mm (0.102

in.), 2.9 mm (0.114 in.), 3.2 mm (0.126 in.), 3.5 mm

(0.138 in.), 3.8 mm (0.150 in.), and 4.1 mm (0.162

in.).

(9) Insert front freewheeling clutch F1 (2) and fit

snap-ring (3). The freewheeling clutch F1 (2) must be

installed in the direction of the arrow.

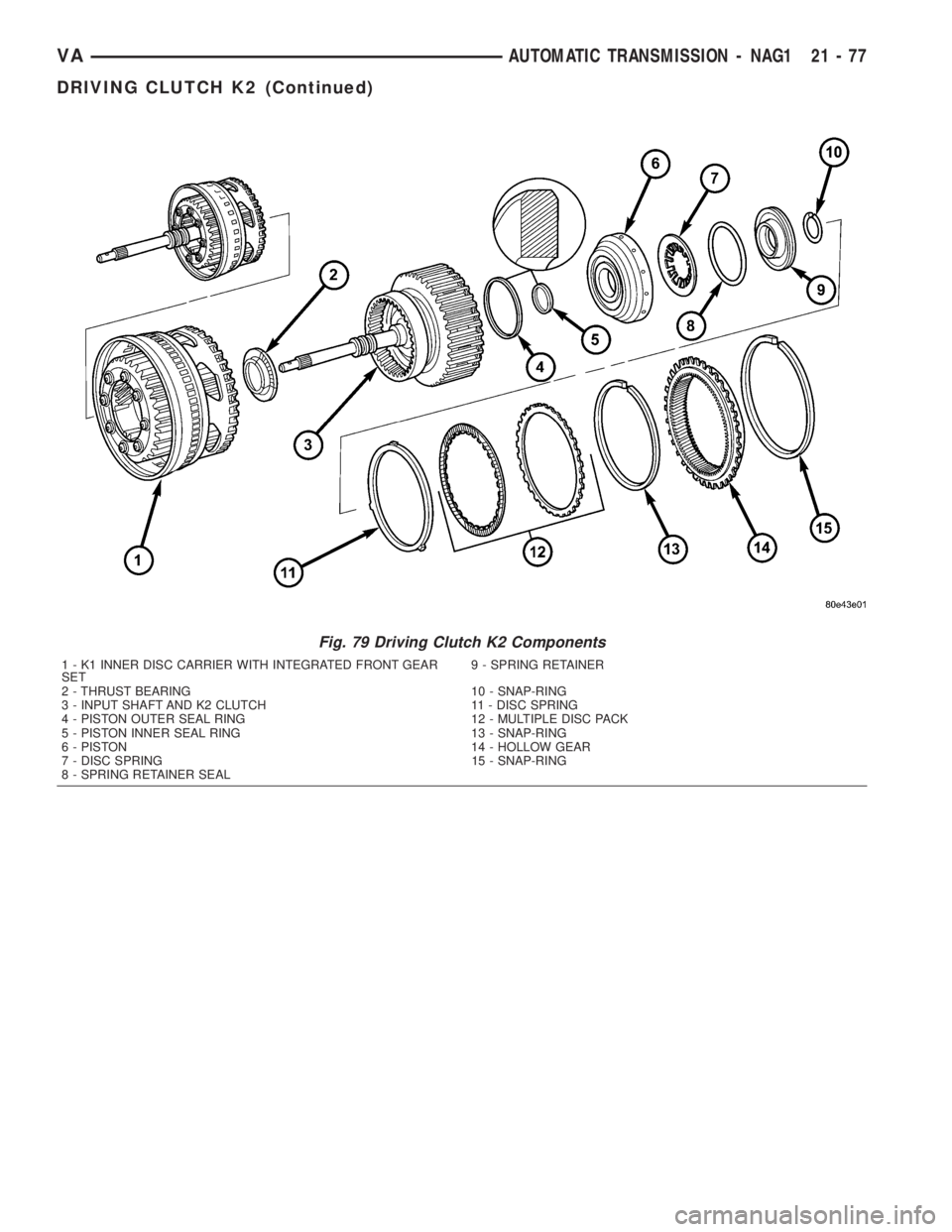

DRIVING CLUTCH K2

DISASSEMBLY

(1) Remove snap-ring (15) from the K1 inner mul-

tiple-disc carrier with integrated front gear set (1)

and take off hollow gear (14).

(2) Remove drive shaft with clutch K2 (3) (Fig. 79).

(3) Remove needle thrust bearing (2).

(4) Remove snap-ring (13) (Fig. 79) from K2 outer

multiple-disc carrier.

(5) Take out multiple-disc pack (12).

(6) Take out disk spring (11) (Fig. 79).

(7) Fit Multi-use Spring Compressor 8900 (Fig. 80)

onto spring retainer (9) and press until snap-ring

(10) is released.

(8) Remove snap-ring (10) (Fig. 79).

(9) Take out disc spring (7) and pull piston (6) out

of outer multiple-disc carrier.

Fig. 77 Measure K1 Clutch Clearance

1 - PRESSING TOOL 8901

2 - K1 OUTER DISC CARRIER

Fig. 78 Driving Clutch K1 Stack-up

1 - OUTER MULTIPLE DISC - 1.8MM (0.071 IN.)

2 - OUTER MULTIPLE DISC - 2.8MM (0.110 IN.)

3 - OUTER MULTIPLE DISC - 4.0MM (0.158 IN.)

4 - K1 OUTER DISC CARRIER

5 - SNAP-RING

6 - FRICTION DISCS

7 - DISC SPRING

8 - PISTON

21 - 76 AUTOMATIC TRANSMISSION - NAG1VA

DRIVING CLUTCH K1 (Continued)

Page 953 of 1232

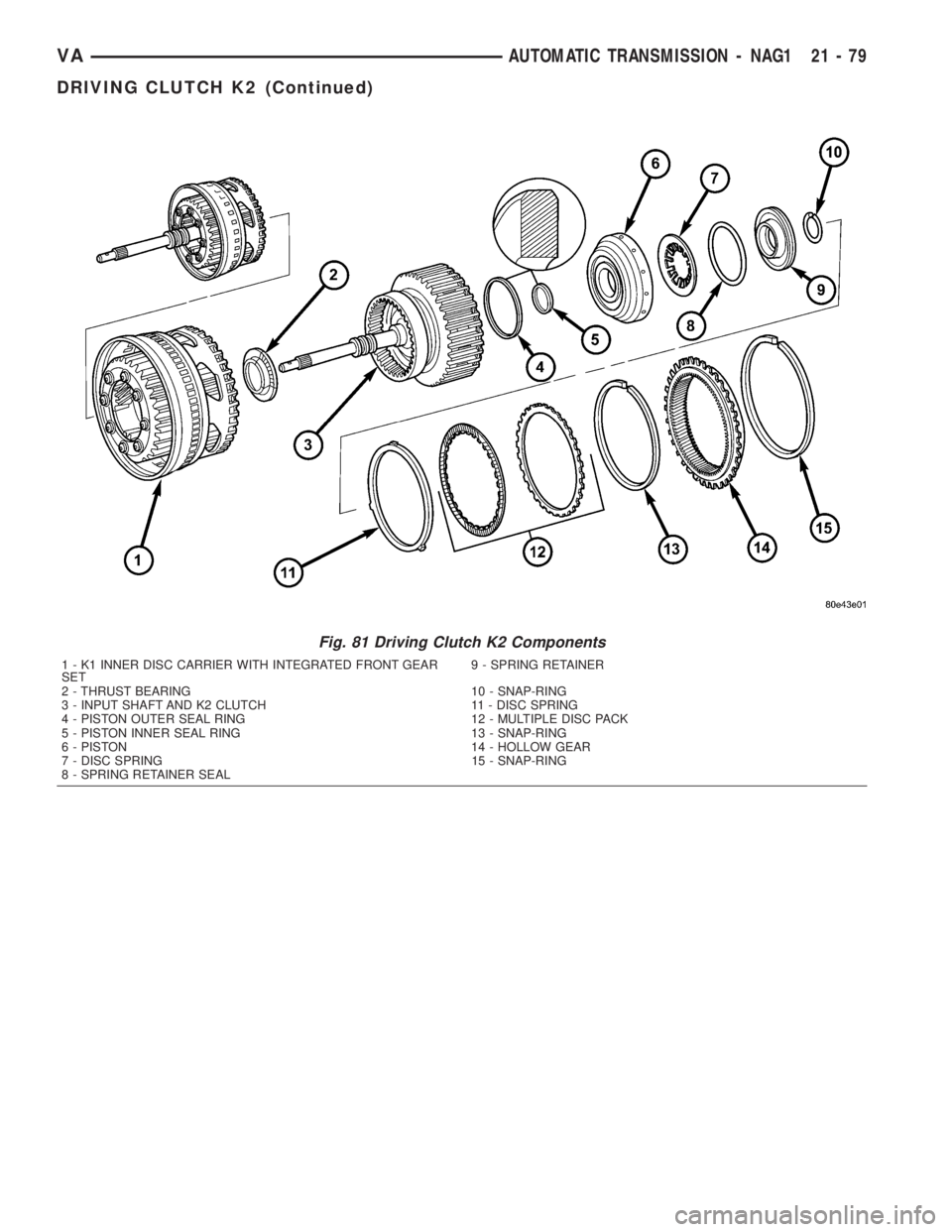

Fig. 79 Driving Clutch K2 Components

1 - K1 INNER DISC CARRIER WITH INTEGRATED FRONT GEAR

SET9 - SPRING RETAINER

2 - THRUST BEARING 10 - SNAP-RING

3 - INPUT SHAFT AND K2 CLUTCH 11 - DISC SPRING

4 - PISTON OUTER SEAL RING 12 - MULTIPLE DISC PACK

5 - PISTON INNER SEAL RING 13 - SNAP-RING

6 - PISTON 14 - HOLLOW GEAR

7 - DISC SPRING 15 - SNAP-RING

8 - SPRING RETAINER SEAL

VAAUTOMATIC TRANSMISSION - NAG1 21 - 77

DRIVING CLUTCH K2 (Continued)

Page 954 of 1232

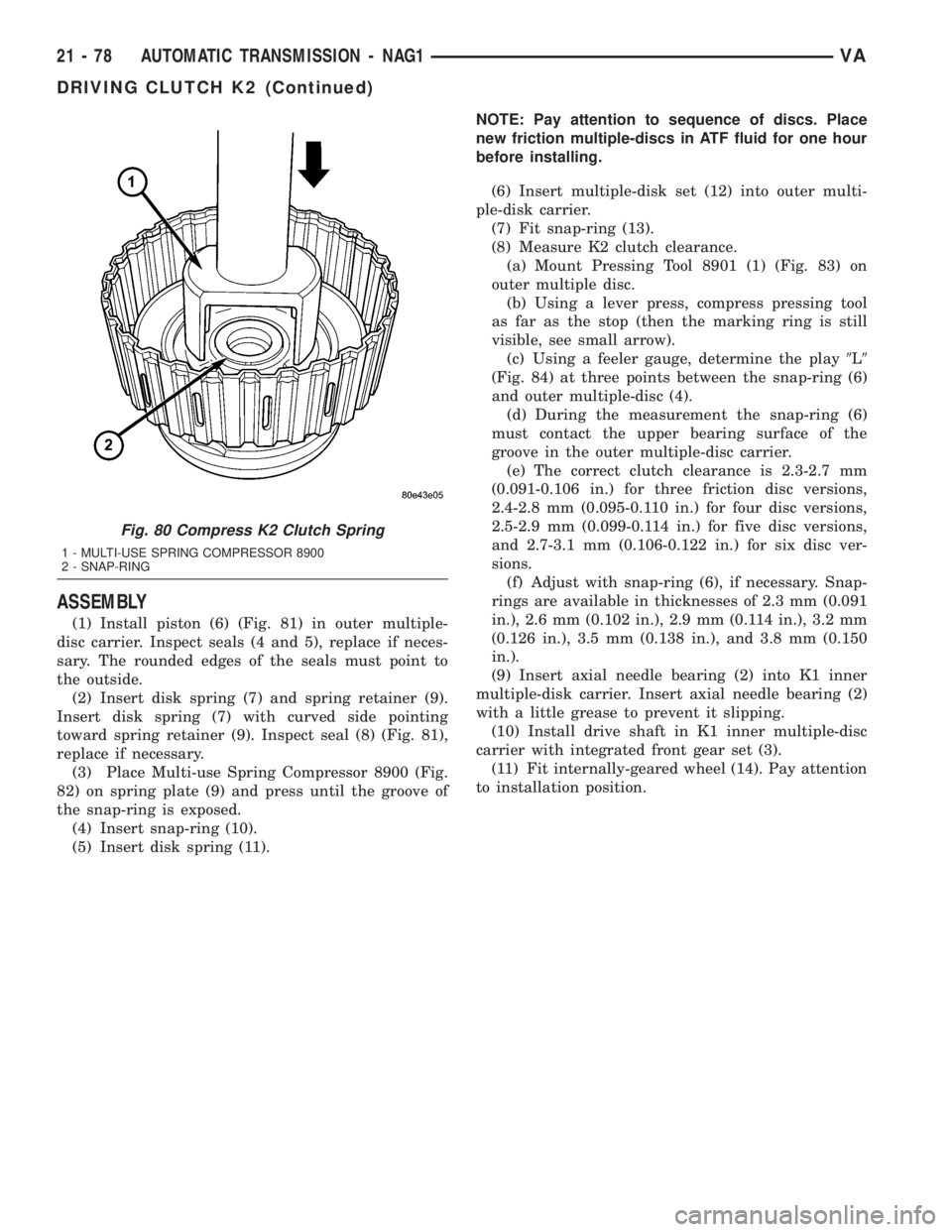

ASSEMBLY

(1) Install piston (6) (Fig. 81) in outer multiple-

disc carrier. Inspect seals (4 and 5), replace if neces-

sary. The rounded edges of the seals must point to

the outside.

(2) Insert disk spring (7) and spring retainer (9).

Insert disk spring (7) with curved side pointing

toward spring retainer (9). Inspect seal (8) (Fig. 81),

replace if necessary.

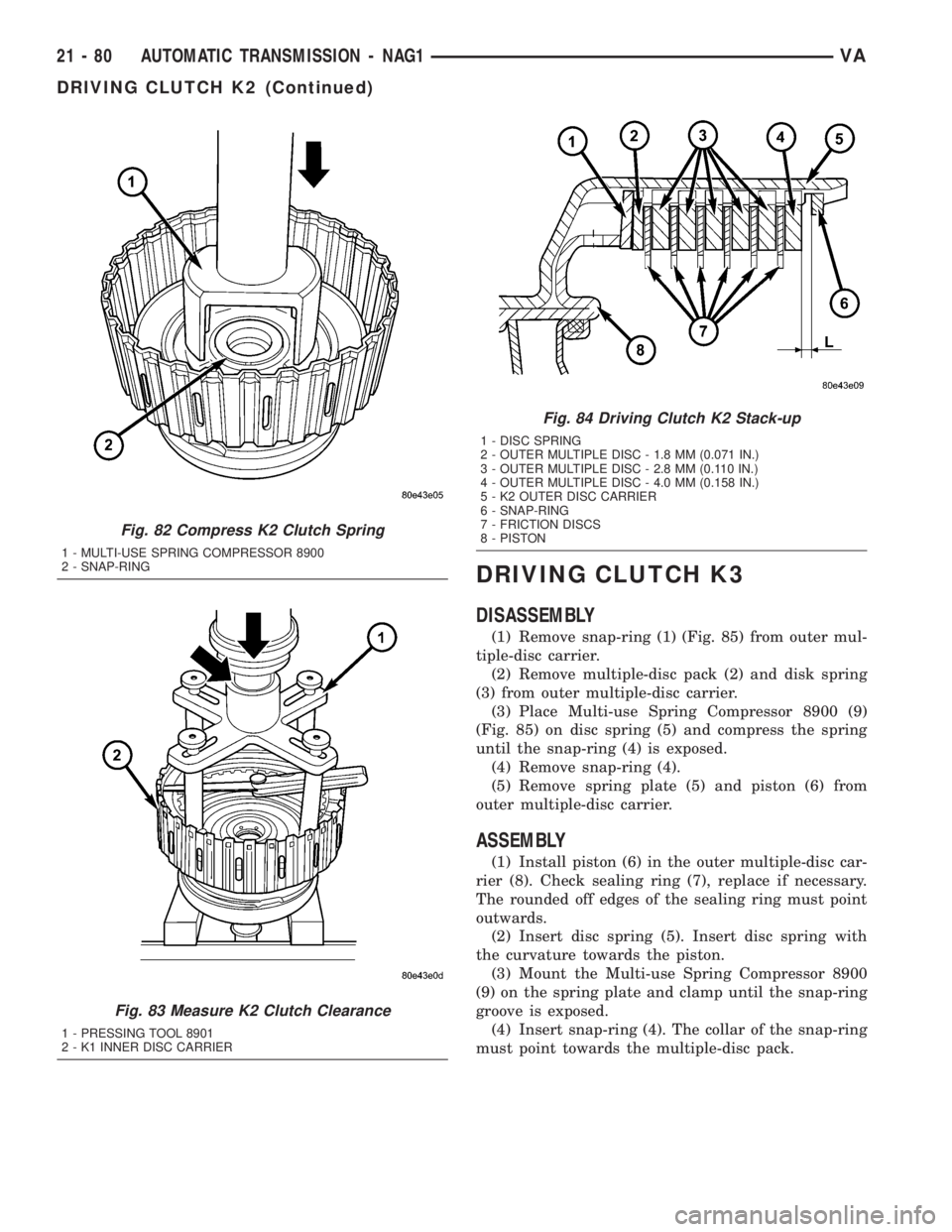

(3) Place Multi-use Spring Compressor 8900 (Fig.

82) on spring plate (9) and press until the groove of

the snap-ring is exposed.

(4) Insert snap-ring (10).

(5) Insert disk spring (11).NOTE: Pay attention to sequence of discs. Place

new friction multiple-discs in ATF fluid for one hour

before installing.

(6) Insert multiple-disk set (12) into outer multi-

ple-disk carrier.

(7) Fit snap-ring (13).

(8) Measure K2 clutch clearance.

(a) Mount Pressing Tool 8901 (1) (Fig. 83) on

outer multiple disc.

(b) Using a lever press, compress pressing tool

as far as the stop (then the marking ring is still

visible, see small arrow).

(c) Using a feeler gauge, determine the play9L9

(Fig. 84) at three points between the snap-ring (6)

and outer multiple-disc (4).

(d) During the measurement the snap-ring (6)

must contact the upper bearing surface of the

groove in the outer multiple-disc carrier.

(e) The correct clutch clearance is 2.3-2.7 mm

(0.091-0.106 in.) for three friction disc versions,

2.4-2.8 mm (0.095-0.110 in.) for four disc versions,

2.5-2.9 mm (0.099-0.114 in.) for five disc versions,

and 2.7-3.1 mm (0.106-0.122 in.) for six disc ver-

sions.

(f) Adjust with snap-ring (6), if necessary. Snap-

rings are available in thicknesses of 2.3 mm (0.091

in.), 2.6 mm (0.102 in.), 2.9 mm (0.114 in.), 3.2 mm

(0.126 in.), 3.5 mm (0.138 in.), and 3.8 mm (0.150

in.).

(9) Insert axial needle bearing (2) into K1 inner

multiple-disk carrier. Insert axial needle bearing (2)

with a little grease to prevent it slipping.

(10) Install drive shaft in K1 inner multiple-disc

carrier with integrated front gear set (3).

(11) Fit internally-geared wheel (14). Pay attention

to installation position.

Fig. 80 Compress K2 Clutch Spring

1 - MULTI-USE SPRING COMPRESSOR 8900

2 - SNAP-RING

21 - 78 AUTOMATIC TRANSMISSION - NAG1VA

DRIVING CLUTCH K2 (Continued)

Page 955 of 1232

Fig. 81 Driving Clutch K2 Components

1 - K1 INNER DISC CARRIER WITH INTEGRATED FRONT GEAR

SET9 - SPRING RETAINER

2 - THRUST BEARING 10 - SNAP-RING

3 - INPUT SHAFT AND K2 CLUTCH 11 - DISC SPRING

4 - PISTON OUTER SEAL RING 12 - MULTIPLE DISC PACK

5 - PISTON INNER SEAL RING 13 - SNAP-RING

6 - PISTON 14 - HOLLOW GEAR

7 - DISC SPRING 15 - SNAP-RING

8 - SPRING RETAINER SEAL

VAAUTOMATIC TRANSMISSION - NAG1 21 - 79

DRIVING CLUTCH K2 (Continued)

Page 956 of 1232

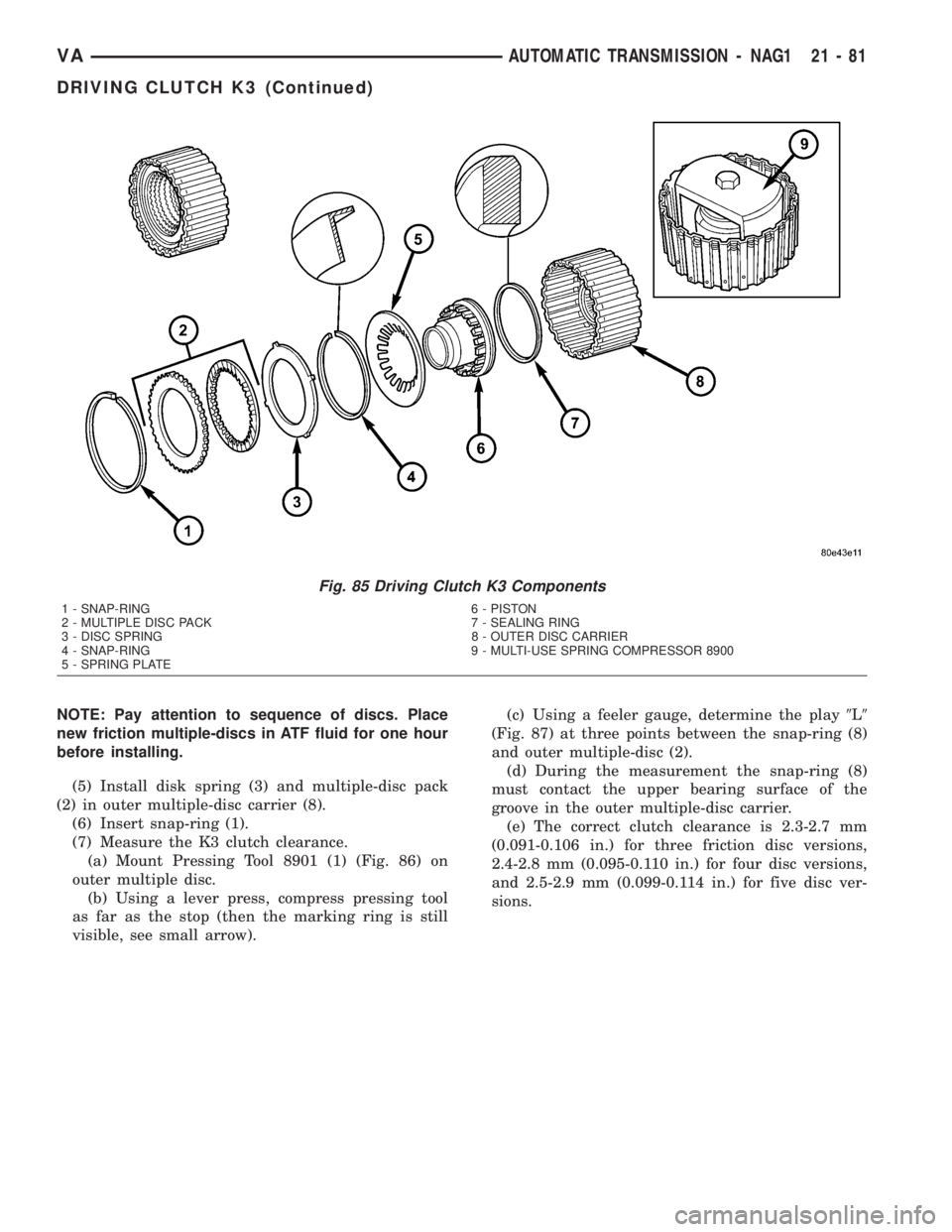

DRIVING CLUTCH K3

DISASSEMBLY

(1) Remove snap-ring (1) (Fig. 85) from outer mul-

tiple-disc carrier.

(2) Remove multiple-disc pack (2) and disk spring

(3) from outer multiple-disc carrier.

(3) Place Multi-use Spring Compressor 8900 (9)

(Fig. 85) on disc spring (5) and compress the spring

until the snap-ring (4) is exposed.

(4) Remove snap-ring (4).

(5) Remove spring plate (5) and piston (6) from

outer multiple-disc carrier.

ASSEMBLY

(1) Install piston (6) in the outer multiple-disc car-

rier (8). Check sealing ring (7), replace if necessary.

The rounded off edges of the sealing ring must point

outwards.

(2) Insert disc spring (5). Insert disc spring with

the curvature towards the piston.

(3) Mount the Multi-use Spring Compressor 8900

(9) on the spring plate and clamp until the snap-ring

groove is exposed.

(4) Insert snap-ring (4). The collar of the snap-ring

must point towards the multiple-disc pack.

Fig. 82 Compress K2 Clutch Spring

1 - MULTI-USE SPRING COMPRESSOR 8900

2 - SNAP-RING

Fig. 83 Measure K2 Clutch Clearance

1 - PRESSING TOOL 8901

2 - K1 INNER DISC CARRIER

Fig. 84 Driving Clutch K2 Stack-up

1 - DISC SPRING

2 - OUTER MULTIPLE DISC - 1.8 MM (0.071 IN.)

3 - OUTER MULTIPLE DISC - 2.8 MM (0.110 IN.)

4 - OUTER MULTIPLE DISC - 4.0 MM (0.158 IN.)

5 - K2 OUTER DISC CARRIER

6 - SNAP-RING

7 - FRICTION DISCS

8 - PISTON

21 - 80 AUTOMATIC TRANSMISSION - NAG1VA

DRIVING CLUTCH K2 (Continued)

Page 957 of 1232

NOTE: Pay attention to sequence of discs. Place

new friction multiple-discs in ATF fluid for one hour

before installing.

(5) Install disk spring (3) and multiple-disc pack

(2) in outer multiple-disc carrier (8).

(6) Insert snap-ring (1).

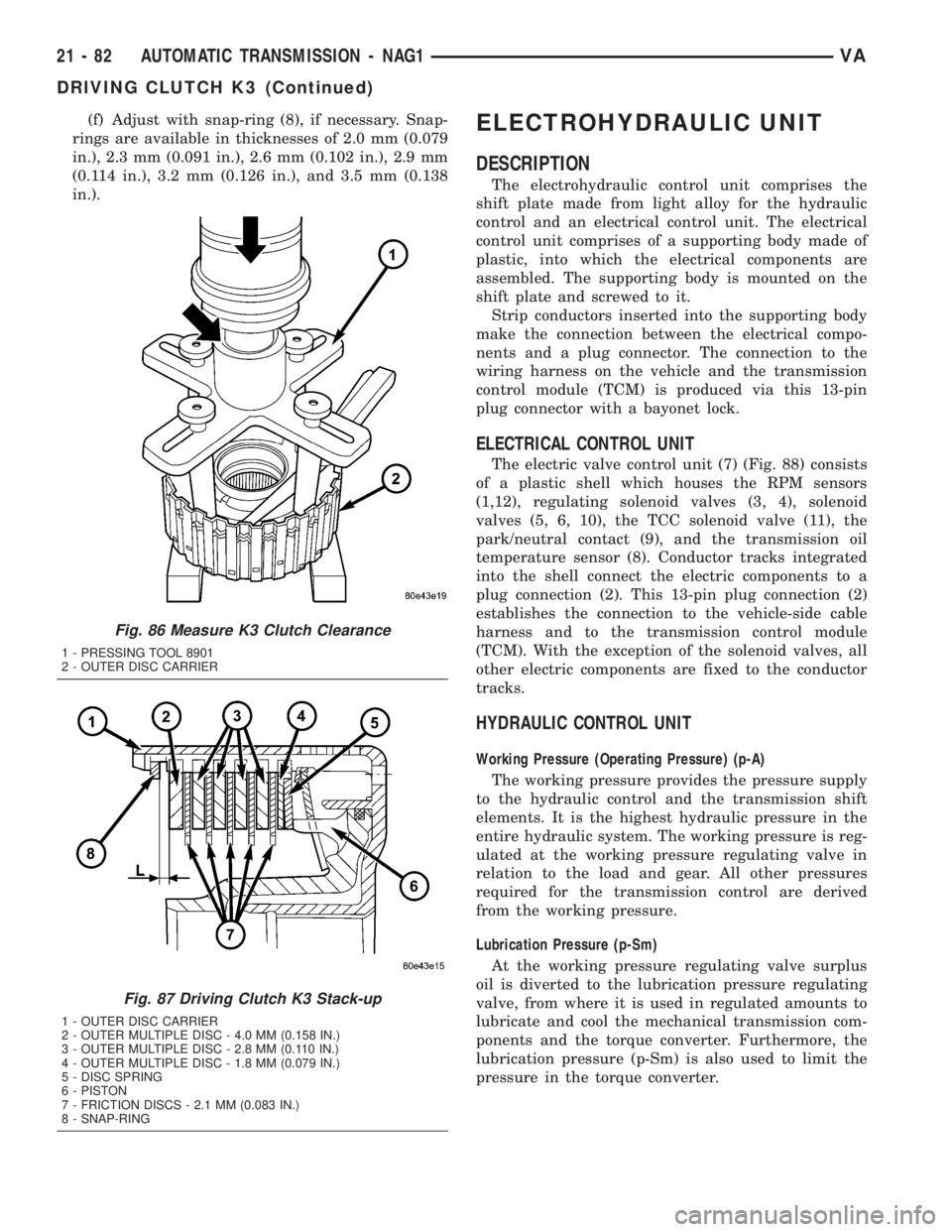

(7) Measure the K3 clutch clearance.

(a) Mount Pressing Tool 8901 (1) (Fig. 86) on

outer multiple disc.

(b) Using a lever press, compress pressing tool

as far as the stop (then the marking ring is still

visible, see small arrow).(c) Using a feeler gauge, determine the play9L9

(Fig. 87) at three points between the snap-ring (8)

and outer multiple-disc (2).

(d) During the measurement the snap-ring (8)

must contact the upper bearing surface of the

groove in the outer multiple-disc carrier.

(e) The correct clutch clearance is 2.3-2.7 mm

(0.091-0.106 in.) for three friction disc versions,

2.4-2.8 mm (0.095-0.110 in.) for four disc versions,

and 2.5-2.9 mm (0.099-0.114 in.) for five disc ver-

sions.

Fig. 85 Driving Clutch K3 Components

1 - SNAP-RING 6 - PISTON

2 - MULTIPLE DISC PACK 7 - SEALING RING

3 - DISC SPRING 8 - OUTER DISC CARRIER

4 - SNAP-RING 9 - MULTI-USE SPRING COMPRESSOR 8900

5 - SPRING PLATE

VAAUTOMATIC TRANSMISSION - NAG1 21 - 81

DRIVING CLUTCH K3 (Continued)

Page 958 of 1232

(f) Adjust with snap-ring (8), if necessary. Snap-

rings are available in thicknesses of 2.0 mm (0.079

in.), 2.3 mm (0.091 in.), 2.6 mm (0.102 in.), 2.9 mm

(0.114 in.), 3.2 mm (0.126 in.), and 3.5 mm (0.138

in.).ELECTROHYDRAULIC UNIT

DESCRIPTION

The electrohydraulic control unit comprises the

shift plate made from light alloy for the hydraulic

control and an electrical control unit. The electrical

control unit comprises of a supporting body made of

plastic, into which the electrical components are

assembled. The supporting body is mounted on the

shift plate and screwed to it.

Strip conductors inserted into the supporting body

make the connection between the electrical compo-

nents and a plug connector. The connection to the

wiring harness on the vehicle and the transmission

control module (TCM) is produced via this 13-pin

plug connector with a bayonet lock.

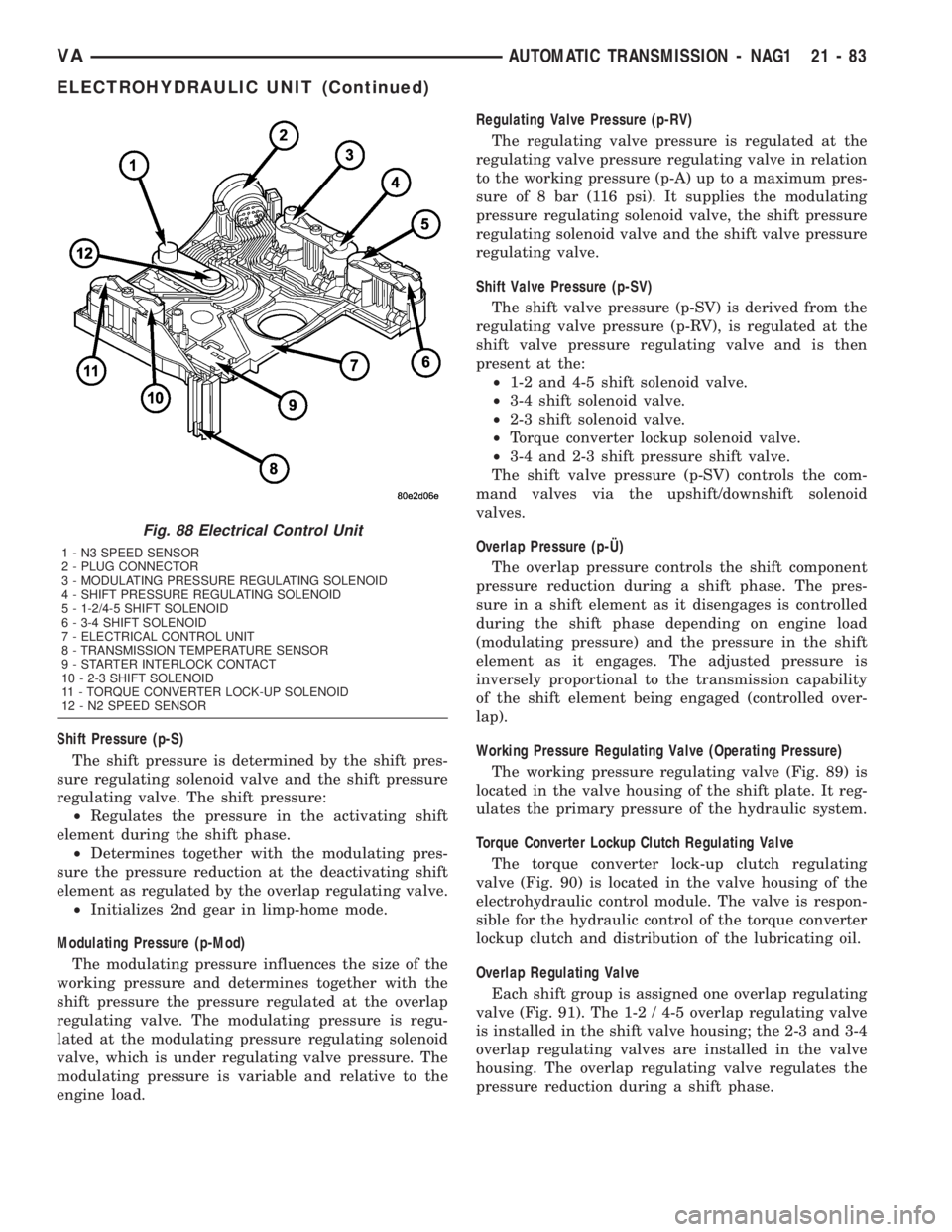

ELECTRICAL CONTROL UNIT

The electric valve control unit (7) (Fig. 88) consists

of a plastic shell which houses the RPM sensors

(1,12), regulating solenoid valves (3, 4), solenoid

valves (5, 6, 10), the TCC solenoid valve (11), the

park/neutral contact (9), and the transmission oil

temperature sensor (8). Conductor tracks integrated

into the shell connect the electric components to a

plug connection (2). This 13-pin plug connection (2)

establishes the connection to the vehicle-side cable

harness and to the transmission control module

(TCM). With the exception of the solenoid valves, all

other electric components are fixed to the conductor

tracks.

HYDRAULIC CONTROL UNIT

Working Pressure (Operating Pressure) (p-A)

The working pressure provides the pressure supply

to the hydraulic control and the transmission shift

elements. It is the highest hydraulic pressure in the

entire hydraulic system. The working pressure is reg-

ulated at the working pressure regulating valve in

relation to the load and gear. All other pressures

required for the transmission control are derived

from the working pressure.

Lubrication Pressure (p-Sm)

At the working pressure regulating valve surplus

oil is diverted to the lubrication pressure regulating

valve, from where it is used in regulated amounts to

lubricate and cool the mechanical transmission com-

ponents and the torque converter. Furthermore, the

lubrication pressure (p-Sm) is also used to limit the

pressure in the torque converter.

Fig. 86 Measure K3 Clutch Clearance

1 - PRESSING TOOL 8901

2 - OUTER DISC CARRIER

Fig. 87 Driving Clutch K3 Stack-up

1 - OUTER DISC CARRIER

2 - OUTER MULTIPLE DISC - 4.0 MM (0.158 IN.)

3 - OUTER MULTIPLE DISC - 2.8 MM (0.110 IN.)

4 - OUTER MULTIPLE DISC - 1.8 MM (0.079 IN.)

5 - DISC SPRING

6 - PISTON

7 - FRICTION DISCS - 2.1 MM (0.083 IN.)

8 - SNAP-RING

21 - 82 AUTOMATIC TRANSMISSION - NAG1VA

DRIVING CLUTCH K3 (Continued)

Page 959 of 1232

Shift Pressure (p-S)

The shift pressure is determined by the shift pres-

sure regulating solenoid valve and the shift pressure

regulating valve. The shift pressure:

²Regulates the pressure in the activating shift

element during the shift phase.

²Determines together with the modulating pres-

sure the pressure reduction at the deactivating shift

element as regulated by the overlap regulating valve.

²Initializes 2nd gear in limp-home mode.

Modulating Pressure (p-Mod)

The modulating pressure influences the size of the

working pressure and determines together with the

shift pressure the pressure regulated at the overlap

regulating valve. The modulating pressure is regu-

lated at the modulating pressure regulating solenoid

valve, which is under regulating valve pressure. The

modulating pressure is variable and relative to the

engine load.Regulating Valve Pressure (p-RV)

The regulating valve pressure is regulated at the

regulating valve pressure regulating valve in relation

to the working pressure (p-A) up to a maximum pres-

sure of 8 bar (116 psi). It supplies the modulating

pressure regulating solenoid valve, the shift pressure

regulating solenoid valve and the shift valve pressure

regulating valve.

Shift Valve Pressure (p-SV)

The shift valve pressure (p-SV) is derived from the

regulating valve pressure (p-RV), is regulated at the

shift valve pressure regulating valve and is then

present at the:

²1-2 and 4-5 shift solenoid valve.

²3-4 shift solenoid valve.

²2-3 shift solenoid valve.

²Torque converter lockup solenoid valve.

²3-4 and 2-3 shift pressure shift valve.

The shift valve pressure (p-SV) controls the com-

mand valves via the upshift/downshift solenoid

valves.

Overlap Pressure (p-š)

The overlap pressure controls the shift component

pressure reduction during a shift phase. The pres-

sure in a shift element as it disengages is controlled

during the shift phase depending on engine load

(modulating pressure) and the pressure in the shift

element as it engages. The adjusted pressure is

inversely proportional to the transmission capability

of the shift element being engaged (controlled over-

lap).

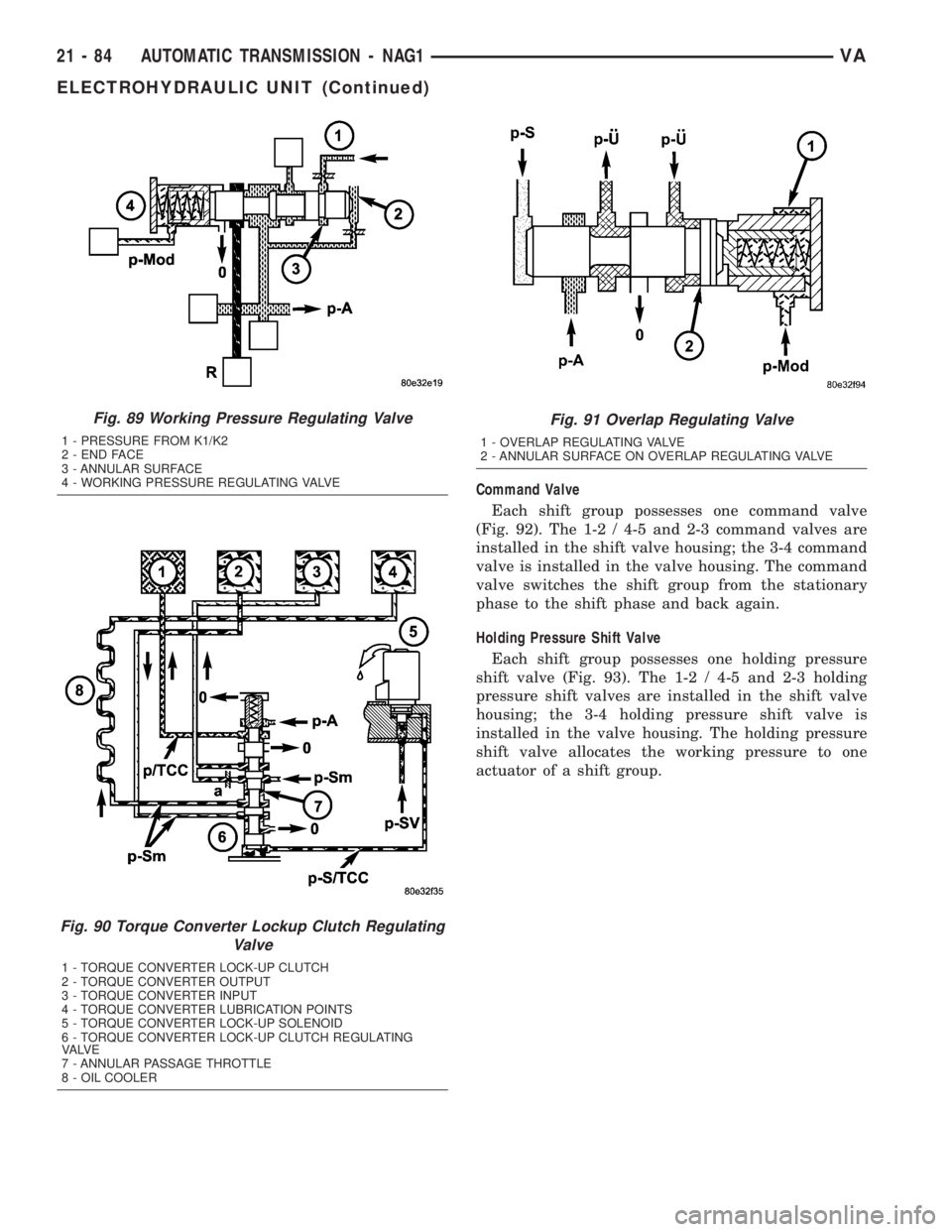

Working Pressure Regulating Valve (Operating Pressure)

The working pressure regulating valve (Fig. 89) is

located in the valve housing of the shift plate. It reg-

ulates the primary pressure of the hydraulic system.

Torque Converter Lockup Clutch Regulating Valve

The torque converter lock-up clutch regulating

valve (Fig. 90) is located in the valve housing of the

electrohydraulic control module. The valve is respon-

sible for the hydraulic control of the torque converter

lockup clutch and distribution of the lubricating oil.

Overlap Regulating Valve

Each shift group is assigned one overlap regulating

valve (Fig. 91). The 1-2 / 4-5 overlap regulating valve

is installed in the shift valve housing; the 2-3 and 3-4

overlap regulating valves are installed in the valve

housing. The overlap regulating valve regulates the

pressure reduction during a shift phase.

Fig. 88 Electrical Control Unit

1 - N3 SPEED SENSOR

2 - PLUG CONNECTOR

3 - MODULATING PRESSURE REGULATING SOLENOID

4 - SHIFT PRESSURE REGULATING SOLENOID

5 - 1-2/4-5 SHIFT SOLENOID

6 - 3-4 SHIFT SOLENOID

7 - ELECTRICAL CONTROL UNIT

8 - TRANSMISSION TEMPERATURE SENSOR

9 - STARTER INTERLOCK CONTACT

10 - 2-3 SHIFT SOLENOID

11 - TORQUE CONVERTER LOCK-UP SOLENOID

12 - N2 SPEED SENSOR

VAAUTOMATIC TRANSMISSION - NAG1 21 - 83

ELECTROHYDRAULIC UNIT (Continued)

Page 960 of 1232

Command Valve

Each shift group possesses one command valve

(Fig. 92). The 1-2 / 4-5 and 2-3 command valves are

installed in the shift valve housing; the 3-4 command

valve is installed in the valve housing. The command

valve switches the shift group from the stationary

phase to the shift phase and back again.

Holding Pressure Shift Valve

Each shift group possesses one holding pressure

shift valve (Fig. 93). The 1-2 / 4-5 and 2-3 holding

pressure shift valves are installed in the shift valve

housing; the 3-4 holding pressure shift valve is

installed in the valve housing. The holding pressure

shift valve allocates the working pressure to one

actuator of a shift group.

Fig. 89 Working Pressure Regulating Valve

1 - PRESSURE FROM K1/K2

2 - END FACE

3 - ANNULAR SURFACE

4 - WORKING PRESSURE REGULATING VALVE

Fig. 90 Torque Converter Lockup Clutch Regulating

Valve

1 - TORQUE CONVERTER LOCK-UP CLUTCH

2 - TORQUE CONVERTER OUTPUT

3 - TORQUE CONVERTER INPUT

4 - TORQUE CONVERTER LUBRICATION POINTS

5 - TORQUE CONVERTER LOCK-UP SOLENOID

6 - TORQUE CONVERTER LOCK-UP CLUTCH REGULATING

VA LV E

7 - ANNULAR PASSAGE THROTTLE

8 - OIL COOLER

Fig. 91 Overlap Regulating Valve

1 - OVERLAP REGULATING VALVE

2 - ANNULAR SURFACE ON OVERLAP REGULATING VALVE

21 - 84 AUTOMATIC TRANSMISSION - NAG1VA

ELECTROHYDRAULIC UNIT (Continued)