check engine MERCEDES-BENZ SPRINTER 2005 Service Repair Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 3 of 1232

INTRODUCTION

TABLE OF CONTENTS

page page

VEHICLE IDENTIFICATION NUMBER

DESCRIPTION..........................1

INTERNATIONAL SYMBOLS

DESCRIPTION..........................2

FASTENER IDENTIFICATION

DESCRIPTION..........................2

FASTENER USAGE

DESCRIPTION - FASTENER USAGE.........5THREADED HOLE REPAIR

DESCRIPTION - THREADED HOLE REPAIR....5

METRIC SYSTEM

DESCRIPTION..........................5

TORQUE REFERENCES

DESCRIPTION..........................7

VEHICLE IDENTIFICATION

NUMBER

DESCRIPTION

The Vehicle Identification Number (VIN) plate is

located on the lower windshield fence next to the left

a-pillar. The VIN contains 17 characters that provide

data concerning the vehicle. Refer to the VIN

DECODING INFORMATION table to determine the

identification of a vehicle.To protect the consumer from theft and possible

fraud the manufacturer is required to include a

Check Digit at the ninth position of the Vehicle Iden-

tification Number. The check digit is used by the

manufacturer and government agencies to verify the

authenticity of the vehicle and official documenta-

tion. The formula to use the check digit is not

released to the general public.

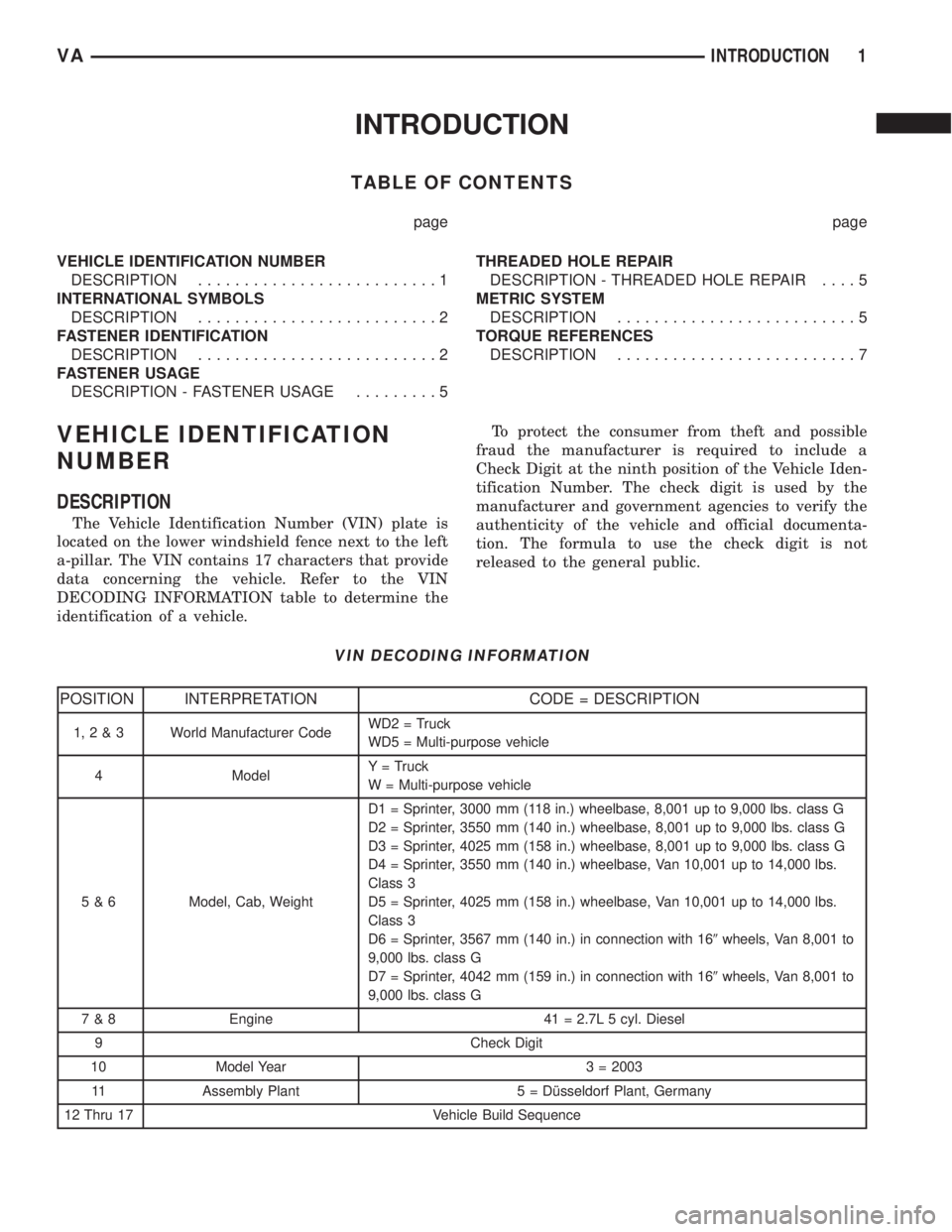

VIN DECODING INFORMATION

POSITION INTERPRETATION CODE = DESCRIPTION

1,2&3 World Manufacturer CodeWD2 = Truck

WD5 = Multi-purpose vehicle

4 ModelY = Truck

W = Multi-purpose vehicle

5 & 6 Model, Cab, WeightD1 = Sprinter, 3000 mm (118 in.) wheelbase, 8,001 up to 9,000 lbs. class G

D2 = Sprinter, 3550 mm (140 in.) wheelbase, 8,001 up to 9,000 lbs. class G

D3 = Sprinter, 4025 mm (158 in.) wheelbase, 8,001 up to 9,000 lbs. class G

D4 = Sprinter, 3550 mm (140 in.) wheelbase, Van 10,001 up to 14,000 lbs.

Class 3

D5 = Sprinter, 4025 mm (158 in.) wheelbase, Van 10,001 up to 14,000 lbs.

Class 3

D6 = Sprinter, 3567 mm (140 in.) in connection with 169wheels, Van 8,001 to

9,000 lbs. class G

D7 = Sprinter, 4042 mm (159 in.) in connection with 169wheels, Van 8,001 to

9,000 lbs. class G

7 & 8 Engine 41 = 2.7L 5 cyl. Diesel

9 Check Digit

10 Model Year 3 = 2003

11 Assembly Plant 5 = Dîsseldorf Plant, Germany

12 Thru 17 Vehicle Build Sequence

VAINTRODUCTION 1

Page 11 of 1232

LUBRICATION & MAINTENANCE

TABLE OF CONTENTS

page page

FLUID TYPES

DESCRIPTION

DESCRIPTION - FUEL REQUIREMENTS -

DIESEL ENGINE.......................1

DESCRIPTION - ENGINE COOLANT........1

DESCRIPTION - HOAT COOLANT..........2

DESCRIPTION - AXLE...................3

DESCRIPTION - BRAKE FLUID............3

DESCRIPTION - POWER STEERING FLUID . . 3

DESCRIPTION - ENGINE OIL - DIESEL

ENGINES............................3

DESCRIPTION - AUTOMATIC

TRANSMISSION FLUID - NAG1............4

OPERATION - AUTOMATIC TRANSMISSION

FLUID...............................4

FLUID CAPACITIES

SPECIFICATIONS - FLUID CAPACITIES.......4FLUID FILL/CHECK LOCATIONS

INSPECTION - FLUID FILL/CHECK

LOCATIONS..........................4

PARTS & LUBRICANT RECOMMENDATION

STANDARD PROCEDURE - PARTS &

LUBRICANT RECOMMENDATIONS.........5

HOISTING

STANDARD PROCEDURE - HOISTING........5

JUMP STARTING

STANDARD PROCEDURE - JUMP STARTING . . 6

TOWING

STANDARD PROCEDURE - TOWING.........6

MAINTENANCE SCHEDULES

DESCRIPTION..........................7

INTERNATIONAL SYMBOLS

DESCRIPTION..........................9

FLUID TYPES

DESCRIPTION

DESCRIPTION - FUEL REQUIREMENTS -

DIESEL ENGINE

DESCRIPTION

WARNING: Do not use alcohol or gasoline as a fuel

blending agent. They can be unstable under certain

conditions and hazardous or explosive when mixed

with diesel fuel.

Use good quality diesel fuel from a reputable sup-

plier in your Dodge truck. For most year-round ser-

vice, number 2 diesel fuel meeting ASTM

specification D-975 will provide good performance. If

the vehicle is exposed to extreme cold (below 0ÉF/-

18ÉC), or is required to operate at colder-than-normal

conditions for prolonged periods, use climatized No. 2

diesel fuel or dilute the No. 2 diesel fuel with 50%

No. 1 diesel fuel. This will provide better protection

from fuel gelling or wax-plugging of the fuel filters.

Diesel fuel is seldom completely free of water. To

prevent fuel system trouble, including fuel line freez-

ing in winter, drain the accumulated water from the

fuel/water separator using the fuel/water separator

drain provided. If you buy good-quality fuel and fol-low the cold-weather advice above, fuel conditioners

should not be required in your vehicle. If available in

your area, a high cetane ªpremiumº diesel fuel may

offer improved cold starting and warm-up perfor-

mance.

DESCRIPTION - ENGINE COOLANT

ETHYLENE-GLYCOL MIXTURES

CAUTION: Richer antifreeze mixtures cannot be

measured with normal field equipment and can

cause problems associated with 100 percent ethyl-

ene-glycol.

The required ethylene-glycol (antifreeze) and water

mixture depends upon the climate and vehicle oper-

ating conditions. The recommended mixture of 50/50

ethylene-glycol and water will provide protection

against freezing to -37É C (-34É F). The antifreeze

concentrationmust alwaysbe a minimum of 44 per-

cent, year-round in all climates.If percentage is

lower than 44 percent, engine parts may be

eroded by cavitation, and cooling system com-

ponents may be severely damaged by corrosion.

Maximum protection against freezing is provided

with a 68 percent antifreeze concentration, which

prevents freezing down to -67.7É C (-90É F). A higher

percentage will freeze at a warmer temperature.

Also, a higher percentage of antifreeze can cause the

VALUBRICATION & MAINTENANCE 0 - 1

Page 14 of 1232

Full synthetic oils, such as Mobilt1 0W-40, is

required if the ASSYST Oil Service Reminder is fol-

lowed. Use of a lower quality oil on this service

schedule may cause severe engine damage.

DESCRIPTION - AUTOMATIC TRANSMISSION

FLUID - NAG1

NOTE: Refer to Service Procedures in this group for

fluid level checking procedures.

Shellt3403 Automatic Transmission Fluid is the

recommended fluid for the NAG1 DaimlerChrysler

automatic transmission.

Dexron II fluid IS NOT recommended. Clutch

chatter can result from the use of improper

fluid.

MopartATF+4, Automatic Transmission Fluid, or

other fluids meeting MS-9602, may be used if Shellt

3403 Automatic Transmission Fluid is not available.

Shellt3403 Automatic Transmission Fluid when

new is red in color. The ATF is dyed red so it can be

identified from other fluids used in the vehicle such

as engine oil or antifreeze. The red color is not per-

manent and is not an indicator of fluid condition. As

the vehicle is driven, the ATF will begin to look

darker in color and may eventually become brown.

This is normal.

FLUID ADDITIVES

DaimlerChrysler strongly recommends against the

addition of any fluids to the transmission, other than

those automatic transmission fluids listed above.

Exceptions to this policy are the use of special dyes

to aid in detecting fluid leaks.

Various ªspecialº additives and supplements exist

that claim to improve shift feel and/or quality. These

additives and others also claim to improve converter

clutch operation and inhibit overheating, oxidation,

varnish, and sludge. These claims have not been sup-

ported to the satisfaction of DaimlerChrysler and

these additivesmust not be used.The use of trans-

mission ªsealersº should also be avoided, since they

may adversely affect the integrity of transmission

seals.

OPERATION - AUTOMATIC TRANSMISSION

FLUID

The automatic transmission fluid is selected based

upon several qualities. The fluid must provide a high

level of protection for the internal components by

providing a lubricating film between adjacent metal

components. The fluid must also be thermally stable

so that it can maintain a consistent viscosity through

a large temperature range. If the viscosity stays con-

stant through the temperature range of operation,transmission operation and shift feel will remain con-

sistent. Transmission fluid must also be a good con-

ductor of heat. The fluid must absorb heat from the

internal transmission components and transfer that

heat to the transmission case.

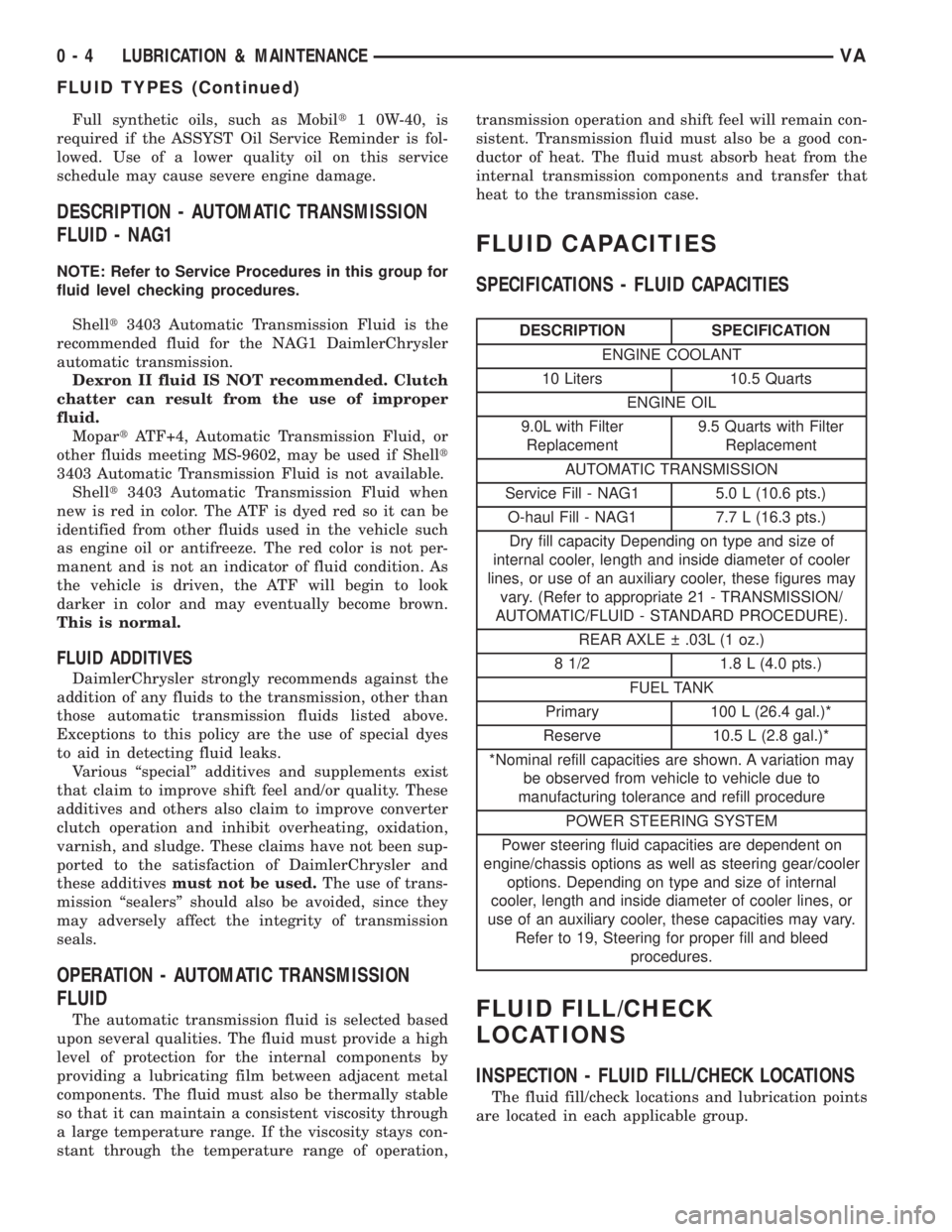

FLUID CAPACITIES

SPECIFICATIONS - FLUID CAPACITIES

DESCRIPTION SPECIFICATION

ENGINE COOLANT

10 Liters 10.5 Quarts

ENGINE OIL

9.0L with Filter

Replacement9.5 Quarts with Filter

Replacement

AUTOMATIC TRANSMISSION

Service Fill - NAG1 5.0 L (10.6 pts.)

O-haul Fill - NAG1 7.7 L (16.3 pts.)

Dry fill capacity Depending on type and size of

internal cooler, length and inside diameter of cooler

lines, or use of an auxiliary cooler, these figures may

vary. (Refer to appropriate 21 - TRANSMISSION/

AUTOMATIC/FLUID - STANDARD PROCEDURE).

REAR AXLE .03L (1 oz.)

8 1/2 1.8 L (4.0 pts.)

FUEL TANK

Primary 100 L (26.4 gal.)*

Reserve 10.5 L (2.8 gal.)*

*Nominal refill capacities are shown. A variation may

be observed from vehicle to vehicle due to

manufacturing tolerance and refill procedure

POWER STEERING SYSTEM

Power steering fluid capacities are dependent on

engine/chassis options as well as steering gear/cooler

options. Depending on type and size of internal

cooler, length and inside diameter of cooler lines, or

use of an auxiliary cooler, these capacities may vary.

Refer to 19, Steering for proper fill and bleed

procedures.

FLUID FILL/CHECK

LOCATIONS

INSPECTION - FLUID FILL/CHECK LOCATIONS

The fluid fill/check locations and lubrication points

are located in each applicable group.

0 - 4 LUBRICATION & MAINTENANCEVA

FLUID TYPES (Continued)

Page 18 of 1232

MAINTENANCE - WITH ASSYST MAINTENANCE

COMPUTER

ASSYST provides information on the best possible

timing for maintenance work.

NOTE: The engine manufacturer strongly recom-

mends the use of synthetic engine oils, such as

TMobil 1 SAE 0W-40.

When the next maintenance service is due, this

will be indicated in the multi-function display with

the wrench icon symbol displayed in km/miles or

days.

²One wrench icon showing indicates Oil Service

is necessary.

²Two wrench icons showing indicates Mainte-

nance Service is necessary ± displayed in km/miles or

days.

If the display shows the number of days, a clock

symbol will also appear in the multi-function display.

You should have the maintenance performed

within the stated period/distance.

The service indicator should be reset after an oil

service and/or maintenance service has been per-

formed.

REGULAR CHECK-UPS

To maintain the safe operation of the vehicle, it is

recommended that the following tasks be performed

on a regular basis (i.e. weekly or whenever the vehi-

cle is refueled). Check:

²Engine oil level

²Brake system, clutch mechanism ± fluid level

²Battery ± acid level

²Windshield washer system and headlamp clean-

ing system ± fluid level

²Mechanical assemblies (e. g. engine, transmis-

sion, etc.) ± check for leaks

²Condition of tires and tires pressures

²All exterior lights

SPECIAL MAINTENANCE REQUIREMENTS

If bodies built by manufacturers other than

DaimlerChrysler Corporation are fitted to the vehi-

cle, the maintenance requirements and lubrication

intervals specified by the body manufacturer must be

adhered to, in addition to all standard maintenance

requirements.

Brake Fluid

Only use brake fluids approved by the manufac-

turer (DOT 4 plus).

Coolant

Corrosion inhibitor/antifreeze concentration in the

coolant should be checked before the onset of winter

(once year in countries with high prevailing temper-

atures).Replace the coolant every five years or 100,000

miles.

Dust Filter for Heating/Ventilation Replace-

ment

The dust filter and the tailgate interior filter are to

be renewed during routine maintenance service. If

operating conditions are dusty, these filters should be

renewed more frequently.

ENGINE OIL CHANGE AND FILTER REPLACEMENT

At the minimum, change the engine oil and oil fil-

ter once a year ± even if the vehicle mileage per year

is extremely low. For standard oil service schedules

refer to the chapter oil service and maintenance ser-

vice.

Once a Year

Select the viscosity of the engine oil (SAE classes)

according to the outside air temperature.

Only use engine oil approved by DaimlerChrysler

Corporation if following the ASSYST system guide-

lines.

If the fuel used has a sulphur content exceeding

0.05% by weight, the service intervals should be split

in half.

SCOPE OF WORK FOR MAINTENANCE SERVICE

Oil Service

²Engine:

Oil change and filter replacement

Check fluid levels of the following system,

refill as necessary.

²If fluid is lost, trace and eliminate cause ± as a

separate order.

²Power-assisted steering

Lubrication work:

²Trailer tow hitch (original equipment)

Maintenance

²ASSYST maintenance computer reset

Function check

²Signalling system, warning and indicator lamps

²Headlamps, exterior lighting

²Windshield wipers, windshield washer system

Check for leaks and damage.

²Check for abrasion points and ensure that lines

are correctly routed!

²All lines and hoses, sensor cables

²Rubber boots on front axle drive shafts, rubber

boots on front axle suspension ball joints, shock

absorbers

Check fluid levels for the following systems,

correct as necessary.

NOTE: Should there be a loss of fluid which cannot

be explained by regular use, trace and eliminate the

cause.

0 - 8 LUBRICATION & MAINTENANCEVA

MAINTENANCE SCHEDULES (Continued)

Page 19 of 1232

²Engine cooling system. Check corrosion inhibi-

tor/antifreeze, refill as necessary.

²Hydraulic brake system

²Battery

²Windshield washer system

Engine

²Fuel filter renewal

²Air cleaner with maintenance indicator:

²Check degree of contamination.

²Air cleaner filter element renewed as necessary.

Chassis and body

²Trailer coupling:

Check operation, play and retaining fixtures

²Secondary rubber springs:

Visual check

²Tire pressures:

Correct as necessary, including spare tire

²Check thickness of brake pads

²Brake test

²Check condition of steering mechanism

²Heating/ventilation dust filter renewal

ADDITIONAL MAINTENANCE WORK

Automatic transmission once only at 80,000

miles/128000 km

Oil and filter change

During every second maintenance service

Air cleaner without maintenance indicator:

Air cleaner filter element renewal

Check poly-V-belt for wear and signs of damage

During every 6th maintenance service

Rear axle

ADDITIONAL MAINTENANCE WORK AFTER YEARS

Every 3 years

Air cleaner filter element renewal (note installa-

tion date)

Every 5 years or 100,000 miles

Coolant renewal

Note coolant composition

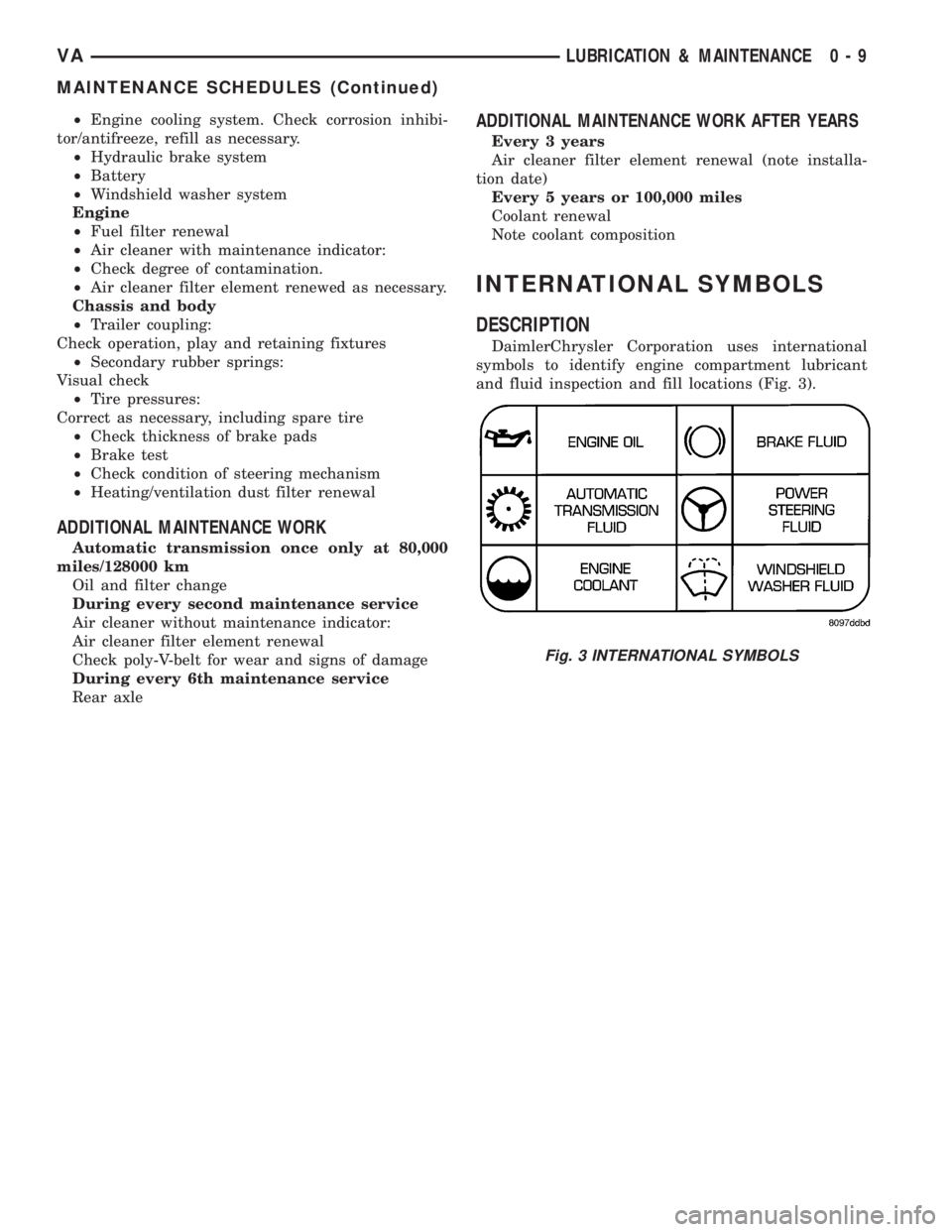

INTERNATIONAL SYMBOLS

DESCRIPTION

DaimlerChrysler Corporation uses international

symbols to identify engine compartment lubricant

and fluid inspection and fill locations (Fig. 3).

Fig. 3 INTERNATIONAL SYMBOLS

VALUBRICATION & MAINTENANCE 0 - 9

MAINTENANCE SCHEDULES (Continued)

Page 42 of 1232

DRIVELINE VIBRATION

Drive Condition Possible Cause Correction

Propeller Shaft Noise 1) Undercoating or other foreign

material on shaft.1) Clean exterior of shaft and wash

with solvent.

2) Loose U-joint clamp screws. 2) Install new clamps and screws

and tighten to proper torque.

3) Loose or bent U-joint yoke or

excessive runout.3) Install new yoke.

4) Incorrect driveline angularity. 4) Measure and correct driveline

angles.

5) Rear spring center bolt not in

seat.5) Loosen spring u-bolts and seat

center bolt.

6) Worn U-joint bearings. 6) Install new U-joint.

7) Propeller shaft damaged or out

of balance.7) Installl new propeller shaft.

8) Broken rear spring. 8) Install new rear spring.

9) Excessive runout or unbalanced

condition.9) Re-index propeller shaft, test,

and evaluate.

10) Excessive drive pinion gear

shaft runout.10) Re-index propeller shaft and

evaluate.

11) Excessive axle yoke deflection. 11) Inspect and replace yoke if

necessary.

12) Excessive transfer case runout. 12) Inspect and repair as necessary.

Universal Joint Noise 1) Loose U-joint clamp screws. 1) Install new clamps and screws

and tighten to proper torque.

2) Lack of lubrication. 2) Replace as U-joints as

necessary.

PROPELLER SHAFT BALANCE

NOTE: Removing and indexing the propeller shaft

180É relative to the yoke may eliminate some vibra-

tions.

If propeller shaft is suspected of being out of bal-

ance, verify with the following procedure:

(1) Place vehicle in netrual.

(2) Raise and support the vehicle by the axles as

level as possible.

(3) Clean all foreign material from propeller shaft

and universal joints.

(4) Inspect propeller shaft for missing balance

weights, broken welds, and bent areas.

NOTE: If propeller shaft is bent, it must be replaced.

(5) Inspect universal joints for wear, properly

installed and correct alignment with the shaft.

(6) Check universal joint clamp screws torque.

(7) Remove wheels and tires. Install wheel lug

nuts to retain the brake drums/rotors.(8) Mark and number propeller shaft six inches

from the pinion yoke end at four positions 90É apart.

(9) Run and accelerate the vehicle until vibration

occurs. Note intensity and speed the vibration

occurred. Stop the engine.

(10) Install a screw clamp at position 1 (Fig. 1).

(11) Start engine and re-check for vibration. If lit-

tle or no change in vibration is evident, move clamp

to the next positions and repeat vibration test.

NOTE: If there is no difference in vibration at the

other positions, the vibration may not be propeller

shaft.

(12) If vibration decreased, install a second clamp

(Fig. 2) and repeat vibration test.

(13) If additional clamp causes additional vibra-

tion, separate clamps 1/2 inch above and below the

mark. Repeat the vibration test (Fig. 3).

(14) Increase distance between clamps and repeat

test until vibration is at the lowest level. Bend the

slack end of the clamps so the screws will not loosen.

3 - 2 PROPELLER SHAFTVA

PROPELLER SHAFT (Continued)

Page 50 of 1232

REAR AXLE

TABLE OF CONTENTS

page page

REAR AXLE

DESCRIPTION.........................10

OPERATION...........................10

DIAGNOSIS AND TESTING................10

STANDARD PROCEDURE - DRAIN AND FILL . . 11

REMOVAL.............................11

INSTALLATION.........................12

SPECIFICATIONS.......................13

SPECIAL TOOLS.......................14

AXLE SHAFTS

REMOVAL.............................15

INSTALLATION.........................15AXLE BEARINGS/SEALS

REMOVAL.............................17

INSTALLATION.........................17

AXLE SHAFTS - DUAL REAR WHEELS

REMOVAL.............................19

INSTALLATION.........................19

AXLE HUB BEARINGS/SEALS

REMOVAL.............................20

INSTALLATION.........................20

PINION SEAL

REMOVAL.............................22

INSTALLATION.........................22

REAR AXLE

DESCRIPTION

The axle housings consist of a cast iron center sec-

tion with axle tubes extending from either side. The

tubes are pressed into and welded to the differential

housing to form a one-piece axle housing. The SRW

axle has semi-floating axle shafts, DRW has full-

floating axle shafts.

NOTE: Axle seals, axle bearings, pinion seal and

differential cover are the only serviceble compo-

nents. If differential is damaged/noisy the axle must

be replaced.

OPERATION

The axle receives power from the transmission

through the rear propeller shaft. The rear propeller

shaft is connected to the pinion gear which rotates

the differential through the gear mesh with the ring

gear bolted to the differential case. The engine power

is transmitted to the axle shafts through the pinion

mate and side gears. The side gears are splined to

the axle shafts.

DIAGNOSIS AND TESTING

NOTE: Axle seals, axle bearings, pinion seals and

differential cover are the only serviceble compo-

nents. If differential is damaged/noisy the axle must

be replaced.

GEAR NOISE

Axle gear noise can be caused by insufficient lubri-

cant, incorrect backlash, incorrect pinion depth, tooth

contact, worn/damaged gears, or the carrier housing

not having the proper offset and squareness.

Gear noise usually happens at a specific speed

range. The noise can also occur during a specific type

of driving condition. These conditions are accelera-

tion, deceleration, coast, or constant load.

When road testing, first warm-up the axle fluid by

driving the vehicle at least 5 miles and then acceler-

ate the vehicle to the speed range where the noise is

the greatest. Shift out-of-gear and coast through the

peak-noise range. If the noise stops or changes

greatly:

²Check for insufficient lubricant.

²Incorrect ring gear backlash.

²Gear damage.

Differential side gears and pinions can be checked

by turning the vehicle. They usually do not cause

noise during straight-ahead driving when the gears

are unloaded. The side gears are loaded during vehi-

cle turns. A worn pinion shaft can also cause a snap-

ping or a knocking noise.

BEARING NOISE

The axle shaft, differential and pinion bearings can

all produce noise when worn or damaged. Bearing

noise can be either a whining, or a growling sound.

Pinion bearingshave a constant-pitch noise. This

noise changes only with vehicle speed. Pinion bearing

noise will be higher pitched because it rotates at a

faster rate. Drive the vehicle and load the differen-

tial. If bearing noise occurs, the rear pinion bearing

is the source of the noise. If the bearing noise is

3 - 10 REAR AXLEVA

Page 51 of 1232

heard during a coast, the front pinion bearing is the

source.

Differential bearings usually produce a low pitch

noise. Differential bearing noise is similar to pinion

bearing noise. The pitch of differential bearing noise

is also constant and varies only with vehicle speed.

Axle shaft bearingsproduce noise and vibration

when worn or damaged. The noise generally changes

when the bearings are loaded. Road test the vehicle.

Turn the vehicle sharply to the left and to the right.

This will load the bearings and change the noise

level. Where axle bearing damage is slight, the noise

is usually not noticeable at speeds above 30 mph.

LOW SPEED KNOCK

Low speed knock is generally caused by a worn

U-joint or by worn side-gear thrust washers. A worn

pinion shaft bore will also cause low speed knock.

VIBRATION

Vibration at the rear of the vehicle is usually

caused by a:

²Damaged drive shaft.

²Missing drive shaft balance weight(s).

²Worn or out-of-balance wheels.

²Loose wheel lug nuts.

²Worn U-joint(s).

²Loose/broken springs.

²Damaged axle shaft bearing(s).

²Loose pinion gear nut.

²Excessive pinion yoke run out.

²Bent axle shaft(s).

Check for loose or damaged front-end components

or engine/transmission mounts. These components

can contribute to what appears to be a rearend vibra-

tion. Do not overlook engine accessories, brackets

and drive belts.

NOTE: All driveline components should be exam-

ined before starting any repair.

DRIVELINE SNAP

A snap or clunk noise when the vehicle is shifted

into gear (or the clutch engaged), can be caused by:

²High engine idle speed.

²Transmission shift operation.

²Loose engine/transmission/transfer case mounts.

²Worn U-joints.

²Loose spring mounts.

²Loose pinion gear nut and yoke.

²Excessive ring gear backlash.

²Excessive side gear to case clearance.

The source of a snap or a clunk noise can be deter-

mined with the assistance of a helper. Raise the vehi-

cle on a hoist with the wheels free to rotate. Instruct

the helper to shift the transmission into gear. Listenfor the noise, a mechanics stethoscope is helpful in

isolating the source of a noise.

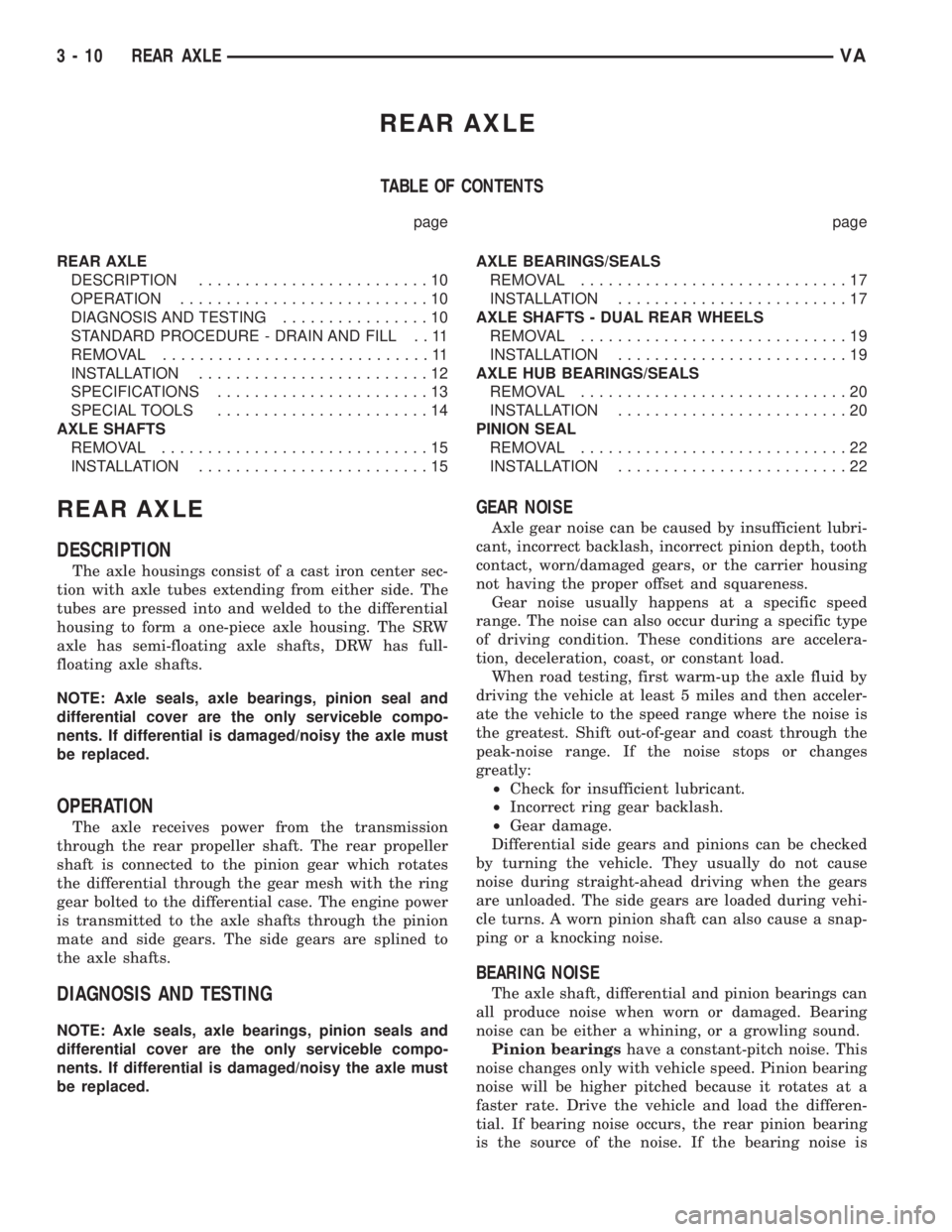

STANDARD PROCEDURE - DRAIN AND FILL

NOTE: Drain oil when warm.

(1) Clean area around oil fill plug and drain plug.

(2) Remove oil drain plug and drain oil (Fig. 1).

(3) Install oil drain plug and tighten to N´m 100

(74 ft. lbs.).

(4) Remove oil fill plug and fill housing up to bot-

tom edge of oil fill hole (Fig. 1).

(5) Install oil fill plug and tighten to N´m 100 (74

ft. lbs.).

REMOVAL

(1) Raise and support the vehicle.

(2) Position a suitable lifting device under the axle

and secure axle to device.

(3) Remove wheels and tires.

(4) Unplug wear indicator cable (Fig. 2) and (Fig.

3).

(5) Detach cable connector for brake pad wear

indicator.

(6) Remove ABS sensor and clamp bushing from

mounting bore.

NOTE: The right-hand ABS sensor cable is labeled

at the factory with a white tag.

(7) Remove cable ties from the park brake cables.

Release connection cable of brake pad wear indicator

and ABS sensor cable up to the relay unit of the

parking brake.

(8) Remove brake cables from adjuster.

(9) Remove brake calipers with adapters and lines.

Fig. 1 FILL PLUG

1 - FILL PLUG

2 - DRAIN PLUG

VAREAR AXLE 3 - 11

REAR AXLE (Continued)

Page 67 of 1232

ROAD TESTING

(1) If complaint involved low brake pedal, pump

pedal and note if it comes back up to normal height.

(2) Check brake pedal response with transmission

in Neutral and engine running. Pedal should remain

firm under constant foot pressure.

(3) During road test, make normal and firm brake

stops in 25-40 mph range. Note faulty brake opera-

tion such as low pedal, hard pedal, fade, pedal pulsa-

tion, pull, grab, drag, noise, etc.

(4) Attempt to stop the vehicle with the parking

brake only and note grab, drag, noise, etc.

PEDAL FALLS AWAY

A brake pedal that falls away under steady foot

pressure is generally the result of a system leak. The

leak point could be at a brake line, fitting, hose, or

caliper/wheel cylinder. If leakage is severe, fluid will

be evident at or around the leaking component.

Internal leakage (seal by-pass) in the master cylin-

der caused by worn or damaged piston cups, may

also be the problem cause.

An internal leak in the ABS or RWAL system may

also be the problem with no physical evidence.

LOW PEDAL

If a low pedal is experienced, pump the pedal sev-

eral times. If the pedal comes back up worn linings,

rotors, drums, or rear brakes out of adjustment are

the most likely causes. The proper course of action is

to inspect and replace all worn component and make

the proper adjustments.

SPONGY PEDAL

A spongy pedal is most often caused by air in the

system. However, thin brake drums or substandard

brake lines and hoses can also cause a spongy pedal.

The proper course of action is to bleed the system,

and replace thin drums and substandard quality

brake hoses if suspected.

HARD PEDAL OR HIGH PEDAL EFFORT

A hard pedal or high pedal effort may be due to

lining that is water soaked, contaminated, glazed, or

badly worn. The power booster or check valve could

also be faulty.

PEDAL PULSATION

Pedal pulsation is caused by components that are

loose, or beyond tolerance limits.

The primary cause of pulsation are disc brake

rotors with excessive lateral runout or thickness vari-

ation, or out of round brake drums. Other causes are

loose wheel bearings or calipers and worn, damaged

tires.NOTE: Some pedal pulsation may be felt during

ABS activation.

BRAKE DRAG

Brake drag occurs when the lining is in constant

contact with the rotor or drum. Drag can occur at one

wheel, all wheels, fronts only, or rears only.

Drag is a product of incomplete brake shoe release.

Drag can be minor or severe enough to overheat the

linings, rotors and drums.

Minor drag will usually cause slight surface char-

ring of the lining. It can also generate hard spots in

rotors and drums from the overheat-cool down pro-

cess. In most cases, the rotors, drums, wheels and

tires are quite warm to the touch after the vehicle is

stopped.

Severe drag can char the brake lining all the way

through. It can also distort and score rotors and

drums to the point of replacement. The wheels, tires

and brake components will be extremely hot. In

severe cases, the lining may generate smoke as it

chars from overheating.

Common causes of brake drag are:

²Seized or improperly adjusted parking brake

cables.

²Loose/worn wheel bearing.

²Seized caliper or wheel cylinder piston.

²Caliper binding on corroded bushings or rusted

slide surfaces.

²Loose caliper mounting.

²Drum brake shoes binding on worn/damaged

support plates.

²Mis-assembled components.

²Long booster output rod.

If brake drag occurs at all wheels, the problem

may be related to a blocked master cylinder return

port, or faulty power booster (binds-does not release).

BRAKE FADE

Brake fade is usually a product of overheating

caused by brake drag. However, brake overheating

and resulting fade can also be caused by riding the

brake pedal, making repeated high deceleration stops

in a short time span, or constant braking on steep

mountain roads. Refer to the Brake Drag information

in this section for causes.

BRAKE PULL

Front brake pull condition could result from:

²Contaminated lining in one caliper

²Seized caliper piston

²Binding caliper

²Loose caliper

²Rusty caliper slide surfaces

²Improper brake pads

²Damaged rotor

VABRAKES - BASE 5 - 3

BRAKES - BASE (Continued)

Page 78 of 1232

INSTALLATION

INSTALLATION - FRONT

(1) Install the brake caliper adapter to the steering

knuckle. Tighten to 170 N´m (125 ft. lbs.).

(2) Install the disc brake shoes (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/BRAKE

PADS/SHOES - INSTALLATION).

NOTE: Do not install the brake hose twisted and

ensure freedom of movement.

(3) Install the disc brake caliper. Tighten the bolt

to 14 N´m (124 in. lbs.) (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/DISC BRAKE CALIPERS

- INSTALLATION).

(4) Install the front wheels (Refer to 22 - TIRES/

WHEELS/WHEELS - INSTALLATION).

(5) Lower the vehicle.

INSTALLATION - REAR

(1) Install the brake caliper adapter to the axle

mount. Tighten to 90 N´m (66 ft. lbs.) for M12X1.5

bolt or 170 N´m (125 ft. lbs.) for M14X1.5 bolt.

(2) Install the disc brake pads (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/BRAKE

PADS/SHOES - INSTALLATION).

NOTE: Do not install the brake hose twisted and

ensure freedom of movement.

(3) Install the disc brake caliper (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - INSTALLATION).

(4) Install the rear wheels (Refer to 22 - TIRES/

WHEELS/WHEELS - INSTALLATION).

(5) Lower the vehicle.

FLUID

DIAGNOSIS AND TESTING - BRAKE FLUID

CONTAMINATION

Indications of fluid contamination are swollen or

deteriorated rubber parts.

Swollen rubber parts indicate the presence of

petroleum in the brake fluid.

To test for contamination, put a small amount of

drained brake fluid in clear glass jar. If fluid sepa-

rates into layers, there is mineral oil or other fluid

contamination of the brake fluid.

If brake fluid is contaminated, drain and thor-

oughly flush system. Replace master cylinder, ALB

Controller, caliper seals, Antilock Brakes hydraulic

unit and all hydraulic fluid hoses.

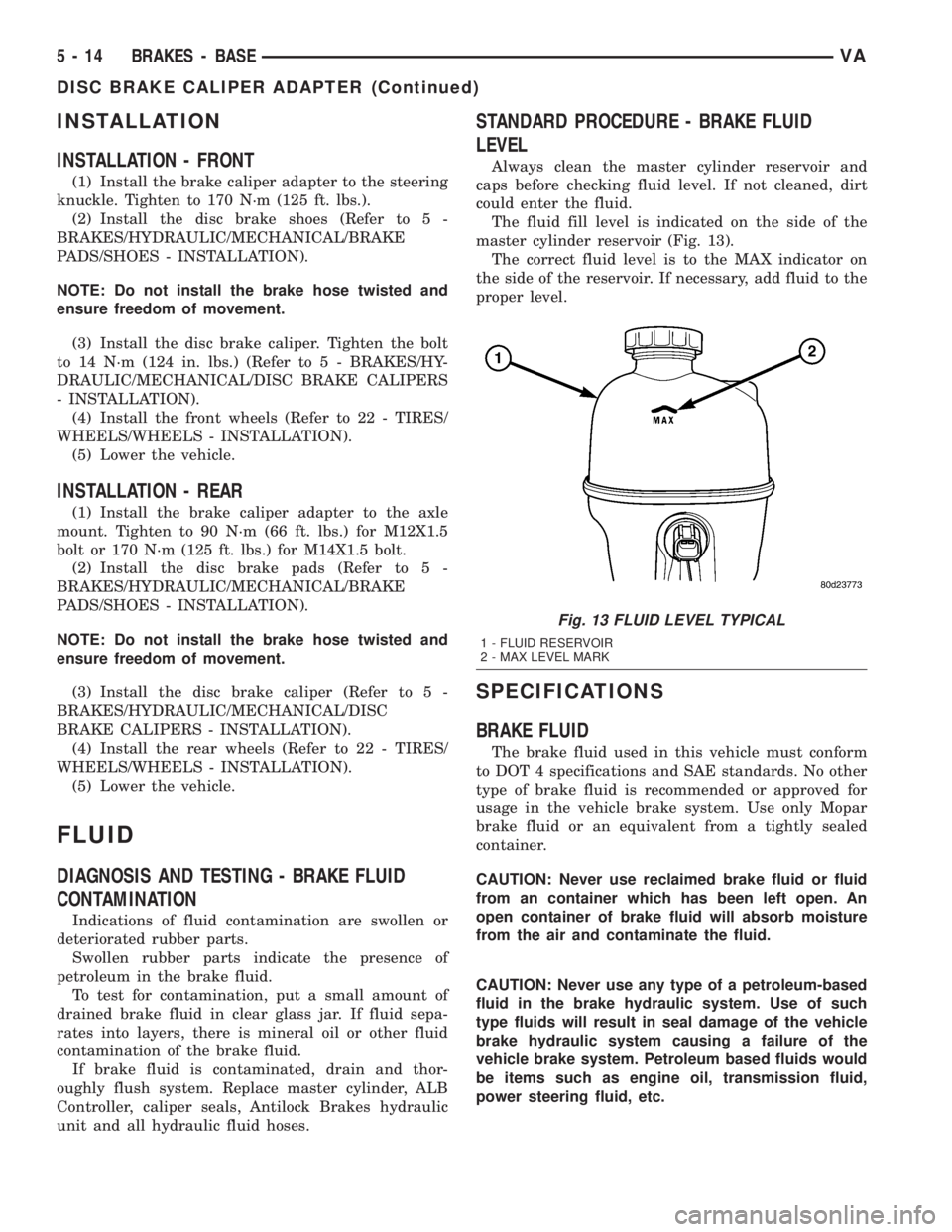

STANDARD PROCEDURE - BRAKE FLUID

LEVEL

Always clean the master cylinder reservoir and

caps before checking fluid level. If not cleaned, dirt

could enter the fluid.

The fluid fill level is indicated on the side of the

master cylinder reservoir (Fig. 13).

The correct fluid level is to the MAX indicator on

the side of the reservoir. If necessary, add fluid to the

proper level.

SPECIFICATIONS

BRAKE FLUID

The brake fluid used in this vehicle must conform

to DOT 4 specifications and SAE standards. No other

type of brake fluid is recommended or approved for

usage in the vehicle brake system. Use only Mopar

brake fluid or an equivalent from a tightly sealed

container.

CAUTION: Never use reclaimed brake fluid or fluid

from an container which has been left open. An

open container of brake fluid will absorb moisture

from the air and contaminate the fluid.

CAUTION: Never use any type of a petroleum-based

fluid in the brake hydraulic system. Use of such

type fluids will result in seal damage of the vehicle

brake hydraulic system causing a failure of the

vehicle brake system. Petroleum based fluids would

be items such as engine oil, transmission fluid,

power steering fluid, etc.

Fig. 13 FLUID LEVEL TYPICAL

1 - FLUID RESERVOIR

2 - MAX LEVEL MARK

5 - 14 BRAKES - BASEVA

DISC BRAKE CALIPER ADAPTER (Continued)