clock MERCEDES-BENZ SPRINTER 2006 User Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 52 of 2305

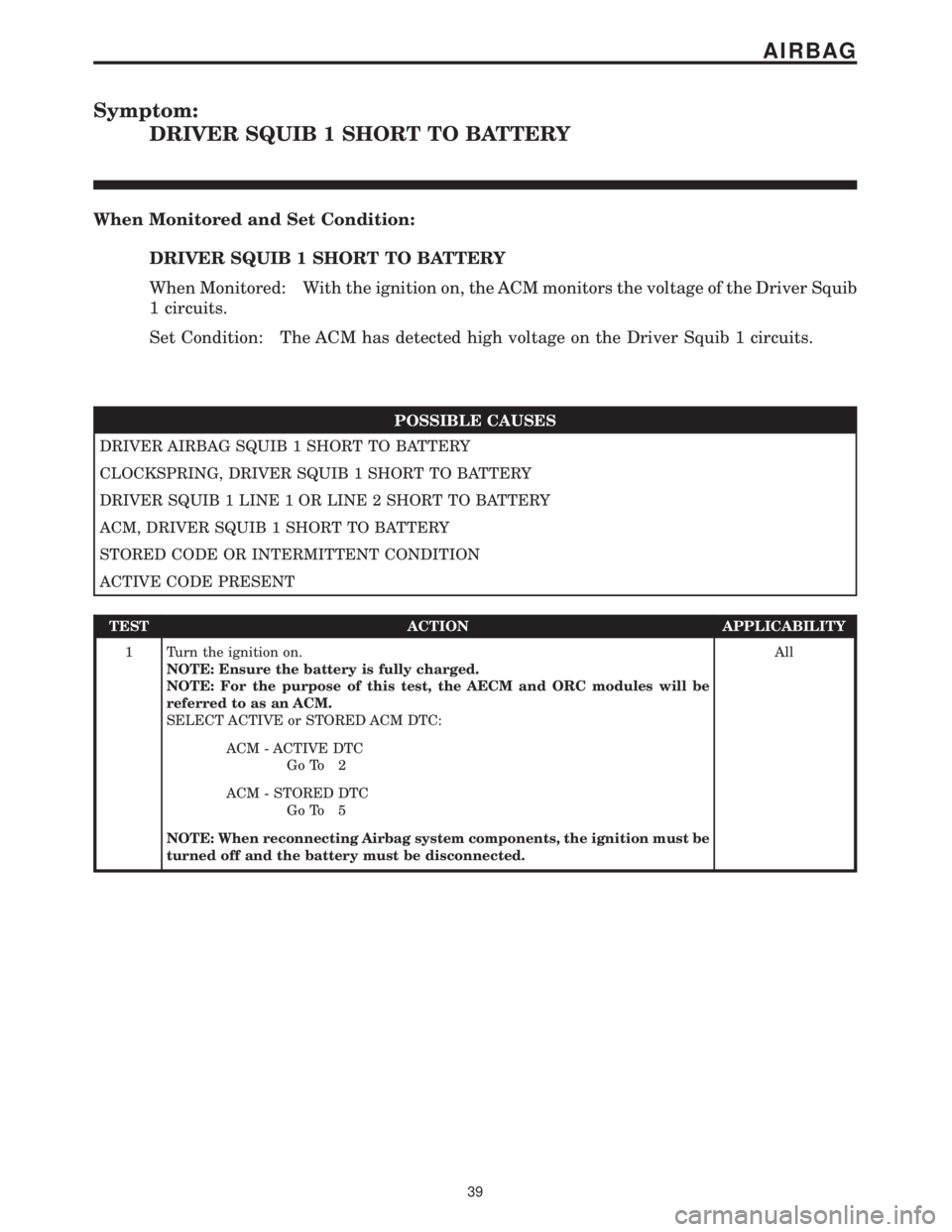

Symptom:

DRIVER SQUIB 1 SHORT TO BATTERY

When Monitored and Set Condition:

DRIVER SQUIB 1 SHORT TO BATTERY

When Monitored: With the ignition on, the ACM monitors the voltage of the Driver Squib

1 circuits.

Set Condition: The ACM has detected high voltage on the Driver Squib 1 circuits.

POSSIBLE CAUSES

DRIVER AIRBAG SQUIB 1 SHORT TO BATTERY

CLOCKSPRING, DRIVER SQUIB 1 SHORT TO BATTERY

DRIVER SQUIB 1 LINE 1 OR LINE 2 SHORT TO BATTERY

ACM, DRIVER SQUIB 1 SHORT TO BATTERY

STORED CODE OR INTERMITTENT CONDITION

ACTIVE CODE PRESENT

TEST ACTION APPLICABILITY

1 Turn the ignition on.

NOTE: Ensure the battery is fully charged.

NOTE: For the purpose of this test, the AECM and ORC modules will be

referred to as an ACM.

SELECT ACTIVE or STORED ACM DTC:All

ACM - ACTIVE DTC

Go To 2

ACM - STORED DTC

Go To 5

NOTE: When reconnecting Airbag system components, the ignition must be

turned off and the battery must be disconnected.

39

AIRBAG

Page 53 of 2305

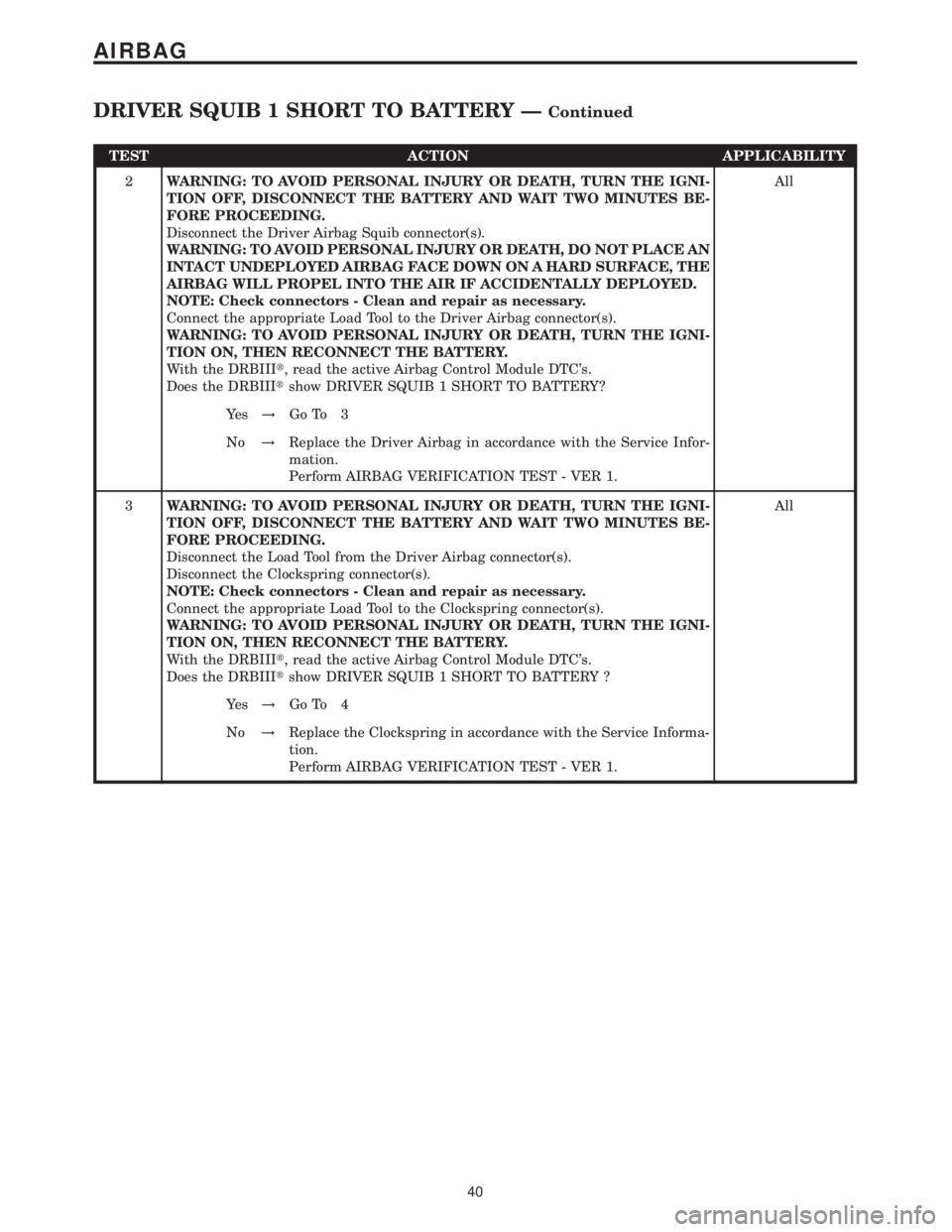

TEST ACTION APPLICABILITY

2WARNING: TO AVOID PERSONAL INJURY OR DEATH, TURN THE IGNI-

TION OFF, DISCONNECT THE BATTERY AND WAIT TWO MINUTES BE-

FORE PROCEEDING.

Disconnect the Driver Airbag Squib connector(s).

WARNING: TO AVOID PERSONAL INJURY OR DEATH, DO NOT PLACE AN

INTACT UNDEPLOYED AIRBAG FACE DOWN ON A HARD SURFACE, THE

AIRBAG WILL PROPEL INTO THE AIR IF ACCIDENTALLY DEPLOYED.

NOTE: Check connectors - Clean and repair as necessary.

Connect the appropriate Load Tool to the Driver Airbag connector(s).

WARNING: TO AVOID PERSONAL INJURY OR DEATH, TURN THE IGNI-

TION ON, THEN RECONNECT THE BATTERY.

With the DRBIIIt, read the active Airbag Control Module DTC's.

Does the DRBIIItshow DRIVER SQUIB 1 SHORT TO BATTERY?All

Ye s!Go To 3

No!Replace the Driver Airbag in accordance with the Service Infor-

mation.

Perform AIRBAG VERIFICATION TEST - VER 1.

3WARNING: TO AVOID PERSONAL INJURY OR DEATH, TURN THE IGNI-

TION OFF, DISCONNECT THE BATTERY AND WAIT TWO MINUTES BE-

FORE PROCEEDING.

Disconnect the Load Tool from the Driver Airbag connector(s).

Disconnect the Clockspring connector(s).

NOTE: Check connectors - Clean and repair as necessary.

Connect the appropriate Load Tool to the Clockspring connector(s).

WARNING: TO AVOID PERSONAL INJURY OR DEATH, TURN THE IGNI-

TION ON, THEN RECONNECT THE BATTERY.

With the DRBIIIt, read the active Airbag Control Module DTC's.

Does the DRBIIItshow DRIVER SQUIB 1 SHORT TO BATTERY ?All

Ye s!Go To 4

No!Replace the Clockspring in accordance with the Service Informa-

tion.

Perform AIRBAG VERIFICATION TEST - VER 1.

40

AIRBAG

DRIVER SQUIB 1 SHORT TO BATTERY ÐContinued

Page 54 of 2305

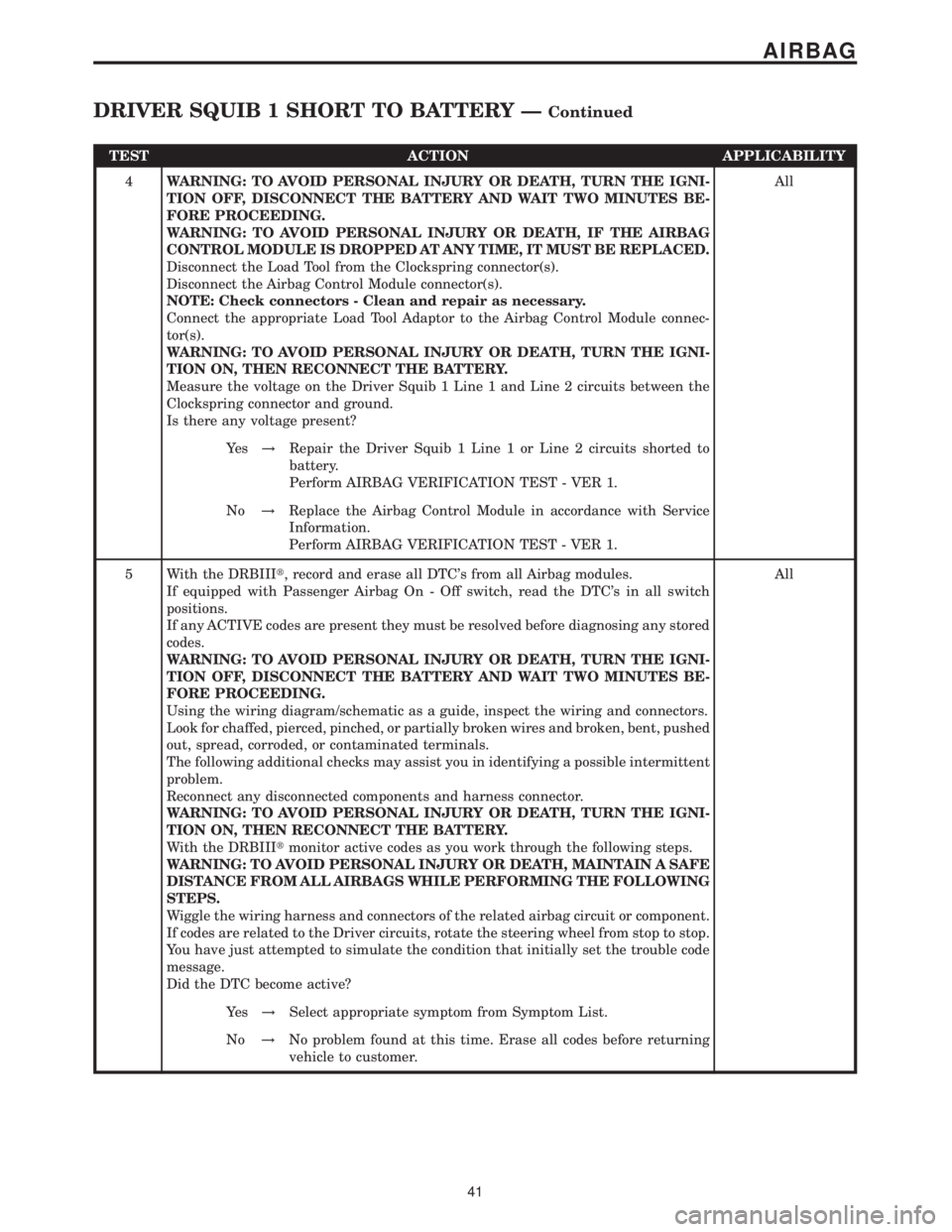

TEST ACTION APPLICABILITY

4WARNING: TO AVOID PERSONAL INJURY OR DEATH, TURN THE IGNI-

TION OFF, DISCONNECT THE BATTERY AND WAIT TWO MINUTES BE-

FORE PROCEEDING.

WARNING: TO AVOID PERSONAL INJURY OR DEATH, IF THE AIRBAG

CONTROL MODULE IS DROPPED AT ANY TIME, IT MUST BE REPLACED.

Disconnect the Load Tool from the Clockspring connector(s).

Disconnect the Airbag Control Module connector(s).

NOTE: Check connectors - Clean and repair as necessary.

Connect the appropriate Load Tool Adaptor to the Airbag Control Module connec-

tor(s).

WARNING: TO AVOID PERSONAL INJURY OR DEATH, TURN THE IGNI-

TION ON, THEN RECONNECT THE BATTERY.

Measure the voltage on the Driver Squib 1 Line 1 and Line 2 circuits between the

Clockspring connector and ground.

Is there any voltage present?All

Ye s!Repair the Driver Squib 1 Line 1 or Line 2 circuits shorted to

battery.

Perform AIRBAG VERIFICATION TEST - VER 1.

No!Replace the Airbag Control Module in accordance with Service

Information.

Perform AIRBAG VERIFICATION TEST - VER 1.

5 With the DRBIIIt, record and erase all DTC's from all Airbag modules.

If equipped with Passenger Airbag On - Off switch, read the DTC's in all switch

positions.

If any ACTIVE codes are present they must be resolved before diagnosing any stored

codes.

WARNING: TO AVOID PERSONAL INJURY OR DEATH, TURN THE IGNI-

TION OFF, DISCONNECT THE BATTERY AND WAIT TWO MINUTES BE-

FORE PROCEEDING.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

Look for chaffed, pierced, pinched, or partially broken wires and broken, bent, pushed

out, spread, corroded, or contaminated terminals.

The following additional checks may assist you in identifying a possible intermittent

problem.

Reconnect any disconnected components and harness connector.

WARNING: TO AVOID PERSONAL INJURY OR DEATH, TURN THE IGNI-

TION ON, THEN RECONNECT THE BATTERY.

With the DRBIIItmonitor active codes as you work through the following steps.

WARNING: TO AVOID PERSONAL INJURY OR DEATH, MAINTAIN A SAFE

DISTANCE FROM ALL AIRBAGS WHILE PERFORMING THE FOLLOWING

STEPS.

Wiggle the wiring harness and connectors of the related airbag circuit or component.

If codes are related to the Driver circuits, rotate the steering wheel from stop to stop.

You have just attempted to simulate the condition that initially set the trouble code

message.

Did the DTC become active?All

Ye s!Select appropriate symptom from Symptom List.

No!No problem found at this time. Erase all codes before returning

vehicle to customer.

41

AIRBAG

DRIVER SQUIB 1 SHORT TO BATTERY ÐContinued

Page 55 of 2305

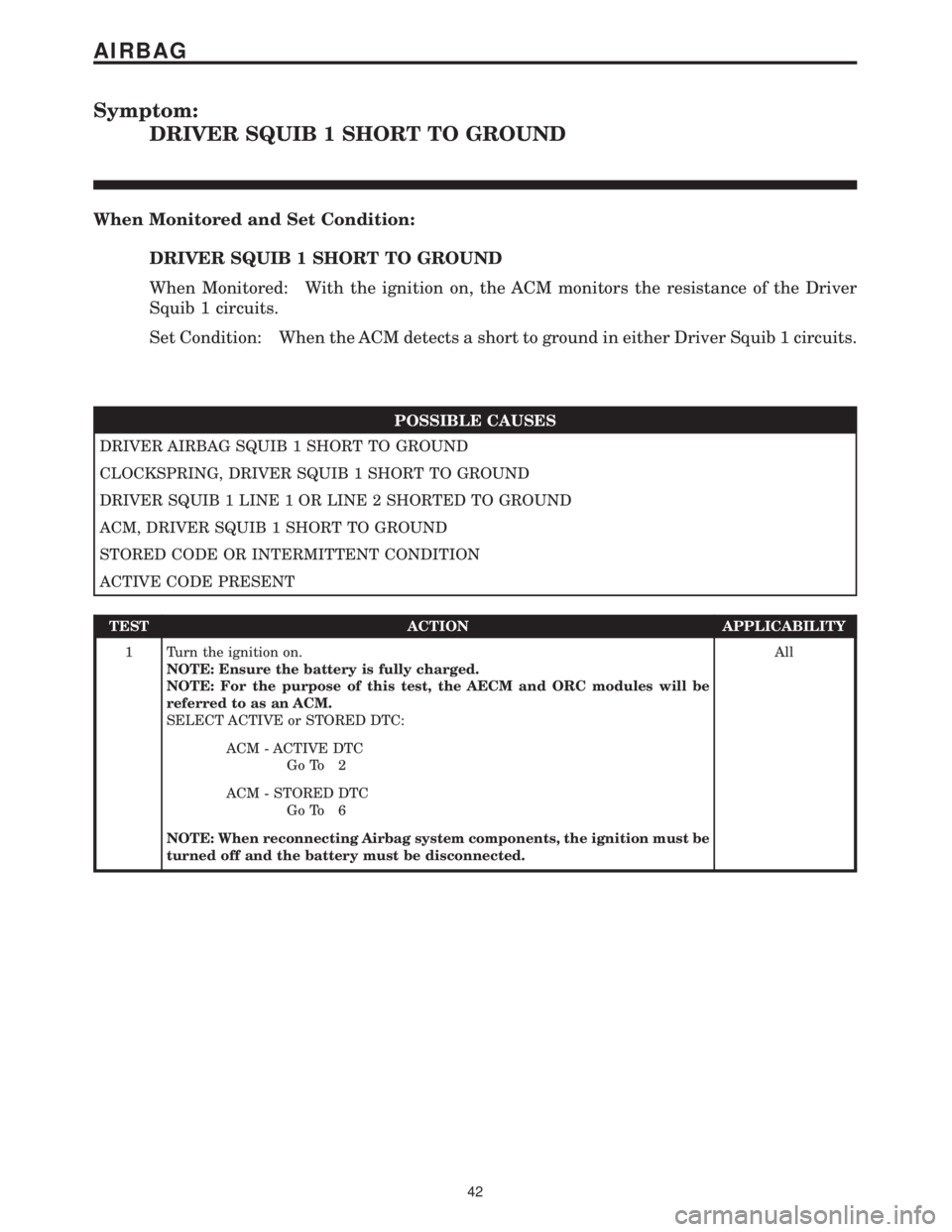

Symptom:

DRIVER SQUIB 1 SHORT TO GROUND

When Monitored and Set Condition:

DRIVER SQUIB 1 SHORT TO GROUND

When Monitored: With the ignition on, the ACM monitors the resistance of the Driver

Squib 1 circuits.

Set Condition: When the ACM detects a short to ground in either Driver Squib 1 circuits.

POSSIBLE CAUSES

DRIVER AIRBAG SQUIB 1 SHORT TO GROUND

CLOCKSPRING, DRIVER SQUIB 1 SHORT TO GROUND

DRIVER SQUIB 1 LINE 1 OR LINE 2 SHORTED TO GROUND

ACM, DRIVER SQUIB 1 SHORT TO GROUND

STORED CODE OR INTERMITTENT CONDITION

ACTIVE CODE PRESENT

TEST ACTION APPLICABILITY

1 Turn the ignition on.

NOTE: Ensure the battery is fully charged.

NOTE: For the purpose of this test, the AECM and ORC modules will be

referred to as an ACM.

SELECT ACTIVE or STORED DTC:All

ACM - ACTIVE DTC

Go To 2

ACM - STORED DTC

Go To 6

NOTE: When reconnecting Airbag system components, the ignition must be

turned off and the battery must be disconnected.

42

AIRBAG

Page 56 of 2305

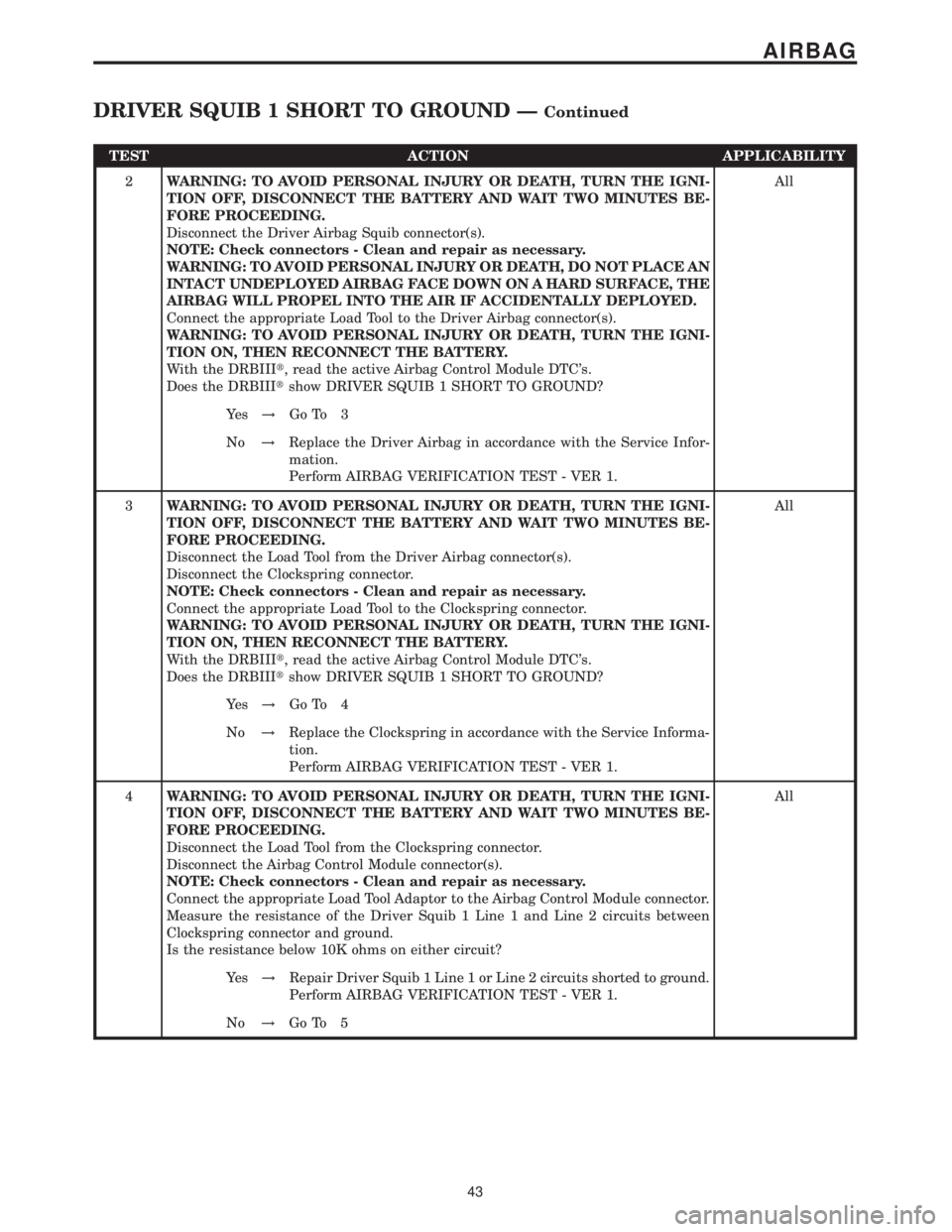

TEST ACTION APPLICABILITY

2WARNING: TO AVOID PERSONAL INJURY OR DEATH, TURN THE IGNI-

TION OFF, DISCONNECT THE BATTERY AND WAIT TWO MINUTES BE-

FORE PROCEEDING.

Disconnect the Driver Airbag Squib connector(s).

NOTE: Check connectors - Clean and repair as necessary.

WARNING: TO AVOID PERSONAL INJURY OR DEATH, DO NOT PLACE AN

INTACT UNDEPLOYED AIRBAG FACE DOWN ON A HARD SURFACE, THE

AIRBAG WILL PROPEL INTO THE AIR IF ACCIDENTALLY DEPLOYED.

Connect the appropriate Load Tool to the Driver Airbag connector(s).

WARNING: TO AVOID PERSONAL INJURY OR DEATH, TURN THE IGNI-

TION ON, THEN RECONNECT THE BATTERY.

With the DRBIIIt, read the active Airbag Control Module DTC's.

Does the DRBIIItshow DRIVER SQUIB 1 SHORT TO GROUND?All

Ye s!Go To 3

No!Replace the Driver Airbag in accordance with the Service Infor-

mation.

Perform AIRBAG VERIFICATION TEST - VER 1.

3WARNING: TO AVOID PERSONAL INJURY OR DEATH, TURN THE IGNI-

TION OFF, DISCONNECT THE BATTERY AND WAIT TWO MINUTES BE-

FORE PROCEEDING.

Disconnect the Load Tool from the Driver Airbag connector(s).

Disconnect the Clockspring connector.

NOTE: Check connectors - Clean and repair as necessary.

Connect the appropriate Load Tool to the Clockspring connector.

WARNING: TO AVOID PERSONAL INJURY OR DEATH, TURN THE IGNI-

TION ON, THEN RECONNECT THE BATTERY.

With the DRBIIIt, read the active Airbag Control Module DTC's.

Does the DRBIIItshow DRIVER SQUIB 1 SHORT TO GROUND?All

Ye s!Go To 4

No!Replace the Clockspring in accordance with the Service Informa-

tion.

Perform AIRBAG VERIFICATION TEST - VER 1.

4WARNING: TO AVOID PERSONAL INJURY OR DEATH, TURN THE IGNI-

TION OFF, DISCONNECT THE BATTERY AND WAIT TWO MINUTES BE-

FORE PROCEEDING.

Disconnect the Load Tool from the Clockspring connector.

Disconnect the Airbag Control Module connector(s).

NOTE: Check connectors - Clean and repair as necessary.

Connect the appropriate Load Tool Adaptor to the Airbag Control Module connector.

Measure the resistance of the Driver Squib 1 Line 1 and Line 2 circuits between

Clockspring connector and ground.

Is the resistance below 10K ohms on either circuit?All

Ye s!Repair Driver Squib 1 Line 1 or Line 2 circuits shorted to ground.

Perform AIRBAG VERIFICATION TEST - VER 1.

No!Go To 5

43

AIRBAG

DRIVER SQUIB 1 SHORT TO GROUND ÐContinued

Page 263 of 2305

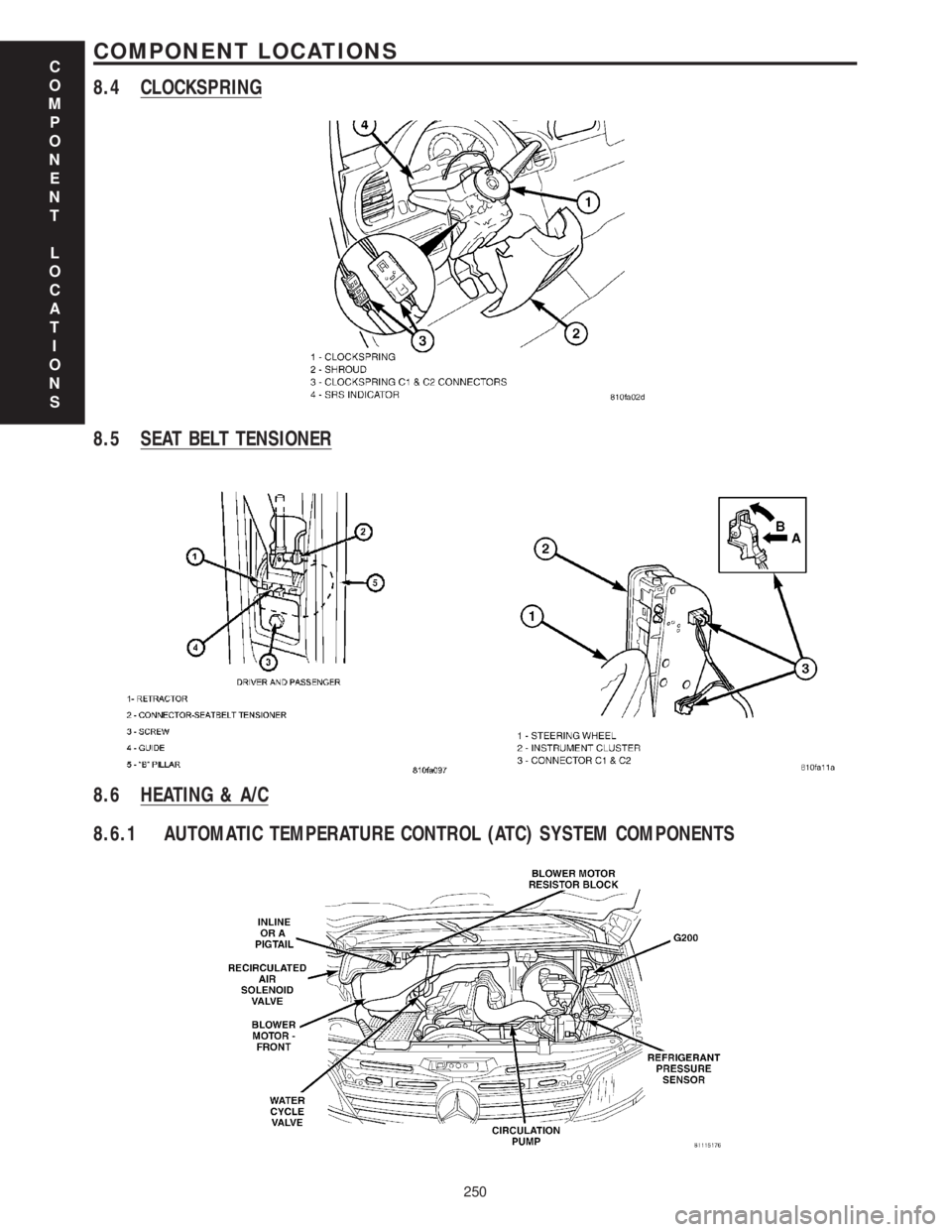

8.4 CLOCKSPRING

8.5 SEAT BELT TENSIONER

8.6 HEATING & A/C

8.6.1 AUTOMATIC TEMPERATURE CONTROL (ATC) SYSTEM COMPONENTS

C

O

M

P

O

N

E

N

T

L

O

C

A

T

I

O

N

S

250

COMPONENT LOCATIONS

Page 275 of 2305

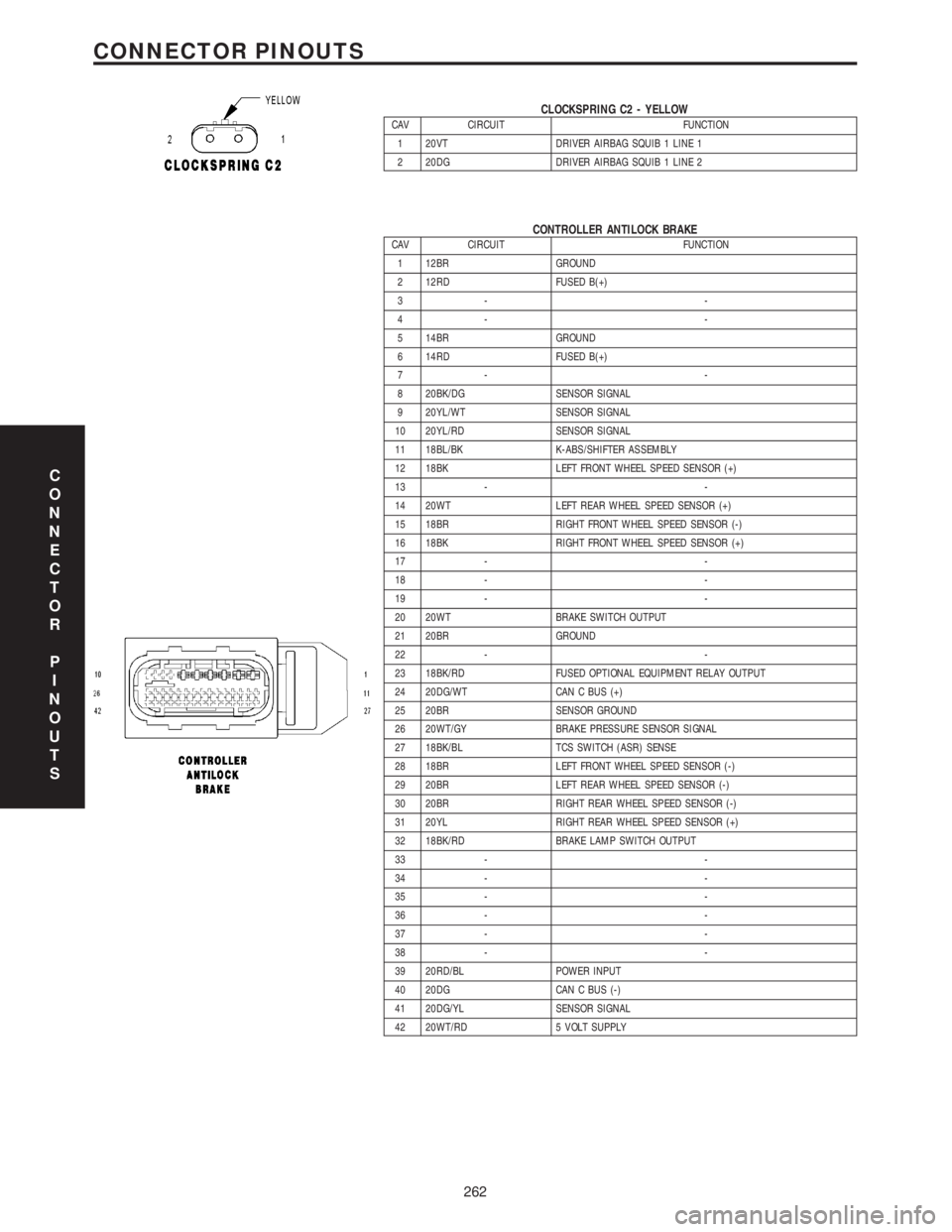

CLOCKSPRING C2 - YELLOWCAV CIRCUIT FUNCTION

1 20VT DRIVER AIRBAG SQUIB 1 LINE 1

2 20DG DRIVER AIRBAG SQUIB 1 LINE 2

CONTROLLER ANTILOCK BRAKECAV CIRCUIT FUNCTION

1 12BR GROUND

2 12RD FUSED B(+)

3- -

4- -

5 14BR GROUND

6 14RD FUSED B(+)

7- -

8 20BK/DG SENSOR SIGNAL

9 20YL/WT SENSOR SIGNAL

10 20YL/RD SENSOR SIGNAL

11 18BL/BK K-ABS/SHIFTER ASSEMBLY

12 18BK LEFT FRONT WHEEL SPEED SENSOR (+)

13 - -

14 20WT LEFT REAR WHEEL SPEED SENSOR (+)

15 18BR RIGHT FRONT WHEEL SPEED SENSOR (-)

16 18BK RIGHT FRONT WHEEL SPEED SENSOR (+)

17 - -

18 - -

19 - -

20 20WT BRAKE SWITCH OUTPUT

21 20BR GROUND

22 - -

23 18BK/RD FUSED OPTIONAL EQUIPMENT RELAY OUTPUT

24 20DG/WT CAN C BUS (+)

25 20BR SENSOR GROUND

26 20WT/GY BRAKE PRESSURE SENSOR SIGNAL

27 18BK/BL TCS SWITCH (ASR) SENSE

28 18BR LEFT FRONT WHEEL SPEED SENSOR (-)

29 20BR LEFT REAR WHEEL SPEED SENSOR (-)

30 20BR RIGHT REAR WHEEL SPEED SENSOR (-)

31 20YL RIGHT REAR WHEEL SPEED SENSOR (+)

32 18BK/RD BRAKE LAMP SWITCH OUTPUT

33 - -

34 - -

35 - -

36 - -

37 - -

38 - -

39 20RD/BL POWER INPUT

40 20DG CAN C BUS (-)

41 20DG/YL SENSOR SIGNAL

42 20WT/RD 5 VOLT SUPPLY

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

262

CONNECTOR PINOUTS

Page 723 of 2305

effect panels. If necessary, remove the wheels from

the lifted end of the vehicle and lower the vehicle

closer to the ground, to increase the ground clearance

at the opposite end of the vehicle. Install lug nuts on

wheel attaching studs to retain brake drums.

RAMP ANGLE

If a vehicle with flat-bed towing equipment is used,

the approach ramp angle should not exceed 15

degrees.

TOWING WHEN KEYS ARE NOT AVAILABLE

When the vehicle is locked and keys are not avail-

able, use a flat bed hauler. A Wheel-lift or Sling-type

device can be used provided all the wheels are lifted

off the ground using tow dollies.

MAINTENANCE SCHEDULES

DESCRIPTION

The use of special lubricant additives is not recom-

mended. The use of such additives may affect the

warranty rights. With regard to legal stipulations

concerning emissions control, please note that

engines have to be serviced and adjusted in accor-

dance with special instructions and using special

measuring equipment. Modifications to or interfer-

ence with the emissions control systems are not per-

missible.

MAINTENANCE - WITHOUT ASSYST MAINTE-

NANCE COMPUTER

Maintenance Intervals

²Oil service ±Normal Operationevery 10,000

miles or 16,000 km or 12 months.

²Maintenance service every 30,000 miles or

48,000 km.

Additional work must be carried out at yearly

intervals.

MAINTENANCE - WITH ASSYST MAINTENANCE

COMPUTER

ASSYST provides information on the best possible

timing for maintenance work.

When the next maintenance service is due, this

will be indicated in the multi-function display with

the wrench icon symbol displayed in km/miles or

days.

²One wrench icon showing indicates Oil Service

is necessary.

²Two wrench icons showing indicates Mainte-

nance Service is necessary ± displayed in km/miles or

days.

If the display shows the number of days, a clock

symbol will also appear in the multi-function display.You should have the maintenance performed

within the stated period/distance.

The service indicator will be reset after an oil ser-

vice and/or maintenance service has been performed.

REGULAR CHECK - UPS

To maintain the safe operation of the vehicle, it is

recommended that the following tasks be performed

on a regular basis (i.e. weekly or whenever the vehi-

cle is refueled). Check:

²Engine oil level

²Brake system - fluid level

²Battery - acid level

²Windshield washer system and headlamp clean-

ing system - fluid level

²Mechanical assemblies (e.g. engine, transmis-

sion, etc.) - check for leaks

²Condition of tires and tires pressures

²All exterior lights

SPECIAL MAINTENANCE REQUIREMENTS

If bodies built by manufacturers other than

DaimlerChrysler Corporation are fitted to the vehi-

cle, the maintenance requirements and lubrication

intervals specified by the body manufacturer must be

adhered to, in addition to all standard maintenance

requirements.

Coolant

Corrosion inhibitor/antifreeze concentration in the

coolant should be checked before the onset of winter

(once year in countries with high prevailing temper-

atures).

Replace the coolant every five years or 100,000

miles.

Dust Filter for Heating / Ventilation Replacement

The dust filter and the tailgate interior filter are to

be renewed during routine maintenance service. If

operating conditions are dusty, these filters should be

renewed more frequently.

ENGINE OIL CHANGE AND FILTER REPLACEMENT

At a minimum, change the engine oil and oil filter

once a year ± even if the vehicle mileage per year is

extremely low. For standard oil service schedules

refer to the chapter oil service and maintenance ser-

vice.

Once a Year

Select the viscosity of the engine oil (SAE classes)

according to the outside air temperature.

Only use engine oil approved by DaimlerChrysler

Corporation if following the ASSYST system guide-

lines.

0 - 8 LUBRICATION & MAINTENANCEVA

Page 815 of 2305

INSTALLATION - REAR

NOTE: Route the park brake cable free of tension

and the risk of chafing.

(1) Install the hand brake cable to the anchor

plate (Fig. 31).

(2) Install the park brake cable lock (Fig. 31).

(3) Install all connections on the hardware cable

(Fig. 31).

(4) Install the park brake cables to the shoe (Fig.

31).

(5) Install the park brake shoes.

(6) Install the rear wheels.

(7) Adjust the park brakes.

(8) Lower the vehicle.

ADJUSTMENTS

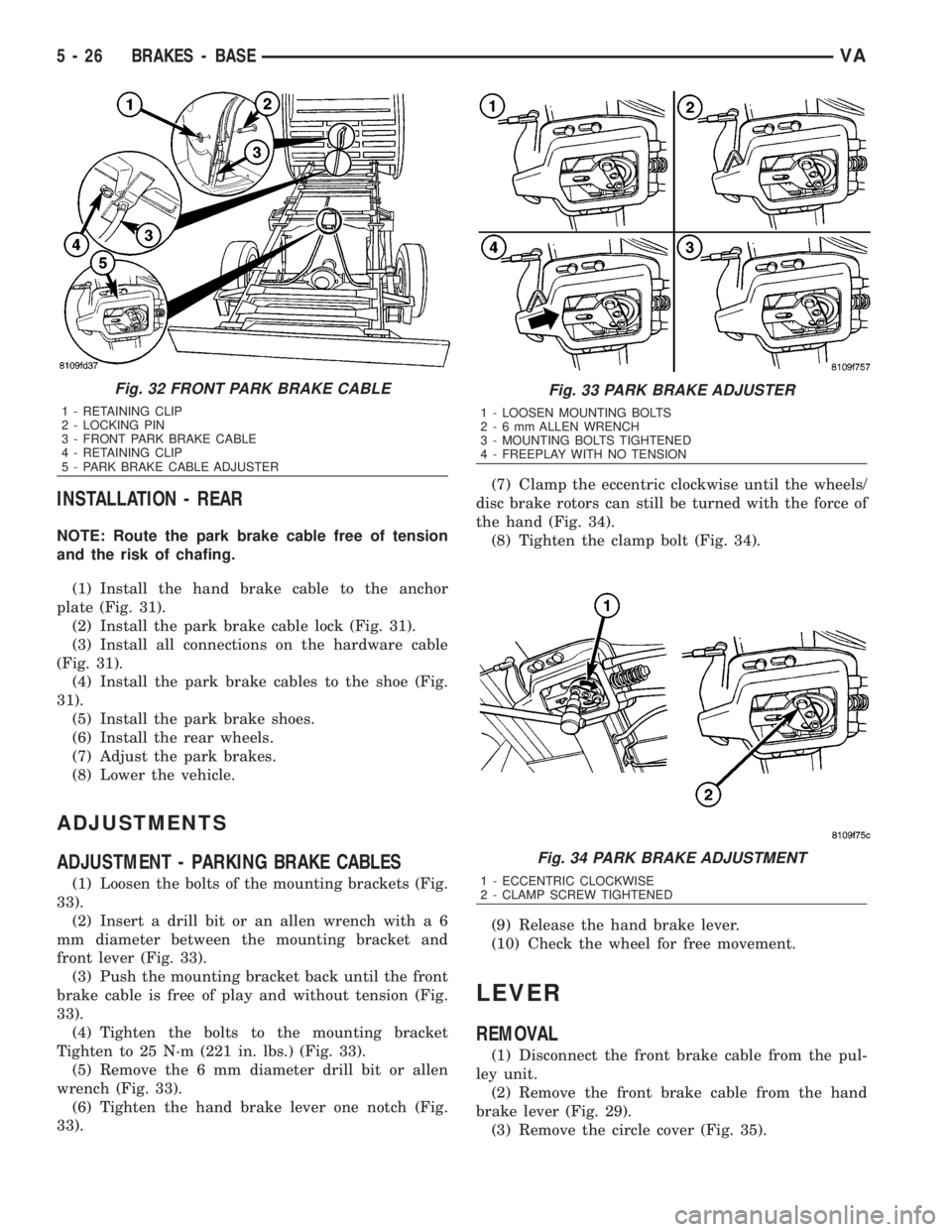

ADJUSTMENT - PARKING BRAKE CABLES

(1) Loosen the bolts of the mounting brackets (Fig.

33).

(2) Insert a drill bit or an allen wrench with a 6

mm diameter between the mounting bracket and

front lever (Fig. 33).

(3) Push the mounting bracket back until the front

brake cable is free of play and without tension (Fig.

33).

(4) Tighten the bolts to the mounting bracket

Tighten to 25 N´m (221 in. lbs.) (Fig. 33).

(5) Remove the 6 mm diameter drill bit or allen

wrench (Fig. 33).

(6) Tighten the hand brake lever one notch (Fig.

33).(7) Clamp the eccentric clockwise until the wheels/

disc brake rotors can still be turned with the force of

the hand (Fig. 34).

(8) Tighten the clamp bolt (Fig. 34).

(9) Release the hand brake lever.

(10) Check the wheel for free movement.

LEVER

REMOVAL

(1) Disconnect the front brake cable from the pul-

ley unit.

(2) Remove the front brake cable from the hand

brake lever (Fig. 29).

(3) Remove the circle cover (Fig. 35).

Fig. 32 FRONT PARK BRAKE CABLE

1 - RETAINING CLIP

2 - LOCKING PIN

3 - FRONT PARK BRAKE CABLE

4 - RETAINING CLIP

5 - PARK BRAKE CABLE ADJUSTER

Fig. 33 PARK BRAKE ADJUSTER

1 - LOOSEN MOUNTING BOLTS

2-6mmALLEN WRENCH

3 - MOUNTING BOLTS TIGHTENED

4 - FREEPLAY WITH NO TENSION

Fig. 34 PARK BRAKE ADJUSTMENT

1 - ECCENTRIC CLOCKWISE

2 - CLAMP SCREW TIGHTENED

5 - 26 BRAKES - BASEVA

Page 821 of 2305

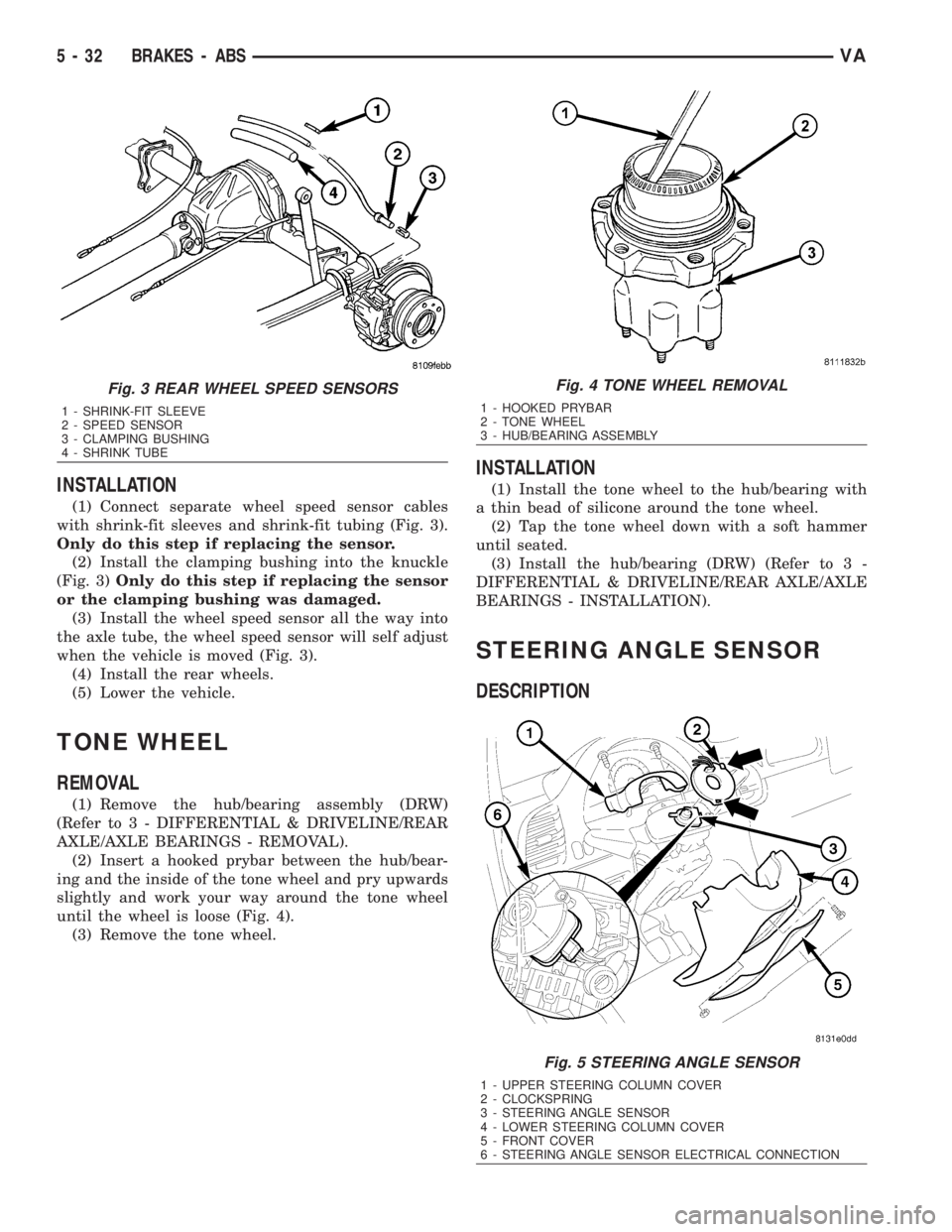

INSTALLATION

(1) Connect separate wheel speed sensor cables

with shrink-fit sleeves and shrink-fit tubing (Fig. 3).

Only do this step if replacing the sensor.

(2) Install the clamping bushing into the knuckle

(Fig. 3)Only do this step if replacing the sensor

or the clamping bushing was damaged.

(3) Install the wheel speed sensor all the way into

the axle tube, the wheel speed sensor will self adjust

when the vehicle is moved (Fig. 3).

(4) Install the rear wheels.

(5) Lower the vehicle.

TONE WHEEL

REMOVAL

(1) Remove the hub/bearing assembly (DRW)

(Refer to 3 - DIFFERENTIAL & DRIVELINE/REAR

AXLE/AXLE BEARINGS - REMOVAL).

(2) Insert a hooked prybar between the hub/bear-

ing and the inside of the tone wheel and pry upwards

slightly and work your way around the tone wheel

until the wheel is loose (Fig. 4).

(3) Remove the tone wheel.

INSTALLATION

(1) Install the tone wheel to the hub/bearing with

a thin bead of silicone around the tone wheel.

(2) Tap the tone wheel down with a soft hammer

until seated.

(3) Install the hub/bearing (DRW) (Refer to 3 -

DIFFERENTIAL & DRIVELINE/REAR AXLE/AXLE

BEARINGS - INSTALLATION).

STEERING ANGLE SENSOR

DESCRIPTION

Fig. 3 REAR WHEEL SPEED SENSORS

1 - SHRINK-FIT SLEEVE

2 - SPEED SENSOR

3 - CLAMPING BUSHING

4 - SHRINK TUBE

Fig. 4 TONE WHEEL REMOVAL

1 - HOOKED PRYBAR

2 - TONE WHEEL

3 - HUB/BEARING ASSEMBLY

Fig. 5 STEERING ANGLE SENSOR

1 - UPPER STEERING COLUMN COVER

2 - CLOCKSPRING

3 - STEERING ANGLE SENSOR

4 - LOWER STEERING COLUMN COVER

5 - FRONT COVER

6 - STEERING ANGLE SENSOR ELECTRICAL CONNECTION

5 - 32 BRAKES - ABSVA