clock MERCEDES-BENZ SPRINTER 2006 Owner's Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 822 of 2305

The Steering Angle Sensor is used to measure rate/

speed and direction of the steering wheel. This sen-

sor has 4 wires 12V, ground and 2 CAN Bus circuits.

This sensor is wired directly to the CAN Bus. This

sensor has to be programmed using the DRB IIIt

(Fig. 5).

REMOVAL

(1) Disconnect the battery.

(2) Remove the airbag (Refer to 8 - ELECTRICAL/

RESTRAINTS/AIRBAG CONTROL MODULE -

REMOVAL).

(3) Remove the steering wheel (Refer to 19 -

STEERING/COLUMN/STEERING WHEEL -

REMOVAL).

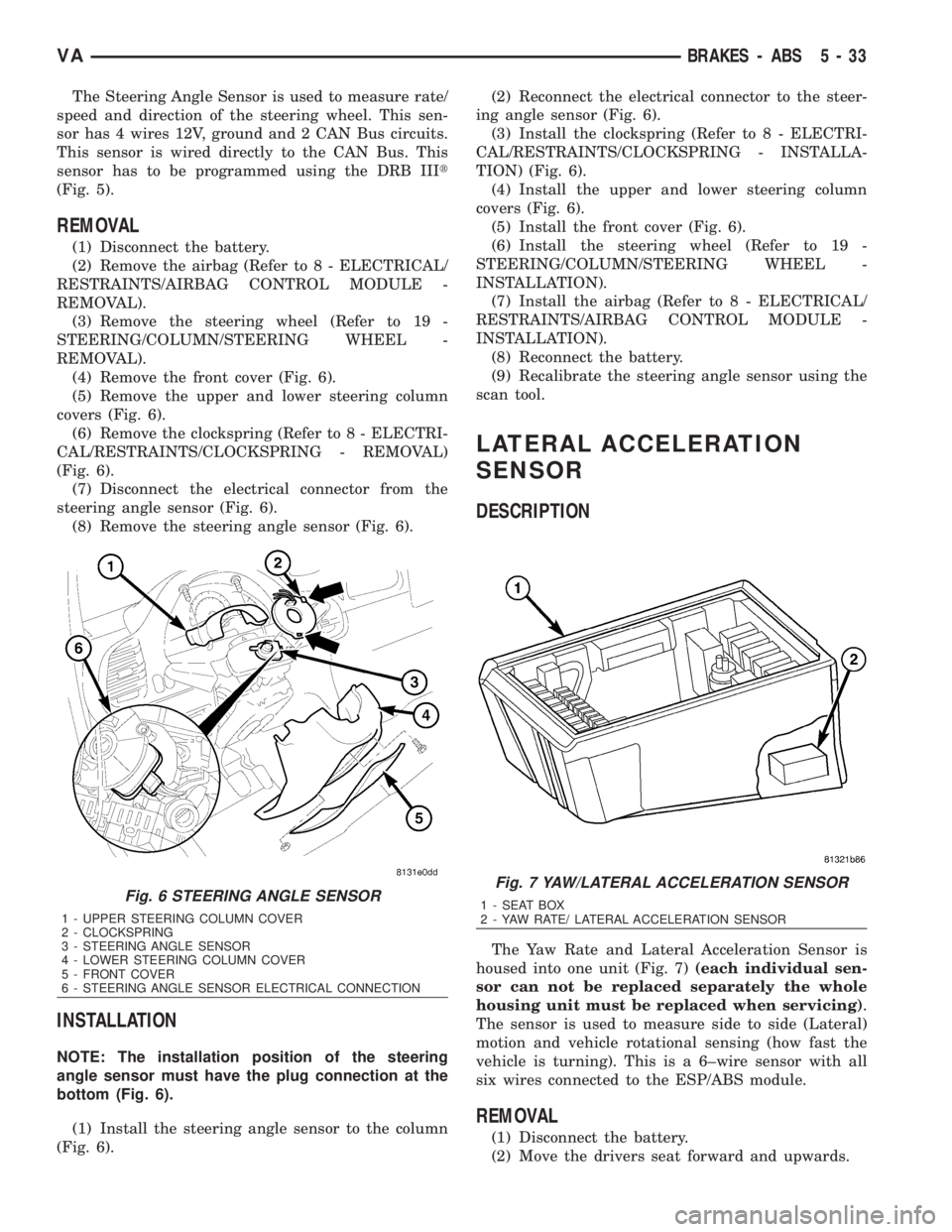

(4) Remove the front cover (Fig. 6).

(5) Remove the upper and lower steering column

covers (Fig. 6).

(6) Remove the clockspring (Refer to 8 - ELECTRI-

CAL/RESTRAINTS/CLOCKSPRING - REMOVAL)

(Fig. 6).

(7) Disconnect the electrical connector from the

steering angle sensor (Fig. 6).

(8) Remove the steering angle sensor (Fig. 6).

INSTALLATION

NOTE: The installation position of the steering

angle sensor must have the plug connection at the

bottom (Fig. 6).

(1) Install the steering angle sensor to the column

(Fig. 6).(2) Reconnect the electrical connector to the steer-

ing angle sensor (Fig. 6).

(3) Install the clockspring (Refer to 8 - ELECTRI-

CAL/RESTRAINTS/CLOCKSPRING - INSTALLA-

TION) (Fig. 6).

(4) Install the upper and lower steering column

covers (Fig. 6).

(5) Install the front cover (Fig. 6).

(6) Install the steering wheel (Refer to 19 -

STEERING/COLUMN/STEERING WHEEL -

INSTALLATION).

(7) Install the airbag (Refer to 8 - ELECTRICAL/

RESTRAINTS/AIRBAG CONTROL MODULE -

INSTALLATION).

(8) Reconnect the battery.

(9) Recalibrate the steering angle sensor using the

scan tool.

LATERAL ACCELERATION

SENSOR

DESCRIPTION

The Yaw Rate and Lateral Acceleration Sensor is

housed into one unit (Fig. 7)(each individual sen-

sor can not be replaced separately the whole

housing unit must be replaced when servicing).

The sensor is used to measure side to side (Lateral)

motion and vehicle rotational sensing (how fast the

vehicle is turning). This is a 6±wire sensor with all

six wires connected to the ESP/ABS module.

REMOVAL

(1) Disconnect the battery.

(2) Move the drivers seat forward and upwards.

Fig. 6 STEERING ANGLE SENSOR

1 - UPPER STEERING COLUMN COVER

2 - CLOCKSPRING

3 - STEERING ANGLE SENSOR

4 - LOWER STEERING COLUMN COVER

5 - FRONT COVER

6 - STEERING ANGLE SENSOR ELECTRICAL CONNECTION

Fig. 7 YAW/LATERAL ACCELERATION SENSOR

1 - SEAT BOX

2 - YAW RATE/ LATERAL ACCELERATION SENSOR

VABRAKES - ABS 5 - 33

Page 835 of 2305

REMOVAL

REMOVAL

CAUTION: Do not attempt to check belt tension with

a belt tension gauge on vehicles equipped with an

automatic belt tensioner.

NOTE: The belt routing schematics are published

from the latest information available at the time of

publication. If anything differs between these sche-

matics and the Belt Routing Label, use the sche-

matics on Belt Routing Label.This label is located in

the engine compartment.

(1) Remove A/C compressor drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

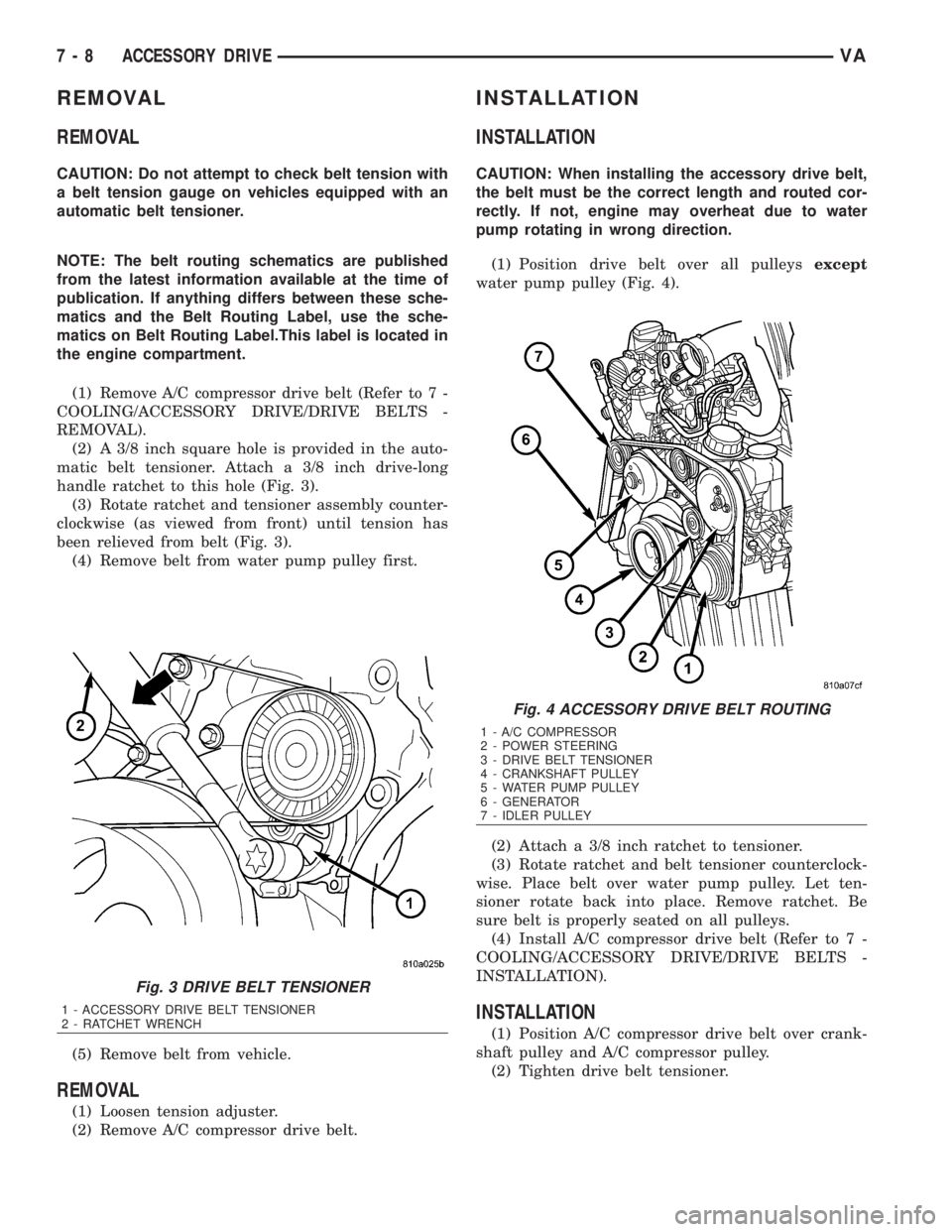

(2) A 3/8 inch square hole is provided in the auto-

matic belt tensioner. Attach a 3/8 inch drive-long

handle ratchet to this hole (Fig. 3).

(3) Rotate ratchet and tensioner assembly counter-

clockwise (as viewed from front) until tension has

been relieved from belt (Fig. 3).

(4) Remove belt from water pump pulley first.

(5) Remove belt from vehicle.

REMOVAL

(1) Loosen tension adjuster.

(2) Remove A/C compressor drive belt.

INSTALLATION

INSTALLATION

CAUTION: When installing the accessory drive belt,

the belt must be the correct length and routed cor-

rectly. If not, engine may overheat due to water

pump rotating in wrong direction.

(1) Position drive belt over all pulleysexcept

water pump pulley (Fig. 4).

(2) Attach a 3/8 inch ratchet to tensioner.

(3) Rotate ratchet and belt tensioner counterclock-

wise. Place belt over water pump pulley. Let ten-

sioner rotate back into place. Remove ratchet. Be

sure belt is properly seated on all pulleys.

(4) Install A/C compressor drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

INSTALLATION

(1) Position A/C compressor drive belt over crank-

shaft pulley and A/C compressor pulley.

(2) Tighten drive belt tensioner.

Fig. 3 DRIVE BELT TENSIONER

1 - ACCESSORY DRIVE BELT TENSIONER

2 - RATCHET WRENCH

Fig. 4 ACCESSORY DRIVE BELT ROUTING

1 - A/C COMPRESSOR

2 - POWER STEERING

3 - DRIVE BELT TENSIONER

4 - CRANKSHAFT PULLEY

5 - WATER PUMP PULLEY

6 - GENERATOR

7 - IDLER PULLEY

7 - 8 ACCESSORY DRIVEVA

Page 841 of 2305

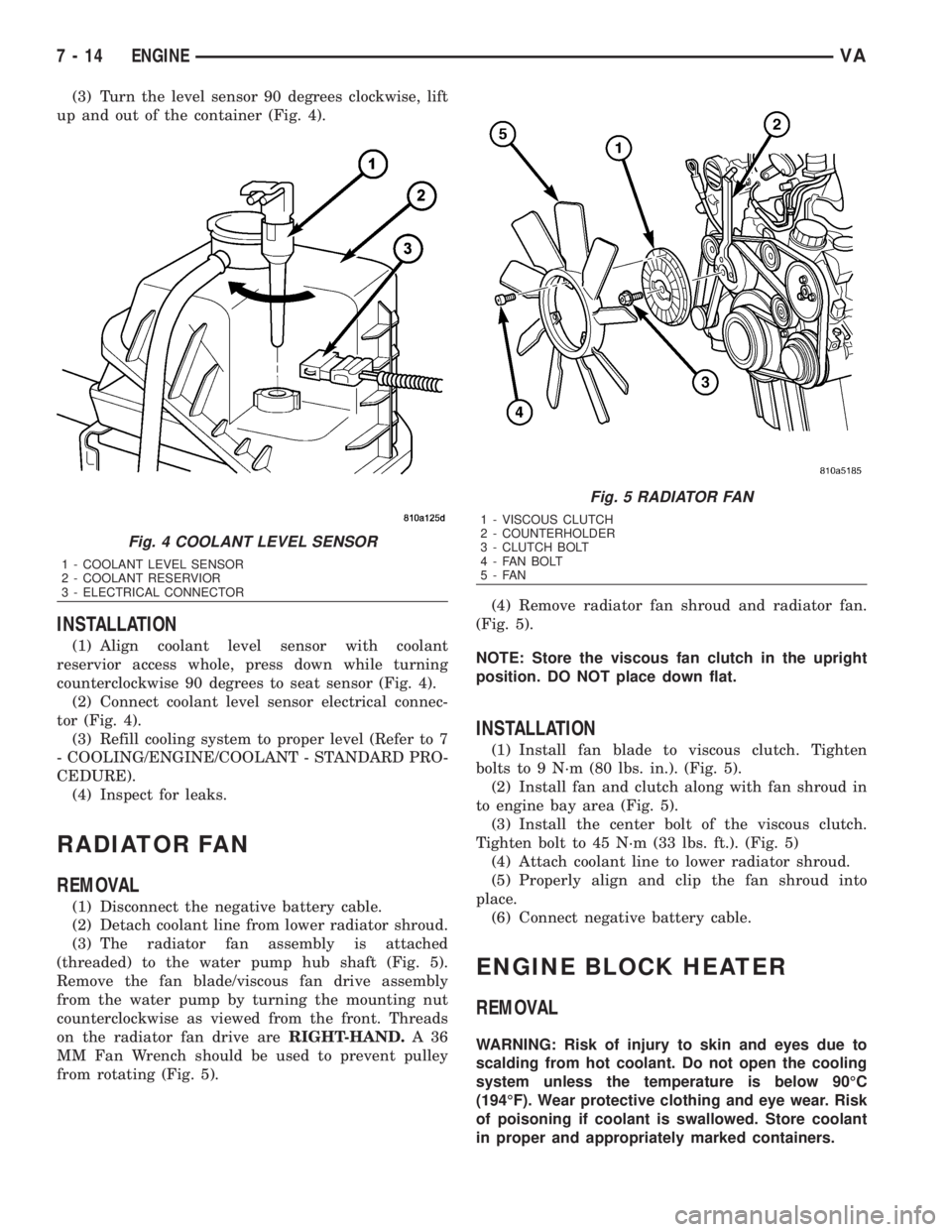

(3) Turn the level sensor 90 degrees clockwise, lift

up and out of the container (Fig. 4).

INSTALLATION

(1) Align coolant level sensor with coolant

reservior access whole, press down while turning

counterclockwise 90 degrees to seat sensor (Fig. 4).

(2) Connect coolant level sensor electrical connec-

tor (Fig. 4).

(3) Refill cooling system to proper level (Refer to 7

- COOLING/ENGINE/COOLANT - STANDARD PRO-

CEDURE).

(4) Inspect for leaks.

RADIATOR FAN

REMOVAL

(1) Disconnect the negative battery cable.

(2) Detach coolant line from lower radiator shroud.

(3) The radiator fan assembly is attached

(threaded) to the water pump hub shaft (Fig. 5).

Remove the fan blade/viscous fan drive assembly

from the water pump by turning the mounting nut

counterclockwise as viewed from the front. Threads

on the radiator fan drive areRIGHT-HAND.A36

MM Fan Wrench should be used to prevent pulley

from rotating (Fig. 5).(4) Remove radiator fan shroud and radiator fan.

(Fig. 5).

NOTE: Store the viscous fan clutch in the upright

position. DO NOT place down flat.

INSTALLATION

(1) Install fan blade to viscous clutch. Tighten

bolts to 9 N´m (80 lbs. in.). (Fig. 5).

(2) Install fan and clutch along with fan shroud in

to engine bay area (Fig. 5).

(3) Install the center bolt of the viscous clutch.

Tighten bolt to 45 N´m (33 lbs. ft.). (Fig. 5)

(4) Attach coolant line to lower radiator shroud.

(5) Properly align and clip the fan shroud into

place.

(6) Connect negative battery cable.

ENGINE BLOCK HEATER

REMOVAL

WARNING: Risk of injury to skin and eyes due to

scalding from hot coolant. Do not open the cooling

system unless the temperature is below 90ÉC

(194ÉF). Wear protective clothing and eye wear. Risk

of poisoning if coolant is swallowed. Store coolant

in proper and appropriately marked containers.

Fig. 4 COOLANT LEVEL SENSOR

1 - COOLANT LEVEL SENSOR

2 - COOLANT RESERVIOR

3 - ELECTRICAL CONNECTOR

Fig. 5 RADIATOR FAN

1 - VISCOUS CLUTCH

2 - COUNTERHOLDER

3 - CLUTCH BOLT

4 - FAN BOLT

5-FAN

7 - 14 ENGINEVA

Page 875 of 2305

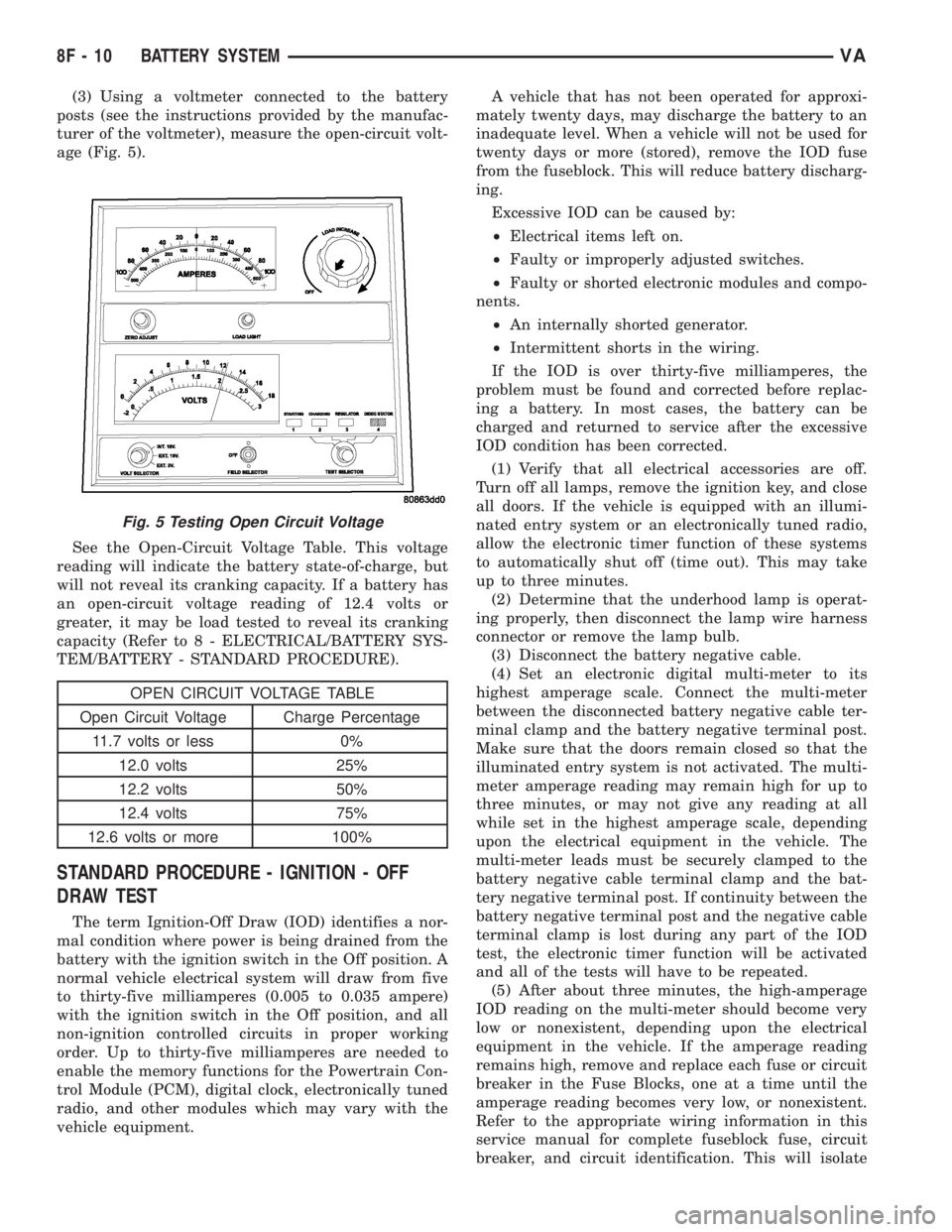

(3) Using a voltmeter connected to the battery

posts (see the instructions provided by the manufac-

turer of the voltmeter), measure the open-circuit volt-

age (Fig. 5).

See the Open-Circuit Voltage Table. This voltage

reading will indicate the battery state-of-charge, but

will not reveal its cranking capacity. If a battery has

an open-circuit voltage reading of 12.4 volts or

greater, it may be load tested to reveal its cranking

capacity (Refer to 8 - ELECTRICAL/BATTERY SYS-

TEM/BATTERY - STANDARD PROCEDURE).

OPEN CIRCUIT VOLTAGE TABLE

Open Circuit Voltage Charge Percentage

11.7 volts or less 0%

12.0 volts 25%

12.2 volts 50%

12.4 volts 75%

12.6 volts or more 100%

STANDARD PROCEDURE - IGNITION - OFF

DRAW TEST

The term Ignition-Off Draw (IOD) identifies a nor-

mal condition where power is being drained from the

battery with the ignition switch in the Off position. A

normal vehicle electrical system will draw from five

to thirty-five milliamperes (0.005 to 0.035 ampere)

with the ignition switch in the Off position, and all

non-ignition controlled circuits in proper working

order. Up to thirty-five milliamperes are needed to

enable the memory functions for the Powertrain Con-

trol Module (PCM), digital clock, electronically tuned

radio, and other modules which may vary with the

vehicle equipment.A vehicle that has not been operated for approxi-

mately twenty days, may discharge the battery to an

inadequate level. When a vehicle will not be used for

twenty days or more (stored), remove the IOD fuse

from the fuseblock. This will reduce battery discharg-

ing.

Excessive IOD can be caused by:

²Electrical items left on.

²Faulty or improperly adjusted switches.

²Faulty or shorted electronic modules and compo-

nents.

²An internally shorted generator.

²Intermittent shorts in the wiring.

If the IOD is over thirty-five milliamperes, the

problem must be found and corrected before replac-

ing a battery. In most cases, the battery can be

charged and returned to service after the excessive

IOD condition has been corrected.

(1) Verify that all electrical accessories are off.

Turn off all lamps, remove the ignition key, and close

all doors. If the vehicle is equipped with an illumi-

nated entry system or an electronically tuned radio,

allow the electronic timer function of these systems

to automatically shut off (time out). This may take

up to three minutes.

(2) Determine that the underhood lamp is operat-

ing properly, then disconnect the lamp wire harness

connector or remove the lamp bulb.

(3) Disconnect the battery negative cable.

(4) Set an electronic digital multi-meter to its

highest amperage scale. Connect the multi-meter

between the disconnected battery negative cable ter-

minal clamp and the battery negative terminal post.

Make sure that the doors remain closed so that the

illuminated entry system is not activated. The multi-

meter amperage reading may remain high for up to

three minutes, or may not give any reading at all

while set in the highest amperage scale, depending

upon the electrical equipment in the vehicle. The

multi-meter leads must be securely clamped to the

battery negative cable terminal clamp and the bat-

tery negative terminal post. If continuity between the

battery negative terminal post and the negative cable

terminal clamp is lost during any part of the IOD

test, the electronic timer function will be activated

and all of the tests will have to be repeated.

(5) After about three minutes, the high-amperage

IOD reading on the multi-meter should become very

low or nonexistent, depending upon the electrical

equipment in the vehicle. If the amperage reading

remains high, remove and replace each fuse or circuit

breaker in the Fuse Blocks, one at a time until the

amperage reading becomes very low, or nonexistent.

Refer to the appropriate wiring information in this

service manual for complete fuseblock fuse, circuit

breaker, and circuit identification. This will isolate

Fig. 5 Testing Open Circuit Voltage

8F - 10 BATTERY SYSTEMVA

Page 885 of 2305

DIAGNOSIS AND TESTING - GENERATOR DECOUPLER

CONDITION POSSIBLE CAUSES CORRECTION

Does not drive generator

(generator not charging)Internal failure Replace decoupler

Noise coming from decou-

plerInternal failure Replace decoupler

REMOVAL

The generator decoupler is used only with

certain engines.

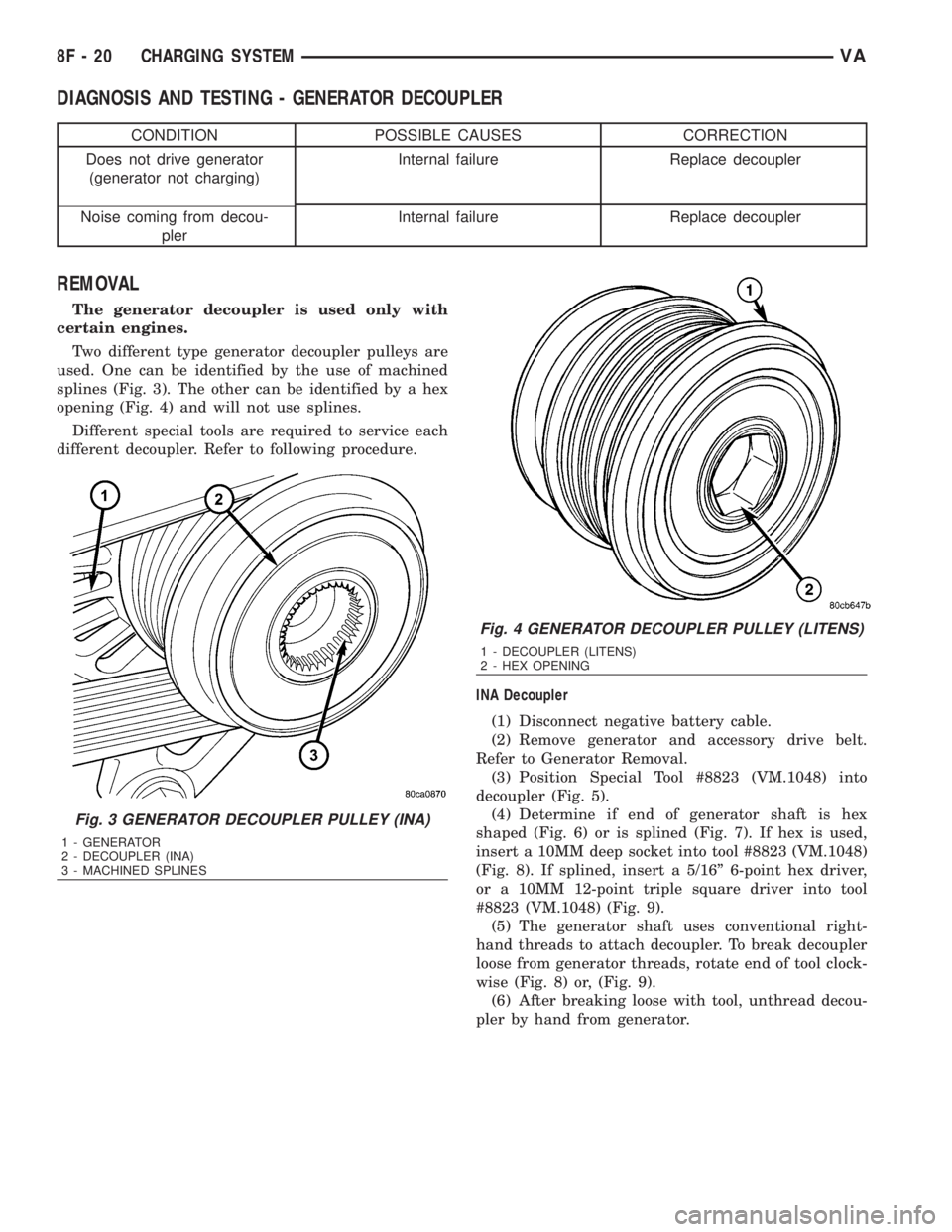

Two different type generator decoupler pulleys are

used. One can be identified by the use of machined

splines (Fig. 3). The other can be identified by a hex

opening (Fig. 4) and will not use splines.

Different special tools are required to service each

different decoupler. Refer to following procedure.

INA Decoupler

(1) Disconnect negative battery cable.

(2) Remove generator and accessory drive belt.

Refer to Generator Removal.

(3) Position Special Tool #8823 (VM.1048) into

decoupler (Fig. 5).

(4) Determine if end of generator shaft is hex

shaped (Fig. 6) or is splined (Fig. 7). If hex is used,

insert a 10MM deep socket into tool #8823 (VM.1048)

(Fig. 8). If splined, insert a 5/16º 6-point hex driver,

or a 10MM 12-point triple square driver into tool

#8823 (VM.1048) (Fig. 9).

(5) The generator shaft uses conventional right-

hand threads to attach decoupler. To break decoupler

loose from generator threads, rotate end of tool clock-

wise (Fig. 8) or, (Fig. 9).

(6) After breaking loose with tool, unthread decou-

pler by hand from generator.

Fig. 3 GENERATOR DECOUPLER PULLEY (INA)

1 - GENERATOR

2 - DECOUPLER (INA)

3 - MACHINED SPLINES

Fig. 4 GENERATOR DECOUPLER PULLEY (LITENS)

1 - DECOUPLER (LITENS)

2 - HEX OPENING

8F - 20 CHARGING SYSTEMVA

Page 887 of 2305

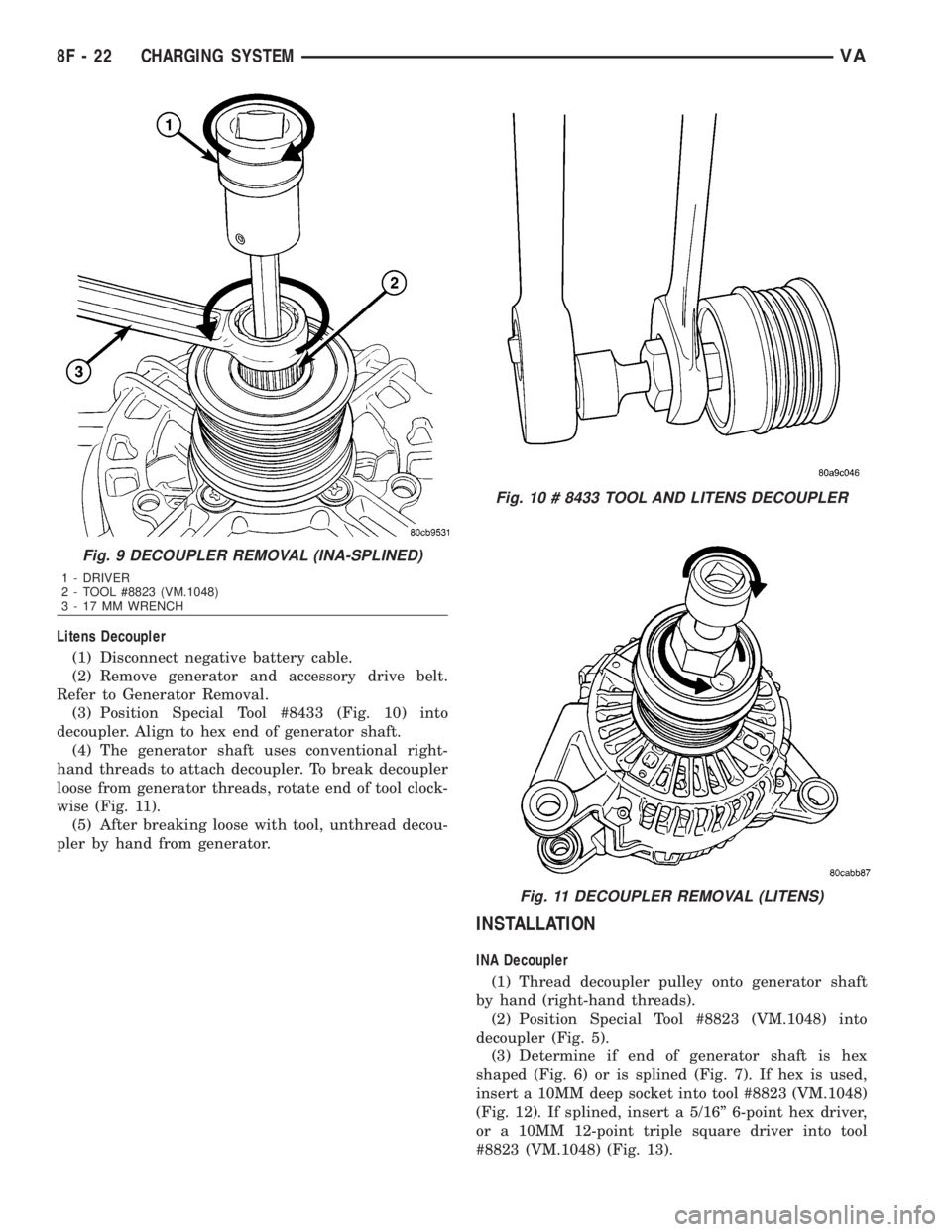

Litens Decoupler

(1) Disconnect negative battery cable.

(2) Remove generator and accessory drive belt.

Refer to Generator Removal.

(3) Position Special Tool #8433 (Fig. 10) into

decoupler. Align to hex end of generator shaft.

(4) The generator shaft uses conventional right-

hand threads to attach decoupler. To break decoupler

loose from generator threads, rotate end of tool clock-

wise (Fig. 11).

(5) After breaking loose with tool, unthread decou-

pler by hand from generator.

INSTALLATION

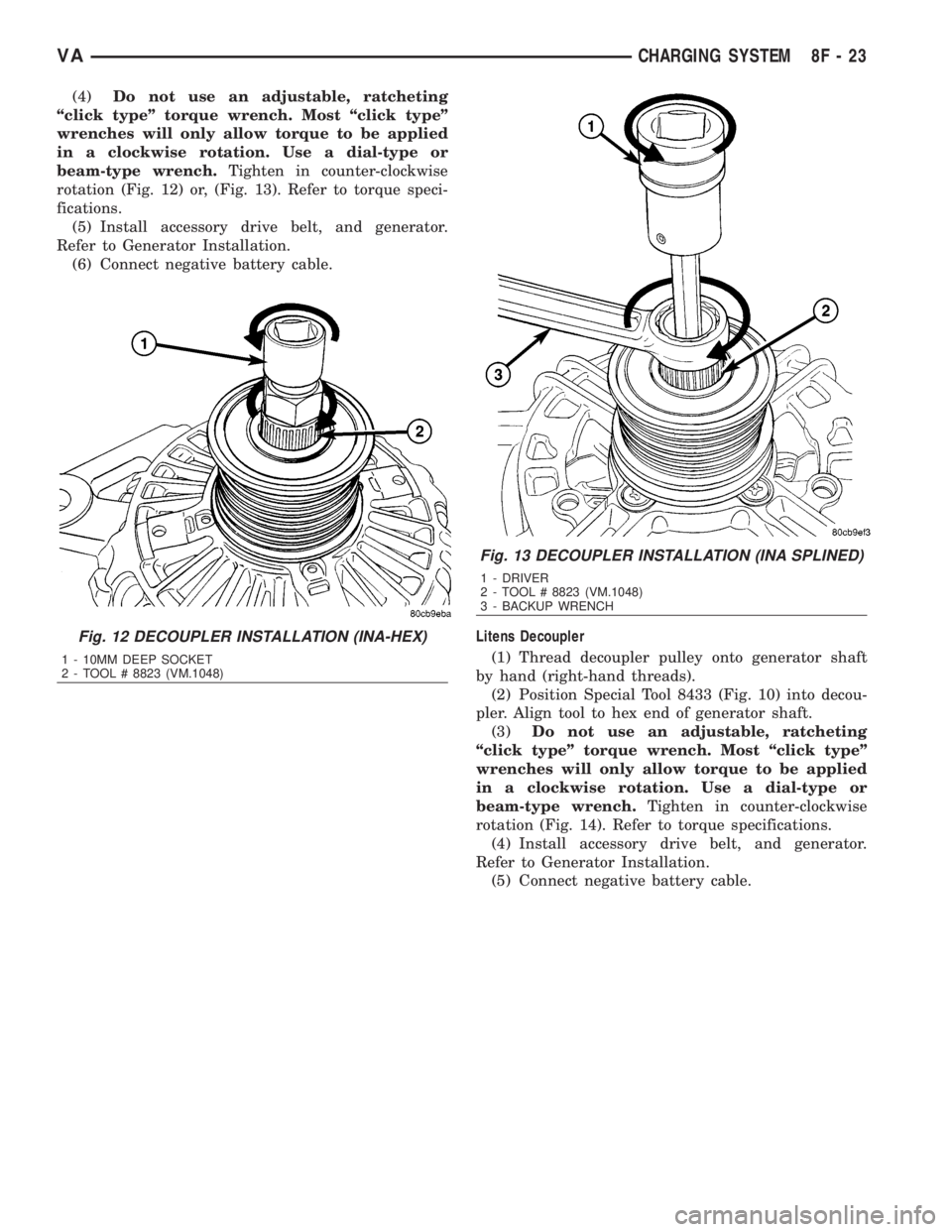

INA Decoupler

(1) Thread decoupler pulley onto generator shaft

by hand (right-hand threads).

(2) Position Special Tool #8823 (VM.1048) into

decoupler (Fig. 5).

(3) Determine if end of generator shaft is hex

shaped (Fig. 6) or is splined (Fig. 7). If hex is used,

insert a 10MM deep socket into tool #8823 (VM.1048)

(Fig. 12). If splined, insert a 5/16º 6-point hex driver,

or a 10MM 12-point triple square driver into tool

#8823 (VM.1048) (Fig. 13).

Fig. 9 DECOUPLER REMOVAL (INA-SPLINED)

1 - DRIVER

2 - TOOL #8823 (VM.1048)

3 - 17 MM WRENCH

Fig. 10 # 8433 TOOL AND LITENS DECOUPLER

Fig. 11 DECOUPLER REMOVAL (LITENS)

8F - 22 CHARGING SYSTEMVA

Page 888 of 2305

(4)Do not use an adjustable, ratcheting

ªclick typeº torque wrench. Most ªclick typeº

wrenches will only allow torque to be applied

in a clockwise rotation. Use a dial-type or

beam-type wrench.Tighten in counter-clockwise

rotation (Fig. 12) or, (Fig. 13). Refer to torque speci-

fications.

(5) Install accessory drive belt, and generator.

Refer to Generator Installation.

(6) Connect negative battery cable.

Litens Decoupler

(1) Thread decoupler pulley onto generator shaft

by hand (right-hand threads).

(2) Position Special Tool 8433 (Fig. 10) into decou-

pler. Align tool to hex end of generator shaft.

(3)Do not use an adjustable, ratcheting

ªclick typeº torque wrench. Most ªclick typeº

wrenches will only allow torque to be applied

in a clockwise rotation. Use a dial-type or

beam-type wrench.Tighten in counter-clockwise

rotation (Fig. 14). Refer to torque specifications.

(4) Install accessory drive belt, and generator.

Refer to Generator Installation.

(5) Connect negative battery cable.

Fig. 12 DECOUPLER INSTALLATION (INA-HEX)

1 - 10MM DEEP SOCKET

2 - TOOL # 8823 (VM.1048)

Fig. 13 DECOUPLER INSTALLATION (INA SPLINED)

1 - DRIVER

2 - TOOL # 8823 (VM.1048)

3 - BACKUP WRENCH

VACHARGING SYSTEM 8F - 23

Page 920 of 2305

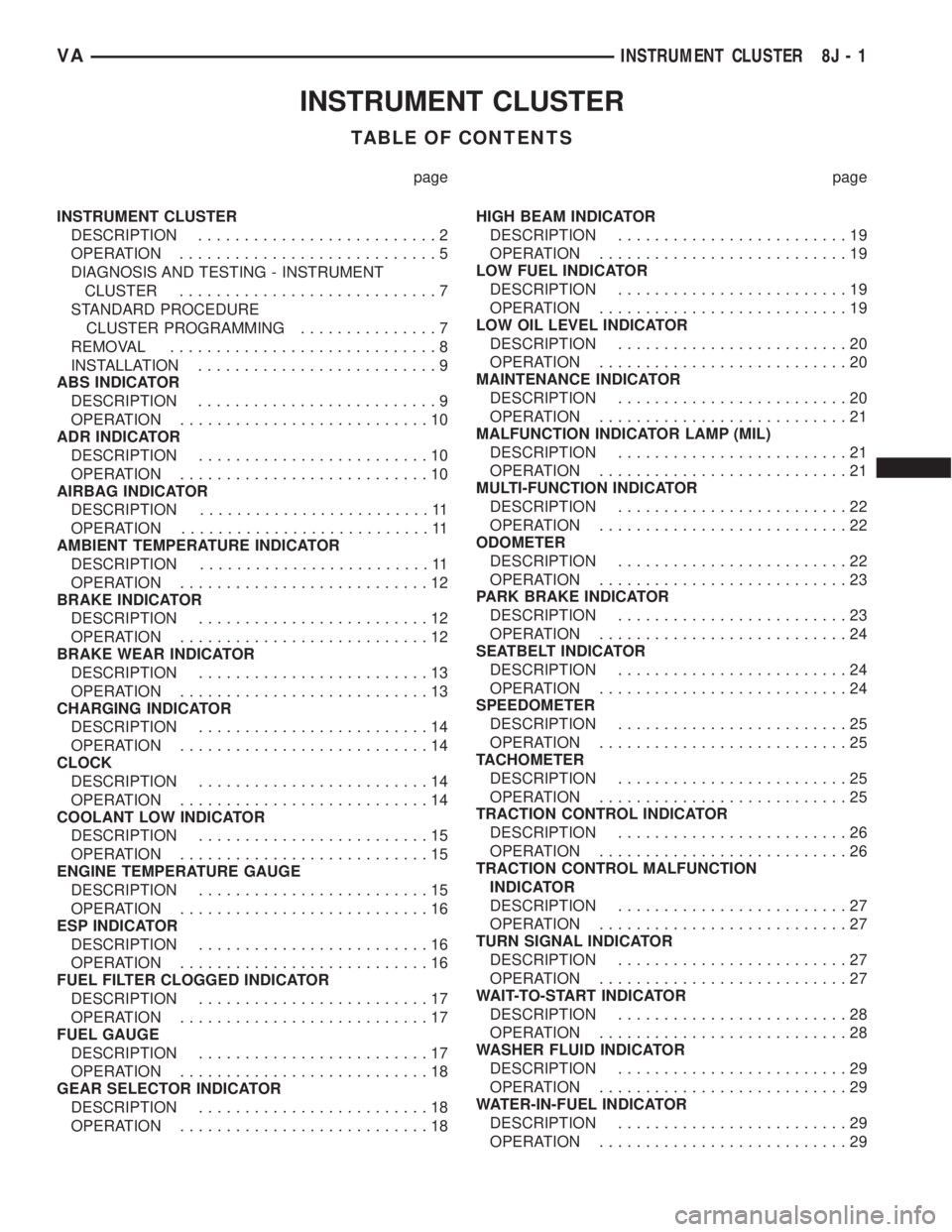

INSTRUMENT CLUSTER

TABLE OF CONTENTS

page page

INSTRUMENT CLUSTER

DESCRIPTION..........................2

OPERATION............................5

DIAGNOSIS AND TESTING - INSTRUMENT

CLUSTER............................7

STANDARD PROCEDURE

CLUSTER PROGRAMMING...............7

REMOVAL.............................8

INSTALLATION..........................9

ABS INDICATOR

DESCRIPTION..........................9

OPERATION...........................10

ADR INDICATOR

DESCRIPTION.........................10

OPERATION...........................10

AIRBAG INDICATOR

DESCRIPTION.........................11

OPERATION...........................11

AMBIENT TEMPERATURE INDICATOR

DESCRIPTION.........................11

OPERATION...........................12

BRAKE INDICATOR

DESCRIPTION.........................12

OPERATION...........................12

BRAKE WEAR INDICATOR

DESCRIPTION.........................13

OPERATION...........................13

CHARGING INDICATOR

DESCRIPTION.........................14

OPERATION...........................14

CLOCK

DESCRIPTION.........................14

OPERATION...........................14

COOLANT LOW INDICATOR

DESCRIPTION.........................15

OPERATION...........................15

ENGINE TEMPERATURE GAUGE

DESCRIPTION.........................15

OPERATION...........................16

ESP INDICATOR

DESCRIPTION.........................16

OPERATION...........................16

FUEL FILTER CLOGGED INDICATOR

DESCRIPTION.........................17

OPERATION...........................17

FUEL GAUGE

DESCRIPTION.........................17

OPERATION...........................18

GEAR SELECTOR INDICATOR

DESCRIPTION.........................18

OPERATION...........................18HIGH BEAM INDICATOR

DESCRIPTION.........................19

OPERATION...........................19

LOW FUEL INDICATOR

DESCRIPTION.........................19

OPERATION...........................19

LOW OIL LEVEL INDICATOR

DESCRIPTION.........................20

OPERATION...........................20

MAINTENANCE INDICATOR

DESCRIPTION.........................20

OPERATION...........................21

MALFUNCTION INDICATOR LAMP (MIL)

DESCRIPTION.........................21

OPERATION...........................21

MULTI-FUNCTION INDICATOR

DESCRIPTION.........................22

OPERATION...........................22

ODOMETER

DESCRIPTION.........................22

OPERATION...........................23

PARK BRAKE INDICATOR

DESCRIPTION.........................23

OPERATION...........................24

SEATBELT INDICATOR

DESCRIPTION.........................24

OPERATION...........................24

SPEEDOMETER

DESCRIPTION.........................25

OPERATION...........................25

TACHOMETER

DESCRIPTION.........................25

OPERATION...........................25

TRACTION CONTROL INDICATOR

DESCRIPTION.........................26

OPERATION...........................26

TRACTION CONTROL MALFUNCTION

INDICATOR

DESCRIPTION.........................27

OPERATION...........................27

TURN SIGNAL INDICATOR

DESCRIPTION.........................27

OPERATION...........................27

WAIT-TO-START INDICATOR

DESCRIPTION.........................28

OPERATION...........................28

WASHER FLUID INDICATOR

DESCRIPTION.........................29

OPERATION...........................29

WATER-IN-FUEL INDICATOR

DESCRIPTION.........................29

OPERATION...........................29

VAINSTRUMENT CLUSTER 8J - 1

Page 921 of 2305

INSTRUMENT CLUSTER

DESCRIPTION

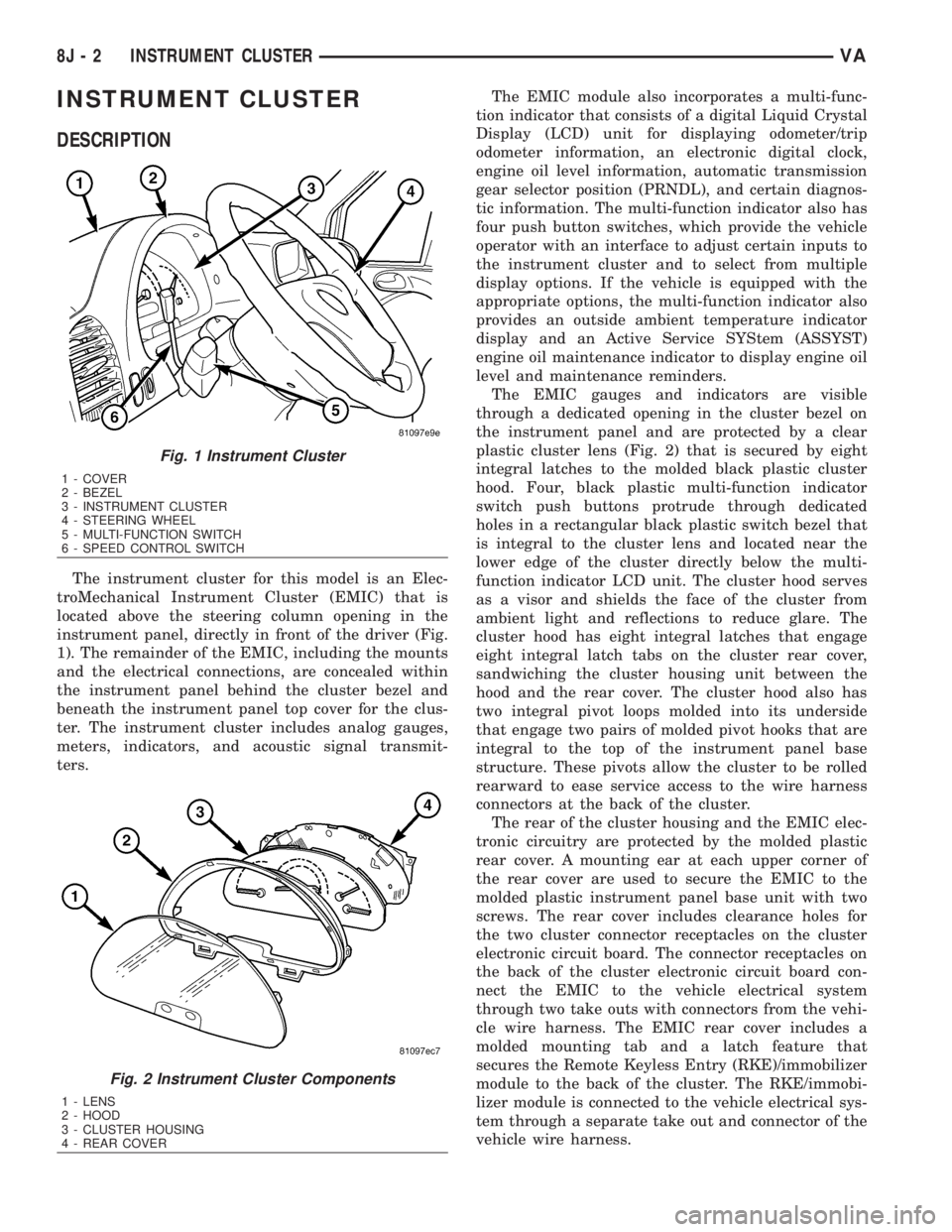

The instrument cluster for this model is an Elec-

troMechanical Instrument Cluster (EMIC) that is

located above the steering column opening in the

instrument panel, directly in front of the driver (Fig.

1). The remainder of the EMIC, including the mounts

and the electrical connections, are concealed within

the instrument panel behind the cluster bezel and

beneath the instrument panel top cover for the clus-

ter. The instrument cluster includes analog gauges,

meters, indicators, and acoustic signal transmit-

ters.The EMIC module also incorporates a multi-func-

tion indicator that consists of a digital Liquid Crystal

Display (LCD) unit for displaying odometer/trip

odometer information, an electronic digital clock,

engine oil level information, automatic transmission

gear selector position (PRNDL), and certain diagnos-

tic information. The multi-function indicator also has

four push button switches, which provide the vehicle

operator with an interface to adjust certain inputs to

the instrument cluster and to select from multiple

display options. If the vehicle is equipped with the

appropriate options, the multi-function indicator also

provides an outside ambient temperature indicator

display and an Active Service SYStem (ASSYST)

engine oil maintenance indicator to display engine oil

level and maintenance reminders.

The EMIC gauges and indicators are visible

through a dedicated opening in the cluster bezel on

the instrument panel and are protected by a clear

plastic cluster lens (Fig. 2) that is secured by eight

integral latches to the molded black plastic cluster

hood. Four, black plastic multi-function indicator

switch push buttons protrude through dedicated

holes in a rectangular black plastic switch bezel that

is integral to the cluster lens and located near the

lower edge of the cluster directly below the multi-

function indicator LCD unit. The cluster hood serves

as a visor and shields the face of the cluster from

ambient light and reflections to reduce glare. The

cluster hood has eight integral latches that engage

eight integral latch tabs on the cluster rear cover,

sandwiching the cluster housing unit between the

hood and the rear cover. The cluster hood also has

two integral pivot loops molded into its underside

that engage two pairs of molded pivot hooks that are

integral to the top of the instrument panel base

structure. These pivots allow the cluster to be rolled

rearward to ease service access to the wire harness

connectors at the back of the cluster.

The rear of the cluster housing and the EMIC elec-

tronic circuitry are protected by the molded plastic

rear cover. A mounting ear at each upper corner of

the rear cover are used to secure the EMIC to the

molded plastic instrument panel base unit with two

screws. The rear cover includes clearance holes for

the two cluster connector receptacles on the cluster

electronic circuit board. The connector receptacles on

the back of the cluster electronic circuit board con-

nect the EMIC to the vehicle electrical system

through two take outs with connectors from the vehi-

cle wire harness. The EMIC rear cover includes a

molded mounting tab and a latch feature that

secures the Remote Keyless Entry (RKE)/immobilizer

module to the back of the cluster. The RKE/immobi-

lizer module is connected to the vehicle electrical sys-

tem through a separate take out and connector of the

vehicle wire harness.

Fig. 1 Instrument Cluster

1 - COVER

2 - BEZEL

3 - INSTRUMENT CLUSTER

4 - STEERING WHEEL

5 - MULTI-FUNCTION SWITCH

6 - SPEED CONTROL SWITCH

Fig. 2 Instrument Cluster Components

1 - LENS

2 - HOOD

3 - CLUSTER HOUSING

4 - REAR COVER

8J - 2 INSTRUMENT CLUSTERVA

Page 923 of 2305

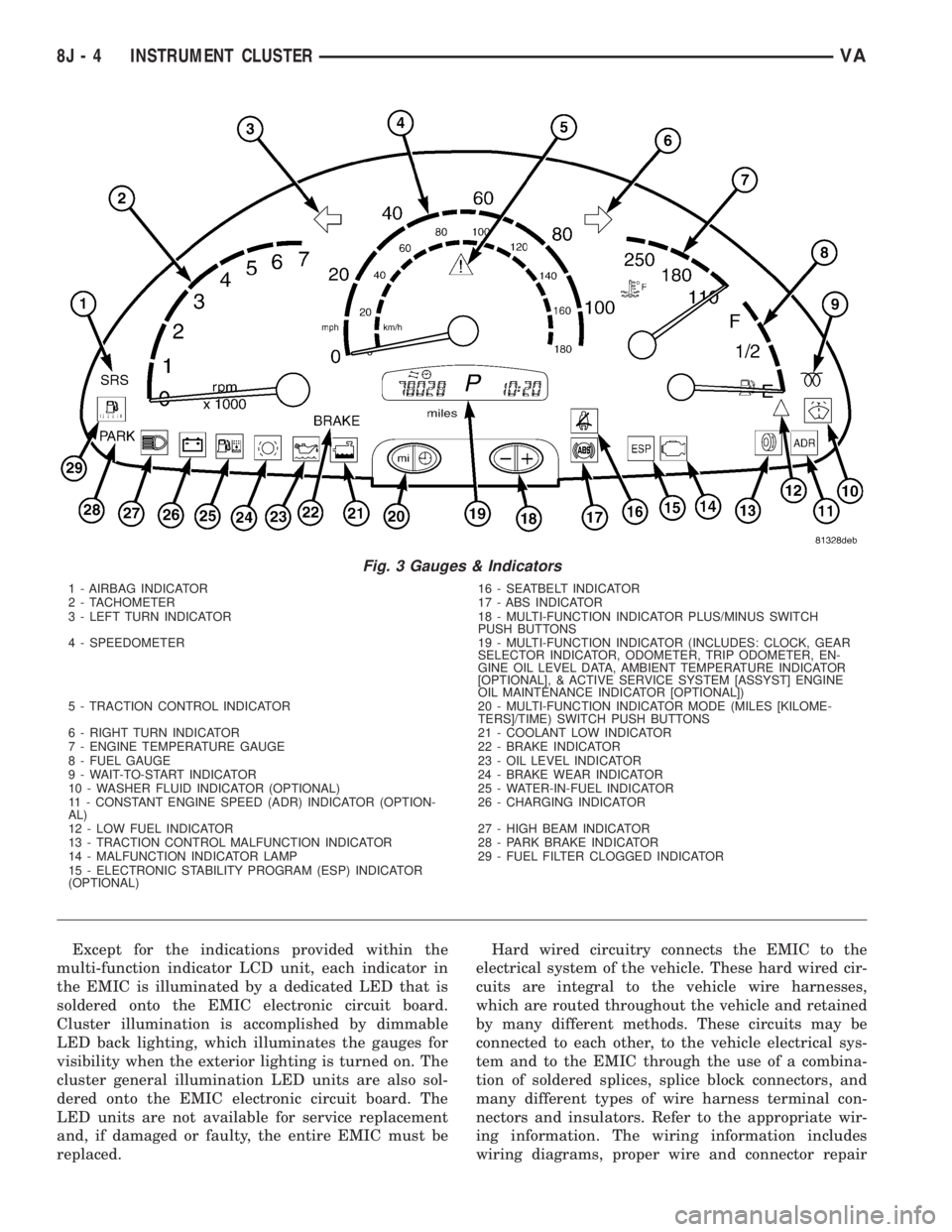

Except for the indications provided within the

multi-function indicator LCD unit, each indicator in

the EMIC is illuminated by a dedicated LED that is

soldered onto the EMIC electronic circuit board.

Cluster illumination is accomplished by dimmable

LED back lighting, which illuminates the gauges for

visibility when the exterior lighting is turned on. The

cluster general illumination LED units are also sol-

dered onto the EMIC electronic circuit board. The

LED units are not available for service replacement

and, if damaged or faulty, the entire EMIC must be

replaced.Hard wired circuitry connects the EMIC to the

electrical system of the vehicle. These hard wired cir-

cuits are integral to the vehicle wire harnesses,

which are routed throughout the vehicle and retained

by many different methods. These circuits may be

connected to each other, to the vehicle electrical sys-

tem and to the EMIC through the use of a combina-

tion of soldered splices, splice block connectors, and

many different types of wire harness terminal con-

nectors and insulators. Refer to the appropriate wir-

ing information. The wiring information includes

wiring diagrams, proper wire and connector repair

Fig. 3 Gauges & Indicators

1 - AIRBAG INDICATOR 16 - SEATBELT INDICATOR

2 - TACHOMETER 17 - ABS INDICATOR

3 - LEFT TURN INDICATOR 18 - MULTI-FUNCTION INDICATOR PLUS/MINUS SWITCH

PUSH BUTTONS

4 - SPEEDOMETER 19 - MULTI-FUNCTION INDICATOR (INCLUDES: CLOCK, GEAR

SELECTOR INDICATOR, ODOMETER, TRIP ODOMETER, EN-

GINE OIL LEVEL DATA, AMBIENT TEMPERATURE INDICATOR

[OPTIONAL], & ACTIVE SERVICE SYSTEM [ASSYST] ENGINE

OIL MAINTENANCE INDICATOR [OPTIONAL])

5 - TRACTION CONTROL INDICATOR 20 - MULTI-FUNCTION INDICATOR MODE (MILES [KILOME-

TERS]/TIME) SWITCH PUSH BUTTONS

6 - RIGHT TURN INDICATOR 21 - COOLANT LOW INDICATOR

7 - ENGINE TEMPERATURE GAUGE 22 - BRAKE INDICATOR

8 - FUEL GAUGE 23 - OIL LEVEL INDICATOR

9 - WAIT-TO-START INDICATOR 24 - BRAKE WEAR INDICATOR

10 - WASHER FLUID INDICATOR (OPTIONAL) 25 - WATER-IN-FUEL INDICATOR

11 - CONSTANT ENGINE SPEED (ADR) INDICATOR (OPTION-

AL)26 - CHARGING INDICATOR

12 - LOW FUEL INDICATOR 27 - HIGH BEAM INDICATOR

13 - TRACTION CONTROL MALFUNCTION INDICATOR 28 - PARK BRAKE INDICATOR

14 - MALFUNCTION INDICATOR LAMP 29 - FUEL FILTER CLOGGED INDICATOR

15 - ELECTRONIC STABILITY PROGRAM (ESP) INDICATOR

(OPTIONAL)

8J - 4 INSTRUMENT CLUSTERVA