MERCEDES-BENZ SPRINTER 2006 Service Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 831 of 2305

CONDITION POSSIBLE CAUSES CORRECTION

INADEQUATE HEATER PERFOR-

MANCE. GUAGE MAY OR MAY

NOT READ LOW.1. Heavy duty cooling system, and

cooler ambient temperatures.1. None. Normal condition.

2. Obstruction in heater hoses. 2. Remove hoses, remove obstruc-

tion.

3. Water pump damaged. 3. Replace water pump.

HEAT ODOR 1. Damaged or missing drive line

heat shields.1. Repair or replace damaged or

missing heat shields.

2. Thermal viscous fan drive dam-

aged.2. Check thermal viscous fan drive.

(Refer to 7 - COOLING/ENGINE/

FAN DRIVE VISCOUS CLUTCH -

DIAGNOSIS AND TESTING)

7 - 4 COOLINGVA

Page 832 of 2305

ACCESSORY DRIVE

TABLE OF CONTENTS

page page

BELT TENSIONERS

DESCRIPTION..........................5

OPERATION............................5

DRIVE BELTS

DIAGNOSIS AND TESTING - ACCESSORY

DRIVE BELT..........................5REMOVAL

REMOVAL............................8

REMOVAL............................8

INSTALLATION

INSTALLATION........................8

INSTALLATION........................8

BELT TENSIONERS

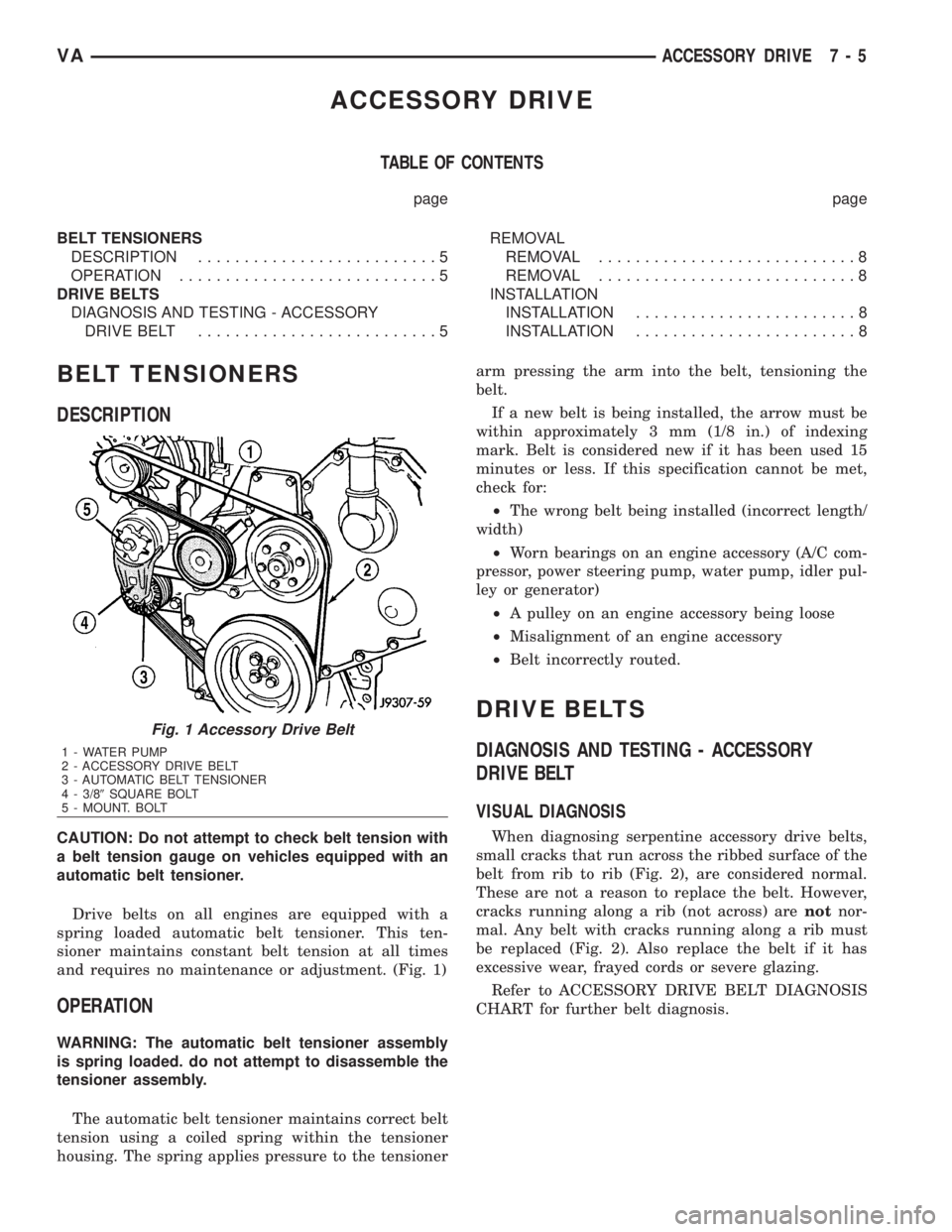

DESCRIPTION

CAUTION: Do not attempt to check belt tension with

a belt tension gauge on vehicles equipped with an

automatic belt tensioner.

Drive belts on all engines are equipped with a

spring loaded automatic belt tensioner. This ten-

sioner maintains constant belt tension at all times

and requires no maintenance or adjustment. (Fig. 1)

OPERATION

WARNING: The automatic belt tensioner assembly

is spring loaded. do not attempt to disassemble the

tensioner assembly.

The automatic belt tensioner maintains correct belt

tension using a coiled spring within the tensioner

housing. The spring applies pressure to the tensionerarm pressing the arm into the belt, tensioning the

belt.

If a new belt is being installed, the arrow must be

within approximately 3 mm (1/8 in.) of indexing

mark. Belt is considered new if it has been used 15

minutes or less. If this specification cannot be met,

check for:

²The wrong belt being installed (incorrect length/

width)

²Worn bearings on an engine accessory (A/C com-

pressor, power steering pump, water pump, idler pul-

ley or generator)

²A pulley on an engine accessory being loose

²Misalignment of an engine accessory

²Belt incorrectly routed.

DRIVE BELTS

DIAGNOSIS AND TESTING - ACCESSORY

DRIVE BELT

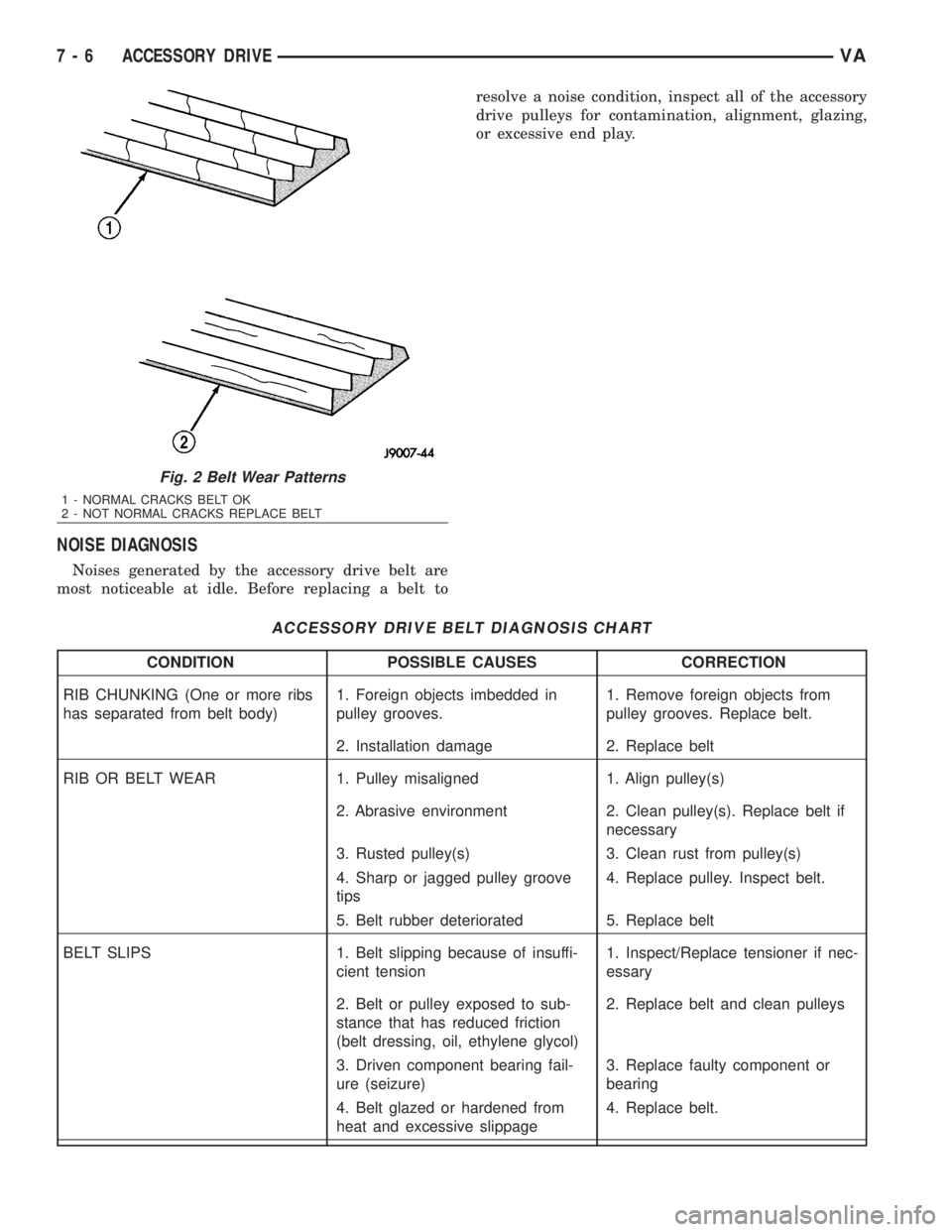

VISUAL DIAGNOSIS

When diagnosing serpentine accessory drive belts,

small cracks that run across the ribbed surface of the

belt from rib to rib (Fig. 2), are considered normal.

These are not a reason to replace the belt. However,

cracks running along a rib (not across) arenotnor-

mal. Any belt with cracks running along a rib must

be replaced (Fig. 2). Also replace the belt if it has

excessive wear, frayed cords or severe glazing.

Refer to ACCESSORY DRIVE BELT DIAGNOSIS

CHART for further belt diagnosis.

Fig. 1 Accessory Drive Belt

1 - WATER PUMP

2 - ACCESSORY DRIVE BELT

3 - AUTOMATIC BELT TENSIONER

4 - 3/89SQUARE BOLT

5 - MOUNT. BOLT

VAACCESSORY DRIVE 7 - 5

Page 833 of 2305

NOISE DIAGNOSIS

Noises generated by the accessory drive belt are

most noticeable at idle. Before replacing a belt toresolve a noise condition, inspect all of the accessory

drive pulleys for contamination, alignment, glazing,

or excessive end play.

ACCESSORY DRIVE BELT DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

RIB CHUNKING (One or more ribs

has separated from belt body)1. Foreign objects imbedded in

pulley grooves.1. Remove foreign objects from

pulley grooves. Replace belt.

2. Installation damage 2. Replace belt

RIB OR BELT WEAR 1. Pulley misaligned 1. Align pulley(s)

2. Abrasive environment 2. Clean pulley(s). Replace belt if

necessary

3. Rusted pulley(s) 3. Clean rust from pulley(s)

4. Sharp or jagged pulley groove

tips4. Replace pulley. Inspect belt.

5. Belt rubber deteriorated 5. Replace belt

BELT SLIPS 1. Belt slipping because of insuffi-

cient tension1. Inspect/Replace tensioner if nec-

essary

2. Belt or pulley exposed to sub-

stance that has reduced friction

(belt dressing, oil, ethylene glycol)2. Replace belt and clean pulleys

3. Driven component bearing fail-

ure (seizure)3. Replace faulty component or

bearing

4. Belt glazed or hardened from

heat and excessive slippage4. Replace belt.

Fig. 2 Belt Wear Patterns

1 - NORMAL CRACKS BELT OK

2 - NOT NORMAL CRACKS REPLACE BELT

7 - 6 ACCESSORY DRIVEVA

Page 834 of 2305

CONDITION POSSIBLE CAUSES CORRECTION

LONGITUDAL BELT CRACKING 1. Belt has mistracked from pulley

groove1. Replace belt

2. Pulley groove tip has worn

away rubber to tensile member2. Replace belt

9GROOVE JUMPINGº

(Belt does not maintain correct po-

sition on pulley)1. Incorrect belt tension 1. Inspect/Replace tensioner if nec-

essary

2. Pulley(s) not within design toler-

ance2. Replace pulley(s)

3. Foreign object(s) in grooves 3. Remove foreign objects from

grooves

4. Pulley misalignment 4. Align component

5. Belt cordline is broken 5. Replace belt

BELT BROKEN

(Note: Identify and correct problem

before new belt is installed)1. Incorrect belt tension 1. Replace Inspect/Replace ten-

sioner if necessary

2. Tensile member damaged dur-

ing belt installation2. Replace belt

3. Severe misalignment 3. Align pulley(s)

4. Bracket, pulley, or bearing fail-

ure4. Replace defective component

and belt

NOISE (Objectional squeal,

squeek, or rumble is heard or felt

while drive belt is in operation)1. Incorrect belt tension 1. Inspect/Replace tensioner if nec-

essary

2. Bearing noise 2. Locate and repair

3. Belt misalignment 3. Align belt/pulley(s)

4. Belt to pulley mismatch 4. Install correct belt

5. Driven component induced vi-

bration5. Locate defective driven compo-

nent and repair

6. System resonent frequency in-

duced vibration6. Vary belt tension within specifi-

cations

TENSION SHEETING FABRIC

FAILURE

(Woven fabric on outside, circum-

ference of belt has cracked or sep-

arated from body of belt)1. Tension sheeting contacting sta-

tionary object1. Correct rubbing condition

2. Excessive heat causing woven

fabric to age2. Replace belt

3. Tension sheeting splice has

fractured3. Replace belt

CORD EDGE FAILURE

(Tensile member exposed at edges

of belt or separated from belt body)1. Incorrect belt tension 1. Inspect/Replace tensioner if nec-

essary

2. Belt contacting stationary object 2. Replace belt

3. Pulley(s) out of tolerance 3. Replace pulley

4. Insufficient adhesion between

tensile member and rubber matrix4. Replace belt

VAACCESSORY DRIVE 7 - 7

Page 835 of 2305

REMOVAL

REMOVAL

CAUTION: Do not attempt to check belt tension with

a belt tension gauge on vehicles equipped with an

automatic belt tensioner.

NOTE: The belt routing schematics are published

from the latest information available at the time of

publication. If anything differs between these sche-

matics and the Belt Routing Label, use the sche-

matics on Belt Routing Label.This label is located in

the engine compartment.

(1) Remove A/C compressor drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

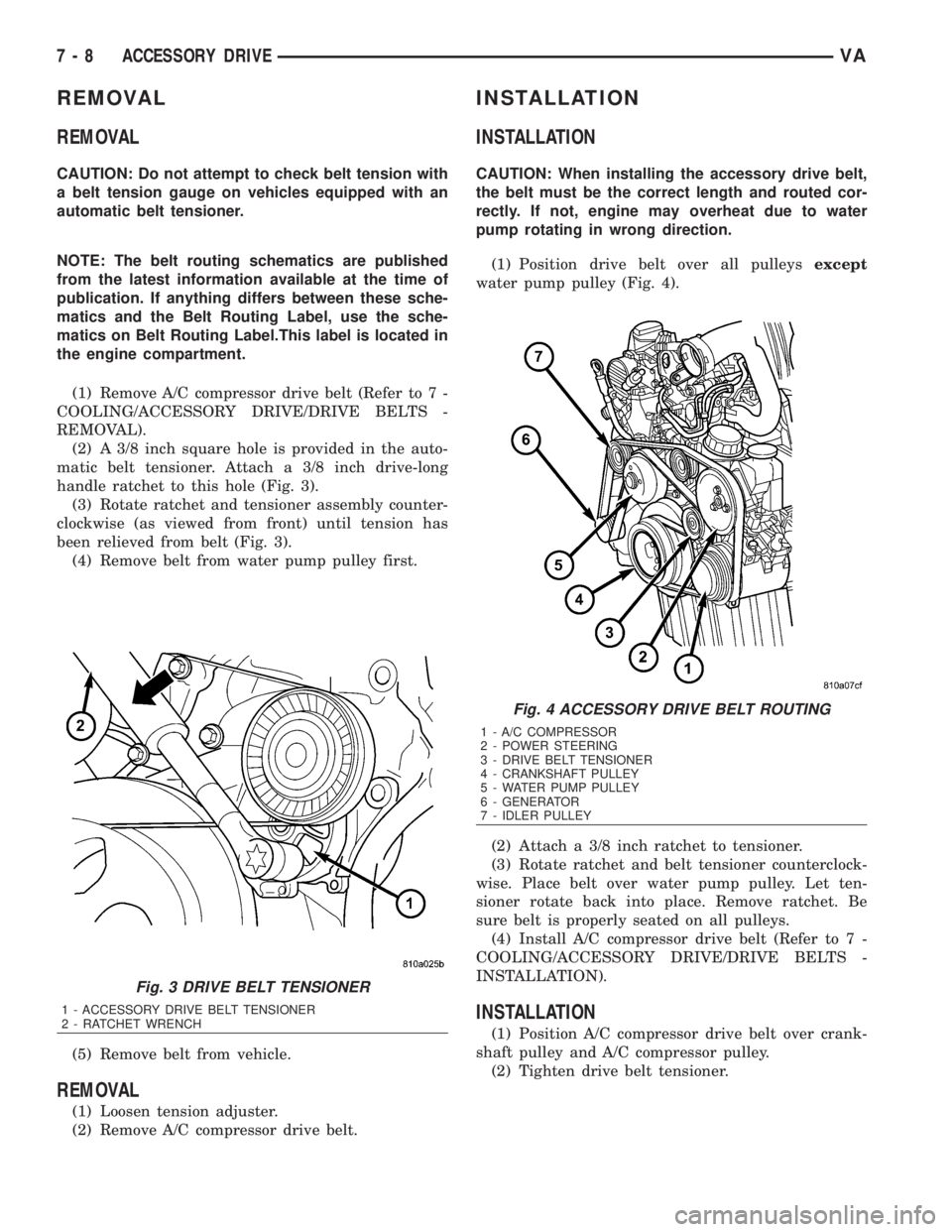

(2) A 3/8 inch square hole is provided in the auto-

matic belt tensioner. Attach a 3/8 inch drive-long

handle ratchet to this hole (Fig. 3).

(3) Rotate ratchet and tensioner assembly counter-

clockwise (as viewed from front) until tension has

been relieved from belt (Fig. 3).

(4) Remove belt from water pump pulley first.

(5) Remove belt from vehicle.

REMOVAL

(1) Loosen tension adjuster.

(2) Remove A/C compressor drive belt.

INSTALLATION

INSTALLATION

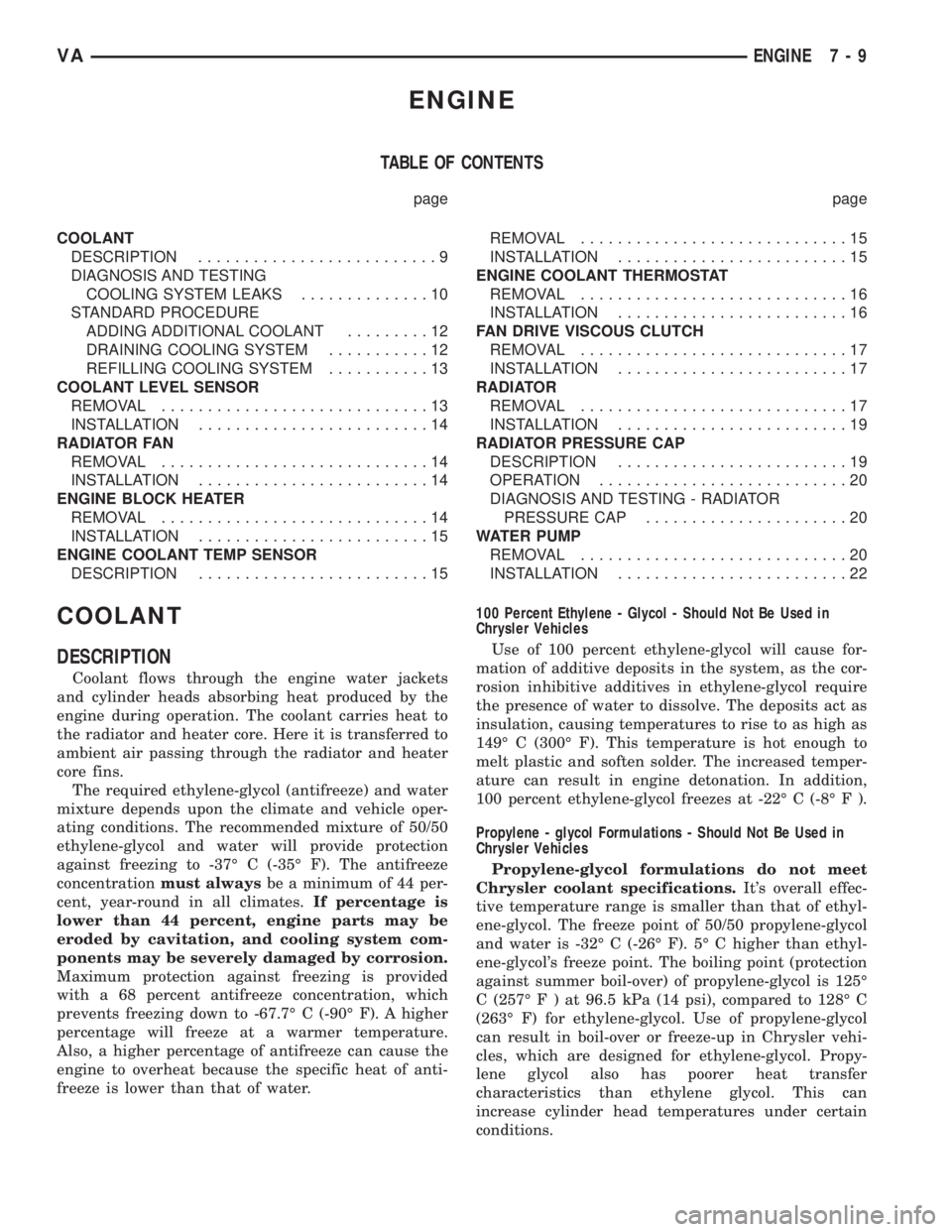

CAUTION: When installing the accessory drive belt,

the belt must be the correct length and routed cor-

rectly. If not, engine may overheat due to water

pump rotating in wrong direction.

(1) Position drive belt over all pulleysexcept

water pump pulley (Fig. 4).

(2) Attach a 3/8 inch ratchet to tensioner.

(3) Rotate ratchet and belt tensioner counterclock-

wise. Place belt over water pump pulley. Let ten-

sioner rotate back into place. Remove ratchet. Be

sure belt is properly seated on all pulleys.

(4) Install A/C compressor drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

INSTALLATION

(1) Position A/C compressor drive belt over crank-

shaft pulley and A/C compressor pulley.

(2) Tighten drive belt tensioner.

Fig. 3 DRIVE BELT TENSIONER

1 - ACCESSORY DRIVE BELT TENSIONER

2 - RATCHET WRENCH

Fig. 4 ACCESSORY DRIVE BELT ROUTING

1 - A/C COMPRESSOR

2 - POWER STEERING

3 - DRIVE BELT TENSIONER

4 - CRANKSHAFT PULLEY

5 - WATER PUMP PULLEY

6 - GENERATOR

7 - IDLER PULLEY

7 - 8 ACCESSORY DRIVEVA

Page 836 of 2305

ENGINE

TABLE OF CONTENTS

page page

COOLANT

DESCRIPTION..........................9

DIAGNOSIS AND TESTING

COOLING SYSTEM LEAKS..............10

STANDARD PROCEDURE

ADDING ADDITIONAL COOLANT.........12

DRAINING COOLING SYSTEM...........12

REFILLING COOLING SYSTEM...........13

COOLANT LEVEL SENSOR

REMOVAL.............................13

INSTALLATION.........................14

RADIATOR FAN

REMOVAL.............................14

INSTALLATION.........................14

ENGINE BLOCK HEATER

REMOVAL.............................14

INSTALLATION.........................15

ENGINE COOLANT TEMP SENSOR

DESCRIPTION.........................15REMOVAL.............................15

INSTALLATION.........................15

ENGINE COOLANT THERMOSTAT

REMOVAL.............................16

INSTALLATION.........................16

FAN DRIVE VISCOUS CLUTCH

REMOVAL.............................17

INSTALLATION.........................17

RADIATOR

REMOVAL.............................17

INSTALLATION.........................19

RADIATOR PRESSURE CAP

DESCRIPTION.........................19

OPERATION...........................20

DIAGNOSIS AND TESTING - RADIATOR

PRESSURE CAP......................20

WATER PUMP

REMOVAL.............................20

INSTALLATION.........................22

COOLANT

DESCRIPTION

Coolant flows through the engine water jackets

and cylinder heads absorbing heat produced by the

engine during operation. The coolant carries heat to

the radiator and heater core. Here it is transferred to

ambient air passing through the radiator and heater

core fins.

The required ethylene-glycol (antifreeze) and water

mixture depends upon the climate and vehicle oper-

ating conditions. The recommended mixture of 50/50

ethylene-glycol and water will provide protection

against freezing to -37É C (-35É F). The antifreeze

concentrationmust alwaysbe a minimum of 44 per-

cent, year-round in all climates.If percentage is

lower than 44 percent, engine parts may be

eroded by cavitation, and cooling system com-

ponents may be severely damaged by corrosion.

Maximum protection against freezing is provided

with a 68 percent antifreeze concentration, which

prevents freezing down to -67.7É C (-90É F). A higher

percentage will freeze at a warmer temperature.

Also, a higher percentage of antifreeze can cause the

engine to overheat because the specific heat of anti-

freeze is lower than that of water.100 Percent Ethylene - Glycol - Should Not Be Used in

Chrysler Vehicles

Use of 100 percent ethylene-glycol will cause for-

mation of additive deposits in the system, as the cor-

rosion inhibitive additives in ethylene-glycol require

the presence of water to dissolve. The deposits act as

insulation, causing temperatures to rise to as high as

149É C (300É F). This temperature is hot enough to

melt plastic and soften solder. The increased temper-

ature can result in engine detonation. In addition,

100 percent ethylene-glycol freezes at -22É C (-8É F ).

Propylene - glycol Formulations - Should Not Be Used in

Chrysler Vehicles

Propylene-glycol formulations do not meet

Chrysler coolant specifications.It's overall effec-

tive temperature range is smaller than that of ethyl-

ene-glycol. The freeze point of 50/50 propylene-glycol

and water is -32É C (-26É F). 5É C higher than ethyl-

ene-glycol's freeze point. The boiling point (protection

against summer boil-over) of propylene-glycol is 125É

C (257ÉF)at96.5 kPa (14 psi), compared to 128É C

(263É F) for ethylene-glycol. Use of propylene-glycol

can result in boil-over or freeze-up in Chrysler vehi-

cles, which are designed for ethylene-glycol. Propy-

lene glycol also has poorer heat transfer

characteristics than ethylene glycol. This can

increase cylinder head temperatures under certain

conditions.

VAENGINE 7 - 9

Page 837 of 2305

Propylene - glycol / Ethylene - glycol Mixtures - Should Not

Be Used in Chrysler Vehicles

Propylene-glycol/ethylene-glycol Mixtures can

cause the destabilization of various corrosion inhibi-

tors, causing damage to the various cooling system

components. Also, once ethylene-glycol and propy-

lene-glycol based coolants are mixed in the vehicle,

conventional methods of determining freeze point will

not be accurate. Both the refractive index and spe-

cific gravity differ between ethylene glycol and propy-

lene glycol.

CAUTION: Richer antifreeze mixtures cannot be

measured with normal field equipment and can

cause problems associated with 100 percent ethyl-

ene-glycol.

DIAGNOSIS AND TESTING

COOLING SYSTEM LEAKS

ULTRAVIOLET LIGHT METHOD

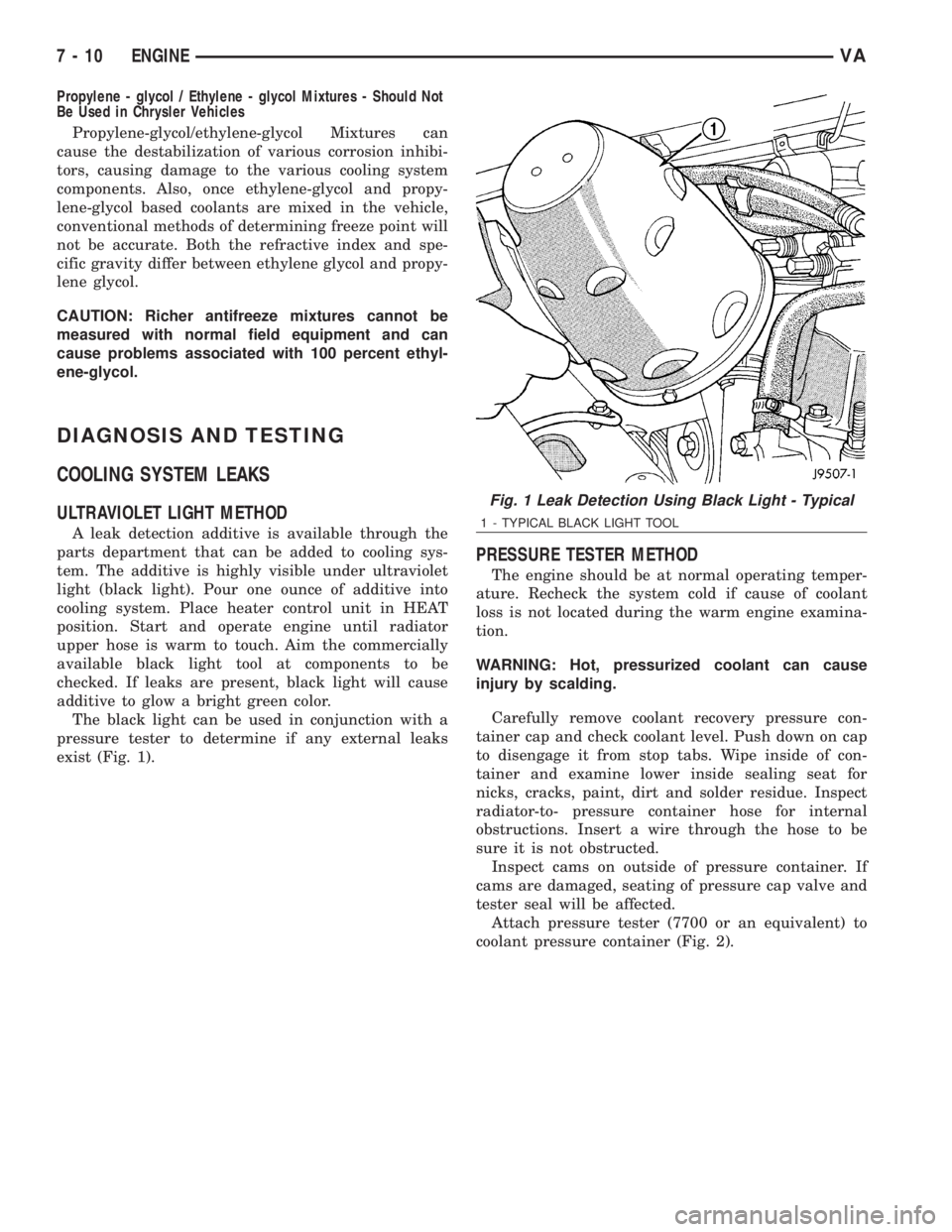

A leak detection additive is available through the

parts department that can be added to cooling sys-

tem. The additive is highly visible under ultraviolet

light (black light). Pour one ounce of additive into

cooling system. Place heater control unit in HEAT

position. Start and operate engine until radiator

upper hose is warm to touch. Aim the commercially

available black light tool at components to be

checked. If leaks are present, black light will cause

additive to glow a bright green color.

The black light can be used in conjunction with a

pressure tester to determine if any external leaks

exist (Fig. 1).

PRESSURE TESTER METHOD

The engine should be at normal operating temper-

ature. Recheck the system cold if cause of coolant

loss is not located during the warm engine examina-

tion.

WARNING: Hot, pressurized coolant can cause

injury by scalding.

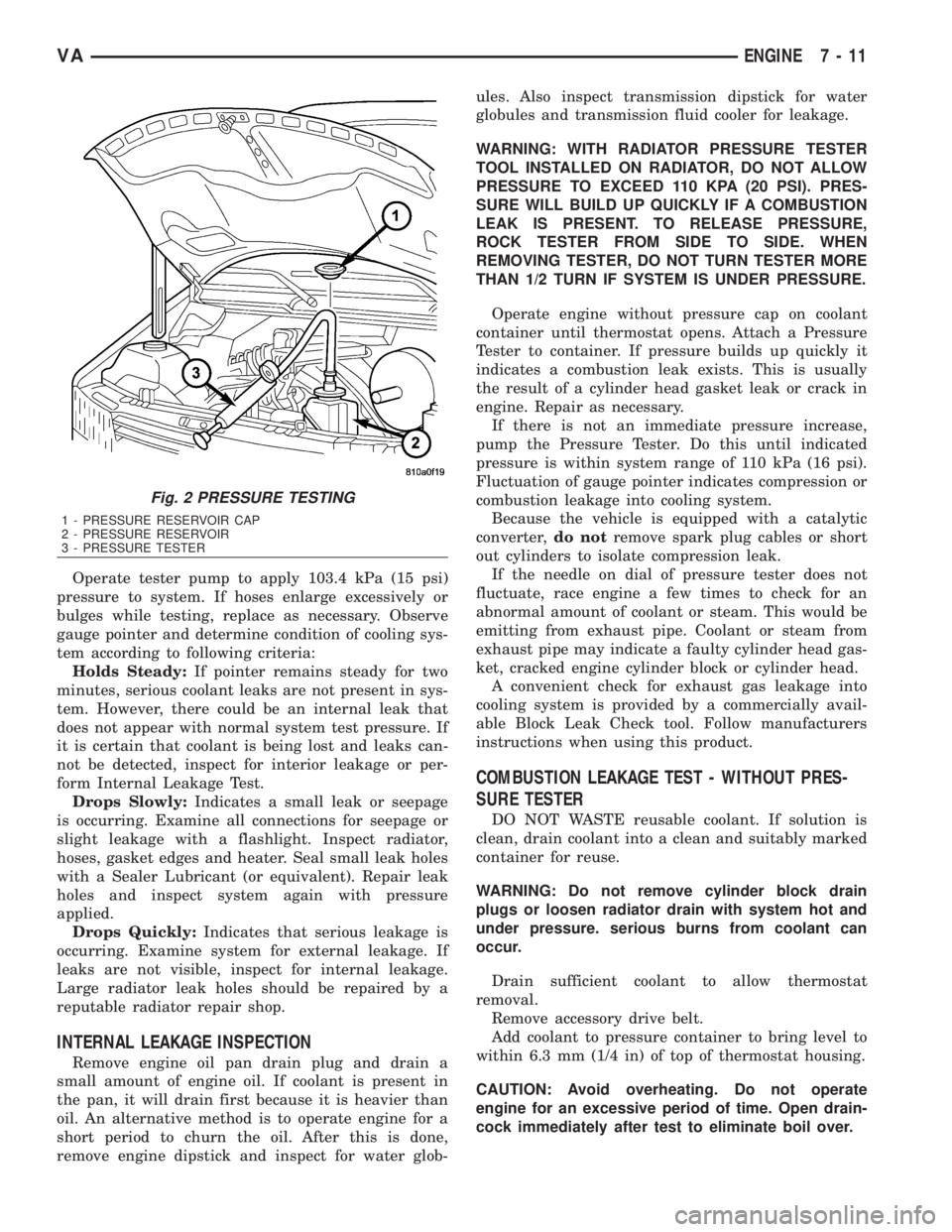

Carefully remove coolant recovery pressure con-

tainer cap and check coolant level. Push down on cap

to disengage it from stop tabs. Wipe inside of con-

tainer and examine lower inside sealing seat for

nicks, cracks, paint, dirt and solder residue. Inspect

radiator-to- pressure container hose for internal

obstructions. Insert a wire through the hose to be

sure it is not obstructed.

Inspect cams on outside of pressure container. If

cams are damaged, seating of pressure cap valve and

tester seal will be affected.

Attach pressure tester (7700 or an equivalent) to

coolant pressure container (Fig. 2).

Fig. 1 Leak Detection Using Black Light - Typical

1 - TYPICAL BLACK LIGHT TOOL

7 - 10 ENGINEVA

Page 838 of 2305

Operate tester pump to apply 103.4 kPa (15 psi)

pressure to system. If hoses enlarge excessively or

bulges while testing, replace as necessary. Observe

gauge pointer and determine condition of cooling sys-

tem according to following criteria:

Holds Steady:If pointer remains steady for two

minutes, serious coolant leaks are not present in sys-

tem. However, there could be an internal leak that

does not appear with normal system test pressure. If

it is certain that coolant is being lost and leaks can-

not be detected, inspect for interior leakage or per-

form Internal Leakage Test.

Drops Slowly:Indicates a small leak or seepage

is occurring. Examine all connections for seepage or

slight leakage with a flashlight. Inspect radiator,

hoses, gasket edges and heater. Seal small leak holes

with a Sealer Lubricant (or equivalent). Repair leak

holes and inspect system again with pressure

applied.

Drops Quickly:Indicates that serious leakage is

occurring. Examine system for external leakage. If

leaks are not visible, inspect for internal leakage.

Large radiator leak holes should be repaired by a

reputable radiator repair shop.

INTERNAL LEAKAGE INSPECTION

Remove engine oil pan drain plug and drain a

small amount of engine oil. If coolant is present in

the pan, it will drain first because it is heavier than

oil. An alternative method is to operate engine for a

short period to churn the oil. After this is done,

remove engine dipstick and inspect for water glob-ules. Also inspect transmission dipstick for water

globules and transmission fluid cooler for leakage.

WARNING: WITH RADIATOR PRESSURE TESTER

TOOL INSTALLED ON RADIATOR, DO NOT ALLOW

PRESSURE TO EXCEED 110 KPA (20 PSI). PRES-

SURE WILL BUILD UP QUICKLY IF A COMBUSTION

LEAK IS PRESENT. TO RELEASE PRESSURE,

ROCK TESTER FROM SIDE TO SIDE. WHEN

REMOVING TESTER, DO NOT TURN TESTER MORE

THAN 1/2 TURN IF SYSTEM IS UNDER PRESSURE.

Operate engine without pressure cap on coolant

container until thermostat opens. Attach a Pressure

Tester to container. If pressure builds up quickly it

indicates a combustion leak exists. This is usually

the result of a cylinder head gasket leak or crack in

engine. Repair as necessary.

If there is not an immediate pressure increase,

pump the Pressure Tester. Do this until indicated

pressure is within system range of 110 kPa (16 psi).

Fluctuation of gauge pointer indicates compression or

combustion leakage into cooling system.

Because the vehicle is equipped with a catalytic

converter,do notremove spark plug cables or short

out cylinders to isolate compression leak.

If the needle on dial of pressure tester does not

fluctuate, race engine a few times to check for an

abnormal amount of coolant or steam. This would be

emitting from exhaust pipe. Coolant or steam from

exhaust pipe may indicate a faulty cylinder head gas-

ket, cracked engine cylinder block or cylinder head.

A convenient check for exhaust gas leakage into

cooling system is provided by a commercially avail-

able Block Leak Check tool. Follow manufacturers

instructions when using this product.

COMBUSTION LEAKAGE TEST - WITHOUT PRES-

SURE TESTER

DO NOT WASTE reusable coolant. If solution is

clean, drain coolant into a clean and suitably marked

container for reuse.

WARNING: Do not remove cylinder block drain

plugs or loosen radiator drain with system hot and

under pressure. serious burns from coolant can

occur.

Drain sufficient coolant to allow thermostat

removal.

Remove accessory drive belt.

Add coolant to pressure container to bring level to

within 6.3 mm (1/4 in) of top of thermostat housing.

CAUTION: Avoid overheating. Do not operate

engine for an excessive period of time. Open drain-

cock immediately after test to eliminate boil over.

Fig. 2 PRESSURE TESTING

1 - PRESSURE RESERVOIR CAP

2 - PRESSURE RESERVOIR

3 - PRESSURE TESTER

VAENGINE 7 - 11

Page 839 of 2305

Start engine and accelerate rapidly three times, to

approximately 3000 rpm while observing coolant. If

internal engine combustion gases are leaking into

cooling system, bubbles will appear in coolant. If bub-

bles do not appear, internal combustion gas leakage

is not present.

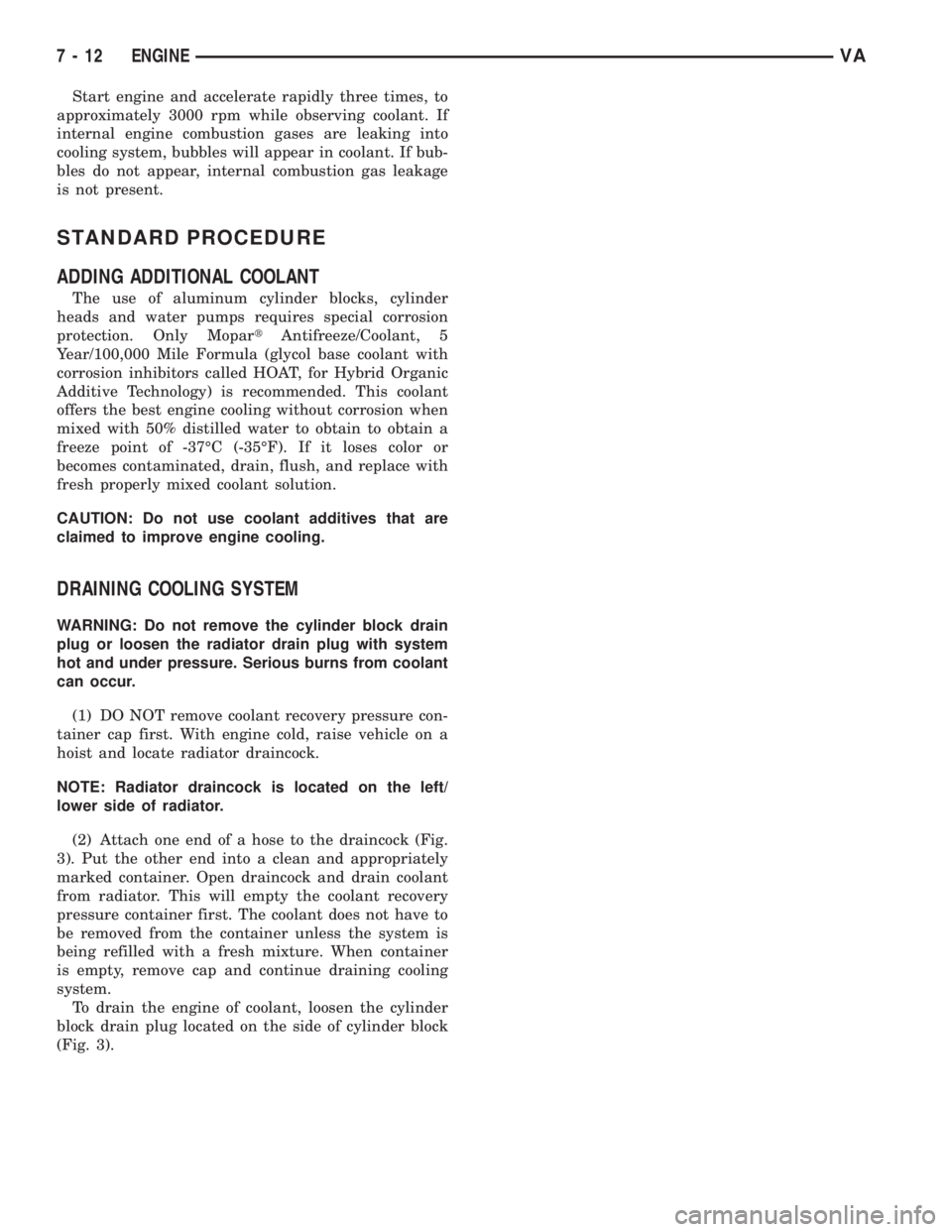

STANDARD PROCEDURE

ADDING ADDITIONAL COOLANT

The use of aluminum cylinder blocks, cylinder

heads and water pumps requires special corrosion

protection. Only MopartAntifreeze/Coolant, 5

Year/100,000 Mile Formula (glycol base coolant with

corrosion inhibitors called HOAT, for Hybrid Organic

Additive Technology) is recommended. This coolant

offers the best engine cooling without corrosion when

mixed with 50% distilled water to obtain to obtain a

freeze point of -37ÉC (-35ÉF). If it loses color or

becomes contaminated, drain, flush, and replace with

fresh properly mixed coolant solution.

CAUTION: Do not use coolant additives that are

claimed to improve engine cooling.

DRAINING COOLING SYSTEM

WARNING: Do not remove the cylinder block drain

plug or loosen the radiator drain plug with system

hot and under pressure. Serious burns from coolant

can occur.

(1) DO NOT remove coolant recovery pressure con-

tainer cap first. With engine cold, raise vehicle on a

hoist and locate radiator draincock.

NOTE: Radiator draincock is located on the left/

lower side of radiator.

(2) Attach one end of a hose to the draincock (Fig.

3). Put the other end into a clean and appropriately

marked container. Open draincock and drain coolant

from radiator. This will empty the coolant recovery

pressure container first. The coolant does not have to

be removed from the container unless the system is

being refilled with a fresh mixture. When container

is empty, remove cap and continue draining cooling

system.

To drain the engine of coolant, loosen the cylinder

block drain plug located on the side of cylinder block

(Fig. 3).

7 - 12 ENGINEVA

Page 840 of 2305

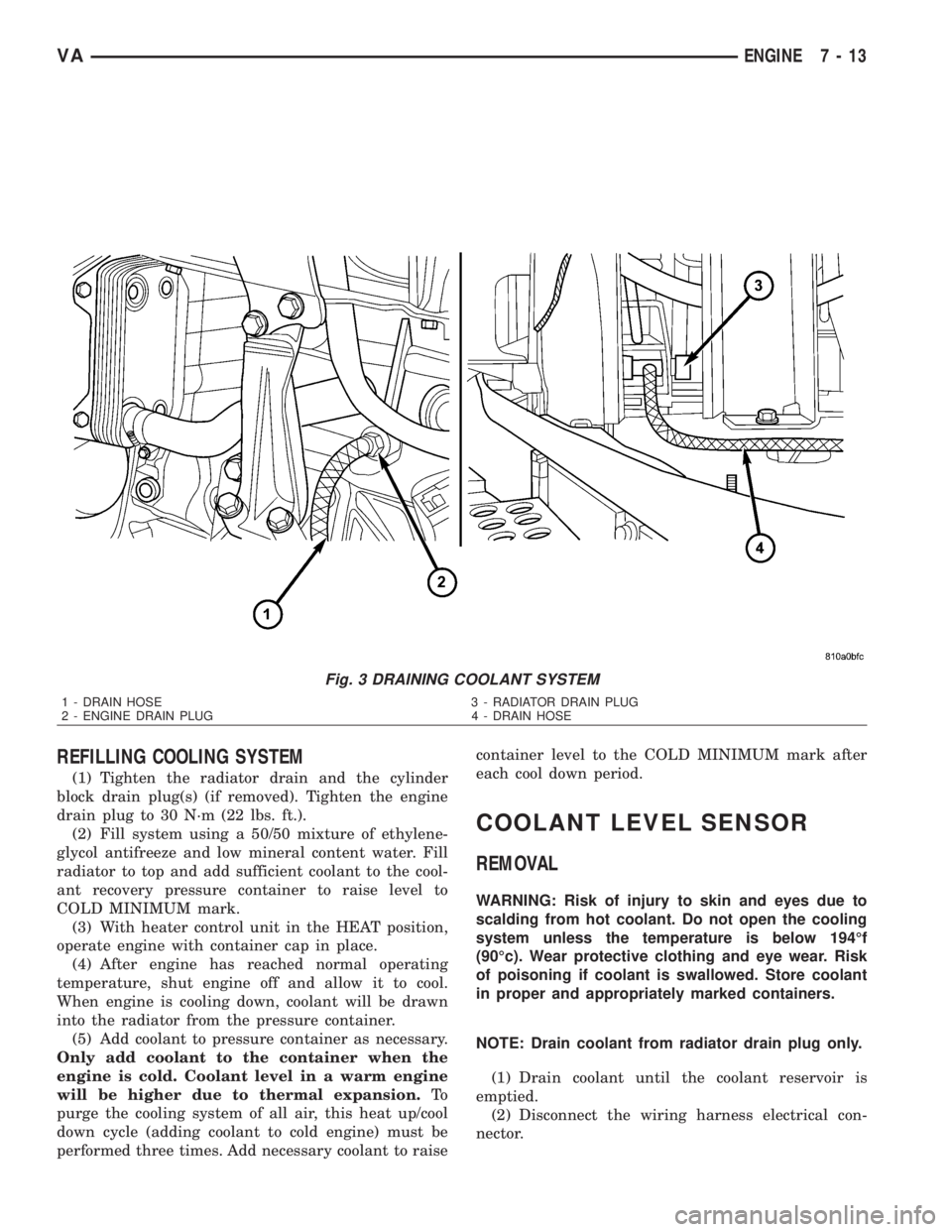

REFILLING COOLING SYSTEM

(1) Tighten the radiator drain and the cylinder

block drain plug(s) (if removed). Tighten the engine

drain plug to 30 N´m (22 lbs. ft.).

(2) Fill system using a 50/50 mixture of ethylene-

glycol antifreeze and low mineral content water. Fill

radiator to top and add sufficient coolant to the cool-

ant recovery pressure container to raise level to

COLD MINIMUM mark.

(3) With heater control unit in the HEAT position,

operate engine with container cap in place.

(4) After engine has reached normal operating

temperature, shut engine off and allow it to cool.

When engine is cooling down, coolant will be drawn

into the radiator from the pressure container.

(5) Add coolant to pressure container as necessary.

Only add coolant to the container when the

engine is cold. Coolant level in a warm engine

will be higher due to thermal expansion.To

purge the cooling system of all air, this heat up/cool

down cycle (adding coolant to cold engine) must be

performed three times. Add necessary coolant to raisecontainer level to the COLD MINIMUM mark after

each cool down period.

COOLANT LEVEL SENSOR

REMOVAL

WARNING: Risk of injury to skin and eyes due to

scalding from hot coolant. Do not open the cooling

system unless the temperature is below 194Éf

(90Éc). Wear protective clothing and eye wear. Risk

of poisoning if coolant is swallowed. Store coolant

in proper and appropriately marked containers.

NOTE: Drain coolant from radiator drain plug only.

(1) Drain coolant until the coolant reservoir is

emptied.

(2) Disconnect the wiring harness electrical con-

nector.

Fig. 3 DRAINING COOLANT SYSTEM

1 - DRAIN HOSE 3 - RADIATOR DRAIN PLUG

2 - ENGINE DRAIN PLUG 4 - DRAIN HOSE

VAENGINE 7 - 13