stop start MERCEDES-BENZ SPRINTER 2013 MY13 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2013, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2013Pages: 334, PDF Size: 3.88 MB

Page 216 of 334

Problem Possible causes/consequences and

0004 Solutions

0008

The red 0008

warning lamp

does not go out

approximately

4s econds after

the ignition is

switched on, or

it lights up again. The restraint systems have malfunctioned.

G WARNING

If SRS is malfunctioning, individual systems could be triggered

inadvertently or might not be triggered at all in the event of an

accident.

There is an increased risk of injury and accidents.

X Drive on with care.

X Visit a qualified specialist workshop immediately. 0010

The red battery

indicator lamp is

lit while the

engine is

running. The battery is not being charged. Possible causes are a defective

alternator or a torn poly-V-belt.

X

Stop the vehicle as soon as possible, paying attention to road

and traffic conditions.

X Check the poly-V-belt.

X If the poly-V-belt is torn: do not continue driving. Consult the

nearest qualified specialist workshop.

X If the poly-V-belt is not damaged: have the vehicle checked as

soon as possible by a qualified specialist workshop. 0010

The red battery

indicator lamp is

lit while the

engine is

running. The battery is faulty.

X

Stop the vehicle as soon as possible, paying attention to road

and traffic conditions.

X Do not continue driving under any circumstances.

X Consult a qualified specialist workshop. 0005

The yellow brake

pad wear

indicator lamp is

lit after the

engine is started

or while the

vehicle is in

motion. The brake pads/linings have reached their wear limit.

G WARNING

Braking performance can be impaired.

There is a risk of an accident.

X Have the brake pads/linings replaced as soon as possible at a

qualified specialist workshop. 001D

The yellow

engine oil level

warning lamp is

lit after the

engine is started

or while the

vehicle is in

motion. The oil level has dropped to the minimum level.

X

Check the engine for oil loss.

X If oil loss is detected: consult a qualified specialist workshop

immediately.

X If no oil loss is detected: chec kthe oil level and add engine oil

(Y page 243). 214

Indicator and warning lamps in the instrument clusterOn-board computer and displays

Page 217 of 334

Problem Possible causes/consequences and

0004 Solutions

001D

The yellow

engine oil level

warning lamp

flashes and the

warning buzzer

sounds after the

engine is started

or while the

vehicle is in

motion. On vehicles with a diesel engine, the oil level display additionally

appears in the display, e.g.

– 2.0 qts (Canada:

– 2.0 ltr ).

There is not enough or no oil in the engine.

There is a danger of engine damage.

X Stop the vehicle as soon as possible, paying attention to road

and traffic conditions.

X Check the oil level with the oil dipstick (Y page 243).

X If the engine oil level is correct: have the malfunction rectified

immediately at a qualified specialist workshop.

X If the engine oil level is too low: have the vehicle towed to a

qualified specialist workshop. 001D

The yellow

engine oil level

warning lamp

lights up and the

warning buzzer

sounds after the

engine is started

or while the

vehicle is in

motion. The engine oil level is above the maximum level.

There is a risk of damaging the engine or catalytic converter.

X Check the oil level.

X If the oil level is too high: have the engine oil extracted as soon

as possible at a qualified specialist workshop.

X If the oil level is correct: have the malfunction rectified as soon

as possible at a qualified specialist workshop. 001D

On vehicles with

a diesel engine,

the yellow

engine oil level

warning lamp

lights up

repeatedly

during the

journey. There is a malfunction in the engine oil level display.

X

Have the vehicle checked immediately at a qualified specialist

workshop. 001A

The yellow

coolant level

warning lamp

lights up while

the engine is

running. The coolant level is too low.

Never run the engine if the coolant level is too low. The engine

could overheat and be damaged.

X

Stop the vehicle as soon as possible, paying attention to road

and traffic conditions.

X Switch off the engine and let it cool down.

X Add coolant and be sure to observe the warning notes

(Y page 244).

X If you need to add coolant frequently, have the engine cooling

system checked at a qualified specialist workshop. Indicator and warning lamps in the instrument cluster

215On-board computer and displays Z

Page 218 of 334

Problem Possible causes/consequences and

0004 Solutions

0014

The red coolant

warning lamp is

lit while the

engine is

running. The coolant temperature is too high.

X

Stop the vehicle as soon as possible, paying attention to road

and traffic conditions.

X Consult a qualified specialist workshop. 0014

The red coolant

warning lamp is

lit while the

engine is

running. The coolant temperature is too high.

If the vehicle is stopped after being subjected to extreme loads,

the coolant warning lamp may come on when the ignition is

switched on or the engine is restarted. Such loads can be, for

example, driving in mountainous terrain or driving with a trailer.

X

Run the engine for approximately 1minute at idling speed.

X Consult a qualified specialist workshop if the display message

continues to be shown. 0016

0006

The yellow

reserve fuel

warning lamp is

on. At the same

time

0 appears

in the fuel tank

conten tdisplay

while the engine

is running,

although there is

fuel in the fuel

tank The fuel filler cap is not closed.

X

Close the fuel filler cap.

You will hear a clic kwhen the fuel filler cap is closed fully.

X If the malfunction continues to be displayed, have it rectified

immediately at a qualified specialist workshop. 0018

The yellow

engine

diagnostic

indicator lamp is

lit up or flashes

while the engine

is running. You have used up all fuel in the tank.

The engine is running in emergency mode.

X

Refuel at the nearest gas station (Y page 142).

X Bleed the fuel system (Y page 137).

X Start the engine three to four times in succession after refueling.

Emergency running mode will be canceled. The vehicle does not

need to be checked. 216

Indicator and warning lamps in the instrument clusterOn-board computer and displays

Page 242 of 334

Useful information

This Operator's Manual describes all models

as well as standard and optional equipment

of your vehicle that were available at the time

of going to print. Country-specific variations

are possible. Note that your vehicle may not

be equipped with all of the described

functions. This also applies to systems and

functions relevant to safety.

Read the information on qualified specialist

workshops (Y page 26). Engine compartment

Hood

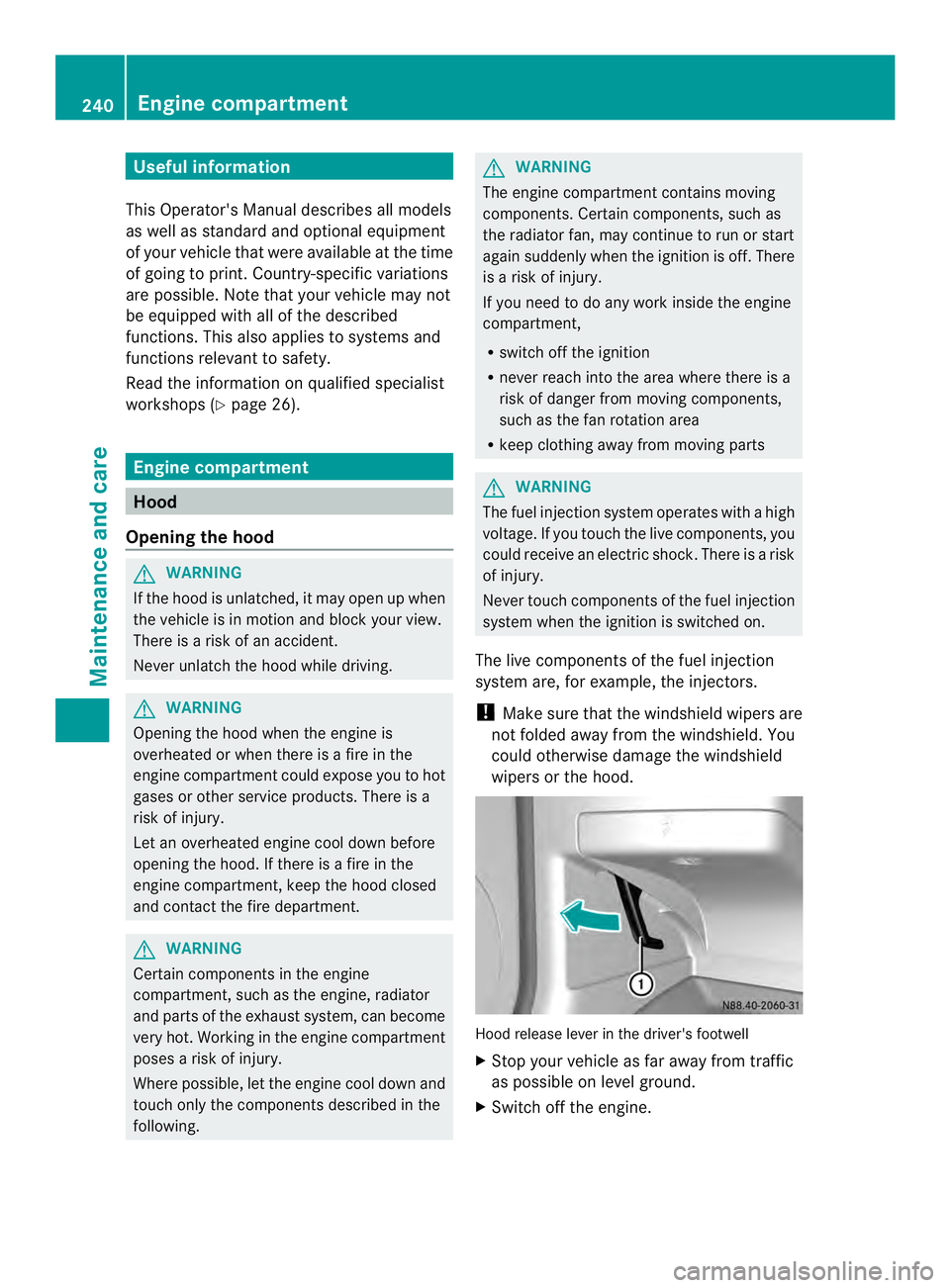

Opening the hood G

WARNING

If the hood is unlatched, it may open up when

the vehicle is in motion and block your view.

There is a risk of an accident.

Never unlatch the hood while driving. G

WARNING

Opening the hood when the engine is

overheated or when there is a fire in the

engine compartmen tcould expose you to hot

gases or other service products. There is a

risk of injury.

Let an overheated engine cool down before

opening the hood. If there is a fire in the

engine compartment, keep the hood closed

and contact the fire department. G

WARNING

Certain components in the engine

compartment, such as the engine, radiator

and parts of the exhaust system, can become

very hot. Working in the engine compartment

poses a risk of injury.

Where possible, let the engine cool down and

touch only the components described in the

following. G

WARNING

The engine compartment contains moving

components. Certain components, such as

the radiator fan, may continue to run or start

again suddenly when the ignition is off. There

is a risk of injury.

If you need to do any work inside the engine

compartment,

R switch off the ignition

R never reach into the area where there is a

risk of danger from moving components,

such as the fan rotation area

R keep clothing away from moving parts G

WARNING

The fuel injection system operates with a high

voltage. If you touch the live components, you

could receive an electric shock. There is a risk

of injury.

Never touch components of the fuel injection

system when the ignition is switched on.

The live components of the fuel injection

system are, for example, the injectors.

! Make sure that the windshield wipers are

not folded away from the windshield. You

could otherwise damage the windshield

wipers or the hood. Hood release lever in the driver's footwell

X

Stop your vehicle as far away from traffic

as possible on level ground.

X Switch off the engine. 240

Engine compartmentMaintenance and care

Page 247 of 334

G

WARNING

Coolant contains glycol and is therefore toxic.

Do not swallow the coolant. See a doctor

immediately if you swallow coolant.

Make sure that coolant does not come into

contact with skin, eyesorc lothing. In case of

contac twith eyes, rinse immediately with

plenty of clean water .Clean affected areas of

skin and clothing with soap and water

immediately. Change any affected clothing

immediately. G

WARNING

If antifreeze comes into contact with hot

components in the engine compartment, it

may ignite. There is a risk of fire and injury.

Let the engine cool down before you add

antifreeze. Make sure that antifreeze is not

spilled nex tto the filler neck.T horoughly

clean the antifreeze from components before

starting the engine.

! Take care not to spill any coolant on

painted surfaces. You could otherwise

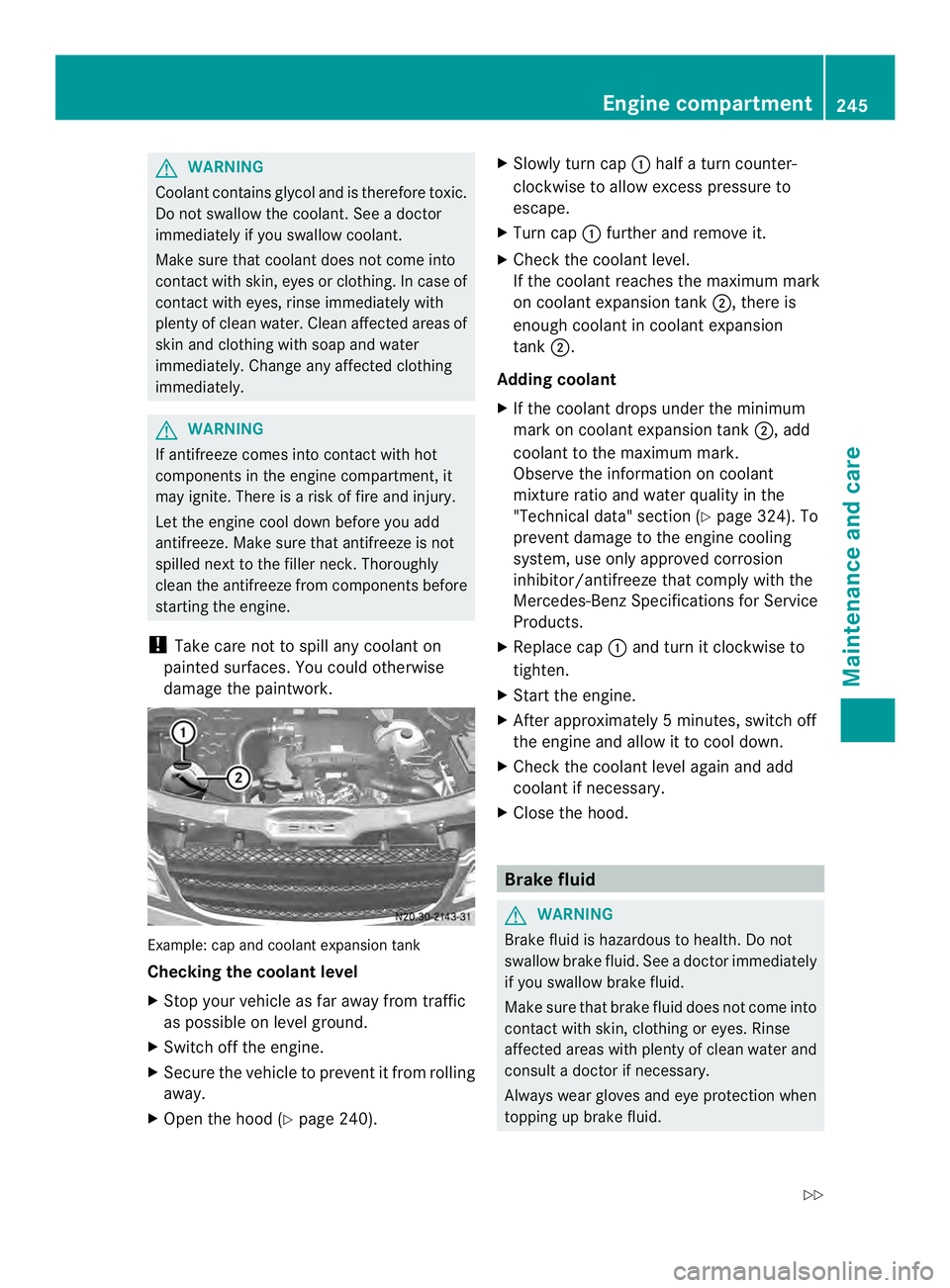

damage the paintwork. Example: cap and coolant expansion tank

Checking the coolant level

X

Stop your vehicle as far away from traffic

as possible on level ground.

X Switch off the engine.

X Secure the vehicle to prevent it from rolling

away.

X Open the hood (Y page 240). X

Slowly turn cap 0005half a turn counter-

clockwise to allow excess pressure to

escape.

X Turn cap 0005further and remove it.

X Check the coolant level.

If the coolant reaches the maximum mark

on coolant expansion tank 0006, there is

enough coolant in coolant expansion

tank 0006.

Adding coolant

X If the coolant drops under the minimum

mark on coolant expansion tank 0006, add

coolant to the maximum mark.

Observe the information on coolant

mixture ratio and water quality in the

"Technical data" section (Y page 324). To

prevent damage to the engine cooling

system, use only approved corrosion

inhibitor/antifreeze that comply with the

Mercedes-Benz Specifications for Service

Products.

X Replace cap 0005and turn it clockwise to

tighten.

X Start the engine.

X After approximately 5minutes, switch off

the engine and allow it to cool down.

X Check the coolan tlevel again and add

coolant if necessary.

X Close the hood. Brake fluid

G

WARNING

Brake fluid is hazardous to health. Do not

swallow brake fluid. See adoctor immediately

if you swallow brake fluid.

Make sure that brake fluid does not come into

contact with skin, clothing or eyes. Rinse

affected areas with plenty of clean water and

consult a doctor if necessary.

Always wear gloves and eye protection when

topping up brake fluid. Engine compartment

245Maintenance and care

Z

Page 271 of 334

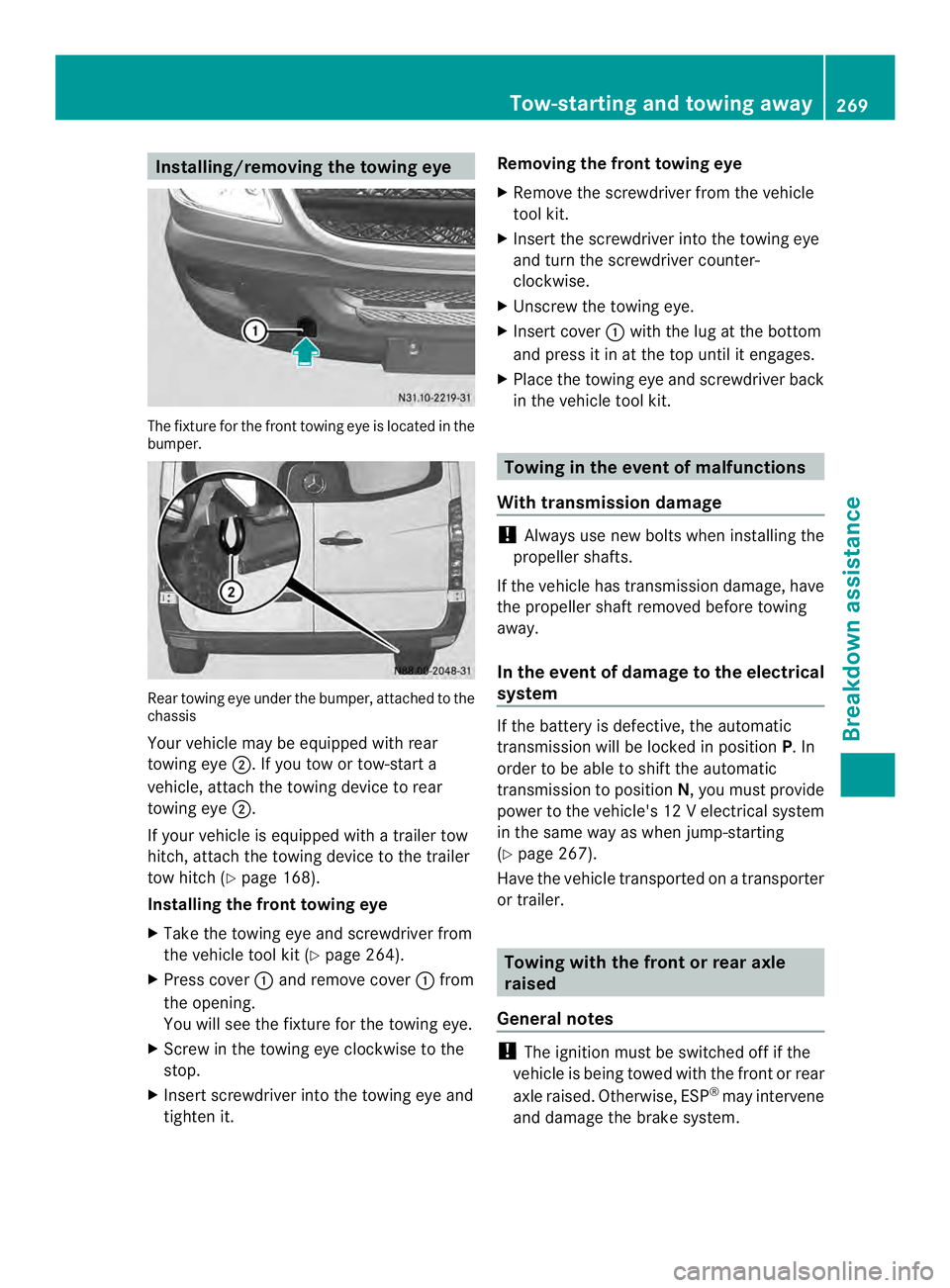

Installing/removing the towing eye

The fixture for the fron

ttowing eye is located in the

bumper. Rear towing eye under the bumper, attached to the

chassis

Your vehicle may be equipped with rear

towing eye 0006. If you tow or tow-start a

vehicle, attach the towing device to rear

towing eye 0006.

If your vehicle is equipped with a trailer tow

hitch, attach the towing device to the trailer

tow hitch (Y page 168).

Installing the front towing eye

X Take the towing eye and screwdriver from

the vehicle tool kit (Y page 264).

X Press cover 0005and remove cover 0005from

the opening.

You will see the fixture for the towing eye.

X Screw in the towing eye clockwise to the

stop.

X Insert screwdriver into the towing eye and

tighten it. Removing the front towing eye

X

Remove the screwdriver from the vehicle

tool kit.

X Insert the screwdriver into the towing eye

and turn the screwdriver counter-

clockwise.

X Unscrew the towing eye.

X Insert cover 0005with the lug at the bottom

and press it in at the top until it engages.

X Place the towing eye and screwdriver back

in the vehicle tool kit. Towing in the event of malfunctions

With transmission damage !

Always use new bolts when installing the

propeller shafts.

If the vehicle has transmission damage, have

the propeller shaft removed before towing

away.

In the event of damage to the electrical

system If the battery is defective, the automatic

transmission will be locked in position

P. In

order to be able to shift the automatic

transmission to position N, you must provide

power to the vehicle's 12 Velectrical system

in the same way as when jump-starting

(Y page 267).

Have the vehicle transported on a transporter

or trailer. Towing with the front or rear axle

raised

General notes !

The ignition must be switched off if the

vehicle is being towed with the front or rear

axle raised. Otherwise, ESP ®

may intervene

and damage the brake system. Tow-starting and towing away

269Breakdown assistance Z

Page 283 of 334

X

Read the tire pressure and compare it with

the recommended value on the loading

information table or th etire pressure table

(Y page 278).

X If the tire pressure is too low, increase it to

the recommended value.

X If the tire pressure is too high, release air

by pressing down the metal pin in the valve.

Use the tip of a pen, for example. Then,

chec kthe tire pressure again using the tire

pressure gauge.

X Screw the valve cap onto the valve.

X Repeatt he steps for the other tires. Tire pressure monitor

Important safety notes G

WARNING

Each tire, including the spare (if provided),

should be checked at least once a month

when cold and inflated to the pressure

recommended by the vehicle manufacturer

on the Tire and Loading Information placard

on the driver's door B-pillar or the tire

pressure label on the inside of the fuel filler

flap. If your vehicle has tires of a different size

than the size indicated on the Tire and Loading

Information placard or the tire pressure label,

you should determine the proper tire pressure

for those tires.

As an added safety feature, your vehicle has

been equipped with a tire pressure monitoring

system (TPMS) that illuminates a low tire

pressure telltale when one or more of your

tires are significantly underinflated.

Accordingly, when the low tire pressure

telltale illuminates, you should stop and check

your tires as soon as possible, and inflate

them to the proper pressure. Driving on a

significantly underinflated tire causes the tire

to overheat and can lead to tire failure.

Underinflation also reduces fuel efficiency

and tire tread life, and may affect the vehicle's

handling and stopping ability. Please note that the TPMS is not a substitute

for proper tire maintenance, and it is the

driver's responsibility to maintain correct tire

pressure, even if underinflation has not

reached the level to trigger illumination of the

TPMS low tire pressure telltale.

USA only:

Your vehicle has also been equipped with a

TPMS malfunction indicator to indicate if the

system is not operating properly. The TPMS

malfunction indicator is combined with the

low tire pressure telltale. When the system

detects a malfunction, the warning lamp will

flash for approximately a minute and then

remain continuously illuminated. This

sequence will be repeated every time the

vehicle is started as long as the malfunction

exists.

When the malfunction indicator is illuminated,

the system may not be able to detect or signal

low tire pressure as intended. TPMS

malfunctions may occur for a variety of

reasons, including the installation of

incompatible replacement or alternate tires

or wheels on the vehicle that prevent the

TPMS from functioning properly. Always

check the TPMS malfunction telltale after

replacing one or more tires or wheels on your

vehicle to ensure that the replacement or

alternate tires and wheels allow the TPMS to

continue to function properly.

Vehicles with a tire pressure monitor are

equipped with sensors in the wheels that

monitor the tire pressure of all four tires. The

tire pressure monitor monitors the pressure

in all four tires; you set this pressure when

you activate the tire pressure monitor. The

tire pressure monitor warns you when the

pressure drops in one or more of the tires. The

tire pressure monitor only functions if the

corresponding sensors are installed to all

wheels.

You should always adjust the tire pressure

according to the vehicle load. Restart the tire

pressure monitor if you change the tire

pressure. Tire pressure

281Wheels and tires Z

Page 299 of 334

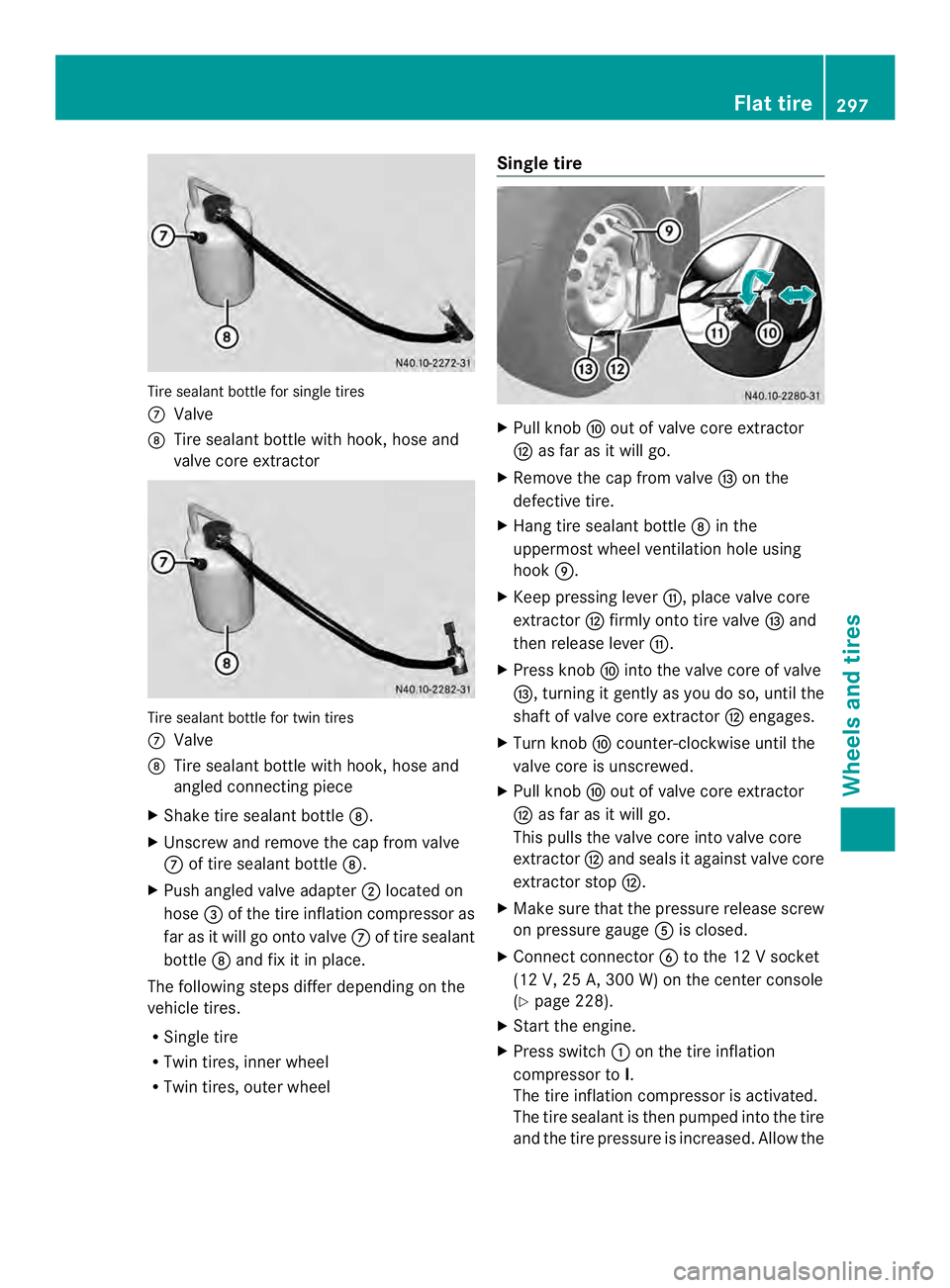

Tire sealant bottle for single tires

0018

Valve

0019 Tire sealant bottle with hook, hose and

valve core extractor Tire sealant bottle for twin tires

0018

Valve

0019 Tire sealant bottle with hook, hose and

angled connecting piece

X Shake tire sealant bottle 0019.

X Unscrew and remove the cap from valve

0018 of tire sealant bottle 0019.

X Push angled valve adapter 0006located on

hose 0026of the tire inflation compressor as

far as it will go ontov alve0018of tire sealant

bottle 0019and fix it in place.

The following steps differ depending on the

vehicle tires.

R Single tire

R Twin tires, inner wheel

R Twin tires, outer wheel Single tire

X

Pull knob 001Bout of valve core extractor

001D as far as it will go.

X Remove the cap from valve 001Eon the

defective tire.

X Hang tire sealan tbottle 0019in the

uppermost wheel ventilation hole using

hook 001A.

X Keep pressing lever 001C, place valve core

extractor 001Dfirmly onto tire valve 001Eand

then release lever 001C.

X Press knob 001Binto the valve core of valve

001E, turning it gently as you do so, until the

shaft of valve core extractor 001Dengages.

X Turn knob 001Bcounter-clockwise until the

valve core is unscrewed.

X Pull knob 001Bout of valve core extractor

001D as far as it will go.

This pulls the valve core into valve core

extractor 001Dand seals it against valve core

extractor stop 001D.

X Make sure that the pressure release screw

on pressure gauge 0023is closed.

X Connect connector 0024to the 12 V socket

(12 V, 25 A, 300 W) on the center console

(Y page 228).

X Start the engine.

X Press switch 0005on the tire inflation

compressor to I.

The tire inflation compressor is activated.

The tire sealant is then pumped into the tire

and the tire pressure is increased. Allow the Flat tire

297Wheels and tires Z

Page 301 of 334

X

Turn knob 001Dcounter-clockwise until the

valve core is unscrewed.

X Pull knob 001Dout of valve core extractor

001B as far as it will go.

This pulls the valve core into valve core

extractor 001Band seals it against valve core

extractor stop 001B.

X Hang tire sealant bottle 0019in the

uppermost wheel ventilation hole 001C.

X Push angled valve adapter 001Elocated on

the hose of tire sealant filler bottle 0019as

far as it will go on to valve core extractor

001B and fix it in place.

X Make sure that the pressure release screw

on pressure gauge 0023is closed.

X Connect connector 0024to the 12 V socket

(12 V, 25 A, 300 W) on the center console

(Y page 228).

X Start the engine.

X Press switch 0005on the tire inflation

compressor to move to position I.

The tire inflation compressor is activated.

The tire sealant is then pumped into the tire

and the tire pressure is increased. Allow the

tire inflation compressor to run for at least

10 minutes until tire sealant bottle 0019is

completely empty and the tire pressure is

at least 300 kPa (3.0 bar/43.5 psi).

If possible, inflate the tire to the

recommended tire pressure. You will find a

table of recommended tire pressure on the

Tire and Loading Information placard 9

or

the tire pressure plate on the B-pillar on the

driver's side of the vehicle ( Ypage 278).

X Then press 0on tire inflation compressor

switch 0005.

The tire inflation compressor is

deactivated.

X Quickly slide knob 001Dto the stop in valve

core extractor 001B.

X Turn knob 001Dclockwise until the valve core

is firmly screwed into tire valve 001F.i

Do not pull valve core extractor 001Bfrom

tire valve 001Fwhile the valve core is

unscrewed from tire valve 001F. The tire

sealant could otherwise run out and get on

your skin or clothes.

X Pull knob 001Dout of valve core extractor

001B as far as it will go.

X Unscrew valve core extractor 001Bcounter-

clockwise from tire valve 001F.

X Screw valve extension 001Aonto tire valve

001F and tighten it.

X Screw the valve cap onto valve extension

001A.

X Observe the following notes and

instructions:

R

Tire pressure of 300 kPa (3.0 bar/

43.5 psi) not reached (Y page 301).

R Tire pressure of 300 kPa (3.0 bar/

43.5p si) reached (Y page 301).

9 Only for vehicles with a gross vehicle weight of less than 10,000 lbs(4,536 kg). Flat tire

299Wheels and tires Z