weight MERCEDES-BENZ SPRINTER 2013 MY13 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2013, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2013Pages: 334, PDF Size: 3.88 MB

Page 295 of 334

DOT (Department of Transportation)

DOT marked tires fulfill the requirements of

the United States Department of

Transportation.

Average weigh tofvehicle occupants

The number of occupants for which the

vehicle is designed multiplied by

68 kilograms (15 0lbs).

Uniform Tire Quality Grading Standards

Au niform standard to grade the quality of

tires with regard to tread quality, tractio nand

temperature characteristics. The quality

grading assessment is made by the

manufacturer following specifications from

the U.S government. The quality grade of a

tire is imprinted on the sidewall of the tire.

Recommended tire pressure

The recommended tire pressure are the

pressures specified for the tires mounted on

the vehicle at the factory.

The Tire and Loading Informatio nplacard 7

contains the recommended tire pressure for

cold tires, the maximum permissible load and

the maximum permissible vehicle speed.

The tire pressure table contains the

recommended tire pressure for cold tires

under various operating conditions, i.e.

loading and/or speed of the vehicle.

Increased vehicle weight due to optional

equipment

The combined weight of all standard and

optional equipmen tavailable for the vehicle,

regardless of whethe ritis actually installed

on the vehicle or not.

Wheel rim

The part of the wheel on which the tire is

mounted.

GAWR (Gross Axle Weight Rating)

GAWR is the maximum gross axle weight

rating. The actual load on an axle must never

exceed the gross axle weight rating. The Gross Axle Weight Rating can be found on the

vehicle identification plate on the driver seat

frame (Y

page 315).

Speed index

The speed index is part of the tire

identification. It specifies the speed range for

which the tire is approved.

GTW (Gross Trailer Weight)

GTW is the total of weight of a trailer and the

weight of the load, accessories etc. on the

trailer.

GVW (Gross Vehicle Weight)

The gross vehicle weight includes the weight

of the vehicle including fuel, tools, spare

wheel, accessories installed, occupants,

luggage and the drawbarn oseweight if

applicable. The gross vehicle weight may

never exceed the gross vehicle weight rating

(GVWR) specified on the vehicle identification

plate at the base of the driver's seat

(Y page 315).

GVWR (Gross Vehicle Weight Rating)

The GVWR is the maximum permitted gross

weight of the fully laden vehicle (weight of the

vehicle including all accessories, occupants,

fuel, luggage and the drawbar noseweight if

applicable). The Gross Vehicle Weight Rating

is specified on the vehicle identification plate

on the driver seat frame (Y page 315).

Maximum weight of the laden vehicle

The maximum weight is the sum of:

R the curb weight of the vehicle

R the weight of the accessories

R the load limit

R the weight of the factory installed optional

equipment

Kilopascal (kPa)

Metric unit for tire pressure. 6.9 kPa are the

equivalent of 1psi. Another tire pressure unit

7 Only for vehicles with a gross weight of less than 10,000 lbs (4,536 kg). What you should know about wheels and tires

293Wheels and tires Z

Page 296 of 334

is bar. 100 kilopascals (kPa) are the

equivalen tof1bar.

Load index

In addition to the load bearing index, a load

index can be stamped onto the sidewall of the

tire. It specifies the load-bearing capacity of

the tire more precisely.

Curb weight

The weigh tofavehicle with standard

equipment including the maximu mfilling

capacity of fuel, oil, and coolant. It also

includes the air-conditionin gsystem and

optional equipmen tifthese are installed on

the vehicle, but does not include passengers

or luggage.

Maximum tire load

The maximum tire load in kilograms or

pounds is the maximum weight for which a

tire is approved.

Maximum permissible tire pressure

Maximum permissible tire pressure for one

tire.

Maximum load on one tire

Maximum load on one tire. This is calculated

by dividing the maximum axle load of one axle

by two.

PSI (Pounds per square inch)

Standard unit of measurement for tire

pressure.

Aspect ratio

Relationship between tire height and width in

percent.

Tire pressure

Pressure inside the tire applying an outward

force to every square inch of the tire's

surface. Tire pressure is specified in pounds

per square inch (psi), in kilopascal (kPa) or in

bar. Tire pressure should only be corrected

when the tires are cold. Cold tire pressure

The tires are cold:

R if the vehicle has been parked for at least

three hours without direct sunlight on the

tires, and

R if the vehicle has not been driven further

than 1 mile (1.6 km)

Tire tread

The part of the tire that comes into contact

with the road.

Tire bead

The tire bead ensures that the tire sits

securely on the wheel. There are several steel

wires in the bead to prevent the tire from

coming loose from the wheel rim.

Sidewall

The part of the tire between the tread and the

tire bead.

Weight of optional extras

The combined weight of those optional extras

that weigh more than the replaced standard

parts and more than 2.3 kg (5 lbs). These

optional extras, such as high-performance

brakes, level control, a roof rack or a high-

performance battery, are not included in the

curb weight and the weight of the

accessories.

TIN (Tire Identification Number)

Au nique identificatio nnumbe rwhich can be

used by a tire manufacturer to identify tires,

for example for a product recall, and thus

identify the purchasers. The TIN is composed

of the manufacturer identification code, tire

size, tire model code and manufacturing date.

Load bearing index

The load bearing index (also load index) is a

code that contains the maximum load bearing

capacity of a tire. 294

What you should know about wheels and tiresWheels and tires

Page 297 of 334

Traction

Traction is the result of friction between the

tires and the road surface.

TWR (permissible trailer drawbar load)

The TWR is the maximu mpermissible weight

that may act on the ball coupling of the trailer

tow hitch.

Wear indicator

Narrow bars (tread wear bars) that are

distributed over the tire tread. If the tire tread

is level with the bars, the wear limit of 000Bin

(1.6 mm) has been reached.

Distribution of the vehicle occupants

The distribution of vehicle occupants over

designated seat positions in avehicle.

Maximum permissible payload weight

Nominal load and goods/luggage load plus

68 kg (150 lbs) multiplied by the number of

seats in the vehicle. Flat tire

General notes

Your vehicle may be equipped with Premium

tire sealant or with a spare wheel. The spare

wheel is under the vehicle at the rear

(Y page 308). The Premium tire sealant is

located in the stowage compartment in the

right-hand door sill (Y page 264).

You can find information on changing/

mounting wheels in the "Wheel change"

section (Y page 303).

When you replace a tire, we recommend that

you also replace the tire valve. Please observe

the safety-relevant information on tire valve

(Y page 280). Vehicle preparation

X Stop the vehicle as far away as possible

from traffic and on a level, firm and non-slip

surface.

X Switch on the hazard warning lamps if the

vehicle poses a hazard to passing vehicles.

X Turn the fron twheels to the straight-ahead

position.

X Move the selector lever of the automatic

transmission to position P.

X Switch off the engine.

X Passengers should leave the vehicle. Make

sure that the passengers are not

endangered as they do so.

X Make sure that no one is near the danger

area while a wheel is being changed.

Anyone who is not directly assisting in the

wheel change should, for example, stand

behind the barrier.

X Place the warning triangle or warning lamp

at a suitable distance.

Observe legal requirements. Using Premium tire sealant

Using Premium tire sealant You can use Premium tire sealant to seal

punctures of up to 0.23 in (6 mm), particularly

those in the tire tread. Tire sealant can be

used at outside temperatures down to

002722 ‡ (002730 †).

G

WARNING

In the following situations, the tire sealant is

unable to provide sufficient breakdown

assistance, as it is unable to seal the tire

properly:

R there are cuts or punctures in the tire larger

than those mentioned above.

R the wheel rim is damaged.

R you have driven at very low tire pressures

or on a flat tire.

There is a risk of an accident. Flat tire

295Wheels and tires

Z

Page 300 of 334

tire inflatio

ncompressor to run for at least

10 minutes until tire sealant bottle 0019is

completely empty and the tire pressure is

at least 300 kPa (3.0 bar/43.5 psi).

If possible, inflate the tire to the

recommended tire pressure. You will find a

table of recommended tire pressure on the

Tire and Loading Information placard 8

or

the tire pressure plate on the B-pillar on the

driver's side of the vehicle ( Ypage 278).

X Then press 0on tire inflation compressor

switch 0005.

The tire inflation compressor is

deactivated.

X Quickly slide knob 001Bto the stop in valve

core extractor 001D.

X Turn knob 001Bclockwise until the valve core

is firmly screwed into tire valve 001E.

i Do not pull valve core extractor 001Doff tire

valve 001Ewhile the valve core is unscrewed

from tire valve 001E.The tire sealant could

otherwise run out and get on your skin or

clothes.

X Press lever 001Cand pull valve core extractor

001D from tire valve 001E.

X Screw the valve cap onto tire valve 001E.

X Observe the following notes and

instructions:

R

Tire pressure of 300 kPa (3.0 bar/

43.5 psi) not reached (Y page 301).

R Tire pressure of 300 kPa (3.0 bar/

43.5 psi) reached (Y page 301). Twin tires, inner wheel X

Unscrew the valve cap from valve

extension 001Aon the defective wheel.

X Screw valve core extractor 001Bclockwise as

far as it will go onto valve extension 001A.

X Screw valve core extractor 001B

approximately a further 0003turn to release

valve extension 001A.

X Unscrew valve extension 001Aand the valve

core extractor 001Bcounter-clockwise from

tire valve 001F.

X Unscrew valve extension 001Afrom valve

core extractor 001B. X

Pull knob 001Dout of valve core extractor

001B as far as it will go.

X Screw valve core extractor 001Bclockwise

onto tire valve 001F.

X Press knob 001Dinto the valve core of valve

001F, turning it gently as you do so, until the

shaft of valve core extractor 001Bengages.

8 Only for vehicles with a gross vehicle weight of less than 10,000 lbs(4,536 kg). 298

Flat tireWheels and tires

Page 301 of 334

X

Turn knob 001Dcounter-clockwise until the

valve core is unscrewed.

X Pull knob 001Dout of valve core extractor

001B as far as it will go.

This pulls the valve core into valve core

extractor 001Band seals it against valve core

extractor stop 001B.

X Hang tire sealant bottle 0019in the

uppermost wheel ventilation hole 001C.

X Push angled valve adapter 001Elocated on

the hose of tire sealant filler bottle 0019as

far as it will go on to valve core extractor

001B and fix it in place.

X Make sure that the pressure release screw

on pressure gauge 0023is closed.

X Connect connector 0024to the 12 V socket

(12 V, 25 A, 300 W) on the center console

(Y page 228).

X Start the engine.

X Press switch 0005on the tire inflation

compressor to move to position I.

The tire inflation compressor is activated.

The tire sealant is then pumped into the tire

and the tire pressure is increased. Allow the

tire inflation compressor to run for at least

10 minutes until tire sealant bottle 0019is

completely empty and the tire pressure is

at least 300 kPa (3.0 bar/43.5 psi).

If possible, inflate the tire to the

recommended tire pressure. You will find a

table of recommended tire pressure on the

Tire and Loading Information placard 9

or

the tire pressure plate on the B-pillar on the

driver's side of the vehicle ( Ypage 278).

X Then press 0on tire inflation compressor

switch 0005.

The tire inflation compressor is

deactivated.

X Quickly slide knob 001Dto the stop in valve

core extractor 001B.

X Turn knob 001Dclockwise until the valve core

is firmly screwed into tire valve 001F.i

Do not pull valve core extractor 001Bfrom

tire valve 001Fwhile the valve core is

unscrewed from tire valve 001F. The tire

sealant could otherwise run out and get on

your skin or clothes.

X Pull knob 001Dout of valve core extractor

001B as far as it will go.

X Unscrew valve core extractor 001Bcounter-

clockwise from tire valve 001F.

X Screw valve extension 001Aonto tire valve

001F and tighten it.

X Screw the valve cap onto valve extension

001A.

X Observe the following notes and

instructions:

R

Tire pressure of 300 kPa (3.0 bar/

43.5 psi) not reached (Y page 301).

R Tire pressure of 300 kPa (3.0 bar/

43.5p si) reached (Y page 301).

9 Only for vehicles with a gross vehicle weight of less than 10,000 lbs(4,536 kg). Flat tire

299Wheels and tires Z

Page 303 of 334

X

Loosen angled valve adapter 001Dfrom tire

valve 001Cand remove it.

X Screw in the valve core again using the

valve tool and remove the valve tool

through the opening.

i If the valve insert is damaged or lost when

it is unscrewed, you can use the valve insert

from tire sealant bottle 0019after you have

used the tire sealant.

X Unscrew the valve insert from the valve of

tire sealant bottle 0019using the valve

extractor.

X Push angled valve adapter 0006located on

hose 0026of the tire inflatio ncompressor as

far as it will go ontot ire valve001Cand clamp

it in place.

X Press tire inflation compressor switch 0005

to Iand inflate the tire.

If possible, inflate the tire to the

recommended tire pressure. You will find a

table of recommended tir epressure on the

Tire and Loading Information placard 10

or

the tire pressure plate on the B-pillar on the

driver's side of the vehicle (Y page 278).

X Then press 0on tire inflation compressor

switch 0005.

The tire inflation compresso ris

deactivated.

X Screw the valve cap onto tire valve 001C.

X Observe the following notes and

instructions:

R

Tire pressure of 300 kPa (3.0 bar/

43.5 psi) not reached (Y page 301).

R Tire pressure of 300 kPa (3.0 bar/

43. 5psi) reached (Y page 301).

Tire pressure of 300 kPa (3.0 bar/

43.5 psi) not reached G

WARNING

If the specified tire pressure is not reached,

the tire is too severely damaged.T he tire

sealant cannot offer assistance with a flat tire in this case. Damaged tires as well as tire

pressure that is too low can impair the braking

and driving characteristics. There is a risk of

an accident.

Do not drive any further. Notify a qualified

specialist workshop.

i The Mercedes-Benz Service24h

telephone numbers can be found on a

sticker in the driver's door entrance area

and in the vehicle Maintenance Booklet.

Tire pressure of 300 kPa (3.0 bar/

43.5 psi) reached G

WARNING

At ire temporarily sealed with tire sealant

impairs the driving characteristics and is not

suitable for higher speeds. There is a risk of

accident.

You should therefore adapt your driving style

accordingly and drive carefully. Do not exceed

the specified maximum speed with a tire that

has been repaired using tire sealant.

The maximum speed for a tire sealed with tire

sealant is 50 mph (80 km/h).

The "max. 50 mph" (80 km/h) sticker must

be affixed within the driver's field of vision.

X Turn the pressure release screw on

pressure gauge 0023counter-clockwise and

bleed the system.

X Turn the key in the ignition lock to

position 0.

X Pull connector 0024on the tire inflation

compressor out of the 12 V socket.

X Clean the valve core extractor with clean

water.

X Remove angled valve adapter 0006from valve

0018 of tire sealant filler bottle 0019and screw

the valve cap onto valve 0018.

X Stow the tire inflation compressor, tire

sealant bottle 0019with valve core extractor

10 Only for vehicles with a gross vehicle weight of less than 10,000 lbs(4,536 kg). Flat tire

301Wheels and tires Z

Page 310 of 334

X

Wheel with hub cap: position the opening

for the tire valve in the hub cap over the tire

valve.

X Push the edge of the hub cap with both

hands against the wheel until it clicks into

place. Make sure the hub cap retaining

catches engage on the steel wheel.

X Wheel with central hub cap: position the

retaining lugs of the central hub cap over

the wheel bolts.

X Hit the middle of the hub cap to engage it

on the wheel.

X Secure the faulty wheel in the spare wheel

bracket (Y page 309).

X Check the tire pressure of the newly

mounted wheel and adjust it if necessary.

Observe the recommended tire pressure

(Y page 278).

X Retighten the wheel bolts or wheel nuts to

the specified tightening torque after the

vehicle has been driven for 30 miles

(50 km).

When using a wheel/spare wheel with a new

or newly painted wheel rim, have the wheel

bolts/nuts retightened again after

approximately 600 to 3,000 miles (1,000 to

5,000 km). Observe the specified tightening

torque.

i Vehicles with the tire pressure monitor

system: all mounted wheels must be

equipped with functioning sensors. Wheel and tire combination

General notes

! Retreaded tires are neither tested nor

recommended for Sprinter vehicles, since

previous damage cannot always be

detected on retreaded tires. We can

therefore not guarantee driving safety. Do

not mount used tires if you have no

information about their previous usage. The recommended tire pressures can be

found:

R

on the Tire and Loading Information

placard 11

on the B-pillar on the driver's side

R on the tire pressure table on the B-pillar on

the driver's side

The recommended tire pressure can also be

found in the "Tire pressure table" section in

these Operating Instructions (Y page 285).

The wheel/tire combination for your vehicle

can be found on the tire pressure table.

Further information on wheel/tire

combination can be obtained at any qualified

specialist workshop.

Check tire pressures regularly and only when

the tires are cold. Observe the notes on the

recommended tire pressures (Y page 278).

Follow the maintenance recommendations in

the tire manufacturer's warranty book in your

vehicle documents.

Notes on the vehicle equipment –always

install the vehicle:

R with tires of the same size across an axle

(left/right)

R with the same type of tires on all wheels at

a given time (summer tires, winter tires) Spare wheel

Important safety notes

G

WARNING

Wheel and tire dimensions as well as the type

of tire can vary between the spare wheel and

the wheel to be replaced. When the spare

wheel is installed, driving characteristics may

be severely affected. There is a risk of an

accident.

In order to reduce risks:

R you should therefore adapt your driving

style and drive carefully.

R never install more than one spare wheel

that differs fro mthe wheel to be replaced.

11 Only for vehicles with a gross weight of less than 10,000 lbs(4,536 kg). 308

Spare wheelWheels and tires

Page 312 of 334

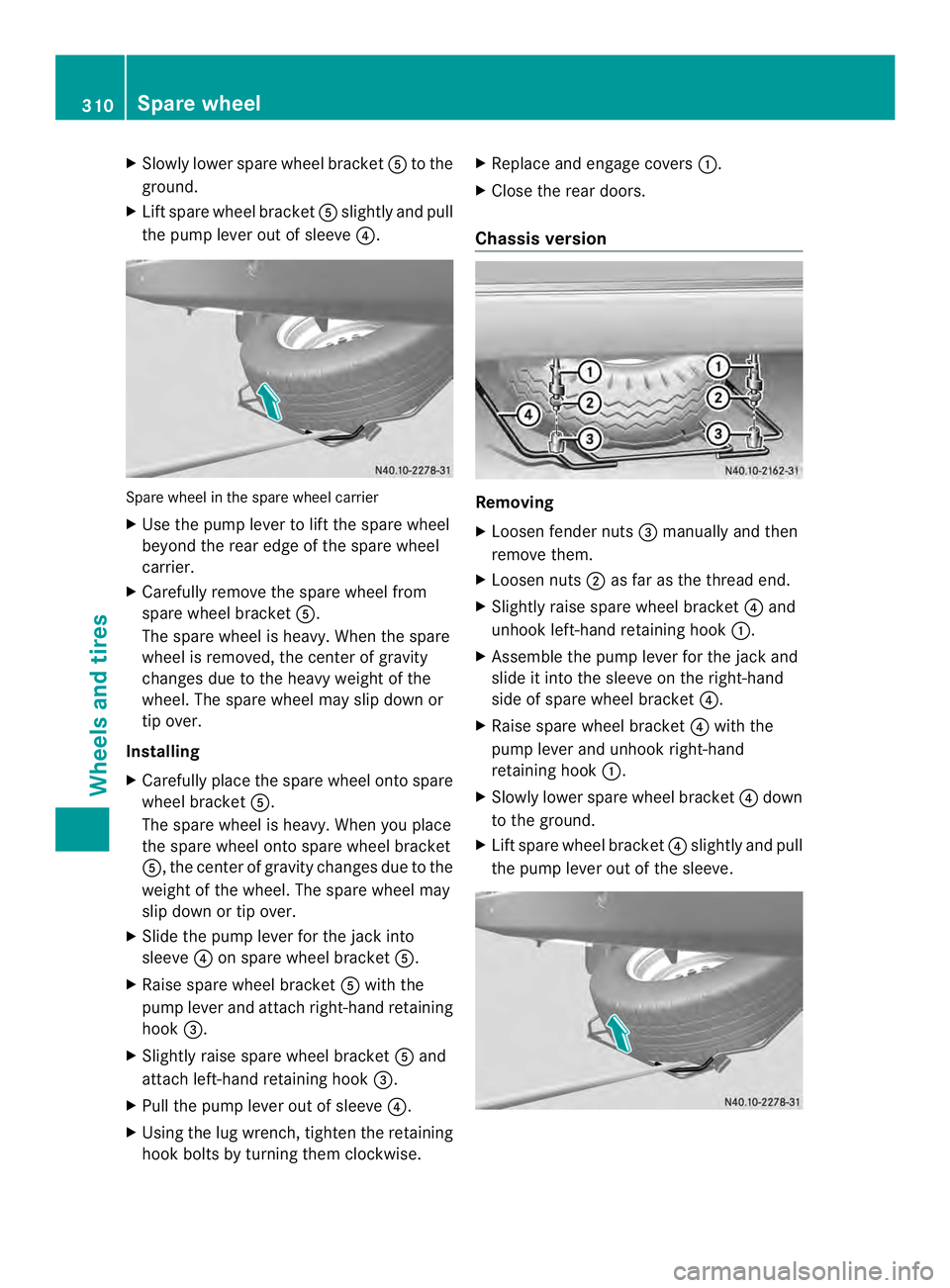

X

Slowly lowe rspare wheel bracket 0023to the

ground.

X Lift spare wheel bracket 0023slightly and pull

the pump lever out of sleeve 0025.Spare wheel in the spare wheel carrier

X

Use the pump lever to lift the spare wheel

beyond the rear edge of the spare wheel

carrier.

X Carefully remove the spare wheel from

spare wheel bracket 0023.

The spare wheel is heavy. When the spare

wheel is removed, the center of gravity

changes due to the heavy weight of the

wheel. The spare wheel may slip down or

tip over.

Installing

X Carefully place the spare wheel onto spare

wheel bracket 0023.

The spare wheel is heavy. When you place

the spare wheel onto spare wheel bracket

0023, the center of gravity changes due to the

weight of the wheel. The spare wheel may

slip down or tip over.

X Slide the pump lever for the jack into

sleeve 0025on spare wheel bracket 0023.

X Raise spare wheel bracket 0023with the

pump lever and attach right-hand retaining

hook 0026.

X Slightly raise spare wheel bracket 0023and

attach left-hand retaining hook 0026.

X Pull the pump lever out of sleeve 0025.

X Using the lug wrench, tighten the retaining

hook bolts by turning them clockwise. X

Replace and engage covers 0005.

X Close the rear doors.

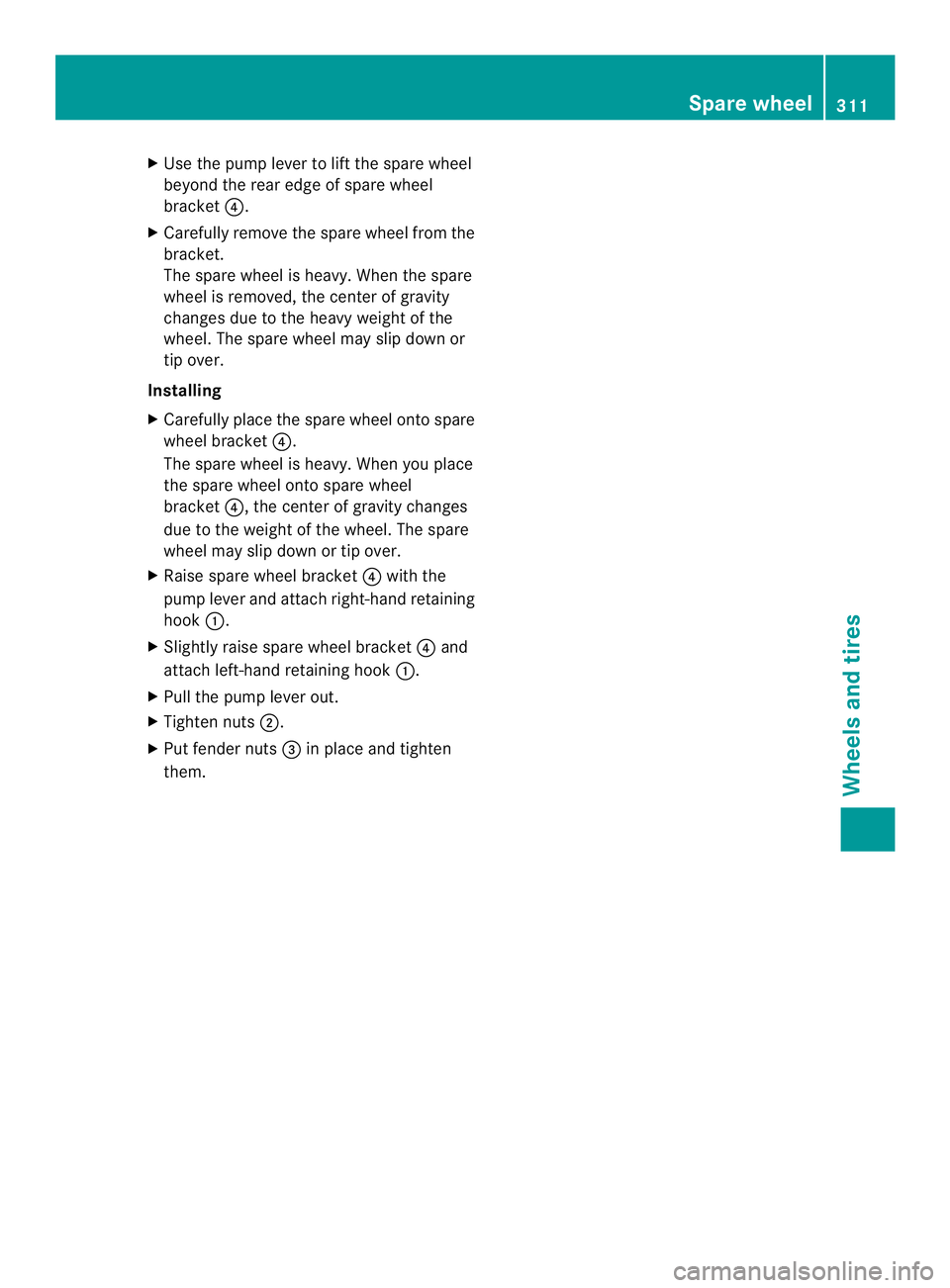

Chassis version Removing

X

Loosen fender nuts 0026manually and then

remove them.

X Loosen nuts 0006as far as the thread end.

X Slightly raise spare wheel bracket 0025and

unhook left-hand retaining hook 0005.

X Assemble the pump lever for the jack and

slide it into the sleeve on the right-hand

side of spare wheel bracket 0025.

X Raise spare wheel bracket 0025with the

pump lever and unhook right-hand

retaining hook 0005.

X Slowly lower spare wheel bracket 0025down

to the ground.

X Lift spare wheel bracket 0025slightly and pull

the pump lever out of the sleeve. 310

Spare wheelWheels and tires

Page 313 of 334

X

Use the pump lever to lift the spare wheel

beyond the rear edge of spare wheel

bracket 0025.

X Carefully remove the spare wheel from the

bracket.

The spare wheel is heavy. When the spare

wheel is removed, the center of gravity

changes due to the heavy weight of the

wheel. The spare wheel may slip down or

tip over.

Installing

X Carefully place the spare wheel onto spare

wheel bracket 0025.

The spare wheel is heavy. When you place

the spare wheel onto spare wheel

bracket 0025, the center of gravity changes

due to the weight of the wheel. The spare

wheel may slip down or tip over.

X Raise spare wheel bracket 0025with the

pump lever and attach right-hand retaining

hook 0005.

X Slightly raise spare wheel bracket 0025and

attach left-hand retaining hook 0005.

X Pull the pump lever out.

X Tighten nuts 0006.

X Put fender nuts 0026in place and tighten

them. Spare wheel

311Wheels and tires Z

Page 317 of 334

equipment of this kind is retrofitted, its

electromagnetic compatibility must be

checked and verified.

If these devices are linked to functions

associated with resistance to interference,

they must have type approval. This applies to

the device or its interfaces to the vehicle

electronics, e.g. charging brackets.

At elephone or two-way radio to be installed

in the vehicle must be approved. Further

information can be obtained from any

Sprinter Dealer.

For operation of mobile phones and two-way

radios, we recommend connection to an

approved exterior antenna. This is the only

way to ensure optimum reception quality

inside the vehicle and to minimize mutual

interference between the vehicle electronics,

mobile phones and two-way radios.

The transmission output of the mobile phone

or two-way radio may not exceed the

following maximum transmission output

(PEAK): Frequency range Maximum

transmission

output (PEAK)

Short wave

(f < 50 MHz) 100 W

4 m waveband 30 W

2 m waveband 50 W

Trunked radio/Tetra 35 W

70 cm waveband 35 W

GSM 900/AMPS 10 W

GSM 1800 10 W

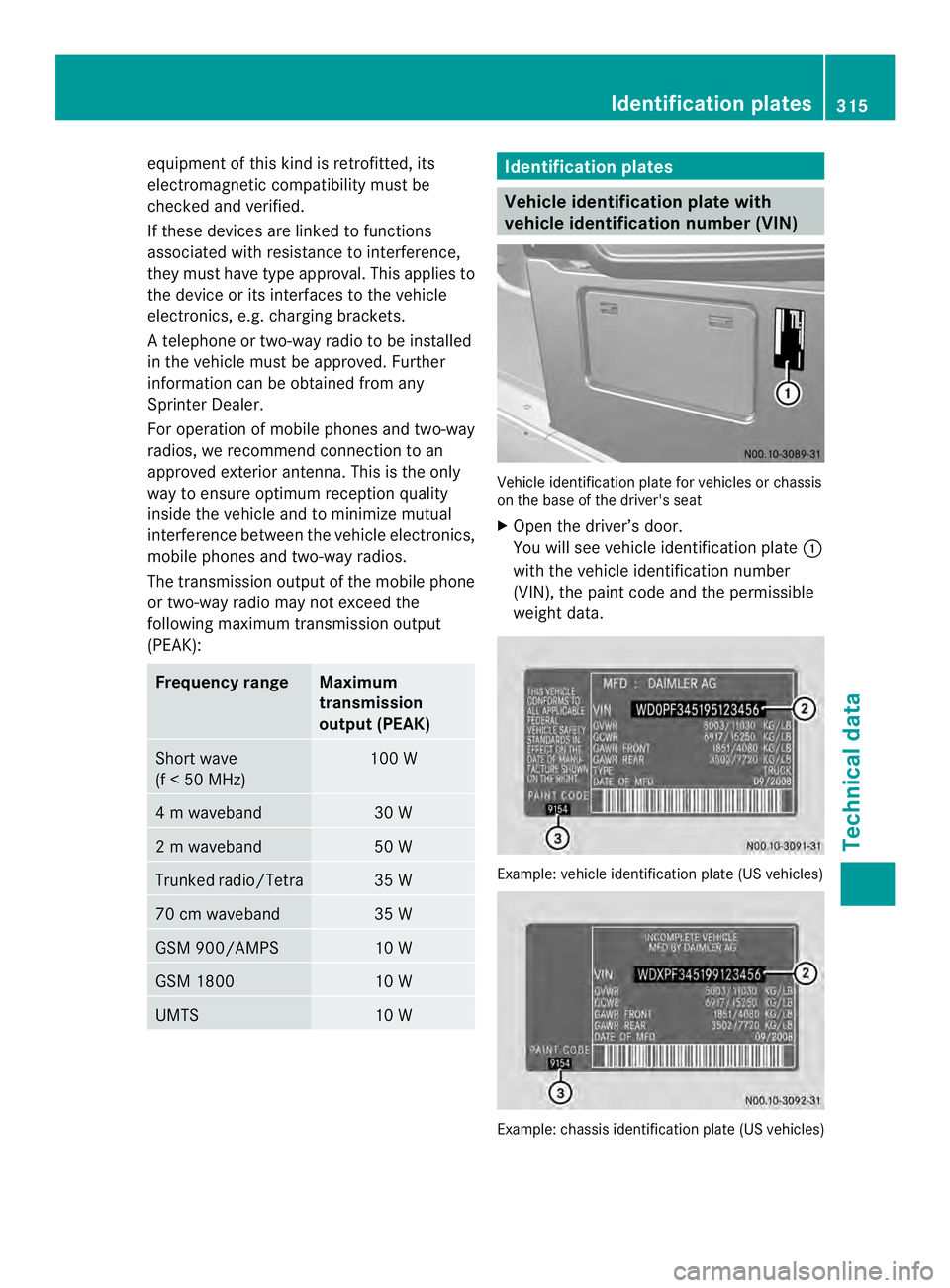

UMTS 10 W Identification plates

Vehicle identification plate with

vehicle identification number (VIN)

Vehicle identification plate for vehicles or chassis

on the base of the driver's seat

X

Open the driver’s door.

You will see vehicle identification plate 0005

with the vehicle identification number

(VIN), the paint code and the permissible

weight data. Example: vehicle identification plate (US vehicles)

Example: chassis identification plate (US vehicles) Identification plates

315Technical data Z