maintenance MERCEDES-BENZ SPRINTER 2013 MY13 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2013, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2013Pages: 334, PDF Size: 3.88 MB

Page 283 of 334

X

Read the tire pressure and compare it with

the recommended value on the loading

information table or th etire pressure table

(Y page 278).

X If the tire pressure is too low, increase it to

the recommended value.

X If the tire pressure is too high, release air

by pressing down the metal pin in the valve.

Use the tip of a pen, for example. Then,

chec kthe tire pressure again using the tire

pressure gauge.

X Screw the valve cap onto the valve.

X Repeatt he steps for the other tires. Tire pressure monitor

Important safety notes G

WARNING

Each tire, including the spare (if provided),

should be checked at least once a month

when cold and inflated to the pressure

recommended by the vehicle manufacturer

on the Tire and Loading Information placard

on the driver's door B-pillar or the tire

pressure label on the inside of the fuel filler

flap. If your vehicle has tires of a different size

than the size indicated on the Tire and Loading

Information placard or the tire pressure label,

you should determine the proper tire pressure

for those tires.

As an added safety feature, your vehicle has

been equipped with a tire pressure monitoring

system (TPMS) that illuminates a low tire

pressure telltale when one or more of your

tires are significantly underinflated.

Accordingly, when the low tire pressure

telltale illuminates, you should stop and check

your tires as soon as possible, and inflate

them to the proper pressure. Driving on a

significantly underinflated tire causes the tire

to overheat and can lead to tire failure.

Underinflation also reduces fuel efficiency

and tire tread life, and may affect the vehicle's

handling and stopping ability. Please note that the TPMS is not a substitute

for proper tire maintenance, and it is the

driver's responsibility to maintain correct tire

pressure, even if underinflation has not

reached the level to trigger illumination of the

TPMS low tire pressure telltale.

USA only:

Your vehicle has also been equipped with a

TPMS malfunction indicator to indicate if the

system is not operating properly. The TPMS

malfunction indicator is combined with the

low tire pressure telltale. When the system

detects a malfunction, the warning lamp will

flash for approximately a minute and then

remain continuously illuminated. This

sequence will be repeated every time the

vehicle is started as long as the malfunction

exists.

When the malfunction indicator is illuminated,

the system may not be able to detect or signal

low tire pressure as intended. TPMS

malfunctions may occur for a variety of

reasons, including the installation of

incompatible replacement or alternate tires

or wheels on the vehicle that prevent the

TPMS from functioning properly. Always

check the TPMS malfunction telltale after

replacing one or more tires or wheels on your

vehicle to ensure that the replacement or

alternate tires and wheels allow the TPMS to

continue to function properly.

Vehicles with a tire pressure monitor are

equipped with sensors in the wheels that

monitor the tire pressure of all four tires. The

tire pressure monitor monitors the pressure

in all four tires; you set this pressure when

you activate the tire pressure monitor. The

tire pressure monitor warns you when the

pressure drops in one or more of the tires. The

tire pressure monitor only functions if the

corresponding sensors are installed to all

wheels.

You should always adjust the tire pressure

according to the vehicle load. Restart the tire

pressure monitor if you change the tire

pressure. Tire pressure

281Wheels and tires Z

Page 303 of 334

X

Loosen angled valve adapter 001Dfrom tire

valve 001Cand remove it.

X Screw in the valve core again using the

valve tool and remove the valve tool

through the opening.

i If the valve insert is damaged or lost when

it is unscrewed, you can use the valve insert

from tire sealant bottle 0019after you have

used the tire sealant.

X Unscrew the valve insert from the valve of

tire sealant bottle 0019using the valve

extractor.

X Push angled valve adapter 0006located on

hose 0026of the tire inflatio ncompressor as

far as it will go ontot ire valve001Cand clamp

it in place.

X Press tire inflation compressor switch 0005

to Iand inflate the tire.

If possible, inflate the tire to the

recommended tire pressure. You will find a

table of recommended tir epressure on the

Tire and Loading Information placard 10

or

the tire pressure plate on the B-pillar on the

driver's side of the vehicle (Y page 278).

X Then press 0on tire inflation compressor

switch 0005.

The tire inflation compresso ris

deactivated.

X Screw the valve cap onto tire valve 001C.

X Observe the following notes and

instructions:

R

Tire pressure of 300 kPa (3.0 bar/

43.5 psi) not reached (Y page 301).

R Tire pressure of 300 kPa (3.0 bar/

43. 5psi) reached (Y page 301).

Tire pressure of 300 kPa (3.0 bar/

43.5 psi) not reached G

WARNING

If the specified tire pressure is not reached,

the tire is too severely damaged.T he tire

sealant cannot offer assistance with a flat tire in this case. Damaged tires as well as tire

pressure that is too low can impair the braking

and driving characteristics. There is a risk of

an accident.

Do not drive any further. Notify a qualified

specialist workshop.

i The Mercedes-Benz Service24h

telephone numbers can be found on a

sticker in the driver's door entrance area

and in the vehicle Maintenance Booklet.

Tire pressure of 300 kPa (3.0 bar/

43.5 psi) reached G

WARNING

At ire temporarily sealed with tire sealant

impairs the driving characteristics and is not

suitable for higher speeds. There is a risk of

accident.

You should therefore adapt your driving style

accordingly and drive carefully. Do not exceed

the specified maximum speed with a tire that

has been repaired using tire sealant.

The maximum speed for a tire sealed with tire

sealant is 50 mph (80 km/h).

The "max. 50 mph" (80 km/h) sticker must

be affixed within the driver's field of vision.

X Turn the pressure release screw on

pressure gauge 0023counter-clockwise and

bleed the system.

X Turn the key in the ignition lock to

position 0.

X Pull connector 0024on the tire inflation

compressor out of the 12 V socket.

X Clean the valve core extractor with clean

water.

X Remove angled valve adapter 0006from valve

0018 of tire sealant filler bottle 0019and screw

the valve cap onto valve 0018.

X Stow the tire inflation compressor, tire

sealant bottle 0019with valve core extractor

10 Only for vehicles with a gross vehicle weight of less than 10,000 lbs(4,536 kg). Flat tire

301Wheels and tires Z

Page 304 of 334

and/or valve tool, warning triangle and

warning lamps in the vehicle.

X Pull away immediately.

This enables the tire sealan tto distribute

inside the tire and create a more effective

seal.

X After driving for approximately 3 minutes,

stop the vehicle at a suitable location, e.g.

at a car park or gas station.

X Check the tire pressure again.

The tire pressure must be at least

300 kPa (3.0 bar/43.5 psi). G

WARNING

If the required tire pressure is not reached

after driving for a short period, the tire is too

badly damaged. The tire sealant cannot repair

the tire in this instance. Damaged tires and a

tire pressure that is too low can significantly

impair the vehicle's braking and driving

characteristics. There is a risk of accident.

Do not continue driving. Contact a qualified

specialist workshop.

i The Mercedes-Benz Service24h

telephone numbers can be found on a

sticker in the driver's door entrance area

and in the vehicle Maintenance Booklet.

i If you check the tire pressure with the tire

inflation compressor, connect angled valve

adapter 0006on tire inflation compressor

hose 0026directly to the tire valve. The tire

pressure will increase when you switch the

tire inflation compressor on. You can

reduce the tire pressure by opening the

pressure release screw on pressure gauge

0023.

If the tire pressure is still at least 300 kPa

(3.0 bar/43.5 psi):

X If possible, inflate the tire to the

recommended tire pressure (Y page 278).

X Drive to the nearest qualified specialist

workshop as soon as possible and have the

tire and tire sealant 0019replaced. Changing wheels

Rotating the wheels

G

WARNING

Interchanging the front and rear wheels may

severely impair the driving characteristics if

the wheels or tires have different dimensions.

The wheel brakes or suspension components

may also be damaged. There is a risk of

accident.

Rotate front and rear wheels only if the wheels

and tires are of the same dimensions.

! On vehicles equipped with a tire pressure

monitor, electronic components are

located in the wheel.

Tire-mounting tools should not be used

near the valve. This could damage the

electronic components.

Only have tires changed at a qualified

specialist workshop.

Always observe the instructions and safety

notes in the "Mounting awheel" section

(Y page 303).

The wear patterns on the front and rear tires

differ, depending on the operating conditions.

Rotate the wheels before a clear wear pattern

has formed on the tires. Front tires typically

wear more on the shoulders and the rear tires

in the center.

If your vehicle's tire configuration allows, you

can rotate the wheels according to the

intervals in the tire manufacturer's warranty

book in your vehicle documents. If no

warranty book is available, the tires should be

rotated every 3,000 to 6,000 miles (5,000 to

10,000 km), or earlier if tire wear requires. Do

not change the direction of rotation.

Clean the contac tsurface softhe wheel and

the brake disc thoroughly every time a wheel

is rotated. Check the tire pressure and

reactivate the tire pressure monitor if

necessary. 302

Changing wheelsWheels and tires

Page 306 of 334

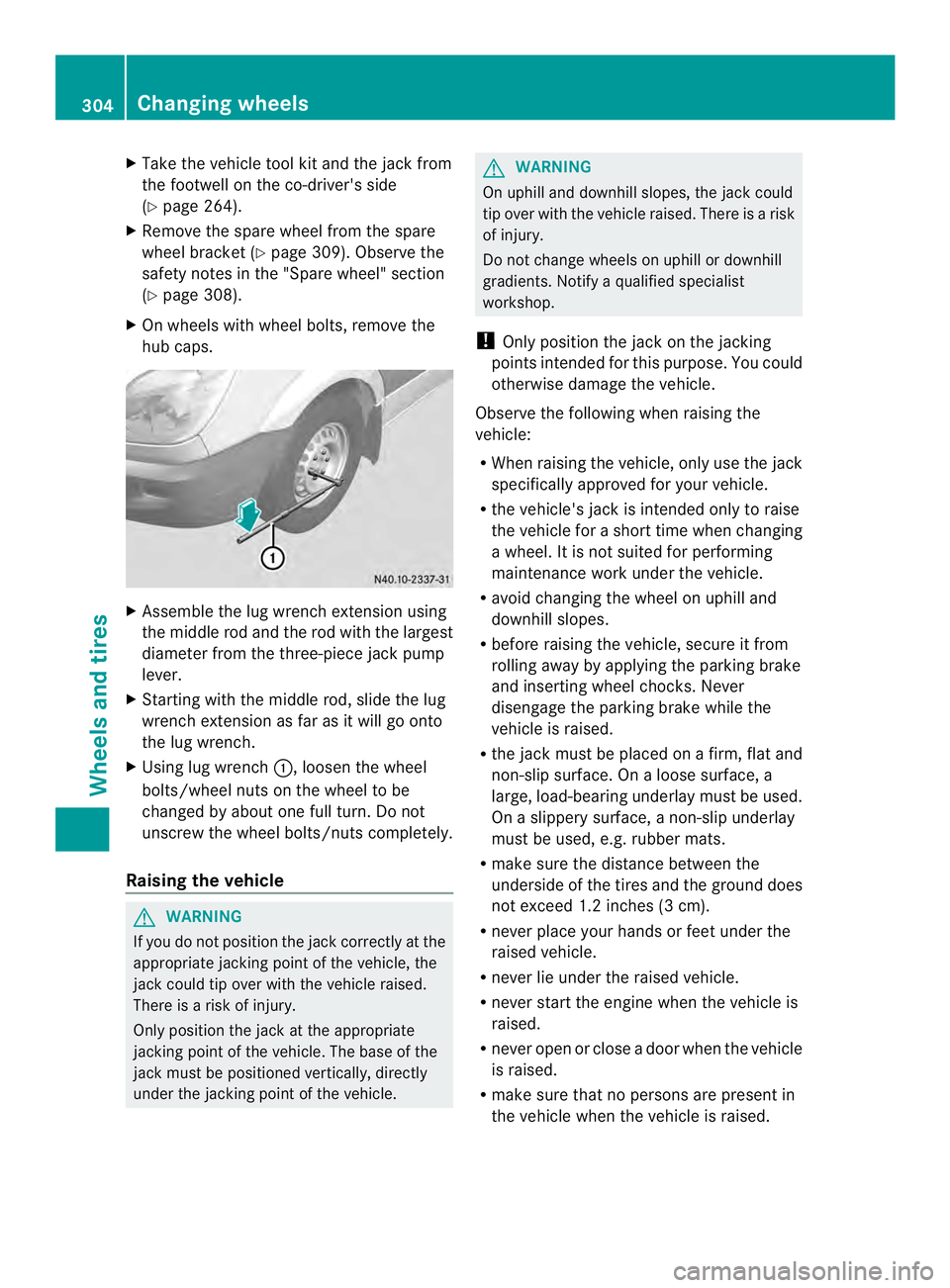

X

Take the vehicle tool kit and the jack from

the footwell on the co-driver's side

(Y page 264).

X Remove the spare wheel from the spare

wheel bracket (Y page 309). Observe the

safety notes in the "Spare wheel" section

(Y page 308).

X On wheels with wheel bolts, remove the

hub caps. X

Assemble the lug wrench extension using

the middle rod and the rod with the largest

diameter from the three-piece jack pump

lever.

X Starting with the middle rod, slide the lug

wrench extension as far as it will go onto

the lug wrench.

X Using lug wrench 0005, loosen the wheel

bolts/wheel nuts on the wheel to be

changed by about one full turn. Do not

unscrew the wheel bolts/nuts completely.

Raising the vehicle G

WARNING

If you do not position the jack correctly at the

appropriate jacking point of the vehicle, the

jack could tip over with the vehicle raised.

There is a risk of injury.

Only position the jack at the appropriate

jacking point of the vehicle. The base of the

jack must be positioned vertically, directly

under the jacking point of the vehicle. G

WARNING

On uphill and downhill slopes, the jack could

tip over with the vehicle raised. There is a risk

of injury.

Do not change wheels on uphill or downhill

gradients. Notify a qualified specialist

workshop.

! Only position the jack on the jacking

points intended for this purpose. You could

otherwise damage the vehicle.

Observe the following when raising the

vehicle:

R When raising the vehicle, only use the jack

specifically approved for your vehicle.

R the vehicle's jack is intended only to raise

the vehicle for a short time when changing

a wheel. It is not suited for performing

maintenance work under the vehicle.

R avoid changing the wheel on uphill and

downhill slopes.

R before raising the vehicle, secure it from

rolling away by applying the parking brake

and inserting wheel chocks. Never

disengage the parking brake while the

vehicle is raised.

R the jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a

large, load-bearing underlay must be used.

On a slippery surface, a non-slip underlay

must be used, e.g. rubber mats.

R make sure the distance between the

underside of the tires and the ground does

not exceed 1.2 inches (3 cm).

R never place your hands or feet under the

raised vehicle.

R never lie under the raised vehicle.

R never start the engine when the vehicle is

raised.

R never open or close a door when the vehicle

is raised.

R make sure that no persons are present in

the vehicle when the vehicle is raised. 304

Changing wheelsWheels and tires

Page 310 of 334

X

Wheel with hub cap: position the opening

for the tire valve in the hub cap over the tire

valve.

X Push the edge of the hub cap with both

hands against the wheel until it clicks into

place. Make sure the hub cap retaining

catches engage on the steel wheel.

X Wheel with central hub cap: position the

retaining lugs of the central hub cap over

the wheel bolts.

X Hit the middle of the hub cap to engage it

on the wheel.

X Secure the faulty wheel in the spare wheel

bracket (Y page 309).

X Check the tire pressure of the newly

mounted wheel and adjust it if necessary.

Observe the recommended tire pressure

(Y page 278).

X Retighten the wheel bolts or wheel nuts to

the specified tightening torque after the

vehicle has been driven for 30 miles

(50 km).

When using a wheel/spare wheel with a new

or newly painted wheel rim, have the wheel

bolts/nuts retightened again after

approximately 600 to 3,000 miles (1,000 to

5,000 km). Observe the specified tightening

torque.

i Vehicles with the tire pressure monitor

system: all mounted wheels must be

equipped with functioning sensors. Wheel and tire combination

General notes

! Retreaded tires are neither tested nor

recommended for Sprinter vehicles, since

previous damage cannot always be

detected on retreaded tires. We can

therefore not guarantee driving safety. Do

not mount used tires if you have no

information about their previous usage. The recommended tire pressures can be

found:

R

on the Tire and Loading Information

placard 11

on the B-pillar on the driver's side

R on the tire pressure table on the B-pillar on

the driver's side

The recommended tire pressure can also be

found in the "Tire pressure table" section in

these Operating Instructions (Y page 285).

The wheel/tire combination for your vehicle

can be found on the tire pressure table.

Further information on wheel/tire

combination can be obtained at any qualified

specialist workshop.

Check tire pressures regularly and only when

the tires are cold. Observe the notes on the

recommended tire pressures (Y page 278).

Follow the maintenance recommendations in

the tire manufacturer's warranty book in your

vehicle documents.

Notes on the vehicle equipment –always

install the vehicle:

R with tires of the same size across an axle

(left/right)

R with the same type of tires on all wheels at

a given time (summer tires, winter tires) Spare wheel

Important safety notes

G

WARNING

Wheel and tire dimensions as well as the type

of tire can vary between the spare wheel and

the wheel to be replaced. When the spare

wheel is installed, driving characteristics may

be severely affected. There is a risk of an

accident.

In order to reduce risks:

R you should therefore adapt your driving

style and drive carefully.

R never install more than one spare wheel

that differs fro mthe wheel to be replaced.

11 Only for vehicles with a gross weight of less than 10,000 lbs(4,536 kg). 308

Spare wheelWheels and tires

Page 324 of 334

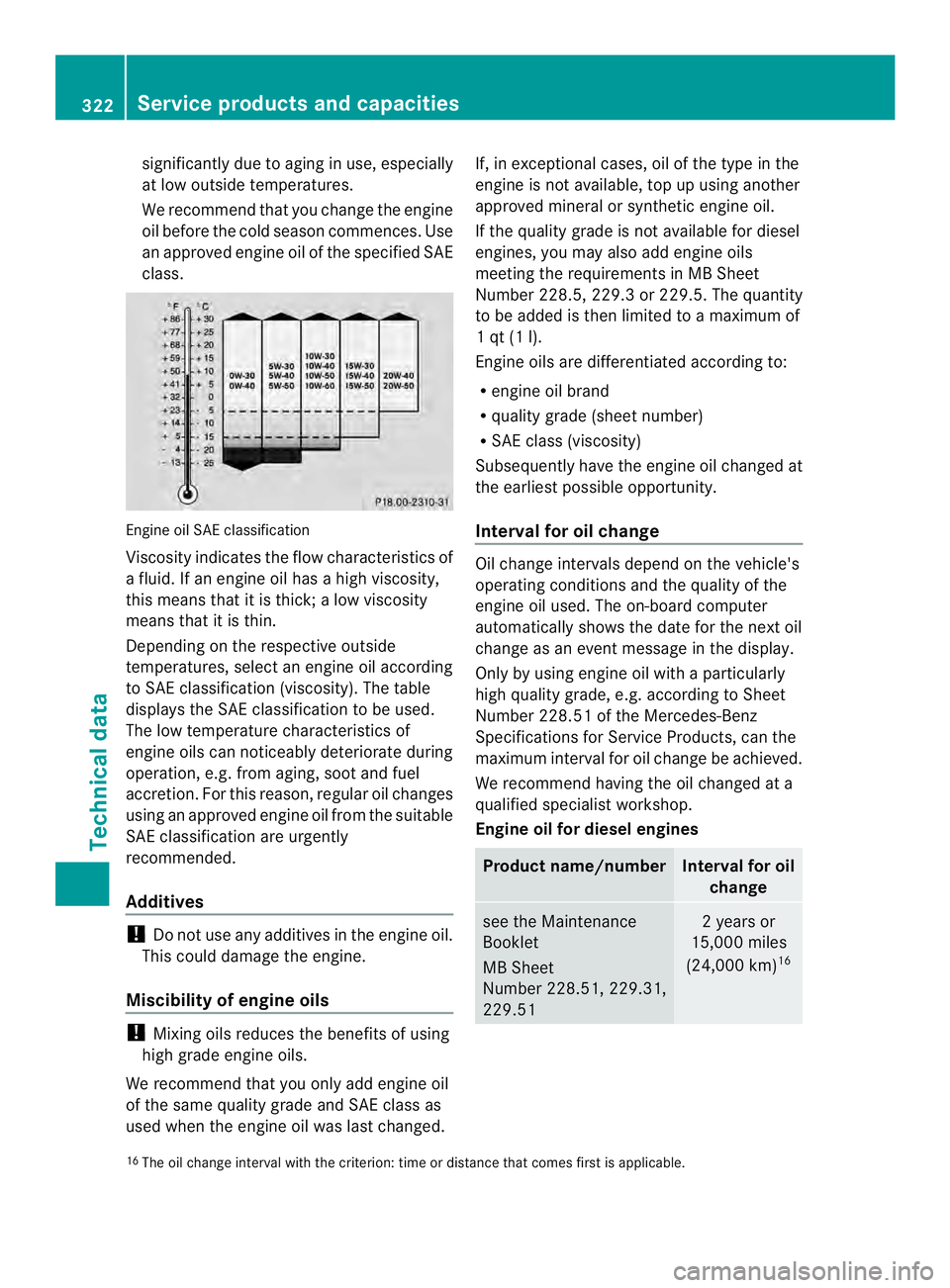

significantly due to aging in use, especially

at low outside temperatures.

We recommend that you change the engine

oil before the cold season commences. Use

an approved engine oil of the specified SAE

class.

Engine oil SAE classification

Viscosity indicates the flow characteristics of

a fluid. If an engine oil has a high viscosity,

this means that it is thick; a low viscosity

means that it is thin.

Depending on the respective outside

temperatures, select an engine oil according

to SAE classification (viscosity). The table

displays the SAE classification to be used.

The low temperature characteristics of

engine oils can noticeably deteriorate during

operation, e.g. from aging, soot and fuel

accretion. For this reason, regularo il changes

using an approved engine oil fro mthe suitable

SAE classification are urgently

recommended.

Additives !

Do not use any additives in the engine oil.

This could damage the engine.

Miscibility of engine oils !

Mixing oils reduces the benefits of using

high grade engine oils.

We recommend that you only add engine oil

of the same quality grade and SAE class as

used when the engine oil was last changed. If, in exceptional cases, oil of the type in the

engine is not available, top up using another

approved mineral or synthetic engine oil.

If the quality grade is not available for diesel

engines, you may also add engine oils

meeting the requirements in MB Sheet

Number 228.5, 229.3 or 229.5. The quantity

to be added is then limited to a maximum of

1 qt (1 l).

Engine oils are differentiated according to:

R

engine oil brand

R quality grade (sheet number)

R SAE class (viscosity)

Subsequently have the engine oil changed at

the earliest possible opportunity.

Interval for oil change Oil change intervals depend on the vehicle's

operating conditions and the quality of the

engine oil used. The on-board computer

automatically shows the date for the next oil

change as an event message in the display.

Only by using engine oil with a particularly

high quality grade, e.g. according to Sheet

Number 228.51 of the Mercedes-Benz

Specifications for Service Products, can the

maximum interval for oil change be achieved.

We recommend having the oil changed at a

qualified specialist workshop.

Engine oil for diesel engines

Product name/number Interval for oil

change see the Maintenance

Booklet

MB Sheet

Number 228.51, 229.31,

229.51 2y

ears or

15,000 miles

(24,000 km) 16 16

The oil change interval with the criterion: time or distance that comes first is applicable. 322

Service products and capacitiesTechnical data

Page 325 of 334

Capacities

!

Do no tadd too much oil. adding too much

engine oil can result in damage to the

engine or to the catalytic converter. Have

excess engine oil siphoned off.

Oil change including oil filter Engine oil

Approximately

13.21 US qt. (12.5 l) Information about oil consumption

!

If the vehicle is predominantly used for

short-distance driving, this could lead to a

malfunction in the automatic cleaning

function for the diesel particle filter. As a

result, fuel may accumulate in the engine

oil and cause engine failure.

Therefore, if you mainly drive short

distances, you should drive on a highway or

on rural roads for 20 minutes every

310 miles (500 km). This ensures sufficient

regeneration of the diesel particle filter.

Depending on the driving style, the vehicle

consumes a maximum of 1.0 US qt (1.0 l)of

engine oil over a distance of 620 miles

(1000 km).

Oil consumption may be higher if:

R the vehicle is new.

R you mainly operate the vehicle under

arduous operating conditions.

R you frequently drive at high engine speeds.

Regula rmaintenance is one of the

preconditions for moderate rates of

consumption.

You can only estimate th eoil consumption

after you have drive naconsiderable distance.

Check the engine oil level on a regular basis,

e.g. weekly or each time you refuel

(Y page 242). Transmission and power steering oil

Automatic transmission Service product: automatic transmission

fluid

Product name/number Maintenance

interval Shell ATF 3403/M-115

MB Sheet No. 236.10 60000 miles

(96000 km) Fuchs/Shell ATF 3353

MB Sheet No. 236.12

Further information can be obtained at any

qualified specialist workshop.

Rear axle

Service product: transmission oil

Product name/number Maintenance

interval BP Energear Hypo DC

80W-90

MB Sheet No. 235.20 10 years or

180000 miles

(288000 km) 17 Mobil Delvac Synthetic

Gear Oil 75W-90

MB Sheet No. 235.8

Further information can be obtained at any

qualified specialist workshop.

Steering

Service product: power steering fluid

Product name/number Maintenance

interval Mobil ATF-D,

Exxon Mobil Corporation

or equivalent

MB Sheet No. 236.3 —

17

The maintenance interval with the criterion (time or distance) that comes first is applicable. Service products and capacities

323Technical data Z

Page 326 of 334

The steering is maintenance-free. Further

information can be obtained at any qualified

specialist workshop.

Brake fluid

G

WARNING

Brake fluid is hazardous to health. Do not

swallow brake fluid. See adoctor immediately

if you swallow brake fluid.

Make sure that brake fluid does not come into

contact with skin, clothing or eyes. Rinse

affected areas with plenty of clean water and

consult a doctor if necessary.

Always wear gloves and eye protection when

topping up brake fluid.

Store brake fluid only in the original closed

container and keep it out of the reach of

children. Comply with safety regulations

when handling brake fluid. G

WARNING

The brake fluid constantly absorbs moisture

from the air. This lowers the boiling point of

the brake fluid. If the boiling point of the brake

fluid is too low, vapor pockets may form in the

brake system when the brakes are applied

hard. This would impair braking efficiency.

There is a risk of an accident.

You should have the brake fluid renewed at

the specified intervals.

! Brake fluid corrodes paint, plastic and

rubber. If paint, plastic or rubber has come

into contact with brake fluid, rinse with

water immediately.

Only use brake fluids approved for Sprinter

vehicles. Always check for the identification

DOT 4plus.

Information about approved brake fluids can

be found in the Maintenance Booklet or

obtained at any qualified specialist workshop. Service product:

brake fluid Produc

tname/

number Intac B026E

R

Boiling point: 500 ‡

(260 †)

R Wet boiling point:

356 ‡ (180 †) MB Sheet No. 331.0

Maintenance

interval 2y

ears i

Have the brake fluid renewed every 2

years at a qualified specialist workshop.

There is usually a notice in the engine

compartment to remind you when the next

brake fluid change is due. Coolant

Important safety notes G

WARNING

Coolant contains glycol and is therefore toxic.

Do not swallow the coolant .See a doctor

immediately if you swallow coolant.

Make sure that coolant does not come into

contact with skin, eyes or clothing. In case of

contact with eyes, rinse immediately with

plenty of clean water. Clean affected areas of

skin and clothing with soap and water

immediately. Change any affected clothing

immediately. G

WARNING

If antifreeze comes into contact with hot

components in the engine compartment, it

may ignite. There is a risk of fire and injury.

Let the engine cool down before you add

antifreeze. Make sure that antifreeze is not

spilled nextt o the filler neck.T horoughly

clean the antifreeze from components before

starting the engine. 324

Service products and capacitiesTechnical data

Page 327 of 334

!

Take care not to spill any coolant on

painted surfaces. You could otherwise

damage the paintwork.

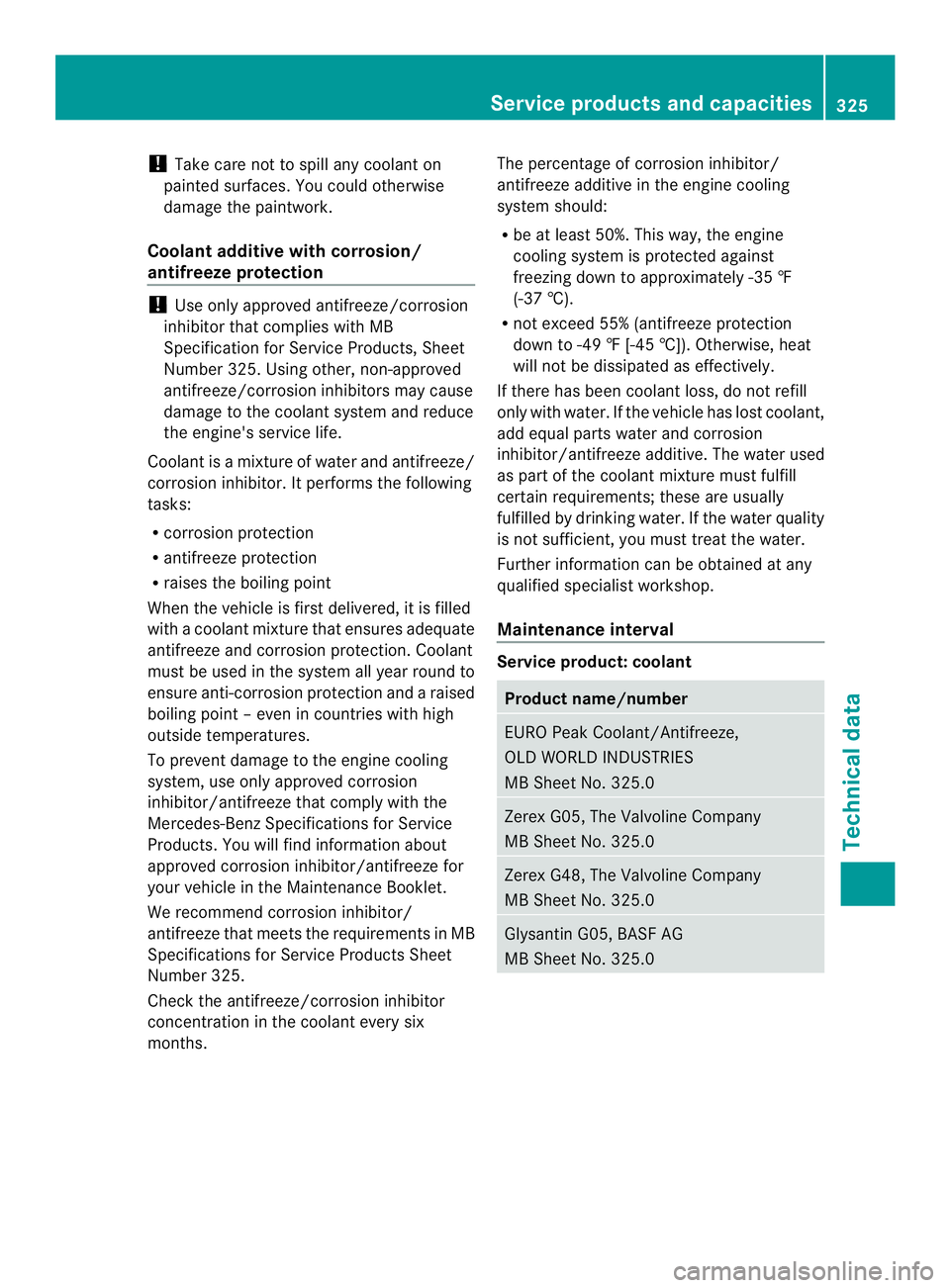

Coolant additive with corrosion/

antifreeze protection !

Use only approved antifreeze/corrosion

inhibitor that complies with MB

Specification for Service Products, Sheet

Number 325. Using other, non-approved

antifreeze/corrosion inhibitors may cause

damage to the coolant system and reduce

the engine's service life.

Coolant is a mixture of water and antifreeze/

corrosion inhibitor. It performs the following

tasks:

R corrosion protection

R antifreeze protection

R raises the boiling point

When the vehicle is first delivered, it is filled

with a coolant mixture that ensures adequate

antifreeze and corrosion protection. Coolant

must be used in the system all yearr ound to

ensure anti-corrosion protection and a raised

boiling point –even in countries with high

outside temperatures.

To prevent damage to the engine cooling

system, use only approved corrosion

inhibitor/antifreeze that comply with the

Mercedes-Benz Specifications for Service

Products. You will find information about

approved corrosio ninhibitor/antifreeze for

your vehicle in the Maintenance Booklet.

We recommend corrosion inhibitor/

antifreeze tha tmeets the requirements in MB

Specifications for Service Products Sheet

Number 325.

Check the antifreeze/corrosion inhibitor

concentration in the coolant every six

months. The percentage of corrosion inhibitor/

antifreeze additive in the engine cooling

system should:

R

be at least 50%. This way, the engine

cooling system is protected against

freezing down to approximately -35 ‡

(-37 †).

R not exceed 55% (antifreeze protection

down to -49 ‡ [-45 †]). Otherwise, heat

will not be dissipated as effectively.

If there has been coolant loss, do not refill

only with water. If the vehicle has lost coolant,

add equal parts water and corrosion

inhibitor/antifreeze additive. The water used

as part of the coolant mixture must fulfill

certain requirements; these are usually

fulfilled by drinking water. If the water quality

is not sufficient, you must treat the water.

Further information can be obtained at any

qualified specialist workshop.

Maintenance interval Service product: coolant

Product name/number

EURO Peak Coolant/Antifreeze,

OLD WORLD INDUSTRIES

MB Sheet No. 325.0

Zerex G05, The Valvoline Company

MB Sheet No. 325.0

Zerex G48, The Valvoline Company

MB Sheet No. 325.0

Glysantin G05, BASF AG

MB Sheet No. 325.0Service products and capacities

325Technical data Z

Page 328 of 334

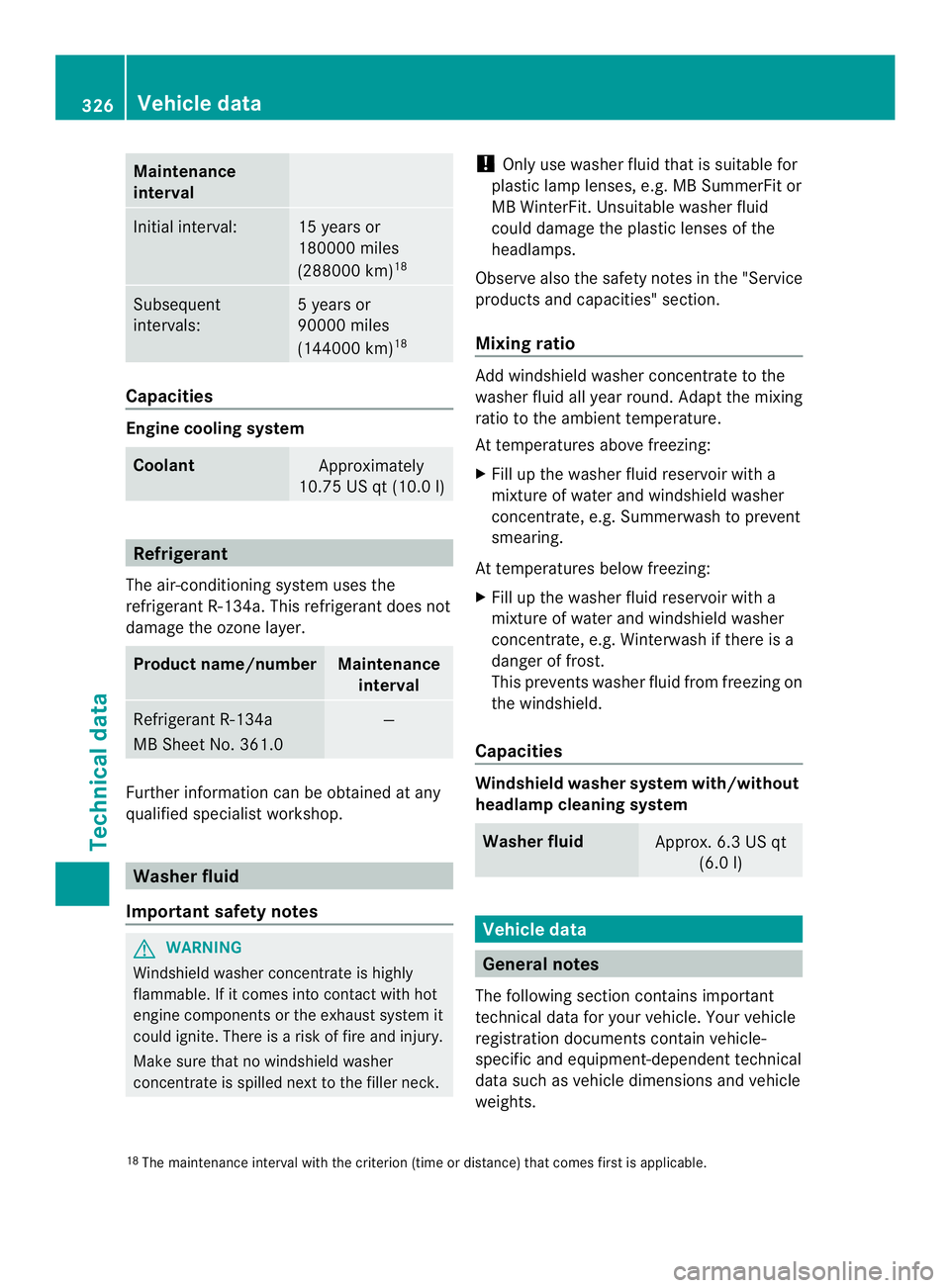

Maintenance

interval

Initial interval: 15 years or

180000 miles

(288000 km)

18 Subsequent

intervals: 5y

ears or

90000 miles

(144000 km) 18 Capacities

Engine cooling system

Coolant

Approximately

10.75 US qt (10.0 l) Refrigerant

The air-conditioning system uses the

refrigerant R-134a. This refrigerant does not

damage the ozone layer. Product name/number Maintenance

interval Refrigerant R-134a

MB Sheet No. 361.0 —

Further information can be obtained at any

qualified specialist workshop.

Washer fluid

Important safety notes G

WARNING

Windshield washer concentrate is highly

flammable. If it comes into contact with hot

engine components or the exhaust system it

could ignite. There is a risk of fire and injury.

Make sure that no windshield washer

concentrate is spilled next to the filler neck. !

Only use washer fluid that is suitable for

plastic lamp lenses, e.g. MB SummerFit or

MB WinterFit .Unsuitabl ewasher fluid

could damage the plastic lenses of the

headlamps.

Observe also the safety notes in the "Service

products and capacities" section.

Mixing ratio Add windshield washe

rconcentrate to the

washer fluid all year round. Adapt the mixing

ratio to the ambient temperature.

At temperatures above freezing:

X Fill up the washer fluid reservoir with a

mixture of water and windshield washer

concentrate, e.g. Summerwash to prevent

smearing.

At temperatures below freezing:

X Fill up the washer fluid reservoir with a

mixture of water and windshield washer

concentrate, e.g. Winterwash if there is a

danger of frost.

This prevents washer fluid from freezing on

the windshield.

Capacities Windshield washer system with/without

headlam

pcleaning system Washer fluid

Approx. 6.3 US qt

(6.0 l) Vehicle data

General notes

The following section contain simportant

technical data for yourv ehicle. Your vehicle

registration documents contain vehicle-

specific and equipment-dependen ttechnical

data such as vehicle dimensions and vehicle

weights.

18 The maintenance interval with the criterion (time or distance) that comes first is applicable. 326

Vehicle dataTechnical data