service MERCEDES-BENZ SPRINTER 2015 MY15 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2015, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2015Pages: 334, PDF Size: 5.94 MB

Page 328 of 334

must be used in the system all year round to

ensure anti-corrosion protection and a raised

boiling point – even in countries with high

outside temperatures.

To prevent damage to the engine cooling sys- tem, use only approved corrosion inhibitor/

antifreeze that comply with the Mercedes-

Benz Specifications for Service Products.

We recommend corrosion inhibitor/anti-

freeze that meets the requirements in MB

Specifications for Service Products Sheet

Number 325.

Check the antifreeze/corrosion inhibitor con- centration in the coolant every six months.

The percentage of corrosion inhibitor/anti-

freeze additive in the engine cooling system

should:

R be at least 50%. This way, the engine cool-

ing system is protected against freezing

down to approximately -35 ‡ (-37 †).

R not exceed 55% (antifreeze protection

down to -49 ‡ [-45 †]). Otherwise, heat

will not be dissipated as effectively.

If there has been coolant loss, do not refill

only with water. If the vehicle has lost coolant,

add equal parts water and corrosion inhibi-

tor/antifreeze additive. The water used as

part of the coolant mixture must fulfill certain requirements; these are usually fulfilled by

drinking water. If the water quality is not suf-ficient, you must treat the water.

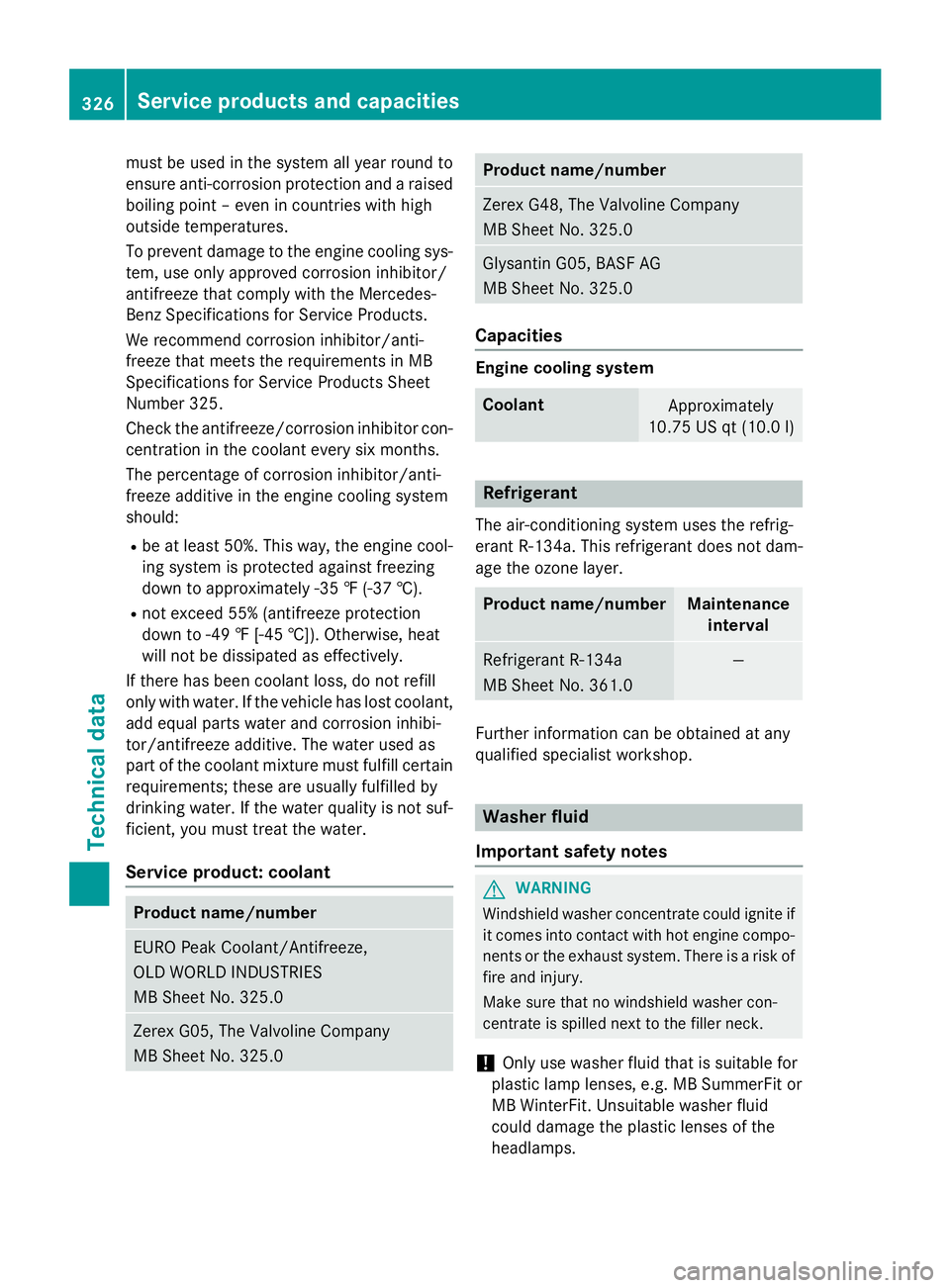

Service product: coolant Product name/number

EURO Peak Coolant/Antifreeze,

OLD WORLD INDUSTRIES

MB Sheet No. 325.0

Zerex G05, The Valvoline Company

MB Sheet No. 325.0 Product name/number

Zerex G48, The Valvoline Company

MB Sheet No. 325.0

Glysantin G05, BASF AG

MB Sheet No. 325.0

Capacities

Engine cooling system

Coolant

Approximately

10.75 US qt (10.0 l) Refrigerant

The air-conditioning system uses the refrig-

erant R‑134a. This refrigerant does not dam-

age the ozone layer. Product name/number Maintenance

interval Refrigerant R‑134a

MB Sheet No. 361.0 —

Further information can be obtained at any

qualified specialist workshop. Washer fluid

Important safety notes G

WARNING

Windshield washer concentrate could ignite if it comes into contact with hot engine compo-

nents or the exhaust system. There is a risk of

fire and injury.

Make sure that no windshield washer con-

centrate is spilled next to the filler neck.

! Only use washer fluid that is suitable for

plastic lamp lenses, e.g. MB SummerFit or

MB WinterFit. Unsuitable washer fluid

could damage the plastic lenses of the

headlamps. 326

Service products and capacitiesTechnical data

Page 329 of 334

When handling washer fluid, observe the

important safety notes on service products

(Y page 318).

Mixing ratio Add windshield washer concentrate to the

washer fluid all year round. Adapt the mixing

ratio to the ambient temperature.

At temperatures above freezing:

X Fill up the washer fluid reservoir with a mix-

ture of water and windshield washer con-

centrate, e.g. Summerwash to prevent

smearing.

At temperatures below freezing: X Fill up the washer fluid reservoir with a mix-

ture of water and windshield washer con-

centrate, e.g. Winterwash if there is a dan- ger of frost.

This prevents washer fluid from freezing on the windshield.

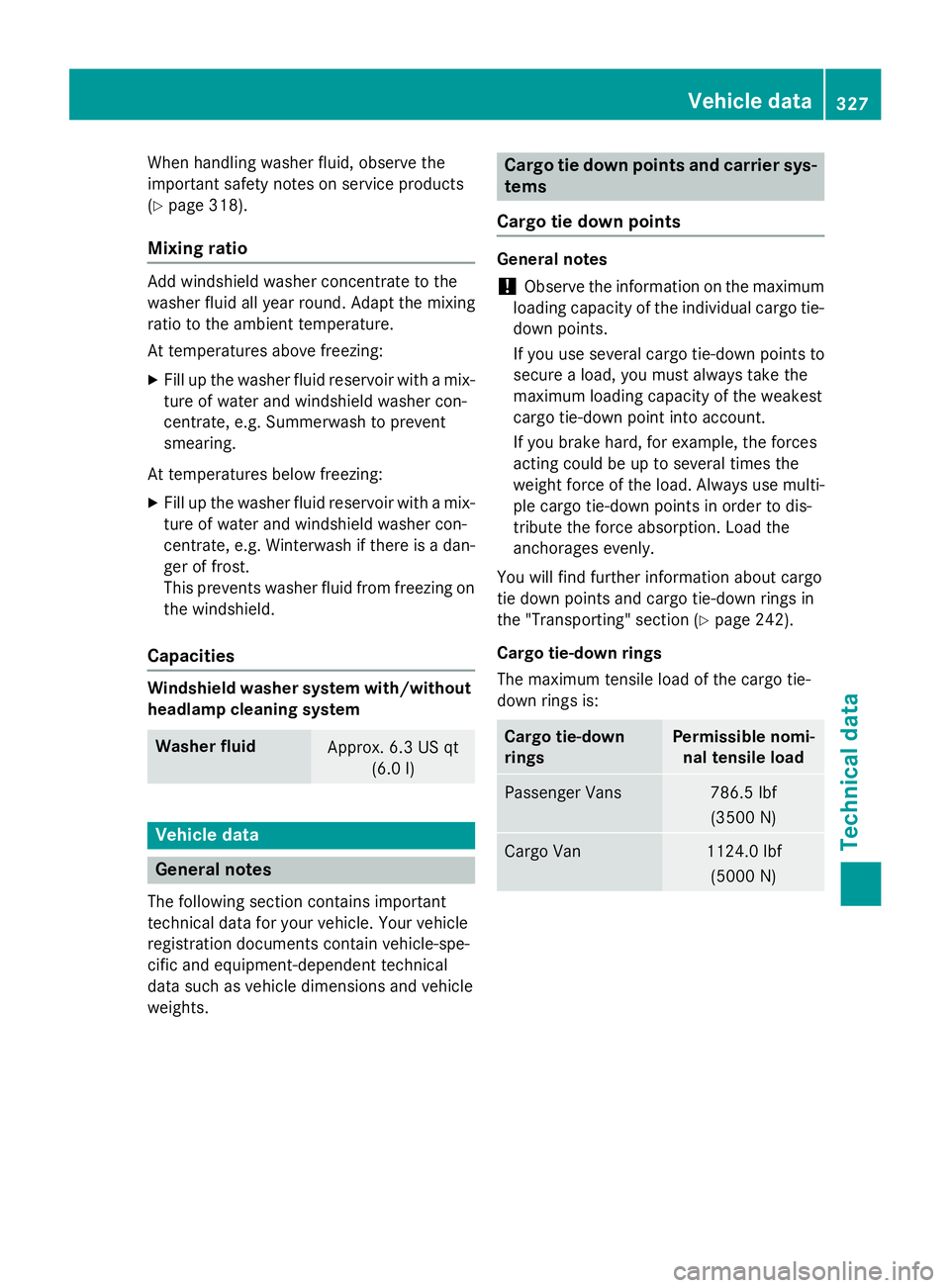

Capacities Windshield washer system with/without

headlamp cleaning system Washer fluid

Approx. 6.3 US qt

(6.0l) Vehicle data

General notes

The following section contains important

technical data for your vehicle. Your vehicle

registration documents contain vehicle-spe-

cific and equipment-dependent technical

data such as vehicle dimensions and vehicle

weights. Cargo tie down points and carrier sys-

tems

Cargo tie down points General notes

! Observe the information on the maximum

loading capacity of the individual cargo tie-

down points.

If you use several cargo tie-down points to

secure a load, you must always take the

maximum loading capacity of the weakest

cargo tie-down point into account.

If you brake hard, for example, the forces

acting could be up to several times the

weight force of the load. Always use multi-

ple cargo tie-down points in order to dis-

tribute the force absorption. Load the

anchorages evenly.

You will find further information about cargo

tie down points and cargo tie-down rings in

the "Transporting" section (Y page 242).

Cargo tie-down rings

The maximum tensile load of the cargo tie-

down rings is: Cargo tie-down

rings Permissible nomi-

nal tensile load Passenger Vans 786.5 lbf

(3500 N) Cargo Van 1124.0 lbf

(5000 N) Vehicle data

327Technical data Z