tires MERCEDES-BENZ SPRINTER 2015 MY15 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2015, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2015Pages: 334, PDF Size: 5.94 MB

Page 308 of 334

Single tires:

if the tires are of identical

dimensions, you can rotate both wheels on

both the front and rear axles so that the tires'

original direction of rotation is maintained. On unidirectional tires, an arrow on the sidewall

shows the prescribed direction of rotation of

the tire.

Twin rear tires: if the tires are of identical

dimensions, you can rotate the wheels on the

front axle and the inner wheels on the rear

axle in pairs such that the original direction of

tire rotation is retained. With unidirectional

tires, you may rotate the outside wheels at

the rear axle from one side to the other. Direction of rotation

Tires with a specified direction of rotation

have additional benefits, e.g. if there is a risk

of hydroplaning. You will only gain these ben-

efits if the correct direction of rotation is

observed.

An arrow on the sidewall of the tire indicates its correct direction of rotation.

You may mount a spare wheel against the

direction of rotation. Observe the time

restriction on use as well as the speed limi-

tation specified on the spare wheel. Storing wheels

Store wheels that are not being used in a cool, dry and preferably dark place. Protect the

tires from contact with oil, grease and fuel. Mounting a wheel

Vehicle preparation X

Stop the vehicle as far away as possible

from traffic and on a level, firm and non-slip

surface.

X If your vehicle poses a risk to approaching

traffic, switch on the hazard warning lamps.

X Apply the parking brake. X

Turn the front wheels to the straight-ahead

position.

X Move the selector lever of the automatic

transmission to position P.

X Switch off the engine.

X Passengers should leave the vehicle. Make

sure that the passengers are not endan-

gered as they do so.

X Make sure that no one is near the danger

area while the wheel is being changed. Any-

one who is not directly assisting in the

wheel change should, for example, stand

behind the barrier.

X Place the warning triangle or warning lamp

at a suitable distance.

Observe legal requirements.

X Secure the vehicle to prevent it from rolling

away.

i Observe the safety notes on parking in the

section on "Driving and parking"

(Y page 149).

X On level terrain: place chocks or other

suitable objects under the front and rear of the wheel that is diagonally opposite the

wheel to be changed.

X On slight inclines: place chocks or other

suitable objects under the wheels on the

front and rear axles opposite the wheel to

be changed.

X Take the vehicle tool kit and the jack from

the footwell on the co-driver's side

(Y page 274).

X Remove the spare wheel from the spare

wheel bracket (Y page 313). Observe the

safety notes in the "Spare wheel" section

(Y page 312).

X On wheels with wheel bolts, remove the

hub caps. 306

Changing wheelsWheels and tires

Page 309 of 334

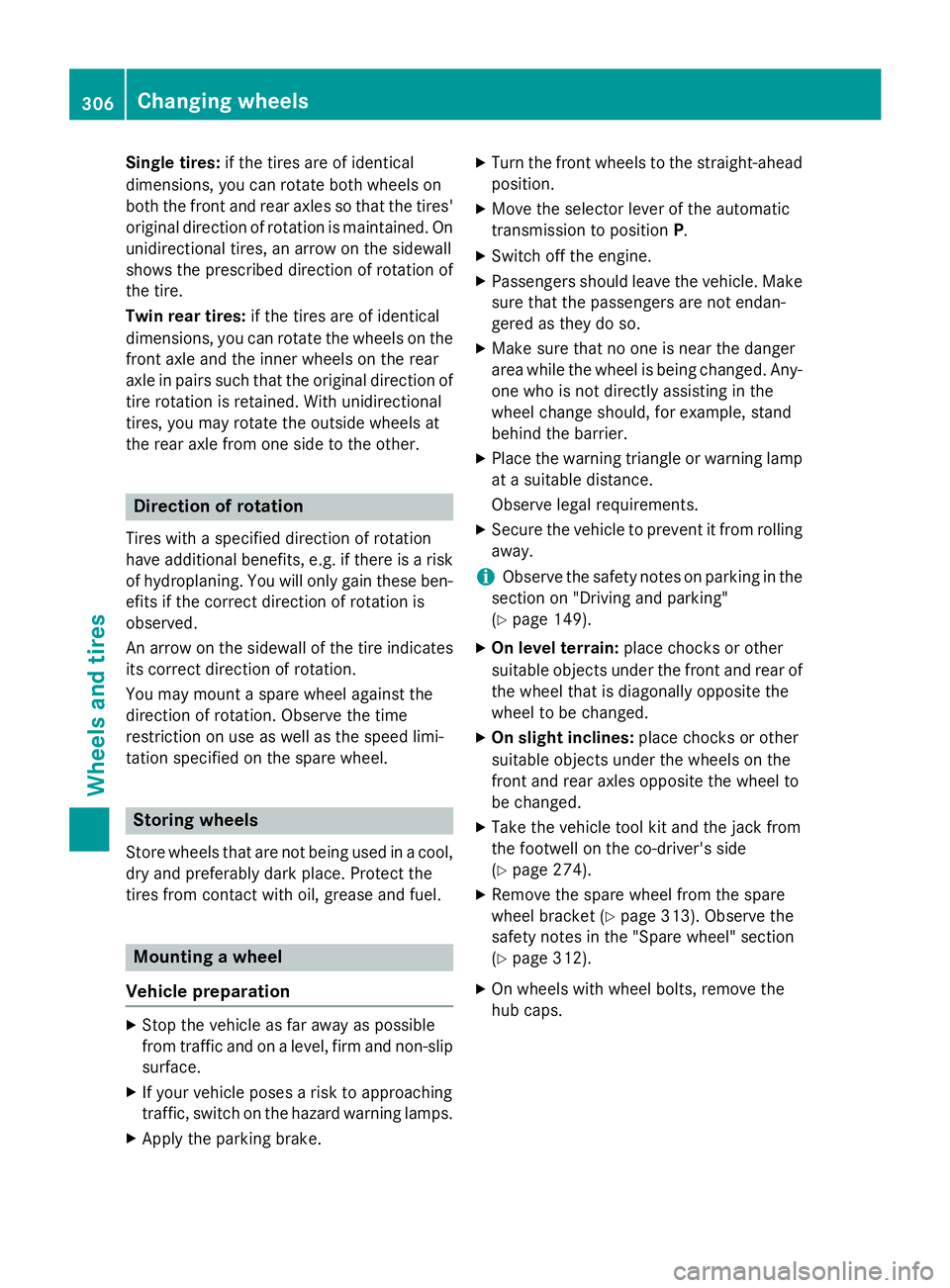

X

Assemble the lug wrench extension using

the middle rod and the rod with the largest diameter from the three-piece jack pump

lever.

X Starting with the middle rod, slide the lug

wrench extension as far as it will go onto

the lug wrench.

X Using lug wrench 0043, loosen the wheel

bolts/wheel nuts on the wheel to be

changed by about one full turn. Do not

unscrew the wheel bolts/nuts completely.

Raising the vehicle G

WARNING

If you do not position the jack correctly at the appropriate jacking point of the vehicle, the

jack could tip over with the vehicle raised.

There is a risk of injury.

Only position the jack at the appropriate jack-

ing point of the vehicle. The base of the jack

must be positioned vertically, directly under

the jacking point of the vehicle. G

WARNING

On uphill and downhill slopes, the jack could

tip over with the vehicle raised. There is a risk of injury.

Do not change wheels on uphill or downhill

gradients. Notify a qualified specialist work-

shop.

! Only position the jack on the jacking

points intended for this purpose. You could

otherwise damage the vehicle. Observe the following when raising the vehi-

cle:

R When raising the vehicle, only use the jack

which Mercedes-Benz has specifically

approved for your vehicle.

R The vehicle's jack is intended only to raise

the vehicle for a short time when changing

a wheel. It is not suited for performing

maintenance work under the vehicle.

R Avoid changing the wheel on uphill and

downhill slopes.

R Before raising the vehicle, secure it from

rolling away by applying the parking brake

and inserting wheel chocks. Never disen-

gage the parking brake while the vehicle is

raised.

R The jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a

large, load-bearing underlay must be used. On a slippery surface, a non-slip underlay

must be used, e.g. rubber mats.

R Make sure that the distance between the

underside of the tires and the ground does

not exceed 1.2 in(3 cm).

R Never place your hands or feet under the

raised vehicle.

R Never lie under the raised vehicle.

R Never start the engine when the vehicle is

raised.

R Never open or close a door when the vehi-

cle is raised.

R Make sure that no persons are present in

the vehicle when the vehicle is raised.

! Only use the jack pump lever middle rod

and the rod with the largest diameter as a

lug wrench extension. Only slide the middle rod as far as it will go onto the lug wrench. The rods may otherwise bend and be dis-

torted to such an extent that they can no

longer be used as a pump lever for the jack.

! Do not place the jack on the leaf spring or

the differential case. Changing wheels

307Wheels and tires Z

Page 310 of 334

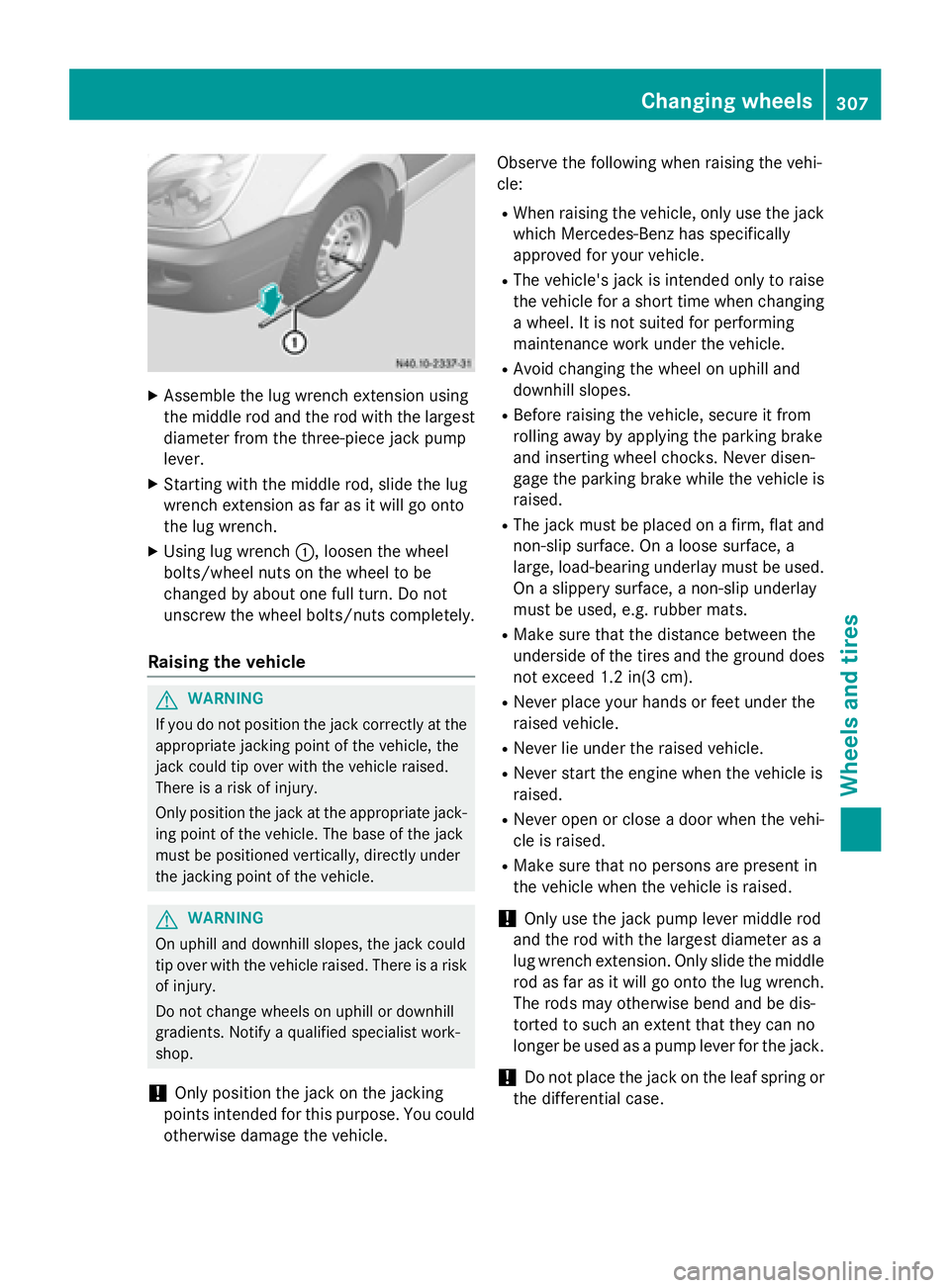

Hydraulic jack

Preparing the hydraulic jack

X Insert the third rod of jack pump lever 0043

into the lug wrench extension.

Jack pump lever 0043is assembled.

X Close pressure release screw 0044.

X To do this, use the flattened section on

pump lever 0043to turn pressure release

screw 0044clockwise to the stop.

i Do not turn pressure release screw

0044

more than 1 or 2 full turns. Hydraulic fluid

could otherwise escape.

X Insert pump lever 0043into the recess on the

jack and secure by turning it clockwise.

X Place the jack vertically beneath the jack-

ing points described below. Jacking point, front axle

Jacking point at the front axle

X Place the jack under the longitudinal mem-

ber in front of the front axle. Jacking point, rear axle (example: vehicle type

2500) Jacking point, rear axle (example: vehicle type

3500)

Jacking point at the rear axle on vehicle

types 2500 and 3500

X Place the jack under the longitudinal mem-

ber in front of the rear axle. Jacking point, rear axle (example: Cab Chassis)

Jacking point at the rear axle on chassis

versions

X Place the jack next to the front leaf spring

support beneath the jacking point. 308

Changing wheelsWheels and tires

Page 311 of 334

Removing a wheel

!

Do not place the wheel bolts or the wheel

nuts in sand or dirt. The threads of the

wheel bolts and wheel nuts could otherwise

be damaged when being tightened.

X Unscrew the wheel bolts or nuts.

X On front wheels with wheel nuts, remove

the wheel nut cover.

X Remove the wheel.

Installing the adapter G

WARNING

If you tighten the adapter bolts when the vehi- cle is raised, the jack could tip over. There is a risk of injury.

Make sure that the vehicle is properly pre-

pared for a wheel change. Tighten the adapter

bolts with particular care and attention.

Always observe the instructions and safety

notes on "Changing a wheel" (Y page 305).G

WARNING

If you do not tighten the bolts of the adapter to the specified tightening torque, the adapter

may come loose with the spare wheel. There

is a risk of an accident.

Tighten the bolts of the adapter to the speci-

fied tightening torque. Have the spare wheel

replaced with a complete wheel and an extra- wide tire at a qualified specialist workshop

immediately.

! Vehicles with Super Single tires:

if you

install the spare wheel, do not exceed the

maximum speed of 40 mph (60 km/h) and

do not drive further than 65 miles(100 km).

The transmission could otherwise be dam-

aged by the difference in wheel rotation

speeds.

On vehicles with Super Single tires, you must

attach the narrow spare wheel to the rear axle by means of an adapter. The adapter is bolted

to the spare wheel using the adapter bolts for transportation. The handling characteristics of your vehicle

are affected when driving with a spare wheel

installed. After changing a wheel, drive to the

nearest specialist workshop and have the

spare wheel replaced with a wheel and tire

assembly that has a Super Single tire.

X Clean the wheel and wheel hub contact

surfaces.

X Unscrew the six adapter bolts on the spare

wheel and remove the adapter.

X Tighten the adapter with the six adapter

bolts evenly in a crosswise pattern through

the outer holes on the wheel hub.

X Tighten the six adapter bolts on the wheel

hub to a tightening torque of 177 lb-ft

(240 Nm).

X Push the wheel onto the adapter and attach

it.

Mounting a new wheel G

WARNING

Oiled or greased wheel bolts or damaged

wheel bolts/hub threads can cause the wheel bolts to come loose. As a result, you could

lose a wheel while driving. There is a risk of

accident.

Never oil or grease wheel bolts. In the event of damage to the threads, contact a qualified

specialist workshop immediately. Have the

damaged wheel bolts or hub threads

replaced/renewed. Do not continue driving. G

WARNING

If you tighten the wheel bolts or wheel nuts

when the vehicle is raised, the jack could tip

over. There is a risk of injury.

Only tighten the wheel bolts or wheel nuts

when the vehicle is on the ground.

Always observe the instructions and safety

notes on "Changing a wheel" (Y page 305).

Only use wheel bolts or wheel nuts that have

been designed for the wheel and the vehicle. For safety reasons, we recommend that you

only use wheel bolts or wheel nuts which have Changing wheels

309Wheels and tires Z

Page 312 of 334

been approved for Sprinter vehicles and the

respective wheel.

! For a steel wheel, only use the short wheel

bolts to mount the steel spare wheel. Using other wheel bolts to mount the steel spare wheel could damage the brake system.

! On vehicles equipped with a tire pressure

monitor, electronic components are loca-

ted in the wheel.

Tire-mounting tools should not be used

near the valve. This could damage the elec-

tronic components.

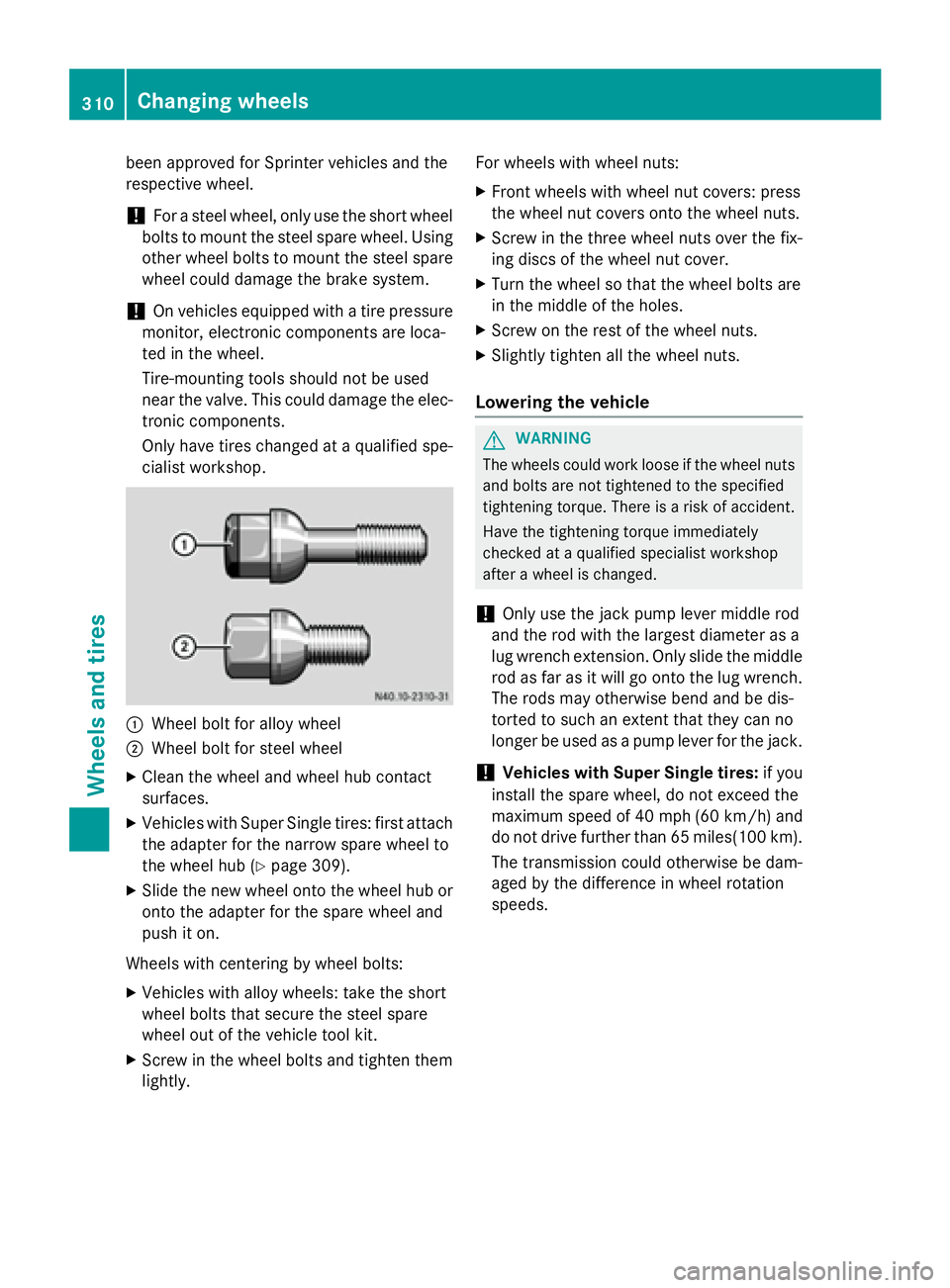

Only have tires changed at a qualified spe- cialist workshop. 0043

Wheel bolt for alloy wheel

0044 Wheel bolt for steel wheel

X Clean the wheel and wheel hub contact

surfaces.

X Vehicles with Super Single tires: first attach

the adapter for the narrow spare wheel to

the wheel hub (Y page 309).

X Slide the new wheel onto the wheel hub or

onto the adapter for the spare wheel and

push it on.

Wheels with centering by wheel bolts:

X Vehicles with alloy wheels: take the short

wheel bolts that secure the steel spare

wheel out of the vehicle tool kit.

X Screw in the wheel bolts and tighten them

lightly. For wheels with wheel nuts:

X Front wheels with wheel nut covers: press

the wheel nut covers onto the wheel nuts.

X Screw in the three wheel nuts over the fix-

ing discs of the wheel nut cover.

X Turn the wheel so that the wheel bolts are

in the middle of the holes.

X Screw on the rest of the wheel nuts.

X Slightly tighten all the wheel nuts.

Lowering the vehicle G

WARNING

The wheels could work loose if the wheel nuts and bolts are not tightened to the specified

tightening torque. There is a risk of accident.

Have the tightening torque immediately

checked at a qualified specialist workshop

after a wheel is changed.

! Only use the jack pump lever middle rod

and the rod with the largest diameter as a

lug wrench extension. Only slide the middle rod as far as it will go onto the lug wrench. The rods may otherwise bend and be dis-

torted to such an extent that they can no

longer be used as a pump lever for the jack.

! Vehicles with Super Single tires:

if you

install the spare wheel, do not exceed the

maximum speed of 40 mph (60 km/ h)and

do not drive further than 65 miles(100 km ).

The transmission could otherwise be dam-

aged by the difference in wheel rotation

speeds. 310

Changing wheelsWheels and tires

Page 313 of 334

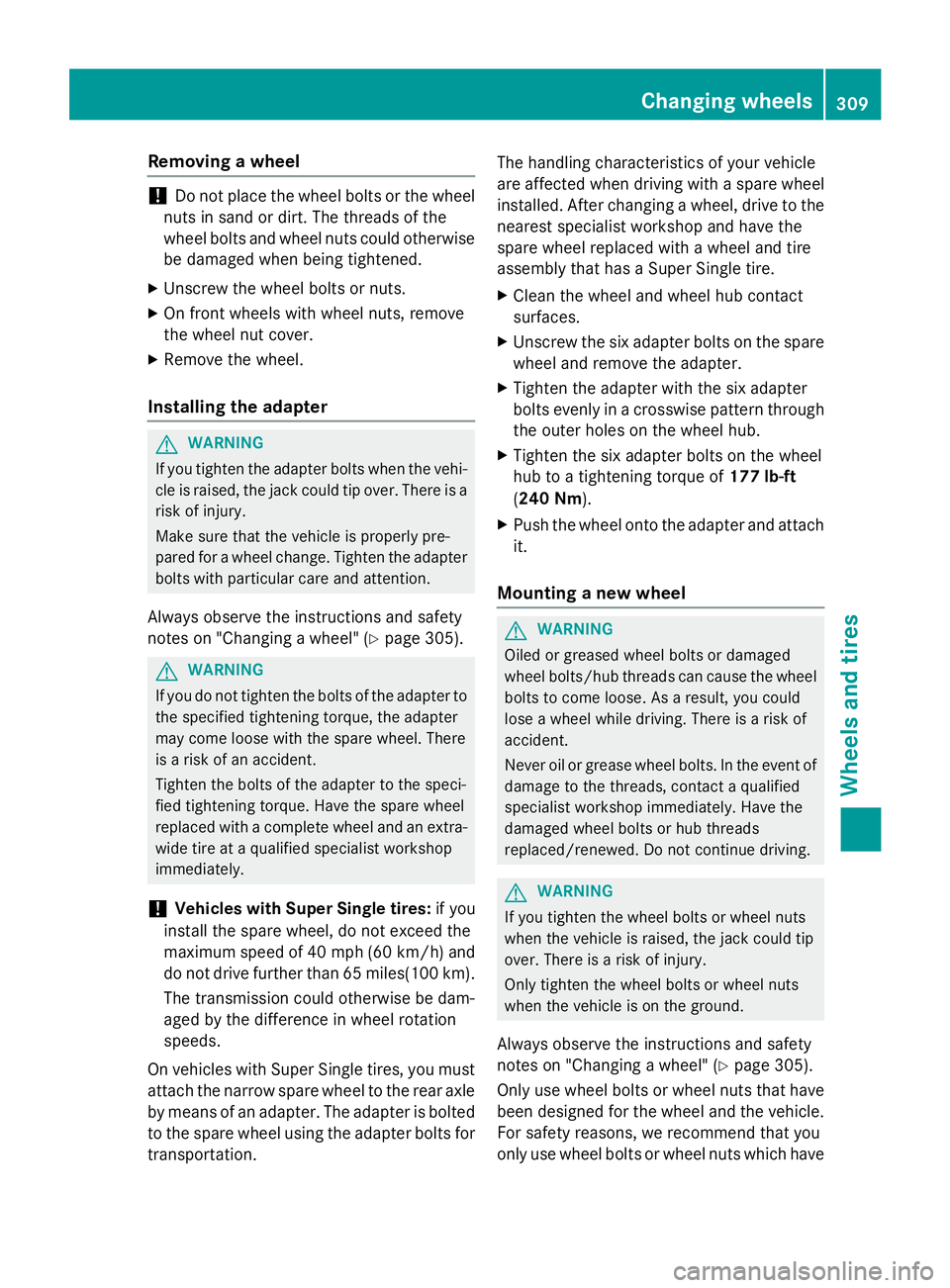

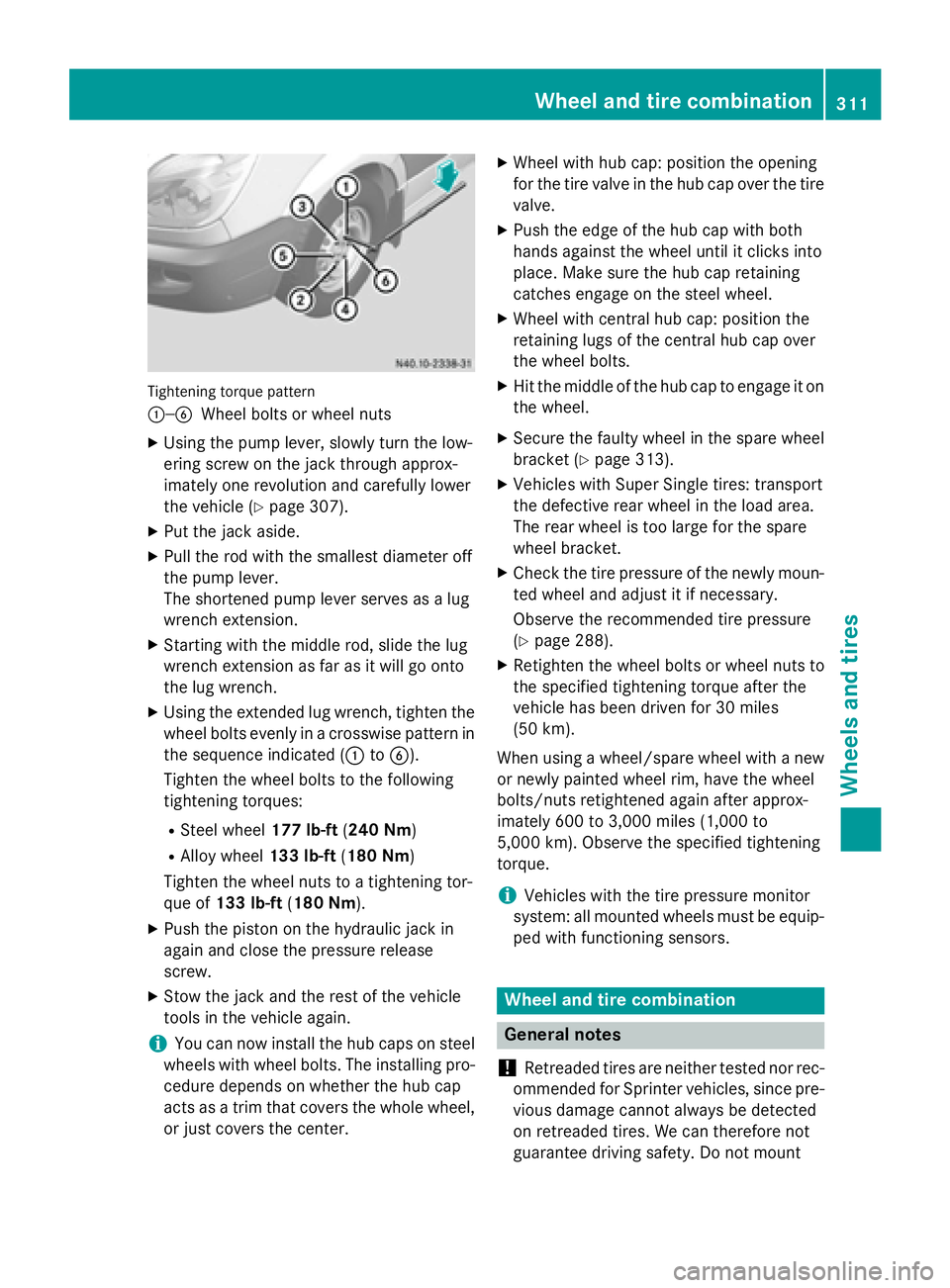

Tightening torque pattern

0043—0084

Wheel bolts or wheel nuts

X Using the pump lever, slowly turn the low-

ering screw on the jack through approx-

imately one revolution and carefully lower

the vehicle (Y page 307).

X Put the jack aside.

X Pull the rod with the smallest diameter off

the pump lever.

The shortened pump lever serves as a lug

wrench extension.

X Starting with the middle rod, slide the lug

wrench extension as far as it will go onto

the lug wrench.

X Using the extended lug wrench, tighten the

wheel bolts evenly in a crosswise pattern in the sequence indicated (0043 to0084).

Tighten the wheel bolts to the following

tightening torques:

R Steel wheel 177 lb-ft(240 Nm)

R Alloy wheel 133 lb-ft(180 Nm)

Tighten the wheel nuts to a tightening tor-

que of 133 lb-ft (180 Nm).

X Push the piston on the hydraulic jack in

again and close the pressure release

screw.

X Stow the jack and the rest of the vehicle

tools in the vehicle again.

i You can now install the hub caps on steel

wheels with wheel bolts. The installing pro-

cedure depends on whether the hub cap

acts as a trim that covers the whole wheel,

or just covers the center. X

Wheel with hub cap: position the opening

for the tire valve in the hub cap over the tire

valve.

X Push the edge of the hub cap with both

hands against the wheel until it clicks into

place. Make sure the hub cap retaining

catches engage on the steel wheel.

X Wheel with central hub cap: position the

retaining lugs of the central hub cap over

the wheel bolts.

X Hit the middle of the hub cap to engage it on

the wheel.

X Secure the faulty wheel in the spare wheel

bracket (Y page 313).

X Vehicles with Super Single tires: transport

the defective rear wheel in the load area.

The rear wheel is too large for the spare

wheel bracket.

X Check the tire pressure of the newly moun-

ted wheel and adjust it if necessary.

Observe the recommended tire pressure

(Y page 288).

X Retighten the wheel bolts or wheel nuts to

the specified tightening torque after the

vehicle has been driven for 30 miles

(50 km).

When using a wheel/spare wheel with a new

or newly painted wheel rim, have the wheel

bolts/nuts retightened again after approx-

imately 600 to 3,000 miles (1,000 to

5,000 km). Observe the specified tightening

torque.

i Vehicles with the tire pressure monitor

system: all mounted wheels must be equip- ped with functioning sensors. Wheel and tire combination

General notes

! Retreaded tires are neither tested nor rec-

ommended for Sprinter vehicles, since pre-

vious damage cannot always be detected

on retreaded tires. We can therefore not

guarantee driving safety. Do not mount Wheel and tire combination

311Wheels and tires Z

Page 314 of 334

used tires if you have no information about

their previous usage.

The recommended tire pressures can be

found:

R on the Tire and Loading Information plac-

ard 10

on the B-pillar on the driver's side

R on the tire pressure table on the B-pillar on

the driver's side

The recommended tire pressure can also be

found in the "Tire pressure table" section in

this Operator's Manual (Y page 294). The

wheel/tire combination for your vehicle can

be found on the tire pressure table. Further

information on wheel/tire combination can

be obtained at any qualified specialist work-

shop.

Check tire pressures regularly and only when

the tires are cold. Observe the notes on the

recommended tire pressure (Y page 288).

Follow the maintenance recommendations in the tire manufacturer's warranty book in your

vehicle documents.

Notes on the vehicle equipment – always

equip the vehicle:

R with tires of the same size across an axle

(left/right)

R with the same type of tires on all wheels at

a given time (summer tires, winter tires)

Tires that have been specially designed and

approved for your vehicle are marked with

MO or MO1 (Mercedes-Benz Original). You

can find this identification on the tires them-

selves and in the following table.

i Not all wheel/tire combinations can be

installed at the factory in all countries. Spare wheel

Important safety notes

G

WARNING

Wheel and tire dimensions as well as the type of tire can vary between the spare wheel and the wheel to be replaced. When the spare

wheel is mounted, driving characteristics may be severely affected. There is a risk of an acci-

dent.

In order to reduce risks:

R you should therefore adapt your driving

style and drive carefully.

R never mount more than one spare wheel

that differs from the wheel to be replaced.

R only use a spare wheel that differs from the

wheel to be replaced for a short time.

R do not deactivate ESP ®

.

R have a spare wheel that differs from the

wheel that has been changed replaced at

the nearest qualified specialist workshop.

You must observe the correct wheel and

tire dimensions as well as the wheel type.

When using a spare wheel of a different size,

do not exceed the maximum speed of

80 km/h. General notes

! Check the spare wheel regularly to see

that it is secure and has the prescribed tire

pressure.

The procedure for mounting the spare wheel

is described in "Mounting a wheel"

(Y page 306).

The following should be checked regularly,

particularly prior to long journeys:

R the tire pressure of the spare wheel, which

should then be corrected if necessary

(Y page 288).

R the fastenings of the spare wheel bracket.

The spare wheel is located in a spare wheel

bracket under the rear of the vehicle.

Replace the tires after 6 years at the latest,

regardless of wear. This also applies to the

spare wheel.

10 Only for vehicles with a gross weight of less than 10,000 lbs (4,536 kg). 312

Spare wheelWheels and ti

res

Page 315 of 334

i

If you have mounted a spare wheel, the

tire pressure monitor (Y page 291) will not

function for this wheel. The spare wheel is

not equipped with a sensor for monitoring

tire pressure. Removing and installing the spare

wheel

Cargo Van/Passenger Van Bolt covers for the safety catches (example: Cargo

Van)

Removing

X Open the rear doors.

X Place a screwdriver into recesses 0044and

then pry off covers 0043.

X Using the lug wrench from the vehicle tool

kit (Y page 274), unscrew the now visible

bolts counter-clockwise by approximately

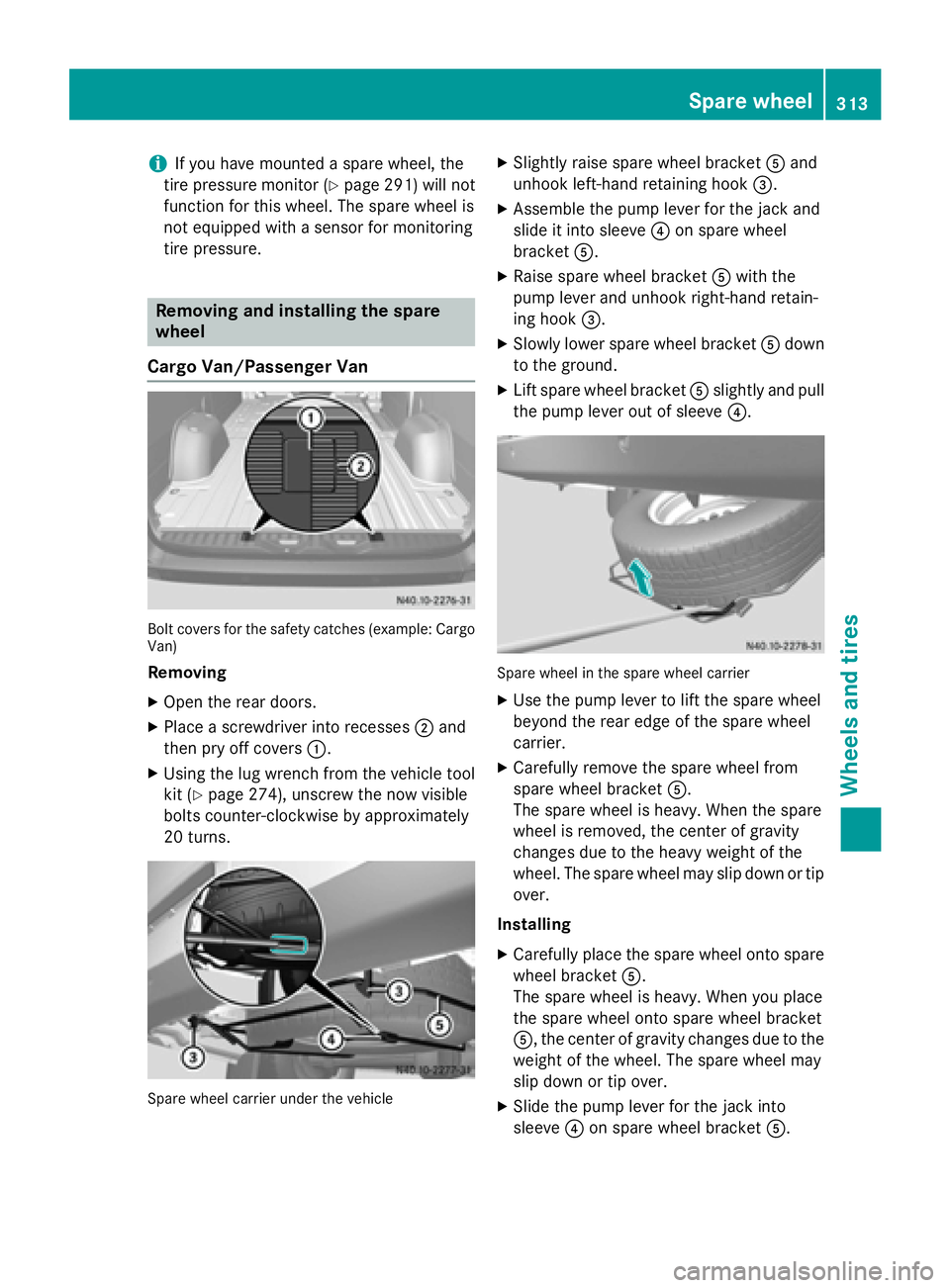

20 turns. Spare wheel carrier under the vehicle X

Slightly raise spare wheel bracket 0083and

unhook left-hand retaining hook 0087.

X Assemble the pump lever for the jack and

slide it into sleeve 0085on spare wheel

bracket 0083.

X Raise spare wheel bracket 0083with the

pump lever and unhook right-hand retain-

ing hook 0087.

X Slowly lower spare wheel bracket 0083down

to the ground.

X Lift spare wheel bracket 0083slightly and pull

the pump lever out of sleeve 0085. Spare wheel in the spare wheel carrier

X Use the pump lever to lift the spare wheel

beyond the rear edge of the spare wheel

carrier.

X Carefully remove the spare wheel from

spare wheel bracket 0083.

The spare wheel is heavy. When the spare

wheel is removed, the center of gravity

changes due to the heavy weight of the

wheel. The spare wheel may slip down or tip over.

Installing X Carefully place the spare wheel onto spare

wheel bracket 0083.

The spare wheel is heavy. When you place

the spare wheel onto spare wheel bracket

0083, the center of gravity changes due to the

weight of the wheel. The spare wheel may

slip down or tip over.

X Slide the pump lever for the jack into

sleeve 0085on spare wheel bracket 0083. Spare wheel

313Wheels and tires Z

Page 316 of 334

X

Raise spare wheel bracket 0083with the

pump lever and attach right-hand retaining hook 0087.

X Slightly raise spare wheel bracket 0083and

attach left-hand retaining hook 0087.

X Pull the pump lever out of sleeve 0085.

X Using the lug wrench, tighten the retaining

hook bolts by turning them clockwise.

X Replace and engage covers 0043.

X Close the rear doors.

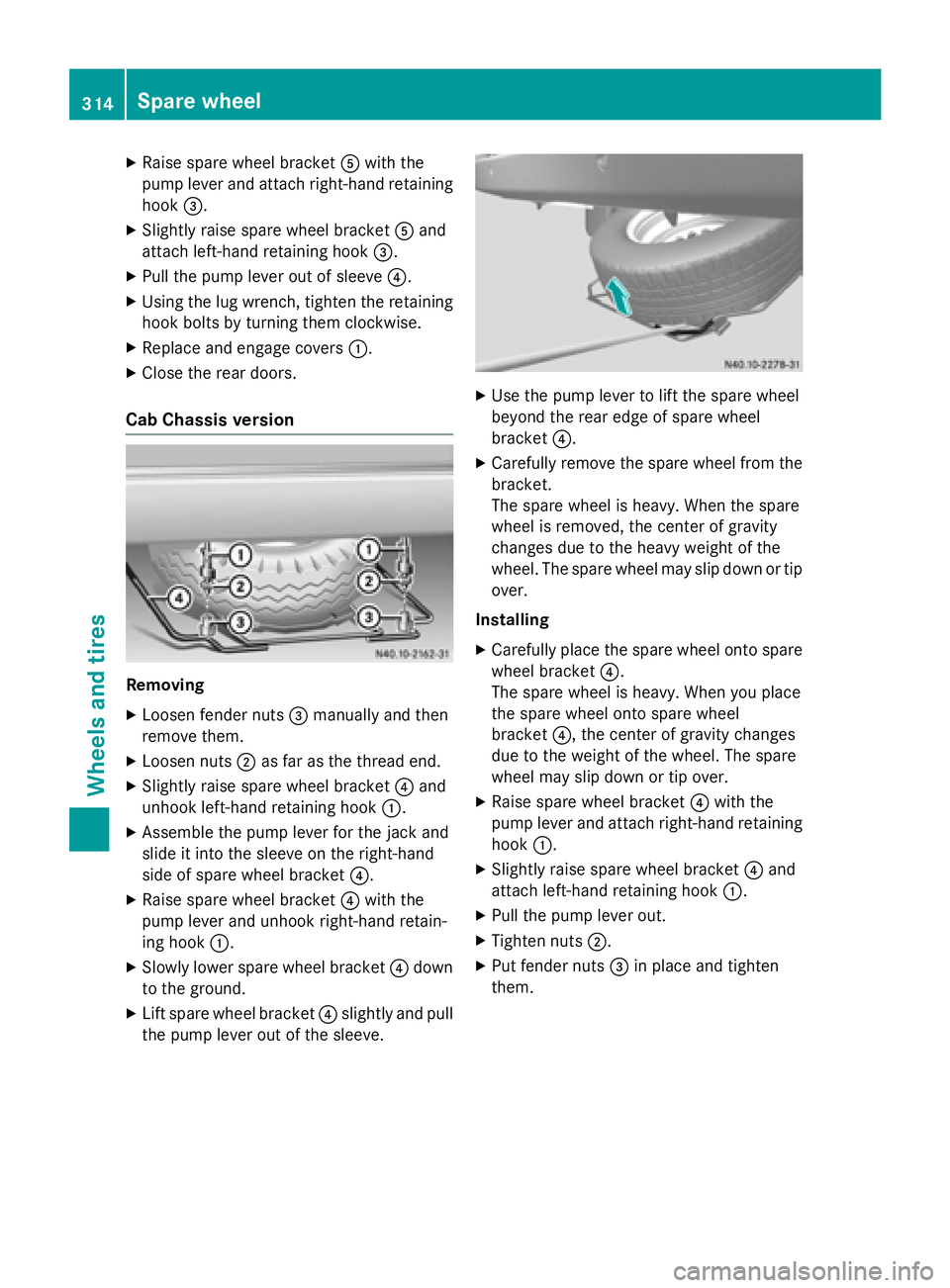

Cab Chassis version Removing

X Loosen fender nuts 0087manually and then

remove them.

X Loosen nuts 0044as far as the thread end.

X Slightly raise spare wheel bracket 0085and

unhook left-hand retaining hook 0043.

X Assemble the pump lever for the jack and

slide it into the sleeve on the right-hand

side of spare wheel bracket 0085.

X Raise spare wheel bracket 0085with the

pump lever and unhook right-hand retain-

ing hook 0043.

X Slowly lower spare wheel bracket 0085down

to the ground.

X Lift spare wheel bracket 0085slightly and pull

the pump lever out of the sleeve. X

Use the pump lever to lift the spare wheel

beyond the rear edge of spare wheel

bracket 0085.

X Carefully remove the spare wheel from the

bracket.

The spare wheel is heavy. When the spare

wheel is removed, the center of gravity

changes due to the heavy weight of the

wheel. The spare wheel may slip down or tip over.

Installing X Carefully place the spare wheel onto spare

wheel bracket 0085.

The spare wheel is heavy. When you place

the spare wheel onto spare wheel

bracket 0085, the center of gravity changes

due to the weight of the wheel. The spare

wheel may slip down or tip over.

X Raise spare wheel bracket 0085with the

pump lever and attach right-hand retaining hook 0043.

X Slightly raise spare wheel bracket 0085and

attach left-hand retaining hook 0043.

X Pull the pump lever out.

X Tighten nuts 0044.

X Put fender nuts 0087in place and tighten

them. 314

Spare wheelWheels and

tires