brake MERCEDES-BENZ SPRINTER 2018 MY18 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2018, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2018Pages: 294, PDF Size: 4.36 MB

Page 250 of 294

Useful information

This Operator's Manual describes all models as

well as standard and optional equipment of your

vehicle that were available at the time of going

to print. Country-specific variations are possi-

ble. Note that your vehicle may not be equipped

with all of the described functions. This also

applies to systems and functions relevant to

safety.

Read the information on qualified specialist

workshops (

Ypage 27).

Important safety notes

GWarning

A flat tire severely impairs the driving, steer-

ing and braking characteristics of the vehicle.

There is a risk of an accident.

do not drive with a flat tire. Immediately

replace the flat tire with your spare wheel, or

consult a qualified specialist workshop.

GWARNING

If wheels and tires of the wrong size are used, the wheel brakes or suspension components

may be damaged. There is a risk of an acci-

dent.

Always replace wheels and tires with those

that fulfill the specifications of the original

part.

When replacing wheels, make sure to use the

correct:

Rdesignation

Rmodel

When replacing tires, make sure to use the

correct:

Rdesignation

Rmanufacturer

Rmodel

Accessories that are not approved for your vehi-

cle by Mercedes-Benz or are not being used cor-

rectly can impair operating safety. Before purchasing and using non-approved

accessories, visit a qualified specialist work-

shop and inquire about:

Rsuitability

Rlegal stipulations

Rfactory recommendations

Contact an authorized Sprinter dealer if you

require information on tested and recommen-

ded wheels and tires for summer and winter

driving. Advice on purchasing and caring for

tires is also available there.

Information on tire and wheel dimensions and

types as well as the recommended tire pressure

for your vehicle can be found in the "Tire pres-

sure" section (

Ypage 257).

This data can also be found on the Tire and

Loading Information placard on the B-pillar.

Modifications to the brake system or wheels are

not permitted. The use of a spacer and brake

dust shields is not permitted. This invalidates

the general operating permit for the vehicle.

iFurther information on wheels and tires can

be obtained at any qualified specialist work-

shop.

Operation

Information for a journey

If the vehicle is heavily laden, check the tire

pressures, and correct them, if necessary

(

Ypage 251).

While driving, pay attention to vibrations, noises

and unusual handling characteristics, e.g. pull-

ing to one side. This may indicate that the

wheels or tires are damaged. If you suspect that

a tire is defective, reduce your speed immedi-

ately. Stop the vehicle as soon as possible to

check the wheels and tires for damage. Hidden

tire damage could also be causing the unusual

handling characteristics. If you find no signs of

damage, have the tires and wheels checked at a

qualified specialist workshop.

When parking your vehicle, make sure that the

tires do not get deformed by the curb or other

obstacles. If it is necessary to drive over curbs,

speed humps or similar elevations, try to do so

slowly and not at a sharp angle. Otherwise, the

tires, particularly the sidewalls, can get dam-

aged.

248Operation

Wheels and tires

Page 257 of 294

flated tire causes the tire to overheat and canlead to tire failure. Underinflation also

reduces fuel efficiency and tire tread life, and

may affect the vehicle's handling and stop-

ping ability.

Please note that the TPMS is not a substitute

for proper tire maintenance, and it is the driv-

er's responsibility to maintain correct tire

pressure, even if underinflation has not

reached the level to trigger illumination of the

TPMS low tire pressure telltale.

USA only:

Your vehicle has also been equipped with a

TPMS malfunction indicator to indicate if the

system is not operating properly. The TPMS

malfunction indicator is combined with the

low tire pressure telltale. When the system

detects a malfunction, the warning lamp will

flash for approximately a minute and then

remain continuously illuminated. This

sequence will be repeated every time the vehi-

cle is started as long as the malfunction

exists.

When the malfunction indicator is illuminated,

the system may not be able to detect or signal

low tire pressure as intended. TPMS malfunc-

tions may occur for a variety of reasons,

including the mounting of incompatible

replacement or alternate tires or wheels on

the vehicle that prevent the TPMS from func-

tioning properly. Always check the TPMS mal-

function telltale after replacing one or more

tires or wheels on your vehicle to ensure that

the replacement or alternate tires and wheels

allow the TPMS to continue to function prop-

erly.

Vehicles with a tire pressure monitor are equip-

ped with sensors in the wheels that monitor the

tire pressure of all four tires. The tire pressure

monitor monitors the pressure in all four tires;

you set this pressure when you activate the tire pressure monitor. The tire pressure monitor

warns you when the pressure drops in one or

more of the ti

res. The tire pressure monitor only

functions if the corresponding sensors are

installed on all wheels. You should always adjust the tire pressure

according to the vehicle load. Restart the tire

pressure monitor if you change the tire pres-

sure.

The tire pressure monitor does not warn you if a

tire pressure is incorrect. Observe the notes on the recommended tire pressure (

Ypage 251).

The tire pressure monitor is not able to warn you

of a sudden loss of pressure, e.g. following pen- etration by a foreign object. In this event, brake

the vehicle until it comes to a standstill. Do not

carry out any sudden steering maneuvers.

The tire pressure monitor has a yellow h

warning lamp in the instrument cluster for indi-

cating pressure loss/malfunctions (USA) or

pressure loss (Canada). Depending on how the

warning lamp flashes or lights up, an underin-

flated tire or a malfunction in the tire pressure

monitor is displayed:

Rif the h warning lamp is lit continuously,

the tire pressure on one or more tires is sig-

nificantly too low. The tire pressure monitor is

not malfunctioning.

RUSA only: if the hwarning lamp flashes for

60 seconds and then remains lit constantly,

the tire pressure monitor is malfunctioning.

Only vehicles with steering wheel buttons: the

on-board computer displays information on tire

pressure. After a few minutes of driving, the cur-

rent tire pressure of each tire is shown in the on-

board computer.

USA only: if the tire pressure monitor is mal-

functioning, it may be more than 10 minutes

before the malfunction is shown. The htire

pressure warning lamp flashes for 60 seconds

and then remains lit. When the malfunction has been rectified, the htire pressure warning

lam p goes ou

t after a few minutes of driving.

The tire pressure values indicated by the on-

board computer may differ from those meas-

ured at a gas station with a pressure gauge. The

tire pressures shown by the on-board computer

refer to those measured at sea level. At high

altitudes, the tire pressure values indicated by a pressure gauge are higher than those shown by

the on-board computer. In this case, do not

reduce the tire pressures.

If radio transmitting equipment (e.g. wireless

headphones, two-way radios) is operated inside

the vehicle or in the vicinity of the vehicle, this

can interfere with the operation of the tire pres-

sure monitor.

Tire pressure255

Wheels and tires

Z

Page 261 of 294

Loading the vehicle

Instruction labels for tires and loads

GWARNING

Overloaded tires can overheat, causing a

blowout. Overloaded tires can also impair the steering and driving characteristics and lead

to brake failure. There is a risk of accident.

Observe the load rating of the tires. The load

rating must be at least half of the GAWR of

your vehicle. Never overload the tires by

exceeding the maximum load.

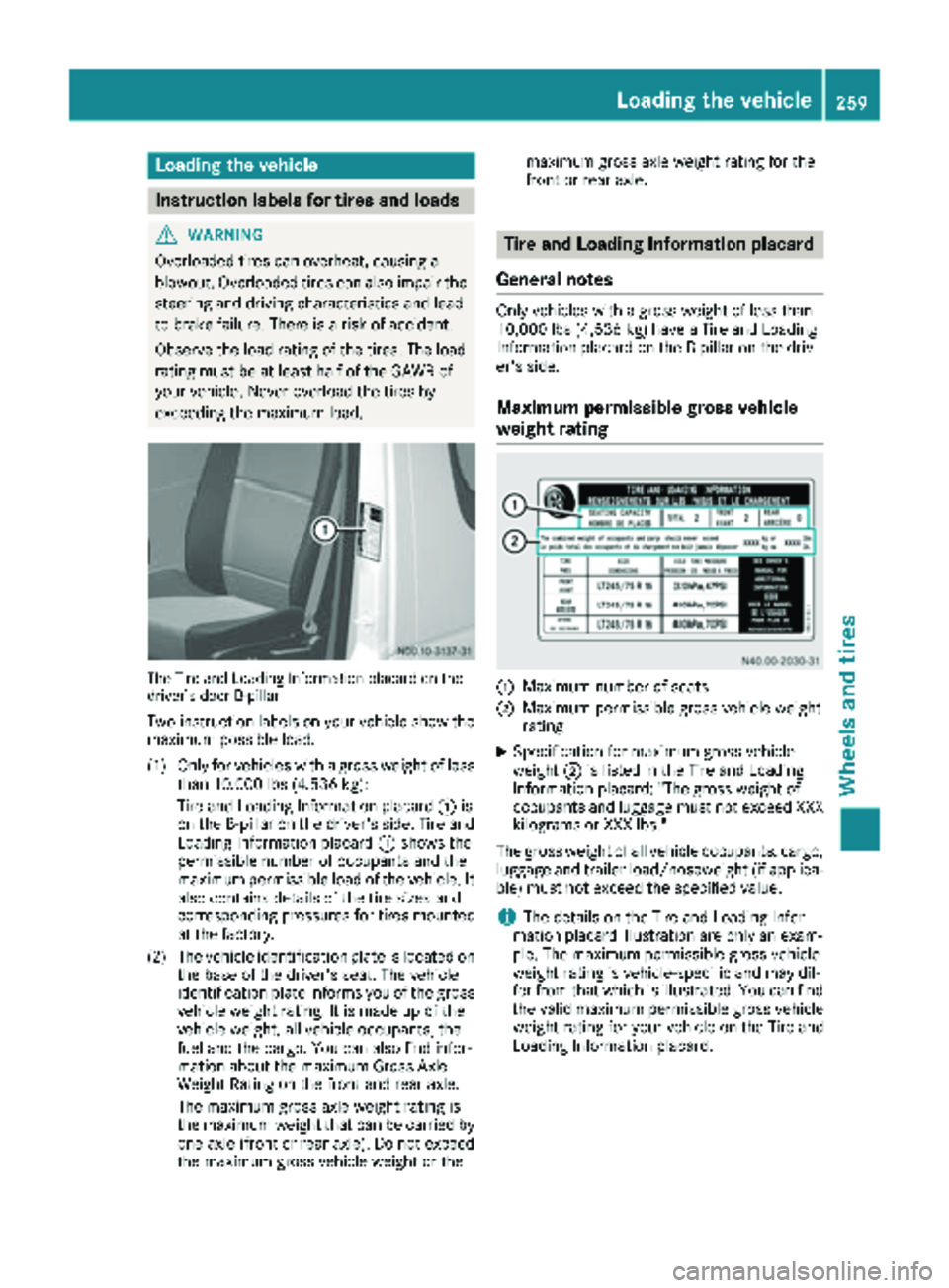

The Tire and Loading Information placard on the

driver’s door B-pillar

Two instruction labels on your vehicle show themaximum possible load.

(1) Only for vehicles with a gross weight of less than 10,000 lbs (4,536 kg):

Tire and Loading Information placard :is

on the B-pillar on the driver's side. Tire and

Loading Information placard :shows the

permissible number of occupants and the

maximum permissible load of the vehicle. It

also contains details of the tire sizes and

corresponding pressures for tires mounted

at the factory.

(2) The vehicle identification plate is located on the base of the driver's seat. The vehicle

identification plate informs you of the gross

vehicle weight rating. It is made up of the

vehicle weight, all vehicle occupants, the

fuel and the cargo. You can also find infor-

mation about the maximum Gross Axle

Weight Rating on the front and rear axle.

The maximum gross axle weight rating is

the maximum weight that can be carried by

one axle (front or rear axle). Do not exceed

the maximum gross vehicle weight or the maximum gross axle weight rating for the

front or rear axle.

Tire and Loading Information placard

General notes

Only vehicles with a gross weight of less than

10,000 lbs (4,536 kg) have a Tire and Loading

Information placard on the B-pillar on the driv-

er's side.

Maximum permissible gross vehicle

weight rating

:Maximum number of seats

;Maximum permissible gross vehicle weight

rating

XSpecification for maximum gross vehicle

weight ;is listed in the Tire and Loading

Information placard: "The gross weight of

occupants and luggage must not exceed XXX

kilograms or XXX lbs."

The gross weight of all vehicle occupants, cargo,

luggage and trailer load/noseweight (if applica-

ble) must not exceed the specified value.

iThe details on the Tire and Loading Infor-

mation placard illustration are only an exam-

ple. The maximum permissible gross vehicle

weight rating is vehicle-specific and may dif-

fer from that which is illustrated. You can find

the valid maximum permissible gross vehicle

weight rating for your vehicle on the Tire and

Loading Information placard.

Loading the vehicle259

Wheels and tires

Z

Page 268 of 294

Curb weight

The weight of a vehicle with standard equipment

including the maximum filling capacity of fuel,

oil, and coolant. It also includes the air-condi-

tioning system and optional equipment if these

are installed on the vehicle, but does not include

passengers or luggage.

Maximum tire load

The maximum tire load in kilograms or pounds is

the maximum weight for which a tire is

approved.

Maximum permissible tire pressure

Maximum permissible tire pressure for one tire.

Maximum load on one tire

Maximum load on one tire. This is calculated by

dividing the maximum axle load of one axle by

two.

PSI (Pounds per square inch)

Standard unit of measurement for tire pressure.

Aspect ratio

Relationship between tire height and width in

percent.

tire pressure

Pressure inside the tire applying an outward

force to every square inch of the tire's surface.

Tire pressure is specified in pounds per square

inch (psi), in kilopascal (kPa) or in bar. Tire pres-

sure should only be corrected when the tires are

cold.

Cold tire pressure

The tires are cold:

Rif the vehicle has been parked for at least

three hours without direct sunlight on the

tires, and

Rif the vehicle has not been driven further than

1 mile (1.6 km)

Tire tread

The part of the tire that comes into contact with the road.

Tire bead

The tire bead ensures that the tire sits securely

on t

he wheel. There are several steel wires in the

bead to prevent the tire from coming loose from

the wheel rim.

Sidewall

The part of the tire between the tread and the

tire bead.

Weight of optional extras

The combined weight of those optional extras

that weigh more than the replaced standard

parts and more than 2.3 kg (5 lbs). These

optional extras, such as high-performance

brakes, a roof rack or a high-performance bat-

tery, are not included in the curb weight and the

weight of the accessories.

TIN (Tire Identification Number)

A unique identification number which can be

used by a tire manufacturer to identify tires, for

example for a product recall, and thus identify

the purchasers. The TIN is composed of the

manufacturer identification code, tire size, tire

model code and manufacturing date.

Load bearing index

The load bearing index (also load index) is a code

that contains the maximum load bearing capa-

city of a tire.

Traction

Traction is the result of friction between the tires

and the road surface.

TWR (permissible trailer drawbar load)

The TWR is the maximum permissible weight

that may act on the ball coupling of the trailer

tow hitch.

Wear indicator

Narrow bars (tread wear bars) that are distrib-

uted over the tire tread. If the tir e tread is level

with the bars, the wear limit of áin (1.6 mm)

has been reached.

Distribution of the vehicle occupants

The distribution of vehicle occupants over des-

ignated seat positions in a vehicle.

Maximum permissible payload weight

Nominal load and goods/luggage load plus

68 kg (150lbs) multiplied by the number of

seats in the vehicle.

266What you should know about wheels and tires

Wheels and tires

Page 269 of 294

Flat tire

General notes

If your vehicleis equipped wit h aspar ewheel,

th espar ewhee lis under th erear of th evehicl e

(

Ypage 273).

Information about installin g awhee lcan be

foun din th e"Whee lchange" section

(

Ypage 268).

Changing wheels

Rotating the wheels

GWARNIN G

Interchangin gth efron tand rear wheels may

severely impair th edriving characteristics if

th ewheels or tires have different dimensions.

The whee lbrakes or suspension component s

may also be damaged. Ther eis aris kof acci-

dent.

Rotate fron tand rear wheels only if th ewheels

and tires are of th esam edimensions.

!On vehicles equipped wit h atire pressur e

monitor, electronic component sare locate d

in th ewheel.

Tire-mounting tools should no tbe used near

th evalve. This could damag eth eelectronic

components.

Only have tires changed at aqualified spe-

cialist workshop.

Always observ eth einstruction sand safet y

note sin th e"Mounting awheel" section

(

Ypage 268).

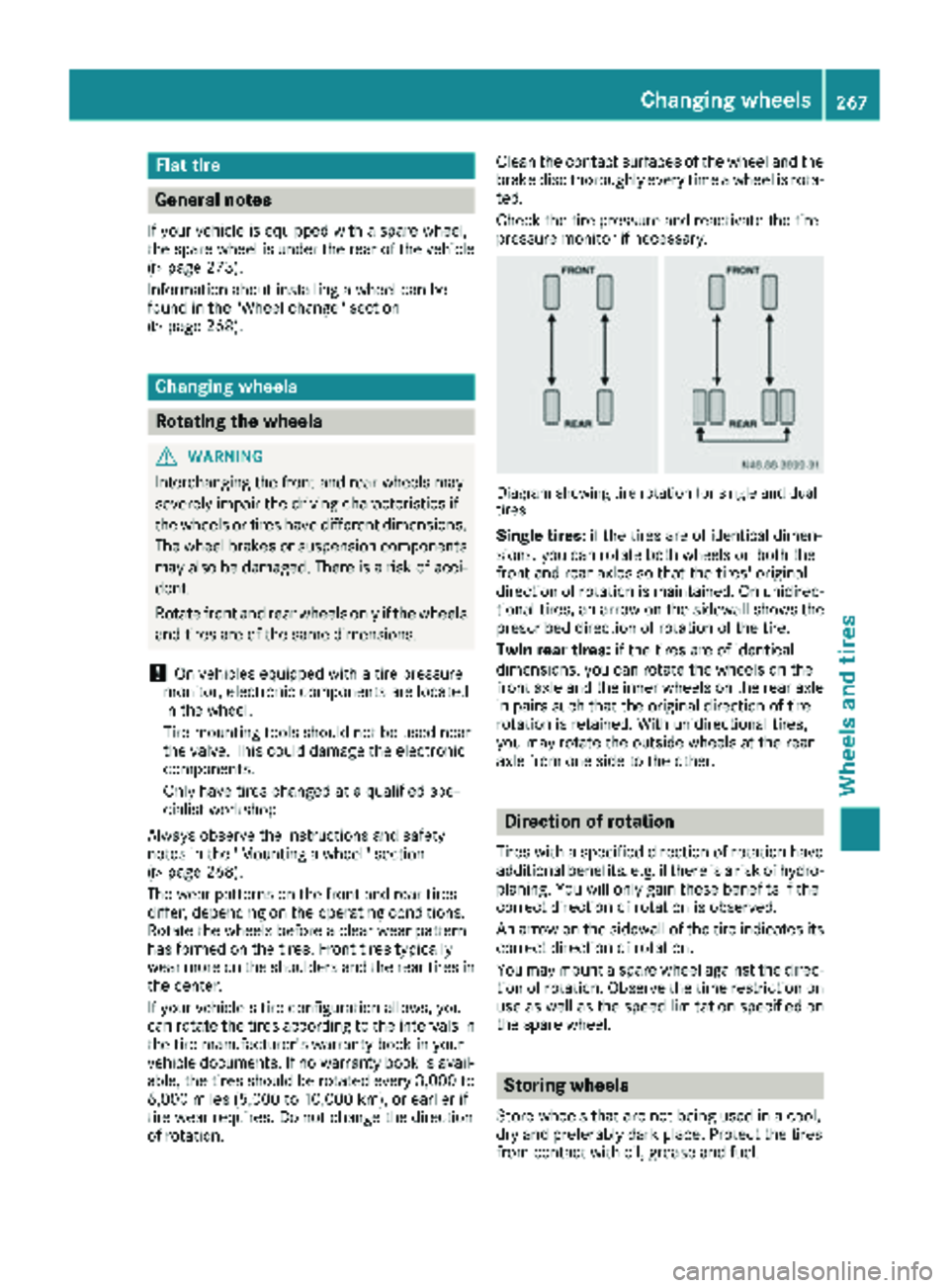

The wear pattern son th efron tand rear tires

differ, depending on th eoperating conditions.

Rotate th ewheels before aclear wear pattern

has formed on th etires .Fron ttires typically

wear mor eon th eshoulder sand th erear tires in

th ecenter.

If your vehicle's tire configuration allows ,you

can rotate th etires according to th eintervals in

th etire manufacturer' swarrant ybook in your

vehicl edocuments .If no warrant ybook is avail-

able, th etires should be rotate devery 3,000 to

6,000 mile

s(

5,00 0to 10,00 0km), or earlier if

tire wear requires. Do no tchang eth edirection

of rotation . Clean th

econtact surface sof th ewhee land th e

brak edisc thoroughly every time awhee lis rota-

ted.

Chec kth etire pressur eand reactivat eth etire

pressur emonitor if necessary.

Diagram showin gtir erotation for single and dual

tires

Single tires: if thetires are of identical dimen-

sions, you can rotate bot hwheels on bot hth e

fron tand rear axle sso that th etires 'original

direction of rotation is maintained. On unidirec -

tional tires ,an arrow on th esidewall shows th e

prescribe ddirection of rotation of th etire.

Twin rea rtires: if thetires are of identical

dimensions, you can rotate th ewheels on th e

fron taxle and th einner wheels on th erear axle

in pair ssuc hthat th eoriginal direction of tire

rotation is retained. Wit hunidirectional tires ,

you may rotate th eoutside wheels at th erear

axle from on eside to th eother .

Direction of rotation

Tires wit h aspecifie ddirection of rotation have

additional benefits ,e.g. if there is aris kof hydro-

planing .You will only gain these benefits if th e

correct direction of rotation is observed.

An arrow on th esidewall of th etire indicates it s

correct direction of rotation .

You may moun t aspar ewhee lagainst th edirec-

tion of rotation .Observ eth etime restriction on

use as well as th espee dlimitation specifie don

th espar ewheel.

Storing wheels

Store wheels that are no tbein gused in acool,

dry and preferably dark place. Protect th etires

from contact wit hoil, grease and fuel .

Changing wheels267

Wheels and tires

Z

Page 270 of 294

Mounting a wheel

Vehicle preparation

XStop the vehicle as far away as possible from

traffic and on a level, firm and non-slip sur-

face.

XIf your vehicle poses a risk to approaching

traffic, switch on the hazard warning lamps.

XApply the parking brake.

XTurn the front wheels to the straight-ahead

position.

XMove the selector lever of the automatic

transmission to position P.

XSwitch off the engine.

XPassengers should leave the vehicle. Make

sure that the passengers are not endangered

as they do so.

XMake sure that no one is near the danger area

while the wheel is being changed. Anyone

who is not directly assisting in the wheel

change should, for example, stand behind the

barrier.

XPlace the warning triangle or warning lamp at

a suitable distance.

Observe legal requirements.

XSecure the vehicle to prevent it from rolling

away.

iObserve the safety notes on parking in the

section on "Driving and parking"

(

Ypage 129).

XOn level terrain: place chocks or other suit-

able objects under the front and rear of the

wheel that is diagonally opposite the wheel to

be changed.

XOn slight inclines: place chocks or other

suitable objects under the wheels on the front and rear axles opposite the wheel to be

changed.

XTake the vehicle tool kit and the jack from the

footwell on the front-passenger side

(

Ypage 241).

XRemove the spare wheel from the spare wheel

bracket (Ypage 274). Observe the safety

notes in the "Spare wheel" section

(

Ypage 273).

XOn wheels with wheel bolts, remove the hub

caps.

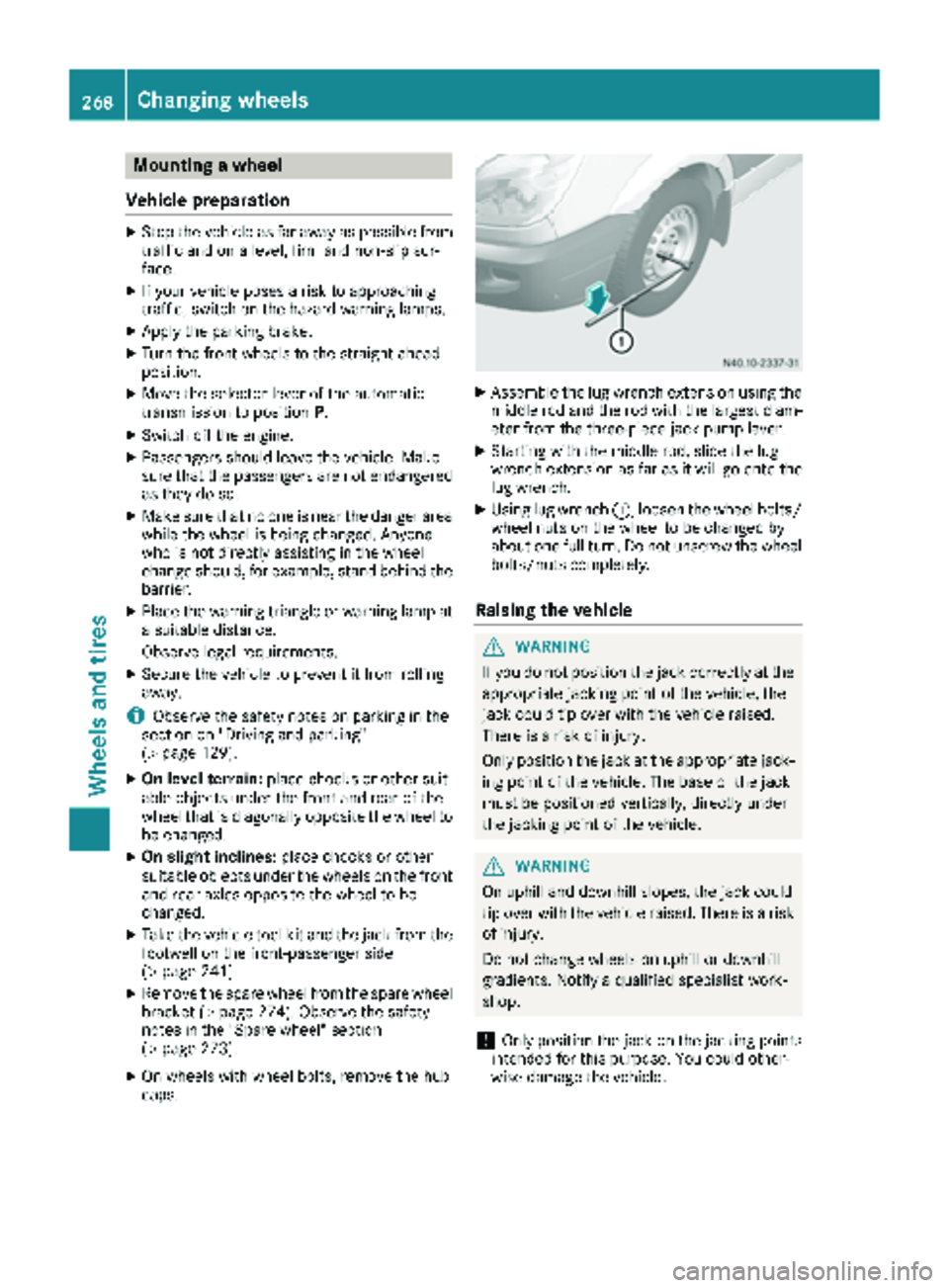

XAssemble the lug wrench extension using the

middle rod and the rod with the largest diam-

eter from the three-piece jack pump lever.

XStarting with the middle rod, slide the lug

wrench extension as far as it will go onto the

lug wrench.

XUsing lug wrench :, loosen the wheel bolts/

wheel nuts on the wheel to be changed by

about one full turn. Do not unscrew the wheel bolts/nuts completely.

Raising the vehicle

GWARNING

If you do not position the jack correctly at the

appropriate jacking point of the vehicle, the

jack could tip over with the vehicle raised.

There is a risk of injury.

Only position the jack at the appropriate jack-

ing point of the vehicle. The base of the jack

must be positioned vertically, directly under

the jacking point of the vehicle.

GWARNING

On uphill and downhill slopes, the jack could

tip over with the vehicle raised. There is a risk

of injury.

Do not change wheels on uphill or downhill

gradients. Notify a qualified specialist work-

shop.

!Only position the jack on the jacking points

intended for this purpose. You could other-

wise damage the vehicle.

268Changing wheels

Wheels and tires

Page 271 of 294

Observe the following when raising the vehicle:

RWhen raising the vehicle, only use the jack

which Mercedes-Benz has specifically

approved for your vehicle.

RThe vehicle's jack is intended only to raise the

vehicle for a short time when changing a

wheel. It is not suited for performing mainte-

nance work under the vehicle.

RAvoid changing the wheel on uphill and down-

hill slopes.

RBefore raising the vehicle, secure it from roll-

ing away by applying the parking brake and

inserting wheel chocks. Never disengage the

parking brake while the vehicle is raised.

RThe jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a large,

load-bearing underlay must be used. On a

slippery surface, a non-slip underlay must be

used, e.g. rubber mats.

RMake sure that the distance between the

underside of the tires and the ground does not

exceed 1.2 in(3 cm).

RNever place your hands or feet under the

raised vehicle.

RNever lie under the raised vehicle.

RNever start the engine when the vehicle is

raised.

RNever open or close a door when the vehicle

is raised.

RMake sure that no persons are present in the

vehicle when the vehicle is raised.

!Only use the jack pump lever middle rod and

the rod with the largest diameter as a lug

wrench extension. Only slide the middle rod

as far as it will go onto the lug wrench. The

rods may otherwise bend and be distorted to

such an extent that they can no longer be

used as a pump lever for the jack.

!Do not place the jack on the leaf spring or

the differential case.

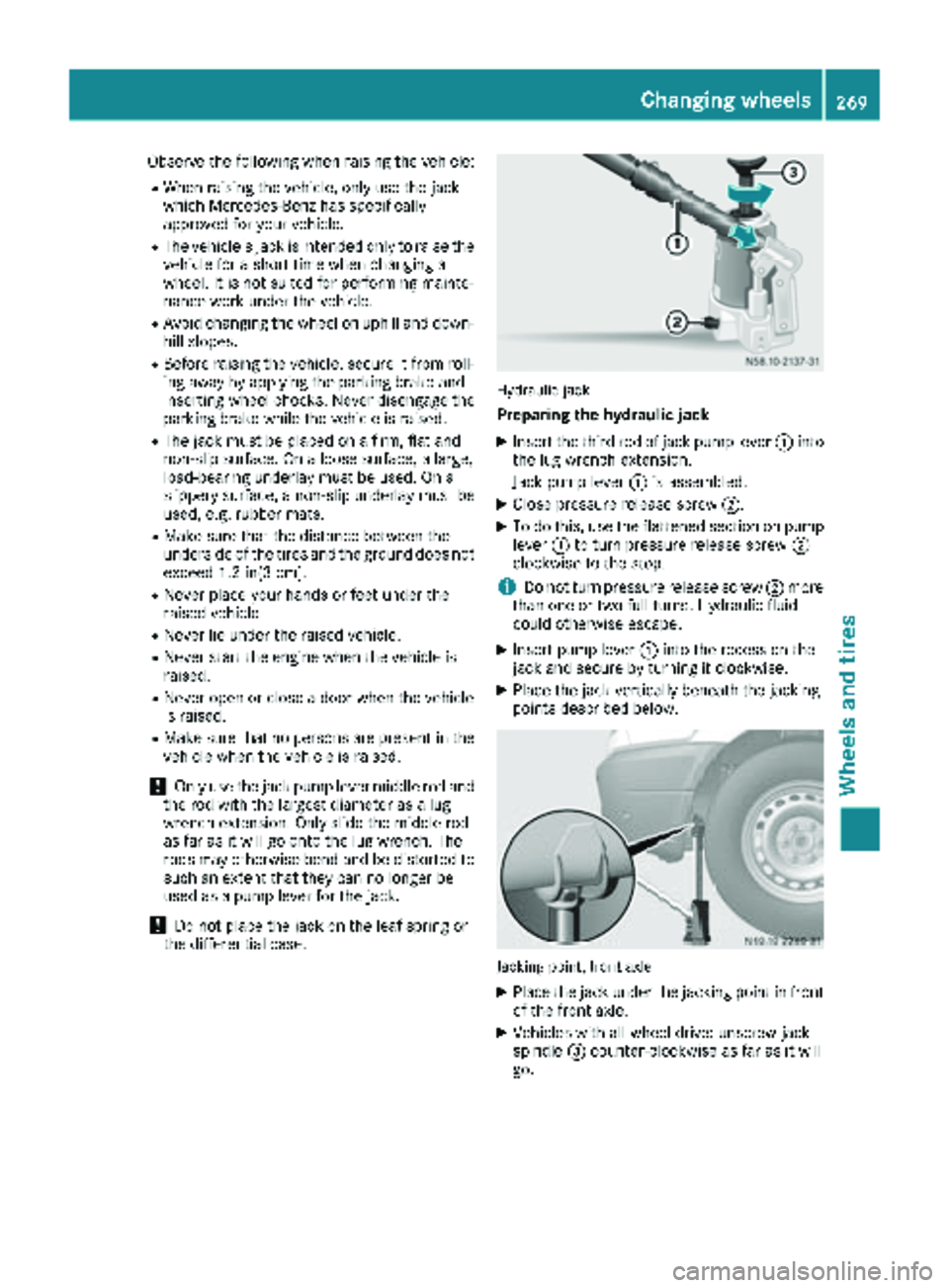

Hydraulic jack

Preparing the hydraulic jack

XInsert the third rod of jack pump lever :into

the lug wrench extension.

Jack pump lever :is assembled.

XClose pressure release screw ;.

XTo do this, use the flattened section on pump

lever:to turn pressure release screw ;

clockwise to the stop.

iDo not turn pressure release screw ;more

than one or two full turns. Hydraulic fluid

could otherwise escape.

XInsert pump lever :into the recess on the

jack and secure by turning it clockwise.

XPlace the jack vertically beneath the jacking

points described below.

Jacking point, front axle

XPlace the jack under the jacking point in front of the front axle.

XVehicles with all-wheel drive: unscrew jack

spindle =counter-clockwise as far as it will

go.

Changing wheels269

Wheels and tires

Z

Page 273 of 294

specialist workshop and have the spare wheel

replaced with a wheel and tire assembly that has

a Super Single tire.

XClean the wheel and wheel hub contact sur-

faces.

XUnscrew the six adapter bolts on the spare

wheel and remove the adapter.

XTighten the adapter with the six adapter bolts

evenly in a crosswise pattern through the

outer holes on the wheel hub.

XTighten the six adapter bolts on the wheel hub

to a tightening torque of177 lb-ft(240 Nm).

XPush the wheel onto the adapter and attach it.

Mounting a new wheel

GWARNING

Oiled or greased wheel bolts or damaged

wheel bolts/hub threads can cause the wheel bolts to come loose. As a result, you could

lose a wheel while driving. There is a risk of

accident.

Never oil or grease wheel bolts. In the event of

damage to the threads, contact a qualified

specialist workshop immediately. Have the

damaged wheel bolts or hub threads

replaced/renewed. Do not continue driving.

GWARNING

If you tighten the wheel bolts or wheel nuts

when the vehicle is raised, the jack could tip

over. There is a risk of injury.

Only tighten the wheel bolts or wheel nuts

when the vehicle is on the ground.

Always observe the instructions and safety

notes on "Changing a wheel" (

Ypage 267).

Only use wheel bolts or wheel nuts that have

been designed for the wheel and the vehicle. For safety reasons, we recommend that you only

use wheel bolts or wheel nuts which have been

approved for Sprinter vehicles and the respec-

tive wheel.

!For a steel wheel, only use the short wheel

bolts to mount the steel spare wheel. Using

other wheel bolts to mount the steel spare

wheel could damage the brake system.

!On vehicles equipped with a tire pressure

monitor, electronic components are located

in the wheel.

Tire-mounting tools should not be used near

the valve. This could damage the electronic

components.

Only have tires changed at a qualified spe-

cialist workshop.

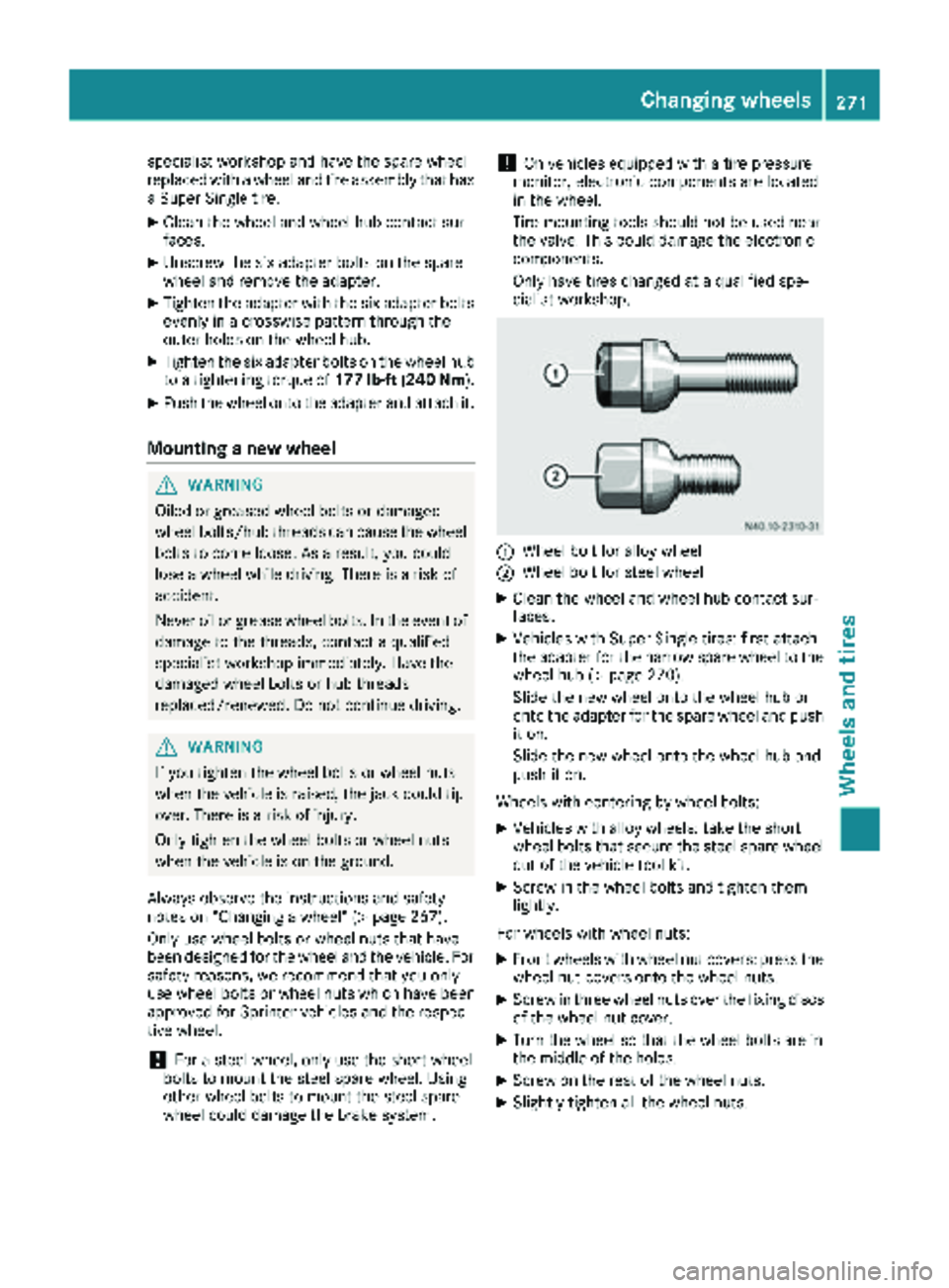

:Wheel bolt for alloy wheel

;Wheel bolt for steel wheel

XClean the wheel and wheel hub contact sur-

faces.

XVehicles with Super Single tires: first attach

the adapter for the narrow spare wheel to the

wheel hub (

Ypage 270).

Slide the new wheel onto the wheel hub or

onto the adapter for the spare wheel and push

it on.

Slide the new wheel onto the wheel hub and

push it on.

Wheels with centering by wheel bolts:

XVehicles with alloy wheels: take the short

wheel bolts that secure the steel spare wheel

out of the vehicle tool kit.

XScrew in the wheel bolts and tighten them

lightly.

For wheels with wheel nuts:

XFront wheels with wheel nut covers: press the wheel nut covers onto the wheel nuts.

XScrew in three wheel nuts over the fixing discs

of the wheel nut cover.

XTurn the wheel so that the wheel bolts are in

the middle of the holes.

XScrew on the rest of the wheel nuts.

XSlightly tighten all the wheel nuts.

Changing wheels271

Wheels and tires

Z

Page 280 of 294

iSuch data is vehicle-specific and may differ

from that shown. Always observe the specifi-

cations on your vehicle's identification plate.

Engine number

The engine number is stamped on the crank-

case. More information may be obtained at any

qualified specialist workshop.

Service products and capacities

Important safety notes

GWARNING

Service products may be poisonous and haz-

ardous to health. There is a risk of injury.

Comply with instructions on the use, storage

and disposal of service products on the labels

of the respective original containers. Always

store service products sealed in their original

containers. Always keep service products out

of the reach of children.

HEnvironmental note

Dispose of service products in an environ-

mentally responsible manner.

Service products include the following:

RFuels, e.g. diesel

RAdditives for the exhaust gas aftertreatment,

e.g. Diesel Exhaust Fluid (DEF)

RLubricants, e.g. engine oil, transmission oil

RCoolant

RBrake fluid

RWasher fluid

RClimate control system refrigerants

Approved service products comply with the

highest quality standards and are listed in the

MB Specifications for Service Products. Only

use service products approved for the vehicle.

This is an important condition for the warranty.

You will recognize the approved service prod-

ucts by the inscription on the container: MB

Approval (e.g. MB Approval 228.5)

Other identifications and recommendations

refer to quality level or a specification according to an MB Sheet Number (e.g. MB 228.5). They

are therefore not necessarily approved.

More information can be obtained at any quali-

fied specialist workshop.

Additives for approved service products are nei-

ther required nor permitted. Approved fuel addi- tives are the exception. Additives can cause

engine damage and must therefore not be

added to the service products.

The use of additives is always the responsibility

of the vehicle operator. The use of additives may

result in the restriction or loss of you

r Limited

Warranty entitlements.

Fuel

Important safety notes

GWARNING

Fuel is highly flammable. Improper handling of

fuel creates a risk of fire and explosion.

Avoid fire, open flames, smoking and creating

sparks under all circumstances. Switch off the

engine and, if applicable, the auxiliary heating

before refueling.

GWARNING

Fuel is poisonous and hazardous to health.

There is a risk of injury.

You must make sure that fuel does not come into contact with your skin, eyes or clothing

and that it is not swallowed. Do not inhale fuel

vapors. Keep fuel away from children.

If you or others come into contact with fuel,

observe the following:

RWash away fuel from skin immediately

using soap and water.

RIf fuel comes into contact with your eyes,

immediately rinse them thoroughly with

clean water. Seek medical assistance with-

out delay.

RIf fuel is swallowed, seek medical assis-

tance without delay. Do not induce vomit-

ing.

RImmediately change out of clothing which

has come into contact with fuel.

278Service products and capacities

Technical data

Page 286 of 294

Depending on the driving style, the vehicle con-

sumes a maximum of 1.0 qt (1.0l)of engine oil

over a distance of 620 miles (1000 km).

Oil consumption may be higher if:

RThe vehicle is new.

RYou mainly operate the vehicle under arduous

operating conditions.

RYou frequently drive at high engine speeds.

Regular maintenance is one of the preconditions

for moderate rates of consumption.

You can only estimate the oil consumption after

you have driven a considerable distance.

Check the engine oil level on a regular basis, e.g.

weekly or each time you refuel (

Ypage 221).

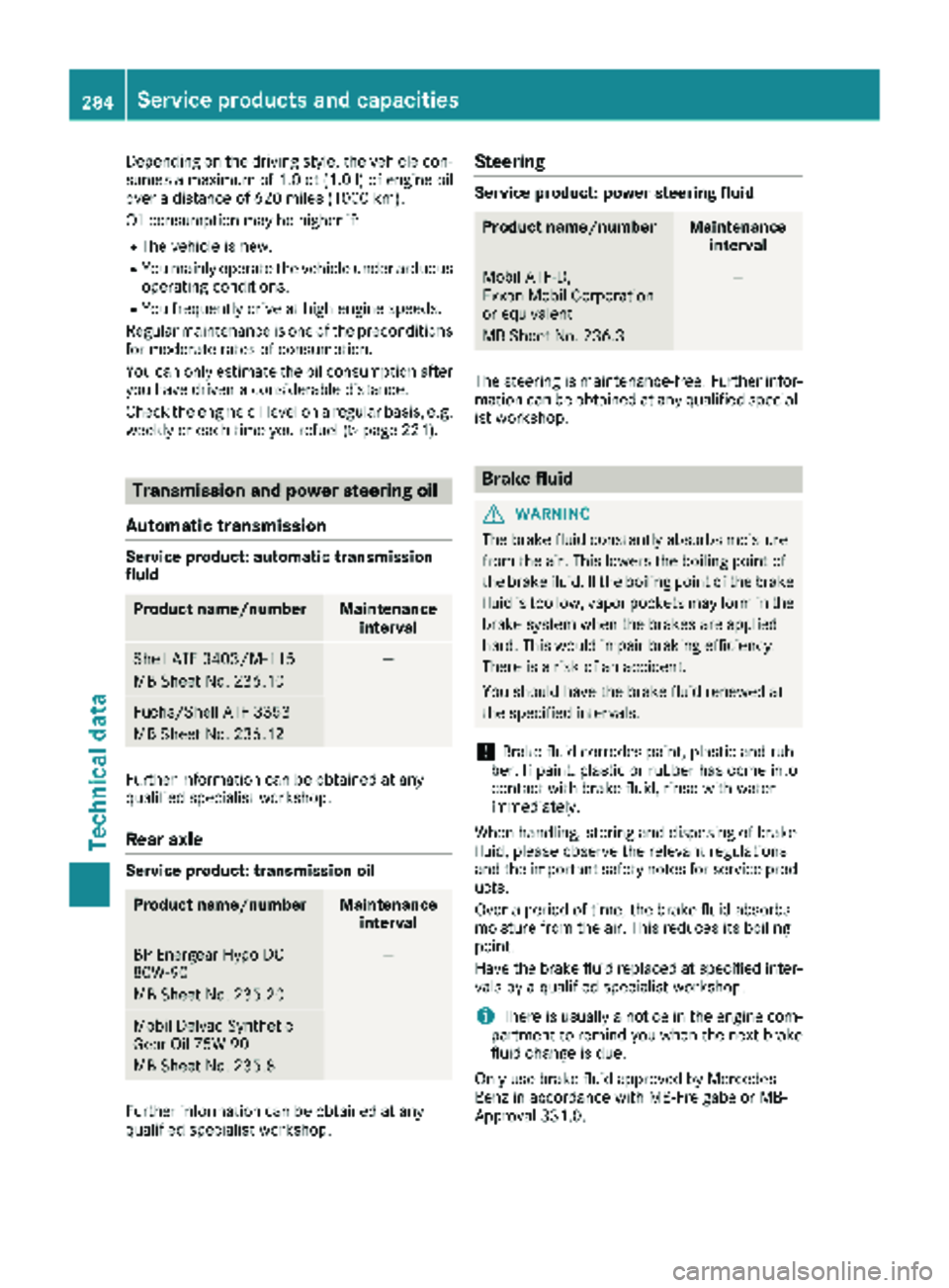

Transmission and power steering oil

Automatic transmission

Service product: automatic transmission

fluid

Product name/numberMaintenance interval

Shell ATF 3403/M-115

MB Sheet No. 236.10—

Fuchs/Shell ATF 3353

MB Sheet No. 236.12

Further information can be obtained at any

qualified specialist workshop.

Rear axle

Service product: transmission oil

Product name/numberMaintenanceinterval

BP Energear Hypo DC

80W-90

MB Sheet No. 235.20—

Mobil Delvac Synthetic

Gear Oil 75W-90

MB Sheet No. 235.8

Further information can be obtained at any

qualified specialist workshop.

Steering

Service product: power steering fluid

Product name/numberMaintenanceinterval

Mobil ATF‑D,

Exxon Mobil Corporation

or equivalent

MB Sheet No. 236.3—

The steering is maintenance-free. Further infor-

mation can be obtained at any qualified special-

ist workshop.

Brake fluid

GWARNING

The brake fluid constantly absorbs moisture

from the air. This lowers the boiling point of

the brake fluid. If the boiling point of the brake

fluid is too low, vapor pockets may form in the

brake system when the brakes are applied

hard. This would impair braking efficiency.

There is a risk of an accident.

You should have the brake fluid renewed at

the specified intervals.

!Brake fluid corrodes paint, plastic and rub-

ber. If paint, plastic or rubber has come into

contact with brake fluid, rinse with water

immediately.

When handling, storing and disposing of brake

fluid, please observe the relevant regulations

and the important safety notes for service prod-

ucts.

Over a period of time, the brake fluid absorbs

moisture from the air. This reduces its boiling

point.

Have the brake fluid replaced at specified inter-

vals by a qualified specialist workshop.

iThere is usually a notice in the engine com-

partment to remind you when the next brake

fluid change is due.

Only use brake fluid approved by Mercedes-

Benz in accordance with MB-Freigabe or MB-

Approval 331.0.

284Service products and capacities

Technical data