wheel MINI Countryman 2012 (Mini Connected) Workshop Manual

[x] Cancel search | Manufacturer: MINI, Model Year: 2012, Model line: Countryman, Model: MINI Countryman 2012Pages: 259, PDF Size: 3.07 MB

Page 218 of 259

Replacing componentsMOBILITY

217

Replacing the bulb

1.Turn the lamp counterclockwise, arrow 1,

and remove it, arrow 2.

2. Push on the catch, arrow 1, and disconnect

the connector, arrow 2.

3. To insert the new bulb and replace the

cover, proceed in reverse order.

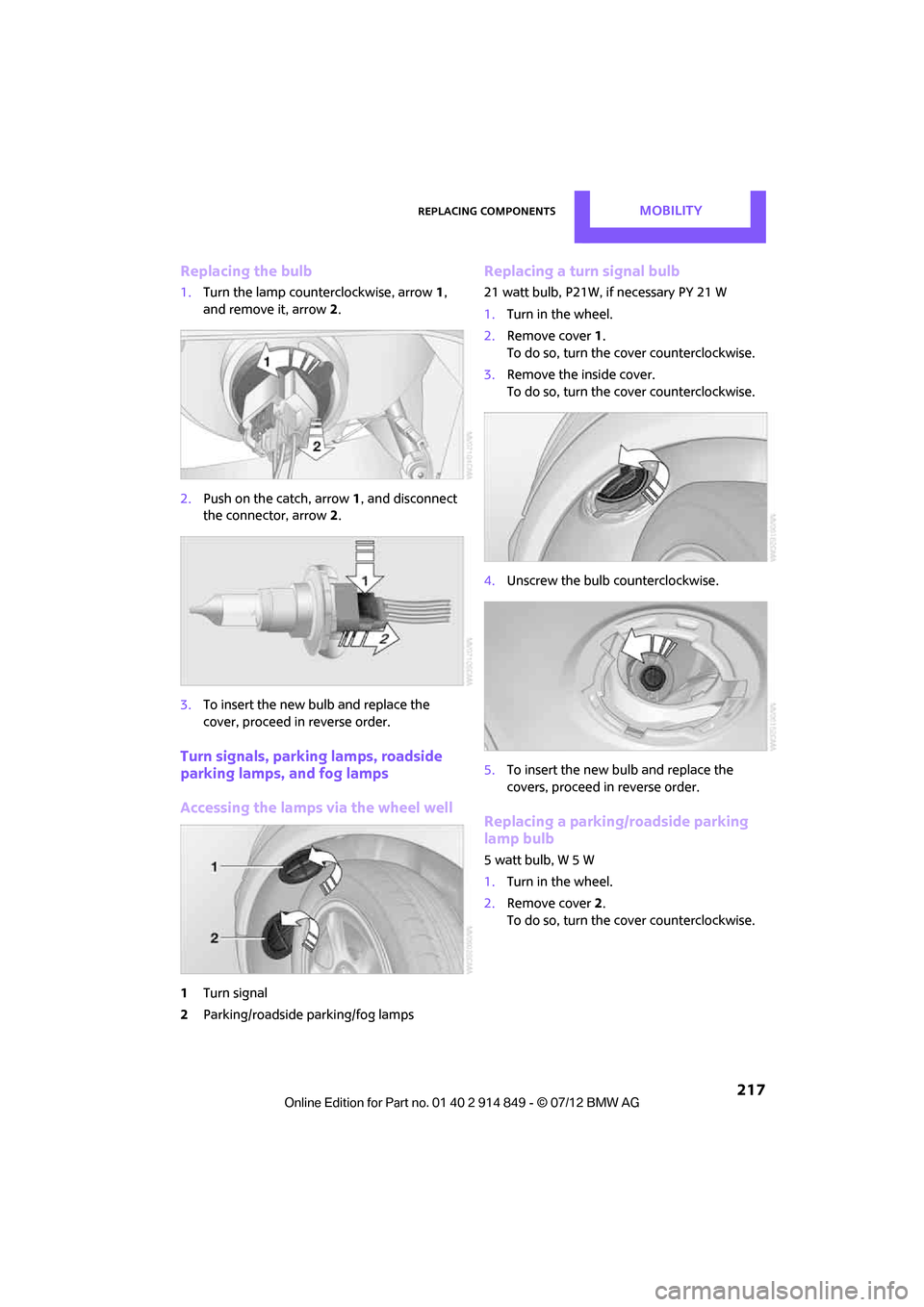

Turn signals, parking lamps, roadside

parking lamps, and fog lamps

Accessing the lamps via the wheel well

1Turn signal

2 Parking/roadside parking/fog lamps

Replacing a turn signal bulb

21 watt bulb, P21W, if necessary PY 21 W

1.Turn in the wheel.

2. Remove cover 1.

To do so, turn the cover counterclockwise.

3. Remove the inside cover.

To do so, turn the cover counterclockwise.

4. Unscrew the bulb counterclockwise.

5. To insert the new bulb and replace the

covers, proceed in reverse order.

Replacing a parking/roadside parking

lamp bulb

5watt bulb, W5W

1.Turn in the wheel.

2. Remove cover 2.

To do so, turn the cover counterclockwise.

Online Edition for Part no. 01 40 2 914 849 - \251 07/12 BMW AG

Page 219 of 259

MOBILITYReplacing components

218

3.Unscrew the upper bulb counterclockwise.

4. To insert the new bulb and replace the

cover, proceed in reverse order.

Replacing a fog lamp bulb

H8 bulb, 35 watts

1.Turn in the wheel.

2. Remove cover 2.

To do so, turn the cover counterclockwise.

3. Pull the cable connector.

4. Unscrew the lower bulb counterclockwise.

5. To insert the new bulb and replace the

cover, proceed in reverse order.

Side turn signals

5 watt bulb, W 5 W

1.Open hood.

2. Squeeze clamping clip , arrows, and remove

bulb holder.

3. Unscrew bulb coun terclockwise and

replace.

4. To insert the new bulb and replace the

cover, proceed in reverse order.

Side marker lamps

Have these bulbs replaced by your MINI dealer.

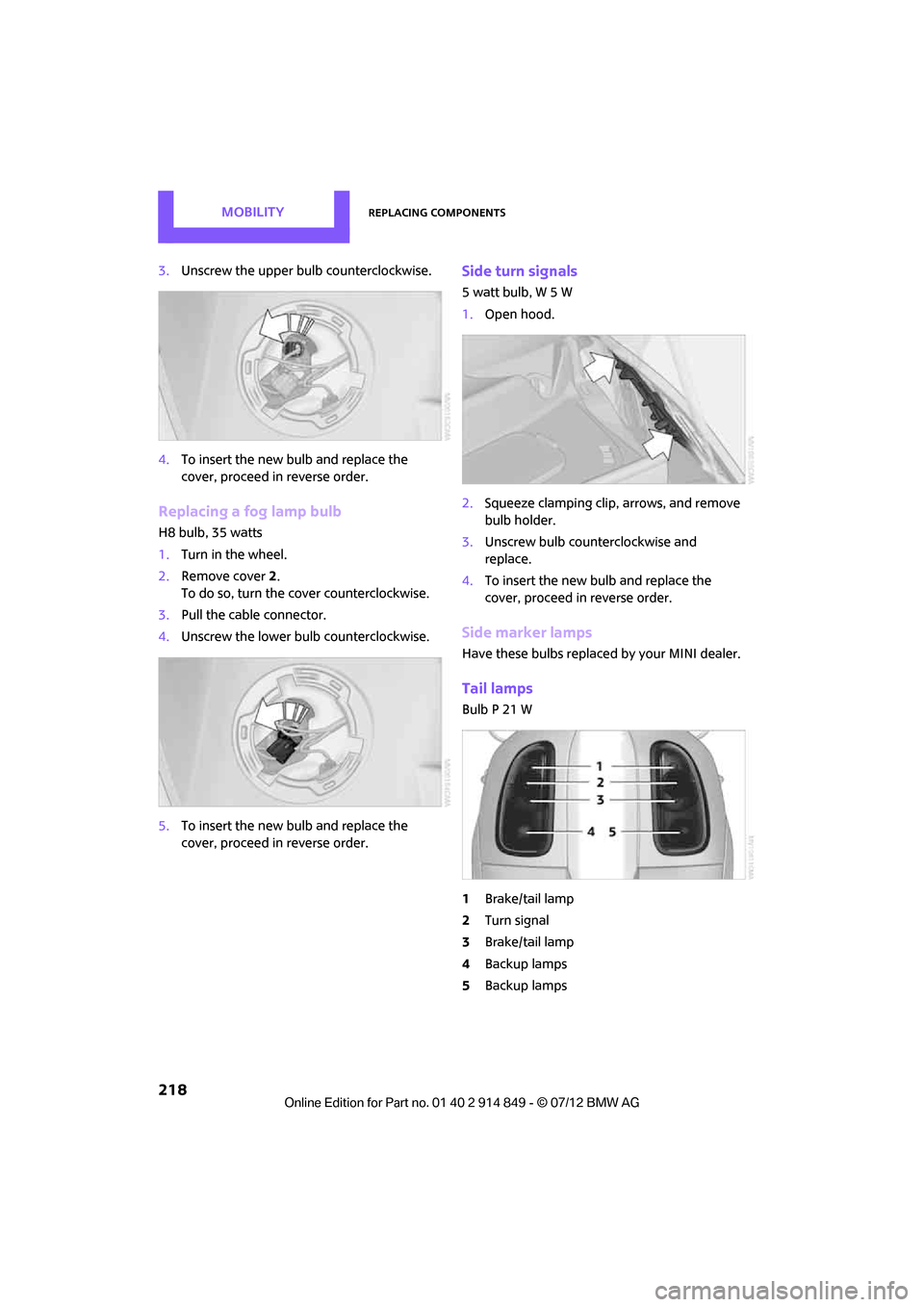

Tail lamps

Bulb P 21 W

1Brake/tail lamp

2 Turn signal

3 Brake/tail lamp

4 Backup lamps

5 Backup lamps

Online Edition for Part no. 01 40 2 914 849 - \251 07/12 BMW AG

Page 220 of 259

Replacing componentsMOBILITY

219

Changing

All bulbs are integrated in a central bulb holder.

1.Switch off the light and remove the infrared

remote control from the ignition lock.

2. Push the cover panel out from the rear of the

cargo area side trim panel and remove it.

3. Open emergency release for the fuel filler

flap, see page 194, and then push to the

side with the foam insert.

Ensure that the emergency release is not

damaged.

4. Disengage the bulb holder by pressing down

on the clamping clip, arrow 1.

5. Take out bulb holder and pull out cable,

arrow 2.

6. Exerting gentle pressure, turn bulb to the left

and remove.

7. To insert the new bulb and install the bulb

holder, proceed in reverse order. Ensure that

the lamp holder engages in all the fasteners.

8. Put foam insert in its original position and

install the emergency fuel flap release.

9. Install cover.

License plate lamps

5watt bulb, C5W

1.Using a screwdriver, push the lamp to the

left in the tab of the lamp housing, arrow 1.

2. Remove the lamp, arrow 2.

3. Replace the bulb.

4. Insert the lamp.

Center brake lamp

This lamp uses LED technology for operation. In

the event of a malfunction, contact your MINI

dealer or a workshop that has specially trained

personnel working in accordance with the

specifications of your MINI manufacturer.

Repairing a flat tire

Safety measures in the event of a break-

down:

Park the vehicle as far as possible from moving

traffic and switch on the hazard warning

flashers.

Turn the steering wheel until the front wheels

are in the straight-ahead position and engage

the steering wheel lock. Engage the parking

brake and shift into 1st or reverse gear or place

the selector lever in position P.

All passengers should be outside the vehicle and

in a safe place, e.g. behind a guardrail.

Erect a warning triangle or warning flasher at the

appropriate distance if necessary. Comply with

all safety guidelines and regulations. <

Online Edition for Part no. 01 40 2 914 849 - \251 07/12 BMW AG

Page 221 of 259

MOBILITYReplacing components

220

In the event of a flat tire, different procedures

should be followed depending on the equip-

ment included in your vehicle:

>MINI Mobility Kit, refer to the following

section

> Run-flat tires, page 203

MINI Mobility Kit

The Mobility Kit is located under the left front

seat.

Preparations

Use of the MINI Mobility Kit may be ineffective if

the tire puncture measures approx. 1/8 in/4 mm

or more. Contact the nearest MINI dealer if the

tire cannot be made drivable with the Mobility

Kit.

Do not remove foreign bodies which have

penetrated the tire if possible.

Follow the instructions on using the

Mobility Kit found on the compressor and

the sealant bottle.<

Remove the adhesive label for the speed limit

from the sealant bottle and affix it to the

steering wheel.

Sealant and compressor

1 Sealant bottle and adhesive label with speed

limit

2 Filling hose

Note the use-by date on the sealant

bottle. < 3

Holder for the sealant bottle

4 Compressor

5 Plug and cable for the socket in the vehicle

interior, page 98

6 Connection hose to connect the compressor

and sealant bottle or the compressor and

wheel

7 On/off switch

8 Pressure gauge for indi cating the tire infla-

tion pressure

9 Release button for reduci ng the tire inflation

pressure

Connector, cable and connection hose are

stored in the co mpressor housing.

Using the Mobility Kit

To repair a tire puncture with the Mobility Kit,

proceed as follows:

>Filling the tire with sealant.

> Distributing the sealant.

> Correct the tire in flation pressure.

Filling the tire with sealant.

Proceed in the specified order; otherwise,

sealant may emerge under high pres-

sure. <

1. Shake the sealant bottle.

2. Pull the connecting hose 6 completely out of

the compressor housing and screw it onto

the connector of the sealant bottle. Make

sure that the hose is not kinked.

3. Insert the sealant bo ttle on the compressor

housing in an upright position.

Online Edition for Part no. 01 40 2 914 849 - \251 07/12 BMW AG

Page 222 of 259

Replacing componentsMOBILITY

221

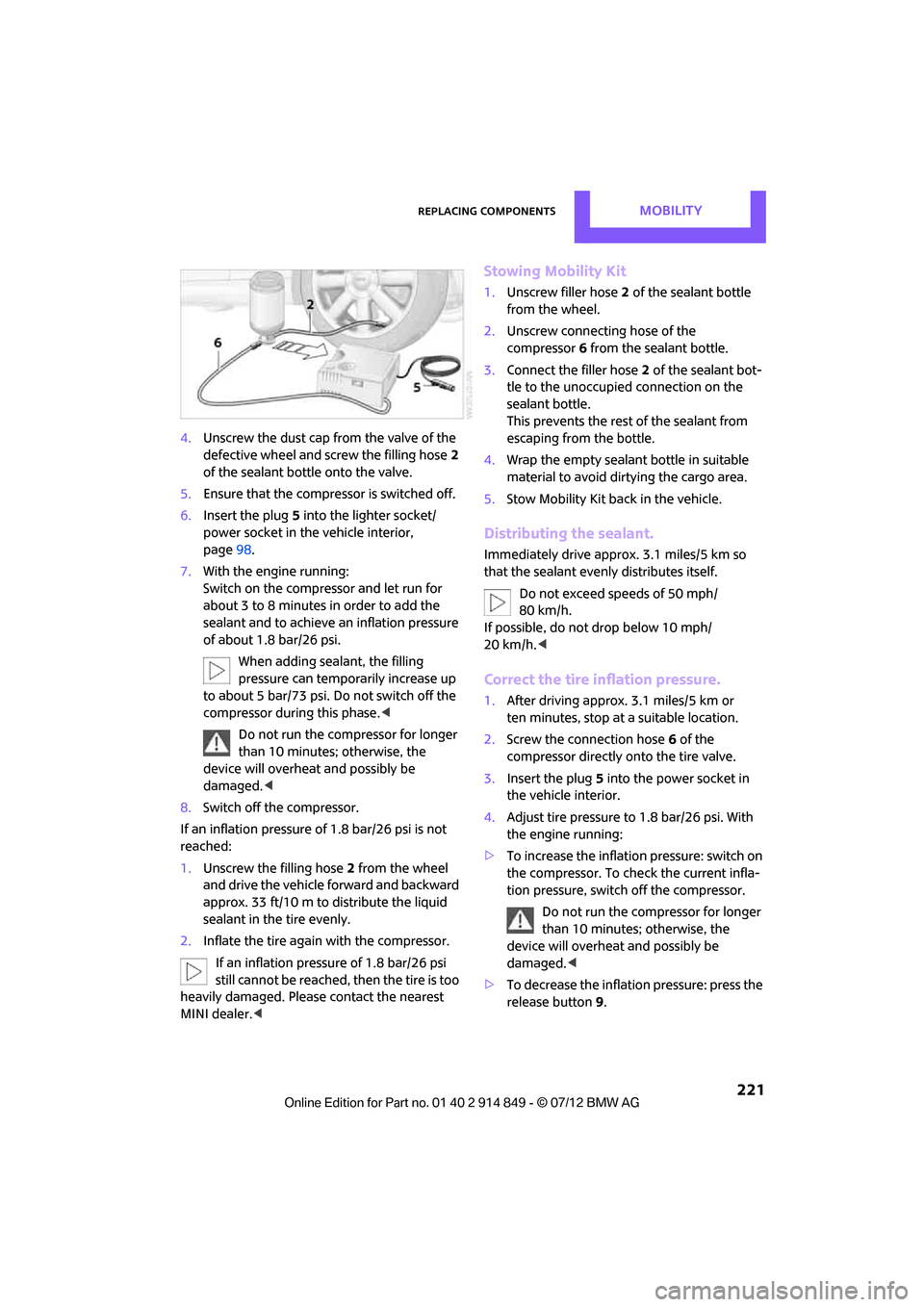

4.Unscrew the dust cap from the valve of the

defective wheel and screw the filling hose 2

of the sealant bottle onto the valve.

5. Ensure that the compre ssor is switched off.

6. Insert the plug 5 into the lighter socket/

power socket in the vehicle interior,

page 98.

7. With the engine running:

Switch on the compre ssor and let run for

about 3 to 8 minutes in order to add the

sealant and to achieve an inflation pressure

of about 1.8 bar/26 psi.

When adding sealant, the filling

pressure can temporarily increase up

to about 5 bar/73 psi. Do not switch off the

compressor during this phase. <

Do not run the compressor for longer

than 10 minutes; otherwise, the

device will overheat and possibly be

damaged. <

8. Switch off the compressor.

If an inflation pressure of 1.8 bar/26 psi is not

reached:

1. Unscrew the filling hose 2 from the wheel

and drive the vehicle forward and backward

approx. 33 ft/10 m to distribute the liquid

sealant in the tire evenly.

2. Inflate the tire again with the compressor.

If an inflation pressure of 1.8 bar/26 psi

still cannot be reached, then the tire is too

heavily damaged. Please contact the nearest

MINI dealer. <

Stowing Mobility Kit

1.Unscrew filler hose 2 of the sealant bottle

from the wheel.

2. Unscrew connecting hose of the

compressor 6 from the sealant bottle.

3. Connect the filler hose 2 of the sealant bot-

tle to the unoccupied connection on the

sealant bottle.

This prevents the rest of the sealant from

escaping from the bottle.

4. Wrap the empty sealant bottle in suitable

material to avoid dirtying the cargo area.

5. Stow Mobility Kit back in the vehicle.

Distributing the sealant.

Immediately drive approx. 3.1 miles/5 km so

that the sealant evenly distributes itself.

Do not exceed speeds of 50 mph/

80 km/h.

If possible, do not drop below 10 mph/

20 km/h.<

Correct the tire inflation pressure.

1. After driving approx. 3.1 miles/5 km or

ten minutes, stop at a suitable location.

2. Screw the connection hose 6 of the

compressor directly onto the tire valve.

3. Insert the plug 5 into the power socket in

the vehicle interior.

4. Adjust tire pressure to 1.8 bar/26 psi. With

the engine running:

> To increase the inflatio n pressure: switch on

the compressor. To check the current infla-

tion pressure, switch off the compressor.

Do not run the compressor for longer

than 10 minutes; otherwise, the

device will overheat and possibly be

damaged. <

> To decrease the inflat ion pressure: press the

release button 9.

Online Edition for Part no. 01 40 2 914 849 - \251 07/12 BMW AG

Page 223 of 259

MOBILITYReplacing components

222

If the tire cannot maintain the inflation

pressure, drive the vehicle again, refer to

Distributing the sealan t. Then repeat steps

1to4.

If an inflation pressure of 1.8 bar/26 psi still

cannot be reached, then the tire is too heavily

damaged. Contact your nearest MINI dealer. <

Driving on

Do not exceed the permitted maximum

speed of 50 mph/80 km/h; doing so may

result in an accident. <

Replace the defective tire as soon as possible

and have the new wheel/tire assembly

balanced.

Have the Mobility Kit refilled.

Changing wheels

The pouch with the wheel changing kit is stored

under the flat load floor.

It includes:

> Vehicle jack

> Reversible ratchet

> Wheel stud wrench

> Extractor hook for wheel center cover

> Chock

Preparing for a wheel change

Observe the safety precautions regarding

flat tires on page 219.<

Additional safety measures when

changing tires:

Only change the tire wh en parked on a surface

that is level, firm and not slippery.

The vehicle or the jack could slip sideways on

soft or slippery support surfaces, such as snow,

ice, flagstones, etc.

Do not use a wooden block or similar object as a

support base for the jack, as this would prevent

it from extending to its full support height and

reduce its load-carrying capacity.

Do not lie under the vehicle or start the engine when the vehicle is supported by the jack; other-

wise, there is a risk of fatal injury.

<

1. Place the foldable chock

behind the front

wheel on the other side of the vehicle or in

front of the wheel if the vehicle is on an

incline. If the wheel is changed on a surface

with a more severe sl ope, take additional

precautions to secure the vehicle from

rolling.

2. Uncover the lug bolts if necessary.

3. Loosen the lug bolts by a half turn.

Jacking up the vehicle

The vehicle jack is designed for changing

wheels only. Do not attempt to raise

another vehicle model with it or to raise any load

of any kind. To do so could cause accidents and

personal injury. <

1. Place the jack at the jacking point closest to

the wheel.

The jack base must be perpendicular to the

surface beneath the jacking point.

2. Slide reversible ratche t onto the fixture on

the jack, arrow 1.

Online Edition for Part no. 01 40 2 914 849 - \251 07/12 BMW AG

Page 224 of 259

Replacing componentsMOBILITY

223

3.As you ratchet up the jack, place the jack

head onto the lifting point on the body,

arrow 2.

4. Jack the vehicle up until the wheel you are

changing is raised off the ground.

Mounting the wheel

1.Unscrew the lug bolts and remove the

wheel.

2. Remove accumulations of mud or dirt from

the mounting surfaces of the wheel and

hub. Clean the lug bolts.

3. Lift the new wheel into place.

4. Screw at least two lug bolts finger-tight into

opposite bolt holes.

5. Screw in the remaining bolts.

6. Tighten all the lug bolts firmly in a diagonal

pattern.

7. Lower the vehicle.

8. Remove the jack.

Tightening the lug bolts

Tighten the lug bolts in a diagonal pattern.

Immediately have the wheels checked

with a calibrated torque wrench to ensure

that the lug bolts are firmly seated. Otherwise,

incorrectly tightened lug bolts can present a

safety hazard. <

Tightening torque: 103.3 lb ft or 140 Nm.

Replace the defective tire as soon as possible

and have the new wheel/tire assembly

balanced.

Vehicle battery

Maintenance

The battery is maintenance-free; that is, the

electrolyte will last for the life of the battery

when the vehicle is operated in a temperate

climate. If you have any questions regarding your

battery, please contact your MINI dealer.

Battery replacement

Only use vehicle batteries that have been

approved for your vehicle by the manu-

facturer; otherwise, the vehicle could be

damaged and systems or functions may not be

fully available. <

After a battery replacement, have the battery

registered on the vehicle by your MINI dealer to

ensure that all convenie nce functions are fully

available and, if nece ssary, the corresponding

Check Control messages are no longer dis-

played.

Charging the battery

Note

Do not connect battery chargers to the

sockets installed in the vehicle at the

factory; otherwise you may cause damage to

the battery. <

Only charge the battery in the vehicle when the

engine is off. Connection s, refer to Jump-start-

ing on page 225.

General information

To guarantee the full service life of the battery,

ensure that the battery is always properly

charged.

It may be necessary to charge the battery in the

following situations:

>If frequent short trips are taken.

> If the vehicle is frequently parked for more

than a month.

Disposal

After replacing old batteries, return the

used batteries to your MINI dealer or to

arecycling center. Maint ain the battery in an

upright position for transport and storage.

Always secure the battery against tipping over

during transport. <

Online Edition for Part no. 01 40 2 914 849 - \251 07/12 BMW AG

Page 228 of 259

Giving and receiving assistanceMOBILITY

227

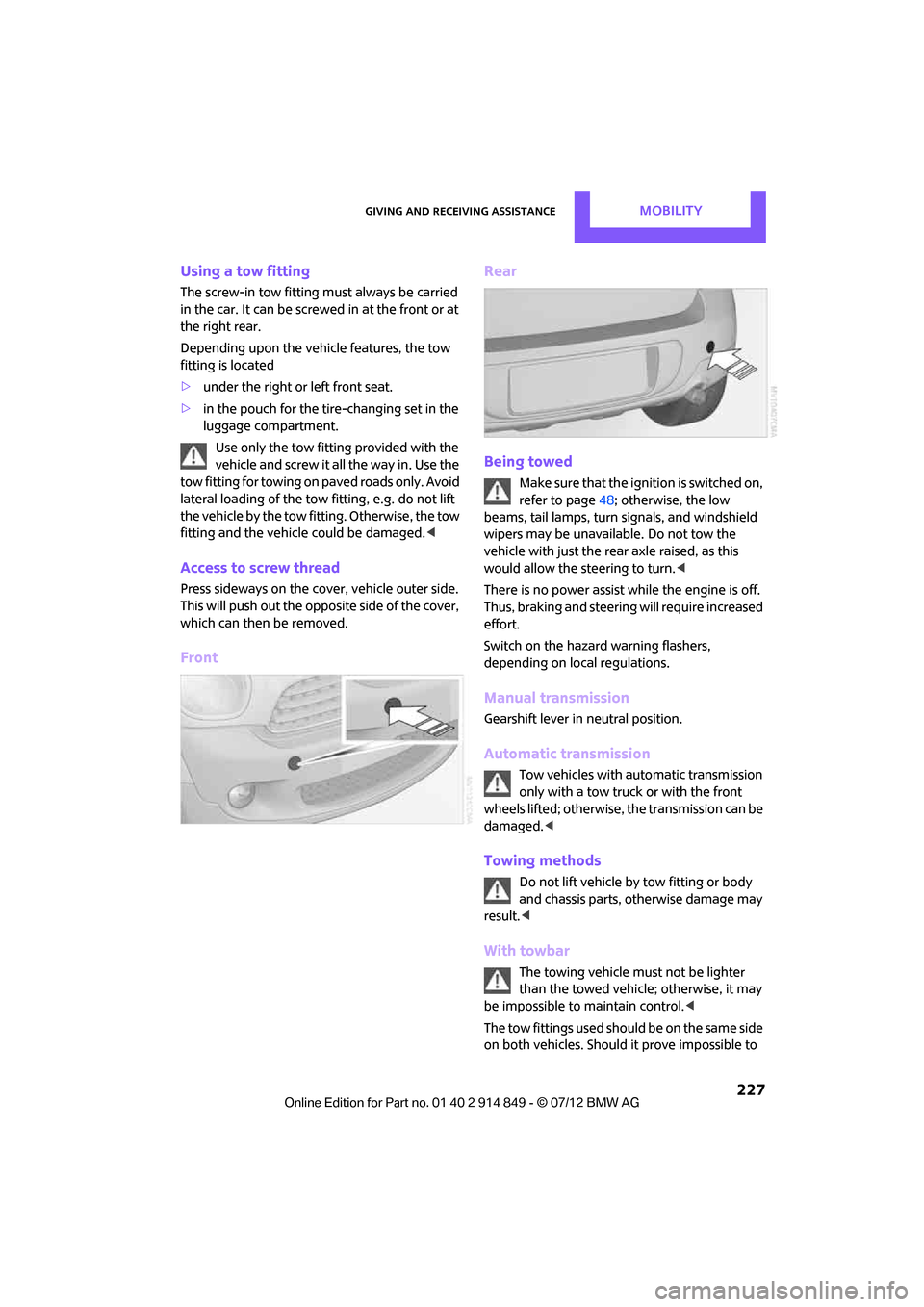

Using a tow fitting

The screw-in tow fitting must always be carried

in the car. It can be screwed in at the front or at

the right rear.

Depending upon the vehicle features, the tow

fitting is located

>under the right or left front seat.

> in the pouch for the tire-changing set in the

luggage compartment.

Use only the tow fitting provided with the

vehicle and screw it all the way in. Use the

tow fitting for towing on paved roads only. Avoid

lateral loading of the tow fitting, e.g. do not lift

the vehicle by the tow fitting. Otherwise, the tow

fitting and the vehicle could be damaged. <

Access to screw thread

Press sideways on the cover, vehicle outer side.

This will push out the oppo site side of the cover,

which can then be removed.

Front Rear

Being towed

Make sure that the ignition is switched on,

refer to page

48; otherwise, the low

beams, tail lamps, turn signals, and windshield

wipers may be unavailable. Do not tow the

vehicle with just the rear axle raised, as this

would allow the steering to turn. <

There is no power assist while the engine is off.

Thus, braking and steering will require increased

effort.

Switch on the hazard warning flashers,

depending on local regulations.

Manual transmission

Gearshift lever in neutral position.

Automatic transmission

Tow vehicles with automatic transmission

only with a tow truck or with the front

wheels lifted; otherwise, the transmission can be

damaged. <

Towing methods

Do not lift vehicle by tow fitting or body

and chassis parts, otherwise damage may

result. <

With towbar

The towing vehicle must not be lighter

than the towed vehicle; otherwise, it may

be impossible to maintain control. <

The tow fittings used should be on the same side

on both vehicles. Should it prove impossible to

Online Edition for Part no. 01 40 2 914 849 - \251 07/12 BMW AG

Page 229 of 259

MOBILITYGiving and receiving assistance

228

avoid mounting the tow bar at an angle, please

observe the following:

>Clearance and maneuver ing capability will

be sharply limited during cornering.

> The tow bar will generate lateral forces if it is

attached offset.

Only attach the tow bar to the tow fittings,

as attachment to other vehicle parts can

lead to damage. <

With tow rope

When starting off in the towing vehicle, make

sure that the tow rope is taut.

To avoid jerking and the associated

stresses on vehicle components when

towing, always use nylon ropes or nylon straps.

Attach the tow rope to the tow fittings only, as

attaching it to other pa rts of the vehicle could

result in damage. <

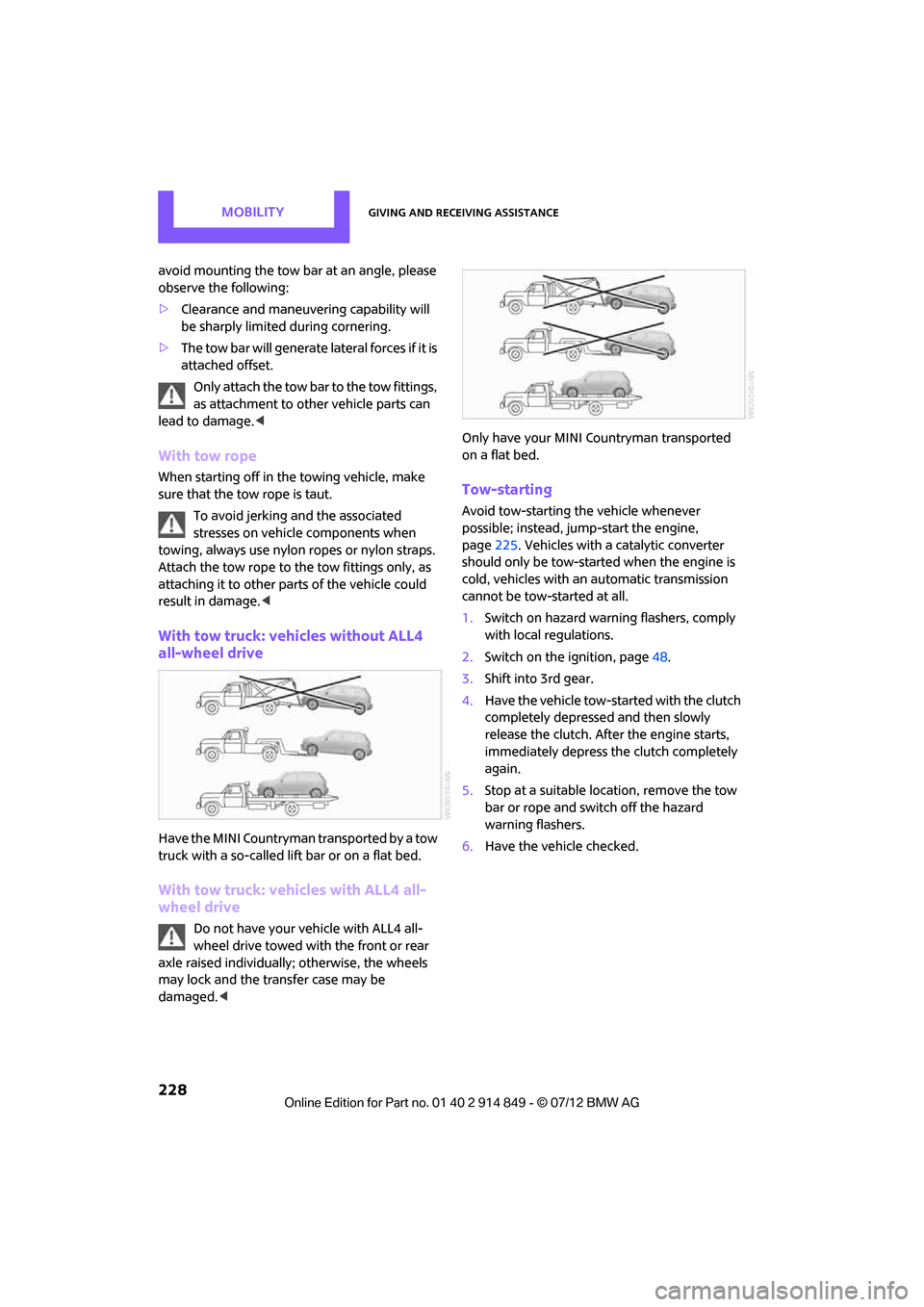

With tow truck: vehicles without ALL4

all-wheel drive

Have the MINI Countryman transported by a tow

truck with a so-called lift bar or on a flat bed.

With tow truck: vehicles with ALL4 all-

wheel drive

Do not have your vehicle with ALL4 all-

wheel drive towed with the front or rear

axle raised individually; otherwise, the wheels

may lock and the transfer case may be

damaged. < Only have your MINI Countryman transported

on a flat bed.

Tow-starting

Avoid tow-starting the vehicle whenever

possible; instead, jump-start the engine,

page

225. Vehicles with a catalytic converter

should only be tow-started when the engine is

cold, vehicles with an automatic transmission

cannot be tow-started at all.

1. Switch on hazard warning flashers, comply

with local regulations.

2. Switch on the ignition, page 48.

3. Shift into 3rd gear.

4. Have the vehicle tow-started with the clutch

completely depressed and then slowly

release the clutch. After the engine starts,

immediately depress the clutch completely

again.

5. Stop at a suitable lo cation, remove the tow

bar or rope and switch off the hazard

warning flashers.

6. Have the vehicle checked.

Online Edition for Part no. 01 40 2 914 849 - \251 07/12 BMW AG

Page 235 of 259

REFERENCETechnical data

234

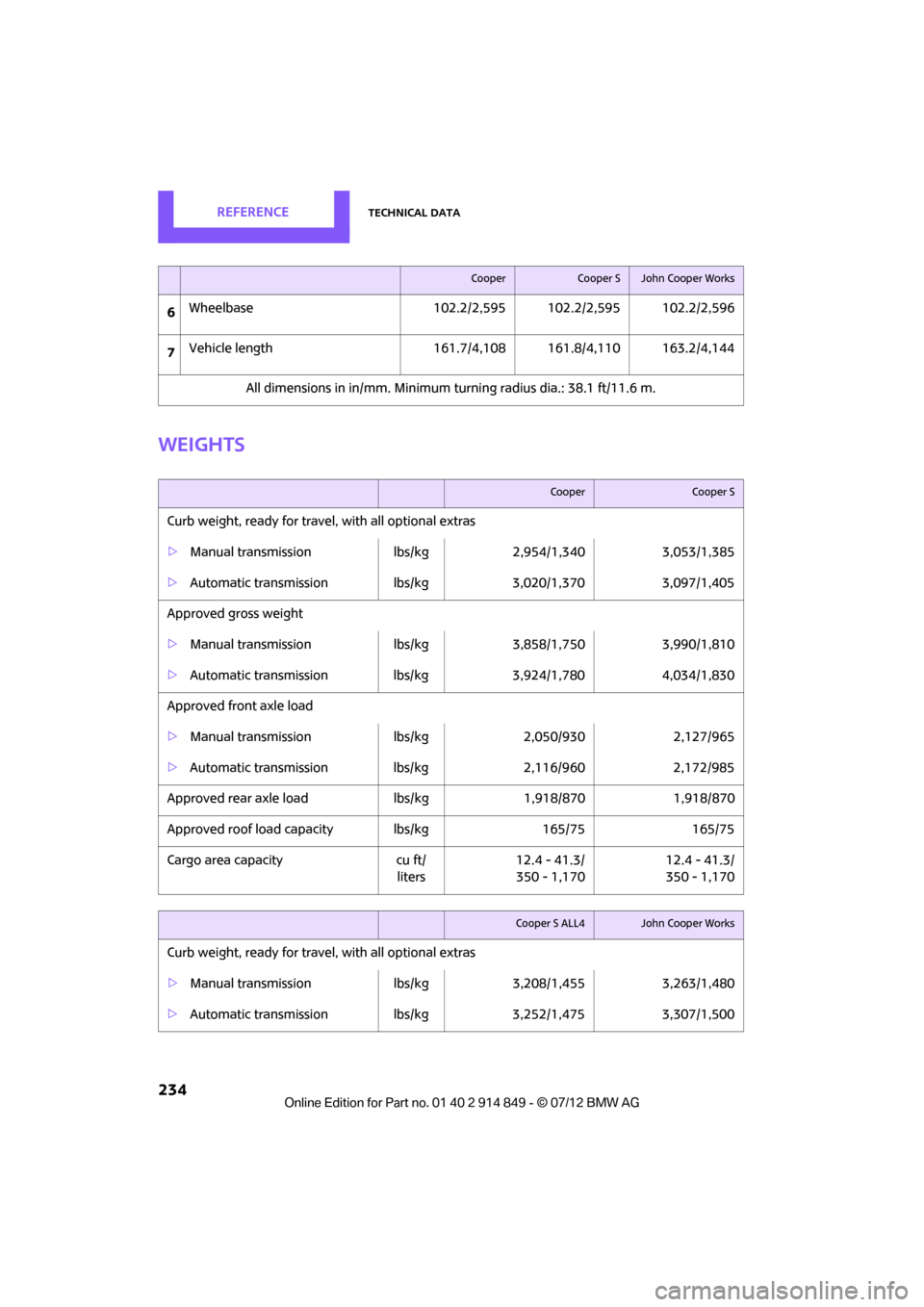

Weights

6Wheelbase

102.2/2,595 102.2/2,595 102.2/2,596

7 Vehicle length

161.7/4,108 161.8/4,110 163.2/4,144

All dimensions in in/mm. Minimum turning radius dia.: 38.1 ft/11.6 m.

CooperCooper SJohn Cooper Works

CooperCooper S

Curb weight, ready for travel, with all optional extras

> Manual transmission lbs/kg2,954/1,340 3,053/1,385

> Automatic transmission lbs/kg 3,020/1,3703,097/1,405

Approved gross weight

> Manual transmission lbs/kg3,858/1,750 3,990/1,810

> Automatic transmission lbs/kg 3,924/1,7804,034/1,830

Approved front axle load

> Manual transmission lbs/kg2,050/930 2,127/965

> Automatic transmission lbs/kg 2,116/9602,172/985

Approved rear axle load lbs/kg1,918/870 1,918/870

Approved roof load ca pacity lbs/kg 165/75165/75

Cargo area capacity cu ft/

liters 12.4 - 41.3/

350 - 1,170 12.4 - 41.3/

350 - 1,170

Cooper S ALL4John Cooper Works

Curb weight, ready for travel , with all optional extras

> Manual transmission lbs/kg3,208/1,455 3,263/1,480

> Automatic transmission lbs/kg 3,252/1,4753,307/1,500

Online Edition for Part no. 01 40 2 914 849 - \251 07/12 BMW AG