light MITSUBISHI 3000GT 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 1078 of 1146

52B-68SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - %%%$kgSRS warning

light

/------ r--l

I

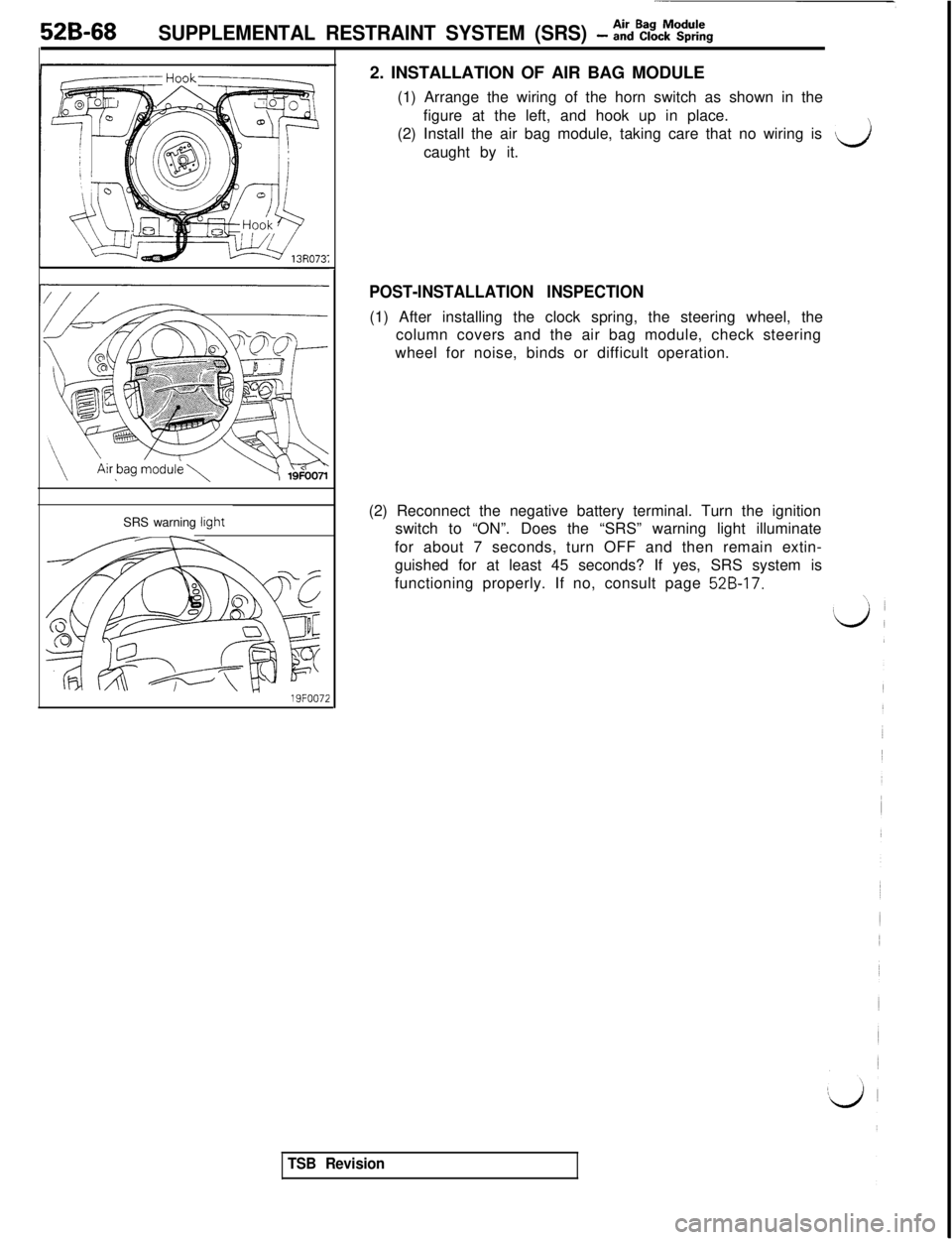

19FOO722. INSTALLATION OF AIR BAG MODULE

(1) Arrange the wiring of the horn switch as shown in the

figure at the left, and hook up in place.

(2) Install the air bag module, taking care that no wiring is

vicaught by it.

POST-INSTALLATION INSPECTION(1) After installing the clock spring, the steering wheel, the

column covers and the air bag module, check steering

wheel for noise, binds or difficult operation.

(2) Reconnect the negative battery terminal. Turn the ignition

switch to “ON”. Does the “SRS” warning light illuminate

for about 7 seconds, turn OFF and then remain extin-

guished for at least 45 seconds? If yes, SRS system is

functioning properly. If no, consult page

52B-17.

TSB Revision

Page 1082 of 1146

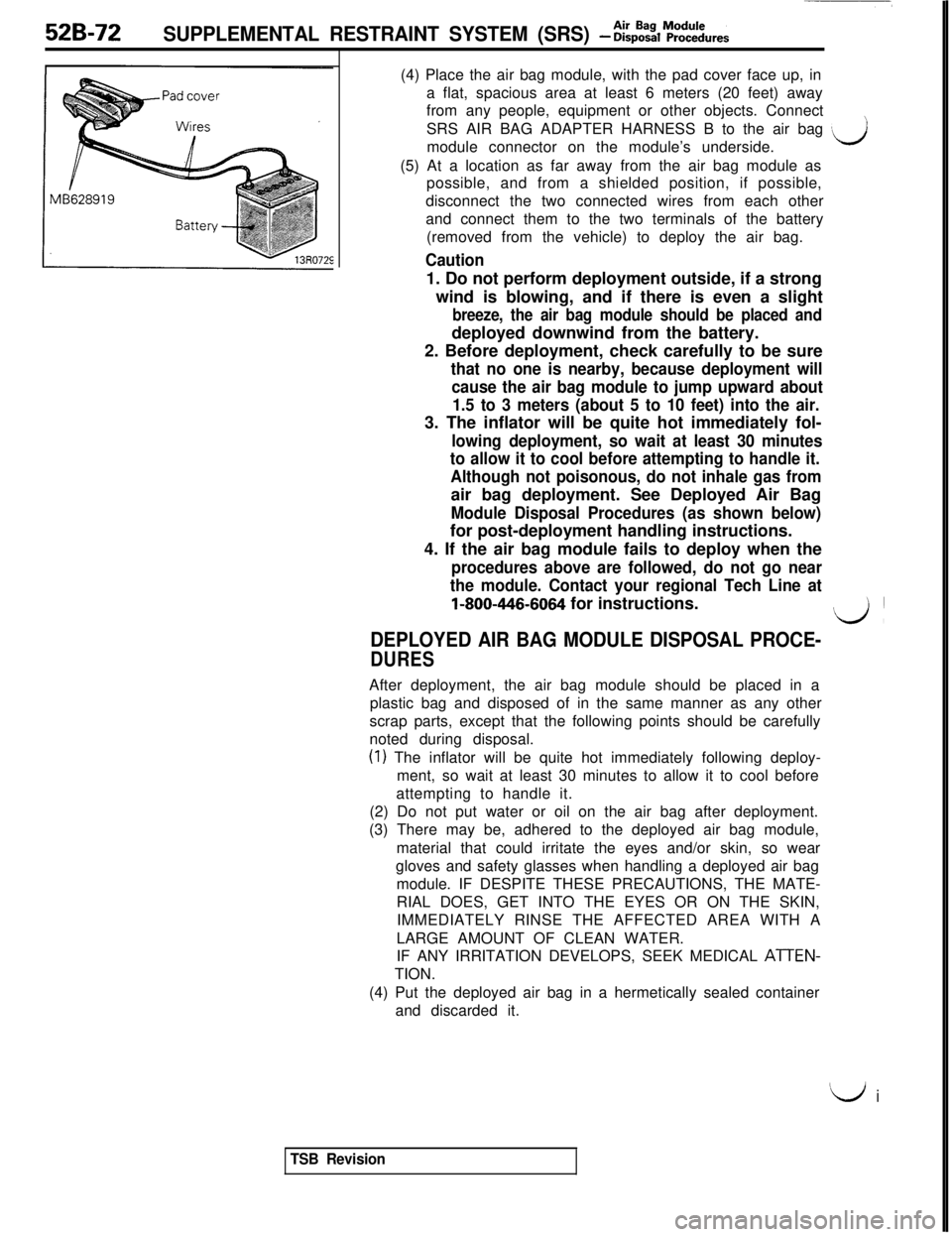

52B-72SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - &%~~~~~ures(4) Place the air bag module, with the pad cover face up, in

a flat, spacious area at least 6 meters (20 feet) away

from any people, equipment or other objects. Connect

SRS AIR BAG ADAPTER HARNESS B to the air bag

mdmodule connector on the module’s underside.

(5) At a location as far away from the air bag module as

possible, and from a shielded position, if possible,

disconnect the two connected wires from each other

and connect them to the two terminals of the battery

(removed from the vehicle) to deploy the air bag.

Caution1. Do not perform deployment outside, if a strong

wind is blowing, and if there is even a slight

breeze, the air bag module should be placed anddeployed downwind from the battery.

2. Before deployment, check carefully to be sure

that no one is nearby, because deployment will

cause the air bag module to jump upward about

1.5 to 3 meters (about 5 to 10 feet) into the air.3. The inflator will be quite hot immediately fol-

lowing deployment, so wait at least 30 minutes

to allow it to cool before attempting to handle it.

Although not poisonous, do not inhale gas fromair bag deployment. See Deployed Air Bag

Module Disposal Procedures (as shown below)for post-deployment handling instructions.

4. If the air bag module fails to deploy when the

procedures above are followed, do not go near

the module. Contact your regional Tech Line at

l-800-446-6064 for instructions.\J’

DEPLOYED AIR BAG MODULE DISPOSAL PROCE-

DURESAfter deployment, the air bag module should be placed in a

plastic bag and disposed of in the same manner as any other

scrap parts, except that the following points should be carefully

noted during disposal.

(1) The inflator will be quite hot immediately following deploy-

ment, so wait at least 30 minutes to allow it to cool before

attempting to handle it.

(2) Do not put water or oil on the air bag after deployment.

(3) There may be, adhered to the deployed air bag module,

material that could irritate the eyes and/or skin, so wear

gloves and safety glasses when handling a deployed air bag

module. IF DESPITE THESE PRECAUTIONS, THE MATE-

RIAL DOES, GET INTO THE EYES OR ON THE SKIN,

IMMEDIATELY RINSE THE AFFECTED AREA WITH A

LARGE AMOUNT OF CLEAN WATER.

IF ANY IRRITATION DEVELOPS, SEEK MEDICAL

A-I-TEN-TION.

(4) Put the deployed air bag in a hermetically sealed container

and discarded it.

‘LJ i

TSB Revision

Page 1083 of 1146

55-1

HEATER, AIR

CONDITIONER

AND VENTILATION

CONTENTSM55AA- -

HEATERS AND AIR CONDITIONING................3HEATER UNIT*........................................................................22

SPECIFICATIONS

....................................................................3REFRIGERANT LINE................................................................35General Specifications

........................................................3RESISTOR................................................................................20Lubricants

............................................................................4SAFETY PRECAUTIONS........................................................9Sealant and Adhesive............................................................4

Service Specifications3SERVICE ADJUSTMENT PROCEDURES............................10........................................................

SPECIAL TOOLS4Charging Procedures............................................................11

i

........................................................................Charging the Refrigerant....................................................12Compressor Drive Belt Adjustment....................................11

HEATERS AND MANUAL AIR CONDITIONER5Compressor Noise................................................................16

................................................16

AIR CONDITIONER SWITCH................................................21Handling Tubing andFittings

Idle-up Operation Check....................................................17

BELT LOCK CONTROLLER20Performance Test................................................................15....................................................

BLOWER ASSEMBLYPower Relay Check............................................................17............................................................23Refrigerant Leak Repair Procedure....................................15COMPRESSOR........................................................................

27TestProcedures....................................................................10

CONDENSER AND CONDENSER FAN MOTOR................33TROUBLESHOOTING............................................................5

ENGINE COOLANT TEMPERATURE SWITCH....................

39VENTILATORS (AIR INLET AND AIR OUTLET)................38

EVAPORATOR

........................................................................

25VENTILATORS (INSTRUMENT PANEL)*............................36

HEATER CONTROL ASSEMBLY*

........................................18CONTINUED ON NEXT PAGE

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

(1)A Supplemental Restraint System (SRS), which uses a driver-side air bag, has been installed in the 3000GT.(2)The SRS includes the following components: impact sensors, SRS diagnosis unit: SRS warning light, air bagmodule, clock spring, interconnecting wiring. Other SRS-related components (that may have to be

removed/installed in connection with SRS service or maintenance) are indicated in the table of contents byan asterisk (*).

WARNING!(1)Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inadvertent firing of the air bag) or to the driver (fromrendering the

SRS inoperative).(2) Service or maintenance of any SRS component or SRS-related component must be performed only at anauthorized MITSUBISHI dealer.

(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B

-Supplemental Restraint System (SRS), before beginning any service or maintenance of any component of theSRS or any SRS-related component.

Page 1097 of 1146

L/

i

HEATERS AND MANUAL AIR CONDITIONER -Service Adjustment Procedures 55 15

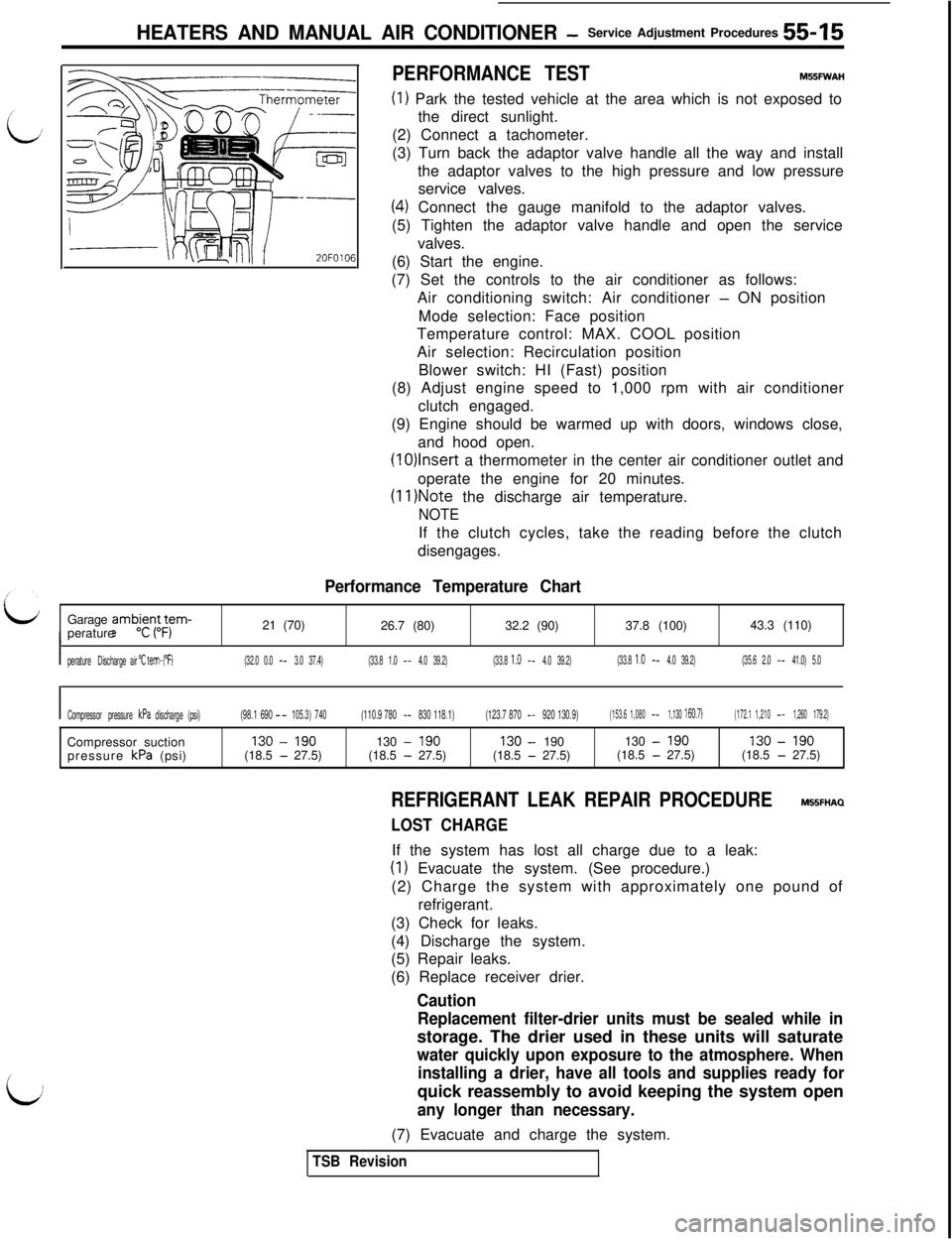

PERFORMANCE TESTM55FWAH

(I) Park the tested vehicle at the area which is not exposed to

the direct sunlight.

(2) Connect a tachometer.

(3) Turn back the adaptor valve handle all the way and install

the adaptor valves to the high pressure and low pressure

service valves.

(4) Connect the gauge manifold to the adaptor valves.

(5) Tighten the adaptor valve handle and open the service

valves.

(6) Start the engine.

(7) Set the controls to the air conditioner as follows:

Air conditioning switch: Air conditioner

- ON position

Mode selection: Face position

Temperature control: MAX. COOL position

Air selection: Recirculation position

Blower switch: HI (Fast) position

(8) Adjust engine speed to 1,000 rpm with air conditioner

clutch engaged.

(9) Engine should be warmed up with doors, windows close,

and hood open.

(1O)lnsert a thermometer in the center air conditioner outlet and

operate the engine for 20 minutes.

(II )Note the discharge air temperature.

NOTEIf the clutch cycles, take the reading before the clutch

disengages.

Performance Temperature ChartGarage

amb;in,L;am-perature21 (70)

26.7 (80)32.2 (90)37.8 (100)43.3 (110)

Iperature Dischargeair "C tem- ("F)(32.0 0.0- -3.0 37.4)(33.8 1.0- -4.0 39.2)(33.8 1.0- -4.0 39.2)(33.8 1.0- -4.0 39.2)(35.6 2.0- -41.0) 5.0

ICompressor pressure kPa discharge (psi)(98.1 690- -105.3) 740(110.9 780- -830 118.1)(123.7 870- -920 130.9)(153.6 1,080- -1,130 160.7)(172.1 1,210- -1,260 179.2)Compressor suction130

-190130-190130-190130-190130-190

pressure kPa (psi)(18.5-27.5)(18.5-27.5)(18.5-27.5)(18.5-27.5)(18.5-27.5)

REFRIGERANT LEAK REPAIR PROCEDUREM55FHAQ

LOST CHARGEIf the system has lost all charge due to a leak:

(1) Evacuate the system. (See procedure.)

(2) Charge the system with approximately one pound of

refrigerant.

(3) Check for leaks.

(4) Discharge the system.

(5) Repair leaks.

(6) Replace receiver drier.

Caution

Replacement filter-drier units must be sealed while instorage. The drier used in these units will saturate

water quickly upon exposure to the atmosphere. When

installing a drier, have all tools and supplies ready forquick reassembly to avoid keeping the system open

any longer than necessary.(7) Evacuate and charge the system.

TSB Revision

Page 1099 of 1146

HEATERS AND MANUAL AIR CbNDlTlONER -Service Adjustment Procedures 55 17

ADJUSTMENT PROCEDURES(1) Select a quiet area for testing. Duplicate conditions as much

as possible. Switch compressor on and off several times to

clearly identify compressor noise.

To duplicate high ambient conditions (high head pressure),

restrict air flow through condenser. Install manifold gauge

set to make sure discharge pressure doesn’t exceed 2,070

kPa (300 psi).

(2) Tighten all compressor mounting bolts, clutch mounting

bolt, and compressor drive belt. Check to assure clutch coil

is tight (no rotation or wobble).

(3) Check refrigerant hoses for rubbing or interference that can

cause unusual noises.

(4) Check refrigerant charge. (See “Charging System”.)

(5) Recheck compressor noise as in Step 1.

(6) If noise still exists, loosen compressor mounting bolts and

retorque. Repeat Step 1.

(7) If noise continues, replace compressor and repeat Step 1.

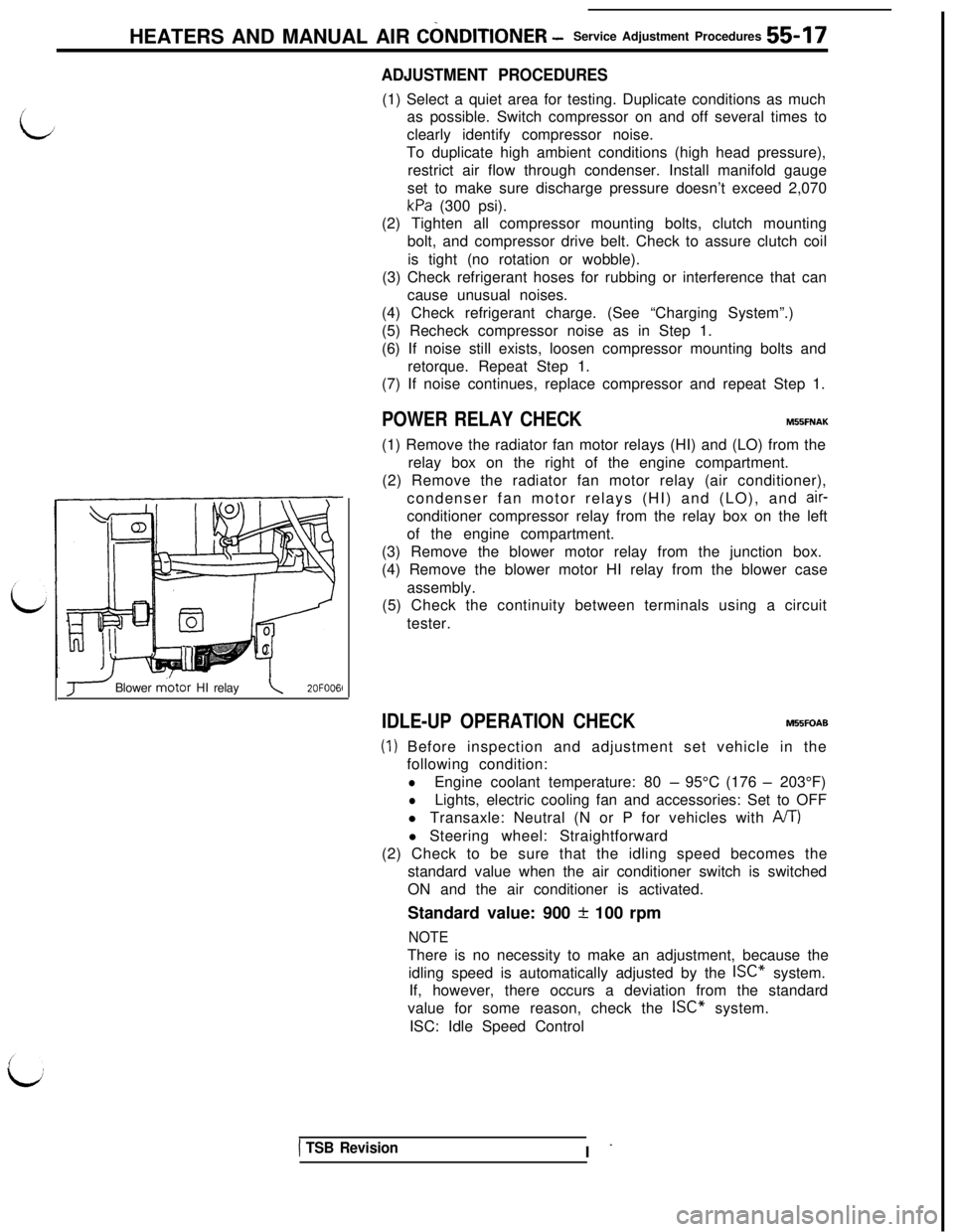

POWER RELAY CHECKMBBFNAK(1) Remove the radiator fan motor relays (HI) and (LO) from the

relay box on the right of the engine compartment.

(2) Remove the radiator fan motor relay (air conditioner),

condenser fan motor relays (HI) and (LO), and

air-conditioner compressor relay from the relay box on the left

of the engine compartment.

(3) Remove the blower motor relay from the junction box.

(4) Remove the blower motor HI relay from the blower case

assembly.

(5) Check the continuity between terminals using a circuit

tester.

J Blower m.otor HI relay\2OFOO6l

IDLE-UP OPERATION CHECKM55FOAB

(1) Before inspection and adjustment set vehicle in the

following condition:

lEngine coolant temperature: 80 - 95°C (176 - 203°F)

lLights, electric cooling fan and accessories: Set to OFF

l Transaxle: Neutral (N or P for vehicles with

A/T)l Steering wheel: Straightforward

(2) Check to be sure that the idling speed becomes the

standard value when the air conditioner switch is switched

ON and the air conditioner is activated.

Standard value: 900

+ 100 rpm

NOTEThere is no necessity to make an adjustment, because the

idling speed is automatically adjusted by the ISC” system.

If, however, there occurs a deviation from the standard

value for some reason, check the ISC” system.

ISC: Idle Speed Control

1 TSB RevisionI -

Page 1103 of 1146

HEATERS AND MANUAL AIR CONDITIONER - Air Condikner Switch55-21

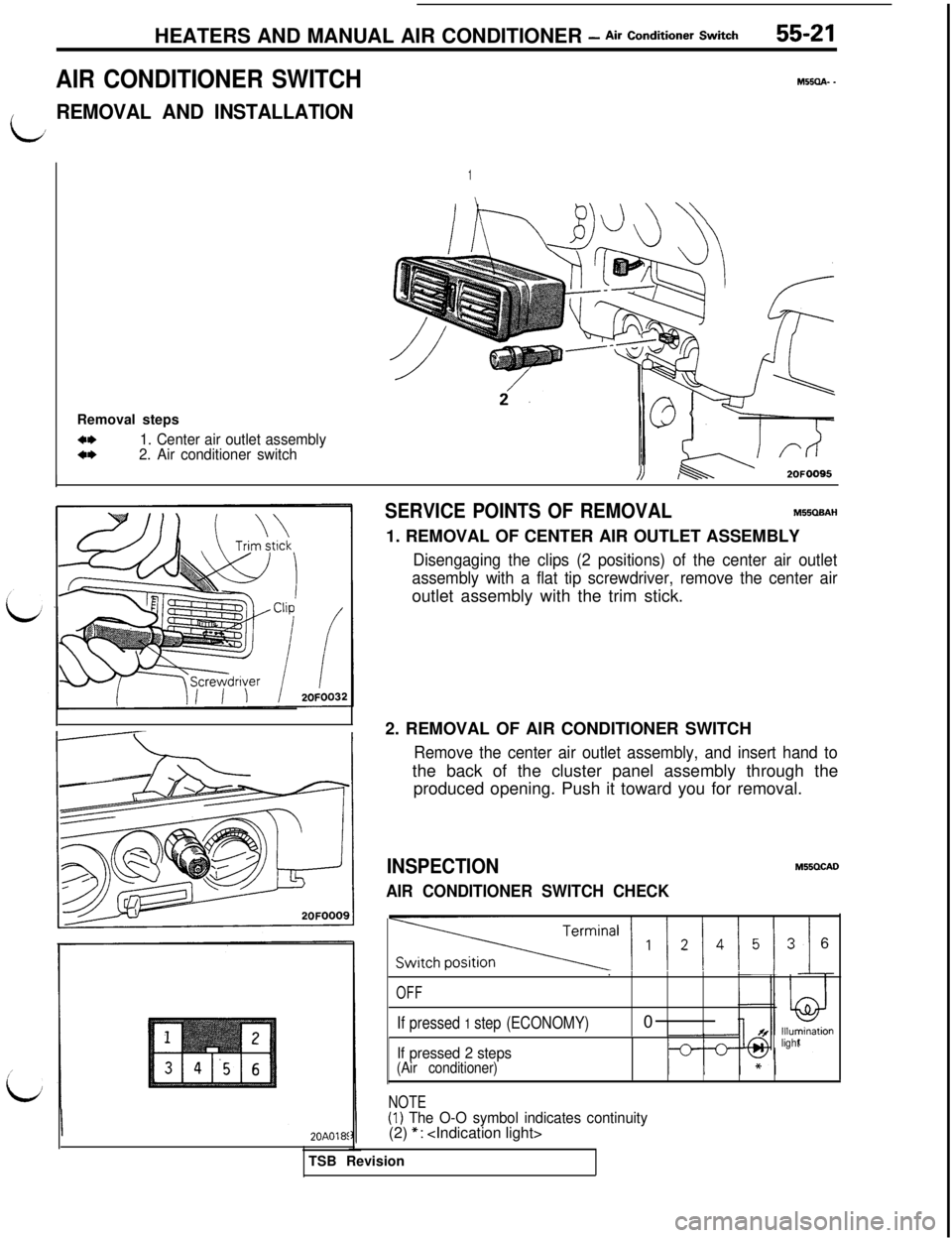

AIR CONDITIONER SWITCH

L

REMOVAL AND INSTALLATIONRemoval steps

1. Center air outlet assembly

2. Air conditioner switch

II/J2OFOO95

M55QA- *

1

I I\L!Y,“~ s/

//

L/

l-----L-I

SERVICE POINTS OF REMOVALM55QBAH1. REMOVAL OF CENTER AIR OUTLET ASSEMBLY

Disengaging the clips (2 positions) of the center air outlet

assembly with a flat tip screwdriver, remove the center airoutlet assembly with the trim stick.

2. REMOVAL OF AIR CONDITIONER SWITCH

Remove the center air outlet assembly, and insert hand tothe back of the cluster panel assembly through the

produced opening. Push it toward you for removal.

INSPECTION

AIR CONDITIONER SWITCH CHECKM55QCAD

OFF.

0

light

If pressed 1 step (ECONOMY)

If pressed 2 steps(Air conditioner)

NOTE(1) The O-O symbol indicates continuity(2) *: