ECO mode MITSUBISHI 3000GT 1991 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 738 of 1146

![MITSUBISHI 3000GT 1991 User Guide 35-16SERVICE BRAKES -Anti-lock Braking System Troubleshooting

BABS warning light stays on when the ignition key is in the “ON” position.

[Explanation]

[Hint]

This is the symptom when the ABS ECU d MITSUBISHI 3000GT 1991 User Guide 35-16SERVICE BRAKES -Anti-lock Braking System Troubleshooting

BABS warning light stays on when the ignition key is in the “ON” position.

[Explanation]

[Hint]

This is the symptom when the ABS ECU d](/img/19/57085/w960_57085-737.png)

35-16SERVICE BRAKES -Anti-lock Braking System Troubleshooting

BABS warning light stays on when the ignition key is in the “ON” position.

[Explanation]

[Hint]

This is the symptom when the ABS ECU does not

Check the diagnosis output and if there is no output

power up due to broken ECU power circuit, etc.,

voltage or if the MUT and ABS ECU cannot

when the fail safe function operates and isolates thecommunicate, there is a good possibility that power

system or when the warning light drive circuit is

is not flowing to the ECU.

short circuited.

!8IGNIISWIT(-

:Et

J’B @

C151

:

E

COMBINATION

METER

-19

7

------____-_---1

2

610 2

~;@lizEFgIIc,

6227J

r bL-1

IN(IGl)

1

,

ig

)

158

7

r-TSB iCaution

lIf the trouble code is output, the system can

be in the fail safe mode. in such a case, erase

the trouble code and then restart the engine

to check if the system is currently in a fault

condition.

~~~~

~~~~1

I,No ,I

Yes6

Replace ECU.

41,No rIDoes the ABS warning light

remain illuminated even with

the HU connector discon-

nected?

Yes

Short-circuit in harness

between HU or ECU and ABS

warning light

> Repair harness or replace

combination meter.

bvision

Page 780 of 1146

35-58SERVICE BRAKES - Service Adjustment Procedures

POINTS IN WAVEFORM MEASUREMENT

Symptom

Too small or zero waveform

amplitudeProbable causes

Faulty wheel speed sensorRemedy

Replace sensor

Incorrect pole piece-to-rotor clearance

Adjust clearance

Waveform amplitude fluctuates

excessively (this is no problem ifAxle hub eccentric or with large runout

Replace hub

the minimum amplitude is

100 mV

or more)

Noisy or disturbed waveformOpen circuit in sensor

Open circuit in harness

Incorrectly mounted wheel speed sensor

Rotor with missing or damaged teethReplace sensor

Correct harness

Mount correctly

Replace rotor

NOTEThe wheel speed sensor cable moves following motion of the front or rear suspension. Therefore, it is likely that it has an

open circuit only when driving on rough roads and it functions normally on ordinary roads. It is, therefore, recommended

to observe sensor output voltage waveform also under special conditions, such as rough road driving,

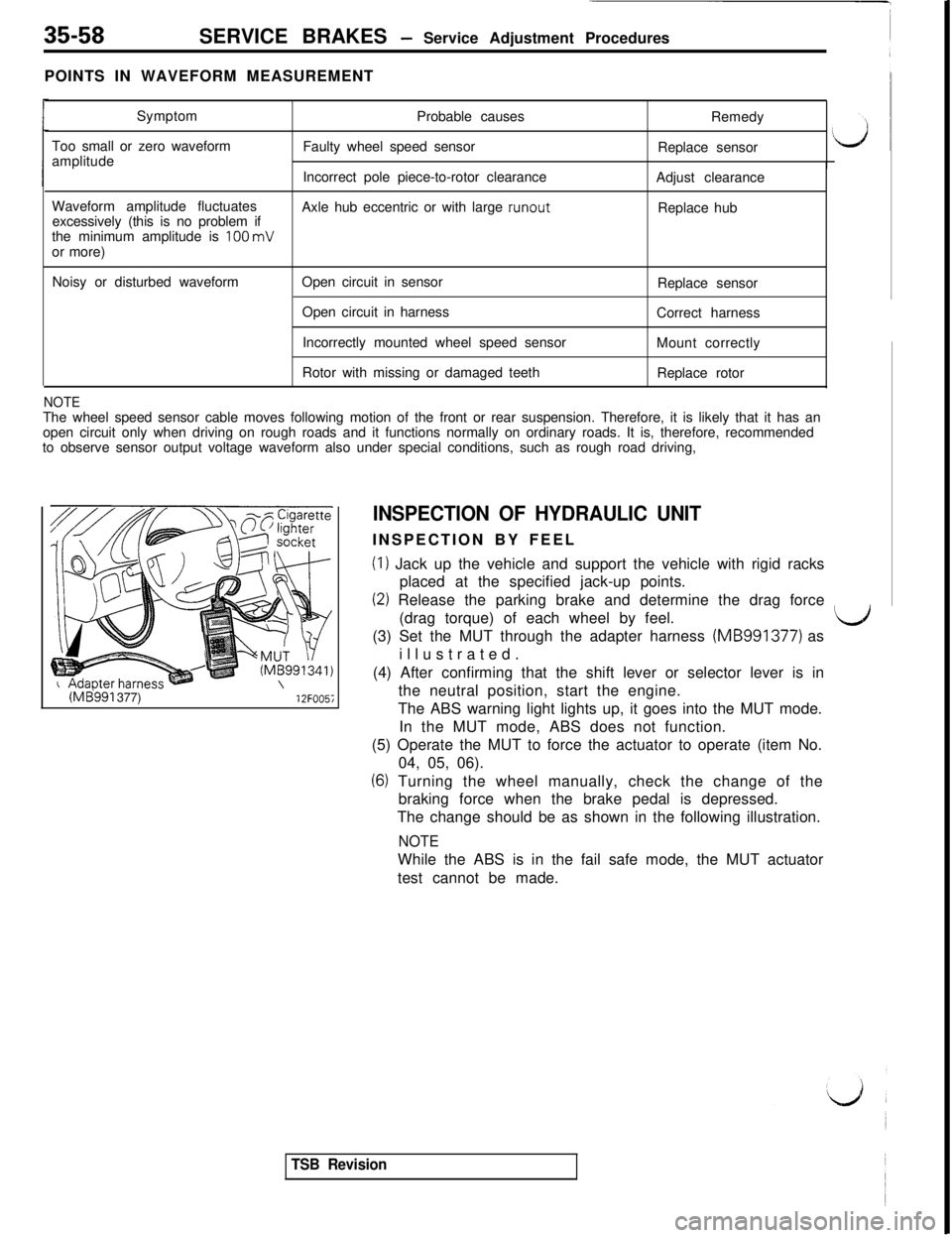

(ME!991 377)12FOO5i

INSPECTION OF HYDRAULIC UNITINSPECTION BY FEEL

(I) Jack up the vehicle and support the vehicle with rigid racks

placed at the specified jack-up points.

(2) Release the parking brake and determine the drag force

(drag torque) of each wheel by feel.

LJ(3) Set the MUT through the adapter harness (MB991377) as

illustrated.

(4) After confirming that the shift lever or selector lever is in

the neutral position, start the engine.

The ABS warning light lights up, it goes into the MUT mode.

In the MUT mode, ABS does not function.

(5) Operate the MUT to force the actuator to operate (item No.

04, 05, 06).

(6) Turning the wheel manually, check the change of the

braking force when the brake pedal is depressed.

The change should be as shown in the following illustration.

NOTEWhile the ABS is in the fail safe mode, the MUT actuator

test cannot be made.

TSB Revision

Page 1012 of 1146

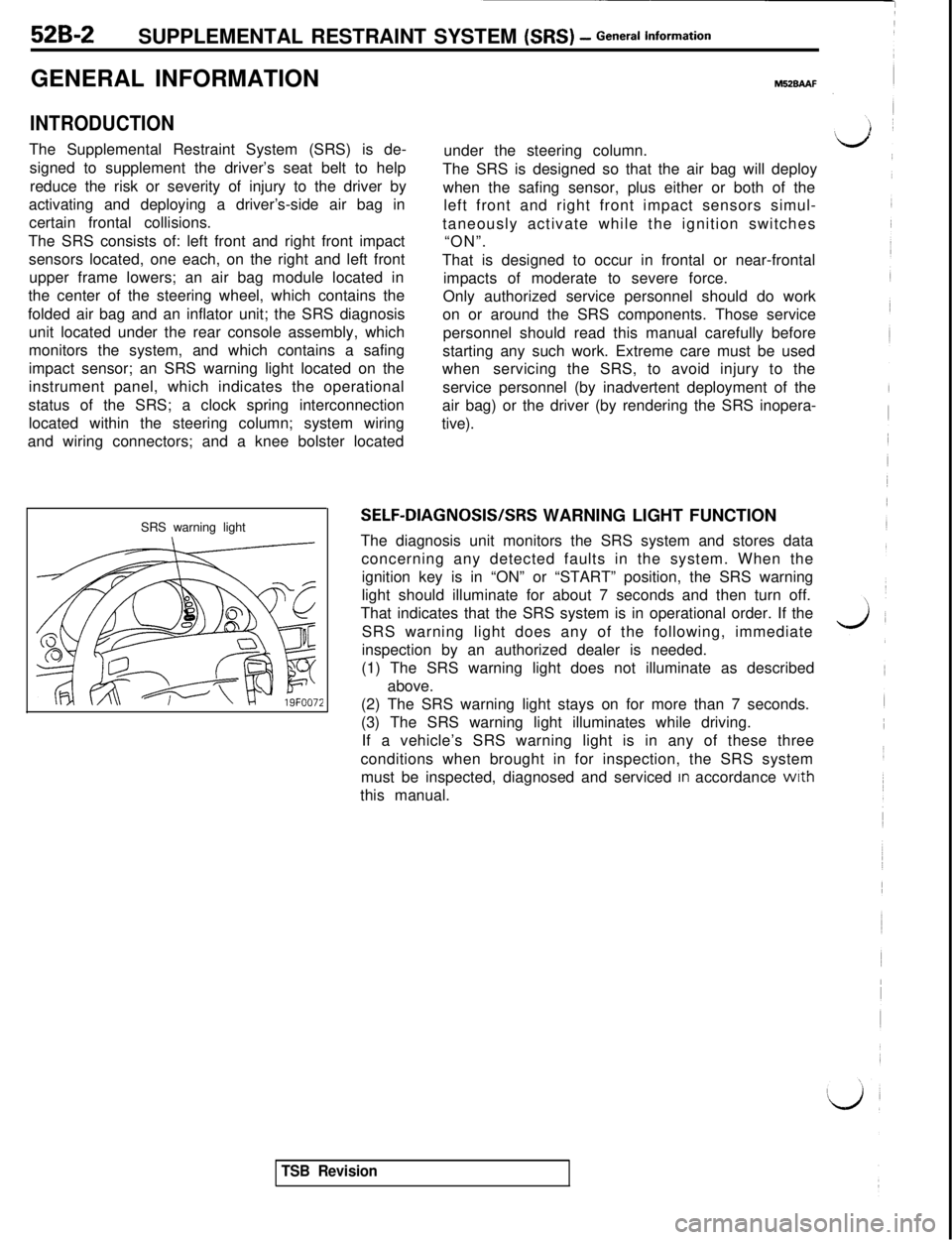

52B-2SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - General informationGENERAL INFORMATION

INTRODUCTIONThe Supplemental Restraint System (SRS) is de-

signed to supplement the driver’s seat belt to help

reduce the risk or severity of injury to the driver by

activating and deploying a driver’s-side air bag in

certain frontal collisions.

The SRS consists of: left front and right front impact

sensors located, one each, on the right and left front

upper frame lowers; an air bag module located in

the center of the steering wheel, which contains the

folded air bag and an inflator unit; the SRS diagnosis

unit located under the rear console assembly, which

monitors the system, and which contains a safing

impact sensor; an SRS warning light located on the

instrument panel, which indicates the operational

status of the SRS; a clock spring interconnection

located within the steering column; system wiring

and wiring connectors; and a knee bolster located

SRS warning light

M52BAAFunder the steering column.

The SRS is designed so that the air bag will deploy

when the safing sensor, plus either or both of the

left front and right front impact sensors simul-

taneously activate while the ignition switches

“ON”.

That is designed to occur in frontal or near-frontal

impacts of moderate to severe force.

Only authorized service personnel should do work

on or around the SRS components. Those service

personnel should read this manual carefully before

starting any such work. Extreme care must be used

whenservicing the SRS, to avoid injury to the

service personnel (by inadvertent deployment of the

air bag) or the driver (by rendering the SRS inopera-

tive).

SELF-DIAGNOSIS/SRS WARNING LIGHT FUNCTION

The diagnosis unit monitors the SRS system and stores data

concerning any detected faults in the system. When the

ignition key is in “ON” or “START” position, the SRS warning

light should illuminate for about 7 seconds and then turn off.

That indicates that the SRS system is in operational order. If the

SRS warning light does any of the following, immediate

inspection by an authorized dealer is needed.

(1) The SRS warning light does not illuminate as described

above.

(2) The SRS warning light stays on for more than 7 seconds.

(3) The SRS warning light illuminates while driving.

If a vehicle’s SRS warning light is in any of these three

conditions when brought in for inspection, the SRS system

must be inspected, diagnosed and serviced

In accordance wrth

this manual.

TSB Revision

Page 1028 of 1146

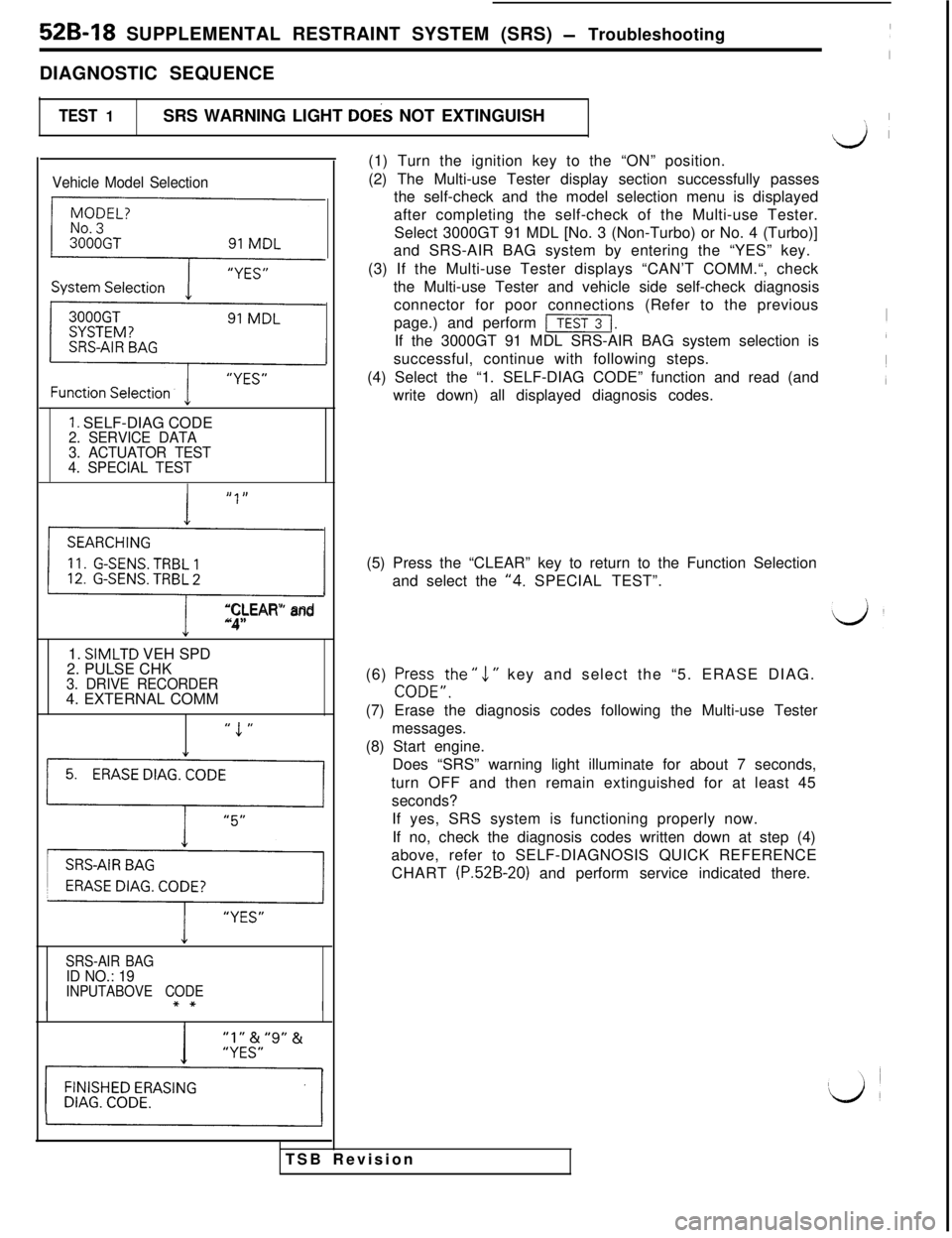

52B-18 SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - Troubleshooting

DIAGNOSTIC SEQUENCE

TEST 1SRS WARNING LIGHT DOES NOT EXTINGUISH

\1 I

Vehicle Model Selection

{

F

1. SELF-DIAG CODE2. SERVICE DATA

3. ACTUATOR TEST

4. SPECIAL TEST

,, I,

0

“CLEAR” and“4”1.

SIMLTD VEH SPD

2. PULSE CHK

3. DRIVE RECORDER4. EXTERNAL COMM

” 1 ”

1’1

y,,

SRS-AIR BAGID NO.: 19INPUTABOVE CODE

I(1) Turn the ignition key to the “ON” position.

(2) The Multi-use Tester display section successfully passes

the self-check and the model selection menu is displayed

after completing the self-check of the Multi-use Tester.

Select 3000GT 91 MDL [No. 3 (Non-Turbo) or No. 4 (Turbo)]

and SRS-AIR BAG system by entering the “YES” key.

(3) If the Multi-use Tester displays “CAN’T COMM.“, check

the Multi-use Tester and vehicle side self-check diagnosis

TSB Revisionconnector for poor connections (Refer to the previous

page.) and perform

[I.If the 3000GT 91 MDL SRS-AIR BAG system selection is

successful, continue with following steps.

(4) Select the “1. SELF-DIAG CODE” function and read (and

write down) all displayed diagnosis codes.

(5) Press the “CLEAR” key to return to the Function Selection

and select the

“4. SPECIAL TEST”.

(6) Pr+FE,the ”

1 ” key and select the “5. ERASE DIAG.

(7) Erase the diagnosis codes following the Multi-use Tester

messages.

(8) Start engine.

Does “SRS” warning light illuminate for about 7 seconds,

turn OFF and then remain extinguished for at least 45

seconds?

If yes, SRS system is functioning properly now.

If no, check the diagnosis codes written down at step (4)

above, refer to SELF-DIAGNOSIS QUICK REFERENCE

CHART

(P.52B-20) and perform service indicated there.

Page 1030 of 1146

![MITSUBISHI 3000GT 1991 User Guide 52B-20 SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - Troubleshooting

SELF-DIAGNOSIS QUICK REFERENCE CHART

Fault

No.

-

11

32

Diagnosis code name

[Failure mode]

(NORMAL)

G-SENS. TRBL

1[Short circuit]

G-SENS. T MITSUBISHI 3000GT 1991 User Guide 52B-20 SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - Troubleshooting

SELF-DIAGNOSIS QUICK REFERENCE CHART

Fault

No.

-

11

32

Diagnosis code name

[Failure mode]

(NORMAL)

G-SENS. TRBL

1[Short circuit]

G-SENS. T](/img/19/57085/w960_57085-1029.png)

52B-20 SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - Troubleshooting

SELF-DIAGNOSIS QUICK REFERENCE CHART

Fault

No.

-

11

32

Diagnosis code name

[Failure mode]

(NORMAL)

G-SENS. TRBL

1[Short circuit]

G-SENS. TRBL 2[One open-circuit]

G-SENS. TRBL 3[Two open-circuit]

SQUIB TRBL 1[Short circuit]

SQUIB TRBL 2

[Open-circuit]

CONDENS. VO. HI

CONDENS. VO. LO

CRANKING TRBL

CONN. UNLOCKED

Explanation

Normal. The SRS is in goodorder.

The circuits for the front impact sensor are shortedto each other.

Right or left impact sensor cirucit is open or the

wire from the sensor to the SDU is open-circuit.

Right and left impact sensor circuits are open or thewires from the sensors to the SDU areopen-circuit.

The circuits for the air bag module (squib) are

shorted to each other or the circuit isgrounded.

The air bag module Isquib) circuit is open or the wire

from the air bag to the SDU (clock spring) is open-circuit.

The capacitor (integrated in the

SDU) terminal voltage

is higher than the specified value for 5 seconds.

The capacitor (integrated in the

SDU) terminal voltage

is lower than the specified value for 5 seconds.

The circuit for the cranking signal is shorted to

some power supply circuits.

It takes at least 45 seconds that the SDU detects

this fault.

The lock switch (short bar) of the SDU double lockconnector isopen.Service

Perform TEST 5

Perform TEST 6(I) Turn the ignition key

to the “LOCK” posi-

tion, disconnect the

negative battery

cable and tape the

terminal.

(2) After waiting atleast 30 seconds,

replace the SDU.

(Refer to P.52B-59.)

Perform TEST 7

Perform TEST 8NOTE

- IMPORTANT

(1) After repairing the SRS, reconnect the battery cable, erase the diagnosis code memory from theMulti-use Tester and check the SRS warning light operation to verify the system functions

properly. (Refer to TEST 1.)

(2) SDU

= SRS Diagnosis Unit

1 TSB Revision

Page 1031 of 1146

![MITSUBISHI 3000GT 1991 User Guide SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - Troubleshooting 52B-21

/

id

FaultDiagnosis code nameNo.[Failure mode]Explanation

Service

41

IG VOLT LOW 1The multi-purpose fuse (No. 18) is blown or the wirefrom MITSUBISHI 3000GT 1991 User Guide SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - Troubleshooting 52B-21

/

id

FaultDiagnosis code nameNo.[Failure mode]Explanation

Service

41

IG VOLT LOW 1The multi-purpose fuse (No. 18) is blown or the wirefrom](/img/19/57085/w960_57085-1030.png)

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - Troubleshooting 52B-21

/

id

FaultDiagnosis code nameNo.[Failure mode]Explanation

Service

41

IG VOLT LOW 1The multi-purpose fuse (No. 18) is blown or the wirefrom the fuse to the SDU is open-circuit or itsresistance value is increased.

It takes at least 5 seconds that the SDU detects

this fault.

Perform TEST 9

42

IG VOLT LOW 2The multi-purpose fuse (No. 11) is blown or the wirefrom the fuse to the SDU is open-circuit or itsresistance value is increased.

It takes at least 5 seconds that the SDU detects

this fault.

Perform TEST 10

SRS LMP TRBL 1

i

The SRS warning light circuits are open or the wireWhen SRS warning lightOpen circuit orfrom the light to the SDU is grounded.does not extinguish:43ground shortIIt takes at least 5 seconds with the light OFF thatPerform TEST 11the SDU detects this fault.When SRS warning light

does not illuminate:

Perform TEST 12

SRS LMP TRBL 2The SRS warning light drive transistor (integrated

(1) Turn the ignition key

44SRS warning light

[I

in the SDU) is open-circuit.to the “LOCK” posi-

drive transistortion, disconnet the

is open-circuitnegative battery

cable and tape the

SRS DIAG. UNITThe EEP ROM or A/D converter (integrated in the SDU)terminal.is defective.(2) After waiting at

45least 30 seconds,

replace the SDU.

(Refer to P.52B-59.)

/NOTE -IMPORTANT

b(1) After repairing the SRS, reconnect the battery cable, erase the diagnosis code memory from theMulti-use Tester and check the SRS warning light operation to verify the system functions

properly. (Refer to TEST 1.)

(2) SDU

= SRS Diagnosis Unit

1 TSB Revision

Page 1036 of 1146

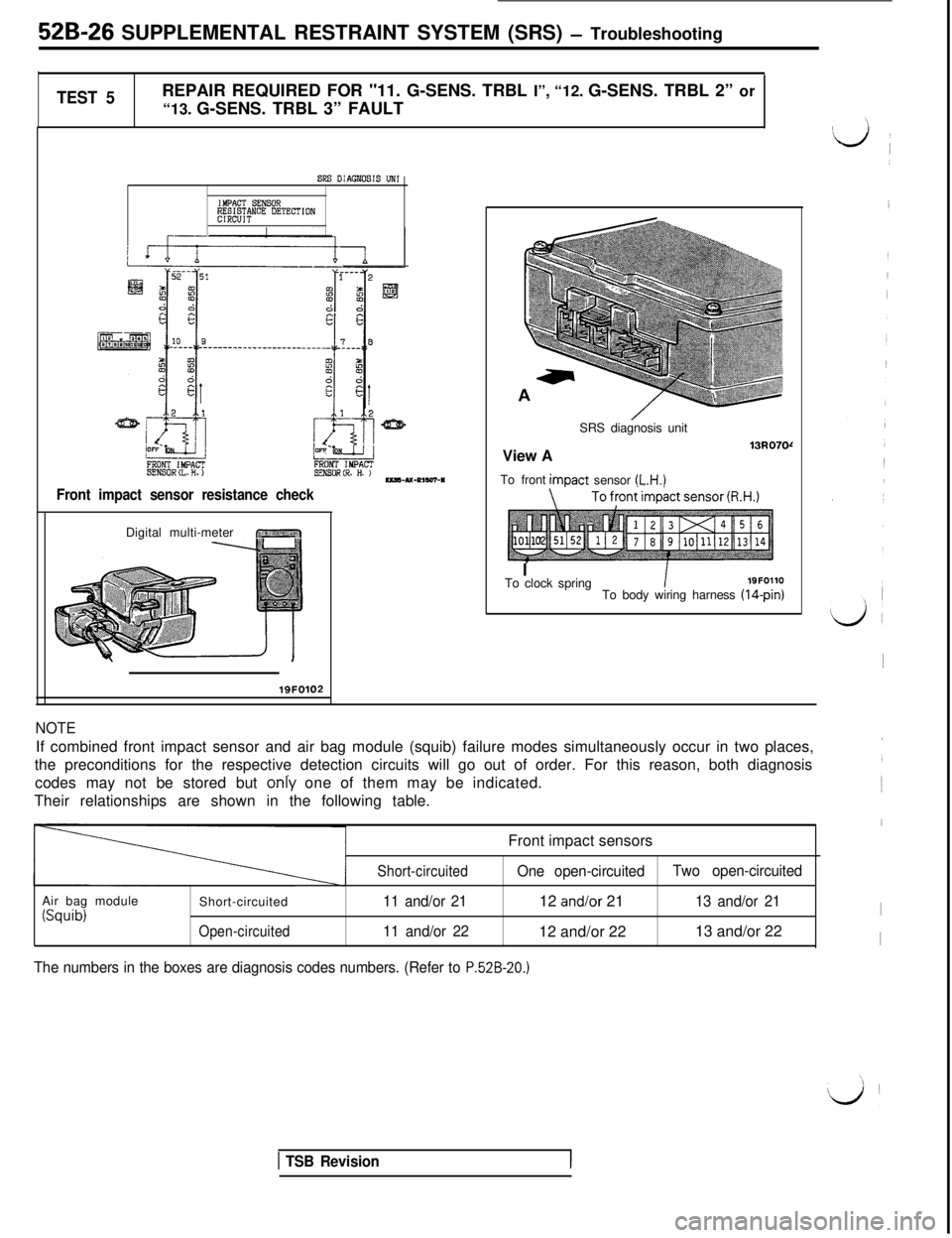

52B-26 SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - Troubleshooting

TEST 5REPAIR REQUIRED FOR "11. G-SENS. TRBL I”, “12. G-SENS. TRBL 2” or

“13. G-SENS. TRBL 3” FAULT

SRS DIAGNOSIS UN1

IMPACT S!NSOR~M&N"E DETECTION

FRONT IMPACTSENS0RtL.H.)FRONT IMPACTsEN80R(R. H. )--u-~,w-*

Front impact sensor resistance checkDigital multi-meter

r ~1iii”~“‘.,,,,/ ?\I. I,// q

NOTEIf combined front impact sensor and air bag module (squib) failure modes simultaneously occur in two places,

the preconditions for the respective detection circuits will go out of order. For this reason, both diagnosis

codes may not be stored but only one of them may be indicated.

Their relationships are shown in the following table.

Front impact sensors

Air bag module

(Squib)Short-circuitedOpen-circuitedShort-circuited

11 and/or 21

11 and/or 22One open-circuitedTwo open-circuited12 and/or 2113 and/or 21I12 and/or 2213 and/or 22

I

The numbers in the boxes are diagnosis codes numbers. (Refer to P.52B-20.)

/SRS diagnosis unit

View A

13u070rTo frontimDact sensor

(L.H.)

ITo clock springI19FOllO

To body wiring harness (14-pin)

lQFO102

1 TSB Revision

Page 1043 of 1146

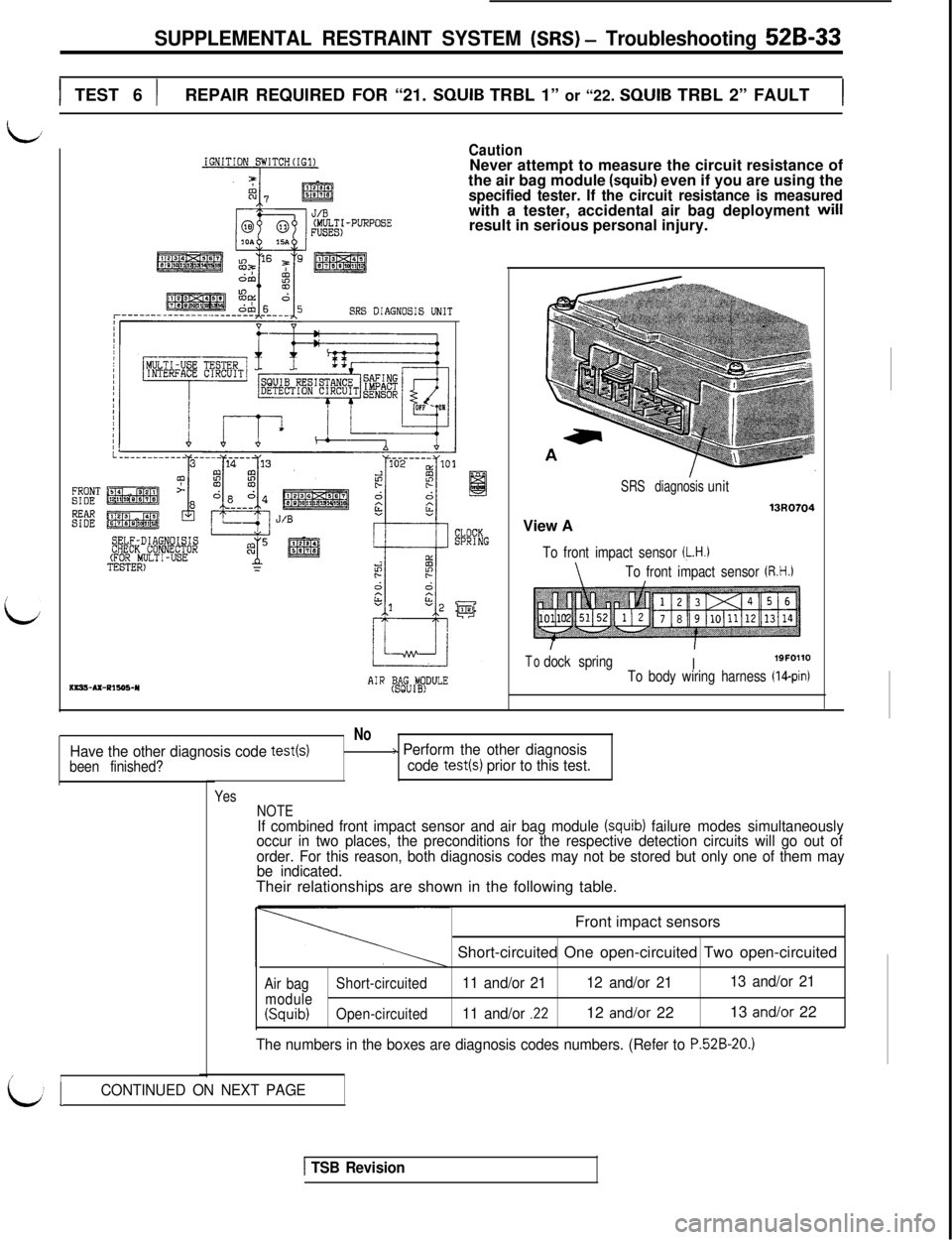

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - Troubleshooting 52B-33

1 TEST 6 )REPAIR REQUIRED FOR “21. SQUIB TRBL 1” or “22. SQUIB TRBL 2” FAULT1

i

FRONTSIDE

Ez

IGNITION SWITCH(IG1)CautionNever attempt to measure the circuit resistance of

the air bag module

(squib) even if you are using thespecified tester. If the circuit resistance is measuredwith a tester, accidental air bag deployment will

result in serious personal injury.

SRS DIAGNOSIS UNIT

------I

SELF-DIAGNOISISCHECK CONNECTOR(FOR MULTI-USETESTER)ms!+Ax-Pls95-Y

J/B

AIR (BSAgGU#DULEView A

SRS diagnosisunit

13uo704

To front impact sensor (L.H.1

\To front impact sensor (R.H.)

Todock springI19FOllOTo body wiring harness (IQpin)

No

Have the other diagnosis code test(s)/> Perform the other diagnosis

been finished?code test(s) prior to this test.

/I

Yes

NOTE

If combined front impact sensor and air bag module (squib) failure modes simultaneously

occur in two places, the preconditions for the respective detection circuits will go out of

order. For this reason, both diagnosis codes may not be stored but only one of them may

be indicated.Their relationships are shown in the following table.

Front impact sensors

Short-circuited One open-circuited Two open-circuited

Air bagShort-circuited11 and/or 2112 and/or 2113 and/or 21

module(Squib)Open-circuited11 and/or .2212 and/or 2213 and/or 22

The numbers in the boxes are diagnosis codes numbers. (Refer to P.52B-20.)

LICONTINUED ON NEXT PAGE

1 TSB Revision

Page 1087 of 1146

HEATERS AND MANUAL AIR CONDITIONER - Troubleshooting55-5

HEATERS AND MANUAL AIR CONDITIONER

t+-/ TROUBLESHOOTING

L

M55ECAE

Symptom

Heater insufficientheatProbable cause

Obstructed heater outlets

Blend air dampers improperly adjusted or binding

Thermostat malfunction

Obstructed heater hoses

Remedy

Correct

Replace

No ventilation evenwhen mode selectionknob is operatedImproperly adjusted control cables

Plugged or partially plugged heater core

Incorrect adjustment of mode selection dampersIncorrect installation of mode selection controlwire

Ducts are incorrectly/incompletely connected,crushed, bent or clogged

Burnt-out fuse

Poor grounding

Malfunction blower switch

Malfunction resistorAdjust

Clean or replace

Adjust

Blower motor

inoperative

Repair or replace

ReplaceCorrect

Replace

Malfunction blower motor

Malfunction heater relay

Malfunction blower motor relay

TSB Revision

Page 1091 of 1146

HEATERS AND MANUAL AIR CONDITIONER - safety Pre=utm55-9

SAFETY PRECAUTIONSR-12 refrigerant is a chlorofluoro-carbon

(CFC) that

can contribute to the depletion of the ozone layer in

the upper atmosphere.

Ozone filters out harmful radiation from the sun.

To assist in protecting the ozone layer, Mitsubishi

Motor Sales of America recommends that a R-12

refrigerant recycling device that meets SAE stan-

dard

J1991 be used.

Contact an automotive service equipment supplier

for refrigerant recycling equipment that is available

in your area.

The refrigerant used in all air conditioner is R-l 2. It is

transparent and colorless in both the liquid and

vapor state. Since it has a boiling point of

-29.8”C(-21.7”F), at atmospheric pressure, it will be a vapor

at all normal temperatures and pressures. The vapor

is heavier than air, non-flammable, and nonexplo-

sive. It is nonpoisonous except when it is in direct

contact with open flame. It is noncorrosive except

when combined with water. The following precau-

tions must be observed when handling R-12.

CautionWear safety goggles when servicing the refri-

geration system.R-12 evaporates so rapidly at normal atmospheric

pressures and temperatures that it tends to freeze

anything it contacts. For this reason, extreme care

must be taken to prevent any liquid refrigerant from

contacting the skin and especially the eyes. Always

wear safety goggles when servicing the refrigera-

tion part of the air conditioning system. Keep a

bottle of sterile mineral oil handy when working on

the refrigeration system. Should any liquid re-

frigerant get into the eyes, use a few drops of

mineral oil to wash them out. R-12 is rapidly

absorbed by the oil. Next splash the eyes with

plenty of cold water. Call your doctor immediately

even though irritation has ceased after treatment.

CautionDo not heat R-12 above 52°C

(125.6”F).

M55PAAFIn most instances, moderate heat is required to

bring the pressure of the refrigerant in its container

above the pressure of the system when charging or

adding refrigerant. A bucket or large pan of hot

water not over 52°C

(125.6”F) is all the heat required

for this purpose. Do not heat the refrigerant contain-

er with a blow torch or any other means that would

raise temperature and pressure above this tempera-

ture. Do not weld or steam clean on or near the

system components or refrigerant lines.

Caution

Keep R-12 containers upright when charging the

system.When metering R-12 into the refrigeration system,

keep the supply tank or cans in an upright position. If

the refrigerant container is on its side or upside

down, liquid refrigerant will enter the system and

damage the compressor.

CautionAlways work in a well-ventilated room.

Good ventilation is vital in the working area.

Although R-12 vapor is normally nonpoisonous,

contact with an open flame can cause the vapor to

become very poisonous. A poisonous gas is pro-

duced when using the flame-type leak detector.

Avoid inhaling the fumes from the leak detector.

CautionDo not allow liquid refrigerant to touch bright

metal.Refrigerant will tarnish bright metal and chrome

surfaces, and in combination with moisture can

severely corrode all metal surfaces.

1 TSB Revision