length MITSUBISHI 3000GT 1991 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 87 of 1146

ENGINE - Cylinder Head and Valve

Oversize I.D.

Valve(2) Rebore the valve seat hole in

oversize valve seat diameter.Seat Insert Oversizescylinderhead to a selected

DescriptionSize mm (in.)1 Size mark /Seat insEt(,ke;ght H/Cylinder head I.D.

mm (in.)

Intake valve0.3i.012)0,s.

I

30

I

7.5-7.7(.295-,303)36.300-36.325(1.4291-1.4301)

seat insert

0.6(.024)O.S.607.8-8.0(.307-,315)36.600-36.625(1.4409-1.4419)

Exhaust valve

seat insert

0.3l.012)0,s.7.9-8.1(.311-.319)33.300-33.325(1.3110-1.3120)

0.6(.024)O.S.8.2-8.4t.323-,331)33.600-33.625(1.3228-1.3238)

7EN02E(3) When press-fitting the valve seat, chill the valve seat with

liquid nitrogen so that the cylinder head bore is not

damaged by galling.

(4)Using the valve seat grinder or cutter, correct the valve seat

to the specified width and angle.

(5) See “VALVE SEAT RECONDITIONING PROCEDURES.”

VALVE GUIDE REPLACEMENT PROCEDURE

MllPJDB

(1) Using suitable rod and a press, press the valve guide out of

the cylinder head toward the cylinder block side.

(2) Rebore the valve guide hole to the oversize valve guide

outside diameter

to be press-fitted.

CautionDo not use a valve guide of the same size as the one

removed.12.250-12.268

(.4823-.4830)12.500-12.518

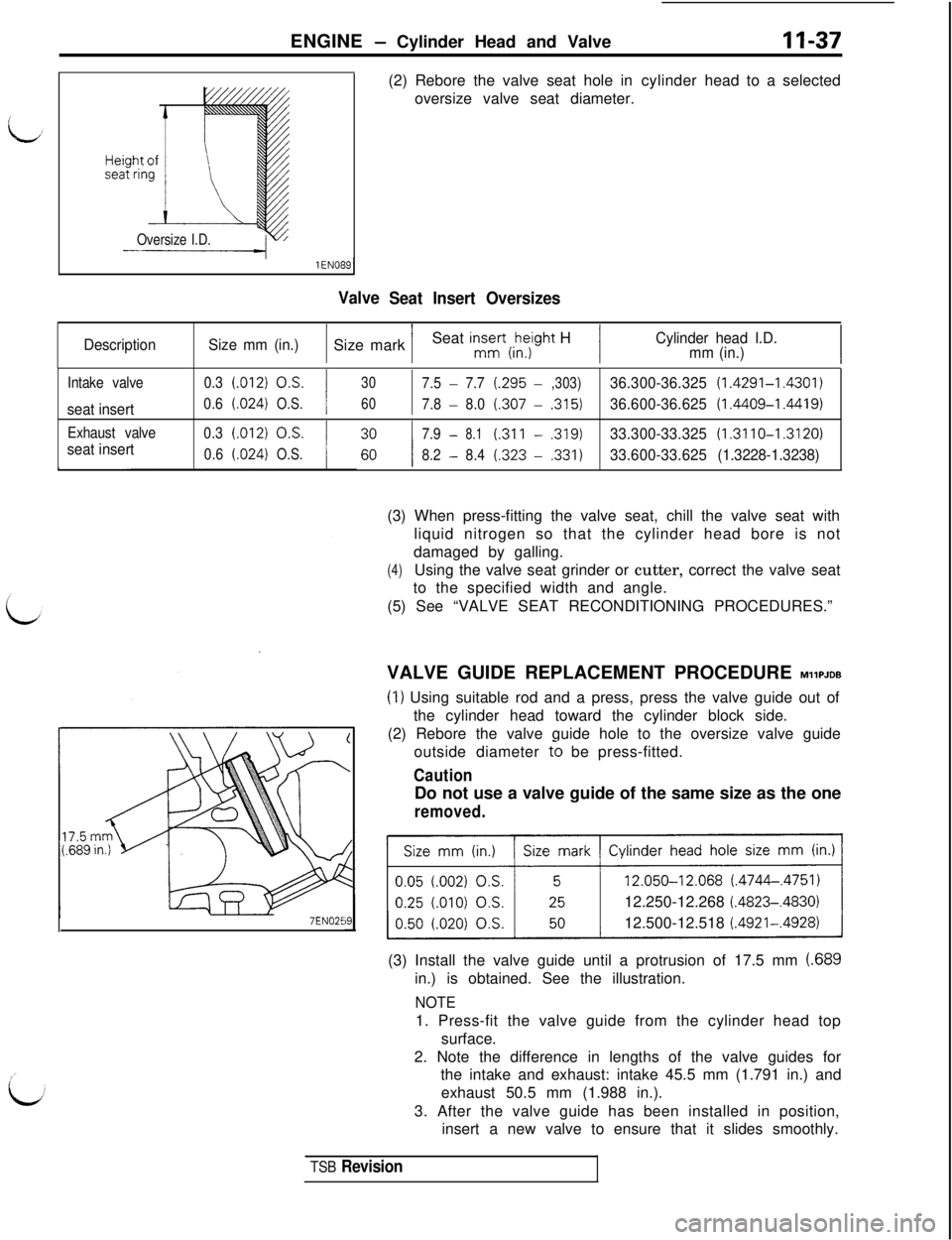

(.4921-.4928)(3) Install the valve guide until a protrusion of 17.5 mm

(.689in.) is obtained. See the illustration.

NOTE1. Press-fit the valve guide from the cylinder head top

surface.

2. Note the difference in lengths of the valve guides for

the intake and exhaust: intake 45.5 mm (1.791 in.) and

exhaust 50.5 mm (1.988 in.).

3. After the valve guide has been installed in position,

insert a new valve to ensure that it slides smoothly.

TSB Revision

Page 101 of 1146

ENGINE - Crankshaft. Flvwheel and Drive Plate11-51

id

PLASTIGAGE METHODMllUlAA

Plastigage may be used to measure the clearance.

(1) Remove oil and grease and any other dirt from bearings and

journals.(2) Cut plastigage to the same length as the width of the

bearing and place it in parallel with the journal, off oil holes.

(3) Install the crankshaft, bearings and caps and tighten them

to the specified torques. During this operation, do NOT turn

the crankshaft. Remove the caps. Measure the width-of the

plastigage at the widest part by using a scale printed on the

plastigage sleeve.

If the clearance exceeds the repair limit, the bearing should

be replaced.

Should the standard clearance not be obtained even after

bearing replacement, replace the crankshaft.

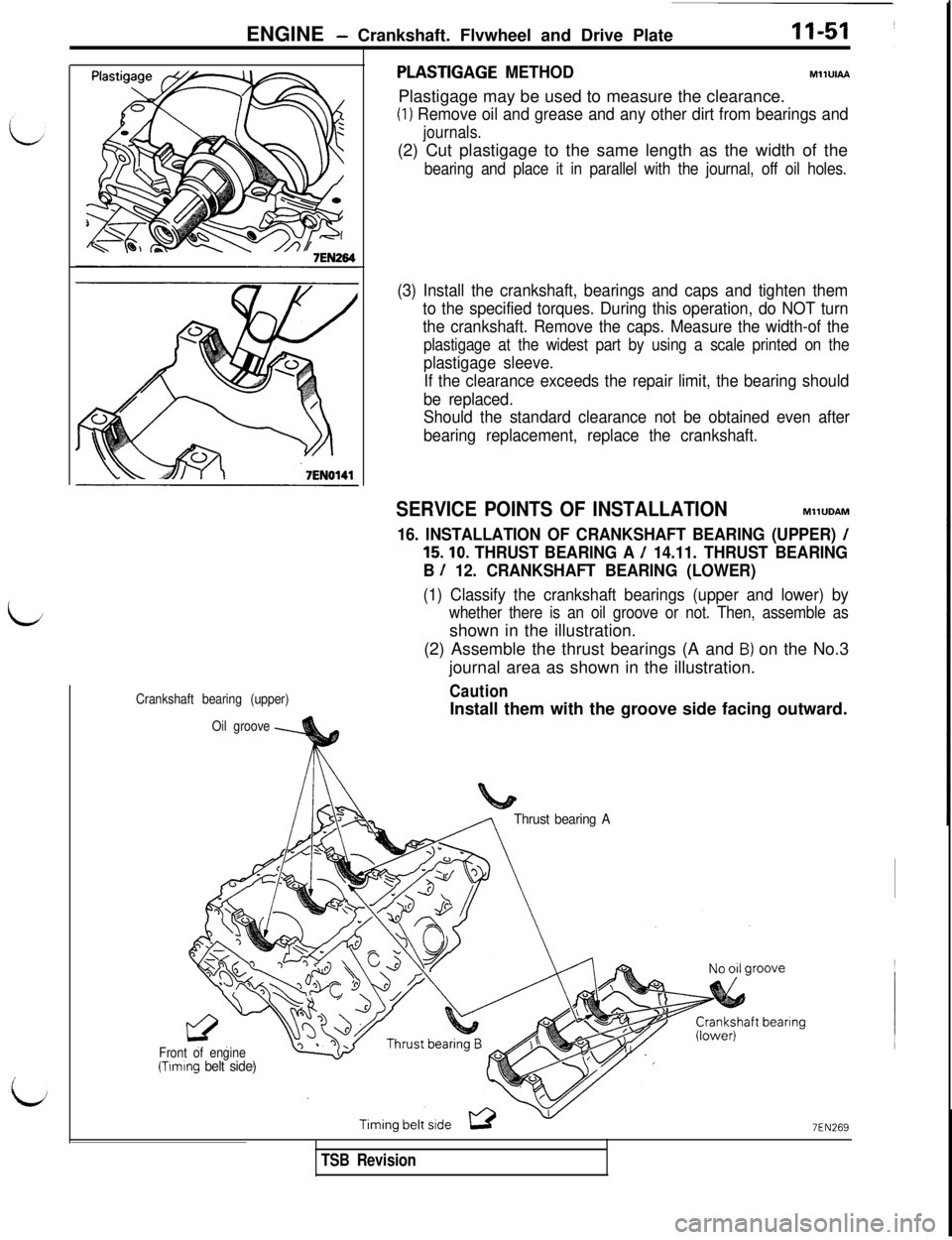

SERVICE POINTS OF INSTALLATIONMllUDAM

16. INSTALLATION OF CRANKSHAFT BEARING (UPPER) /

15.10. THRUST BEARING A / 14.11. THRUST BEARING

B

/ 12. CRANKSHAFT BEARING (LOWER)

(1) Classify the crankshaft bearings (upper and lower) by

whether there is an oil groove or not. Then, assemble asshown in the illustration.

(2) Assemble the thrust bearings (A and

B) on the No.3

journal area as shown in the illustration.

CautionInstall them with the groove side facing outward.Crankshaft bearing (upper)

Oil groove

Thrust bearing A

Front of engine(Tlmlng belt side)

EN269

TSB Revision

Page 371 of 1146

CLUTCH - Clutch Control21-13

14UOO6514U006t14GOO50

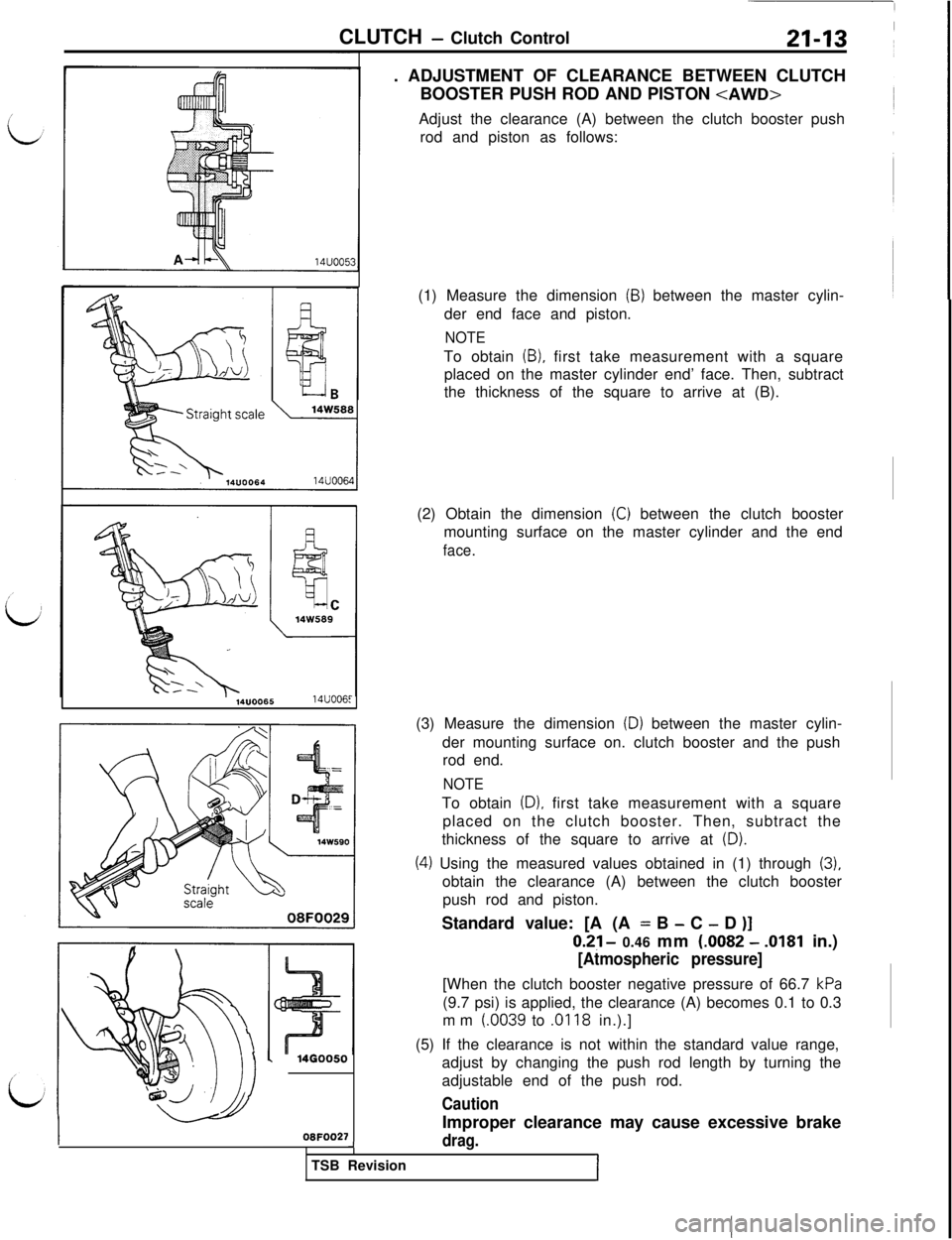

08FOO27. ADJUSTMENT OF CLEARANCE BETWEEN CLUTCH

BOOSTER PUSH ROD AND PISTON

rod and piston as follows:

(1) Measure the dimension

(B) between the master cylin-

der end face and piston.

NOTETo obtain

(B), first take measurement with a square

placed on the master cylinder end’ face. Then, subtract

the thickness of the square to arrive at (B).

(2) Obtain the dimension

(C) between the clutch booster

mounting surface on the master cylinder and the end

face.(3) Measure the dimension

(D) between the master cylin-

der mounting surface on. clutch booster and the push

rod end.

NOTETo obtain

(D). first take measurement with a square

placed on the clutch booster. Then, subtract the

thickness of the square to arrive at

(D).

(4) Using the measured values obtained in (1) through (3).obtain the clearance (A) between the clutch booster

push rod and piston.

Standard value: [A (A = B

- C - D )]

0.2j - 0.46 mm (.0082 - .0181 in.)

[Atmospheric pressure][When the clutch booster negative pressure of 66.7

kPa(9.7 psi) is applied, the clearance (A) becomes 0.1 to 0.3

mm

(.0039 to .0118 in.).]

(5) If the clearance is not within the standard value range,

adjust by changing the push rod length by turning the

adjustable end of the push rod.

CautionImproper clearance may cause excessive brake

drag.JTSB Revision

I

Page 405 of 1146

MANUAL TRANSAXLE

22-25

L

Slit

#Jl

Spring pin

/

II-+Shift rail1 I I201034

er

2150008

MD998325-01

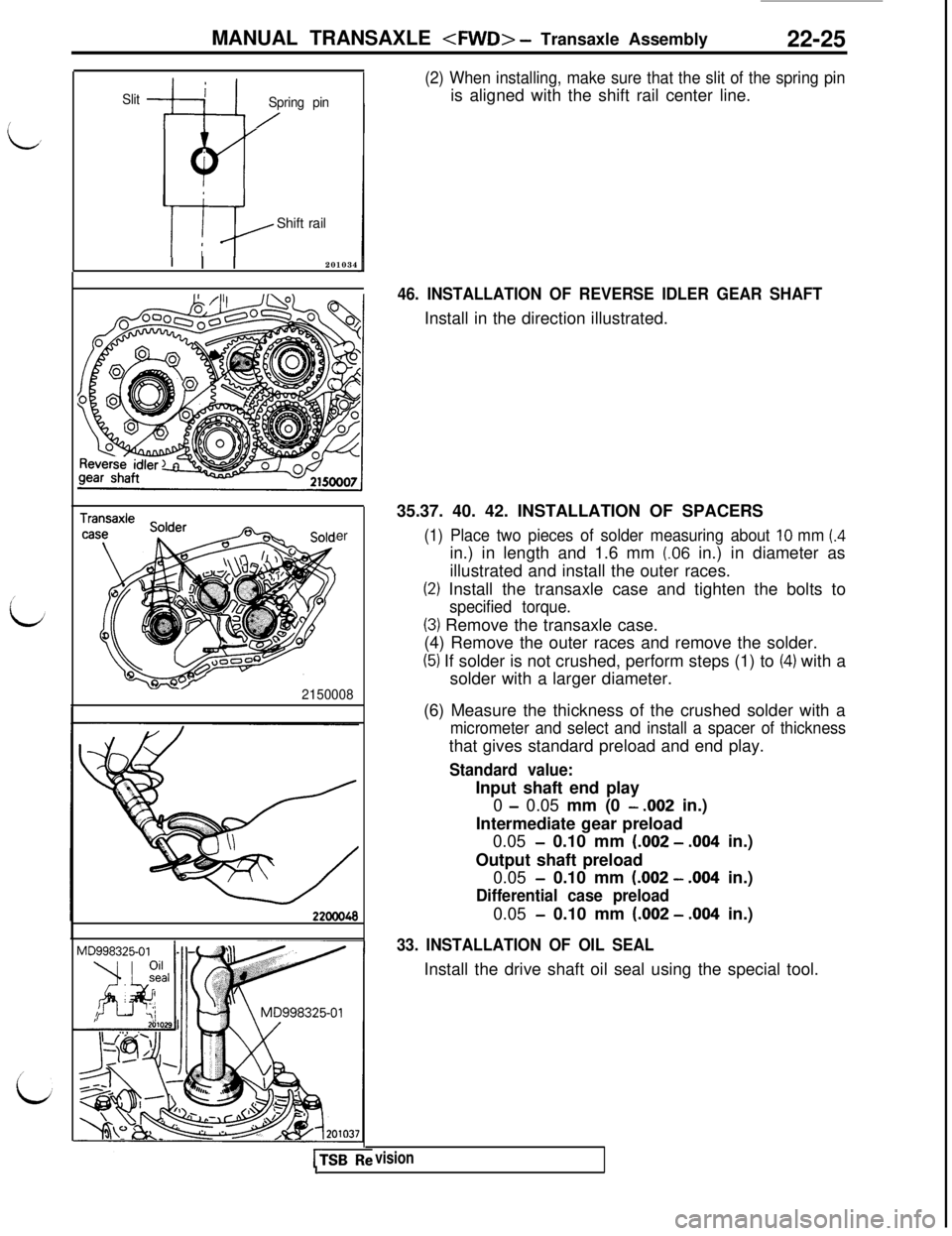

(2) When installing, make sure that the slit of the spring pinis aligned with the shift rail center line.

46. INSTALLATION OF REVERSE IDLER GEAR SHAFTInstall in the direction illustrated.

35.37. 40. 42. INSTALLATION OF SPACERS

(1) Place two pieces of solder measuring about 10 mm (.4in.) in length and 1.6 mm

(.06 in.) in diameter as

illustrated and install the outer races.

(2) Install the transaxle case and tighten the bolts to

specified torque.

(3) Remove the transaxle case.

(4) Remove the outer races and remove the solder.

(5) If solder is not crushed, perform steps (1) to (4) with a

solder with a larger diameter.

(6) Measure the thickness of the crushed solder with a

micrometer and select and install a spacer of thicknessthat gives standard preload and end play.

Standard value:Input shaft end play

0

- 0.05 mm (0 - .002 in.)

Intermediate gear preload

0.05

- 0.10 mm (.002 - .004 in.)

Output shaft preload

0.05

- 0.10 mm (.002 - .004 in.)

Differential case preload0.05

- 0.10 mm (.002 - .004 in.)

33. INSTALLATION OF OIL SEALInstall the drive shaft oil seal using the special tool.

visionI

Page 440 of 1146

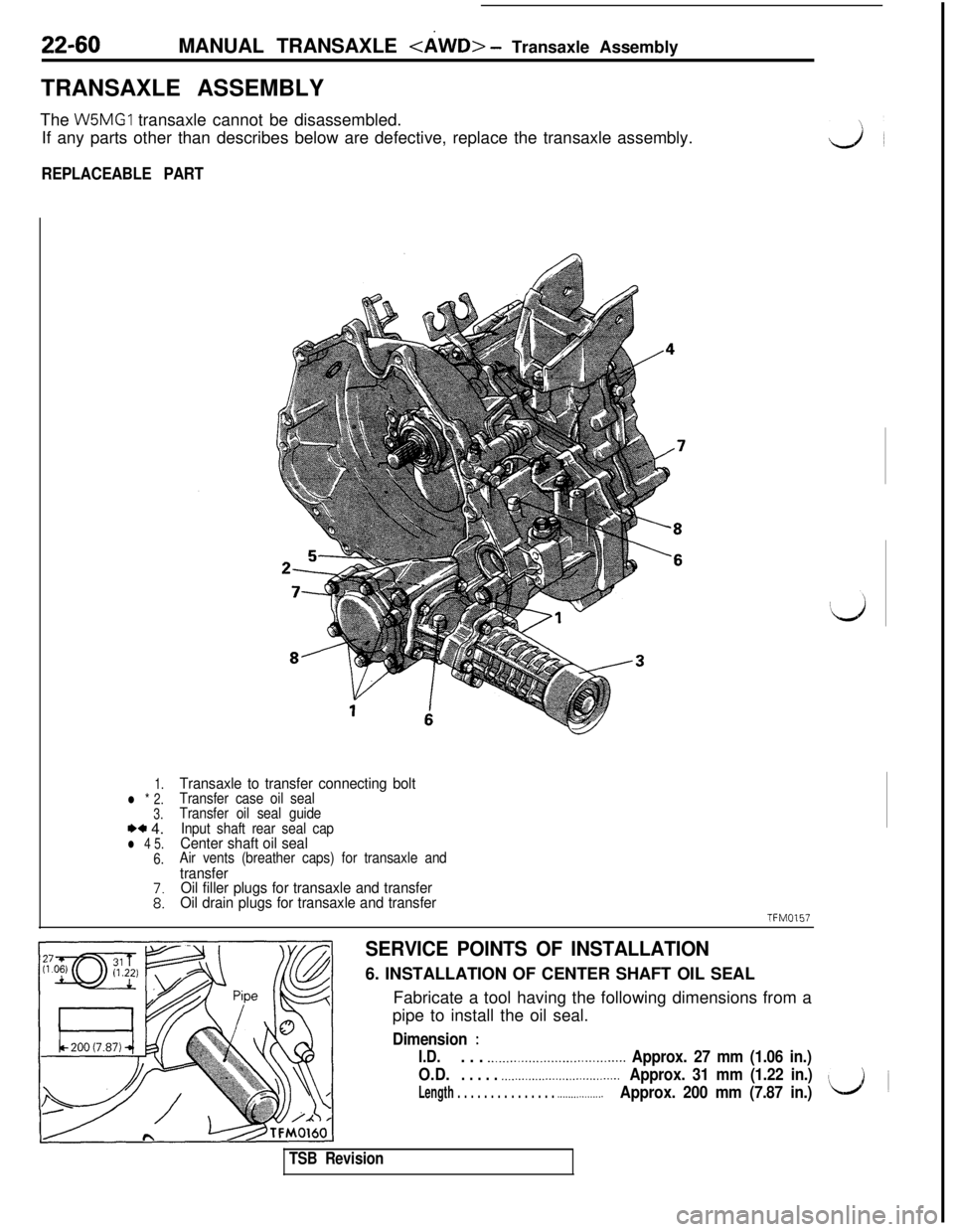

22-60MANUAL TRANSAXLE

TRANSAXLE ASSEMBLY

The W5MGl transaxle cannot be disassembled.

If any parts other than describes below are defective, replace the transaxle assembly.

REPLACEABLE PART

1.l * 2.

3.

*a 4.l 4 5.6.

Transaxle to transfer connecting boltTransfer case oil seal

Transfer oil seal guide

Input shaft rear seal cap

Center shaft oil sealAir vents (breather caps) for transaxle and

transfer

Oil filler plugs for transaxle and transfer

Oil drain plugs for transaxle and transfer

TFM0157

SERVICE POINTS OF INSTALLATION6. INSTALLATION OF CENTER SHAFT OIL SEAL

Fabricate a tool having the following dimensions from a

pipe to install the oil seal.

Dimension :

I.D.. . . ..___........._...................... Approx. 27 mm (1.06 in.)

O.D.

. . . . . .._...........___............_.....Approx. 31 mm (1.22 in.)

Length . . . . . . . . . . . . . . . ..__......._____.Approx. 200 mm (7.87 in.)

TSB Revision

Page 465 of 1146

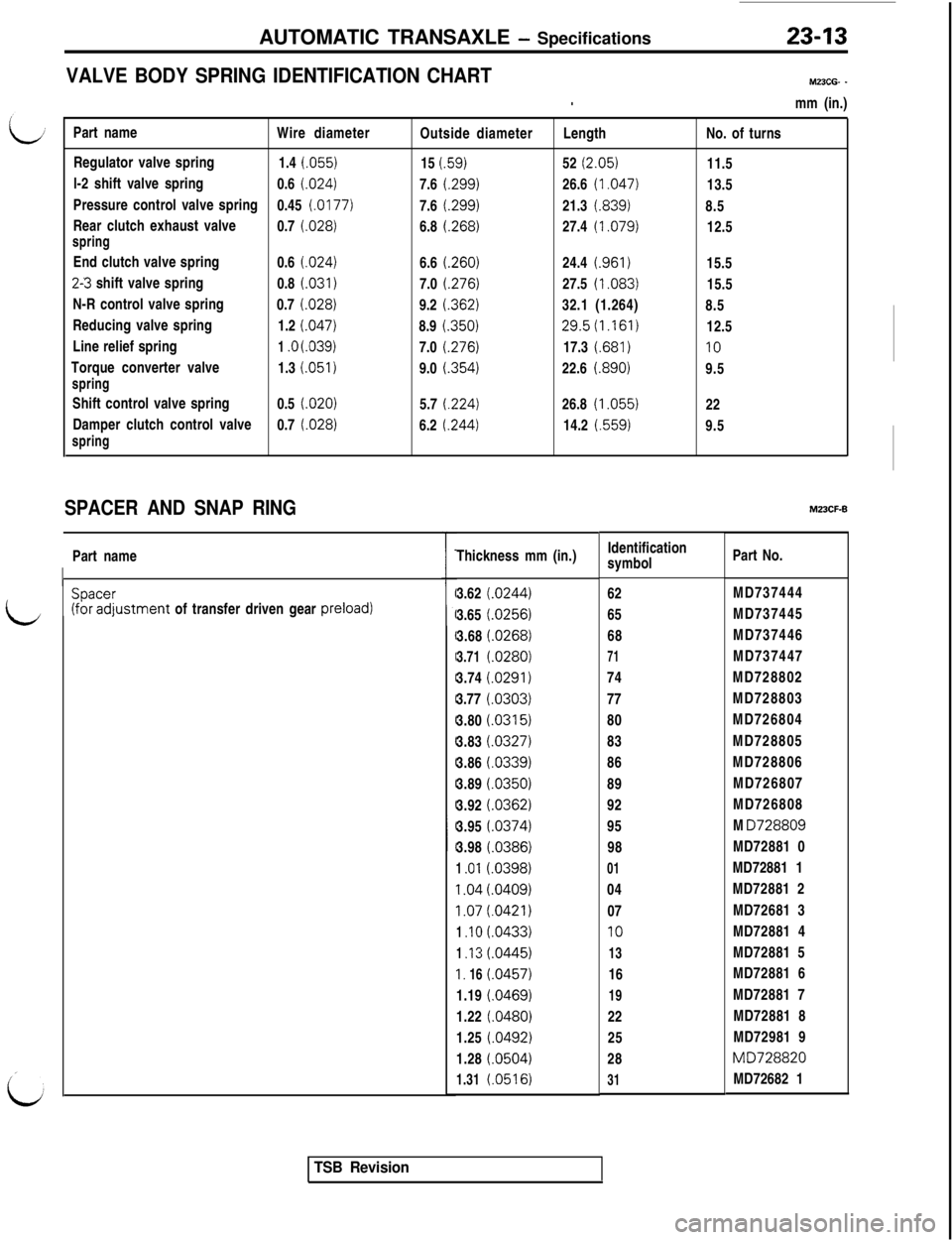

AUTOMATIC TRANSAXLE - Specifications23-13

VALVE BODY SPRING IDENTIFICATION CHARTMZJCG- -

.mm (in.)

Part name

Wire diameter

Outside diameterLengthNo. of turns

Regulator valve spring

1.4 (.055)

15

(59)52 (2.05)

11.5

l-2 shift valve spring

0.6

(024)7.6 (.299)26.6 (1.047)13.5

Pressure control valve spring

0.45

(.0177)7.6 f.299)21.3 (.839)8.5

Rear clutch exhaust valve

0.7

(028)6.8 (268)27.4 (1.079)12.5springEnd clutch valve spring

0.6

(024)6.6 (260)24.4 (.961)15.5

23 shift valve spring

0.8 (031)7.0 (.276)27.5 (1.083)15.5

N-R control valve spring

0.7 (.028)

9.2 (.362)32.1 (1.264)

8.5

Reducing valve spring

1.2 (.047)

8.9

(350)29.5(1.161)12.5

Line relief spring

1 .o (.039)

7.0 (276)17.3 (.681)10Torque converter valve

1.3 (.051)

9.0 (.354)22.6

f.890)9.5springShift control valve spring

0.5 (.020)

5.7 (.224)26.8

(1.055)22

Damper clutch control valve

0.7 (.028)

6.2 (.244)14.2 t.559)

9.5

spring

SPACER AND SNAP RINGPart name

id??$%justment of transfer driven gear preload)Thickness mm (in.)Identification

symbol

3.62(.0244)62

3.65

(.0256)65

3.68

(.0268)68

3.71(0280)713.74

(.0291)74

3.77

(.0303)77

3.80

(.0315)80

3.83

(.0327)83

3.86

l.0339)86

3.89

(0350)89

3.92

(0362)92

3.95

(.0374)95

3.98

(0386)98

1 .Ol(.0398)01

1.04(.0409)041.07

(.0421)07

1 .I0(.0433)10

1 .I3(.0445)13

I. 16(.0457)16

1.19

f.0469)191.22

(.0480)22

1.25

(.0492)25

1.28

(.0504)28

1.31(.0516)31Part No.

MD737444

MD737445

MD737446

MD737447

MD728802

MD728803

MD726804

MD728805

MD728806

MD726807

MD726808

M

D726809MD72881 0

MD72881 1

MD72881 2

MD72681 3

MD72881 4

MD72881 5

MD72881 6

MD72881 7

MD72881 8

MD72981 9

MD729820MD72682 1

TSB Revision

Page 501 of 1146

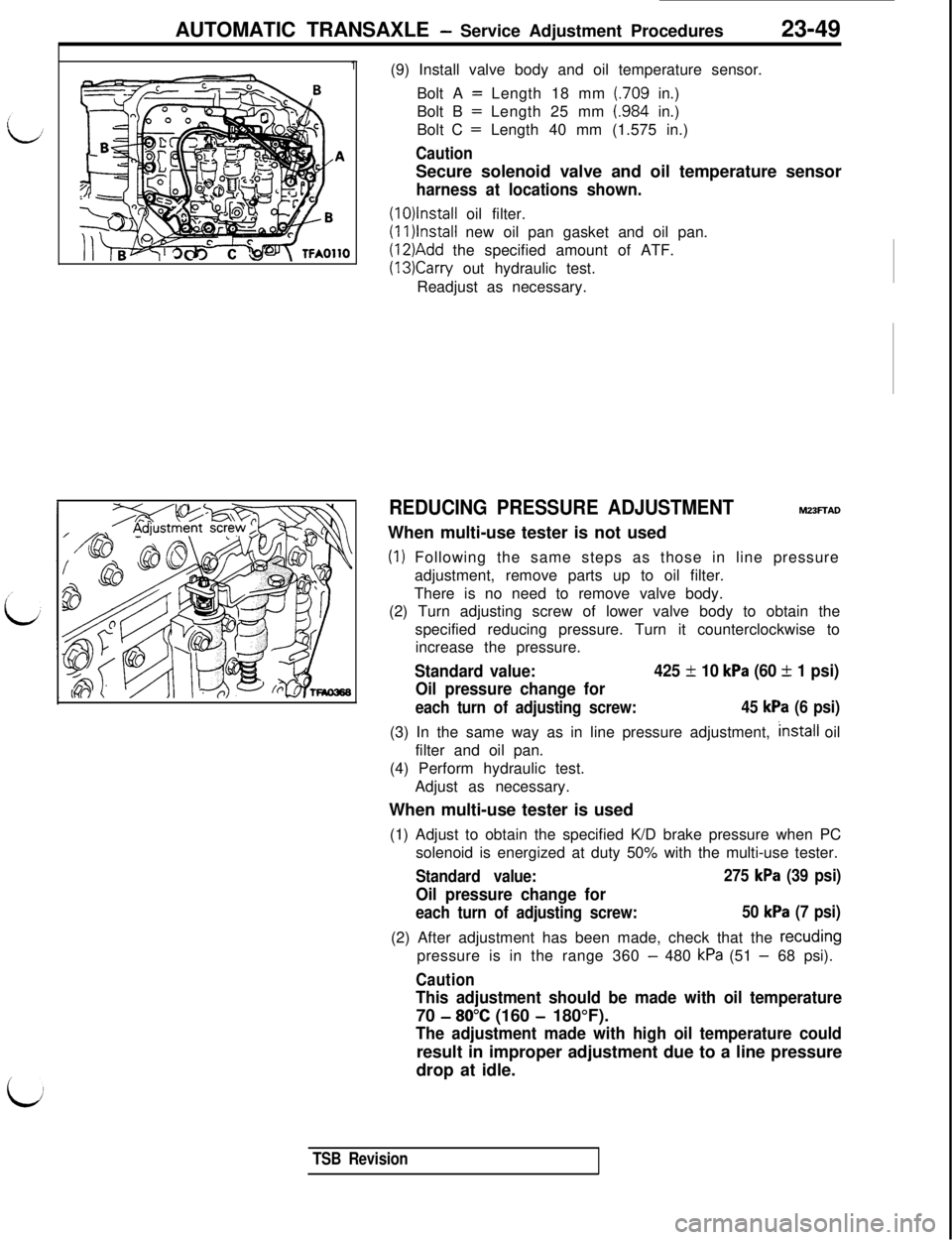

AUTOMATIC TRANSAXLE - Service Adjustment Procedures23-49

1(9) Install valve body and oil temperature sensor.

Bolt A

= Length 18 mm (.709 in.)

Bolt B

= Length 25 mm (.984 in.)

Bolt C

= Length 40 mm (1.575 in.)

CautionSecure solenoid valve and oil temperature sensor

harness at locations shown.

(1O)lnstall oil filter.(1l)lnstall new oil pan gasket and oil pan.

(12)Add the specified amount of ATF.

(13)Carry out hydraulic test.

Readjust as necessary.

REDUCING PRESSURE ADJUSTMENTh323FfADWhen multi-use tester is not used

(1) Following the same steps as those in line pressure

adjustment, remove parts up to oil filter.

There is no need to remove valve body.

(2) Turn adjusting screw of lower valve body to obtain the

specified reducing pressure. Turn it counterclockwise to

increase the pressure.

Standard value:425 f 10 kPa (60 f 1 psi)

Oil pressure change for

each turn of adjusting screw:45 kPa (6 psi)(3) In the same way as in line pressure adjustment,

/nstall oil

filter and oil pan.

(4) Perform hydraulic test.

Adjust as necessary.

When multi-use tester is used

(1) Adjust to obtain the specified K/D brake pressure when PC

solenoid is energized at duty 50% with the multi-use tester.

Standard value:275 kPa (39 psi)

Oil pressure change for

each turn of adjusting screw:50 kPa (7 psi)(2) After adjustment has been made, check that the recuding

pressure is in the range 360

- 480 kPa (51 - 68 psi).

Caution

This adjustment should be made with oil temperature70

- 80°C (160 - 180°F).

The adjustment made with high oil temperature couldresult in improper adjustment due to a line pressure

drop at idle.

TSB Revision

Page 566 of 1146

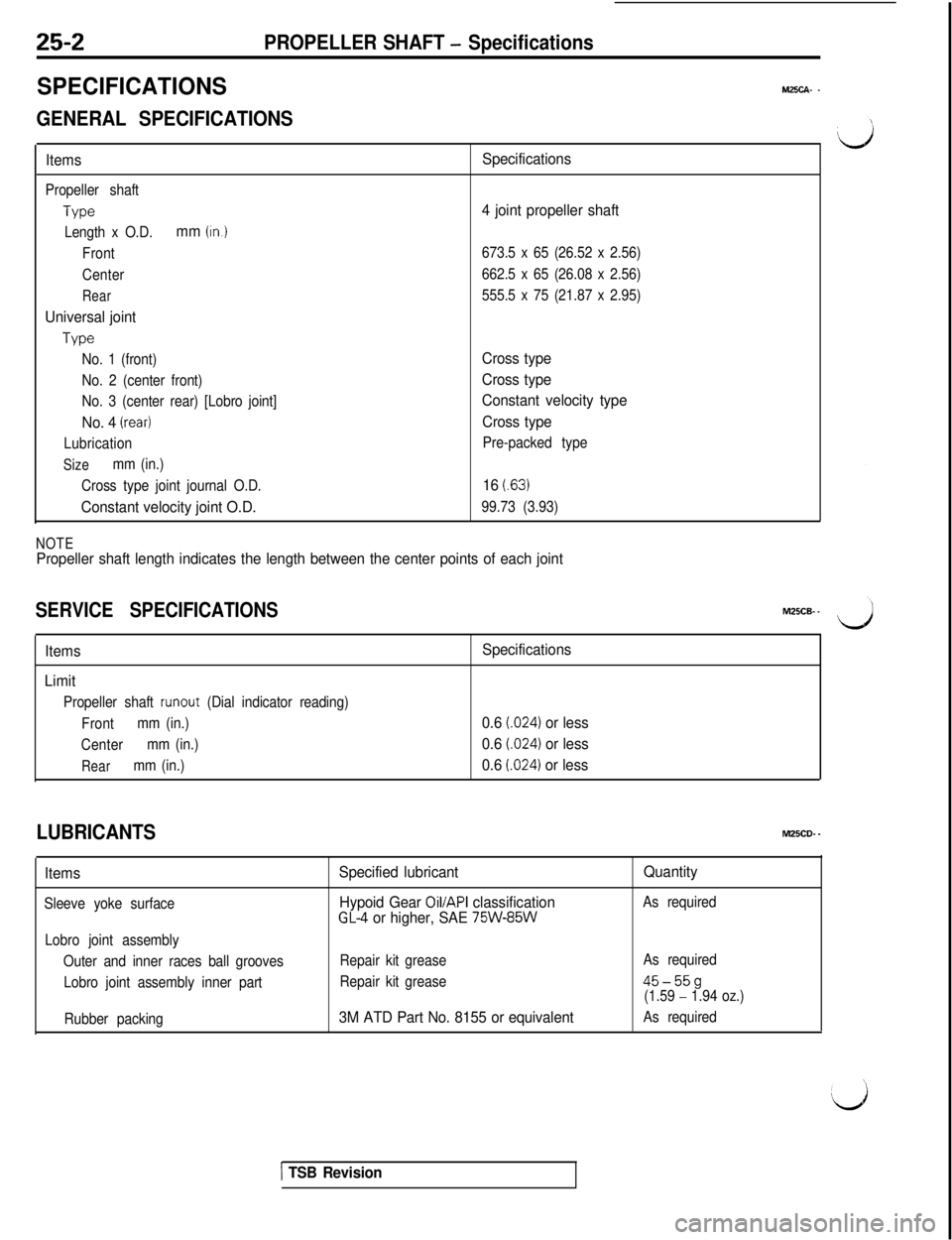

25-2PROPELLER SHAFT - Specifications

SPECIFICATIONSM25CA- -

GENERAL SPECIFICATIONS

Items

Propeller shaft

Type

Length x O.D.

mm (In.)

Front

Center

Rear

Universal joint

Type

No. 1 (front)

No. 2 (center front)

No. 3 (center rear) [Lobro joint]

No. 4 (rear)

Lubrication

Sizemm (in.)

Cross type joint journal O.D.

Constant velocity joint O.D.Specifications

4 joint propeller shaft

673.5 x 65 (26.52 x 2.56)

662.5 x 65 (26.08 x 2.56)

555.5 x 75 (21.87 x 2.95)

Cross type

Cross type

Constant velocity type

Cross type

Pre-packed type

16 t.63)

99.73 (3.93)

NOTEPropeller shaft length indicates the length between the center points of each joint

SERVICE SPECIFICATIONSM25CE -d

Items

Limit

Propeller shaft runout (Dial indicator reading)

Frontmm (in.)

Centermm (in.)

Rearmm (in.)

Specifications

0.6

l.024) or less

0.6

i.024) or less

0.6

t.024) or less

LUBRICANTSM25CD..

Items

Sleeve yoke surface

Lobro joint assembly

Outer and inner races ball grooves

Lobro joint assembly inner part

Rubber packing

Specified lubricant

Hypoid Gear

Oil/API classificationGL-4 or higher, SAE 75W-85W

Repair kit grease

Repair kit grease

3M ATD Part No. 8155 or equivalentQuantity

As required

As required

45-55g(1.59 - 1.94 oz.)

As required

1 TSB Revision

Page 578 of 1146

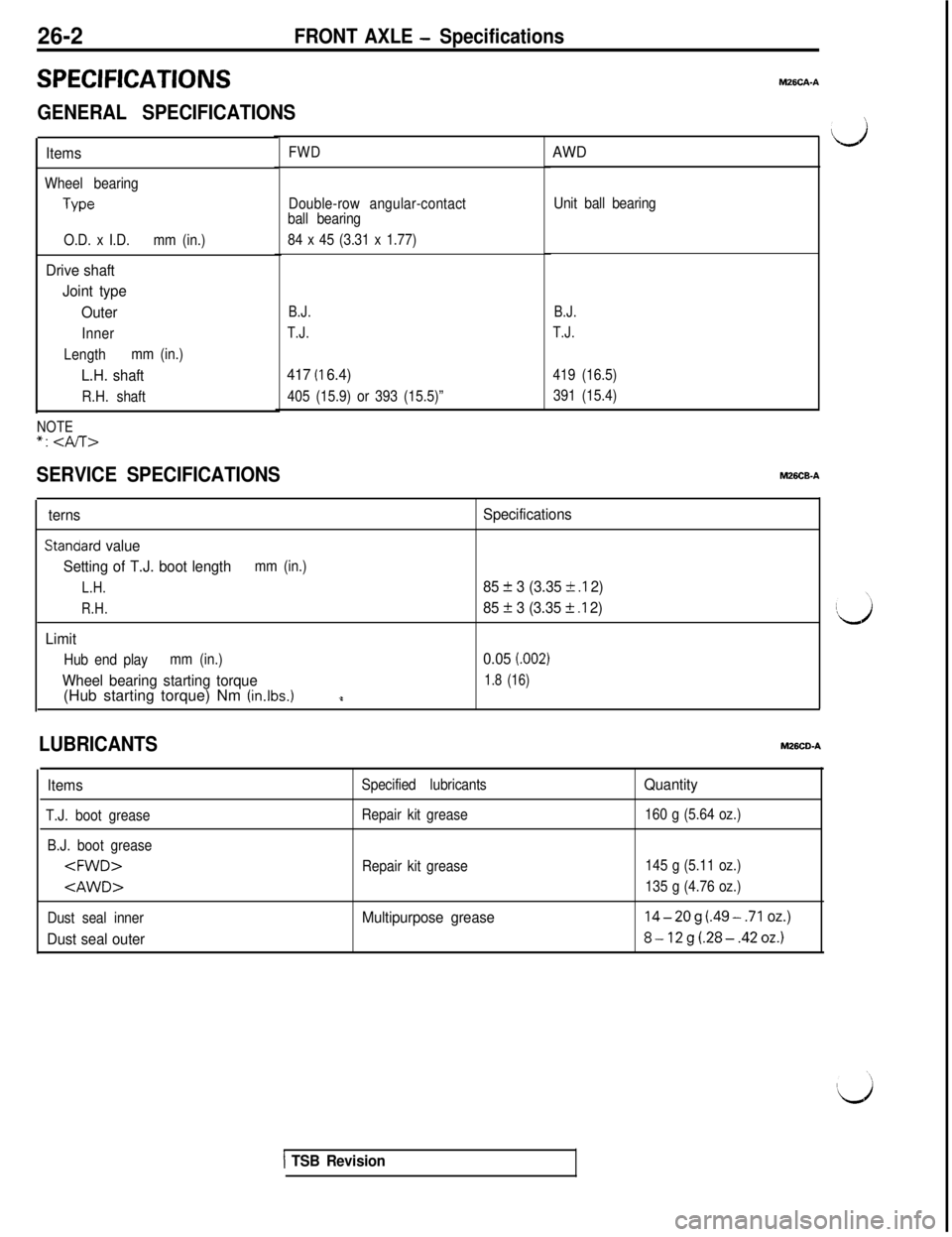

26-2FRONT AXLE - Specifications

SERVICE SPECIFICATIONS

FWD

SPECIFICATIONS

GENERAL SPECIFICATIONS

Items

Wheel bearing

TypeDouble-row angular-contact

ball bearing

O.D. x I.D.mm (in.)

Drive shaft

Joint type

Outer

Inner

Lengthmm (in.)

L.H. shaft

R.H. shaft84 x 45 (3.31 x 1.77)

B.J.

T.J.

417 (I 6.4)

405 (15.9) or 393 (15.5)”

NOTE“1

AWD

Unit ball bearing

B.J.

T.J.

419 (16.5)

391 (15.4)

M26CB-A

terns

standard value

Setting of T.J. boot length

mm (in.)

L.H.

R.H.

Limit

Hub end playmm (in.)

Wheel bearing starting torque(Hub starting torque) Nm (in.lbs.)

Specifications

85

f 3 (3.35 k .I 2)

85

+ 3 (3.35 +- .I 2)

0.05

(.002)

1.8 (16)

LUBRICANTSM26CO-A

Items

T.J. boot grease

B.J. boot grease

Dust seal inner

Dust seal outer

Specified lubricants

Repair kit grease

Repair kit grease

Multipurpose greaseQuantity

160 g (5.64 oz.)

145 g (5.11 oz.)

135 g (4.76 oz.)

14-2og (.49-.71 oz.)

8-12g(.28-.42oz.)

1 TSB Revision

Page 602 of 1146

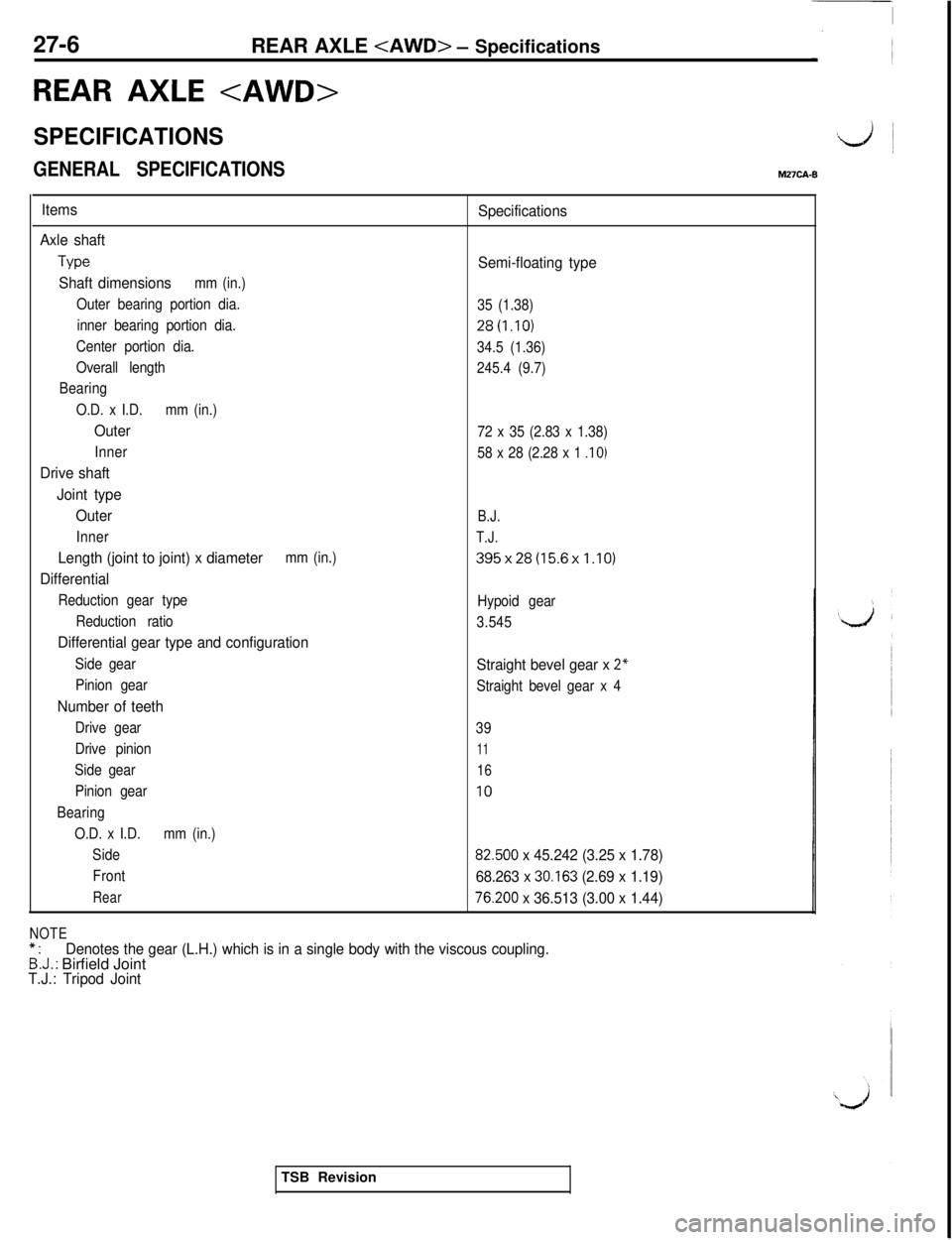

27-6

REAR AXLE tAWD> - Specifications

REAR AXLE

SPECIFICATIONS&L/j ~

GENERAL SPECIFICATIONSM27CA-8

Items

Axle shaft

We

Shaft dimensionsmm (in.)

Outer bearing portion dia.

inner bearing portion dia.

Center portion dia.

Overall length

Bearing

O.D. x I.D.mm (in.)

Outer

Inner

Drive shaft

Joint type

Outer

Inner

Length (joint to joint) x diametermm (in.)

Differential

Reduction gear type

Reduction ratio

Differential gear type and configuration

Side gear

Pinion gear

Number of teeth

Drive gear

Drive pinion

Side gear

Pinion gear

Bearing

O.D. x I.D.mm (in.)

Side

Front

Rear

Specifications

Semi-floating type

35 (1.38)

28(1.10)

34.5 (1.36)

245.4 (9.7)

72 x 35 (2.83 x 1.38)

58 x 28 (2.28 x 1

.I 0)

B.J.

T.J.

395x28(15.6x1.10)

Hypoid gear

3.545

Straight bevel gear x 2”

Straight bevel gear x 4

39

11

16

IO

82.500 x 45.242 (3.25 x 1.78)

68.263 x

30.163 (2.69 x 1.19)

76.200 x 36.513 (3.00 x 1.44)

NOTE*.Denotes the gear (L.H.) which is in a single body with the viscous coupling.B:J.: Birfield JointT.J.: Tripod JointTSB Revision