stop start MITSUBISHI 3000GT 1991 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 285 of 1146

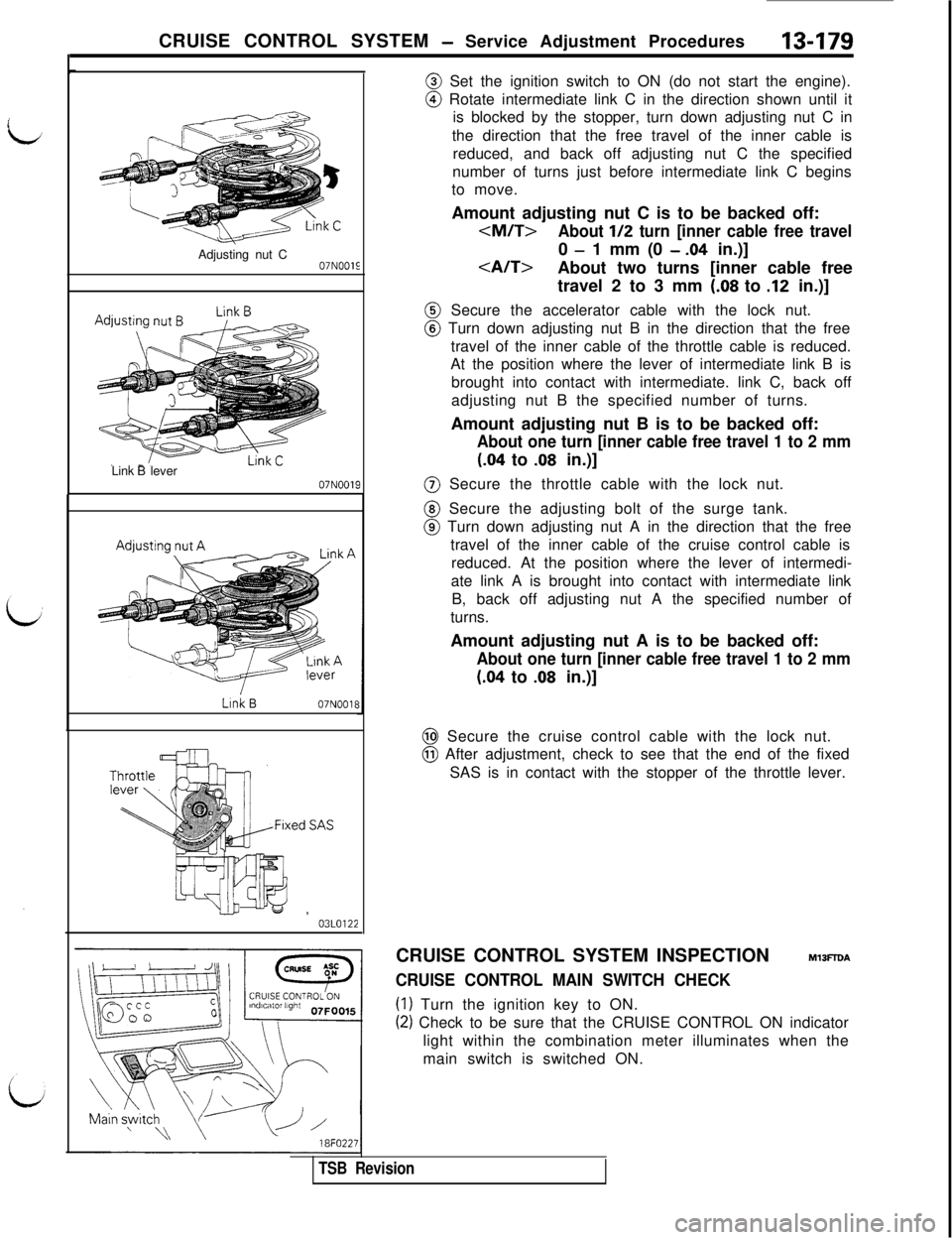

CRUISE CONTROL SYSTEM - Service Adjustment Procedures13-179Adjusting nut C

07NOOlELink Blever

07N0019Link

B07NOOlE

y,jj--ww ,03LO122

\\ \18FO2.2'@ Set the ignition switch to ON (do not start the engine).@ Rotate intermediate link C in the direction shown until it

is blocked by the stopper, turn down adjusting nut C in

the direction that the free travel of the inner cable is

reduced, and back off adjusting nut C the specified

number of turns just before intermediate link C begins

to move.

Amount adjusting nut C is to be backed off:

- 1 mm (0 - .04 in.)]

About two turns [inner cable free

travel 2 to 3 mm

(.08 to .12 in.)]@ Secure the accelerator cable with the lock nut.@ Turn down adjusting nut B in the direction that the free

travel of the inner cable of the throttle cable is reduced.

At the position where the lever of intermediate link B is

brought into contact with intermediate. link C, back off

adjusting nut B the specified number of turns.

Amount adjusting nut B is to be backed off:

About one turn [inner cable free travel 1 to 2 mm

(.04 to .08 in.)]@ Secure the throttle cable with the lock nut.@ Secure the adjusting bolt of the surge tank.@ Turn down adjusting nut A in the direction that the free

travel of the inner cable of the cruise control cable is

reduced. At the position where the lever of intermedi-

ate link A is brought into contact with intermediate link

B, back off adjusting nut A the specified number of

turns.

Amount adjusting nut A is to be backed off:

About one turn [inner cable free travel 1 to 2 mm

(.04 to .08 in.)]@ Secure the cruise control cable with the lock nut.@ After adjustment, check to see that the end of the fixed

SAS is in contact with the stopper of the throttle lever.

CRUISE CONTROL SYSTEM INSPECTION

MlBFlDA

CRUISE CONTROL MAIN SWITCH CHECK

(1) Turn the ignition key to ON.

(2) Check to be sure that the CRUISE CONTROL ON indicator

light within the combination meter illuminates when the

main switch is switched ON.

TSB Revision

Page 356 of 1146

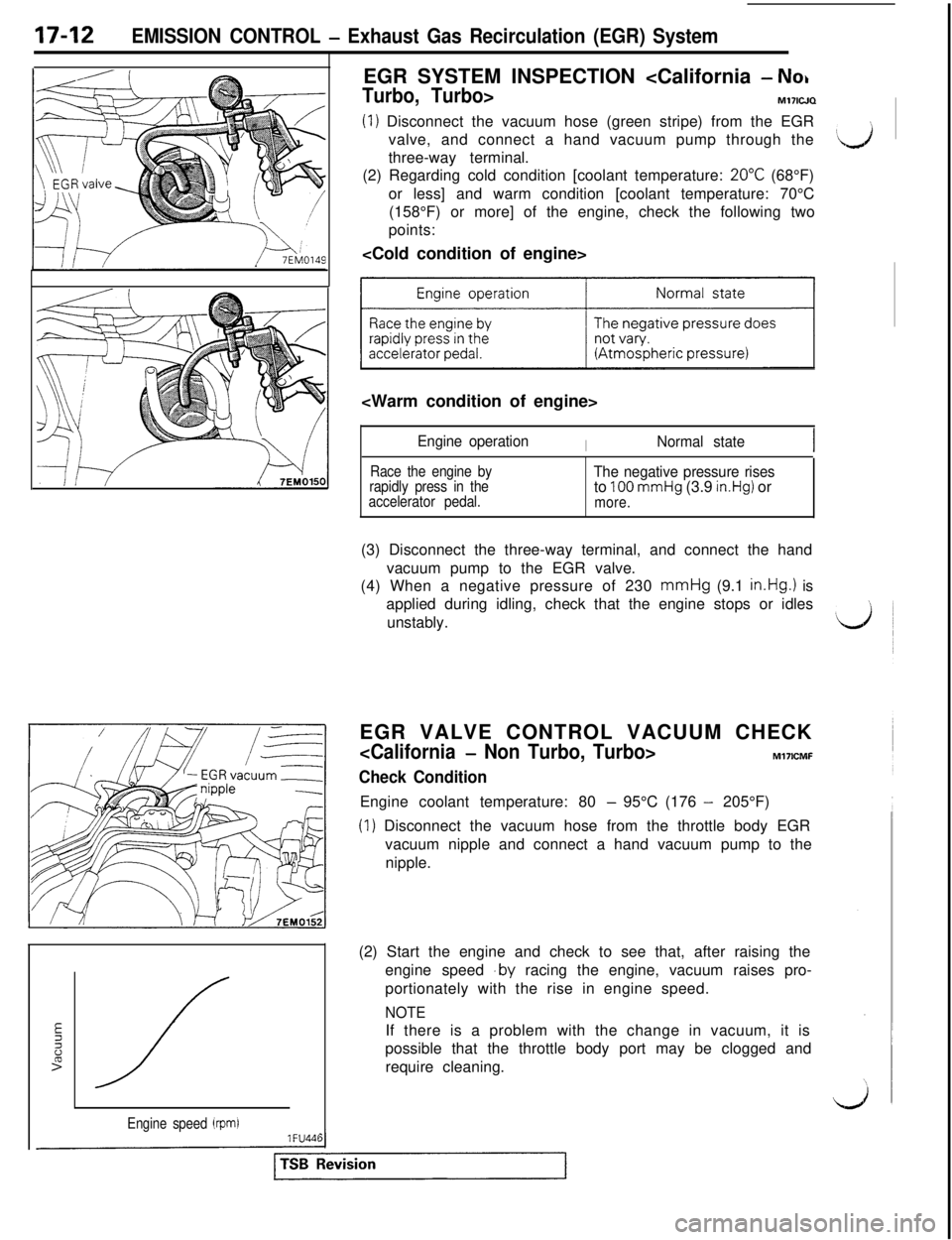

17-12EMISSION CONTROL - Exhaust Gas Recirculation (EGR) System

Engine speed (rpm)1 FU44lEGR SYSTEM INSPECTION

Turbo, Turbo>M171WQ

(1) Disconnect the vacuum hose (green stripe) from the EGR

valve, and connect a hand vacuum pump through the

three-way terminal.

(2) Regarding cold condition [coolant temperature:

20°C (68°F)

or less] and warm condition [coolant temperature: 70°C

(158°F) or more] of the engine, check the following two

points:

~1

Engine operationINormal state

Race the engine by

rapidly press in the

accelerator pedal.The negative pressure risesto 100 mmHg (3.9 in.Hg) ormore.(3) Disconnect the three-way terminal, and connect the hand

vacuum pump to the EGR valve.

(4) When a negative pressure of 230 mmHg (9.1

in.Hg.1 is

applied during idling, check that the engine stops or idles

unstably.

EGR VALVE CONTROL VACUUM CHECK

Check ConditionEngine coolant temperature: 80

- 95°C (176 - 205°F)

(1) Disconnect the vacuum hose from the throttle body EGR

vacuum nipple and connect a hand vacuum pump to the

nipple.

(2) Start the engine and check to see that, after raising the

engine speed

.by racing the engine, vacuum raises pro-

portionately with the rise in engine speed.

NOTEIf there is a problem with the change in vacuum, it is

possible that the throttle body port may be clogged and

require cleaning.

Page 364 of 1146

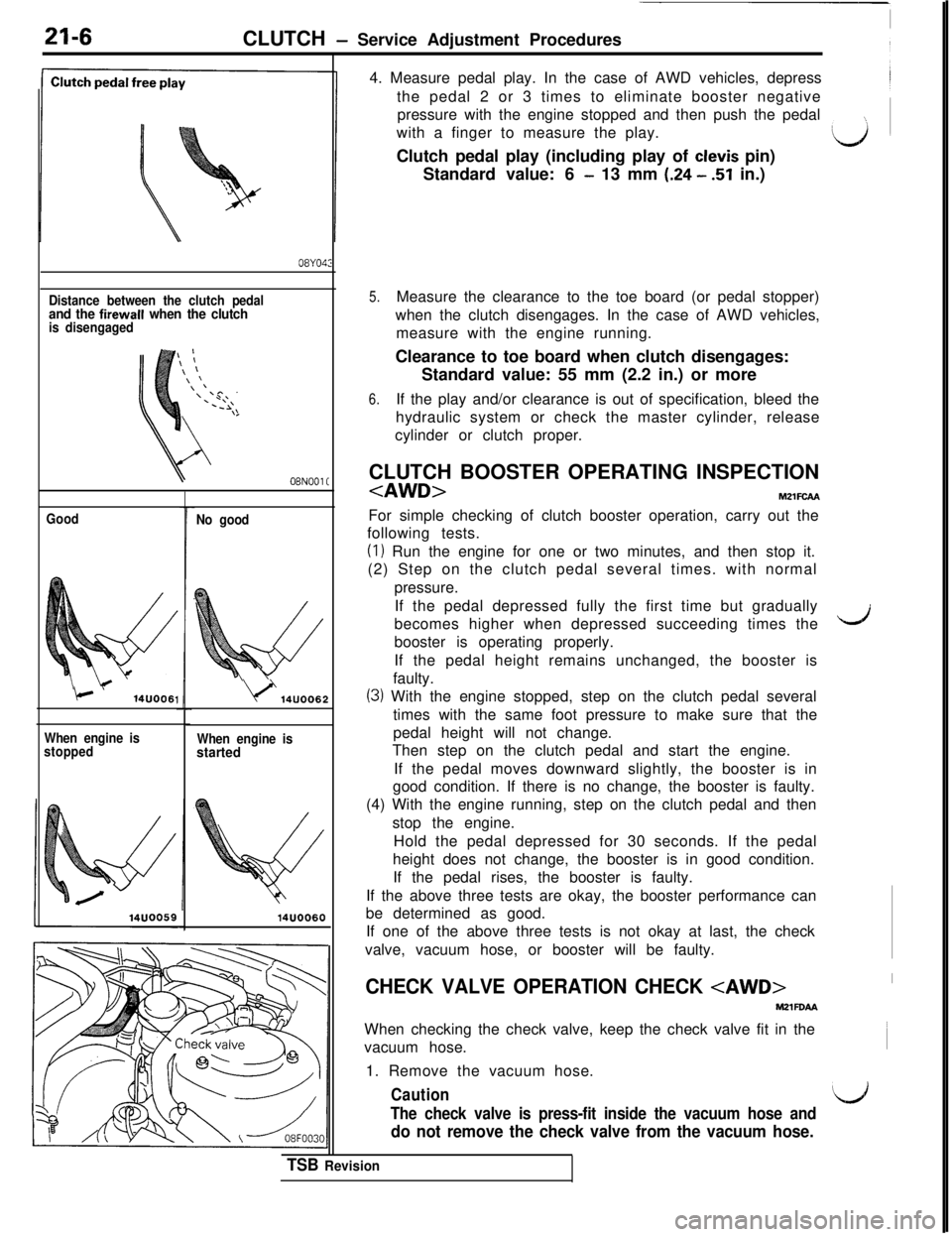

21-6CLUTCH - Service Adjustment Procedures

08YO4Z

Distance between the clutch pedaland the firewall when the clutchis disengaged

08NOOl C

Good

c1‘14UOO61

When engine is

stoppedNo good

\)‘14UOO6:

When engine isstarted

14UOO604. Measure pedal play. In the case of AWD vehicles, depress~

the pedal 2 or 3 times to eliminate booster negative

pressure with the engine stopped and then push the pedal

with a finger to measure the play.

LJClutch pedal play (including play of clevis pin)

Standard value: 6

- 13 mm (.24 - 51 in.)

2

CHECK VALVE OPERATION CHECK

MZlFOAAWhen checking the check valve, keep the check valve fit in the

vacuum hose.

1. Remove the vacuum hose.

CautionL’The check valve is press-fit inside the vacuum hose and

do not remove the check valve from the vacuum hose.

5.Measure the clearance to the toe board (or pedal stopper)

when the clutch disengages. In the case of AWD vehicles,

measure with the engine running.

Clearance to toe board when clutch disengages:

Standard value: 55 mm (2.2 in.) or more

6.If the play and/or clearance is out of specification, bleed the

hydraulic system or check the master cylinder, release

cylinder or clutch proper.

CLUTCH BOOSTER OPERATING INSPECTION

following tests.

(I) Run the engine for one or two minutes, and then stop it.

(2) Step on the clutch pedal several times. with normal

pressure.

If the pedal depressed fully the first time but gradually

becomes higher when depressed succeeding times the

dbooster is operating properly.

If the pedal height remains unchanged, the booster is

faulty.

(3) With the engine stopped, step on the clutch pedal several

times with the same foot pressure to make sure that the

pedal height will not change.

Then step on the clutch pedal and start the engine.

If the pedal moves downward slightly, the booster is in

good condition. If there is no change, the booster is faulty.

(4) With the engine running, step on the clutch pedal and then

stop the engine.

Hold the pedal depressed for 30 seconds. If the pedal

height does not change, the booster is in good condition.

If the pedal rises, the booster is faulty.

If the above three tests are okay, the booster performance can

be determined as good.

If one of the above three tests is not okay at last, the check

valve, vacuum hose, or booster will be faulty.

TSB Revision

Page 395 of 1146

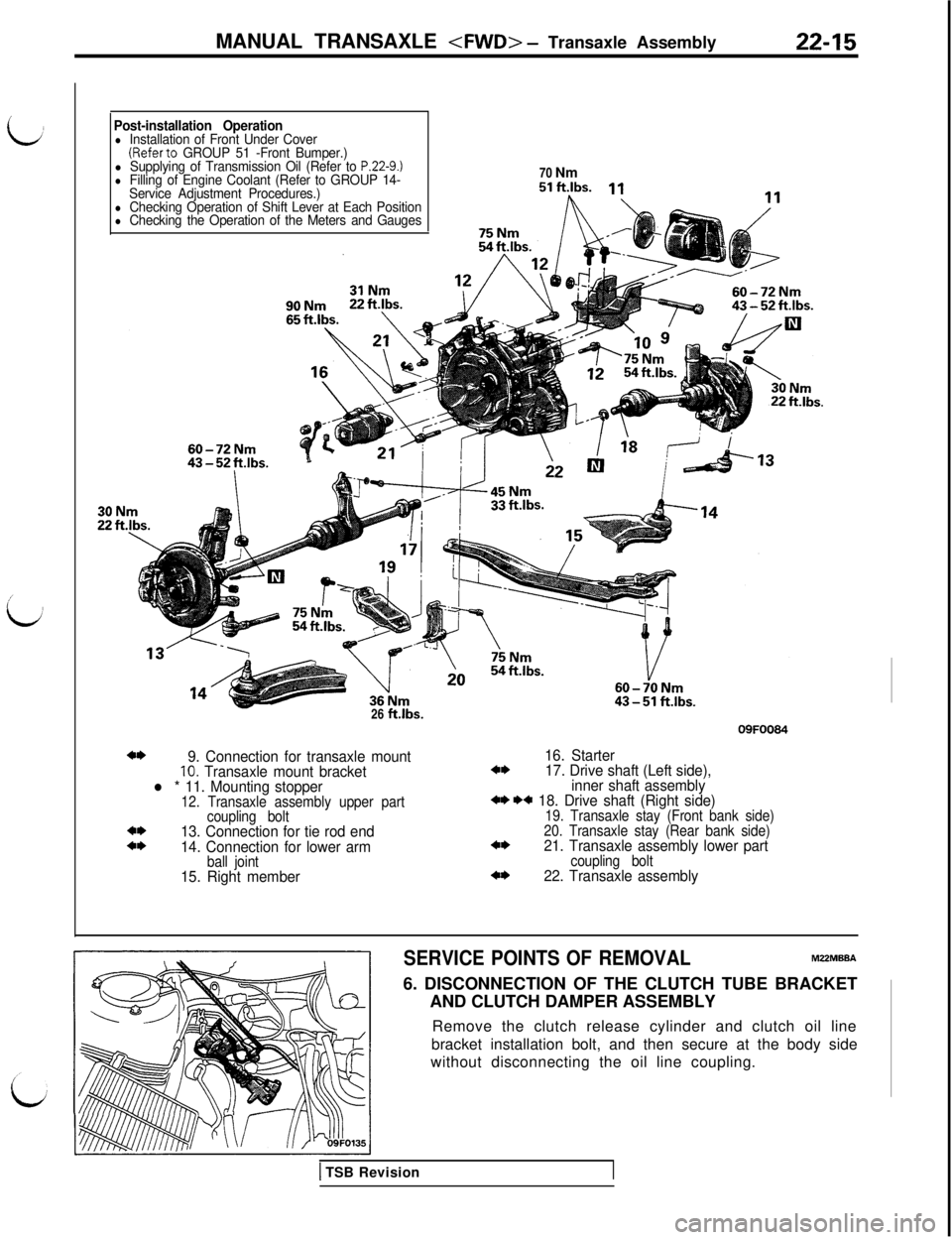

MANUAL TRANSAXLE

idPost-installation Operationl Installation of Front Under Cover(Referto GROUP 51 -Front Bumper.)l Supplying of Transmission Oil (Refer to P.22-9.)l Filling of Engine Coolant (Refer to GROUP 14-

Service Adjustment Procedures.)70 Nm

l Checking Operation of Shift Lever at Each Positionl Checking the Operation of the Meters and Gauges26

ft.lbs.09FOO84

4*9. Connection for transaxle mount16. Starter10. Transaxle mount bracket4*17. Drive shaft (Left side),

l * 11. Mounting stopperinner shaft assembly12. Transaxle assembly upper part+* ** 18. Drive shaft (Right side)

coupling bolt19. Transaxle stay (Front bank side)4*13. Connection for tie rod end20. Transaxle stay (Rear bank side)4*14. Connection for lower arm4*21. Transaxle assembly lower part

ball jointcoupling bolt15. Right member4*22. Transaxle assembly

SERVICE POINTS OF REMOVALMZZMBBA6. DISCONNECTION OF THE CLUTCH TUBE BRACKET

AND CLUTCH DAMPER ASSEMBLY

Remove the clutch release cylinder and clutch oil line

bracket installation bolt, and then secure at the body side

without disconnecting the oil line coupling.

1 TSB Revision

Page 437 of 1146

MANUAL TRANSAXLE

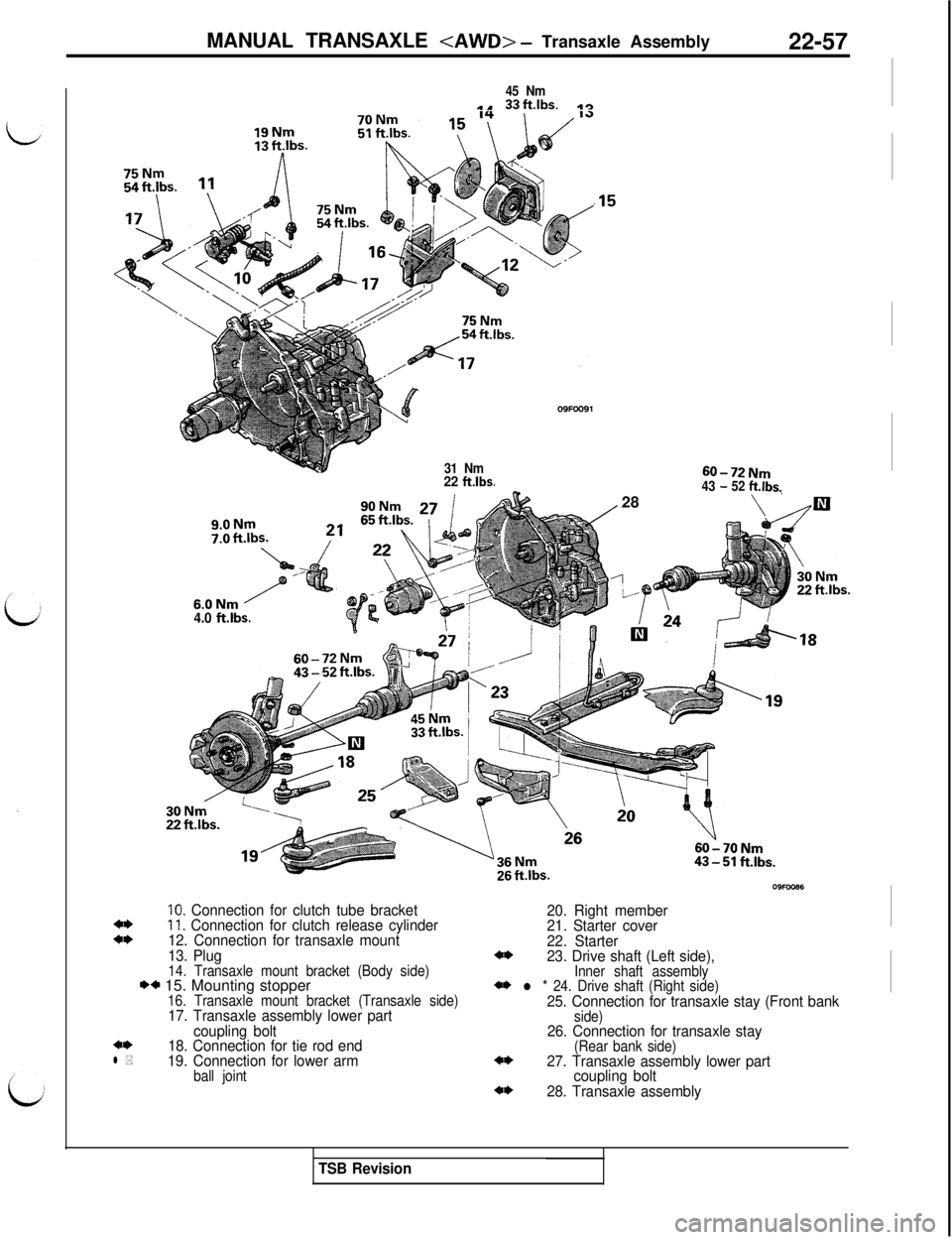

22-57

45 Nmaa 33ftlbs..,.,

31 Nm

09FOO91.15

28

50-72Nm43 - 52 ft.lbs.

\

22 ftlbs.9.0Nm

4.0 ftlbs.

10. Connection for clutch tube bracket11. Connection for clutch release cylinder

12. Connection for transaxle mount

13. Plug

14. Transaxle mount bracket (Body side)I)* 15. Mounting stopper16. Transaxle mount bracket (Transaxle side)17. Transaxle assembly lower part

coupling bolt

4*18. Connection for tie rod endl *19. Connection for lower armball joint

20. Right member

21. Starter cover

22. Starter

Mb23. Drive shaft (Left side),Inner shaft assembly+* l * 24. Drive shaft (Right side)25. Connection for transaxle stay (Front bankside)26. Connection for transaxle stay(Rear bank side)27. Transaxle assembly lower part

coupling bolt

28. Transaxle assembly

TSB Revision

Page 474 of 1146

![MITSUBISHI 3000GT 1991 User Guide 23-22AUTOMATIC TRANSAXLE - Troubleshooting

0”

TM362

DIAGNOSIS AND TEST

FLUID LEVEL AND CONDITION

1.Drive until the fluid temperature reaches the usual tempera-

ture

[70 - 80°C (160 - 18O”F)].2. MITSUBISHI 3000GT 1991 User Guide 23-22AUTOMATIC TRANSAXLE - Troubleshooting

0”

TM362

DIAGNOSIS AND TEST

FLUID LEVEL AND CONDITION

1.Drive until the fluid temperature reaches the usual tempera-

ture

[70 - 80°C (160 - 18O”F)].2.](/img/19/57085/w960_57085-473.png)

23-22AUTOMATIC TRANSAXLE - Troubleshooting

0”

TM362

DIAGNOSIS AND TEST

FLUID LEVEL AND CONDITION

1.Drive until the fluid temperature reaches the usual tempera-

ture

[70 - 80°C (160 - 18O”F)].2. Place vehicle on level floor.

3. Move selector lever sequentially to every position to fill

torque converter and hydraulic circuit with fluid, then place

lever in “N” Neutral position. This operation is necessary to

be sure that fluid level check is accurate.

4. Before removing dipstick, wipe all dirt from area around

dipstick. Then take out the dipstick and check the condition

of the fluid.

The transaxle should be overhauled under the following

conditions.

l If there is a “burning” odor.

l If the fluid color has become noticeably blacker.

lIf there is a noticeably great amount of metal particles in

the fluid.

5.Check to see if fluid level is in “HOT” range on dipstick. If

fluid level is low, add automatic transaxle fluid until level

reaches “HOT” range.

Low fluid level can cause a variety of conditions because it

allows pump to take in air along with fluid. Air trapped in

hydraulic circuit forms bubbles which make fluid spongy.

Therefore, pressures will be erratic.

Improper filling can also raise fluid level too high. When

transaxle has too much fluid, gears churn up foam and

cause same conditions which occur with low fluid level,

resulting in accelerated deterioration of automatic transaxle

fluid.

dIn either case, air bubbles can cause overheating, fluid

oxidation, which can interfere with normal valve, clutch, and

servo operation. Foaming can also result in fluid escaping

from transaxle vent where it may be mistaken for a leak.

6. Be sure to examine fluid on dipstick closely.

,CONTROL CABLEWhether control cable is properly adjusted can be confirmed by

checking whether inhibitor switch is performing well.

1. Apply parking brakes and service brakes securely.

2. Place selector lever to “R” range.

3. Set ignition key to “ST” position.

4. Slowly move the selector lever upward until it clicks as it

fits in notch of “P” range. If starter motor operates when

lever makes a click, “P” position is correct.

5.Then slowly move selector lever to “N” range by the same

procedure as in foregoing paragraph. If starter motor

operates when selector lever fits in

“N”, “N” position is

correct.

6. Also check to be sure the vehicle doesn’t begin to move

and the lever doesn’t stop between P-R-N-D.

7. The control cable is properly adjusted if, as described

above, the starter motor starts at both the “P” range and

the “N” range.

TSB Revision

Page 483 of 1146

AUTOMATIC TRANSAXLE - Troubleshooting

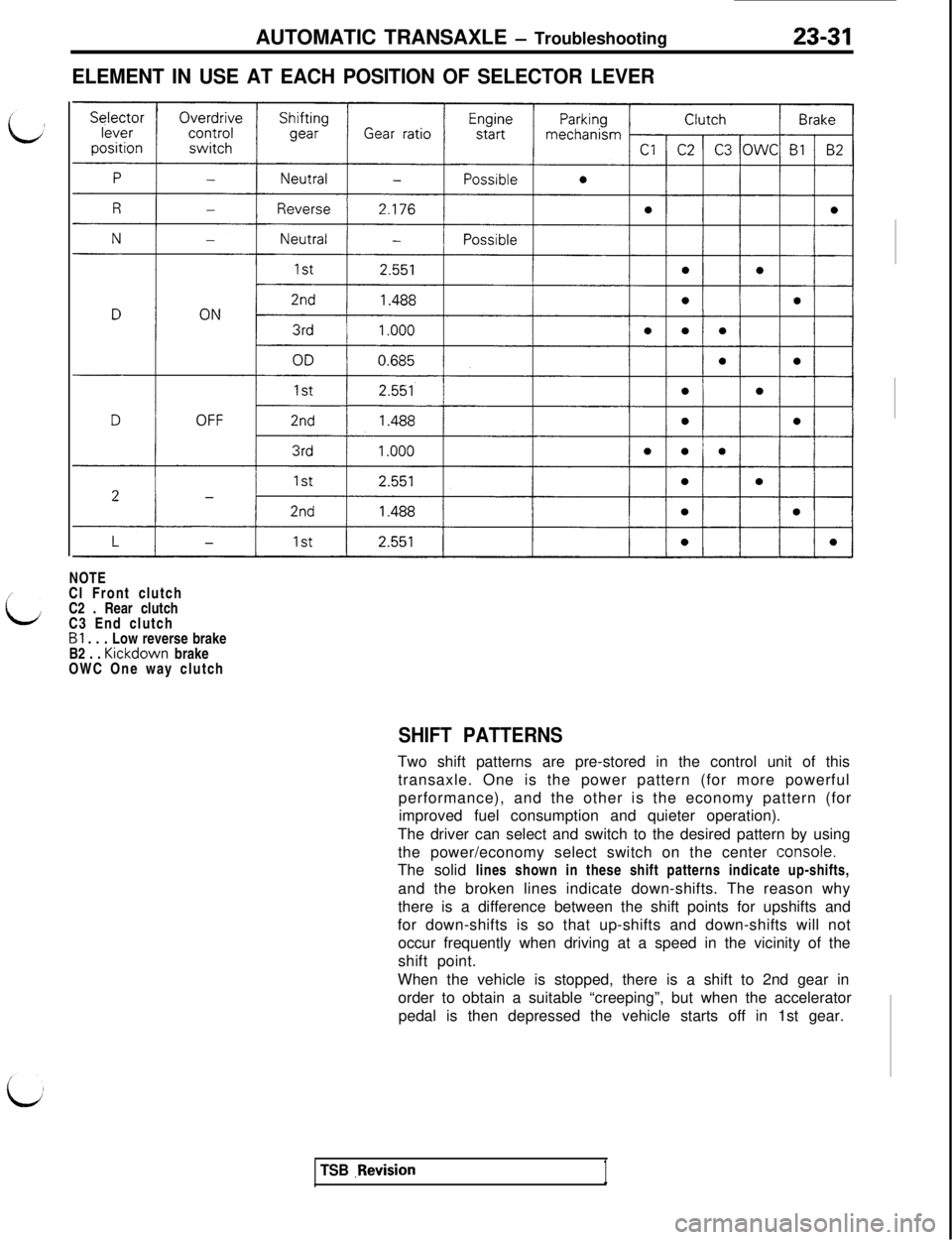

ELEMENT IN USE AT EACH POSITION OF SELECTOR LEVER

23-31NOTE

/

LCl Front clutch

C2 . Rear clutch

C3 End clutch

Bl . . . Low reverse brake

B2 . . Kickdown brake

OWC One way clutch

SHIFT PATTERNSTwo shift patterns are pre-stored in the control unit of this

transaxle. One is the power pattern (for more powerful

performance), and the other is the economy pattern (for

improved fuel consumption and quieter operation).

The driver can select and switch to the desired pattern by using

the power/economy select switch on the center

Iconsole.The solid lines shown in these shift patterns indicate up-shifts,

and the broken lines indicate down-shifts. The reason why

there is a difference between the shift points for upshifts and

for down-shifts is so that up-shifts and down-shifts will not

occur frequently when driving at a speed in the vicinity of the

shift point.

When the vehicle is stopped, there is a shift to 2nd gear in

order to obtain a suitable “creeping”, but when the accelerator

pedal is then depressed the vehicle starts off in 1st gear.

TSB .Revision1

Page 502 of 1146

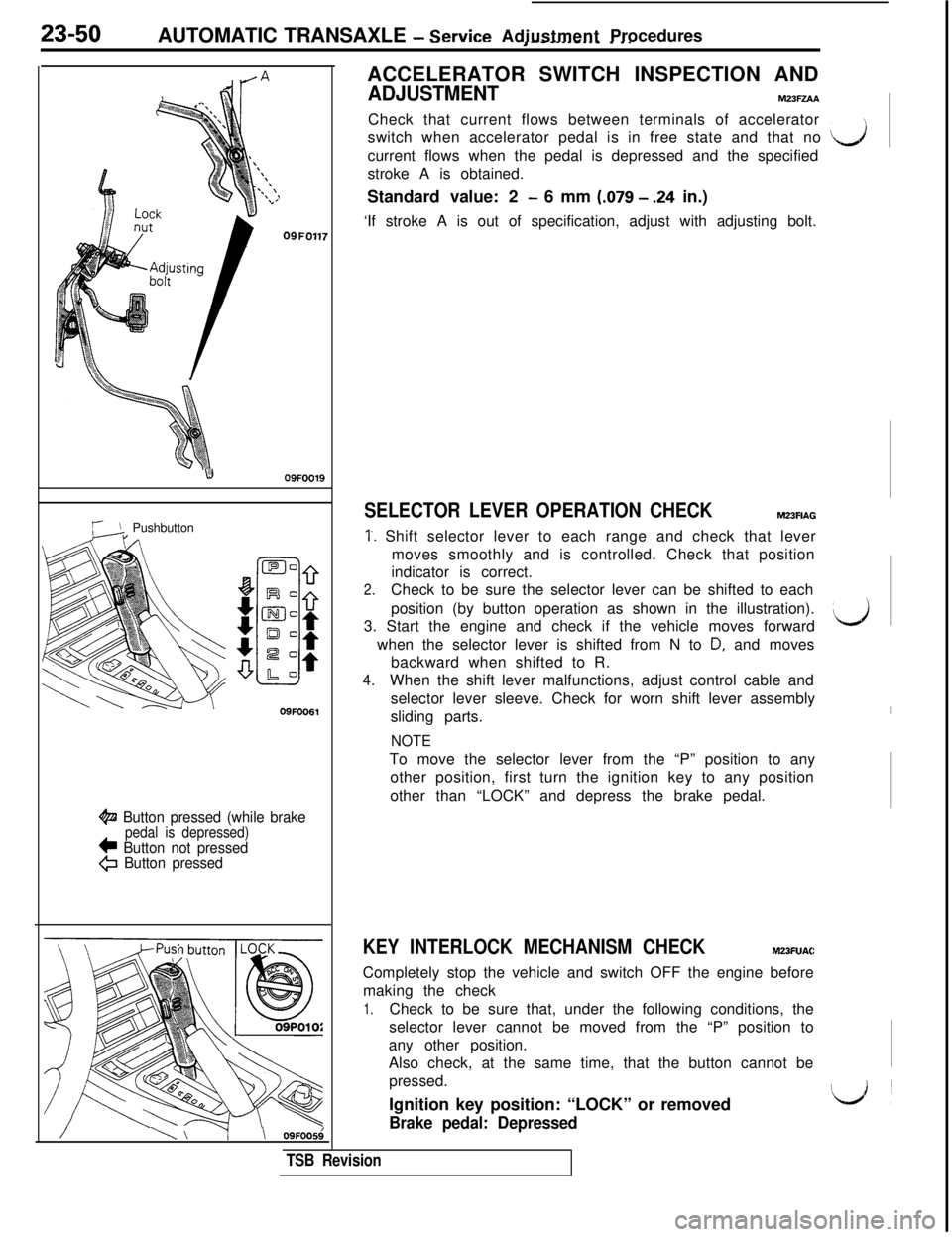

23-50AUTOMATIC TRANSAXLE - service AdiustmentProcedures

09FO117

m09FOO19

L Pushbuttonv09FOO61

@ Button pressed (while brakepedal is depressed)c Button not pressed@ Button pressed

/\ \\ OSFODdACCELERATOR SWITCH INSPECTION AND

ADJUSTMENTM23FZAACheck that current flows between terminals of accelerator

switch when accelerator pedal is in free state and that no

dcurrent flows when the pedal is depressed and the specified

stroke A is obtained.

Standard value: 2

- 6 mm (.079 - .24 in.)

‘If stroke A is out of specification, adjust with adjusting bolt.

SELECTOR LEVER OPERATION CHECKM23FIAG

1.. Shift selector lever to each range and check that lever

moves smoothly and is controlled. Check that position

indicator is correct.

2.Check to be sure the selector lever can be shifted to each

position (by button operation as shown in the illustration).

3. Start the engine and check if the vehicle moves forward

dwhen the selector lever is shifted from N to

D, and moves

backward when shifted to R.

4.When the shift lever malfunctions, adjust control cable and

selector lever sleeve. Check for worn shift lever assembly

sliding parts.

I

NOTETo move the selector lever from the “P” position to any

other position, first turn the ignition key to any position

other than “LOCK” and depress the brake pedal.

KEY INTERLOCK MECHANISM CHECKM23FlJACCompletely stop the vehicle and switch OFF the engine before

making the check

1.Check to be sure that, under the following conditions, the

selector lever cannot be moved from the “P” position to

any other position.

Also check, at the same time, that the button cannot be

pressed.

Ignition key position: “LOCK” or removed

Brake pedal: Depressed

TSB Revision

Page 734 of 1146

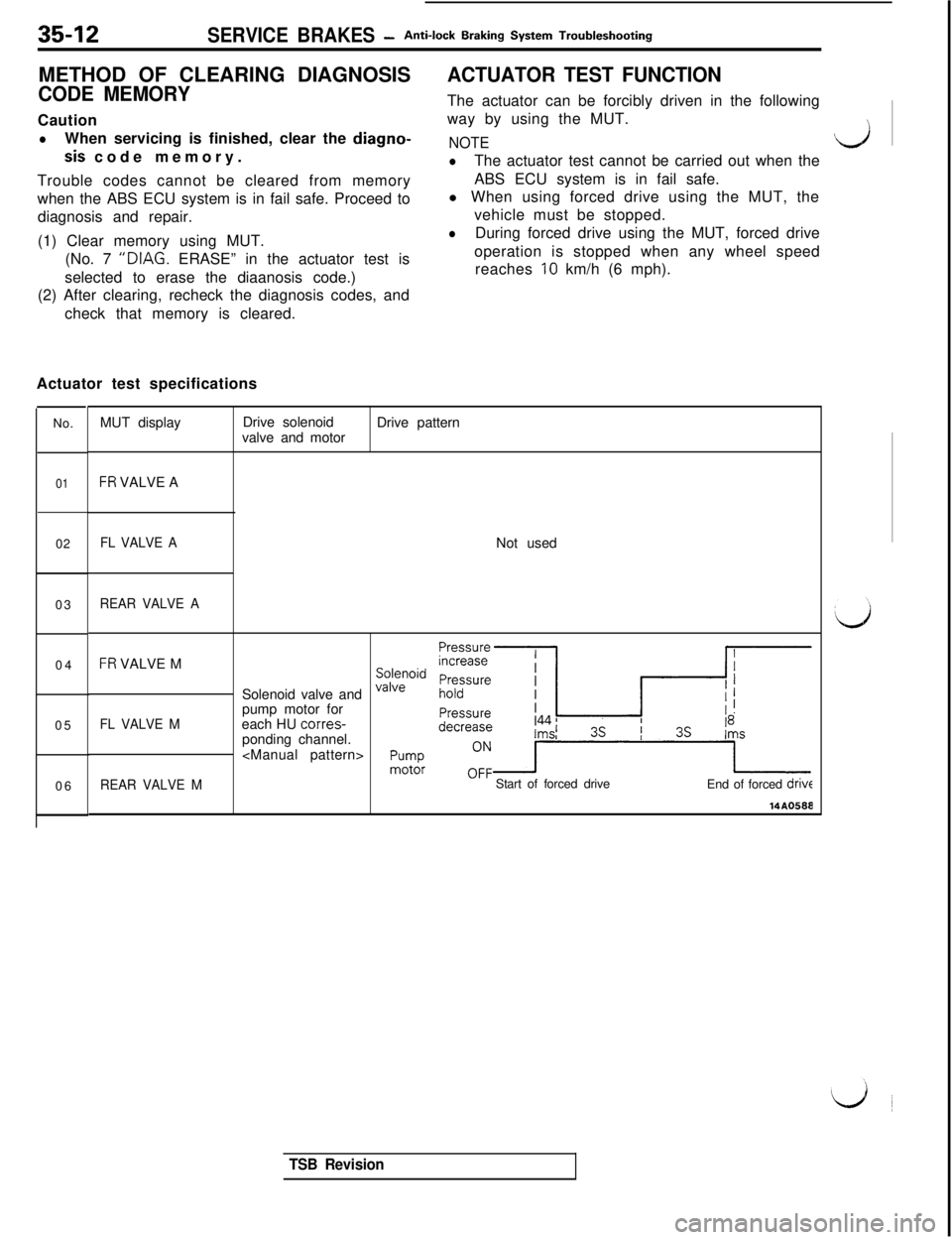

35-12SERVICE BRAKES -Anti-lock Braking System Troubleshooting

METHOD OF CLEARING DIAGNOSIS

ACTUATOR TEST FUNCTION

CODE MEMORYThe actuator can be forcibly driven in the following

Cautionway by using the MUT.

lWhen servicing is finished, clear the diagno-

sis code memory.NOTEd

lThe actuator test cannot be carried out when the

Trouble codes cannot be cleared from memoryABS ECU system is in fail safe.

when the ABS ECU system is in fail safe. Proceed tol When using forced drive using the MUT, the

diagnosis and repair.vehicle must be stopped.

(1) Clear memory using MUT.

lDuring forced drive using the MUT, forced drive

(No. 7

“DIAG. ERASE” in the actuator test isoperation is stopped when any wheel speed

selected to erase the diaanosis code.)reaches 10 km/h (6 mph).

(2) After clearing, recheck the diagnosis codes, and

check that memory is cleared.

Actuator test specifications

No.MUT display

01FR VALVE A

02

FL VALVE A03

REAR VALVE A04

FR VALVE M

05

FL VALVE M06

REAR VALVE MDrive solenoid

valve and motorDrive pattern

Not used

Solenoid valve and

pump motor for

each HU corres-

ponding channel.

Start of forced drive

End of forced drive

1440588

TSB Revision

Page 752 of 1146

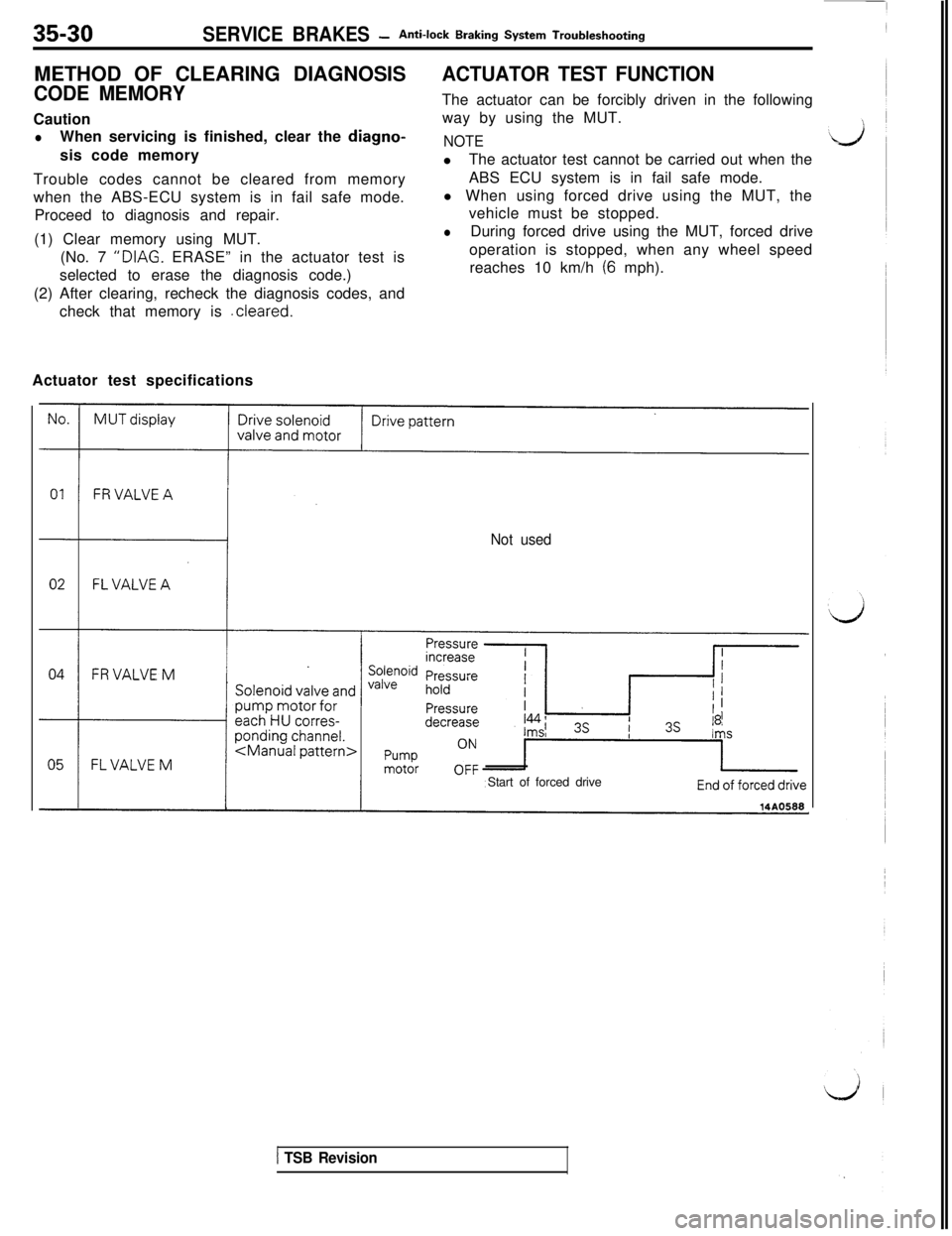

35-30SERVICE BRAKES -Anti-lock Braking System Troubleshooting

METHOD OF CLEARING DIAGNOSIS

ACTUATOR TEST FUNCTION

CODE MEMORYCautionThe actuator can be forcibly driven in the following

way by using the MUT.

lWhen servicing is finished, clear the diagno-

sis code memoryNOTElThe actuator test cannot be carried out when the

Trouble codes cannot be cleared from memoryABS ECU system is in fail safe mode.

when the ABS-ECU system is in fail safe mode.

Proceed to diagnosis and repair.l When using forced drive using the MUT, the

vehicle must be stopped.

(1) Clear memory using MUT.

lDuring forced drive using the MUT, forced drive

(No. 7

“DIAG. ERASE” in the actuator test isoperation is stopped, when any wheel speed

selected to erase the diagnosis code.)reaches 10 km/h (6 mph).

(2) After clearing, recheck the diagnosis codes, and

check that memory is .cleared.

Actuator test specifications

Not usedStart of forced drive

1 TSB Revision