stop start MITSUBISHI 3000GT 1991 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 767 of 1146

SERVICE BRAKES - Set-vice Adiustment Procedures35-45lUF51F

Pedal

7\ \!4FOO7.

F14511

F14519

TSB Revision-_.1

SERVICE ADJUSTMENT PROCEDURES

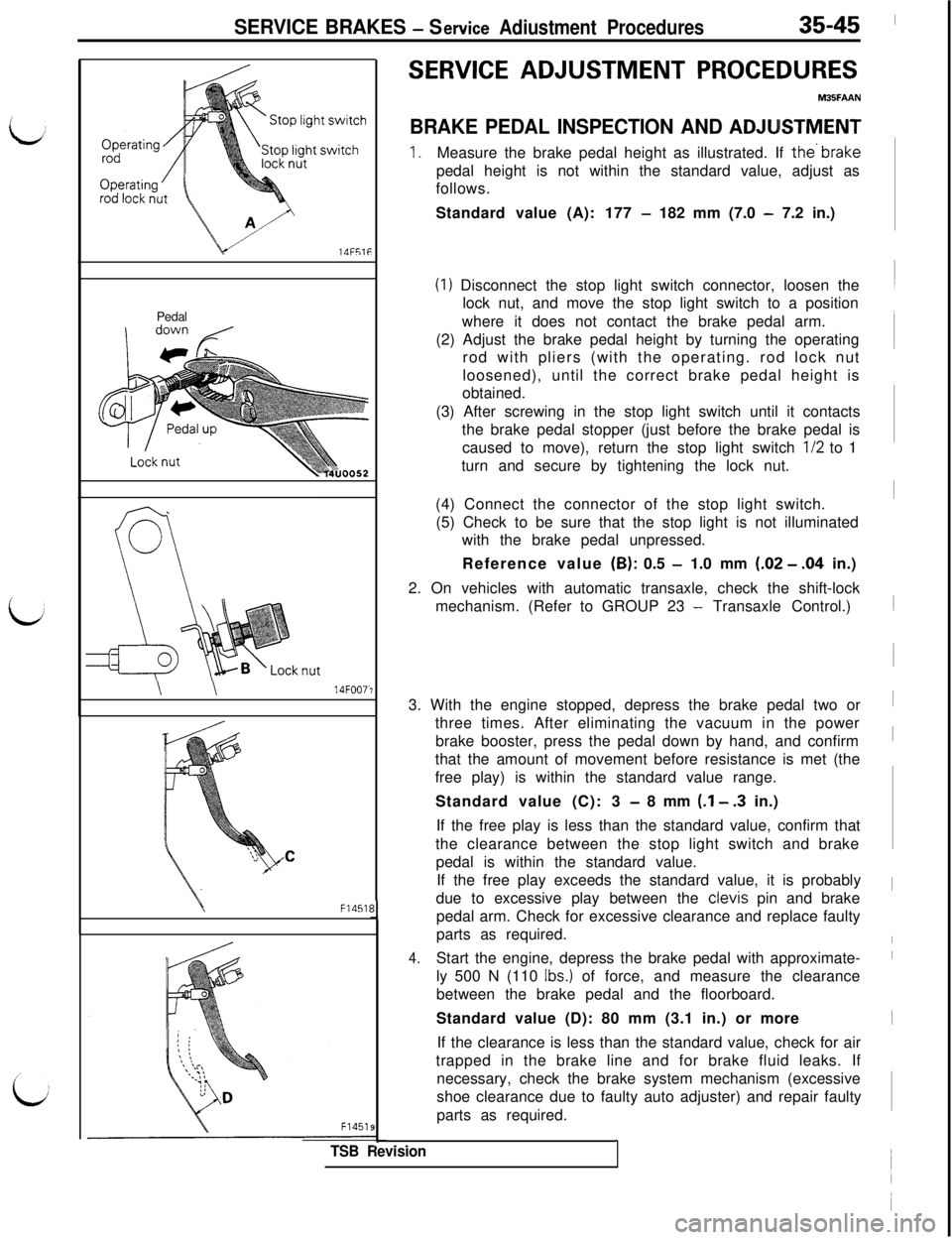

BRAKE PEDAL INSPECTION AND ADJUSTMENT

1.Measure the brake pedal height as illustrated. If the’brakepedal height is not within the standard value, adjust as

follows.

Standard value (A): 177

- 182 mm (7.0 - 7.2 in.)

(I) Disconnect the stop light switch connector, loosen the

lock nut, and move the stop light switch to a position

where it does not contact the brake pedal arm.

(2) Adjust the brake pedal height by turning the operating

rod with pliers (with the operating. rod lock nut

loosened), until the correct brake pedal height is

obtained.

(3) After screwing in the stop light switch until it contacts

the brake pedal stopper (just before the brake pedal is

caused to move), return the stop light switch

l/2 to 1

turn and secure by tightening the lock nut.

(4) Connect the connector of the stop light switch.

(5) Check to be sure that the stop light is not illuminated

with the brake pedal unpressed.

Reference value (6): 0.5

- 1.0 mm (.02 - .04 in.)

2. On vehicles with automatic transaxle, check the shift-lock

mechanism. (Refer to GROUP 23

- Transaxle Control.)

3. With the engine stopped, depress the brake pedal two or

three times. After eliminating the vacuum in the power

brake booster, press the pedal down by hand, and confirm

that the amount of movement before resistance is met (the

free play) is within the standard value range.

Standard value (C): 3

- 8 mm (.I - .3 in.)

If the free play is less than the standard value, confirm that

the clearance between the stop light switch and brake

pedal is within the standard value.

If the free play exceeds the standard value, it is probably

due to excessive play between the clevis pin and brake

pedal arm. Check for excessive clearance and replace faulty

parts as required.

4.Start the engine, depress the brake pedal with approximate-

ly 500 N (110

Ibs.) of force, and measure the clearance

between the brake pedal and the floorboard.

Standard value (D): 80 mm (3.1 in.) or more

If the clearance is less than the standard value, check for air

trapped in the brake line and for brake fluid leaks. If

necessary, check the brake system mechanism (excessive

shoe clearance due to faulty auto adjuster) and repair faulty

parts as required.~1~1

I

I

I

I

I

Page 768 of 1146

35-46SERVICE BRAKES - Service Adjustment Procedures

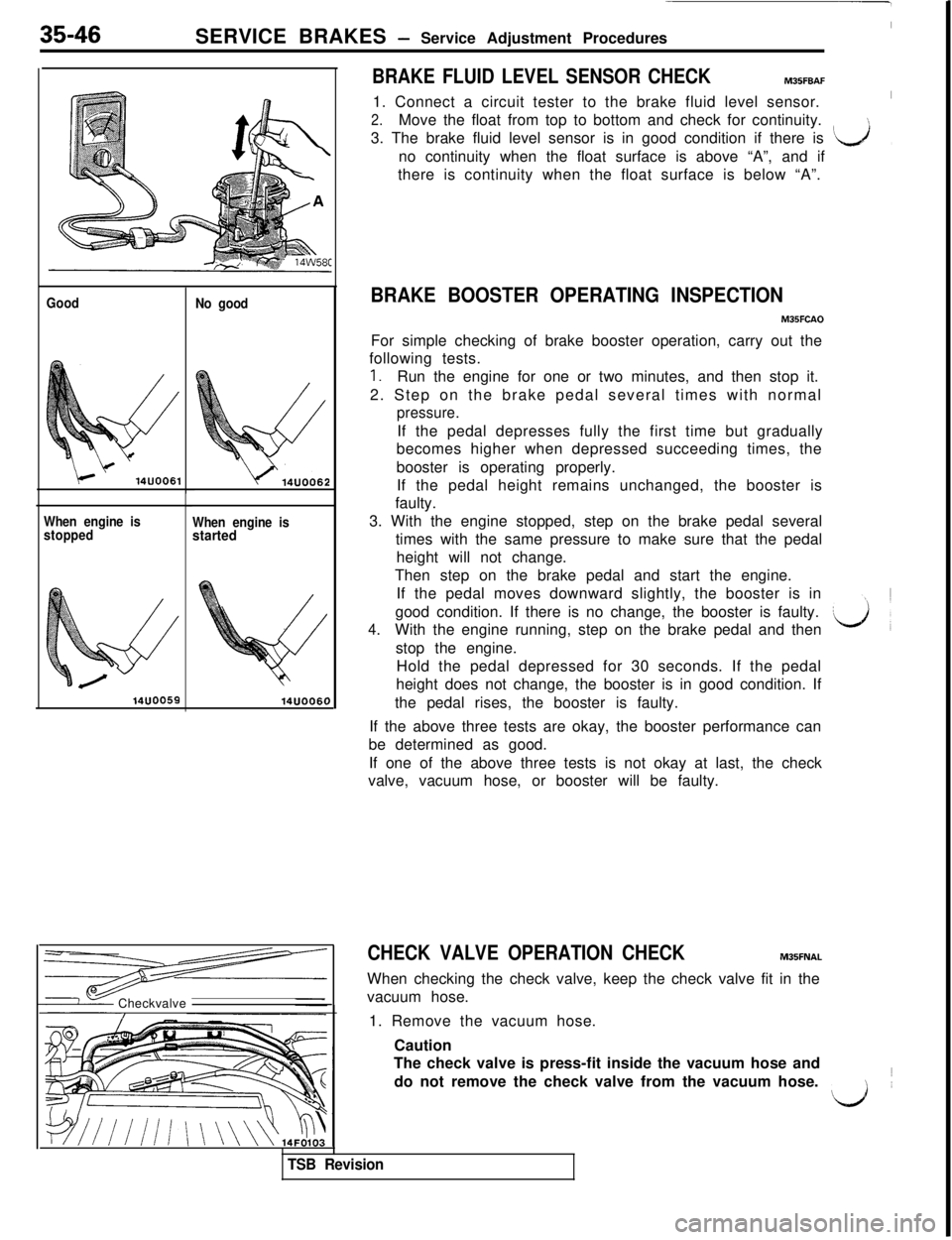

BRAKE FLUID LEVEL SENSOR CHECK

I

MBSFBAF

Good

k‘14UOO61

When engine is

stoppedNo good

When engine isstarted

14UOO6C)Checkvalve/1. Connect a circuit tester to the brake fluid level sensor.

I

2.Move the float from top to bottom and check for continuity.

3. The brake fluid level sensor is in good condition if there is

‘k&Jno continuity when the float surface is above “A”, and if,there is continuity when the float surface is below “A”.

BRAKE BOOSTER OPERATING INSPECTION

M35FCAOFor simple checking of brake booster operation, carry out the

following tests.

1.Run the engine for one or two minutes, and then stop it.

2. Step on the brake pedal several times with normal

pressure.If the pedal depresses fully the first time but gradually

becomes higher when depressed succeeding times, the

booster is operating properly.

If the pedal height remains unchanged, the booster is

faulty.

3. With the engine stopped, step on the brake pedal several

times with the same pressure to make sure that the pedal

height will not change.

Then step on the brake pedal and start the engine.

If the pedal moves downward slightly, the booster is in

good condition. If there is no change, the booster is faulty.

4.With the engine running, step on the brake pedal and then

stop the engine.

Hold the pedal depressed for 30 seconds. If the pedal

height does not change, the booster is in good condition. If

the pedal rises, the booster is faulty.

If the above three tests are okay, the booster performance can

be determined as good.

If one of the above three tests is not okay at last, the check

valve, vacuum hose, or booster will be faulty.

CHECK VALVE OPERATION CHECKM35FNALWhen checking the check valve, keep the check valve fit in the

vacuum hose.

1. Remove the vacuum hose.

Caution

The check valve is press-fit inside the vacuum hose and

do not remove the check valve from the vacuum hose.1

d~

TSB Revision

Page 772 of 1146

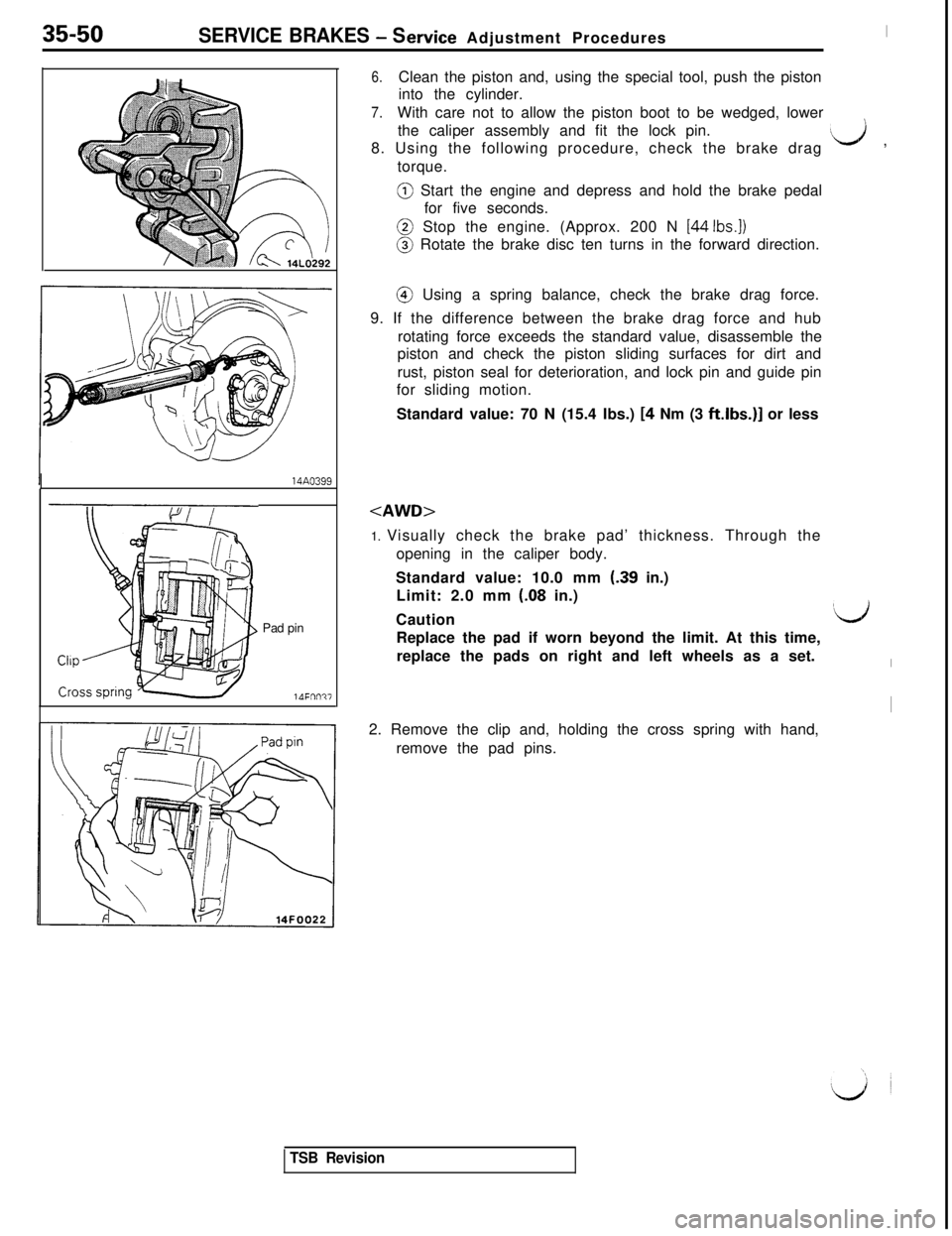

35-50SERVICE BRAKES - Service Adjustment Procedures

Pad pin

1 AFnn97

6.Clean the piston and, using the special tool, push the piston

into the cylinder.

7.With care not to allow the piston boot to be wedged, lower

the caliper assembly and fit the lock pin.

8. Using the following procedure, check the brake drag

‘d ,

torque.@ Start the engine and depress and hold the brake pedal

for five seconds.@ Stop the engine. (Approx. 200 N

[44 Ibs.])@ Rotate the brake disc ten turns in the forward direction.@ Using a spring balance, check the brake drag force.

9. If the difference between the brake drag force and hub

rotating force exceeds the standard value, disassemble the

piston and check the piston sliding surfaces for dirt and

rust, piston seal for deterioration, and lock pin and guide pin

for sliding motion.

Standard value: 70 N (15.4 Ibs.)

[4 Nm (3 ftlbs.)] or less

opening in the caliper body.

Standard value: 10.0 mm

(-39 in.)

Limit: 2.0 mm

(.08 in.)

Caution

‘L&iReplace the pad if worn beyond the limit. At this time,

replace the pads on right and left wheels as a set.

I2. Remove the clip and, holding the cross spring with hand,

remove the pad pins.

TSB Revision

Page 774 of 1146

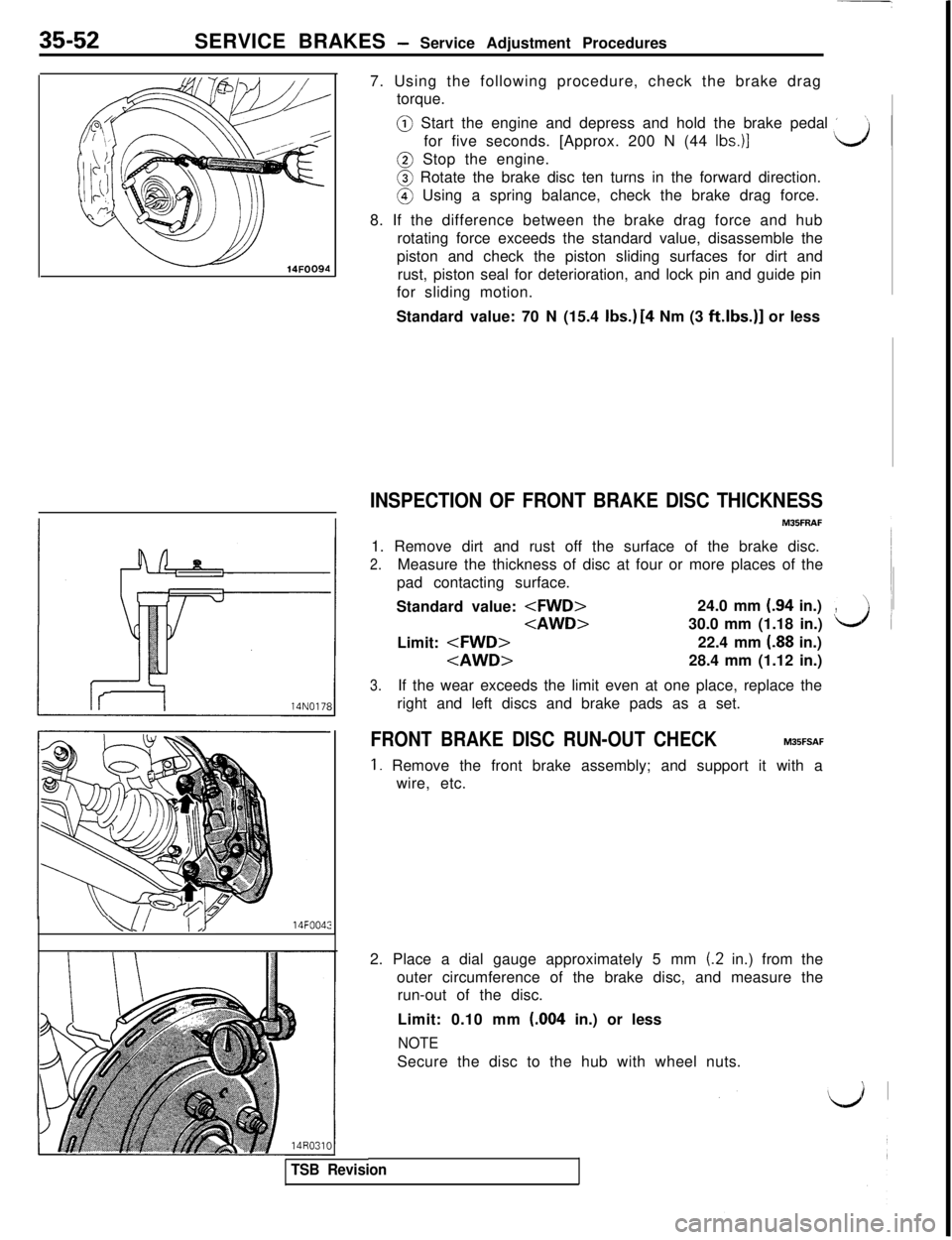

35-52SERVICE BRAKES - Service Adjustment Procedures

14FOO94

k.!! I14FOO427. Using the following procedure, check the brake drag

torque.@ Start the engine and depress and hold the brake pedal

’for five seconds. [Approx. 200 N (44

Ibs.)]@ Stop the engine.@ Rotate the brake disc ten turns in the forward direction.@ Using a spring balance, check the brake drag force.

8. If the difference between the brake drag force and hub

rotating force exceeds the standard value, disassemble the

piston and check the piston sliding surfaces for dirt and

rust, piston seal for deterioration, and lock pin and guide pin

for sliding motion.

Standard value: 70 N (15.4

Ibs.) [4 Nm (3 ft.lbs.)] or less

INSPECTION OF FRONT BRAKE DISC THICKNESS1. Remove dirt and rust off the surface of the brake disc.

2.Measure the thickness of disc at four or more places of the

pad contacting surface.

Standard value:

,Limit:

3.If the wear exceeds the limit even at one place, replace the

right and left discs and brake pads as a set.

FRONT BRAKE DISC RUN-OUT CHECKM35FSAF

1. Remove the front brake assembly; and support it with a

wire, etc.

TSB Revision2. Place a dial gauge approximately 5 mm

(.2 in.) from the

outer circumference of the brake disc, and measure the

run-out of the disc.

Limit: 0.10 mm (.004 in.) or less

NOTESecure the disc to the hub with wheel nuts.

Page 776 of 1146

SERVICE BRAKES - Service Adjustment Procedures

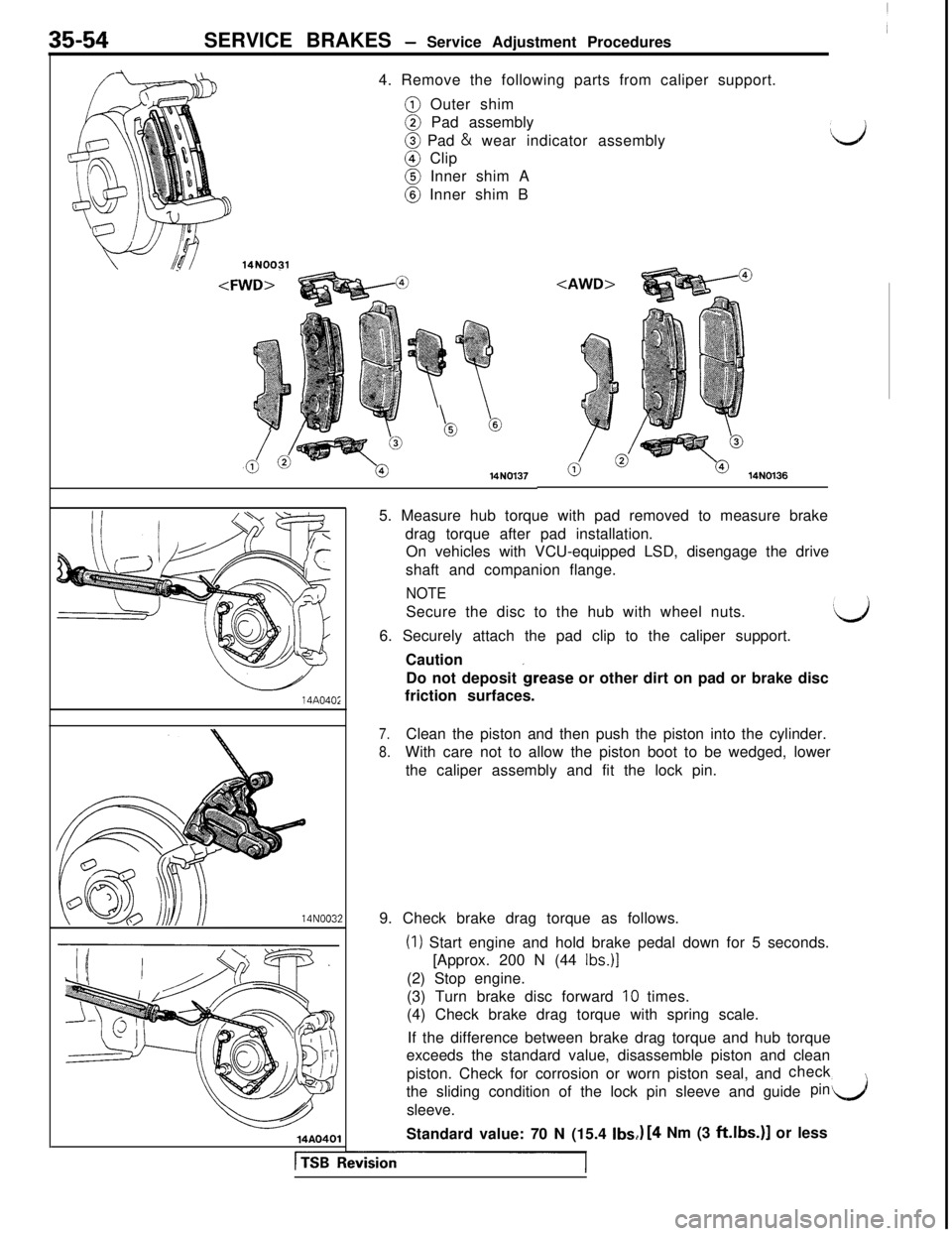

4. Remove the following parts from caliper support.@ Outer shim@ Pad assembly@ Pad & wear indicator assembly@ Clip@ Inner shim A@ Inner shim B

d

14N0031

/0014N013714A040;14N003:

14AO401

l%FLision

14N01365. Measure hub torque with pad removed to measure brake

drag torque after pad installation.

On vehicles with VCU-equipped LSD, disengage the drive

shaft and companion flange.

NOTESecure the disc to the hub with wheel nuts.

6. Securely attach the pad clip to the caliper support.

Caution

Do not deposit

&ease or other dirt on pad or brake disc

friction surfaces.

7.Clean the piston and then push the piston into the cylinder.

8.With care not to allow the piston boot to be wedged, lower

the caliper assembly and fit the lock pin.

9. Check brake drag torque as follows.

(I) Start engine and hold brake pedal down for 5 seconds.

[Approx. 200 N (44

Ibs.)](2) Stop engine.

(3) Turn brake disc forward

10 times.

(4) Check brake drag torque with spring scale.

If the difference between brake drag torque and hub torque

exceeds the standard value, disassemble piston and clean

piston. Check for corrosion or worn piston seal, andcheck

the sliding condition of the lock pin sleeve and guide

pinl/jsleeve.

Standard value: 70 N (15.4

Ibs,,) [4 Nm (3 ft.lbs.)] or less

Page 796 of 1146

35-74

SERVICE BRAKES - Front Disc Brake

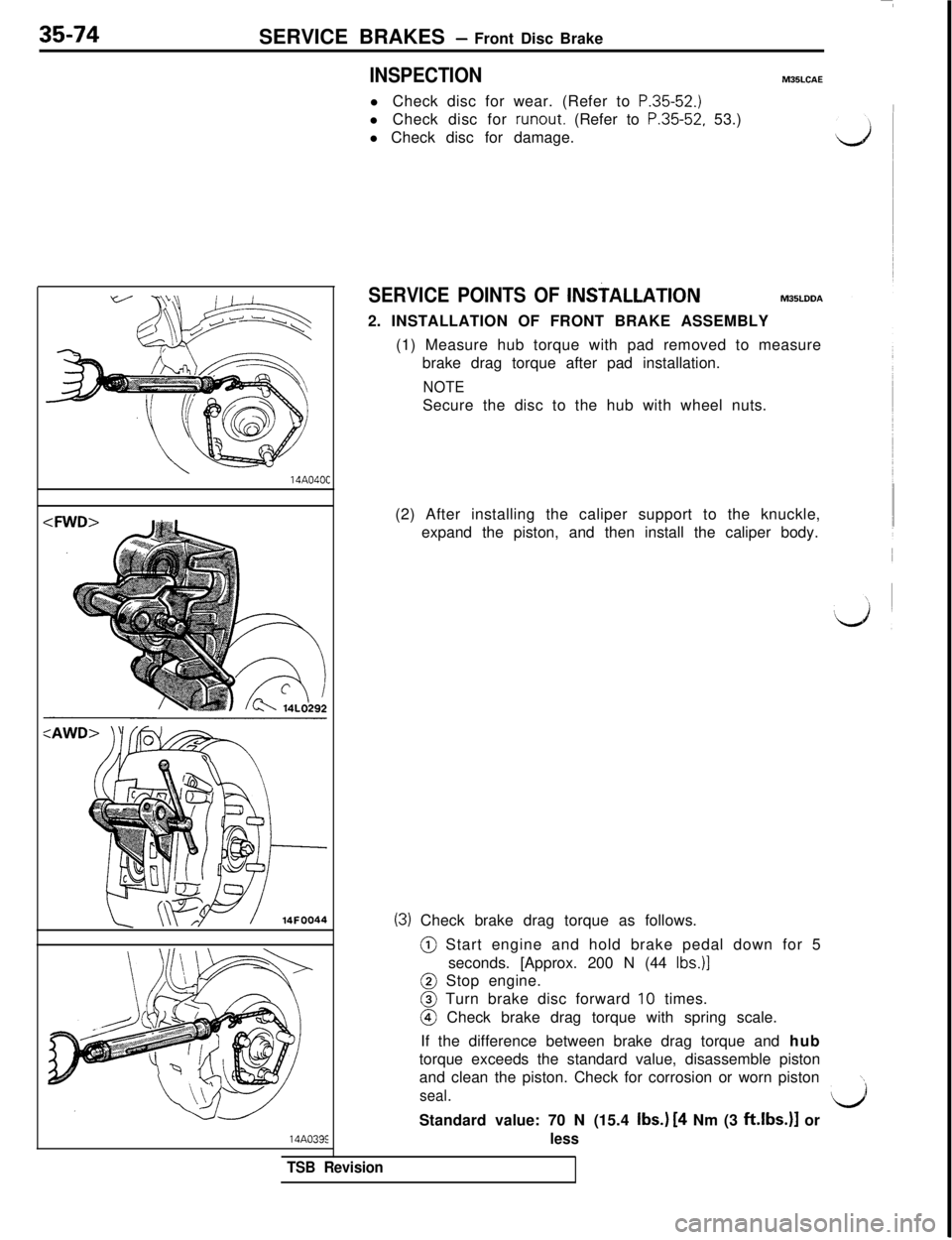

INSPECTIONM35LCAEl Check disc for wear. (Refer to

P.35-52.)l Check disc for runout. (Refer to

P.35-52, 53.)Il Check disc for damage.14A040C

(2) After installing the caliper support to the knuckle,

expand the piston, and then install the caliper body.

(3) Check brake drag torque as follows.@ Start engine and hold brake pedal down for 5

seconds. [Approx. 200 N (44

Ibs.)]@ Stop engine.@ Turn brake disc forward

10 times.@ Check brake drag torque with spring scale.

If the difference between brake drag torque and hub

torque exceeds the standard value, disassemble piston

and clean the piston. Check for corrosion or worn piston

\\

seal.l/iStandard value: 70 N (15.4 Ibs.)

[4 Nm (3 ft.lbs.)l or14A033E

less

SERVICE POINTS OF lNS?ALLATlONM35LDDA2. INSTALLATION OF FRONT BRAKE ASSEMBLY

(1) Measure hub torque with pad removed to measure

brake drag torque after pad installation.

NOTESecure the disc to the hub with wheel nuts.

TSB Revision

Page 830 of 1146

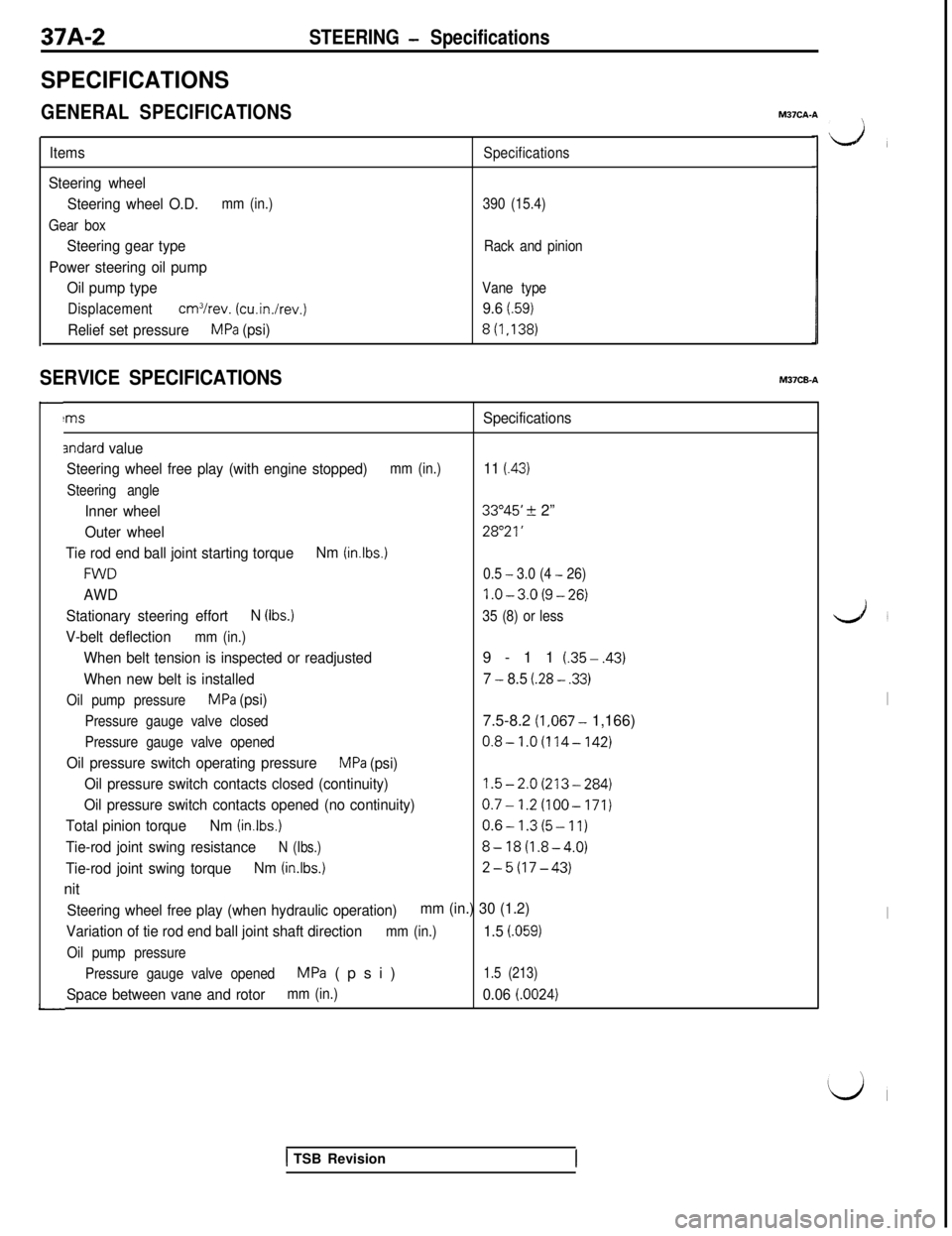

37A-2SPECIFICATIONS

STEERING - Specifications

GENERAL SPECIFICATIONS

M37CA-A

LA,Items

Steering wheel

Steering wheel O.D.

mm (in.)

Gear box

Steering gear type

Power steering oil pump

Oil pump type

Displacementcm3/rev. (cu.in./rev.)

Relief set pressureMPa (psi)

Specifications

390 (15.4)

Rack and pinion

Vane type

9.6 t.59)

8(1,138)

SERVICE SPECIFICATIONSM37CB-A

!msSpecifications

andard value

Steering wheel free play (with engine stopped)

mm (in.)11 (43)

Steering angle

Inner wheel33”45’ 2 2”

Outer wheel28”21’

Tie rod end ball joint starting torqueNm (in.lbs.)

FWD0.5 - 3.0 (4 - 26)

AWDl.O-3.0(9-26)

Stationary steering effortN (Ibs.)35 (8) or less

V-belt deflectionmm (in.)

When belt tension is inspected or readjusted9-11 (.35-.43)

When new belt is installed7 - 8.5 (.28 - .33)

Oil pump pressureMPa (psi)

Pressure gauge valve closed7.5-8.2 (1,067- 1,166)

Pressure gauge valve opened0.8-1.0(114-142)

Oil pressure switch operating pressureMPa (psi)

Oil pressure switch contacts closed (continuity)

1.5-2.0(213-284)

Oil pressure switch contacts opened (no continuity)0.7-1.2(100-171)

Total pinion torqueNm (in.lbs.)0.6-1.3(5-11)

Tie-rod joint swing resistanceN (Ibs.)8-18(1.8-4.0)

Tie-rod joint swing torqueNm (in.lbs.)2-5(17-43)nit

Steering wheel free play (when hydraulic operation)mm (in.) 30 (1.2)

Variation of tie rod end ball joint shaft direction

mm (in.)1.5 i.059)

Oil pump pressure

Pressure gauge valve opened

MPa (psi)1.5 (213)

Space between vane and rotormm (in.)0.06 (0024)

LJ’

I

I

L’l

1 TSB Revision

Page 833 of 1146

STEERING 2 Service Adjustment Procedures37A-5

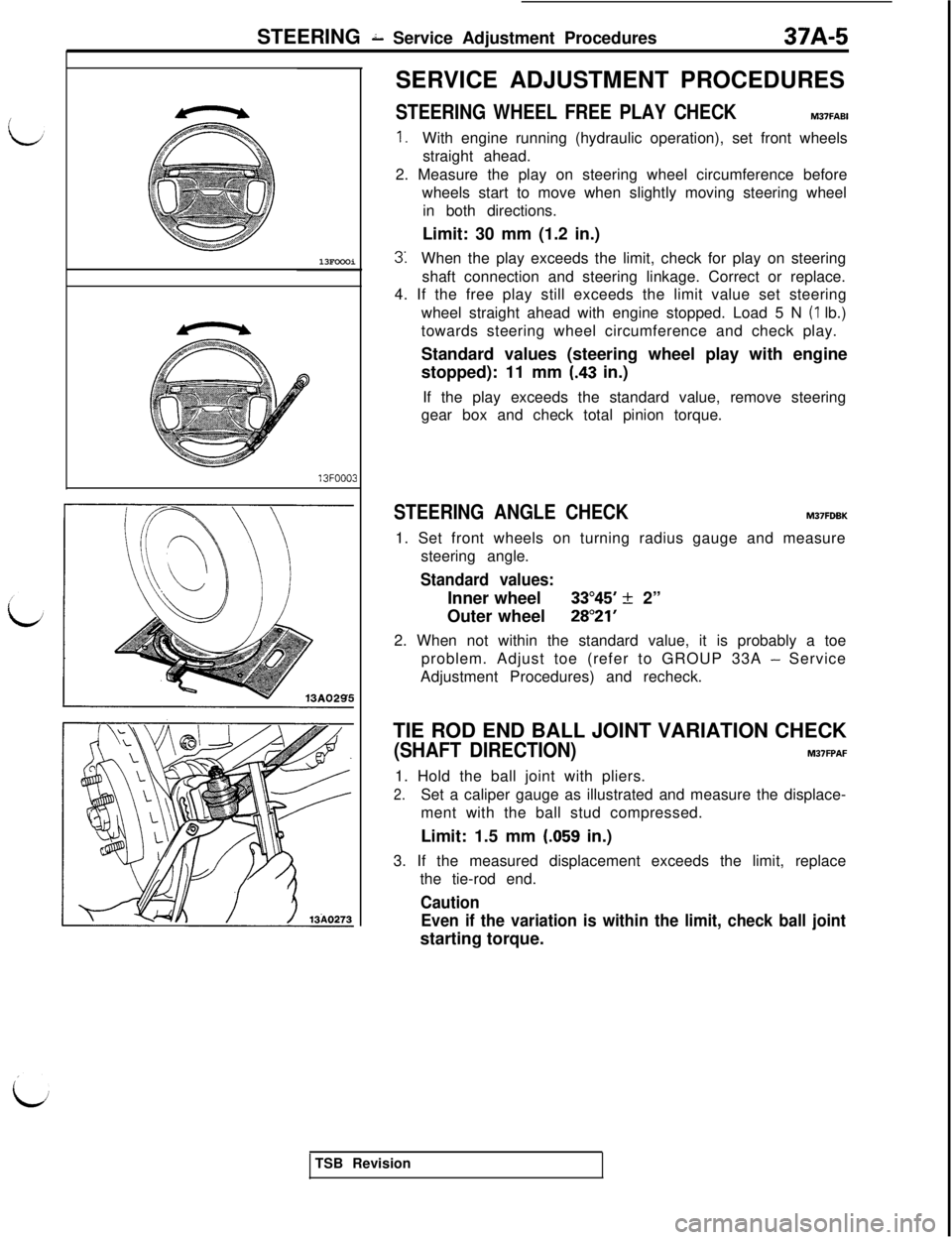

13FOOOi13FOOO3SERVICE ADJUSTMENT PROCEDURES

STEERING WHEEL FREE PLAY CHECKM37FABI

1.With engine running (hydraulic operation), set front wheels

straight ahead.

2. Measure the play on steering wheel circumference before

wheels start to move when slightly moving steering wheel

in both directions.

Limit: 30 mm (1.2 in.)

3:When the play exceeds the limit, check for play on steering

shaft connection and steering linkage. Correct or replace.

4. If the free play still exceeds the limit value set steering

wheel straight ahead with engine stopped. Load 5 N

(1 lb.)

towards steering wheel circumference and check play.

Standard values (steering wheel play with engine

stopped): 11 mm

(.43 in.)

If the play exceeds the standard value, remove steering

gear box and check total pinion torque.

STEERING ANGLE CHECKM37FDBK1. Set front wheels on turning radius gauge and measure

steering angle.

Standard values:Inner wheel

33”45’ k 2”

Outer wheel

28”21’2. When not within the standard value, it is probably a toe

problem. Adjust toe (refer to GROUP 33A

- Service

Adjustment Procedures) and recheck.

TIE ROD END BALL JOINT VARIATION CHECK

(SHAFT DIRECTION)M37FPAF1. Hold the ball joint with pliers.

2.Set a caliper gauge as illustrated and measure the displace-

ment with the ball stud compressed.

Limit: 1.5 mm

(.059 in.)

3. If the measured displacement exceeds the limit, replace

the tie-rod end.

Caution

Even if the variation is within the limit, check ball jointstarting torque.

TSB Revision

Page 834 of 1146

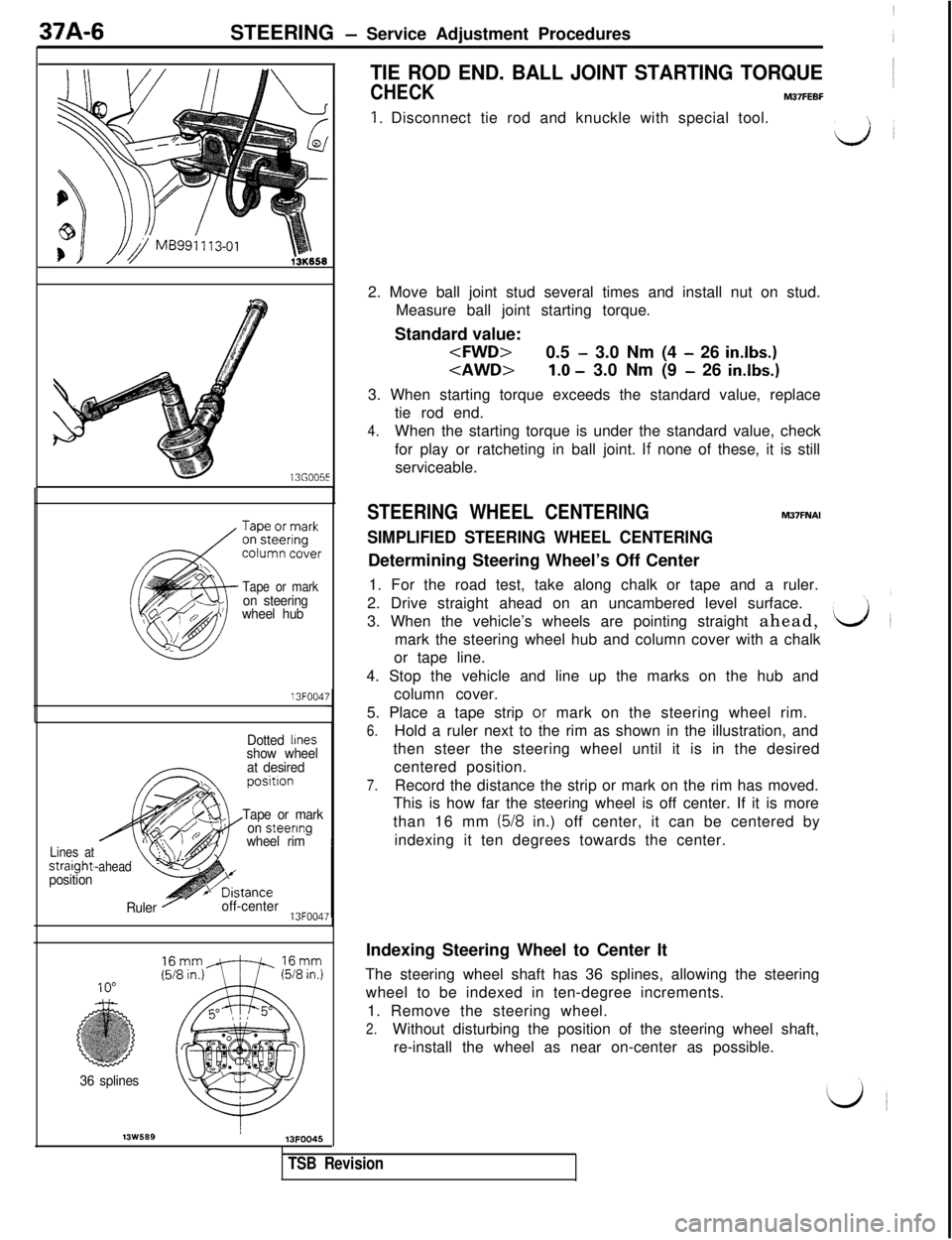

STEERING - Service Adjustment Procedures13G005E

Tape or markon steering

wheel hub

13FOO4:

Lines atstraight-position-ahead

Dotted linesshow wheel

at desired

positlon

Tape or mark

on

steenngwheel rim

tanceRuler 7’off-center13FOO4;

36 splines

13W589/13FOO45

TIE ROD END. BALL JOINT STARTING TORQUE

CHECK~M37FEBF

1. Disconnect tie rod and knuckle with special tool.~

LJ2. Move ball joint stud several times and install nut on stud.

Measure ball joint starting torque.

Standard value:

tie rod end.

4.When the starting torque is under the standard value, check

for play or ratcheting in ball joint.

If none of these, it is still

serviceable.

STEERING WHEEL CENTERINGM37FNAI

SIMPLIFIED STEERING WHEEL CENTERINGDetermining Steering Wheel’s Off Center

1. For the road test, take along chalk or tape and a ruler.

2. Drive straight ahead on an uncambered level surface.

3. When the vehicle’s wheels are pointing straight ahead,

mark the steering wheel hub and column cover with a chalk

or tape line.

4. Stop the vehicle and line up the marks on the hub and

column cover.

5. Place a tape strip

01 mark on the steering wheel rim.

6.Hold a ruler next to the rim as shown in the illustration, and

then steer the steering wheel until it is in the desired

centered position.

7.Record the distance the strip or mark on the rim has moved.

This is how far the steering wheel is off center. If it is more

than 16 mm

(518 in.) off center, it can be centered by

indexing it ten degrees towards the center.

Indexing Steering Wheel to Center It

The steering wheel shaft has 36 splines, allowing the steering

wheel to be indexed in ten-degree increments.

1. Remove the steering wheel.

2.Without disturbing the position of the steering wheel shaft,

re-install the wheel as near on-center as possible.

TSB Revision

Page 836 of 1146

37A-8STEERING - Service Adjustment Procedures13FOOO3

13FOOOl

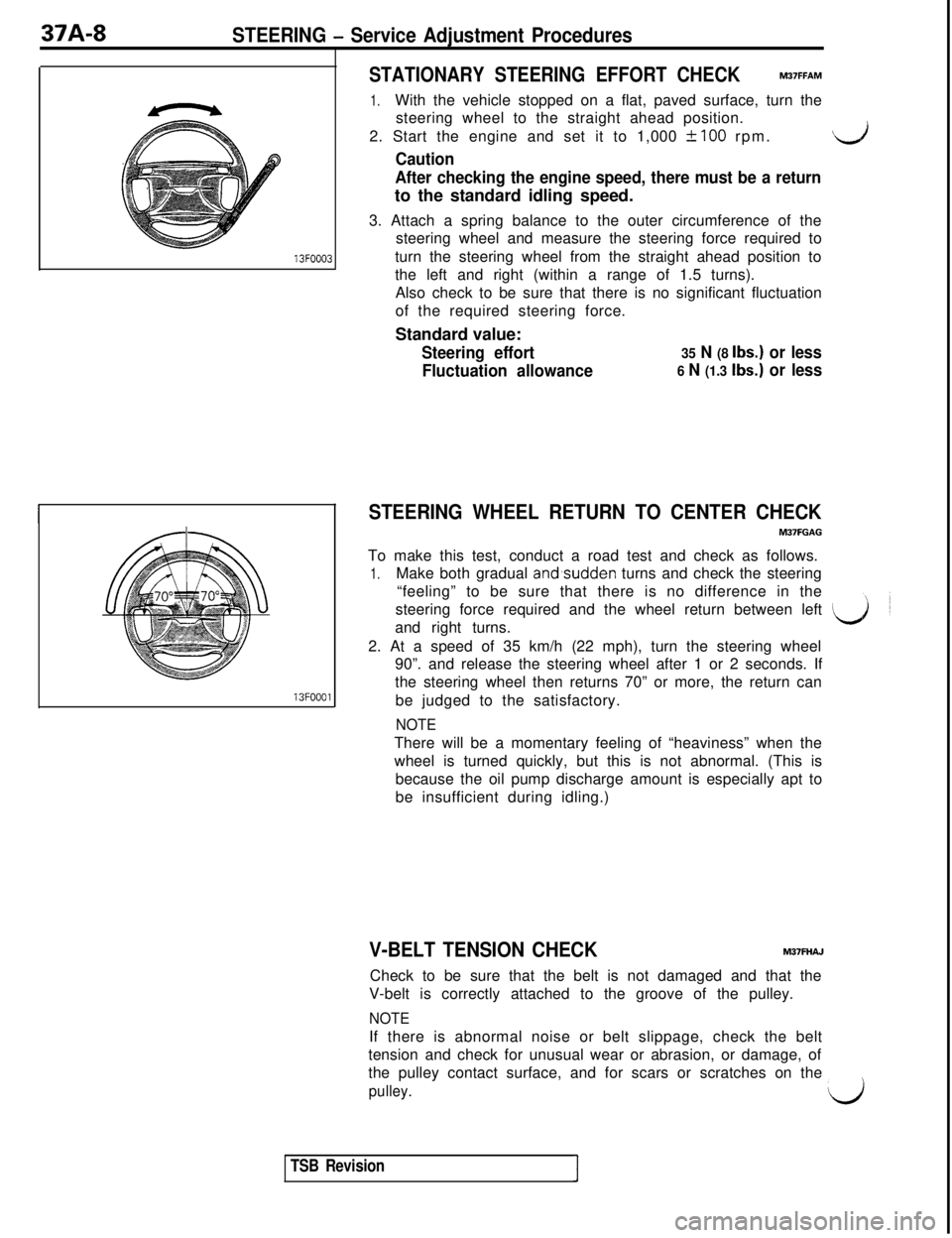

STATIONARY STEERING EFFORT CHECKM37FFAM

1.With the vehicle stopped on a flat, paved surface, turn the

steering wheel to the straight ahead position.

2. Start the engine and set it to 1,000

+ 100 rpm.d

Caution

After checking the engine speed, there must be a returnto the standard idling speed.

3. Attach a spring balance to the outer circumference of the

steering wheel and measure the steering force required to

turn the steering wheel from the straight ahead position to

the left and right (within a range of 1.5 turns).

Also check to be sure that there is no significant fluctuation

of the required steering force.

Standard value:

Steering effort35 N (8 Ibs.) or less

Fluctuation allowance

6 N (1.3 Ibs.) or less

STEERING WHEEL RETURN TO CENTER CHECK

M37FGACiTo make this test, conduct a road test and check as follows.

1.Make both gradual and,sudden turns and check the steering

“feeling” to be sure that there is no difference in the

steering force required and the wheel return between left

and right turns.

2. At a speed of 35 km/h (22 mph), turn the steering wheel

90”. and release the steering wheel after 1 or 2 seconds. If

the steering wheel then returns 70” or more, the return can

be judged to the satisfactory.

NOTEThere will be a momentary feeling of “heaviness” when the

wheel is turned quickly, but this is not abnormal. (This is

because the oil pump discharge amount is especially apt to

be insufficient during idling.)

V-BELT TENSION CHECKM37FHAJCheck to be sure that the belt is not damaged and that the

V-belt is correctly attached to the groove of the pulley.

NOTEIf there is abnormal noise or belt slippage, check the belt

tension and check for unusual wear or abrasion, or damage, of

the pulley contact surface, and for scars or scratches on the

pulley.d

TSB RevisionI