display MITSUBISHI 3000GT 1991 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 217 of 1146

FUEL SYSTEM - On-vehicle .lnspection of MPI Components13-111

INSPECTIONUsing Multi-use Tester

FunctionItem No. Data display

Data reading 45

Stepper

1

motor steps

~

Check condition

l Engine coolant tem-

perature: 80 to 95°C

(176 to 205°F)

0 Lamps, electric cooling

fan, accessory units:

All OFFl Transaxle: Neutral(P range for vehiclewith AA>l Steering wheel: Neutrall Idle position switch: ON(compressor clutch

to be ON if air condi-

tioner switch is ON)l Engine: idling

Load stateStandard value

;;rnditioner switch:2 - 12 stp&conditioner switch:

25 - 65 stp

l $irNconditioner switch:15 - 63 stp

NOTEWhen the vehicle is new [within initial operation of about 500 km (300 miles)], the stepper motor steps may be about 30steps more than standard.

CautionWhen the selector lever is shifted to the “D”range, the brakes must be used to prevent the vehicle frommovingforward.

03A020

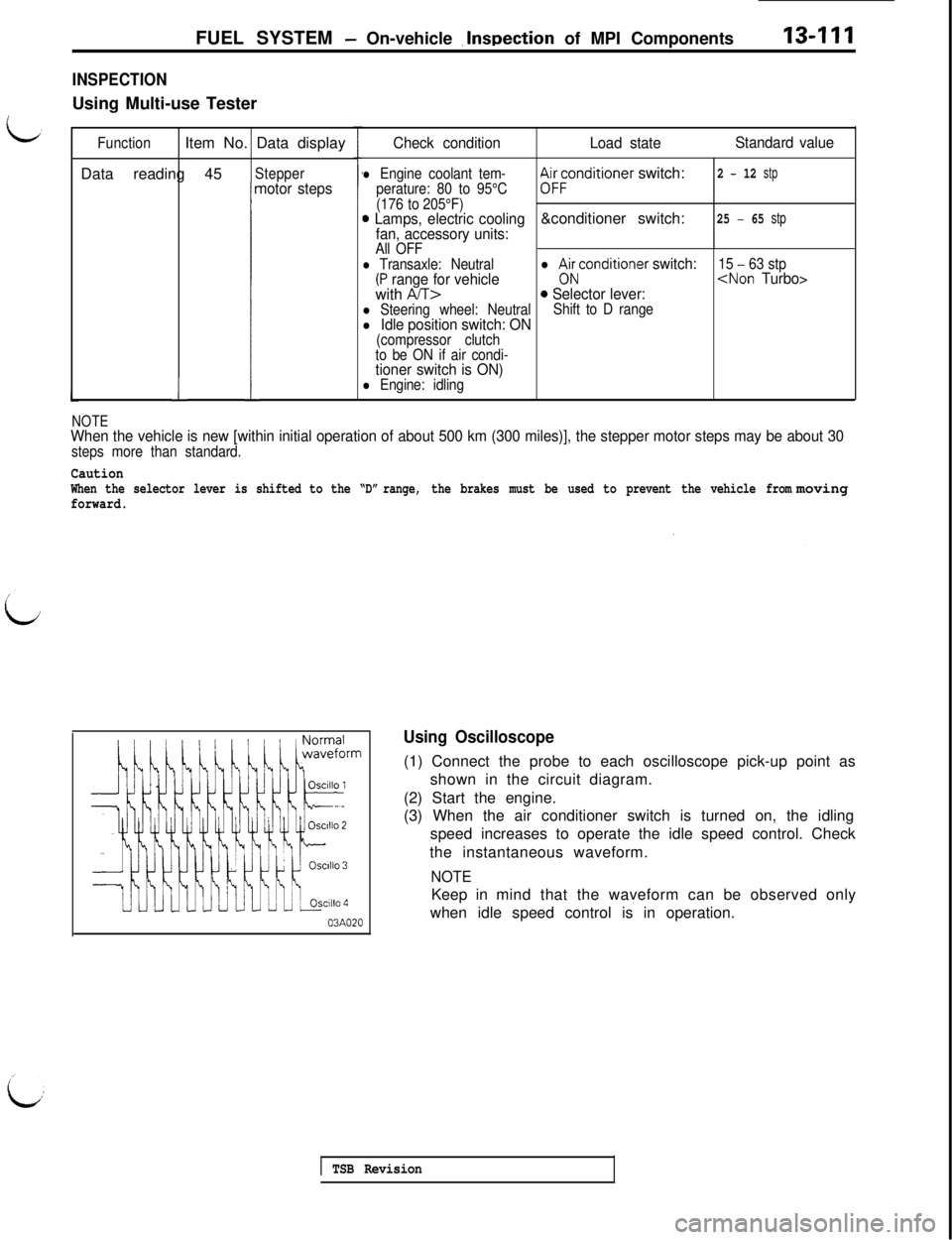

Using Oscilloscope(1) Connect the probe to each oscilloscope pick-up point as

shown in the circuit diagram.

(2) Start the engine.

(3) When the air conditioner switch is turned on, the idling

speed increases to operate the idle speed control. Check

the instantaneous waveform.

NOTEKeep in mind that the waveform can be observed only

when idle speed control is in operation.

1 TSB Revision

Page 222 of 1146

13-116FUEL SYSTEM - 0

n-vehicle Inspection of MPI Components

INSPECTION

Using Multi-use Tester

(d

FunctionItem No. Data displayCheck condition

Engine state

Standard valueData reading 44

Ignitionadvancel Engine: Warming up

750 rpm (Idle)7 - 23”BTDCl Timing light: Set (settiming light to check2,000 rpm30 - 40”BTDC

‘

Function

Data listItem No.Data displayCheckTerminalStandard value

condition

condition

36Continuity present or

not present betweenl Engine:

IdlingIgnition timing ad-ON

ignition timing adjustmentjustment terminal isterminal and groundgrounded

Ignition timing ad-OFFjustment terminal is

disconnected from

ground

Function

Actuator testItem No.

DriveCheck conditionNormal condition

17Set to ignition timingl Engine: idling5”BTDCadjustment model Timing light: set\

($Gizi)

IJ

\LIOV _

ovep~,. ..~_~.~ fA t---.-

I

Normal waveform03AO207

(

j /’ II

IOV _I ’/

/ 1ovIJ

Normal waveform

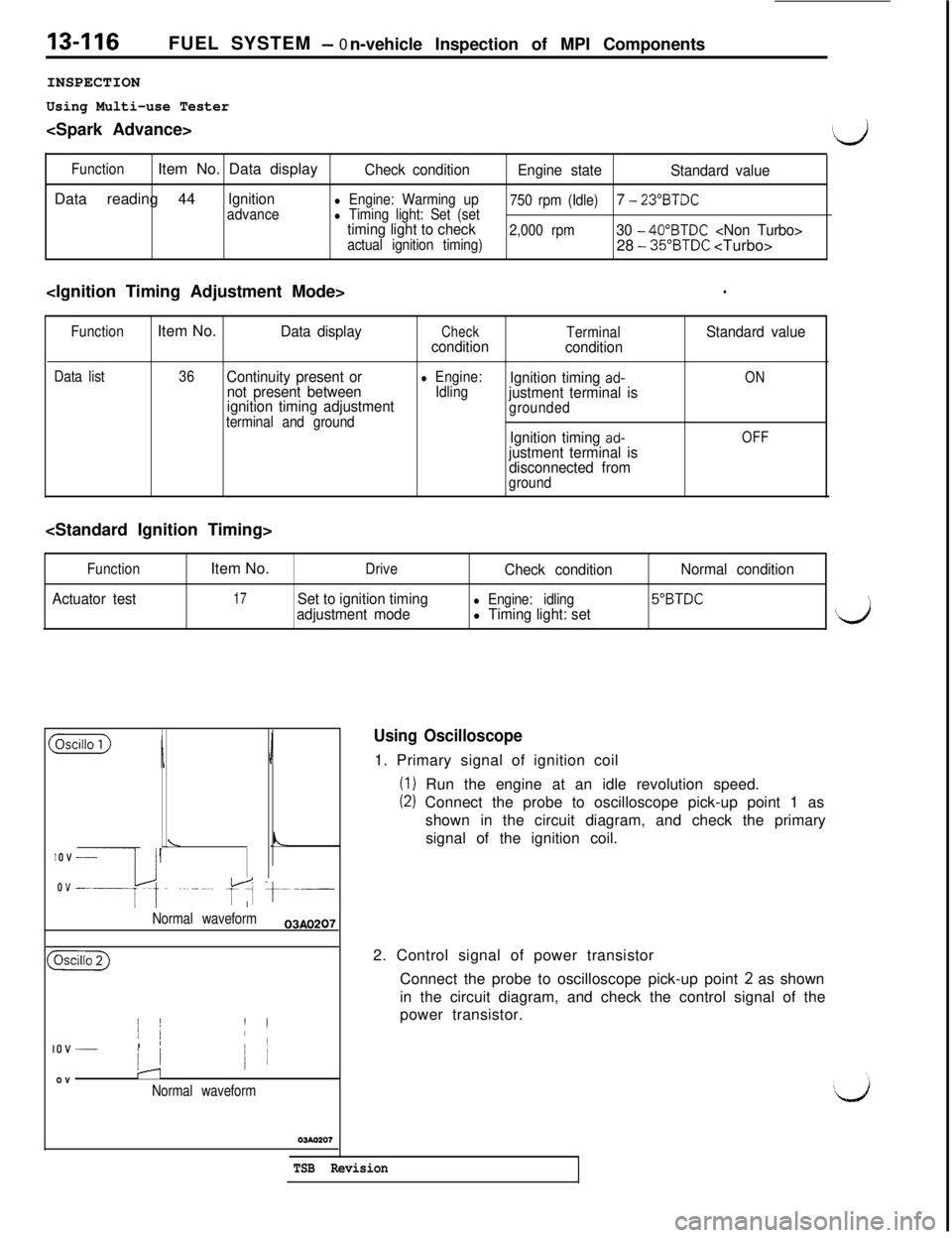

Using Oscilloscope1. Primary signal of ignition coil

(I) Run the engine at an idle revolution speed.

(2) Connect the probe to oscilloscope pick-up point 1 as

shown in the circuit diagram, and check the primary

signal of the ignition coil.

2. Control signal of power transistor

Connect the probe to oscilloscope pick-up point

2 as shown

in the circuit diagram, and check the control signal of the

power transistor.

TSB Revision

Page 227 of 1146

FUEL SYSTEM - On-vehicle lnwection of MPI ComDonents13-121

LEGR CONTROL SOLENOID VALVE

EGR control

solenoid valve@ Equipment side

connector

Engine

control

unitEngine control unit connector

7FUO653

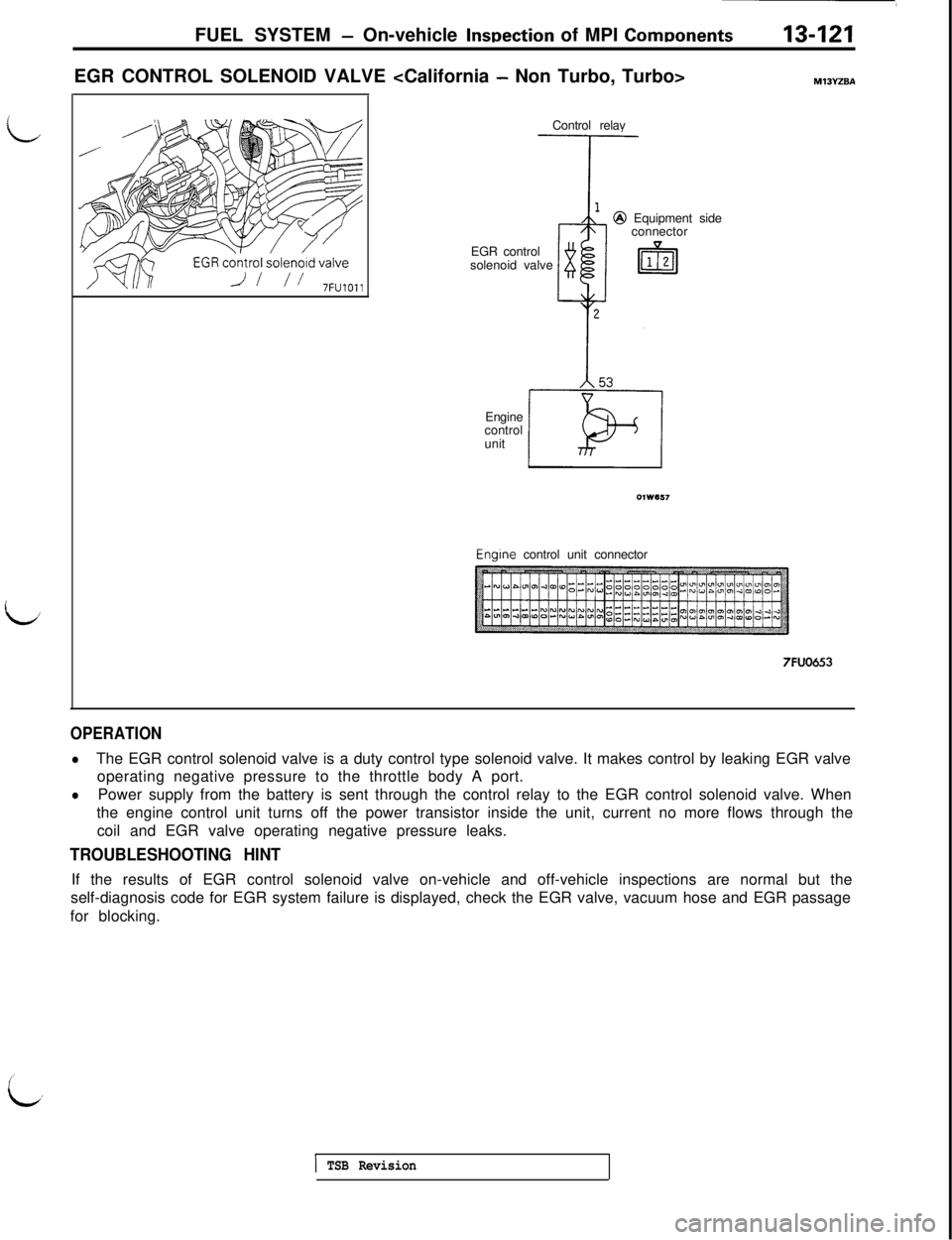

OPERATION

lThe EGR control solenoid valve is a duty control type solenoid valve. It makes control by leaking EGR valve

operating negative pressure to the throttle body A port.

lPower supply from the battery is sent through the control relay to the EGR control solenoid valve. When

the engine control unit turns off the power transistor inside the unit, current no more flows through the

coil and EGR valve operating negative pressure leaks.

TROUBLESHOOTING HINTIf the results of EGR control solenoid valve on-vehicle and off-vehicle inspections are normal but the

self-diagnosis code for EGR system failure is displayed, check the EGR valve, vacuum hose and EGR passage

for blocking.

c.

1 TSB Revision

Page 240 of 1146

13-134FUEL SYSTEM - On-vehicle InsDection of MPI ComDonents

INSPECTIONUsing Multi-use Tester

FunctionItem No. Data displayCheck condition. Driving conditionStandard valueData reading 45

Stepper

Engine warmed up

Apply fairly sharp

To reach tempo-motor stepbraking at 50 km/h

rarily 70 to

(4th speed) to100 stepsstop vehicle

NOTESelect a place where a rear-end collision is unlikely.

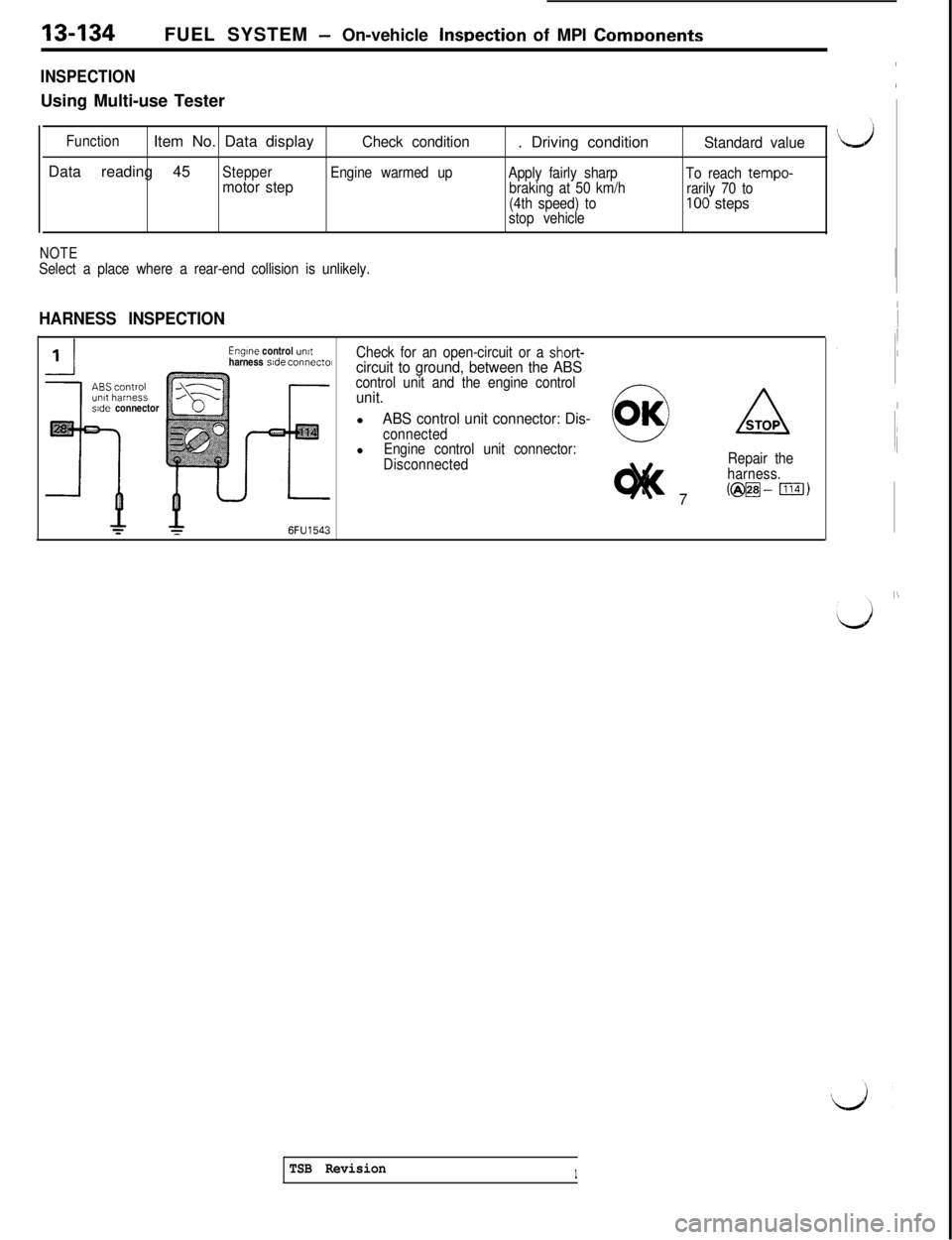

HARNESS INSPECTION

side connector

Engine control umtharness side connecm

6FU1543

Check for an open-circuit or a short-circuit to ground, between the ABScontrol unit and the engine controlunit.l

ABS control unit connector: Dis-connectedlEngine control unit connector:

Disconnected7Repair the

harness.

(@m-ml)

I

I

I

I

IiI

I

~,

I\

TSB Revision1

Page 279 of 1146

CRUISE CONTROL SYSTEM - Troubleshooting

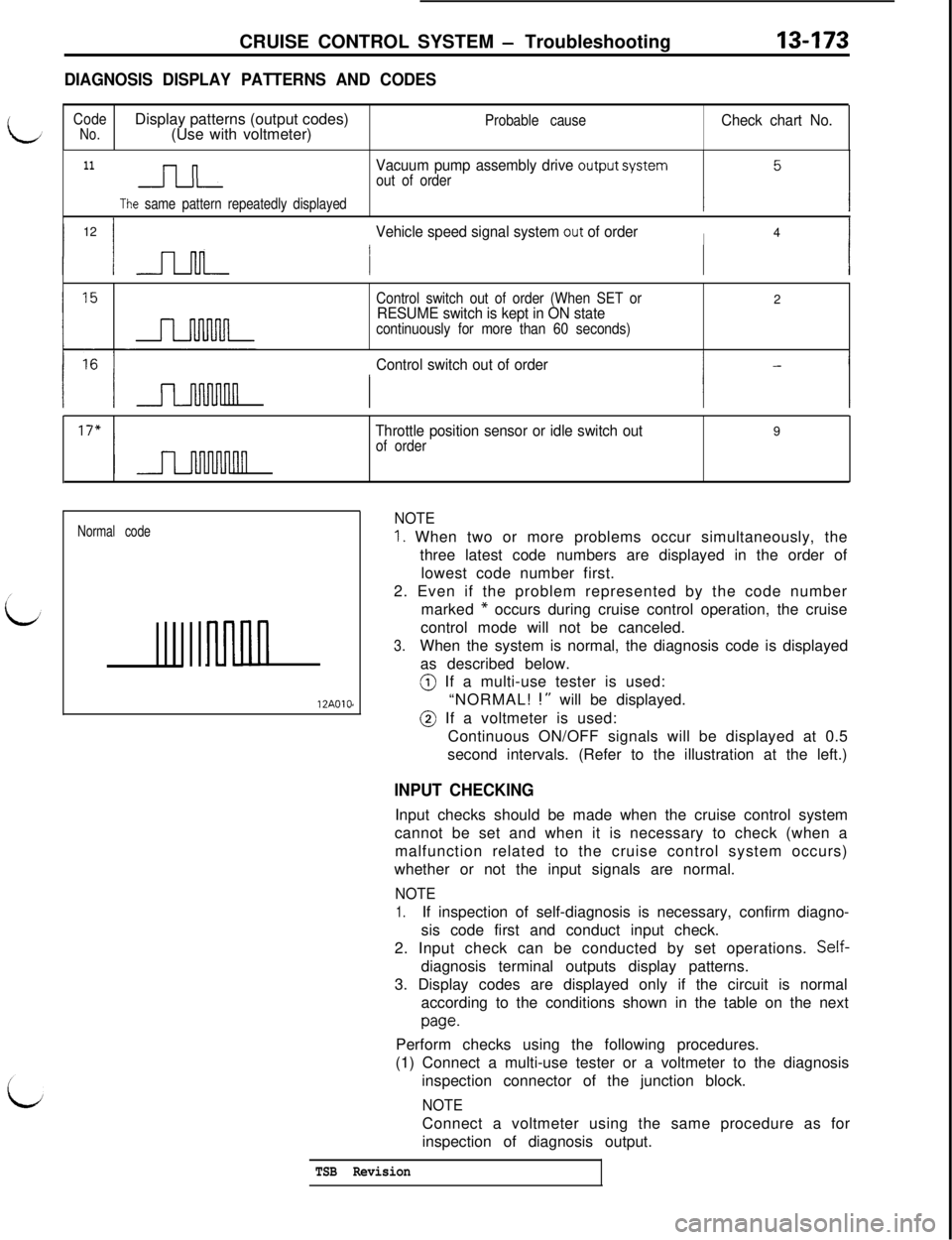

DIAGNOSIS DISPLAY PATTERNS AND CODES

13473

CodeDisplay patterns (output codes)Probable causeCheck chart No.No.(Use with voltmeter)

11l-l n-JILL

The same pattern repeatedly displayed

Vacuum pump assembly drive output systemout of order5

I I12Vehicle speed signal system out of orderI4I

I In

Control switch out of order (When SET or2RESUME switch is kept in ON statecontinuously for more than 60 seconds)

Control switch out of order

Throttle position sensor or idle switch out9

of order

Normal code

12AOlOa

NOTE

1. When two or more problems occur simultaneously, the

three latest code numbers are displayed in the order of

lowest code number first.

2. Even if the problem represented by the code number

marked * occurs during cruise control operation, the cruise

control mode will not be canceled.

3.When the system is normal, the diagnosis code is displayed

as described below.@ If a multi-use tester is used:

“NORMAL!

! I’ will be displayed.@ If a voltmeter is used:

Continuous ON/OFF signals will be displayed at 0.5

second intervals. (Refer to the illustration at the left.)

INPUT CHECKINGInput checks should be made when the cruise control system

cannot be set and when it is necessary to check (when a

malfunction related to the cruise control system occurs)

whether or not the input signals are normal.

NOTE

1.If inspection of self-diagnosis is necessary, confirm diagno-

sis code first and conduct input check.

2. Input check can be conducted by set operations.

Self-diagnosis terminal outputs display patterns.

3. Display codes are displayed only if the circuit is normal

according to the conditions shown in the table on the next

paw.Perform checks using the following procedures.

(1) Connect a multi-use tester or a voltmeter to the diagnosis

inspection connector of the junction block.

NOTEConnect a voltmeter using the same procedure as for

inspection of diagnosis output.

TSB Revision

Page 280 of 1146

13-174CRUISE CONTROL SYSTEM - Troubleshooting

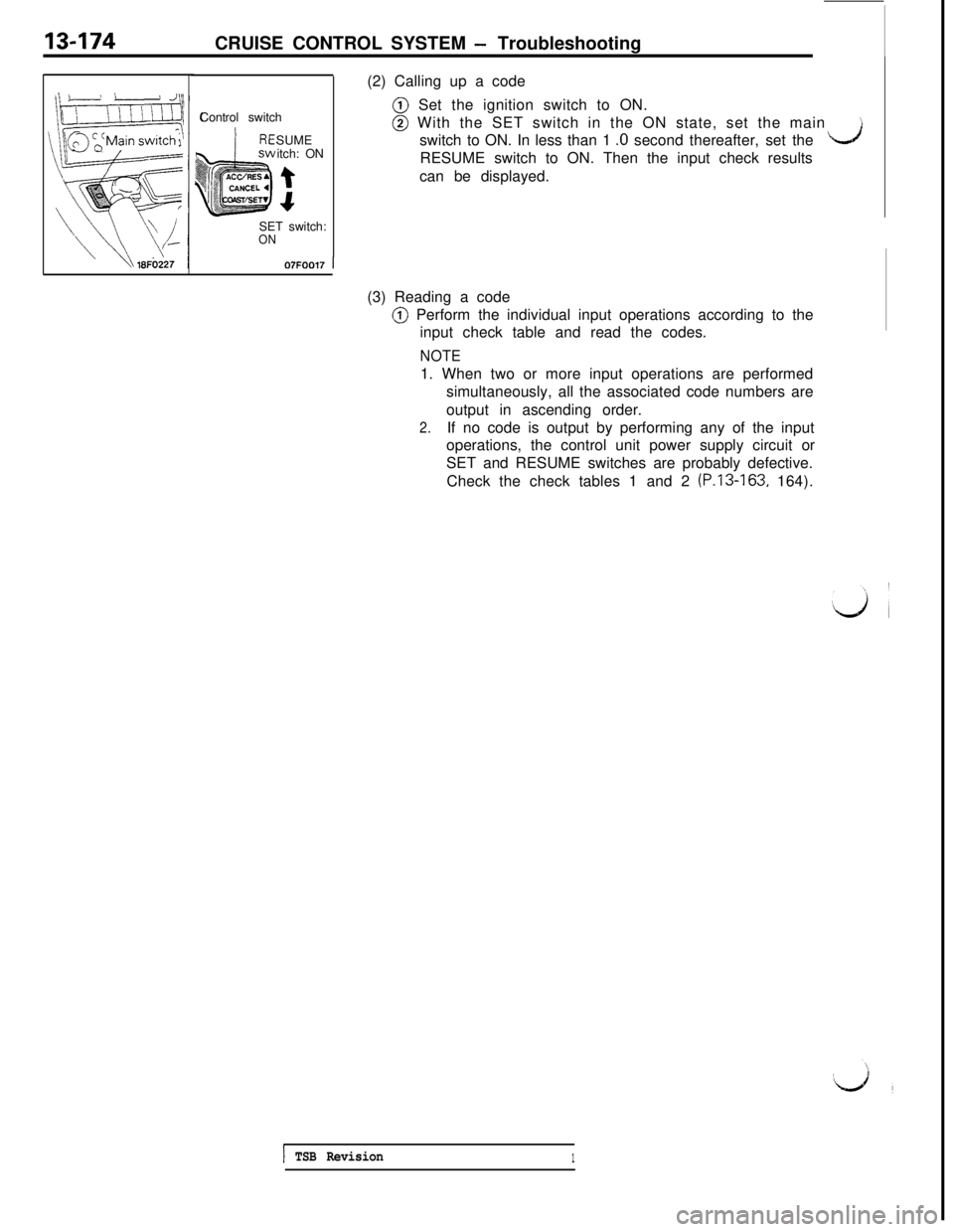

(2) Calling up a code

Control switch

SUME

itch: ON

t

4SET switch:

ON@ Set the ignition switch to ON.@ With the SET switch in the ON state, set the main

switch to ON. In less than 1

.O second thereafter, set theI,/RESUME switch to ON. Then the input check results

can be displayed.

07FOO17 I(3) Reading a code@ Perform the individual input operations according to the

input check table and read the codes.

NOTE1. When two or more input operations are performed

simultaneously, all the associated code numbers are

output in ascending order.

2.If no code is output by performing any of the input

operations, the control unit power supply circuit or

SET and RESUME switches are probably defective.

Check the check tables 1 and 2

(P.13-163, 164).

1 TSB Revision1

Page 281 of 1146

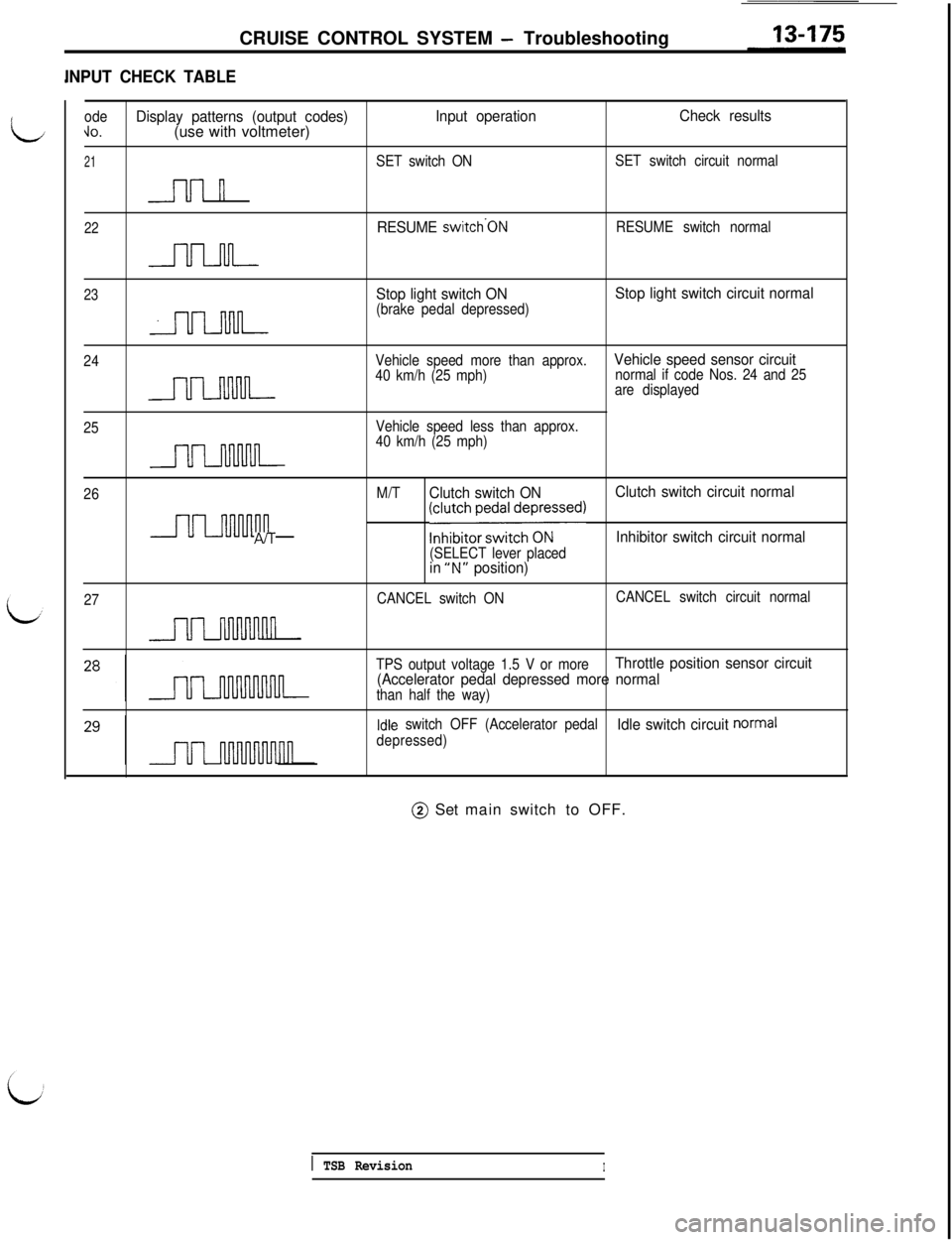

CRUISE CONTROL SYSTEM - Troubleshooting

INPUT CHECK TABLE

odeDisplay patterns (output codes)Input operationCheck results40.(use with voltmeter)

21SET switch ONSET switch circuit normal

n

22RESUME switch.ONRESUME switch normal

23

nn

Stop light switch ON(brake pedal depressed)

Stop light switch circuit normal

24Vehicle speed more than approx.

40 km/h (25 mph)Vehicle speed sensor circuitnormal if code Nos. 24 and 25

are displayed

25Vehicle speed less than approx.

40 km/h (25 mph)

26M/T

Clutch switch ON

-1~ ~~;~~o~~i~~~~;sed’

(SELECT lever placedin “N” position)Clutch switch circuit normal

Inhibitor switch circuit normal

27CANCEL switch ONCANCEL switch circuit normal

TPS output voltage 1.5 V or more

Throttle position sensor circuit

(Accelerator pedal depressed more normal

than half the way)

Idle switch OFF (Accelerator pedalIdle switch circuit normal

depressed)@ Set main switch to OFF.

1 TSB RevisionI

Page 476 of 1146

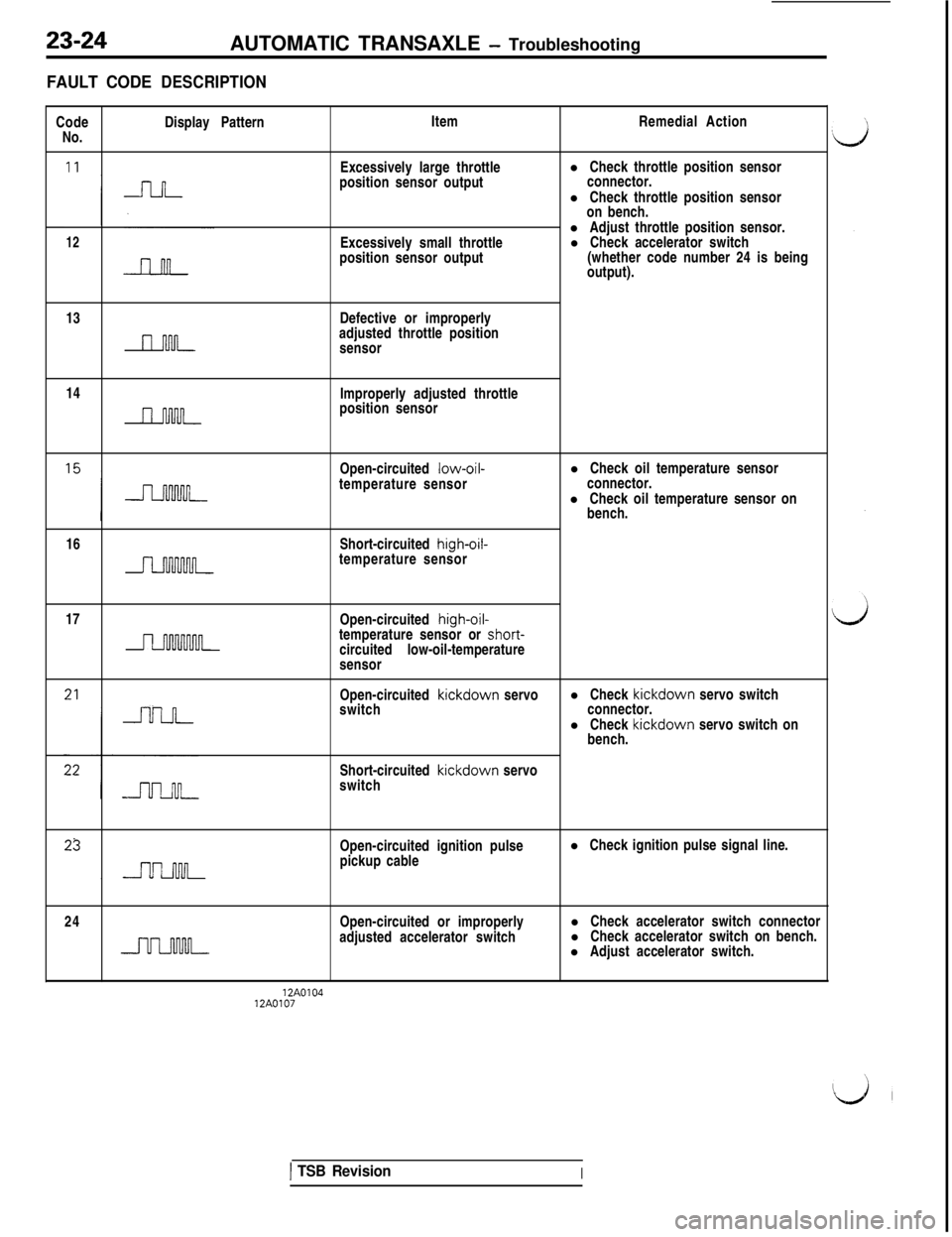

23-24AUTOMATIC TRANSAXLE - Troubleshooting

FAULT CODEDESCRIPTIONCode

No.Display PatternItemRemedial Action

Excessively large throttle

position sensor outputl Check throttle position sensor

connector.

l Check throttle position sensor

on bench.

12Excessively small throttle

position sensor outputl Adjust throttle position sensor.

l Check accelerator switch

(whether code number 24 is being

output).

13Defective or improperly

adjusted throttle position

sensor

14

Improperly adjusted throttle

position sensor

Open-circuited low-oil-

temperature sensorl Check oil temperature sensor

connector.

l Check oil temperature sensor on

bench.

16Short-circuited high-oil-

I-lMnnM-.temperature sensor

17

Open-circuited high-oil-

rlnnnruuvltemperature sensor or short-

circuited low-oil-temperature

sensor

Open-circuited kickdown servo

switch

Short-circuited kickdown servo

switchl Check kickdown servo switch

connector.

l Check kickdown servo switch on

bench.

Open-circuited ignition pulse

pickup cablel Check ignition pulse signal line.

24Open-circuited or improperly

adjusted accelerator switchl Check accelerator switch connector

l Check accelerator switch on bench.

l Adjust accelerator switch.

12A010412A0107

1 TSB RevisionI

Page 477 of 1146

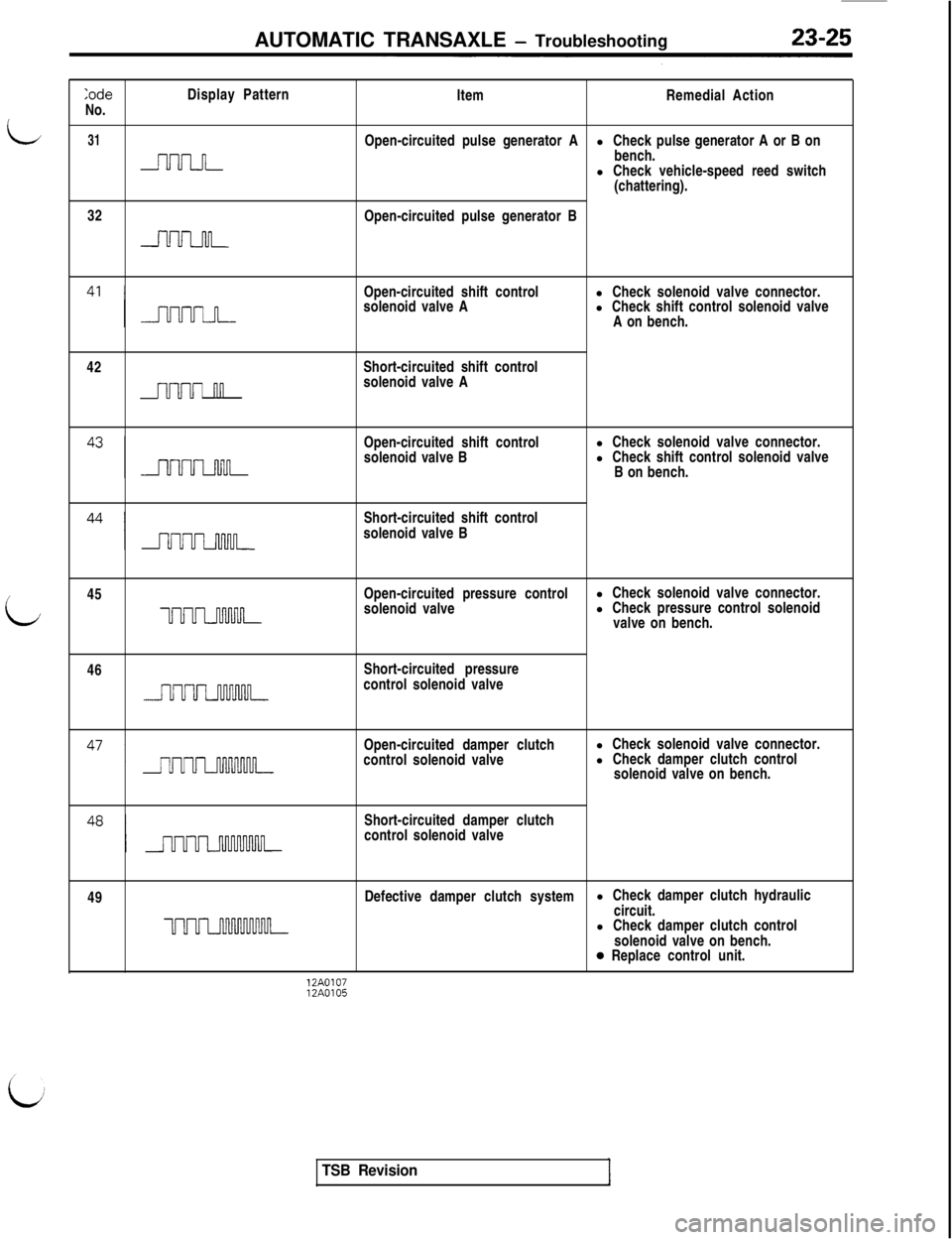

AUTOMATIC TRANSAXLE - Troubleshooting23-25

L

L

ZodeNo.

31Display Pattern

ItemRemedial Action

Open-circuited pulse generator Al Check pulse generator A or B on

bench.

32l Check vehicle-speed reed switch

(chattering).

Open-circuited pulse generator B

Open-circuited shift control

solenoid valve Al Check solenoid valve connector.

l Check shift control solenoid valve

A on bench.

42Short-circuited shift control

solenoid valve A

Open-circuited shift control

solenoid valve Bl Check solenoid valve connector.

l Check shift control solenoid valve

B on bench.

Short-circuited shift control

solenoid valve B

45

uuuLNulM-Open-circuited pressure controll Check solenoid valve connector.

solenoid valvel Check pressure control solenoid

valve on bench.

46Short-circuited pressure

control solenoid valve

Open-circuited damper clutch

control solenoid valvel Check solenoid valve connector.

l Check damper clutch control

solenoid valve on bench.

Short-circuited damper clutch

control solenoid valve

49Defective damper clutch systeml Check damper clutch hydraulic

circuit.

lllJl!-l Check damper clutch control

solenoid valve on bench.0 Replace control unit.

12A010712A0105

TSB Revision

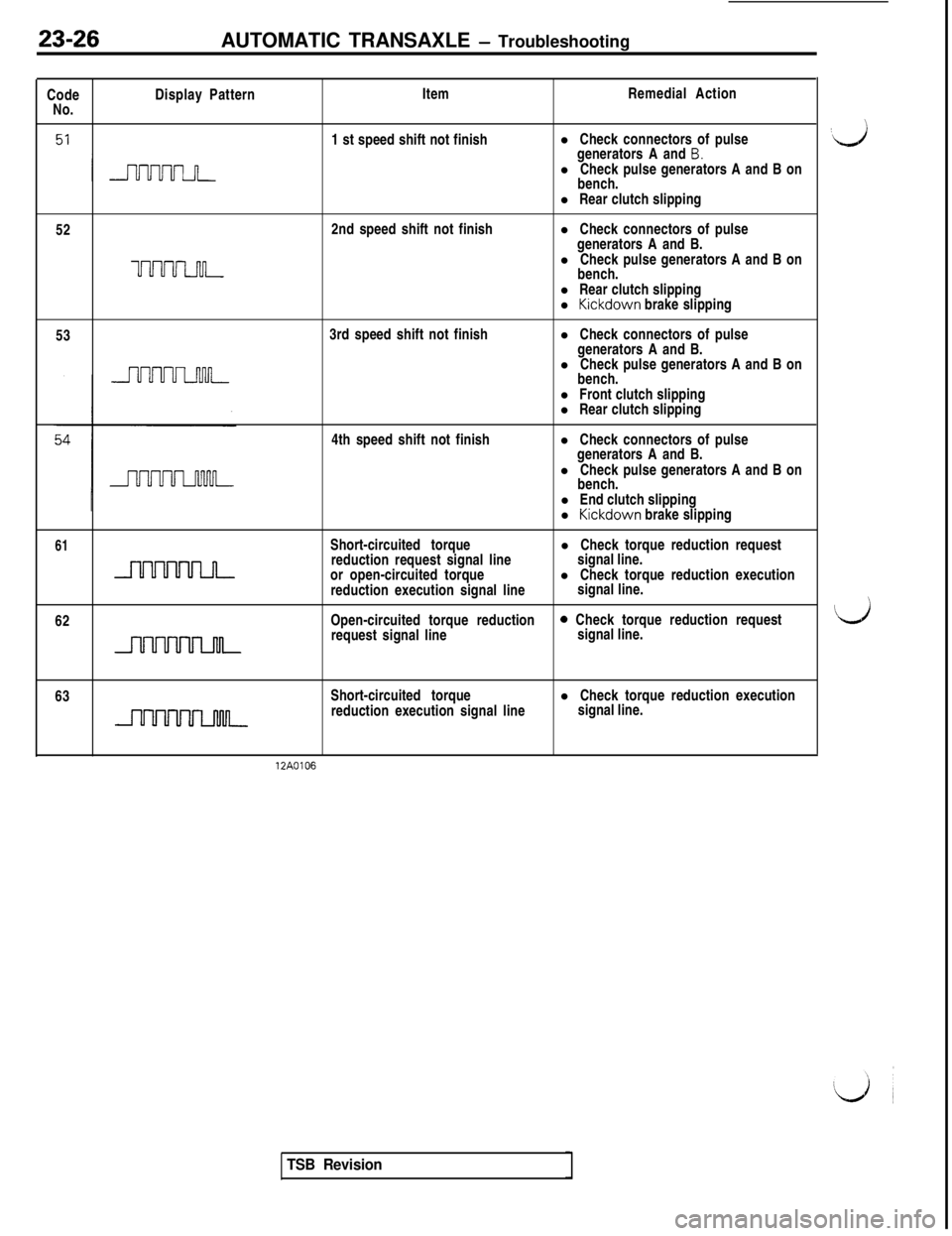

Page 478 of 1146

23-26AUTOMATIC TRANSAXLE - Troubleshooting

Code

No.Display PatternItemRemedial Action

1 st speed shift not finishl Check connectors of pulse

generators A and

B.l Check pulse generators A and B on

bench.

l Rear clutch slipping

52

uuuuu-ln-2nd speed shift not finishl Check connectors of pulse

generators A and B.

l Check pulse generators A and B on

bench.

l Rear clutch slipping

533rd speed shift not finishl Kickdown brake slipping

l Check connectors of pulse

generators A and B.

4th speed shift not finishl Check pulse generators A and B on

bench.

l Front clutch slipping

l Rear clutch slipping

l Check connectors of pulse

generators A and B.

l Check pulse generators A and B on

bench.

l End clutch slipping

6162l Kickdown brake slipping

Short-circuited torque

reduction request signal linel Check torque reduction request

or open-circuited torquesignal line.

reduction execution signal linel Check torque reduction execution

signal line.

Open-circuited torque reduction

request signal line0 Check torque reduction request

signal line.

63Short-circuited torque

reduction execution signal linel Check torque reduction execution

signal line.

12A0106

‘J

\J

TSB Revision