power steering MITSUBISHI 3000GT 1991 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 830 of 1146

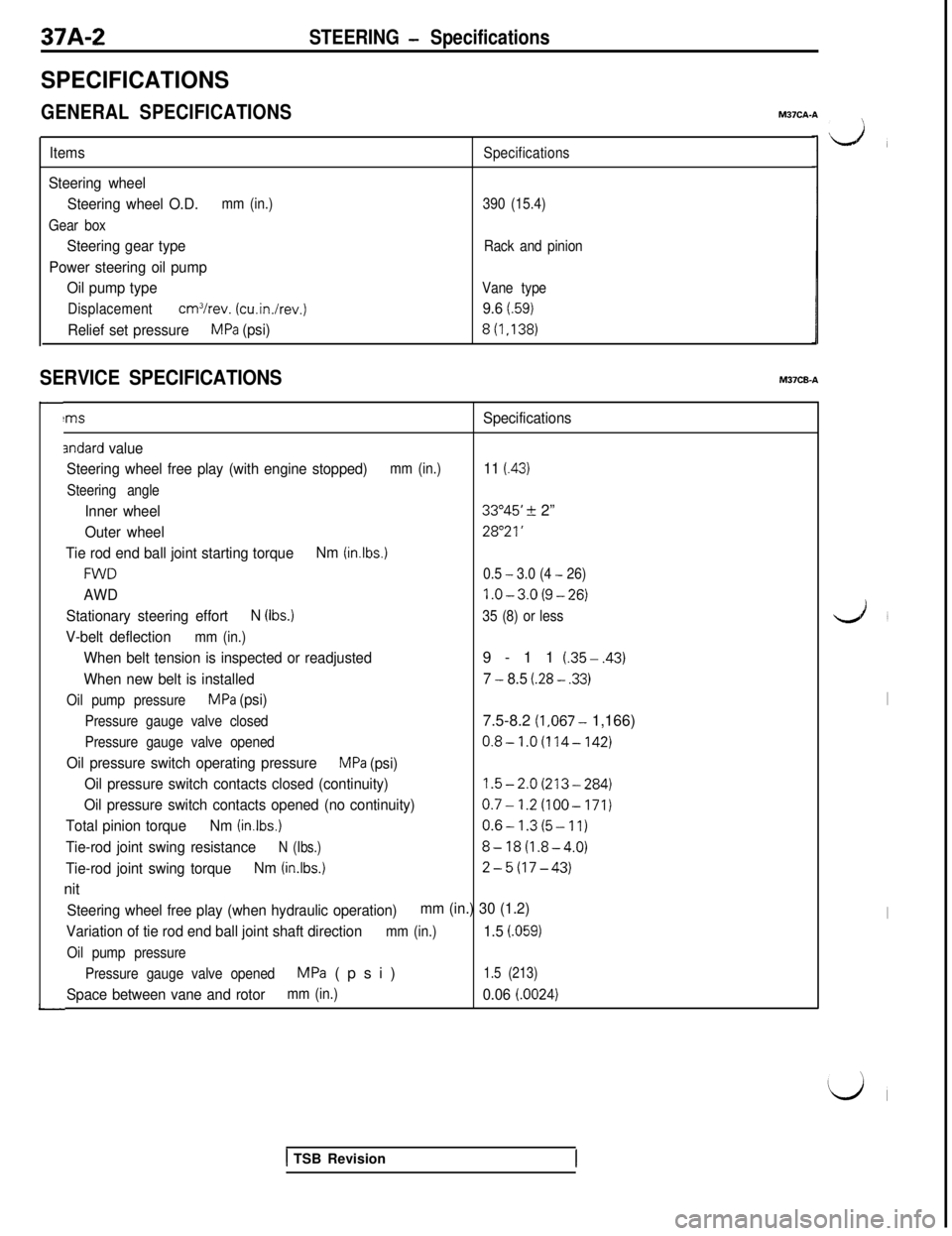

37A-2SPECIFICATIONS

STEERING - Specifications

GENERAL SPECIFICATIONS

M37CA-A

LA,Items

Steering wheel

Steering wheel O.D.

mm (in.)

Gear box

Steering gear type

Power steering oil pump

Oil pump type

Displacementcm3/rev. (cu.in./rev.)

Relief set pressureMPa (psi)

Specifications

390 (15.4)

Rack and pinion

Vane type

9.6 t.59)

8(1,138)

SERVICE SPECIFICATIONSM37CB-A

!msSpecifications

andard value

Steering wheel free play (with engine stopped)

mm (in.)11 (43)

Steering angle

Inner wheel33”45’ 2 2”

Outer wheel28”21’

Tie rod end ball joint starting torqueNm (in.lbs.)

FWD0.5 - 3.0 (4 - 26)

AWDl.O-3.0(9-26)

Stationary steering effortN (Ibs.)35 (8) or less

V-belt deflectionmm (in.)

When belt tension is inspected or readjusted9-11 (.35-.43)

When new belt is installed7 - 8.5 (.28 - .33)

Oil pump pressureMPa (psi)

Pressure gauge valve closed7.5-8.2 (1,067- 1,166)

Pressure gauge valve opened0.8-1.0(114-142)

Oil pressure switch operating pressureMPa (psi)

Oil pressure switch contacts closed (continuity)

1.5-2.0(213-284)

Oil pressure switch contacts opened (no continuity)0.7-1.2(100-171)

Total pinion torqueNm (in.lbs.)0.6-1.3(5-11)

Tie-rod joint swing resistanceN (Ibs.)8-18(1.8-4.0)

Tie-rod joint swing torqueNm (in.lbs.)2-5(17-43)nit

Steering wheel free play (when hydraulic operation)mm (in.) 30 (1.2)

Variation of tie rod end ball joint shaft direction

mm (in.)1.5 i.059)

Oil pump pressure

Pressure gauge valve opened

MPa (psi)1.5 (213)

Space between vane and rotormm (in.)0.06 (0024)

LJ’

I

I

L’l

1 TSB Revision

Page 831 of 1146

STEERING -Specifications / Special Tools37A-3

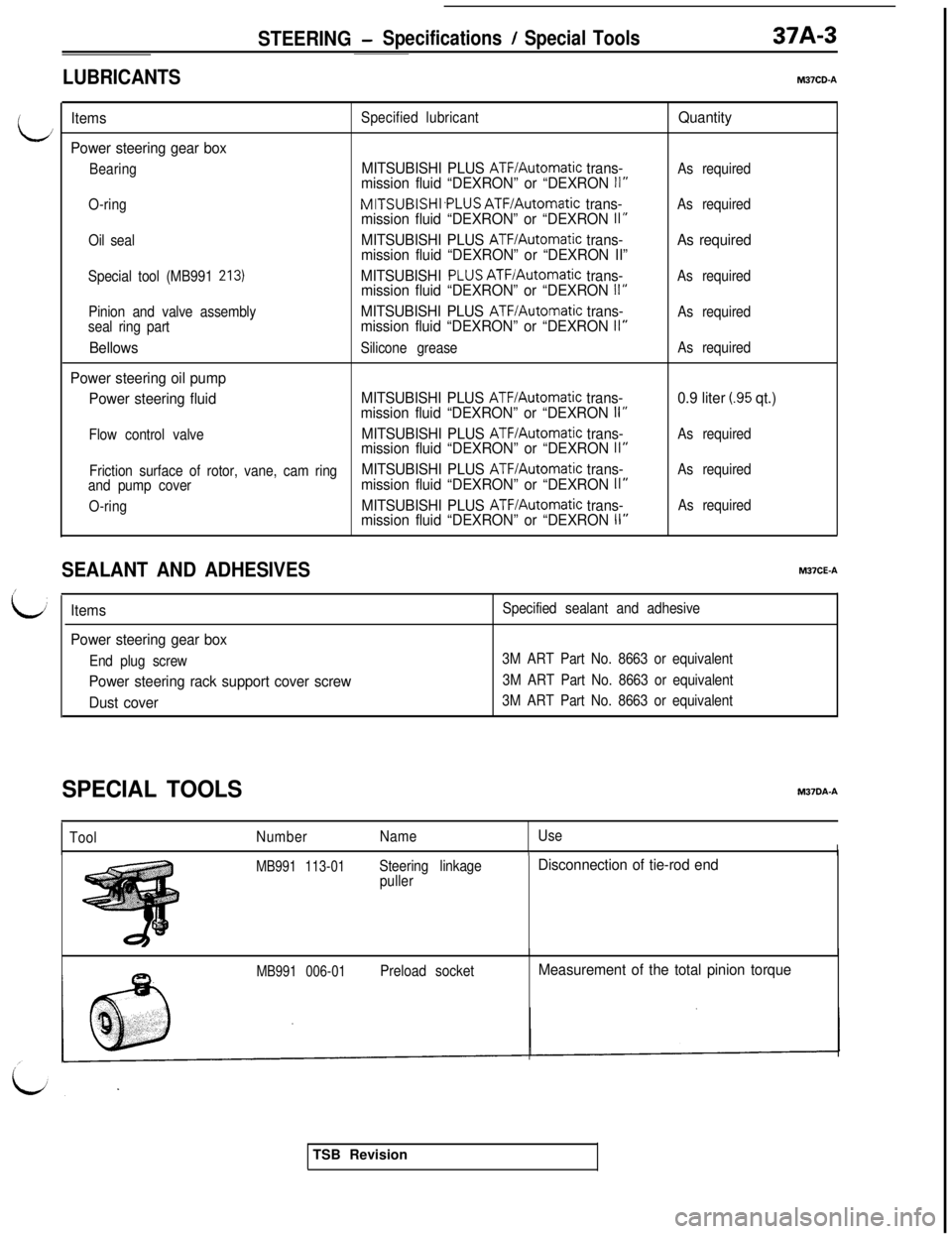

LUBRICANTSM37CD-A

L

/

b

ItemsSpecified lubricantQuantity

Power steering gear box

BearingMITSUBISHI PLUS ATF/Automatic trans-As requiredmission fluid “DEXRON” or “DEXRON II”

O-ringMlTSUBlSHl.PLUS ATF/Automatic trans-As requiredmission fluid “DEXRON” or “DEXRON II”

Oil sealMITSUBISHI PLUS ATF/Automatic trans-As required

mission fluid “DEXRON” or “DEXRON II”

Special tool (MB991 213)MITSUBISHI PLUSATFIAutomatic trans-As requiredmission fluid “DEXRON” or “DEXRON II”

Pinion and valve assemblyMITSUBISHI PLUS ATF/Automatic trans-As required

seal ring partmission fluid “DEXRON” or “DEXRON II”

BellowsSilicone greaseAs required

Power steering oil pump

Power steering fluidMITSUBISHI PLUS

ATF/Automatic trans-0.9 liter (.95 qt.)

mission fluid “DEXRON” or “DEXRON II”

Flow control valveMITSUBISHI PLUS ATF/Automatic trans-As requiredmission fluid “DEXRON” or “DEXRON II”

Friction surface of rotor, vane, cam ringMITSUBISHI PLUS ATF/Automatic trans-As required

and pump covermission fluid “DEXRON” or “DEXRON II”

O-ringMITSUBISHI PLUS ATF/Automatic trans-As requiredmission fluid “DEXRON” or “DEXRON II”

SEALANT AND ADHESIVESM37CE-A

Items

Power steering gear box

End plug screw

Power steering rack support cover screw

Dust cover

Specified sealant and adhesive

3M ART Part No. 8663 or equivalent

3M ART Part No. 8663 or equivalent

3M ART Part No. 8663 or equivalent

SPECIAL TOOLSM37DA.A

ToolNumberNameUseII

MB991 113-01Steering linkage

pullerDisconnection of tie-rod end

MB991 006-01Preload socketMeasurement of the total pinion torqueTSB Revision

Page 832 of 1146

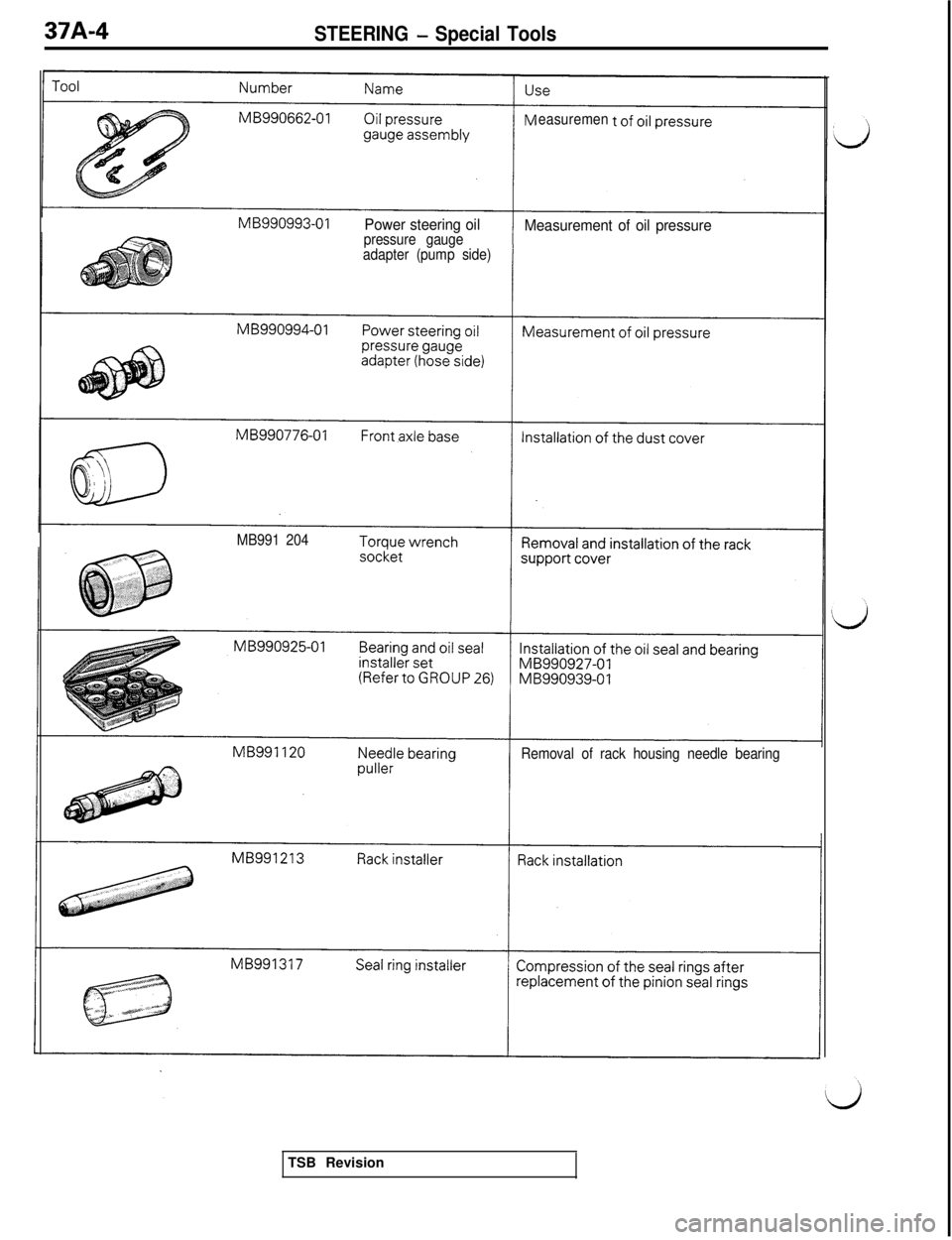

37A-4STEERING - Special Tools

easuremen

MB990993-01Power steering oilpressure gauge

adapter (pump side)Measurement of oil pressure

MB991 204

Removal of rack housing needle bearingTSB Revision

Page 845 of 1146

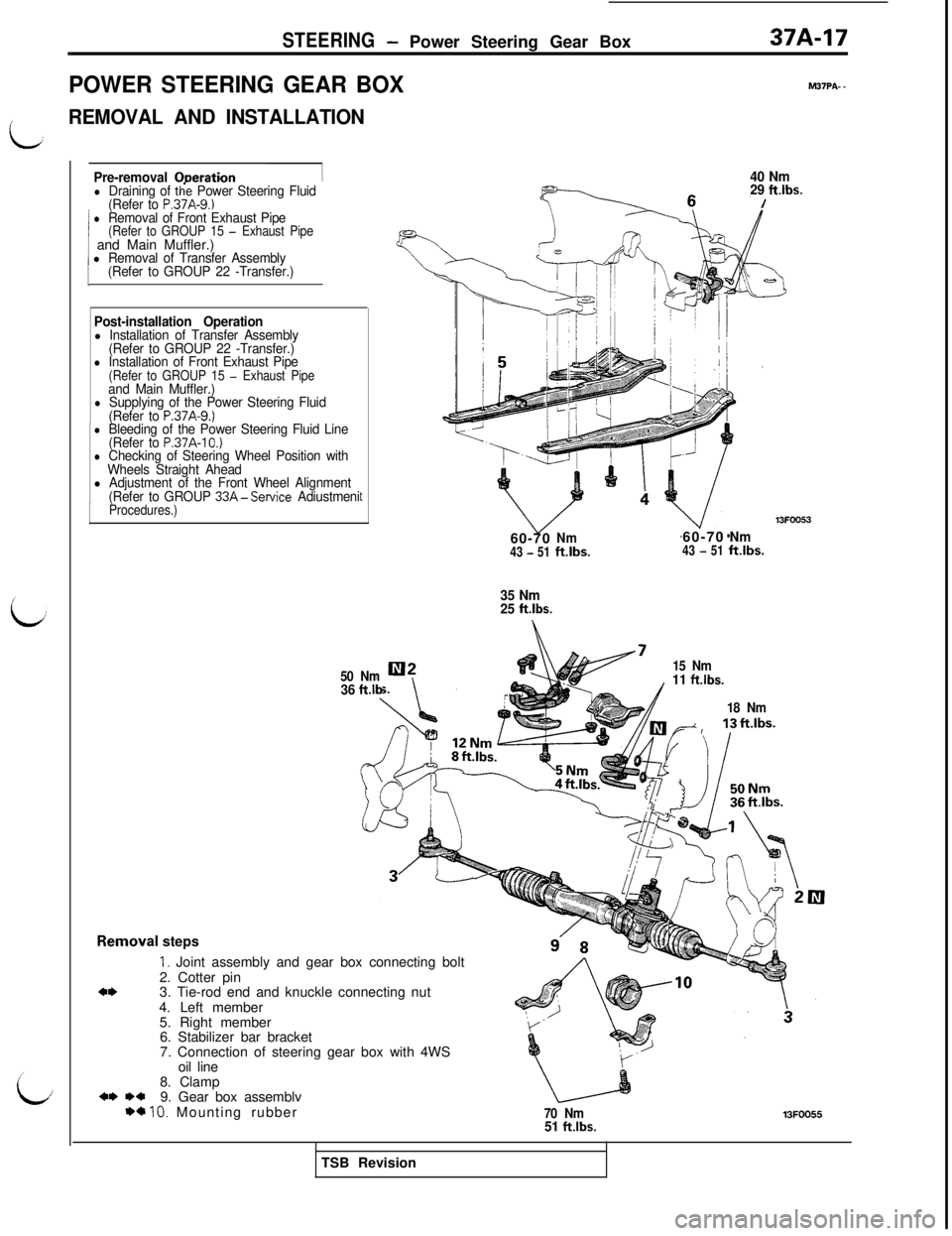

STEERING- Power Steering Gear Box

POWER STEERING GEAR BOX

/REMOVAL AND INSTALLATION37A-17

M37PA- -

i

i/

Pre-removal ODerationl Draining of the Power Steering Fluid

(Refer to P.37A-9.)l Removal of Front Exhaust Pipe(Refer to GROUP 15 - Exhaust Pipe1 and Main Muffler.)1l Removal of Transfer Assembly

(Refer to GROUP 22 -Transfer.)

Post-installation Operationl Installation of Transfer Assembly

(Refer to GROUP 22 -Transfer.)

l Installation of Front Exhaust Pipe(Refer to GROUP 15 - Exhaust Pipeand Main Muffler.)l Supplying of the Power Steering Fluid

(Refer to P.37A-9.)l Bleeding of the Power Steering Fluid Line

(Refer to P.37A-IO.)l Checking of Steering Wheel Position with

Wheels Straight Ahead

l Adjustment of the Front Wheel Alignment

(Refer to GROUP 33A-Service AdiustmeniProcedures.)Removt

50 Nm

c40 Nm

29 ftlbs.

/60-70

Nm43 - 51ft.lbs.60-70Nm43 - 51ft.lbs.

36

ft.lb

35 Nm

25 ft.lbs.

15 Nm

11 ftlbs.

18 Nm

lal steps

1. Joint assembly and gear box connecting bolt

2. Cotter pin

3. Tie-rod end and knuckle connecting nut

4. Left member

5. Right member

6. Stabilizer bar bracket

7. Connection of steering gear box with 4WS

oil line

8. Clamp

9. Gear box assemblv

*a 10. Mounting rubber70 Nm51 ftlbs.13FOOE.5TSB Revision

Page 846 of 1146

37A-18

STEERING - Power Steering Gear Box

MB991 006-01\l\

13R017

8 Mounting clamp13R0077

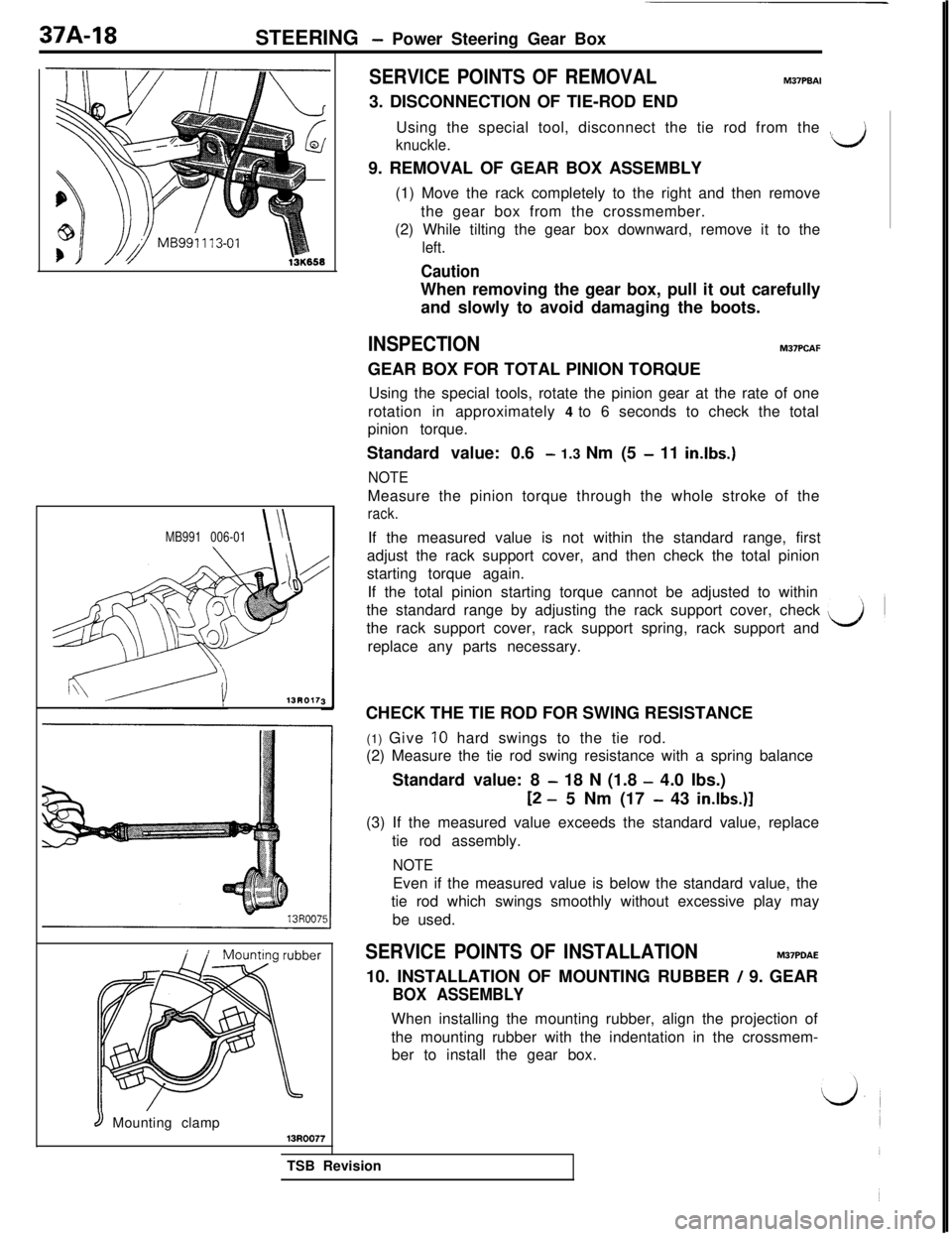

SERVICE POINTS OF REMOVALM37PBAI3. DISCONNECTION OF TIE-ROD END

Using the special tool, disconnect the tie rod from the

,,

knuckle.LJ9. REMOVAL OF GEAR BOX ASSEMBLY

(1) Move the rack completely to the right and then remove

the gear box from the crossmember.

(2) While tilting the gear box downward, remove it to the

left.

CautionWhen removing the gear box, pull it out carefully

and slowly to avoid damaging the boots.

INSPECTIONM37PCAFGEAR BOX FOR TOTAL PINION TORQUE

Using the special tools, rotate the pinion gear at the rate of one

rotation in approximately 4 to 6 seconds to check the total

pinion torque.

Standard value: 0.6

- 1.3 Nm (5 - 11 in.lbs.)

NOTEMeasure the pinion torque through the whole stroke of the

rack.If the measured value is not within the standard range, first

adjust the rack support cover, and then check the total pinion

starting torque again.

If the total pinion starting torque cannot be adjusted to within

the standard range by adjusting the rack support cover, check

the rack support cover, rack support spring, rack support and

replace any parts necessary.

CHECK THE TIE ROD FOR SWING RESISTANCE

(1) Give

10 hard swings to the tie rod.

(2) Measure the tie rod swing resistance with a spring balance

Standard value: 8

- 18 N (1.8 - 4.0 Ibs.)

[2 - 5 Nm (17 - 43 in.lbs.)](3) If the measured value exceeds the standard value, replace

tie rod assembly.

NOTEEven if the measured value is below the standard value, the

tie rod which swings smoothly without excessive play may

be used.

SERVICE POINTS OF INSTALLATIONM37PDAE10. INSTALLATION OF MOUNTING RUBBER

/ 9. GEAR

BOX ASSEMBLYWhen installing the mounting rubber, align the projection of

the mounting rubber with the indentation in the crossmem-

ber to install the gear box.

TSB Revision

Page 847 of 1146

STEERING - Power Steering Gear Box37A-19

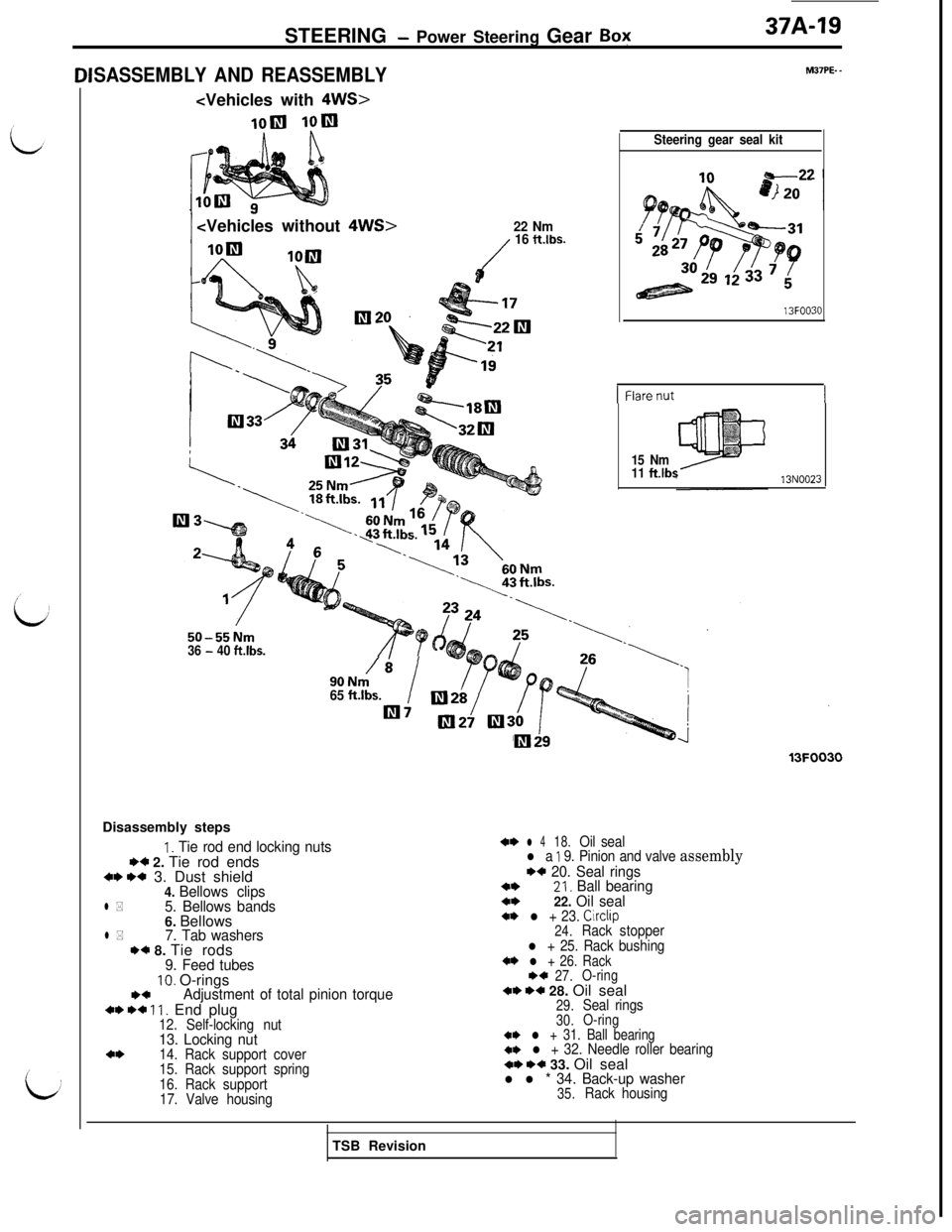

SASSEMBLY AND REASSEMBLY

1olIl IOlill

22 Nm

/

16 ft.lbs.

50-55Nm36 - 40 ft.lbs.

90 Nm’65 ftlbs.i07Disassembly steps

I. Tie rod end locking nuts+4 2. Tie rod ends+W I)+ 3. Dust shield4. Bellows clipsl *5. Bellows bands6. Bellows

l *7. Tab washers+4 8. Tie rods9. Feed tubes10. O-rings+4Adjustment of total pinion torque

Cc* *a II. End plug12. Self-locking nut13. Locking nutcc*14. Rack support cover

15. Rack support spring

16. Rack support

17. Valve housingSteering gear seal kit

13FOO3l

M37PE..

1 Flarenut

15 Nm

11 ft.lbs13NOO23

la29

4*l 418.Oil seall a I 9. Pinion and valve assembly

I)* 20. Seal rings4*21. Ball bearing4*22. Oil seal*I) l + 23. Circlip24.Rack stopperl + 25. Rack bushing+e l + 26. RackI)+27.O-ring4I) I)4 28. Oil seal29.Seal rings30.O-ring*I) l + 31. Ball bearing** l + 32. Needle roller bearing4* *4 33. Oil seall l * 34. Back-up washer35.Rack housingTSB Revision

Page 848 of 1146

37A-20

STEERING - Power Steering Gear Box

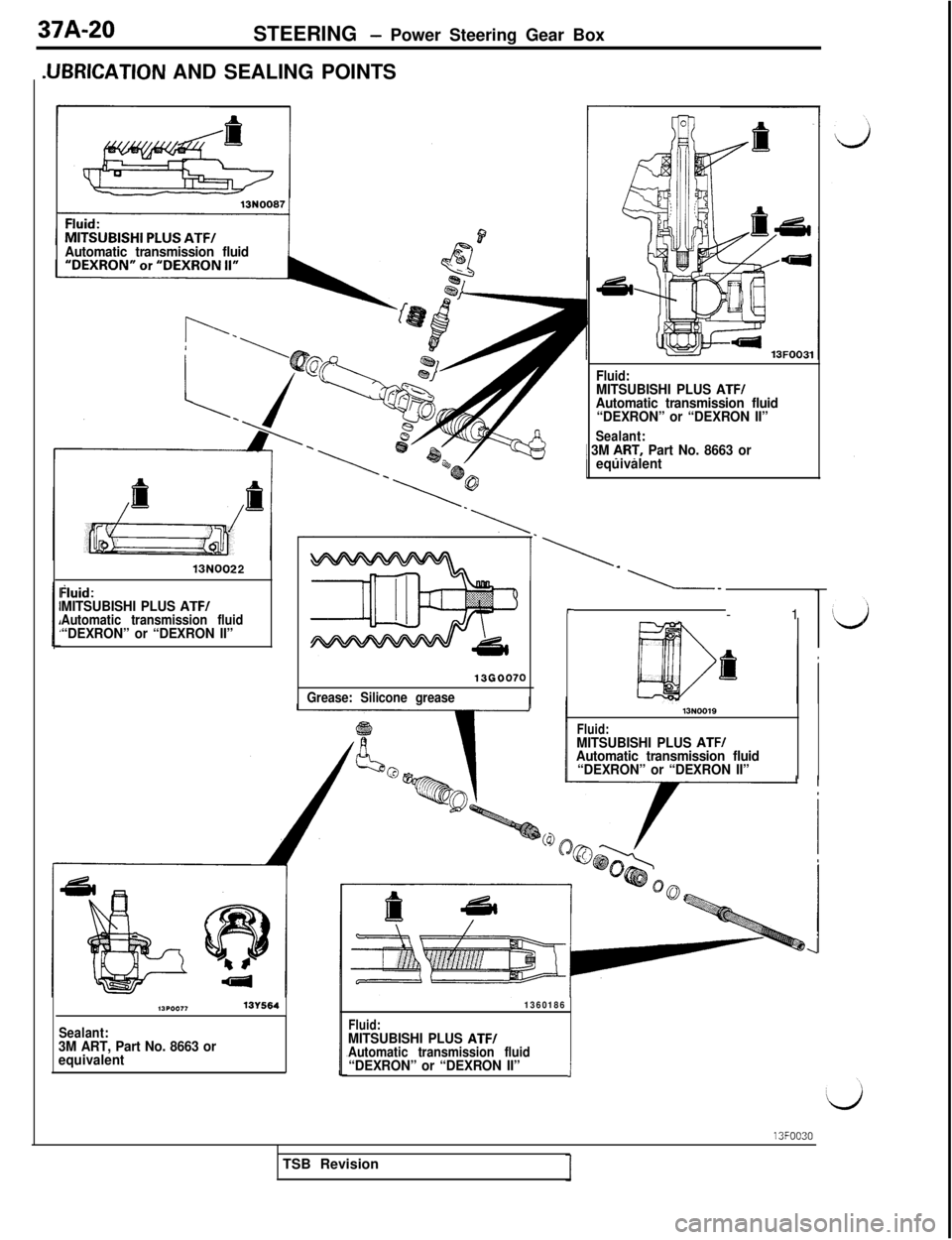

.UBRICATION AND SEALING POINTS

Automatic transmission fluid

13N0022

hid:MITSUBISHI PLUS ATF/Automatic transmission fluid“DEXRON” or “DEXRON II”

13G0070

Grease: Silicone greaseFluid:

MITSUBISHI PLUS ATF/Automatic transmission fluid

“DEXRON” or “DEXRON II”

Sealant:1 3M ART, Part No. 8663 or

equivalent.

L--1

I-

13N0019

Fluid:MITSUBISHI PLUS ATF/Automatic transmission fluid

“DEXRON” or “DEXRON II”

l.?POO,,13Y564

Sealant:3M ART, Part No. 8663 or

equivalent

1360186

Fluid:MITSUBISHI PLUS ATF/

Automatic transmission fluid

“DEXRON” or “DEXRON II”i13FOO30

TSB Revision

Page 849 of 1146

STEERING - Power Steering Gear Box37A-21 ~'13K588

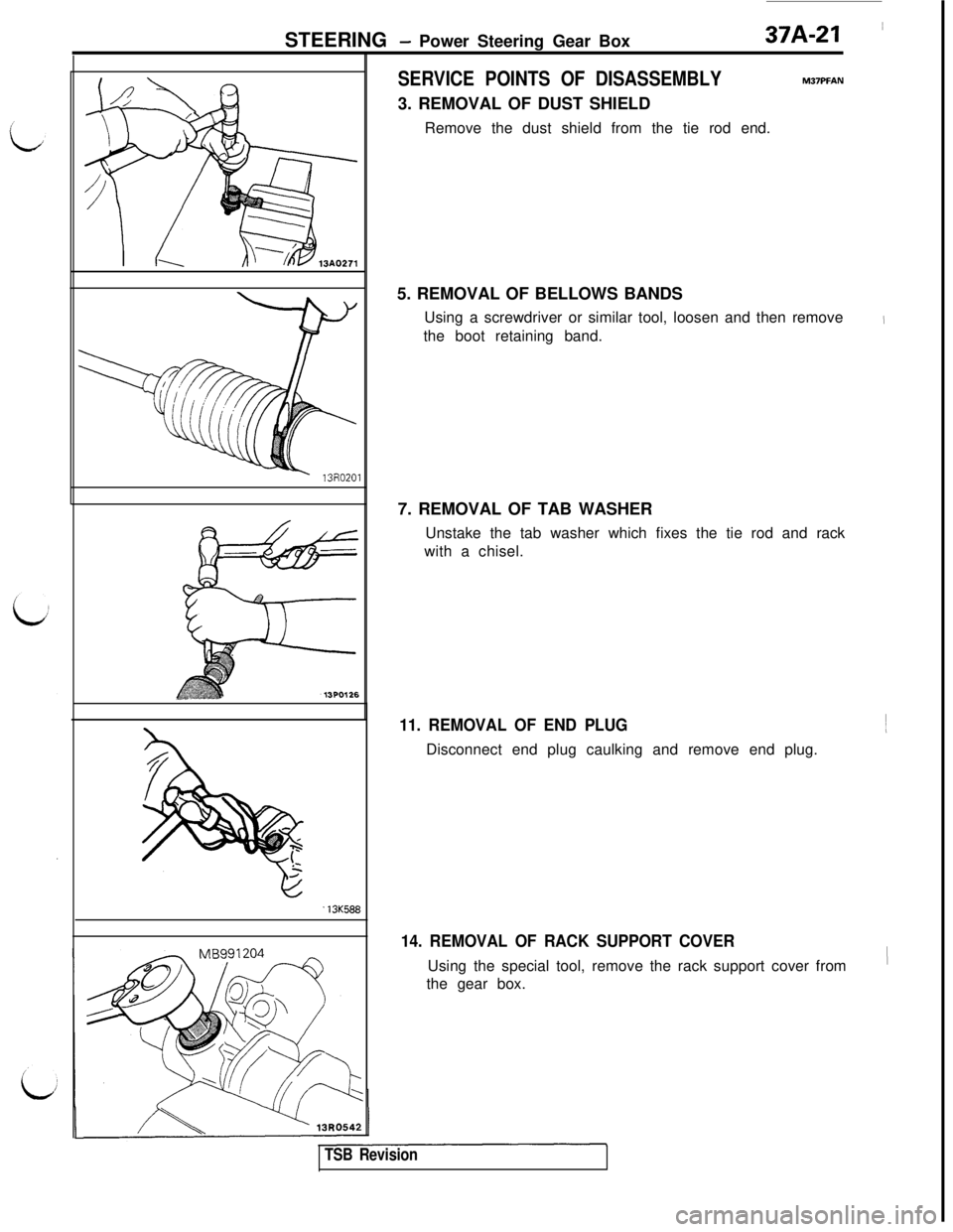

SERVICE POINTS OF DISASSEMBLYM37PFAN3. REMOVAL OF DUST SHIELD

Remove the dust shield from the tie rod end.

5. REMOVAL OF BELLOWS BANDS

Using a screwdriver or similar tool, loosen and then remove

Ithe boot retaining band.

7. REMOVAL OF TAB WASHER

Unstake the tab washer which fixes the tie rod and rack

with a chisel.

11. REMOVAL OF END PLUGDisconnect end plug caulking and remove end plug.

14. REMOVAL OF RACK SUPPORT COVERUsing the special tool, remove the rack support cover from

Ithe gear box.

TSB Revision

Page 850 of 1146

37A-22

STEERING - Power Steering Gear Box13A0284

Socket

13A0285

\kdY13R0541

Rack stopper

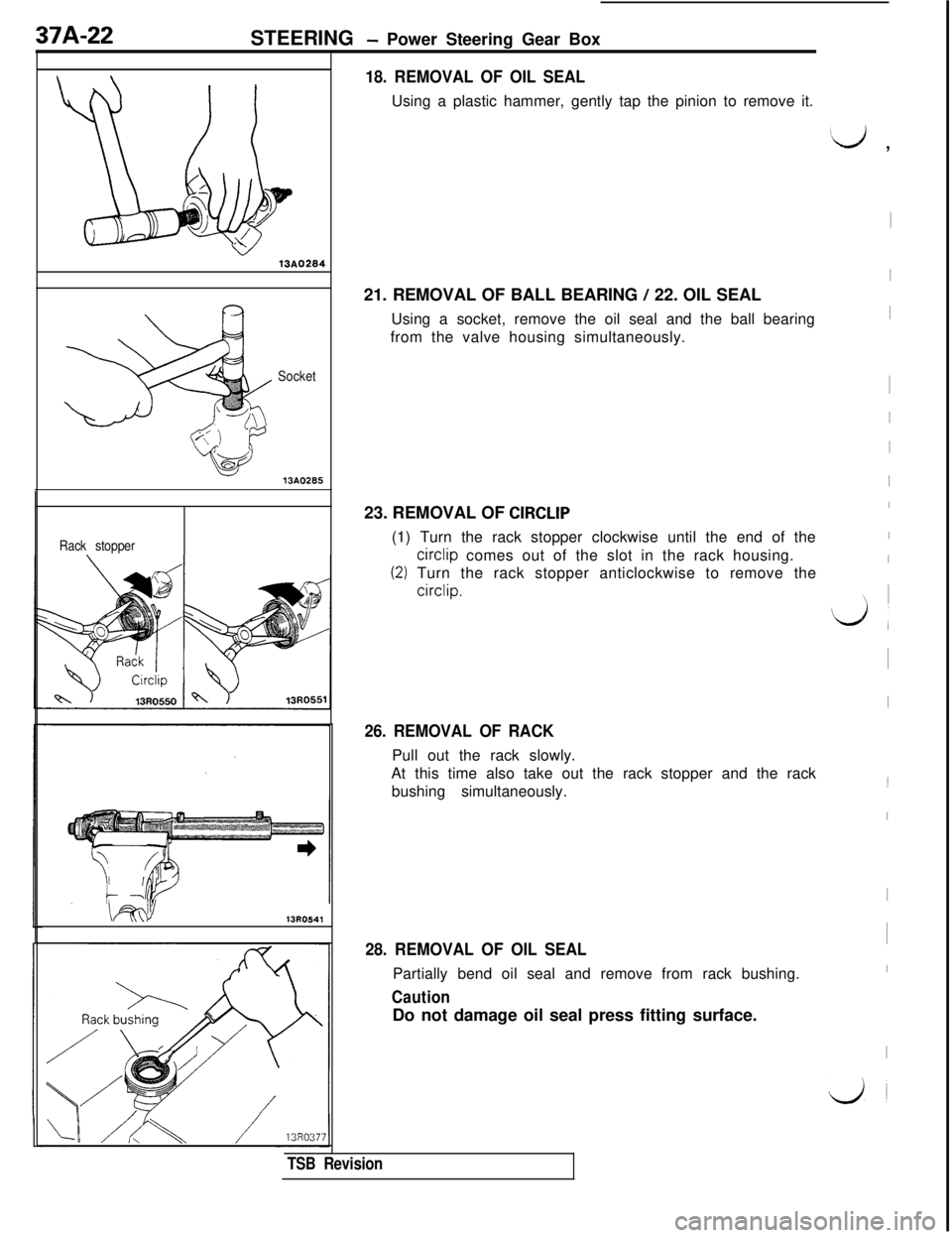

18. REMOVAL OF OIL SEALUsing a plastic hammer, gently tap the pinion to remove it.

21. REMOVAL OF BALL BEARING

/ 22. OIL SEAL

Using a socket, remove the oil seal and the ball bearing

from the valve housing simultaneously.

23. REMOVAL OF

CIRCLIP(1) Turn the rack stopper clockwise until the end of thecirclip comes out of the slot in the rack housing.

(2) Turn the rack stopper anticlockwise to remove thecirclip.

26. REMOVAL OF RACKPull out the rack slowly.

At this time also take out the rack stopper and the rack

bushing simultaneously.

28. REMOVAL OF OIL SEALPartially bend oil seal and remove from rack bushing.

CautionDo not damage oil seal press fitting surface.

TSB Revision

‘d ,

I

I

I

I

I

I

I

I

I

I

:,i;1

I~

I

I

I

I

I

ijl

Page 851 of 1146

i

LSTEERING

- Power Steering Gear Box37A-23

13R054f

_ Needlebearing

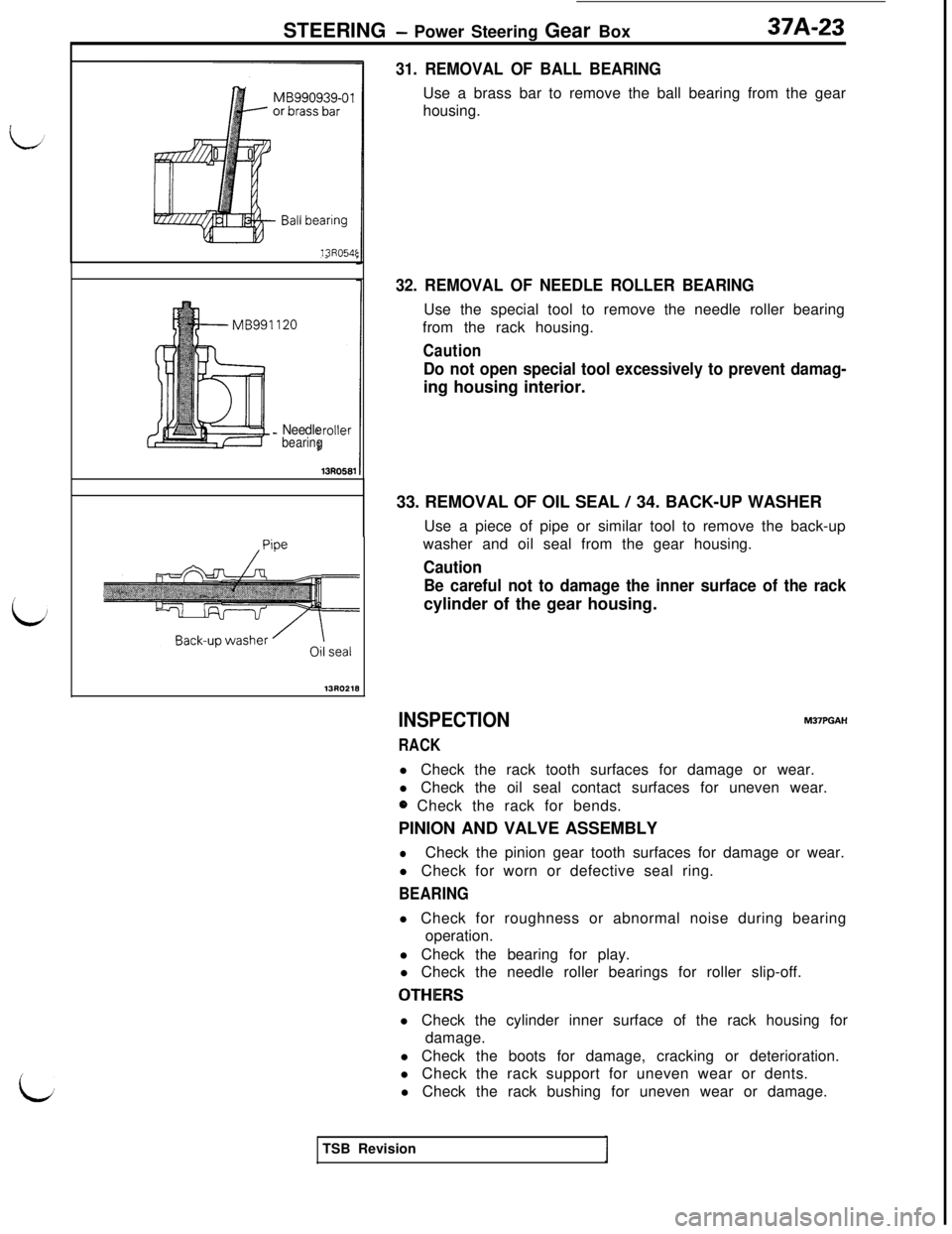

31. REMOVAL OF BALL BEARINGUse a brass bar to remove the ball bearing from the gear

housing.

32. REMOVAL OF NEEDLE ROLLER BEARINGUse the special tool to remove the needle roller bearing

from the rack housing.

Caution

Do not open special tool excessively to prevent damag-ing housing interior.

33. REMOVAL OF OIL SEAL

/ 34. BACK-UP WASHER

Use a piece of pipe or similar tool to remove the back-up

washer and oil seal from the gear housing.

Caution

Be careful not to damage the inner surface of the rackcylinder of the gear housing.

INSPECTION

RACK

M37PGAHl Check the rack tooth surfaces for damage or wear.

l Check the oil seal contact surfaces for uneven wear.

0 Check the rack for bends.

PINION AND VALVE ASSEMBLY

lCheck the pinion gear tooth surfaces for damage or wear.

l Check for worn or defective seal ring.

BEARINGl Check for roughness or abnormal noise during bearing

operation.

l Check the bearing for play.

l Check the needle roller bearings for roller slip-off.

OTHIERSl Check the cylinder inner surface of the rack housing for

damage.

l Check the boots for damage, cracking or deterioration.

l Check the rack support for uneven wear or dents.

l Check the rack bushing for uneven wear or damage.

TSB Revision