steering wheel MITSUBISHI 3000GT 1991 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 581 of 1146

FRONT AXLE - Troubleshooting / Service Adjustment Procedures

TROUBLESHOOTING

26-5

MPBEBAA

i.

Symptom

Vehicle pulls to one

side

Vibration

Shimmy

Excessive noiseProbable cause

Seizure of drive shaft ball joint

Abnormal wear, play or seizure of wheel bearing

Malfunction of front suspension or steering

Bend, damage or abnormal wear of drive shaft

Play in drive shaft and hub serration

Abnormal wear, play or seizure of wheel bearing

Improper wheel alignment

Malfunction of front suspension or steering

Broken boot, grease leakage

Bend, damage or abnormal wear of drive shaft

Play of drive shaft and hub serration

Abnormal wear, play or seizure of center bearing

Abnormal wear, play or seizure of wheel bearing

Loose wheel nut

Malfunction of front suspension and steering

Remedy

Replace

Replace

Adjust or replace

Replace

Replace

Replace

Adjust or replace

Adjust or replace

Replace, repack grease

Replace

Replace

Replace

Replace

Retighten

Adjust or replace

u11 A0285

SERVICE ADJUSTMENT PROCEDURES

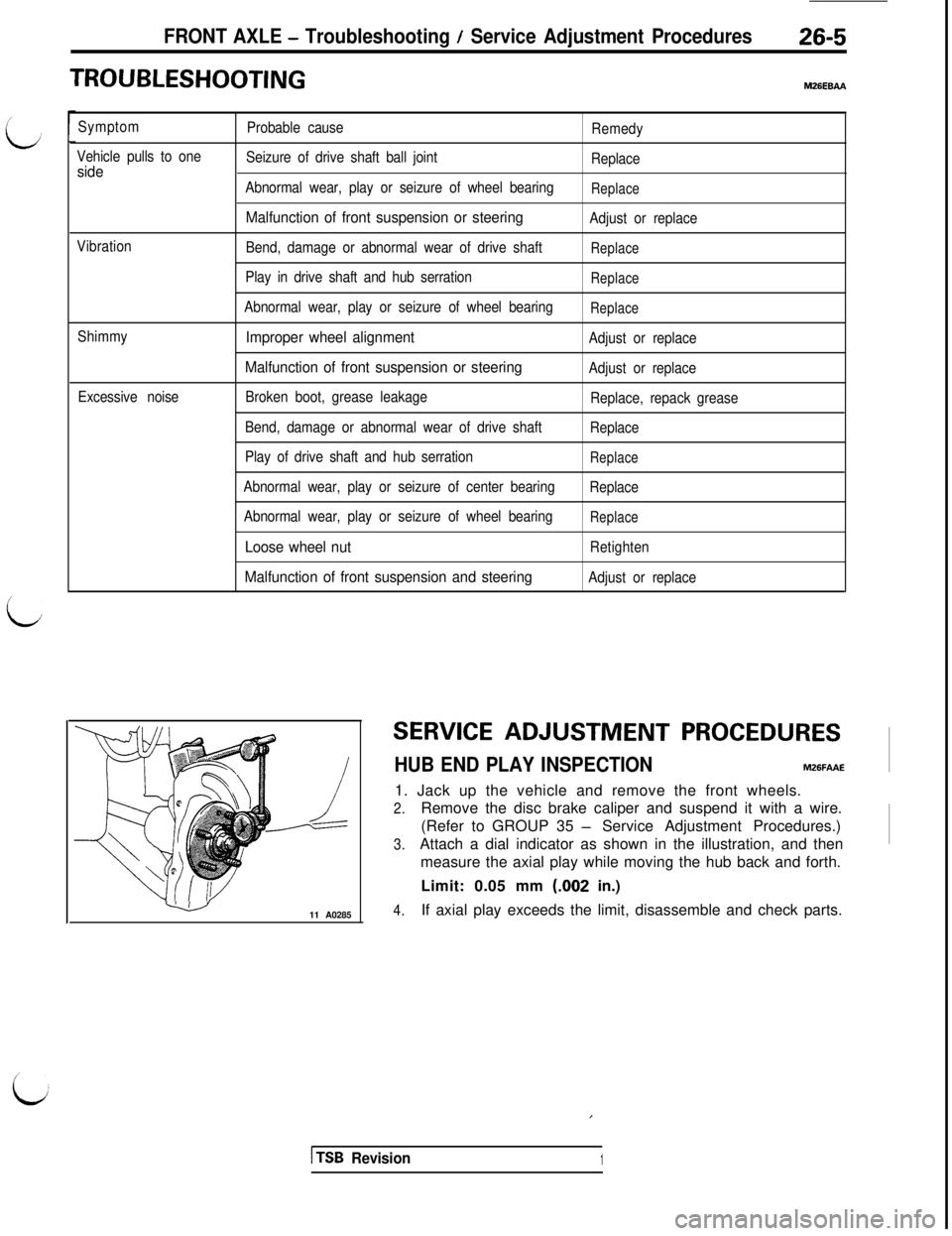

HUB END PLAY INSPECTIONM26FAAE1. Jack up the vehicle and remove the front wheels.

2.Remove the disc brake caliper and suspend it with a wire.

(Refer to GROUP 35

- Service Adjustment Procedures.)

3.Attach a dial indicator as shown in the illustration, and then

measure the axial play while moving the hub back and forth.

Limit: 0.05 mm (.002 in.)

4.If axial play exceeds the limit, disassemble and check parts.

,

1 TSB Revision1

i

Page 648 of 1146

32-6POWER PLANT MOUNT -Right Member, Left Member and Crossmember

RIGHT MEMBER, LEFT MEMBER AND CROSSMEMBER

I

M32YA- _

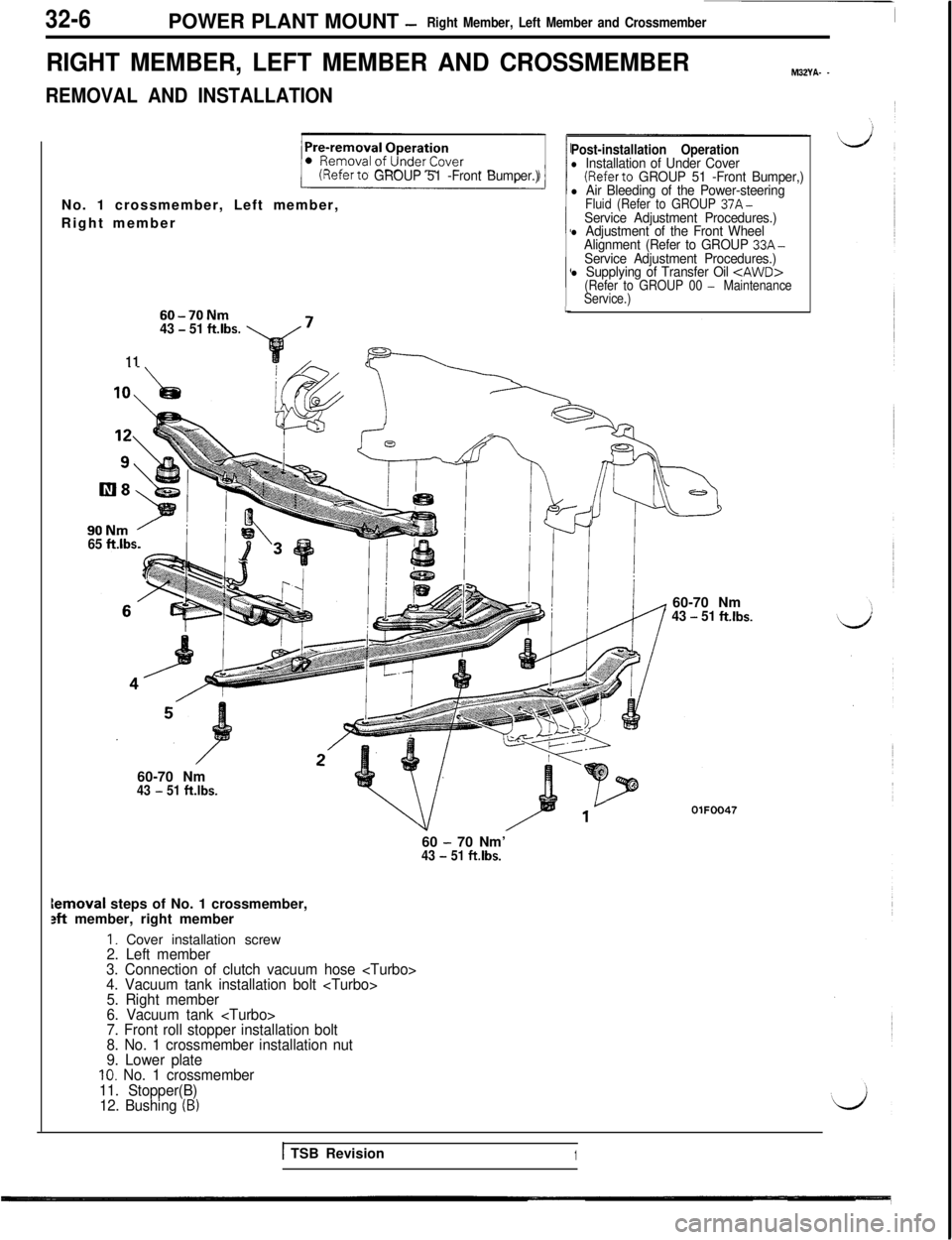

REMOVAL AND INSTALLATION

(Referto GROUP 51 -Front Bumper.)No. 1 crossmember, Left member,

Right member

60-70Nm43 - 51 ft.lbs.

11

F=----lL90Nm

’65 ft.lbs.

/I

Post-installation Operationl Installation of Under Cover(Referto GROUP 51 -Front Bumper,)l Air Bleeding of the Power-steeringFluid (Refer to GROUP 37A-Service Adjustment Procedures.)l Adjustment of the Front Wheel

Alignment (Refer to GROUP 33A-Service Adjustment Procedures.)l Supplying of Transfer Oil

Service.)60-70 Nm

43 - 51 ft.lbs.60-70 Nm

43 - 51 ftlbs.

/aa lVOiFOO4760

- 70 Nm’43 - 51 ft.lbs.lemoval steps of No. 1 crossmember,

M member, right member

I. Cover installation screw2. Left member

3. Connection of clutch vacuum hose

4. Vacuum tank installation bolt

5. Right member

6. Vacuum tank

7. Front roll stopper installation bolt

8. No. 1 crossmember installation nut

9. Lower plate

10. No. 1 crossmember

11. Stopper(B)

12. Bushing

(B)

1 TSB Revision1

Page 652 of 1146

33A-2FRONT SUSPENSION - Specifications

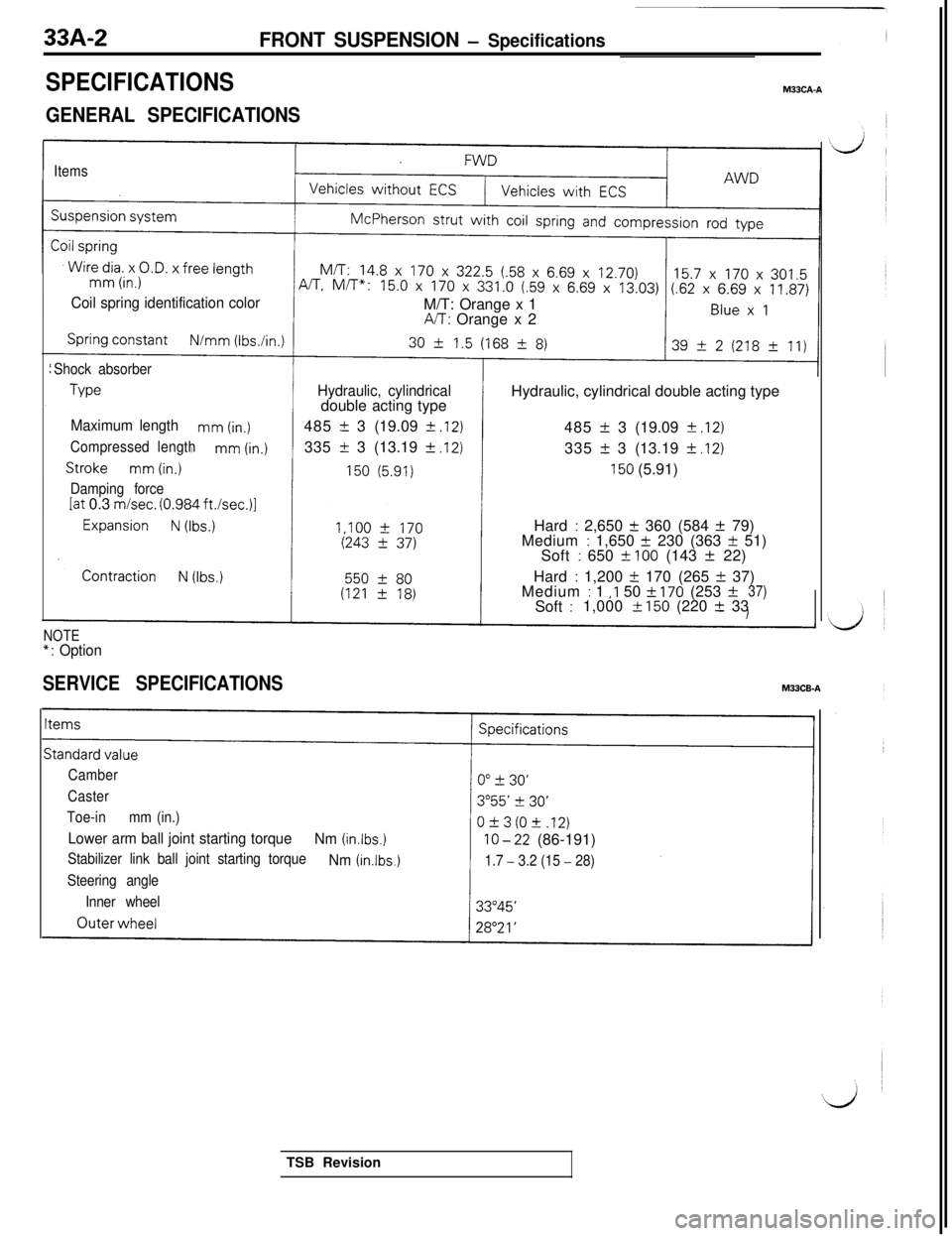

SPECIFICATIONSM33CA-A

GENERAL SPECIFICATIONS

Items

Coil spring identification colorM/T: Orange x 1

ATT: Orange x 2

Shock absorber

Type

Maximum length

Compressed length

Damping force

[at 0.3 m/set. (0.984 ft./set.)]

Hydraulic, cylindricaldouble acting type

485 + 3 (19.09

f .12)335

I 3 (13.19 + .12)Hydraulic, cylindrical double acting type

485

k 3 (19.09 + .12)335 2 3 (13.19 +

.12)

150 (5.91)

NOTE*: OptionHard

: 2,650 + 360 (584 + 79)

Medium : 1,650 t 230 (363 ?I 51)

Soft : 650 f 100 (143 + 22)

Hard

: 1,200 + 170 (265 * 37)

Medium : 1 ,I 50 k 170 (253 +37)Soft :1,000 z!z 150 (220 + 33

SERVICE SPECIFICATIONSM33CB-A

Camber

Caster

Toe-inmm (in.)

Lower arm ball joint starting torque

Nm (in.lbs.)IO-22 (86-191)

Stabilizer link ball joint starting torqueNm (in.lbs.)1.7 - 3.2 (15 - 28)

Steering angle

Inner wheelTSB Revision

Page 653 of 1146

FRONT SUSPENSION - Special Tools / Troubleshooting

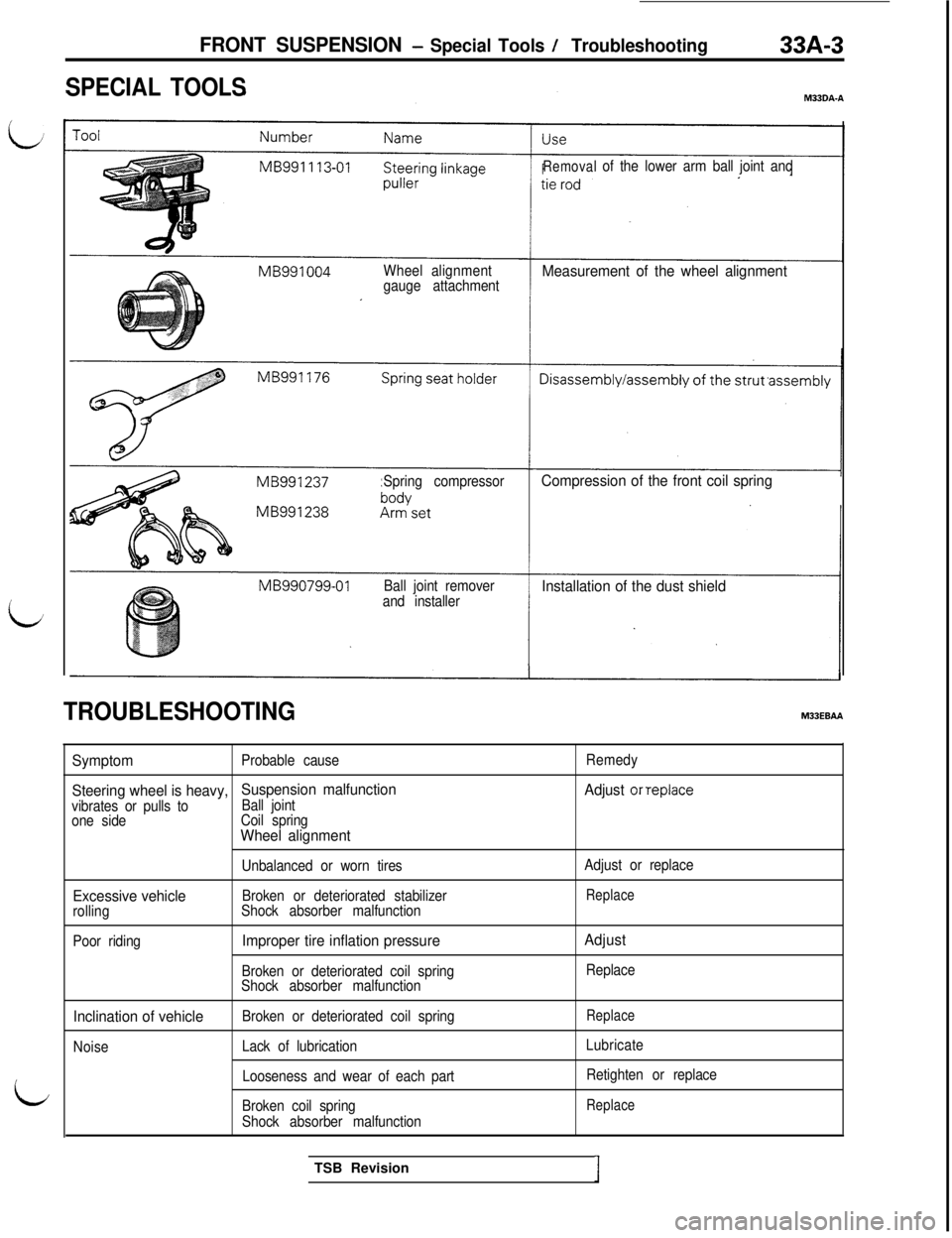

SPECIAL TOOLS

L

L

Removalof the lower arm ball joint and

Wheel alignment

gauge attachment

Measurement of the wheel alignment

Spring compressorCompression of the front coil spring

MB990799-01Ball joint remover

and installerInstallation of the dust shield

TROUBLESHOOTINGM33EBAA

SymptomProbable causeRemedy

Steering wheel is heavy,Suspension malfunctionvibrates or pulls toBall joint

Adjust orreplace

one sideCoil springWheel alignment

Unbalanced or worn tiresAdjust or replace

Excessive vehicleBroken or deteriorated stabilizer

rollingShock absorber malfunctionReplace

Poor ridingImproper tire inflation pressureAdjust

Broken or deteriorated coil spring

Shock absorber malfunctionReplace

Inclination of vehicleBroken or deteriorated coil springReplace

NoiseLack of lubricationLubricate

Looseness and wear of each partRetighten or replace

Broken coil spring

Shock absorber malfunction

ReplaceTSB Revision

I

Page 654 of 1146

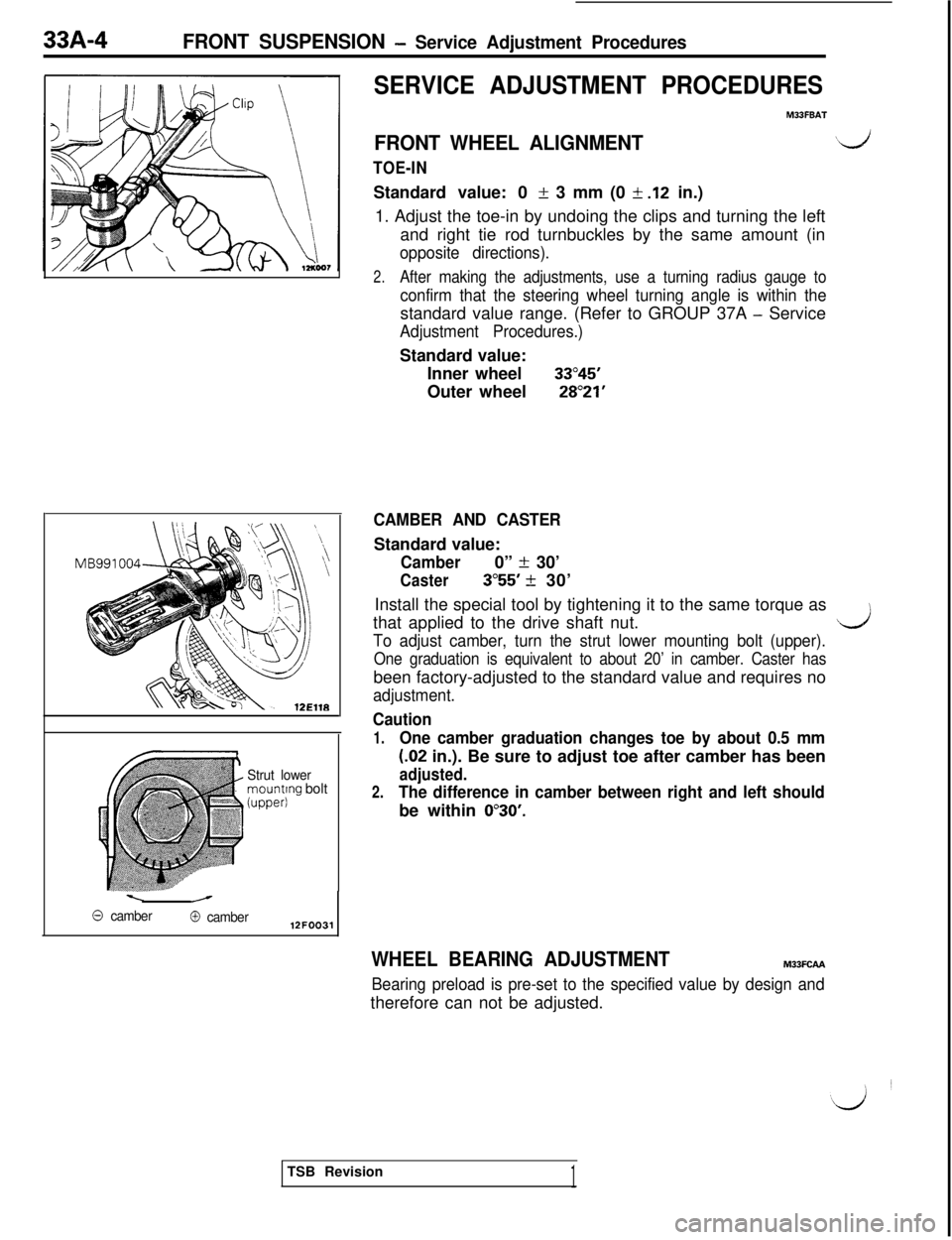

33A-4FRONT SUSPENSION - Service Adjustment Procedures

Strut lowermounting bolt(upper)

\/

0 camber@ camber12FOO31

SERVICE ADJUSTMENT PROCEDURES

M33FBAT

FRONT WHEEL ALIGNMENT‘d

TOE-INStandard value: 0 2 3 mm (0 +

.12 in.)

1. Adjust the toe-in by undoing the clips and turning the left

and right tie rod turnbuckles by the same amount (in

opposite directions).

2.After making the adjustments, use a turning radius gauge to

confirm that the steering wheel turning angle is within thestandard value range. (Refer to GROUP 37A

- Service

Adjustment Procedures.)Standard value:

Inner wheel

33”45’Outer wheel

28”21’

CAMBER AND CASTERStandard value:

Camber0” IL 30’

Caster3”55’ IL 30’

Install the special tool by tightening it to the same torque as

that applied to the drive shaft nut.

a

To adjust camber, turn the strut lower mounting bolt (upper).

One graduation is equivalent to about 20’ in camber. Caster hasbeen factory-adjusted to the standard value and requires no

adjustment.

Caution

1.One camber graduation changes toe by about 0.5 mm

(.02 in.). Be sure to adjust toe after camber has been

adjusted.

2.The difference in camber between right and left shouldbe within

O”30’.

WHEEL BEARING ADJUSTMENTM33FCAA

Bearing preload is pre-set to the specified value by design andtherefore can not be adjusted.

TSB Revision

1

Page 678 of 1146

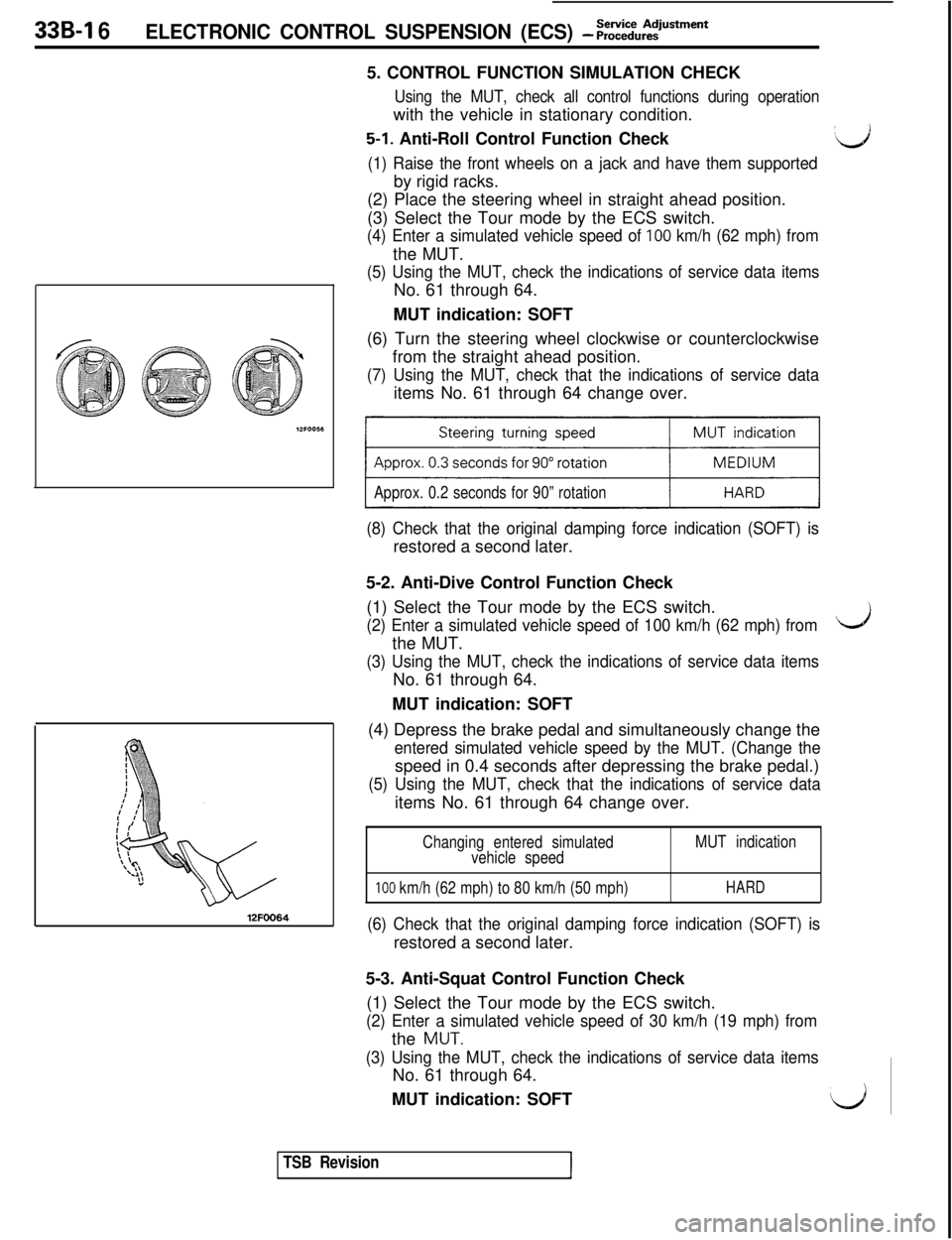

339-l 6ELECTRONIC CONTROL SUSPENSION (ECS) - ;;:%,:?‘Stment5. CONTROL FUNCTION SIMULATION CHECK

Using the MUT, check all control functions during operationwith the vehicle in stationary condition.

5-1. Anti-Roll Control Function Check:d

(1) Raise the front wheels on a jack and have them supportedby rigid racks.

(2) Place the steering wheel in straight ahead position.

(3) Select the Tour mode by the ECS switch.

(4) Enter a simulated vehicle speed of 100 km/h (62 mph) fromthe MUT.

(5) Using the MUT, check the indications of service data itemsNo. 61 through 64.

MUT indication: SOFT

12FOO64(6) Turn the steering wheel clockwise or counterclockwise

from the straight ahead position.

(7) Using the MUT, check that the indications of service dataitems No. 61 through 64 change over.

Approx. 0.2 seconds for 90” rotation

(8) Check that the original damping force indication (SOFT) isrestored a second later.

5-2. Anti-Dive Control Function Check

(1) Select the Tour mode by the ECS switch.

(2) Enter a simulated vehicle speed of 100 km/h (62 mph) fromthe MUT.

(3) Using the MUT, check the indications of service data itemsNo. 61 through 64.

MUT indication: SOFT

(4) Depress the brake pedal and simultaneously change the

entered simulated vehicle speed by the MUT. (Change thespeed in 0.4 seconds after depressing the brake pedal.)

(5) Using the MUT, check that the indications of service dataitems No. 61 through 64 change over.

Changing entered simulated

vehicle speedMUT indication

100 km/h (62 mph) to 80 km/h (50 mph)HARD

(6) Check that the original damping force indication (SOFT) isrestored a second later.

Ls5-3. Anti-Squat Control Function Check

(1) Select the Tour mode by the ECS switch.

(2) Enter a simulated vehicle speed of 30 km/h (19 mph) fromthe

MUT.

(3) Using the MUT, check the indications of service data itemsNo. 61 through 64.

MUT indication: SOFT

l/i

TSB Revision

Page 681 of 1146

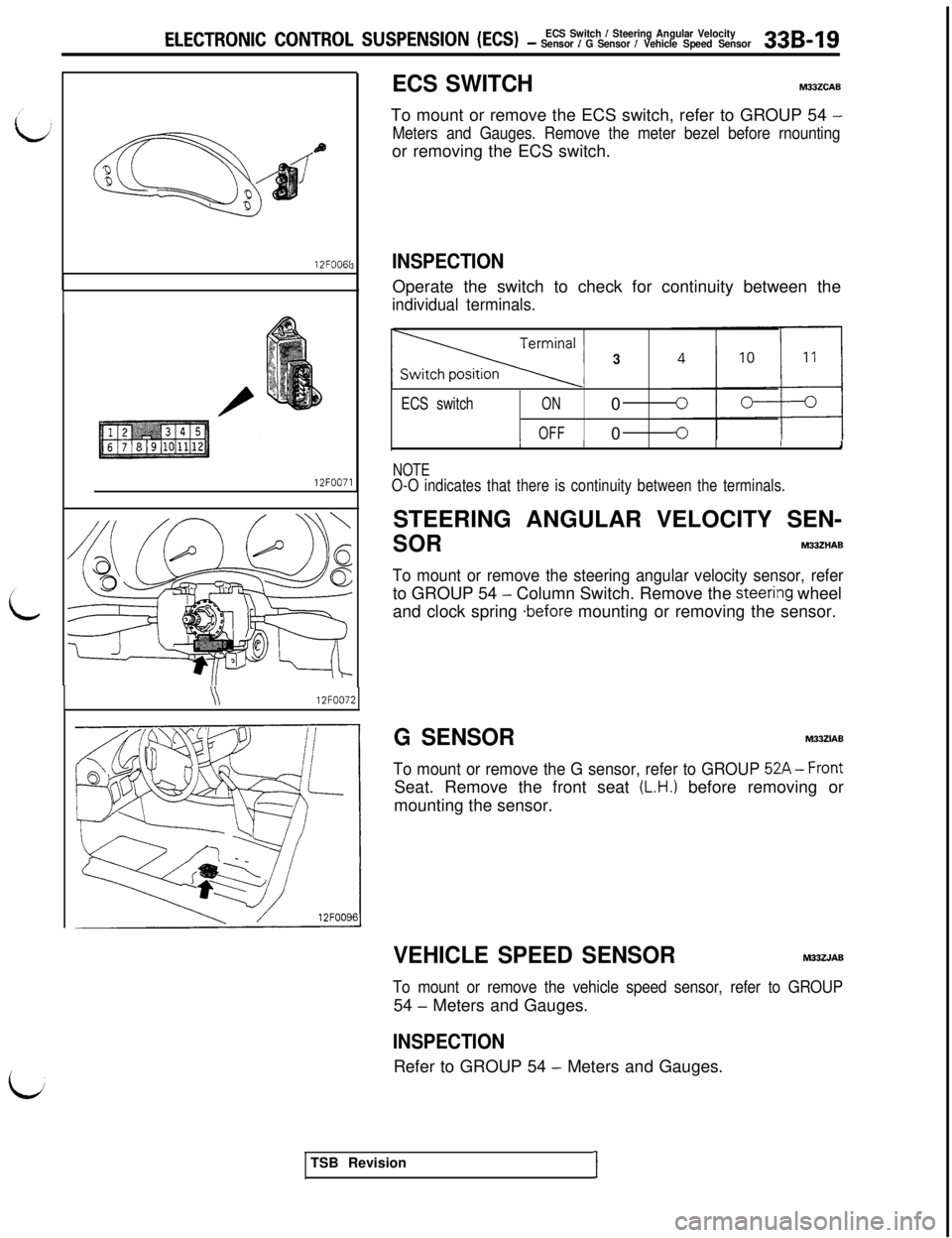

ELECTRONIC CONTROL SUSPENSION (ECS)ECS Switch I Steering Angular Velocity- Sensor I G Sensor I Vehicle Speed Sensor3:3B-19

12FOO6t3INSPECTION12FOO71

i

\\12FOO72

ECS SWITCHMUZCAB

To mount or remove the ECS switch, refer to GROUP 54

-

Meters and Gauges. Remove the meter bezel before rnountingor removing the ECS switch.

Operate the switch to check for continuity between the

individual terminals.

3

ECS switchON0

OFF0IIIIII1

NOTEO-O indicates that there is continuity between the terminals.STEERING ANGULAR VELOCITY SEN-

SORM33ZHAB

To mount or remove the steering angular velocity sensor, referto GROUP 54

- Column Switch. Remove the steerilng wheel

and clock spring

*before mounting or removing the sensor.

G SENSORM33ZIAB

To mount or remove the G sensor, refer to GROUP 52A-Front

Seat. Remove the front seat

(L.H.) before removing or

mounting the sensor.

VEHICLE SPEED SENSORM33ZJAB

To mount or remove the vehicle speed sensor, refer to GROUP54

- Meters and Gauges.

INSPECTIONRefer to GROUP 54

- Meters and Gauges.

TSB Revision

I

Page 685 of 1146

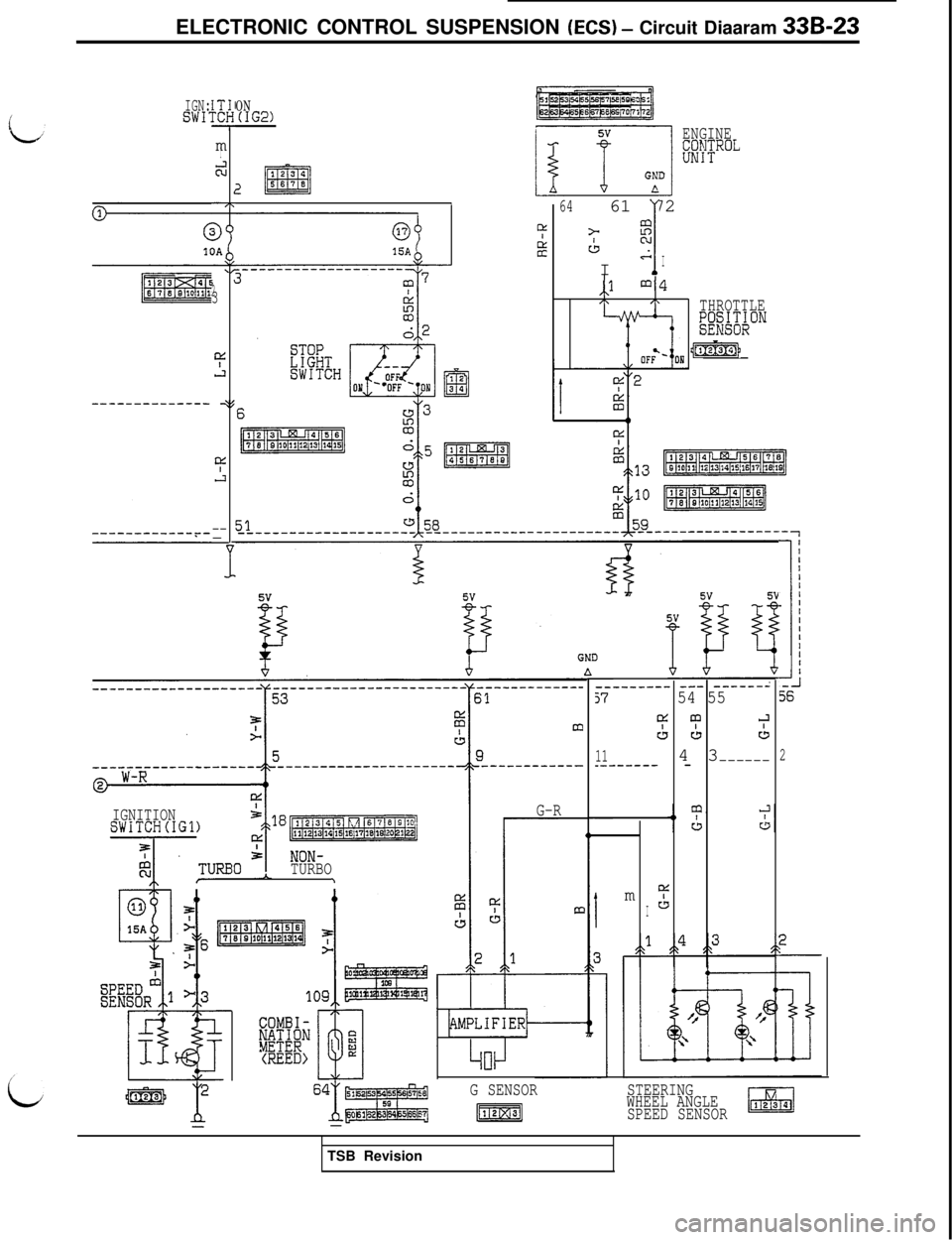

ELECTRONIC CONTROL SUSPENSION (ECS) - Circuit Diaaram 33B-23

IGN:sw1::A?-m

I&

177

i '

3

I

2YJ

-+d

T-J

---

ON(IG2)SV

el

ENGINEf"BTROL

GNDIfi

1234

J333256‘78

6461 72>

I

I

CLL2c

I

,Jm4,\/\THROTTLE;;;EI;;ON

4-1

jV

f

. I

!i

ss’

2

___--_--- _-- ------2354 55F

"pLl

cl w&

114 3__------ -------

I

nimCL

IGNITIONSWITCH(IG1)18Bl

NON-TURBO\

G-R

COMBI-

%kiN'(REED>

G SENSOR

lf?EzJi

STEERING

WHEEL ANGLE

SPEED SENSOR

liZI1 2 3aTSB Revision

Page 710 of 1146

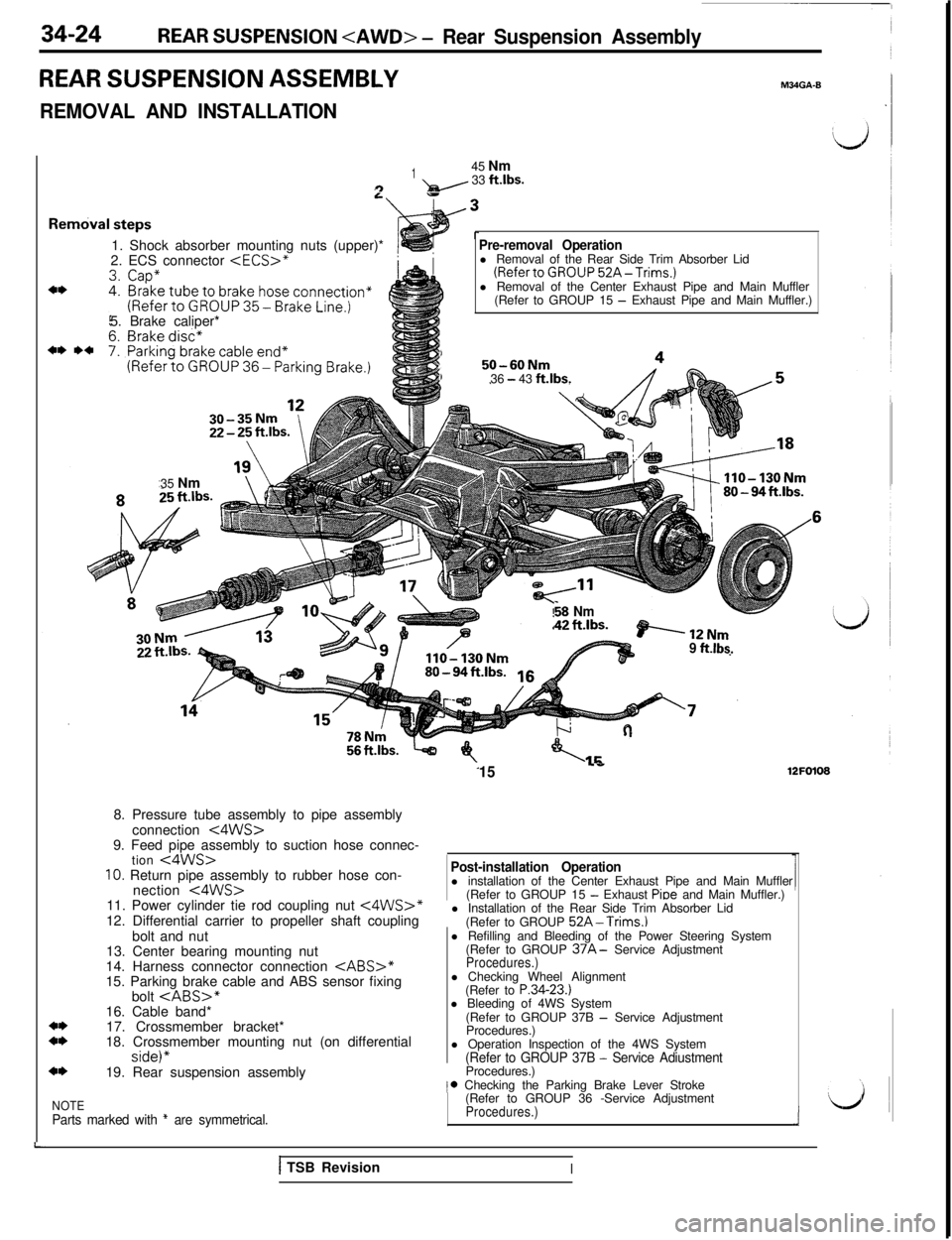

34-24REAR SUSPENSION

REAR SUSPENSION ASSEMBLY

REMOVAL AND INSTALLATION

M34GA-B

L

Rel

145 Nm9- 33 ftlbs.

1. Shock absorber mounting nuts (upper)*

2. ECS connector

(RefertoGROUP52A-Trims.)l Removal of the Center Exhaust Pipe and Main Muffler

(Refer to GROUP 15

- Exhaust Pipe and Main Muffler.)

5. Brake caliper*

1,50-60NmI36 - 43 ft.lbs.35 Nm

$8 Nm“?C,ILc. ashwez I,..“=.BP’----12Nm9 ftlbs.

15..e12FO1088. Pressure tube assembly to pipe assembly

connection

<4WS>9. Feed pipe assembly to suction hose connec-

tion

<4WS>10. Return pipe assembly to rubber hose con-

nection t4WS>11. Power cylinder tie rod coupling nut <4WS>*12. Differential carrier to propeller shaft coupling

bolt and nut

Post-installation Operationl installation of the Center Exhaust Pipe and Main Muffler

(Refer to GROUP 15

- Exhaust Pioe and Main Muffler.)

l Installation of the Rear Side Trim Absorber Lid

(Refer to GROUP

52A-Trims.)13. Center bearing mounting nut

14. Harness connector connection

CABS>*15. Parking brake cable and ABS sensor fixingl Refilling and Bleeding of the Power Steering System

(Refer to GROUP

37A- Service AdjustmentProcedures.)bolt

17. Crossmember bracket*

18. Crossmember mounting nut (on differential

side)”19. Rear suspension assemblyl Checking Wheel Alignment

(Refer to P.34-23.)

l Bleeding of 4WS System

(Refer to GROUP 37B

- Service Adjustment

Procedures.)

l Operation Inspection of the 4WS System

(Refer to GROUP 37B - Service AdiustmentProcedures.)

NOTEParts marked with * are symmetrical.

,* Checking the Parking Brake Lever Stroke

(Refer to GROUP 36 -Service Adjustment

Procedures.)i

1 TSB RevisionI

Page 729 of 1146

SERVICE BRAKES -Anti-lock Braking System Troubleshooting35-7

ANTI-LOCK BRAKING SYSTEM TROUBLESHOOTlilGPARTICULAR PHENOMENA OF THE

LANTI-LOCK BRAKING SYSTEMModels equipped with the anti-lock braking system

(ABS) may exhibit one or more of the following

phenomena from time to time, but none of these

are abnormal.

(1) A pulsing feeling in the brake pedal, or vibration

of the body or the steering wheel, when the

anti-lock braking system is activated by sudden

braking or by braking on a slippery road surface.

.9ctually, this phenomenon is an indication that

the anti-lock braking system is functioning nor-

mally.(2) When the vehicle speed reaches approximately

6 km/h (4 mph) after the engine is started and

the vehicle starts off (for the first time), a

whining motor noise may be heard from the

engine compartment if the vehicle is traveling in

a quiet place, but this noise is simply the result

of a self-check being made of the anti-lock

braking system operation.

TROUBLESHOOTING METHODSProblems related to the anti-lock braking system

(ABS) can be classified into two general categories:

problems in the electrical system and those in the

Lhydraulic system.For problems in the electrical system, the

self-diagnosis function is built into the electronic control

unit (E.C.U.) causing the ABS warning light to

illuminate as a warning to the driver. In this instance,

checks can be made by using the multi-use tester

and oscilloscope.

Problems in the hydraulic system (poor braking,

etc.) can be located in the same way as for ordinary

brakes. There is, however, the necessity to check to

determine whether the problem is related to ordin-

ary brake components or to the components related

to the ABS. To make this check, use the multi-use

tester.

HOW TO USE THE TROUBLESHOOTING

FLOW CHART(1) Using the flow chart, check the ABS warning

light light-up sequence. Read the diagnosis

codes and check the condition of braking opera-

tion.

(2) Following the check chart listed in the remedy

column, perform the checks. There are [Explana-

tion] and [Hint] in each check chart. Refer to

them when troubleshooting.

NOTEECU: Electronic control unit

HU: Hydraulic unit

MUT: Multi-use tester

1 TSB Revision