engine MITSUBISHI 3000GT 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 1092 of 1146

55-10 HEATERS AND MANUAL AIR CONDITIONER -Service Adjustment Procedures

OFF-----__-__1210235 2,1002,700

(30) (33)(299) (384)

Pressure Fil

2OPOOlL

SERVICE ADJUSTMENT PROCEDURES

M55FEAU

TEST PROCEDURESSIGHT GLASS REFRIGERANT LEVEL TEST

The sight glass is a refrigerant level indicator. To check the

refrigerant level, clean the sight glass and start the vehicle

engine. Push the air conditioner button to operate the com-

pressor, place the blower switch to high and move the

temperature control lever to MAX. COOL. After operating for a

few minutes in this manner, check the sight glass.

(I) If the sight glass is clear, the magnetic clutch is engaged,

the compressor discharge line is warm and the compressor

inlet line is cool; the system has a full charge.

(2) If the sight glass is clear, the magnetic clutch is engaged

and there is no significant temperature difference between

compressor inlet and discharge lines; the system has lost

some refrigerant.

(3) If the sight glass shows foam or bubbles, the system could

be low on charge. The system has to be charged with some

refrigerant.

MAGNETIC CLUTCH(1) Disconnect the wiring to the magnetic clutch.

(2) Connect battery (+) voltage directly to the wiring for the

magnetic clutch.

(3) If the magnetic clutch is normal, there will be a “click”. If

the pulley and armature do not make contact (“click”), there

is a malfunction.

v):

I

I

I

I

\,

3’

RECEIVER DRIERTo Test the Receiver Drier

(1) Operate the unit and check the piping temperature by

touching the receiver drier outlet and inlet.

(2) If there is a difference in the temperatures, the receiver

drier is restricted.

Replace the receiver drier.

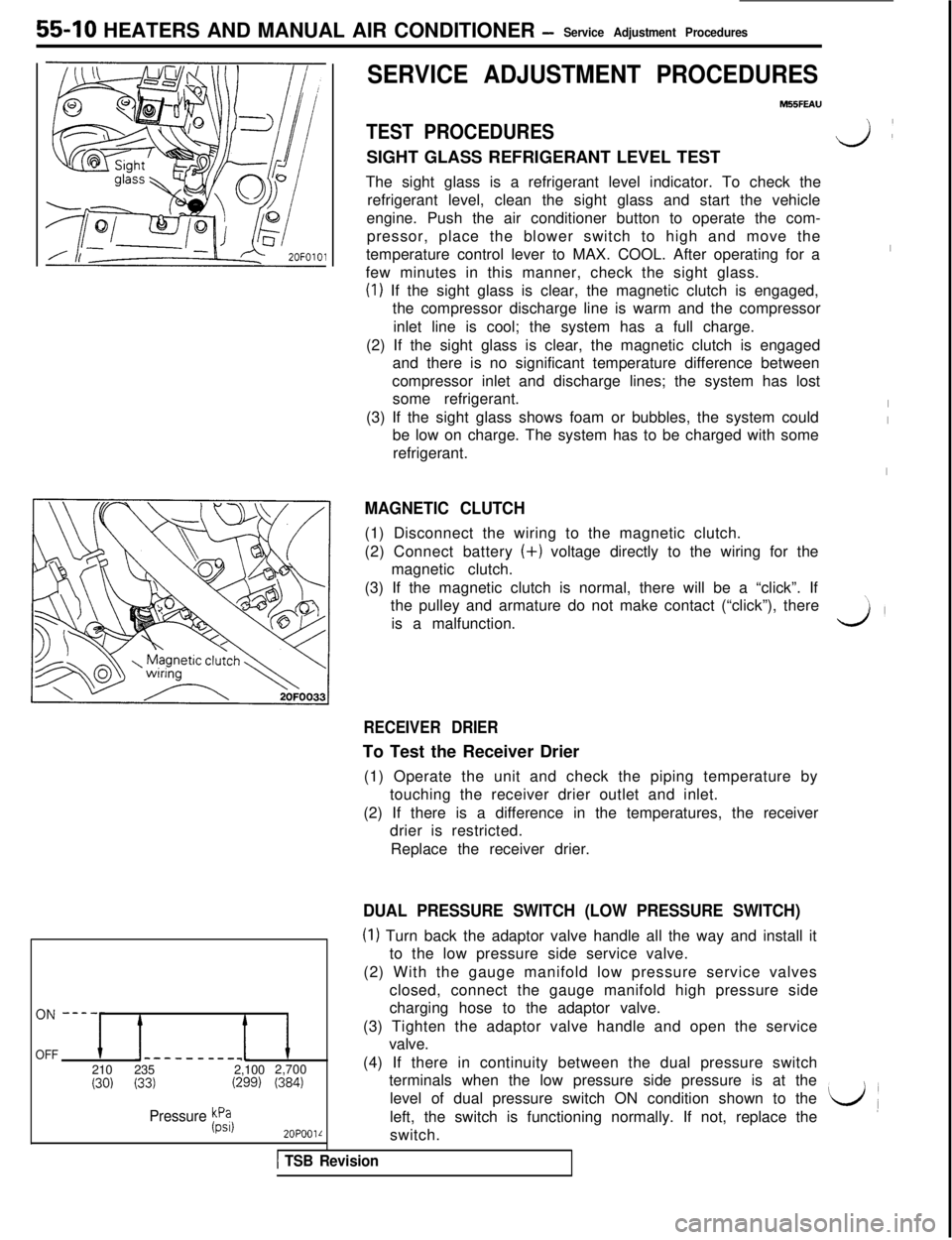

DUAL PRESSURE SWITCH (LOW PRESSURE SWITCH)

(I) Turn back the adaptor valve handle all the way and install it

to the low pressure side service valve.

(2) With the gauge manifold low pressure service valves

closed, connect the gauge manifold high pressure side

charging hose to the adaptor valve.

(3) Tighten the adaptor valve handle and open the service

valve.

(4) If there in continuity between the dual pressure switch

terminals when the low pressure side pressure is at the

level of dual pressure switch ON condition shown to the

left, the switch is functioning normally. If not, replace the

L/(switch.

1 TSB Revision

Page 1093 of 1146

HEATERS AND MANUAL AIR CONDITIONER -Service Adjustment Procedures 55 1 1

lr In et sensor

UC03xD:c.-;am$2lYXSC0x.x

xa0:: :,:::25 cc,ii 77h>Temperature20A043F

argqse

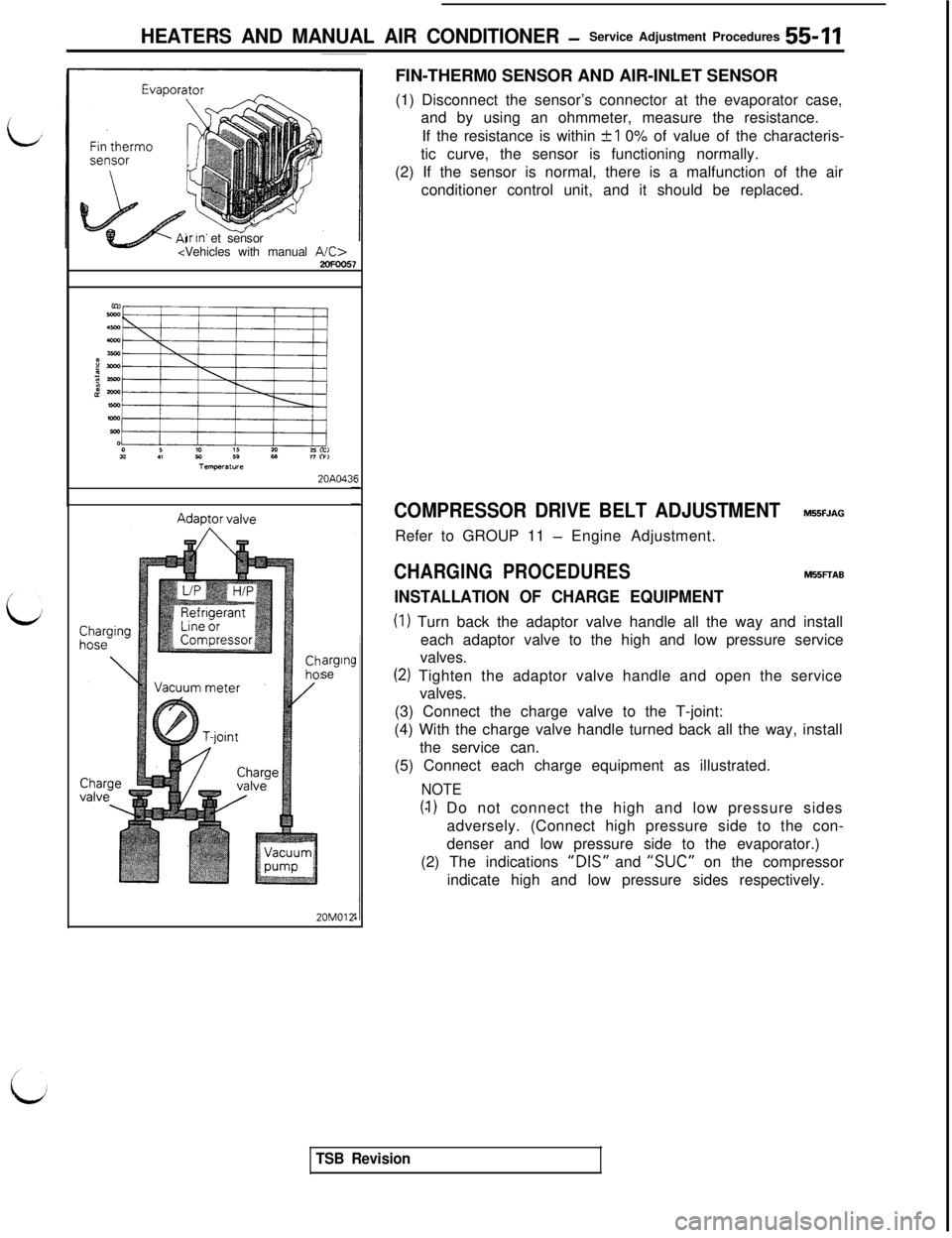

20M012FIN-THERM0 SENSOR AND AIR-INLET SENSOR

(1) Disconnect the sensor’s connector at the evaporator case,

and by using an ohmmeter, measure the resistance.

If the resistance is within

+I 0% of value of the characteris-

tic curve, the sensor is functioning normally.

(2) If the sensor is normal, there is a malfunction of the air

conditioner control unit, and it should be replaced.

COMPRESSOR DRIVE BELT ADJUSTMENTM55FJAGRefer to GROUP 11

- Engine Adjustment.

CHARGING PROCEDURESM55FTAB

INSTALLATION OF CHARGE EQUIPMENT

(I) Turn back the adaptor valve handle all the way and install

each adaptor valve to the high and low pressure service

valves.

(2) Tighten the adaptor valve handle and open the service

valves.

(3) Connect the charge valve to the T-joint:

(4) With the charge valve handle turned back all the way, install

the service can.

(5) Connect each charge equipment as illustrated.

NOTE

(4) Do not connect the high and low pressure sides

adversely. (Connect high pressure side to the con-

denser and low pressure side to the evaporator.)

(2) The indications

“DIS” and “SUC” on the compressor

indicate high and low pressure sides respectively.

TSB Revision

Page 1095 of 1146

HEATERS AND MANUAL AIR CONDITIONER - Service AdWment proceres 55-13. .

Charginglose

\Adaptor valve

Vacuum meter

T-joint

20M0121

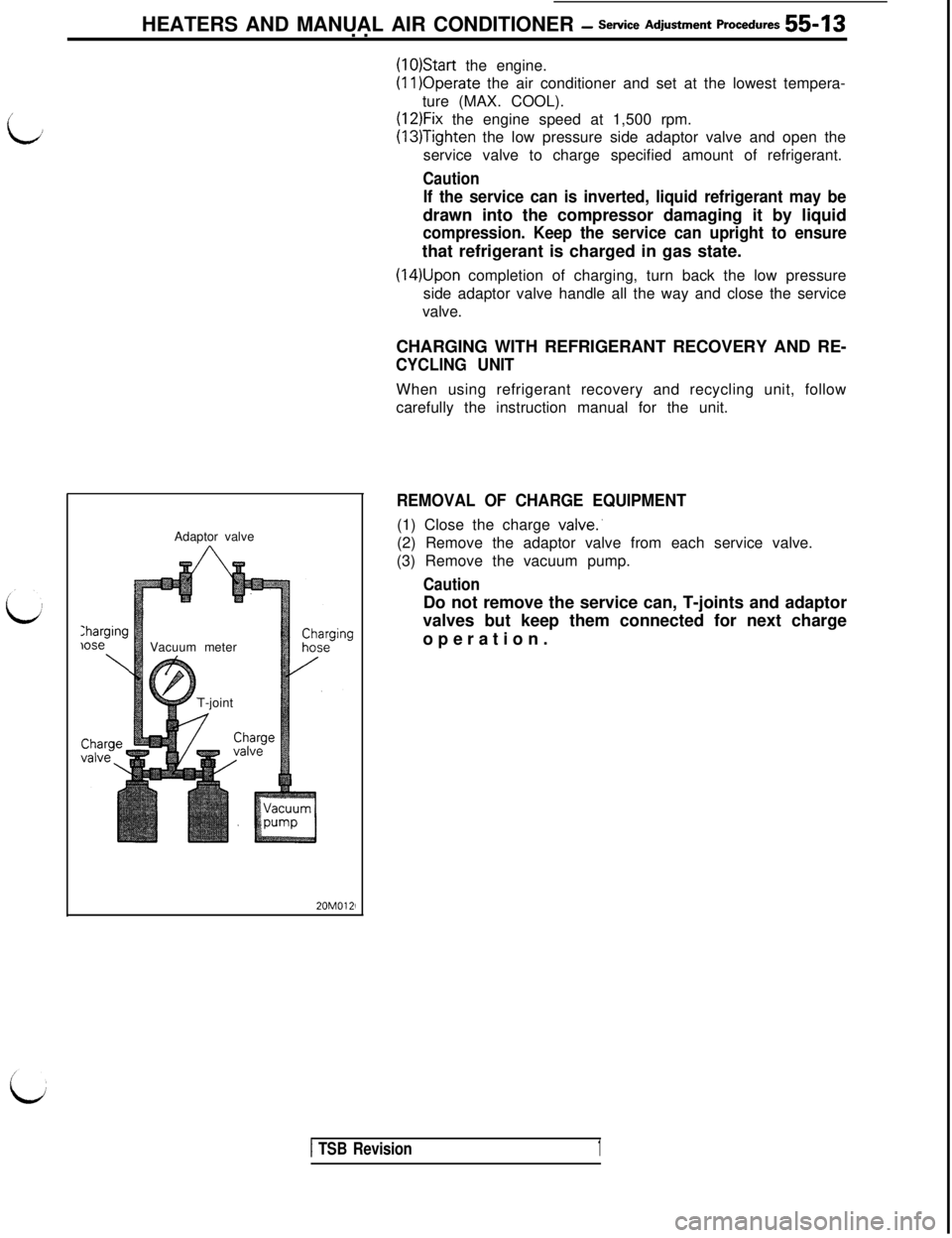

(1O)Start the engine.(1l)Operate the air conditioner and set at the lowest tempera-

ture (MAX. COOL).

(12)Fix the engine speed at 1,500 rpm.

(13)Tighten the low pressure side adaptor valve and open the

service valve to charge specified amount of refrigerant.

Caution

If the service can is inverted, liquid refrigerant may bedrawn into the compressor damaging it by liquid

compression. Keep the service can upright to ensurethat refrigerant is charged in gas state.

(14)Upon completion of charging, turn back the low pressure

side adaptor valve handle all the way and close the service

valve.

CHARGING WITH REFRIGERANT RECOVERY AND RE-

CYCLING UNITWhen using refrigerant recovery and recycling unit, follow

carefully the instruction manual for the unit.

REMOVAL OF CHARGE EQUIPMENT(1) Close the charge

valve:(2) Remove the adaptor valve from each service valve.

(3) Remove the vacuum pump.

CautionDo not remove the service can, T-joints and adaptor

valves but keep them connected for next charge

operation.

1 TSB Revision1

Page 1096 of 1146

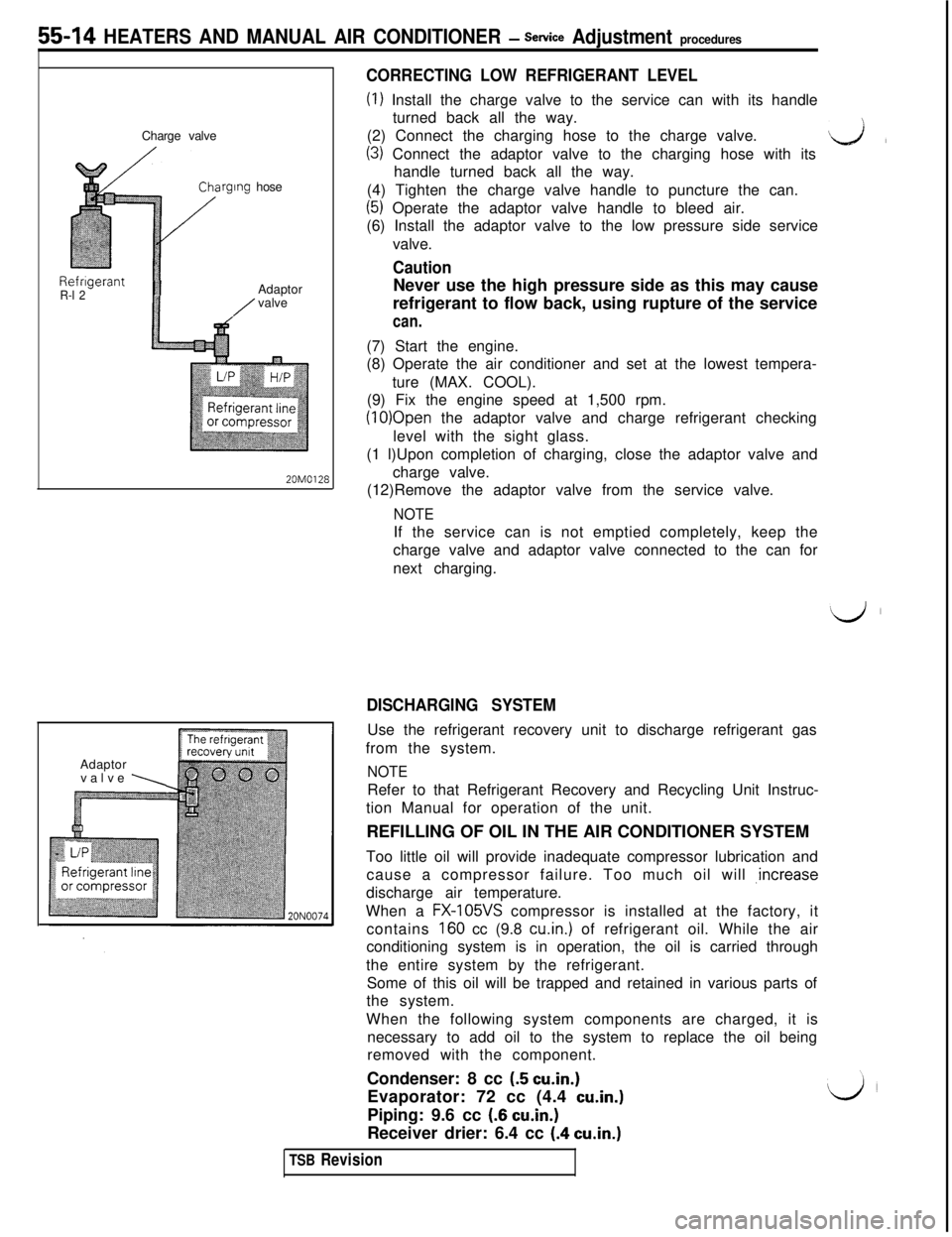

CautionRefrigerantR-l 2iAdaptorNever use the high pressure side as this may cause

/valve

refrigerant to flow back, using rupture of the servicecan.(7) Start the engine. Charge valvergmg hose

55-14 HEATERS AND MANUAL AIR CONDITIONER - Service Adjustment procedures

CORRECTING LOW REFRIGERANT LEVEL

(I) Install the charge valve to the service can with its handle

turned back all the way.

(2) Connect the charging hose to the charge valve.

(3) Connect the adaptor valve to the charging hose with itsL&lhandle turned back all the way.

(4) Tighten the charge valve handle to puncture the can.

(5) Operate the adaptor valve handle to bleed air.

(6) Install the adaptor valve to the low pressure side service

valve.

(8) Operate the air conditioner and set at the lowest tempera-

ture (MAX. COOL).

(9) Fix the engine speed at 1,500 rpm.

(10)Open the adaptor valve and charge refrigerant checking

level with the sight glass.

(1 l)Upon completion of charging, close the adaptor valve and

20M0128charge valve.

(12)Remove the adaptor valve from the service valve.

NOTEIf the service can is not emptied completely, keep the

charge valve and adaptor valve connected to the can for

next charging.

Adaptor

valve

\

DISCHARGING SYSTEMUse the refrigerant recovery unit to discharge refrigerant gas

from the system.

NOTERefer to that Refrigerant Recovery and Recycling Unit Instruc-

tion Manual for operation of the unit.

REFILLING OF OIL IN THE AIR CONDITIONER SYSTEM

Too little oil will provide inadequate compressor lubrication and

cause a compressor failure. Too much oil will ,increase

discharge air temperature.

When a

FX-105VS compressor is installed at the factory, it

contains

160 cc (9.8 cu.in.) of refrigerant oil. While the air

conditioning system is in operation, the oil is carried through

the entire system by the refrigerant.

Some of this oil will be trapped and retained in various parts of

the system.

When the following system components are charged, it is

necessary to add oil to the system to replace the oil being

removed with the component.

Condenser: 8 cc

(5 cu.in.)Evaporator: 72 cc (4.4

cu.in.)Piping: 9.6 cc

(6 cu.in.)Receiver drier: 6.4 cc

(.4 cu.in.)

TSB Revision

Page 1097 of 1146

L/

i

HEATERS AND MANUAL AIR CONDITIONER -Service Adjustment Procedures 55 15

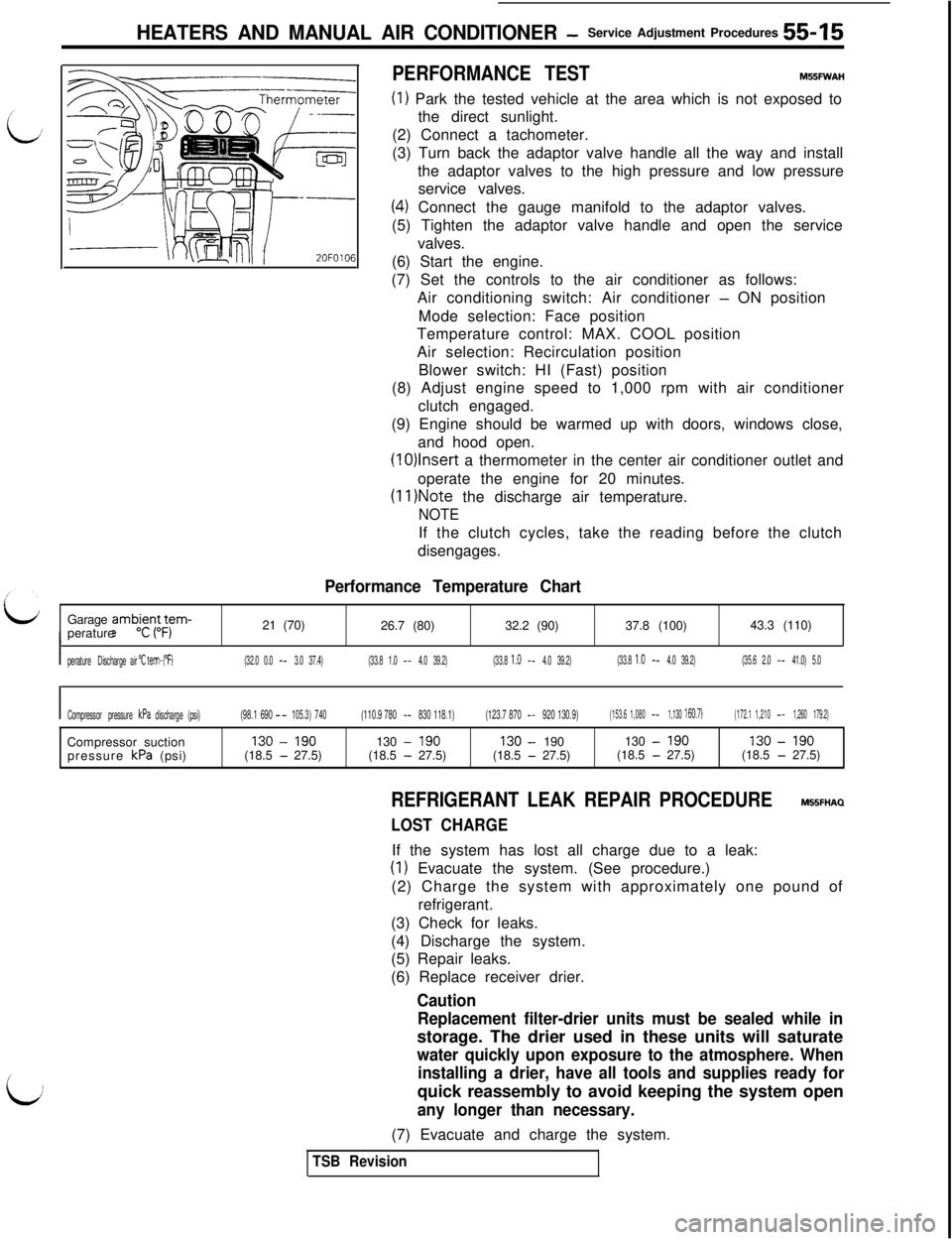

PERFORMANCE TESTM55FWAH

(I) Park the tested vehicle at the area which is not exposed to

the direct sunlight.

(2) Connect a tachometer.

(3) Turn back the adaptor valve handle all the way and install

the adaptor valves to the high pressure and low pressure

service valves.

(4) Connect the gauge manifold to the adaptor valves.

(5) Tighten the adaptor valve handle and open the service

valves.

(6) Start the engine.

(7) Set the controls to the air conditioner as follows:

Air conditioning switch: Air conditioner

- ON position

Mode selection: Face position

Temperature control: MAX. COOL position

Air selection: Recirculation position

Blower switch: HI (Fast) position

(8) Adjust engine speed to 1,000 rpm with air conditioner

clutch engaged.

(9) Engine should be warmed up with doors, windows close,

and hood open.

(1O)lnsert a thermometer in the center air conditioner outlet and

operate the engine for 20 minutes.

(II )Note the discharge air temperature.

NOTEIf the clutch cycles, take the reading before the clutch

disengages.

Performance Temperature ChartGarage

amb;in,L;am-perature21 (70)

26.7 (80)32.2 (90)37.8 (100)43.3 (110)

Iperature Dischargeair "C tem- ("F)(32.0 0.0- -3.0 37.4)(33.8 1.0- -4.0 39.2)(33.8 1.0- -4.0 39.2)(33.8 1.0- -4.0 39.2)(35.6 2.0- -41.0) 5.0

ICompressor pressure kPa discharge (psi)(98.1 690- -105.3) 740(110.9 780- -830 118.1)(123.7 870- -920 130.9)(153.6 1,080- -1,130 160.7)(172.1 1,210- -1,260 179.2)Compressor suction130

-190130-190130-190130-190130-190

pressure kPa (psi)(18.5-27.5)(18.5-27.5)(18.5-27.5)(18.5-27.5)(18.5-27.5)

REFRIGERANT LEAK REPAIR PROCEDUREM55FHAQ

LOST CHARGEIf the system has lost all charge due to a leak:

(1) Evacuate the system. (See procedure.)

(2) Charge the system with approximately one pound of

refrigerant.

(3) Check for leaks.

(4) Discharge the system.

(5) Repair leaks.

(6) Replace receiver drier.

Caution

Replacement filter-drier units must be sealed while instorage. The drier used in these units will saturate

water quickly upon exposure to the atmosphere. When

installing a drier, have all tools and supplies ready forquick reassembly to avoid keeping the system open

any longer than necessary.(7) Evacuate and charge the system.

TSB Revision

Page 1098 of 1146

55-16 HEATERS AND MANUAL AIR CONDITIONER -Service Adjustment Procedures

LOW CHARGE~

If the system has not lost all of its refrigerant charge; locate and

repair all leaks. If it is necessary to increase the system

pressure to find the leak (because of an especially low charge)

‘iaadd of refrigerant. If it is oossible to reoair the leak without

discharging-the refrigerant system, use the procedure for

correcting low refrigerant level.

HANDLING TUBING AND FITTINGSM55FlAFKinks in the refrigerant tubing or sharp bends in the refrigerant

hose lines will greatly reduce the capacity of the entire system.

High pressures are produced in the system when it is

operating. Extreme care must be exercised to make sure that

all connections are pressure tight. Dirt and moisture can enter

the system when it is opened for repair or replacement of lines

or components. The following precautions must be observed.

The system must be completely discharged before opening

any fitting of connection in the refrigeration system. Open

fittings with caution even after the system has been dis-

charged. If any pressure is noticed as a fitting is loosened, allow

trapped pressure to bleed off very slowly.

Never attempt to rebend formed lines to fit. Use the correct

line for the installation you are servicing.

A good rule for the flexible hose lines is keep the radius of all

bends at least 10 times the diameter of the hose.

Sharper bends will reduce the flow of refrigerant. The flexible

hose lines should be routed so that they are at least 80 mm (3

in.) from the exhaust manifold. It is good practice to inspect all

flexible hose lines at least once a year to make sure they are in

good condition and properly routed.

\ Aj iUnified plumbing connections with O-rings. These O-rings are

-not reusable.

I

COMPRESSOR NOISEM55FlAD

When investigating an air conditioning related noise, you must

first know the conditions when the noise occurs. These

conditions are: weather, vehicle speed, in gear on neutral,

engine temperature or any other special conditions.

Noises that develop during air conditioning operation can often

be misleading. For example: what sounds like a failed front

bearing or connecting rod. may be caused by loose bolts, nuts,

mounting brackets, or a loose clutch assembly. Verify acces-

sory drive belt tension (power steering or alternator).

Improper accessory drive belt tension can cause a misleading

noise when the compressor is engaged and little or no noise

when the compressor is disengaged.

Drive belts are speed sensitive. That is, at different engine

speeds, and depending upon belt tension, belts can develop

unusual noises that are often mistaken for mechanical prob-

lems within the compressor.

TSB Revision

Page 1099 of 1146

HEATERS AND MANUAL AIR CbNDlTlONER -Service Adjustment Procedures 55 17

ADJUSTMENT PROCEDURES(1) Select a quiet area for testing. Duplicate conditions as much

as possible. Switch compressor on and off several times to

clearly identify compressor noise.

To duplicate high ambient conditions (high head pressure),

restrict air flow through condenser. Install manifold gauge

set to make sure discharge pressure doesn’t exceed 2,070

kPa (300 psi).

(2) Tighten all compressor mounting bolts, clutch mounting

bolt, and compressor drive belt. Check to assure clutch coil

is tight (no rotation or wobble).

(3) Check refrigerant hoses for rubbing or interference that can

cause unusual noises.

(4) Check refrigerant charge. (See “Charging System”.)

(5) Recheck compressor noise as in Step 1.

(6) If noise still exists, loosen compressor mounting bolts and

retorque. Repeat Step 1.

(7) If noise continues, replace compressor and repeat Step 1.

POWER RELAY CHECKMBBFNAK(1) Remove the radiator fan motor relays (HI) and (LO) from the

relay box on the right of the engine compartment.

(2) Remove the radiator fan motor relay (air conditioner),

condenser fan motor relays (HI) and (LO), and

air-conditioner compressor relay from the relay box on the left

of the engine compartment.

(3) Remove the blower motor relay from the junction box.

(4) Remove the blower motor HI relay from the blower case

assembly.

(5) Check the continuity between terminals using a circuit

tester.

J Blower m.otor HI relay\2OFOO6l

IDLE-UP OPERATION CHECKM55FOAB

(1) Before inspection and adjustment set vehicle in the

following condition:

lEngine coolant temperature: 80 - 95°C (176 - 203°F)

lLights, electric cooling fan and accessories: Set to OFF

l Transaxle: Neutral (N or P for vehicles with

A/T)l Steering wheel: Straightforward

(2) Check to be sure that the idling speed becomes the

standard value when the air conditioner switch is switched

ON and the air conditioner is activated.

Standard value: 900

+ 100 rpm

NOTEThere is no necessity to make an adjustment, because the

idling speed is automatically adjusted by the ISC” system.

If, however, there occurs a deviation from the standard

value for some reason, check the ISC” system.

ISC: Idle Speed Control

1 TSB RevisionI -

Page 1112 of 1146

HEATERS AND MANUAL AIR CONDITIONER - Compressor

Spring

Valve

ompressor

2OPO286~

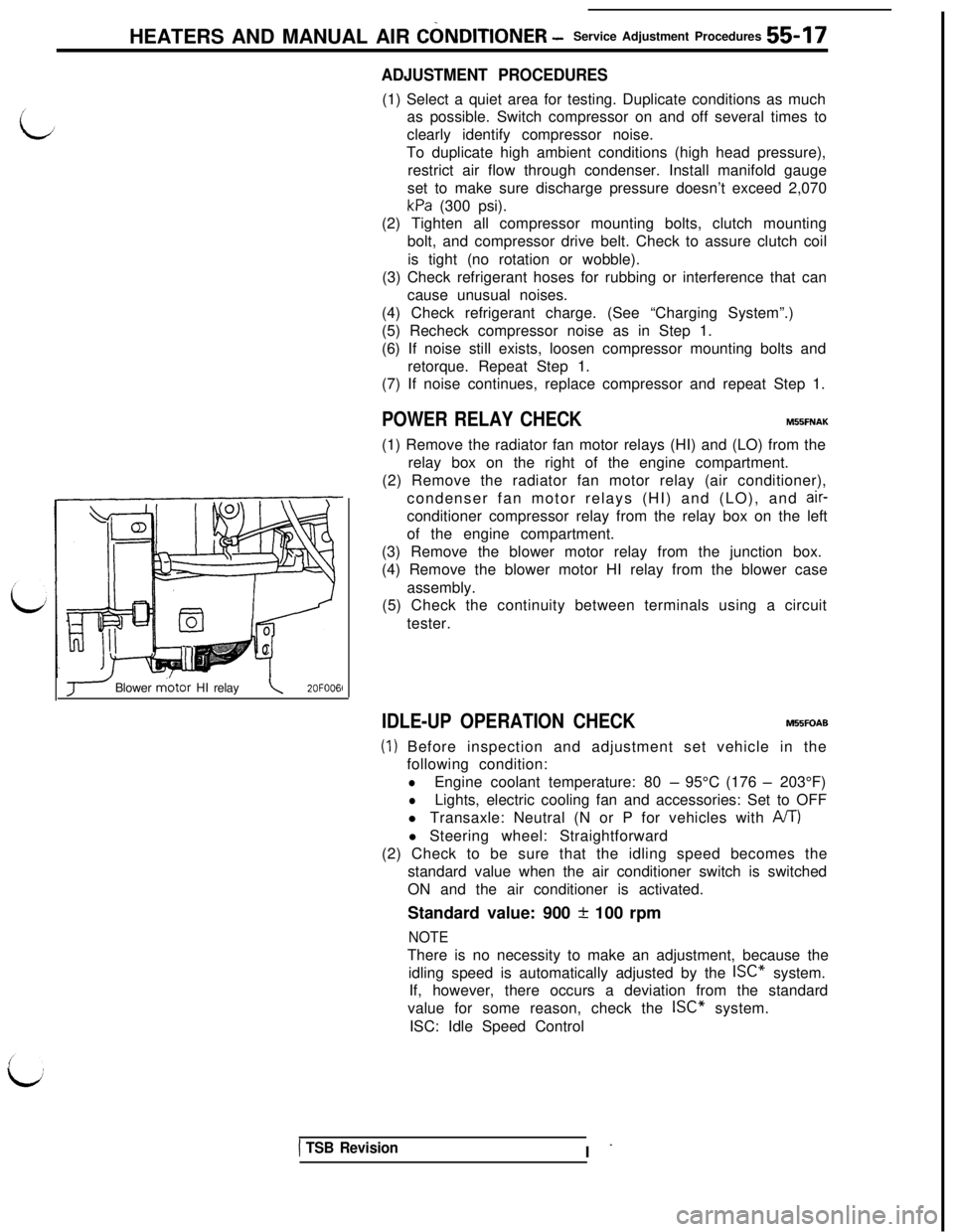

SERVICE POINT OF DISASSEMBLYMSlSFAE3. REMOVAL OF NUT

Use the special tool to loosen the nut,

INSPECTIONM55SGABl Check the surface of the armature for scoring or bluing.

l Check the surface of the rotor for scoring or bluing.

l Check the sealing surfaces for cracks, scratches and

deformation.

0Check the front housing for cracks or scoring on the sealing

surfaces.l Check the compressor shaft for scoring.

J

HIGH PRESSURE RELIEF VALVE CHECK

The high pressure relief valve is a safety feature which releasesI

part of the refrigerant inside the system into the atmospherewhen the high pressure level exceeds 3,550

kPa (505 psi)

during air conditioner operation.Once the pressure inside the system has been reduced to

2,400

kPa (341 psi) or lower, the high pressure relief valveL&Jcloses, thus allowing continued operation.

(1) If a leak is detected at section A, replace the high pressure

relief valve. The valve can be used unless there is a leak(from that section.

(2) If a leak is detected at section B, retighten the valve. If the

leak still persists after retightening the valve, replace the

packing.

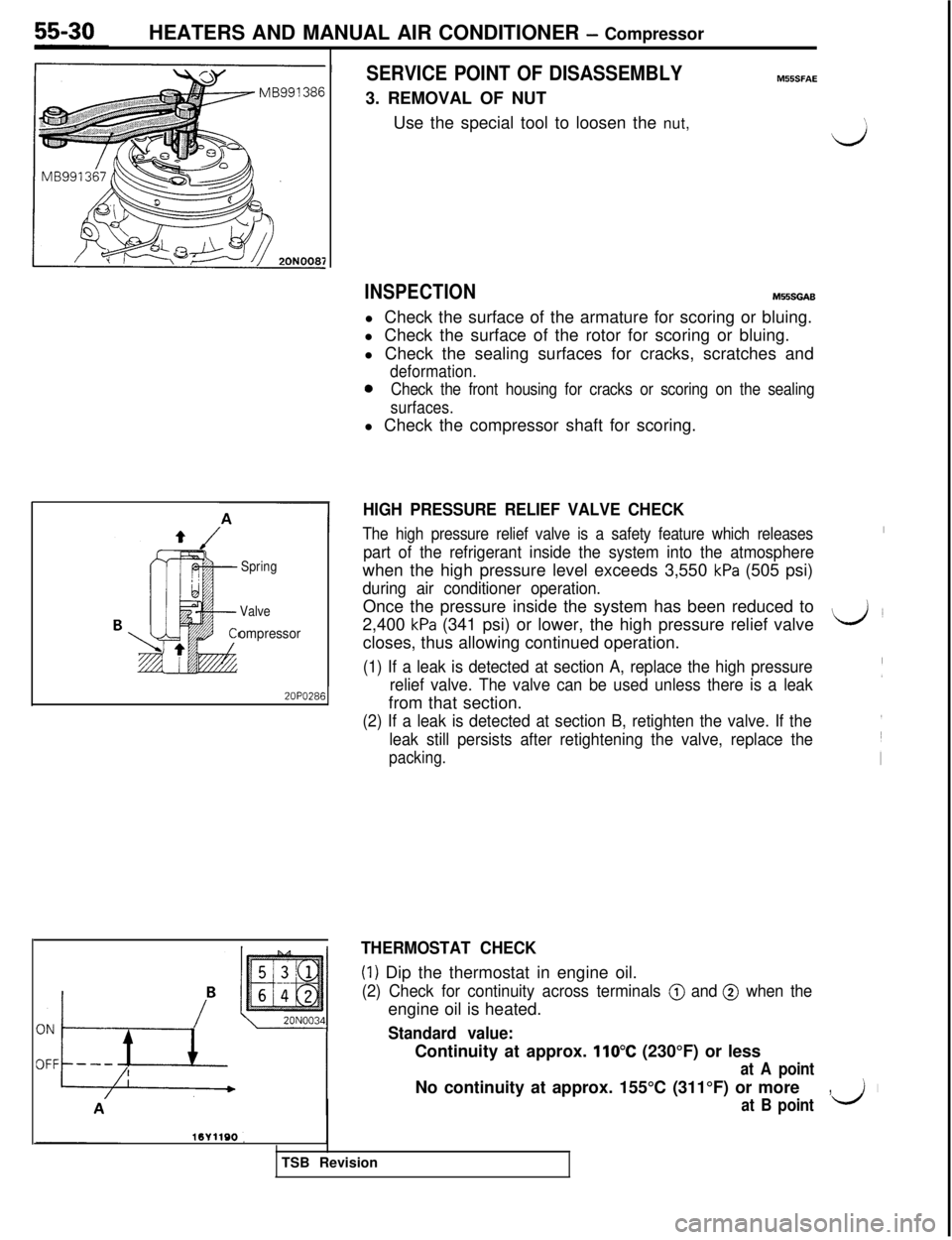

THERMOSTAT CHECK

(1) Dip the thermostat in engine oil.

(2) Check for continuity across terminals @ and @ when theengine oil is heated.

Standard value:Continuity at approx.

110°C (230°F) or less

at A pointNo continuity at approx. 155°C (311°F) or more

,I

at B pointII;TSB Revision

Page 1113 of 1146

HEATERS AND MANUAL AIR CONDITIONER - Compressor55-3120N003d

2OFOO96

I

Ec-3

3180?+I! (25)zz

h34\

*

Engine speed rpm2OPO2S

\CrankshaftTapered part

20A0157

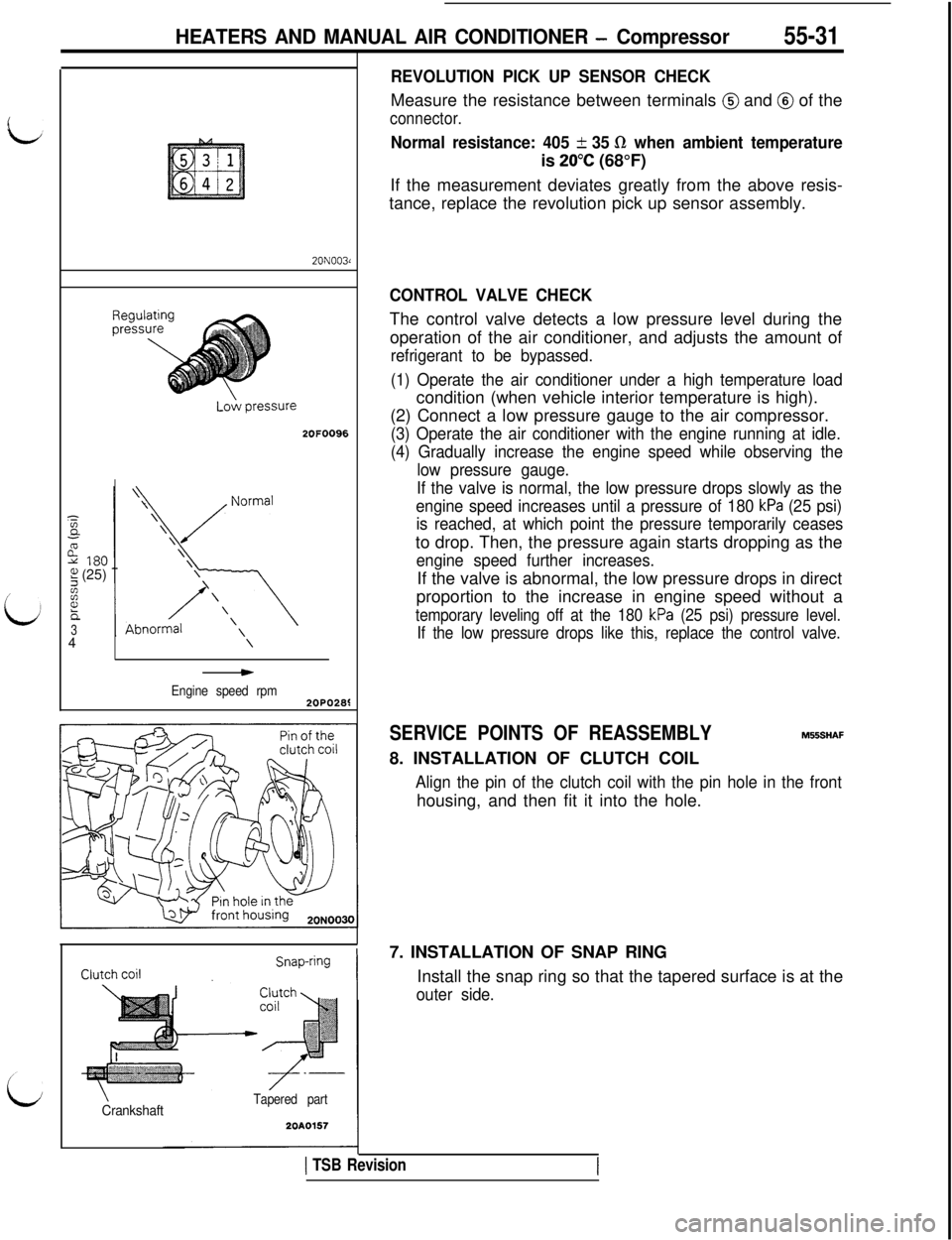

REVOLUTION PICK UP SENSOR CHECKMeasure the resistance between terminals

@ and @ of the

connector.

Normal resistance: 405 + 35 R when ambient temperatureis

20°C (68°F)

If the measurement deviates greatly from the above resis-

tance, replace the revolution pick up sensor assembly.

CONTROL VALVE CHECKThe control valve detects a low pressure level during the

operation of the air conditioner, and adjusts the amount of

refrigerant to be bypassed.

(1) Operate the air conditioner under a high temperature loadcondition (when vehicle interior temperature is high).

(2) Connect a low pressure gauge to the air compressor.

(3) Operate the air conditioner with the engine running at idle.

(4) Gradually increase the engine speed while observing the

low pressure gauge.

If the valve is normal, the low pressure drops slowly as the

engine speed increases until a pressure of 180

kPa (25 psi)

is reached, at which point the pressure temporarily ceasesto drop. Then, the pressure again starts dropping as the

engine speed further increases.If the valve is abnormal, the low pressure drops in direct

proportion to the increase in engine speed without a

temporary leveling off at the 180 kPa (25 psi) pressure level.

If the low pressure drops like this, replace the control valve.

SERVICE POINTS OF REASSEMBLYM556HAF

8. INSTALLATION OF CLUTCH COIL

Align the pin of the clutch coil with the pin hole in the fronthousing, and then fit it into the hole.

7. INSTALLATION OF SNAP RING

Install the snap ring so that the tapered surface is at the

outer side.

1 TSB Revision

Page 1116 of 1146

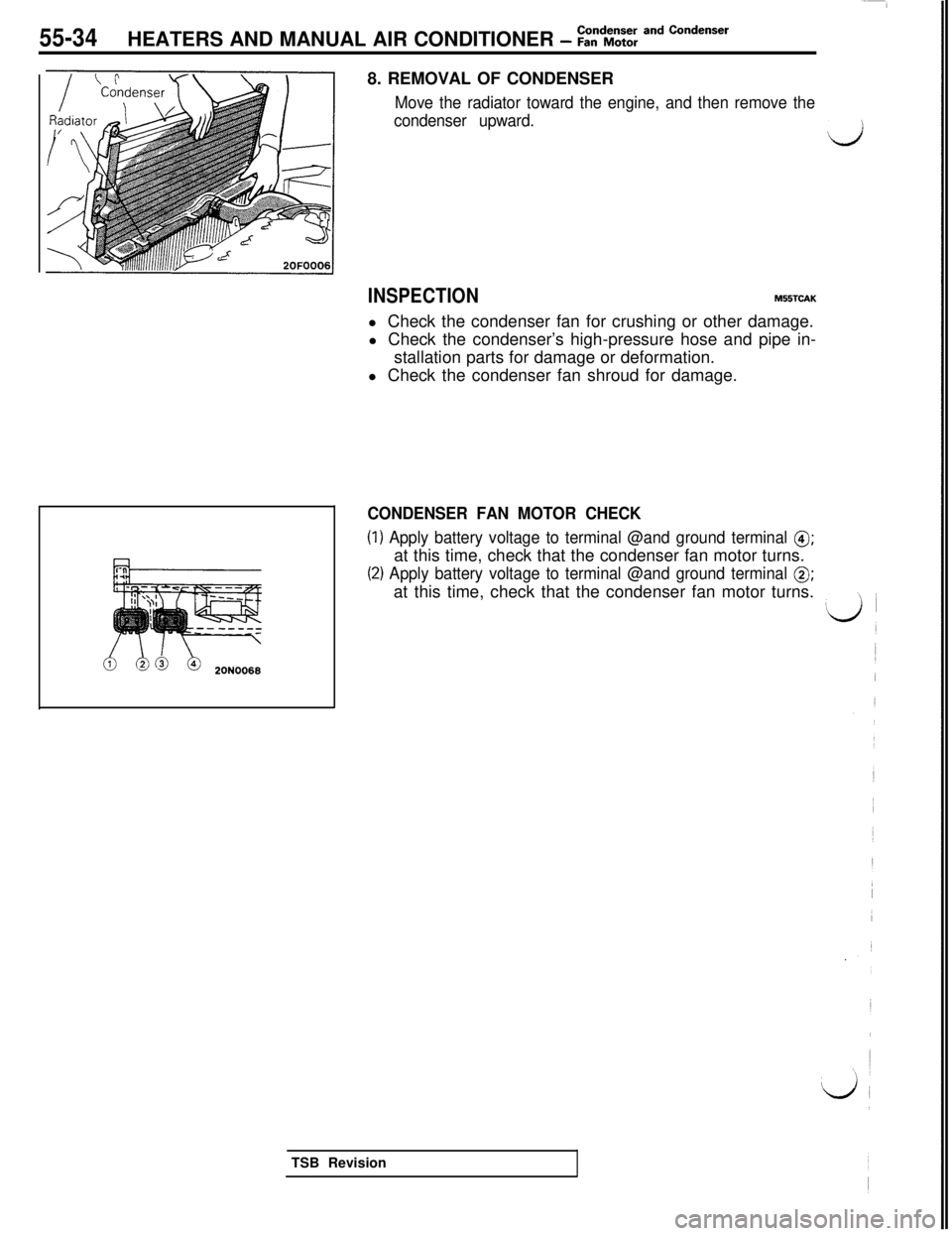

55-34HEATERS AND MANUAL AIR CONDITIONER - :t%%: and Condenser8. REMOVAL OF CONDENSER

Move the radiator toward the engine, and then remove the

condenser upward.

d

INSPECTIONM55TCAKl Check the condenser fan for crushing or other damage.

l Check the condenser’s high-pressure hose and pipe in-

stallation parts for damage or deformation.

l Check the condenser fan shroud for damage.

CONDENSER FAN MOTOR CHECK

(1) Apply battery voltage to terminal @and ground terminal 8;at this time, check that the condenser fan motor turns.

(2) Apply battery voltage to terminal @and ground terminal 0;at this time, check that the condenser fan motor turns.

TSB Revision