engine MITSUBISHI 3000GT 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 1015 of 1146

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - General lnform=*ion52B-5

r1.c

L

E.

,

iiCAUTION: SRS diagnosis unit

This unit cannot be repaired.

If defective, remove and replace entire unit per

service manual instructions.

Do not disassemble or tamper.

See service manual for handling and storage

instructions.Driver’s air bag information

This vehicle

ha% an air bag which will supple-

ment the driver’s seatbelt in certain frontal

collisions. The air bag is not a substitute for the

driver’s seatbelt in any type of collision. The

driver, and all other occupants, should wear

seatbelts at all times.

WARNING!

If the “SRS” warning light does not come.on

for about 7 seconds when ignition key is turned

to “ON” or engine is started, or if it stays on

while driving, drive the vehicle to your nearest

authorized dealer right away. Also do so if

vehicle’s front end is damaged or if air bag has

deployed.

The air bag system must be inspected by an

authorized dealer ten years after vehicle manu-

facture date shown on certification label lo-

cated on left front door-latch post or door

frame.Read “SRS” section of your owner’s manual

before driving, for important information, about

Dperation, service and disposal of the air bag

svstem.

Do no drop: keep dry.

Failure to follow instructions could render air

bag inoperative and result in driver injury.

F. CAUTION: SRS

Before replacing steering wheel, read service

manual, center front wheels

ahd align SRS

clock spring neutral marks.

Failure to do so may render SRS system

inoperative, risking serious driver injury.

I.

J.WARNING: SRS

This air bag module cannot be repaired. Do not

disassemble or tamper.

Do not perform diagnosis. Do not touch with

electrical test equipment or probes. Refer to

service manual for further instructions, and for

special handling, storage and disposal proce-

dures.

Tampering or mishandling can result in injury.

Danger! Poison. Keep out of the reach of

children.

Contains sodium acid and potassium nitrate

contents are poisonous and extremely flamm-

able. Contact with acid, water, or heavy metals

may produce harmful and irritating gases or

explosive compounds. Do not dismantle, in-

cinerate or bring into contact with electricity or

store at temperatures exceeding

(93.3”C)

200°F.Fast aid: If contents are swallowed induce

vomiting. For eye contact flush eye with water

for 15 minutes. If gases from acid or water

contact are inhaled, seek fresh air. In every

case, get prompt medical attention.

For additional information, see material safety

data sheet (MSDS) for this product.

CAUTION: SRS clock spring

This is not a repairable part. Do not disassem-

ble or tamper.

If defective, remove and replace entire unit per

service manual instructions.

Before replacement, read service manual, cen-

ter front wheels and align neutral marks.

Failure to

foHow instructions may render SRS

system inoperative, risking serious driver in-

jury.CAUTION: SRS

Before removal of steering gearbox, read ser-

vice manual, center front wheels and remove

ignition key.

Failure to do so may damage SRS clock spring

and render SRS system inoperative, risking

serious driver injury.

TSB Revision

Page 1017 of 1146

i

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - General Information526-7

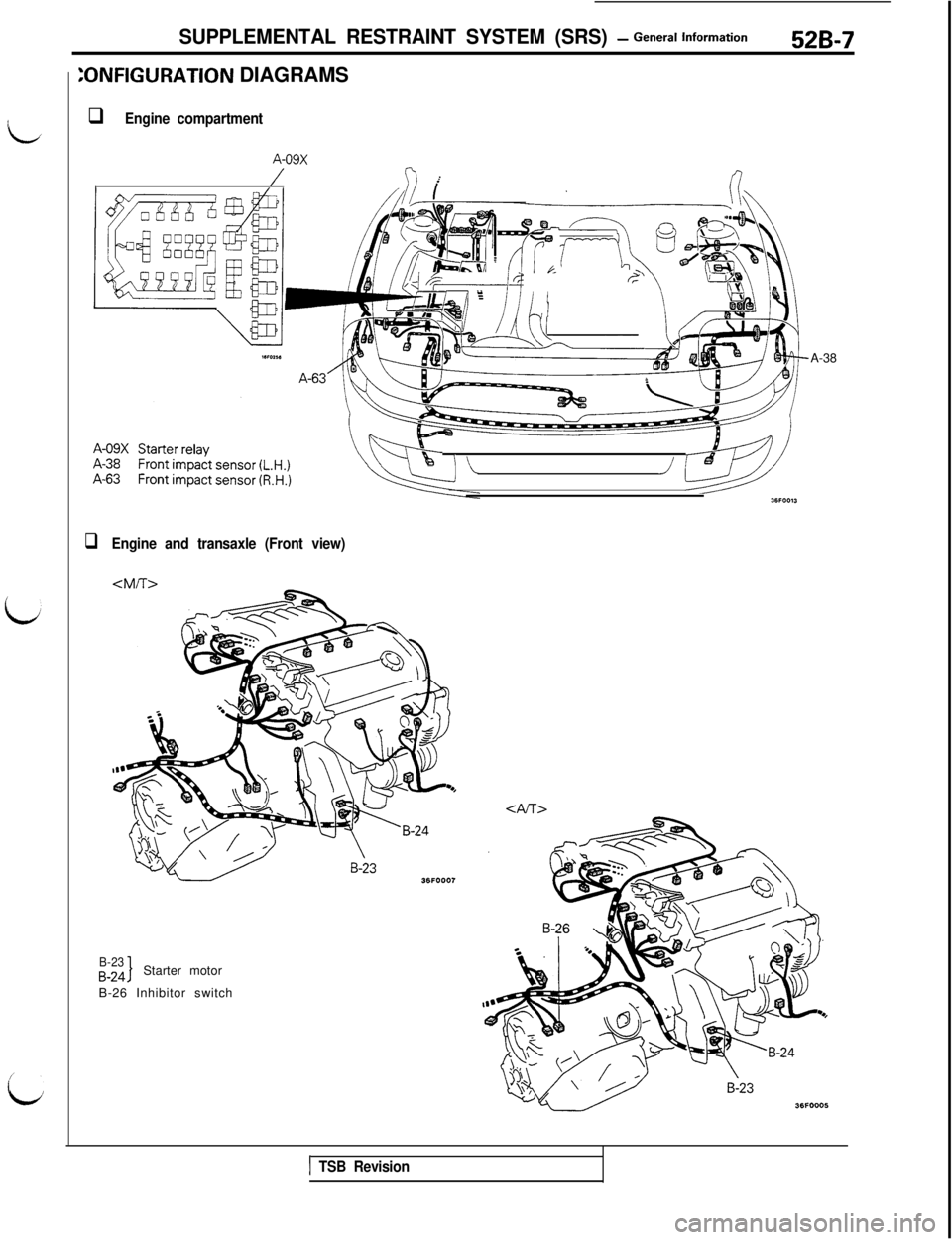

:ONFIGURATION DIAGRAMS

q Engine compartmentA-09X

/

+m*,.16,IIfc’ \=is\ IL\\

\

\iw I \B/f---TJwdD

’ L&/Y&!!

3BFOO13

qEngine and transaxle (Front view)

B-23B-24Starter motor

B-26 Inhibitor switchA-38

1 TSB Revision

Page 1027 of 1146

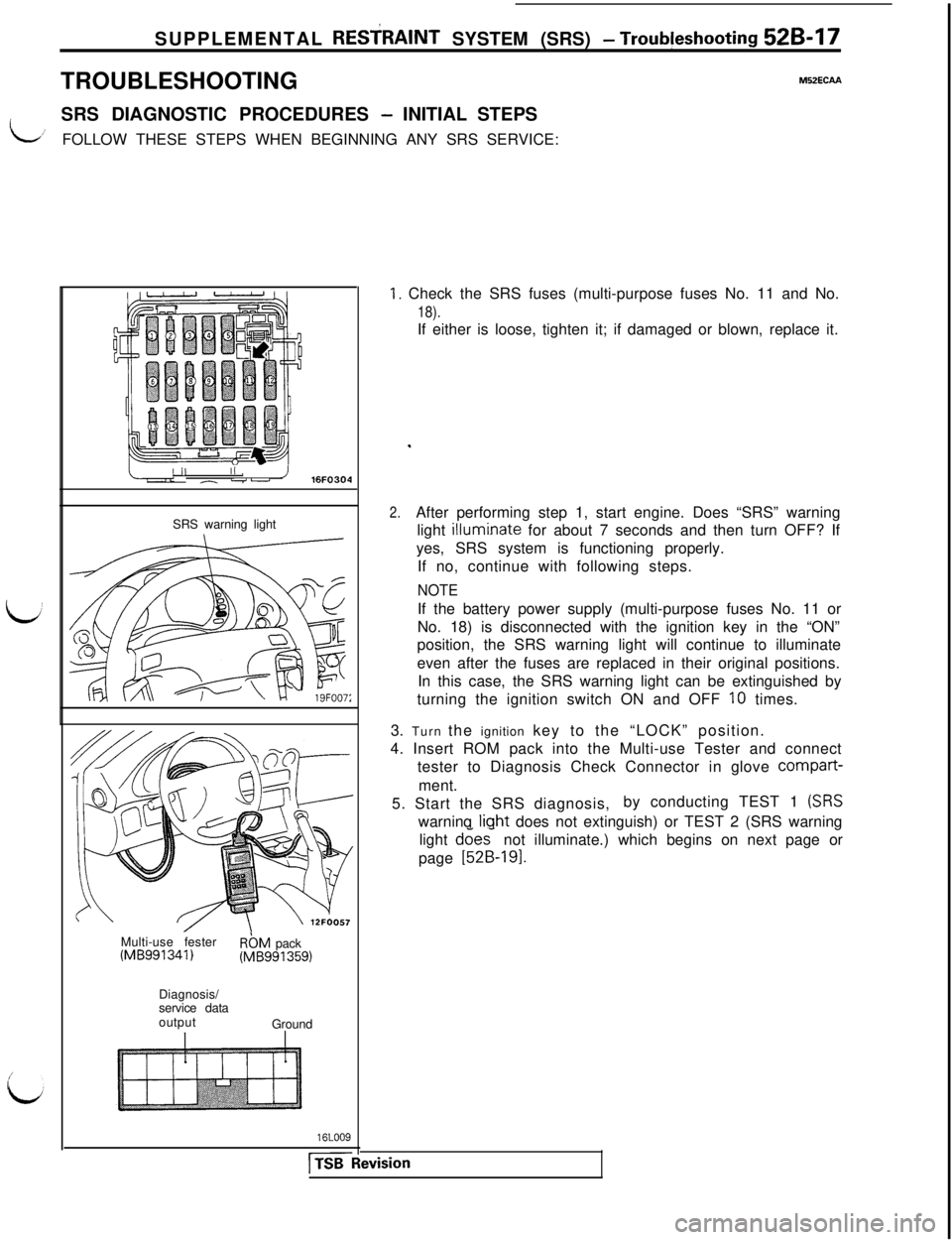

SUPPLEMENTAL RESfRAlNT SYSTEM (SRS) - Troub!eshooting 52B-17TROUBLESHOOTING

M52ECAA

idSRS DIAGNOSTIC PROCEDURES

- INITIAL STEPS’FOLLOW THESE STEPS WHEN BEGINNING ANY SRS SERVICE:

/II/ ,- -u’ 16FO304

SRS warning light

Multi-use fester

(MB991341)RbM pack(MB991359)

Diagnosis/

service data

output

Ground

16LOO9

[TSB

1. Check the SRS fuses (multi-purpose fuses No. 11 and No.

18).If either is loose, tighten it; if damaged or blown, replace it.

.

2.After performing step 1, start engine. Does “SRS” warning

light

illumi.nate for about 7 seconds and then turn OFF? If

yes, SRS system is functioning properly.

If no, continue with following steps.

NOTEIf the battery power supply (multi-purpose fuses No. 11 or

No. 18) is disconnected with the ignition key in the “ON”

position, the SRS warning light will continue to illuminate

even after the fuses are replaced in their original positions.

In this case, the SRS warning light can be extinguished by

turning the ignition switch ON and OFF

10 times.

3. Turn the ignition key to the “LOCK” position.

4. Insert ROM pack into the Multi-use Tester and connect

tester to Diagnosis Check Connector in glove compart-

ment.

5. Start the SRS diagnosis,by conducting TEST 1

(SRSwarninq liqht does not extinguish) or TEST 2 (SRS warning

light does- not illuminate.) which begins on next page or

page

[52B-191.

ivision

Page 1028 of 1146

52B-18 SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - Troubleshooting

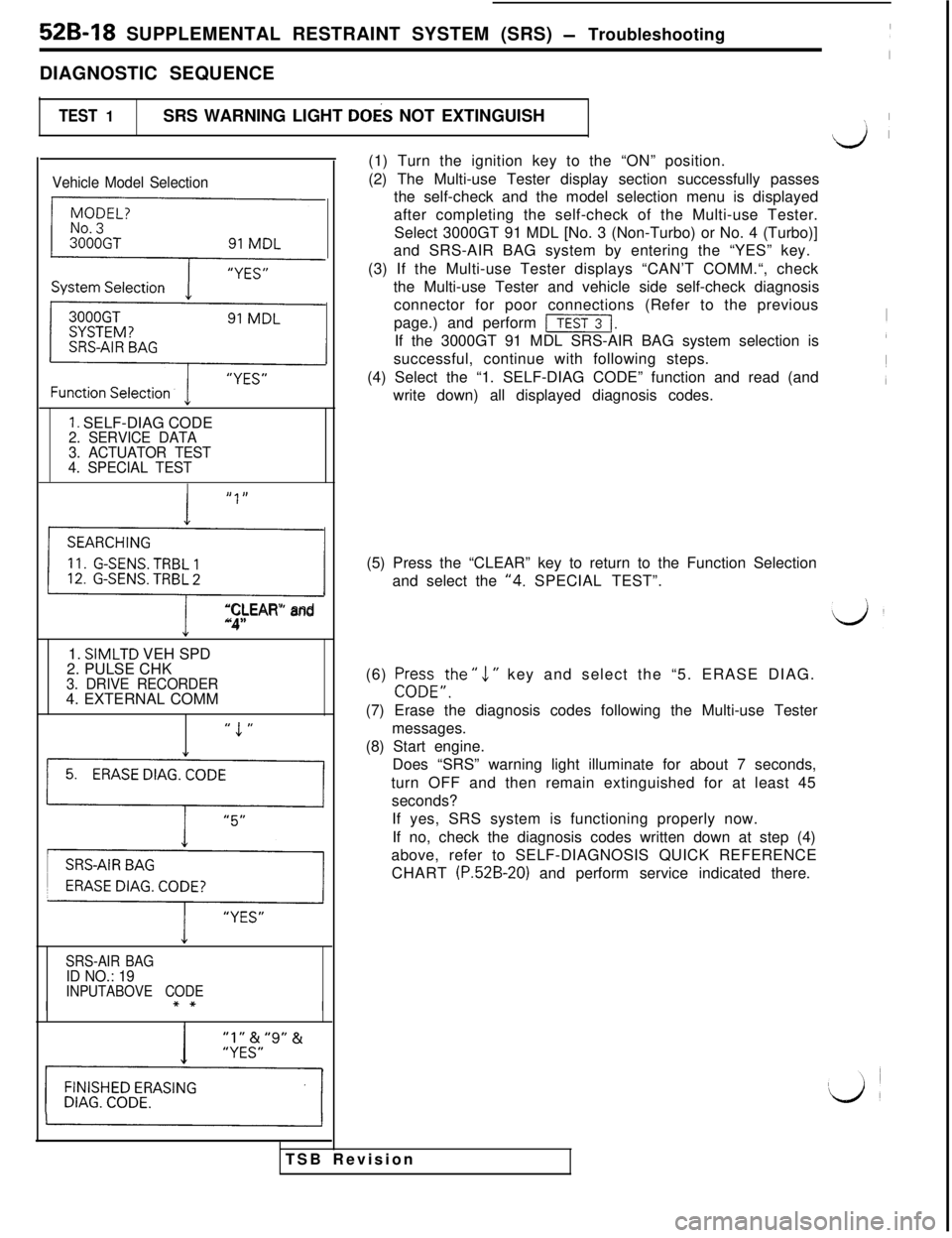

DIAGNOSTIC SEQUENCE

TEST 1SRS WARNING LIGHT DOES NOT EXTINGUISH

\1 I

Vehicle Model Selection

{

F

1. SELF-DIAG CODE2. SERVICE DATA

3. ACTUATOR TEST

4. SPECIAL TEST

,, I,

0

“CLEAR” and“4”1.

SIMLTD VEH SPD

2. PULSE CHK

3. DRIVE RECORDER4. EXTERNAL COMM

” 1 ”

1’1

y,,

SRS-AIR BAGID NO.: 19INPUTABOVE CODE

I(1) Turn the ignition key to the “ON” position.

(2) The Multi-use Tester display section successfully passes

the self-check and the model selection menu is displayed

after completing the self-check of the Multi-use Tester.

Select 3000GT 91 MDL [No. 3 (Non-Turbo) or No. 4 (Turbo)]

and SRS-AIR BAG system by entering the “YES” key.

(3) If the Multi-use Tester displays “CAN’T COMM.“, check

the Multi-use Tester and vehicle side self-check diagnosis

TSB Revisionconnector for poor connections (Refer to the previous

page.) and perform

[I.If the 3000GT 91 MDL SRS-AIR BAG system selection is

successful, continue with following steps.

(4) Select the “1. SELF-DIAG CODE” function and read (and

write down) all displayed diagnosis codes.

(5) Press the “CLEAR” key to return to the Function Selection

and select the

“4. SPECIAL TEST”.

(6) Pr+FE,the ”

1 ” key and select the “5. ERASE DIAG.

(7) Erase the diagnosis codes following the Multi-use Tester

messages.

(8) Start engine.

Does “SRS” warning light illuminate for about 7 seconds,

turn OFF and then remain extinguished for at least 45

seconds?

If yes, SRS system is functioning properly now.

If no, check the diagnosis codes written down at step (4)

above, refer to SELF-DIAGNOSIS QUICK REFERENCE

CHART

(P.52B-20) and perform service indicated there.

Page 1049 of 1146

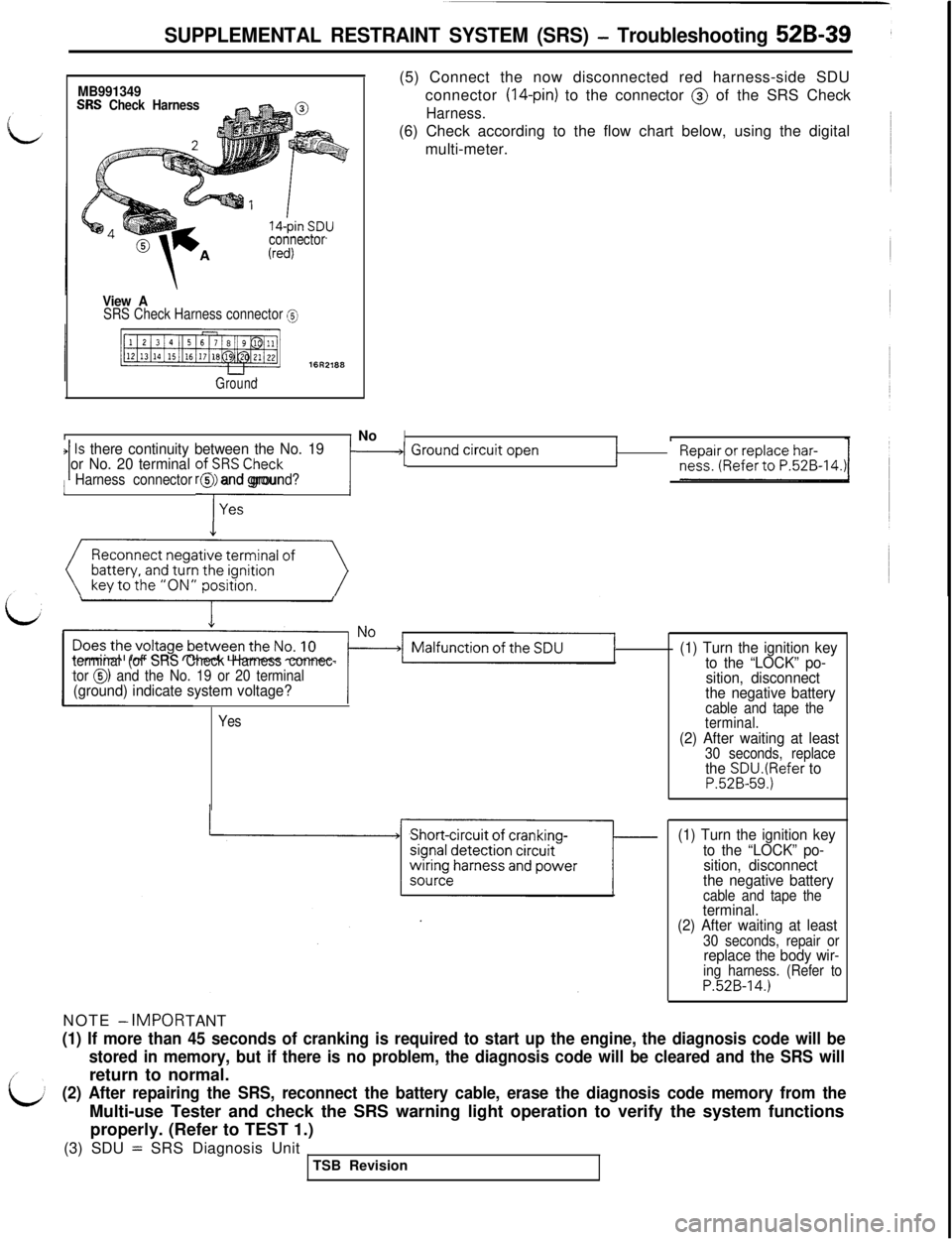

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - Troubleshooting 52B-39

MB991349SRS Check Harness

connector

View ASRS Check Harness connector @

Ground

II No(5) Connect the now disconnected red harness-side SDU

connector

(14-pin) to the connector @ of the SRS Check

Harness.(6) Check according to the flow chart below, using the digital

multi-meter.

IIIIs there continuity between the No. 191 or No. 20 terminal ofi;RSCheck‘1 ~~~~~;,0~~~~~~.~~~-14.~r1 Ground ‘jrcuit Open1Harness connector @ and ground?

Reconnect negative terminal of

(()

terminal (of SRS Check Harness connec-

tor 0) and the No. 19 or 20 terminal(ground) indicate system voltage?NOTE

- IMPOR

TANT

Yes

(1) Turn the ignition key

to the “LOCK” po-

sition, disconnect

the negative battery

cable and tape the

terminal.

(2) After waiting at least30 seconds, replacethe SDU.(Refer toP.52B-59.)

(1) Turn the ignition key

to the “LOCK” po-

sition, disconnect

the negative battery

cable and tape theterminal.

(2) After waiting at least

30 seconds, repair orreplace the body wir-ing harness. (Refer toP.52B-14.)

(1) If more than 45 seconds of cranking is required to start up the engine, the diagnosis code will be

stored in memory, but if there is no problem, the diagnosis code will be cleared and the SRS willreturn to normal.

(2) After repairing the SRS, reconnect the battery cable, erase the diagnosis code memory from theMulti-use Tester and check the SRS warning light operation to verify the system functions

properly. (Refer to TEST 1.)

(3) SDU

= SRS Diagnosis Unit

TSB Revision

Page 1059 of 1146

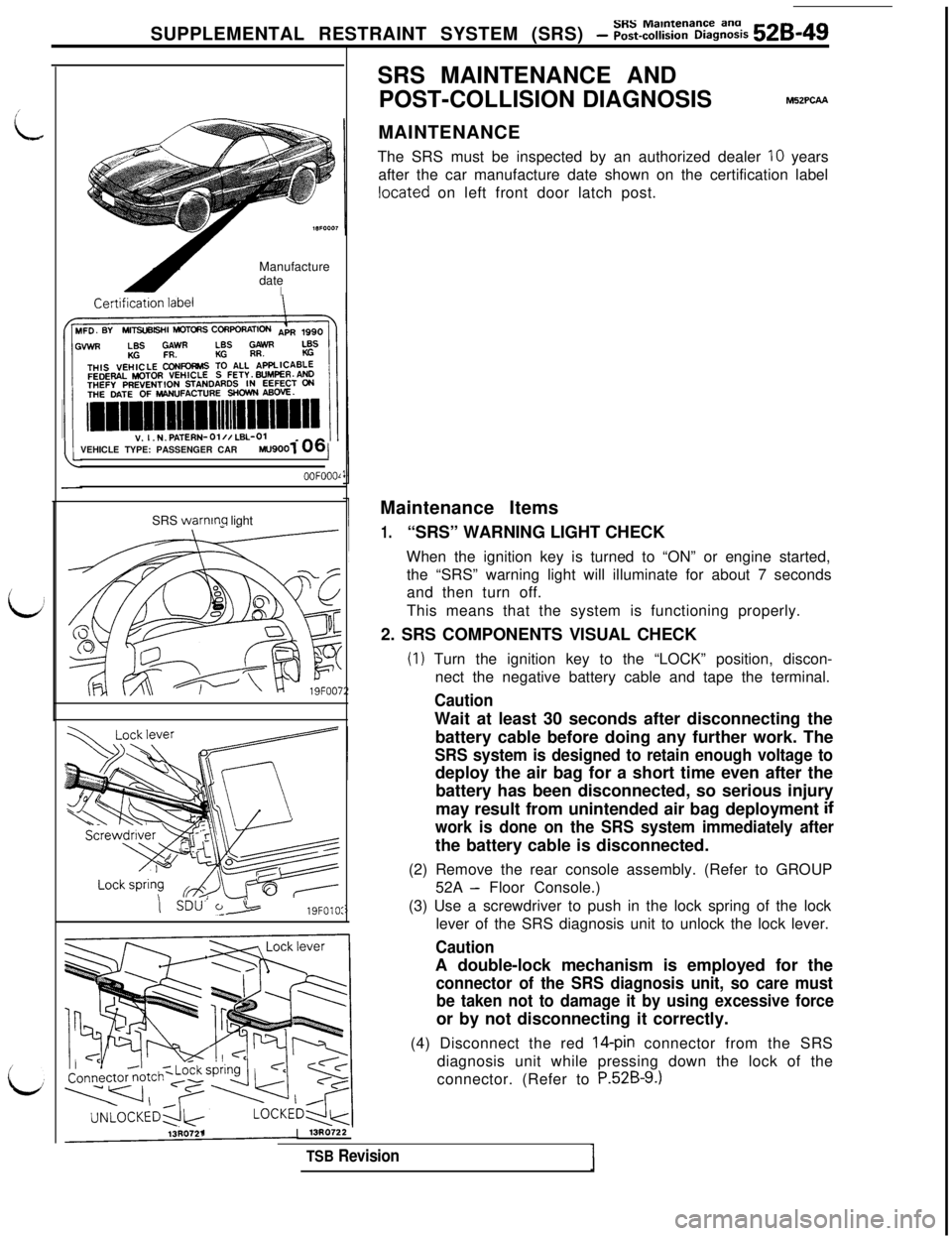

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - Z~-%Z%&Z% 528-49Manufacture

date

IVEHICLE TYPE: PASSENGER CAR

MU9001/

OOFOOOlSRS

warnmq light- -SDU’

t>19FOlO:SRS MAINTENANCE AND

POST-COLLISION DIAGNOSIS

M52PCAAMAINTENANCE

The SRS must be inspected by an authorized dealer

10 years

after the car manufacture date shown on the certification label

located on left front door latch post.

Maintenance Items

1.“SRS” WARNING LIGHT CHECK

When the ignition key is turned to “ON” or engine started,

the “SRS” warning light will illuminate for about 7 seconds

and then turn off.

This means that the system is functioning properly.

2. SRS COMPONENTS VISUAL CHECK

(1) Turn the ignition key to the “LOCK” position, discon-

nect the negative battery cable and tape the terminal.

CautionWait at least 30 seconds after disconnecting the

battery cable before doing any further work. The

SRS system is designed to retain enough voltage todeploy the air bag for a short time even after the

battery has been disconnected, so serious injury

may result from unintended air bag deployment

if

work is done on the SRS system immediately afterthe battery cable is disconnected.

(2) Remove the rear console assembly. (Refer to GROUP

52A

- Floor Console.)

(3) Use a screwdriver to push in the lock spring of the lock

lever of the SRS diagnosis unit to unlock the lock lever.

CautionA double-lock mechanism is employed for the

connector of the SRS diagnosis unit, so care must

be taken not to damage it by using excessive forceor by not disconnecting it correctly.

(4) Disconnect the red

14-pin connector from the SRS

diagnosis unit while pressing down the lock of the

connector. (Refer to

P.52B-9.)

13R0721113R0722

TSB Revision

Page 1083 of 1146

55-1

HEATER, AIR

CONDITIONER

AND VENTILATION

CONTENTSM55AA- -

HEATERS AND AIR CONDITIONING................3HEATER UNIT*........................................................................22

SPECIFICATIONS

....................................................................3REFRIGERANT LINE................................................................35General Specifications

........................................................3RESISTOR................................................................................20Lubricants

............................................................................4SAFETY PRECAUTIONS........................................................9Sealant and Adhesive............................................................4

Service Specifications3SERVICE ADJUSTMENT PROCEDURES............................10........................................................

SPECIAL TOOLS4Charging Procedures............................................................11

i

........................................................................Charging the Refrigerant....................................................12Compressor Drive Belt Adjustment....................................11

HEATERS AND MANUAL AIR CONDITIONER5Compressor Noise................................................................16

................................................16

AIR CONDITIONER SWITCH................................................21Handling Tubing andFittings

Idle-up Operation Check....................................................17

BELT LOCK CONTROLLER20Performance Test................................................................15....................................................

BLOWER ASSEMBLYPower Relay Check............................................................17............................................................23Refrigerant Leak Repair Procedure....................................15COMPRESSOR........................................................................

27TestProcedures....................................................................10

CONDENSER AND CONDENSER FAN MOTOR................33TROUBLESHOOTING............................................................5

ENGINE COOLANT TEMPERATURE SWITCH....................

39VENTILATORS (AIR INLET AND AIR OUTLET)................38

EVAPORATOR

........................................................................

25VENTILATORS (INSTRUMENT PANEL)*............................36

HEATER CONTROL ASSEMBLY*

........................................18CONTINUED ON NEXT PAGE

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

(1)A Supplemental Restraint System (SRS), which uses a driver-side air bag, has been installed in the 3000GT.(2)The SRS includes the following components: impact sensors, SRS diagnosis unit: SRS warning light, air bagmodule, clock spring, interconnecting wiring. Other SRS-related components (that may have to be

removed/installed in connection with SRS service or maintenance) are indicated in the table of contents byan asterisk (*).

WARNING!(1)Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inadvertent firing of the air bag) or to the driver (fromrendering the

SRS inoperative).(2) Service or maintenance of any SRS component or SRS-related component must be performed only at anauthorized MITSUBISHI dealer.

(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B

-Supplemental Restraint System (SRS), before beginning any service or maintenance of any component of theSRS or any SRS-related component.

Page 1084 of 1146

55-2FULL AUTO AIR CONDITIONER........................40OTHER PARTS........................................................................62

AIR-CONDITIONER CONTROL PANEL*,POWER TRANSISTOR, BELT LOCK CONTROLLER........57

AIR-CONDITIONER CONTROL UNIT*................................56

REFRIGERANT LINE................................................................62

COMPRESSOR

........................................................................62SAFETY PRECAUTlONS........................................................56

CONDENSER AND CONDENSER FAN MOTOR

................

62SENSORS....................................................................................60

DAMPER CONTROL MOTOR ASSEMBLY*........................

58SERVICE ADJUSTMENT PROCEDURES............................56

ENGINE COOLANT TEMPERATURE SWITCH

....................62

TROUBLESHOOTING............................................................40

Page 1085 of 1146

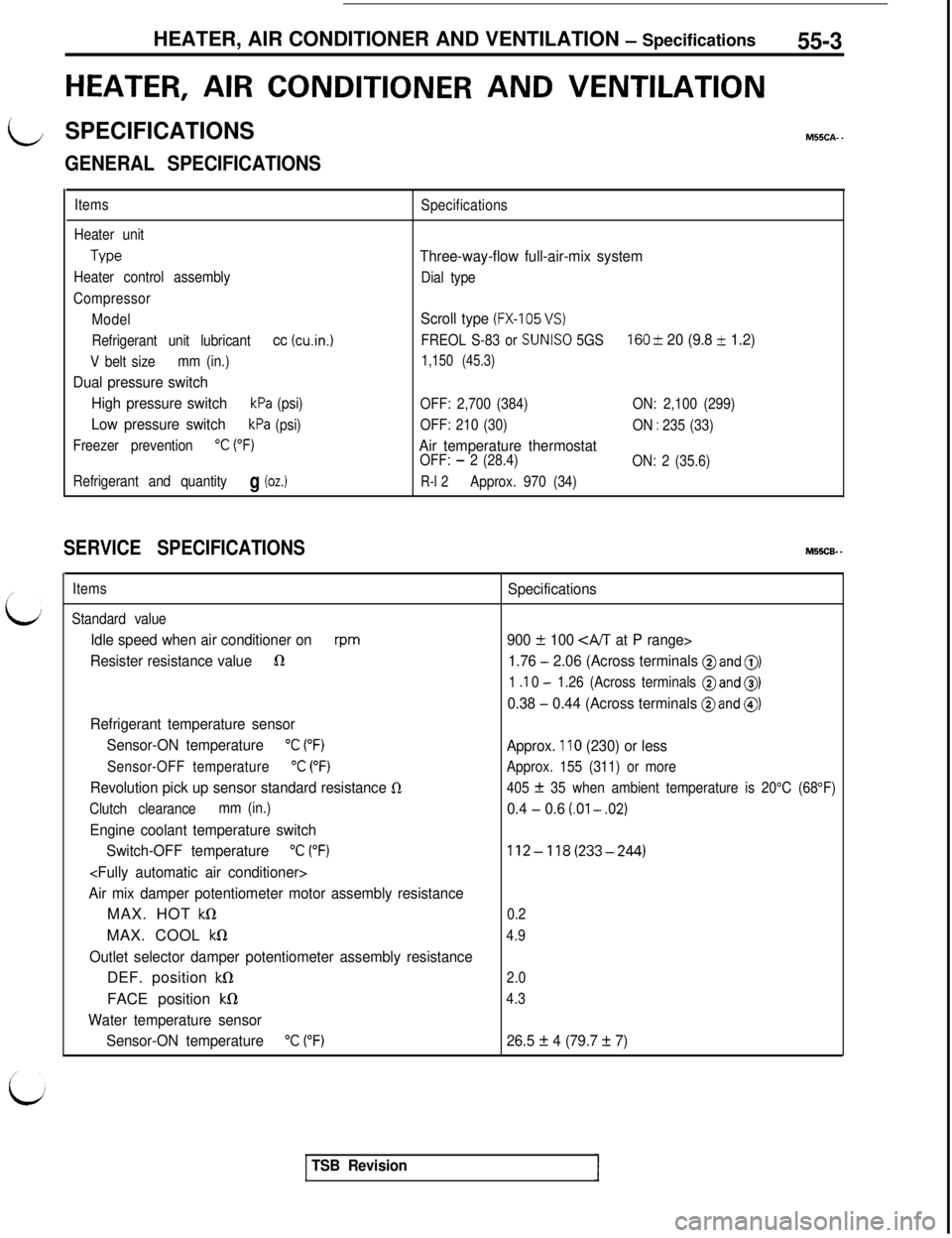

HEATER, AIR CONDITIONER AND VENTILATION - Specifications55-3

HEATER, AIR CONDITIONER AND VENTILATION

LSPECIFICATIONSM55CA. -

/’

L;

GENERAL SPECIFICATIONS

Items

Heater unit

Type

Heater control assembly

Compressor

Model

Refrigerant unit lubricant

cc (cu.in.1

V belt sizemm (in.)

Dual pressure switch

High pressure switch

kPa (psi)

Low pressure switchkPa (psi)

Freezer prevention

“C (“F)

Refrigerant and quantityg (oz.)

Specifications

Three-way-flow full-air-mix system

Dial type

Scroll type (FX-105 VS)

FREOL S-83 or SUNISO 5GS160 & 20 (9.8 + 1.2)

1,150 (45.3)

OFF: 2,700 (384)ON: 2,100 (299)

OFF: 210 (30)

ON

: 235 (33)

Air temperature thermostatOFF: - 2 (28.4)

ON: 2 (35.6)

R-l 2Approx. 970 (34)

SERVICE SPECIFICATIONSM55CB. -

Items

Standard value

Idle speed when air conditioner onrpm

Resister resistance value1R

Refrigerant temperature sensor

Sensor-ON temperature

“C (“F)

Sensor-OFF temperature“C (“F)

Revolution pick up sensor standard resistance 0

Clutch clearancemm (in.)

Engine coolant temperature switch

Switch-OFF temperature

“C (“F)

Air mix damper potentiometer motor assembly resistanceMAX. HOT

kQMAX. COOL

kS1

Outlet selector damper potentiometer assembly resistanceDEF. position

kS1FACE position

kfl

Water temperature sensor

Sensor-ON temperature

“C (“F)

Specifications

900

f 100 CA/T at P range>

1.76

- 2.06 (Across terminals @and 0)

1 .I 0 - 1.26 (Across terminals @and 0)

0.38 - 0.44 (Across terminals @and @)

Approx. 110 (230) or less

Approx. 155 (311) or more

405

f 35 when ambient temperature is 20°C (68°F)

0.4 - 0.6 (.Ol - .02)

112-118(233-244)

0.2

4.9

2.0

4.3

26.5 f 4 (79.7 + 7)

TSB Revision

Page 1086 of 1146

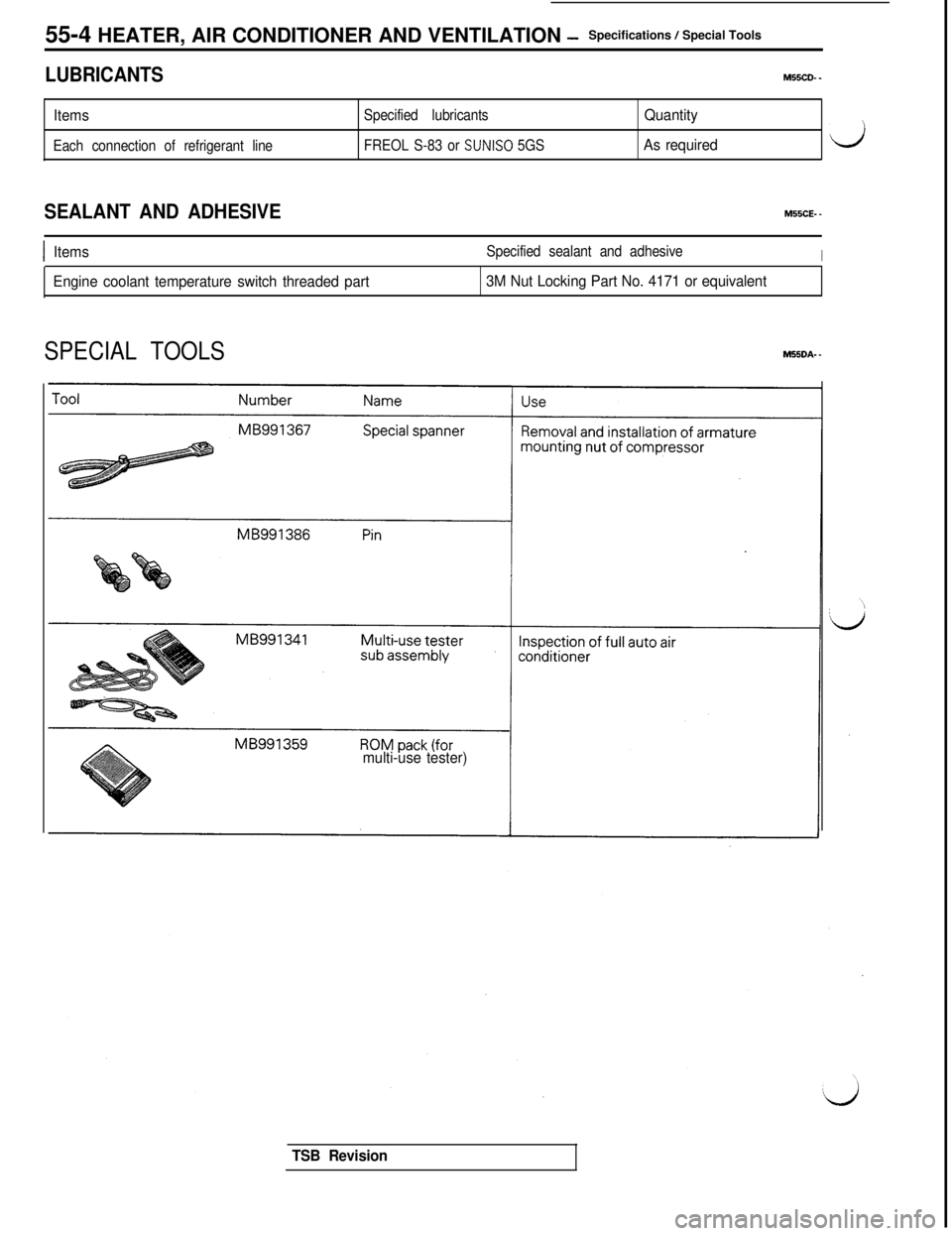

55-4 HEATER, AIR CONDITIONER AND VENTILATION -Specifications / Special Tools

LUBRICANTSM55CD. _

ItemsSpecified lubricants

Each connection of refrigerant lineFREOL S-83 or

SUNISO 5GS

Quantity

As required

SEALANT AND ADHESIVEM55CE- -

IItemsSpecified sealant and adhesiveI

Engine coolant temperature switch threaded part3M Nut Locking Part No. 4171 or equivalent

SPECIAL TOOLSMSSDA- -

multi-use tester)

TSB Revision