roof rack MITSUBISHI 3000GT 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 48 of 1146

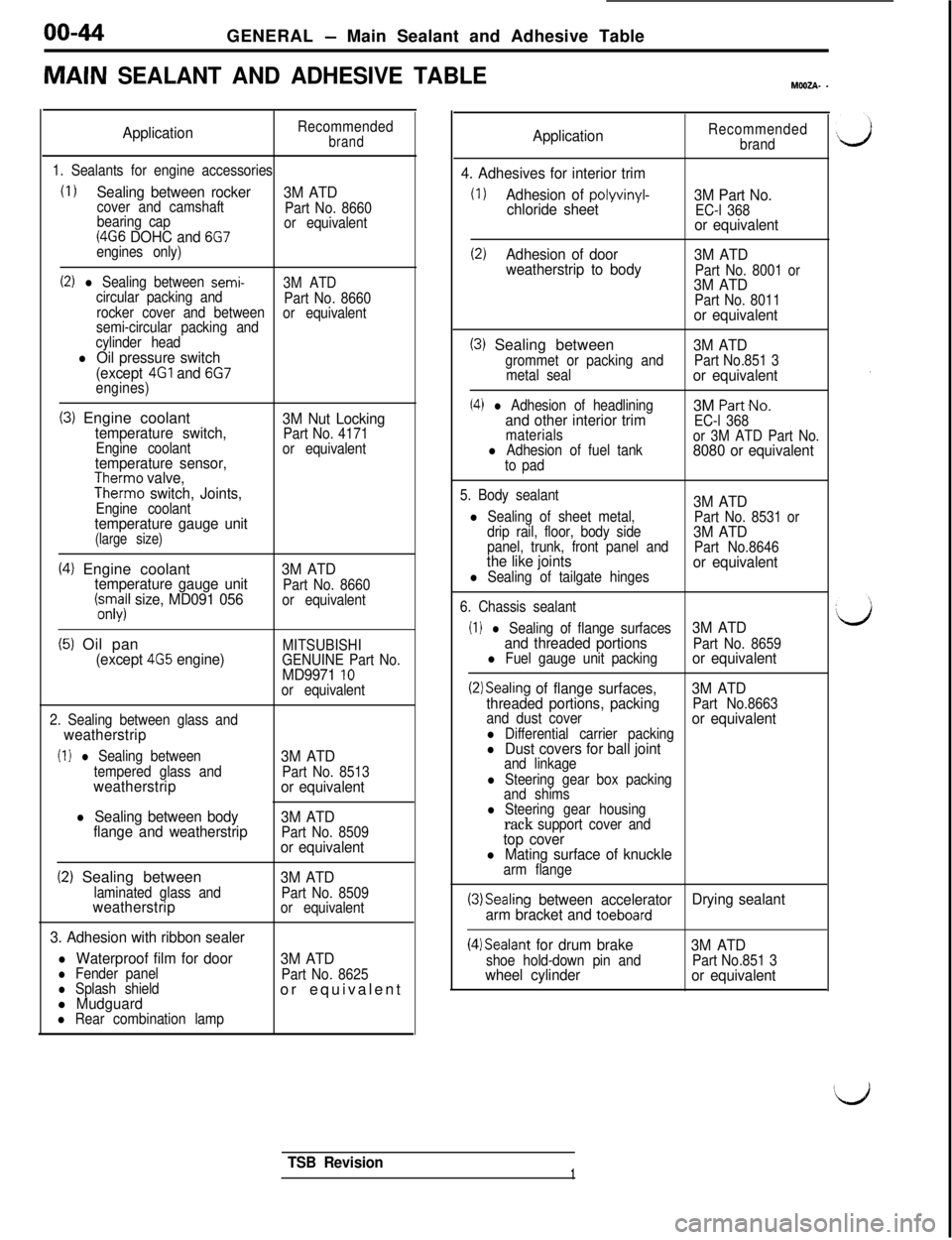

00-44

GENERAL - Main Sealant and Adhesive Table

MAIN SEALANT AND ADHESIVE TABLEMWZA- -

ApplicationRecommendedbrand

1. Sealants for engine accessories

(I 1Sealing between rocker

3M ATDcover and camshaft

Part No. 8660

bearing cap

(4G6 DOHC and 6G7or equivalent

engines only)

(2) l Sealing between semi-3M ATD

circular packing and

Part No. 8660

rocker cover and between

semi-circular packing andor equivalent

cylinder head

l Oil pressure switch

(except 4Gl and 6G7engines)

(3) Engine coolanttemperature switch,Engine coolanttemperature sensor,Therm0 valve,Therm0 switch, Joints,Engine coolanttemperature gauge unit(large size)

3M Nut LockingPart No. 4171

or equivalent

(4) Engine coolanttemperature gauge unit(;.s;il size, MD091 0563M ATDPart No. 8660

or equivalent

(5) Oil pan(except 4G5 engine)MITSUBISHI

GENUINE Part No.

MD9971 10or equivalent

2. Sealing between glass and

weatherstrip

(I 1 l Sealing between

tempered glass and

weatherstrip

l Sealing between body

flange and weatherstrip3M ATD

Part No. 8513or equivalent

3M ATD

Part No. 8509or equivalent

(2) Sealing betweenlaminated glass andweatherstrip

3. Adhesion with ribbon sealer

l Waterproof film for doorl Fender panell Splash shieldl Mudguardl Rear combination lamp

3M ATDPart No. 8509

or equivalent

3M ATDPart No. 8625or equivalent

ApplicationRecommended

brand

4. Adhesives for interior trim

(1)Adhesion of polyvinyl-chloride sheet3M Part No.EC-l 368or equivalent

(2)Adhesion of door

3M ATD

weatherstrip to body

Part No. 8001 or3M ATDPart No. 8011or equivalent

(3) Sealing betweengrommet or packing and

metal seal

(4) l Adhesion of headliningand other interior trimmaterialsl Adhesion of fuel tank

to pad

3M ATDPart No.851 3or equivalent3M

Part-No.

EC-l 368

or 3M ATD Part No.

8080 or equivalent

5. Body sealant3M ATDl Sealing of sheet metal,

Part No. 8531 or

drip rail, floor, body side3M ATDpanel, trunk, front panel and

Part No.8646the like jointsl Sealing of tailgate hingesor equivalent

6. Chassis sealant

(I 1 l Sealing of flange surfaces3M ATD

and threaded portions

Part No. 8659l Fuel gauge unit packingor equivalent

(2)Sealing of flange surfaces,3M ATD

threaded portions, packingPart No.8663

and dust cover

l Differential carrier packingor equivalent

l Dust covers for ball jointand linkage

l Steering gear box packing

and shims

l Steering gear housingrack support cover andtop coverl Mating surface of knucklearm flange

(3)Sealing between accelerator

arm bracket and toeboardDrying sealant

(4)Sealant for drum brakeshoe hold-down pin andwheel cylinder3M ATDPart No.851 3or equivalent

TSB Revision1

Page 877 of 1146

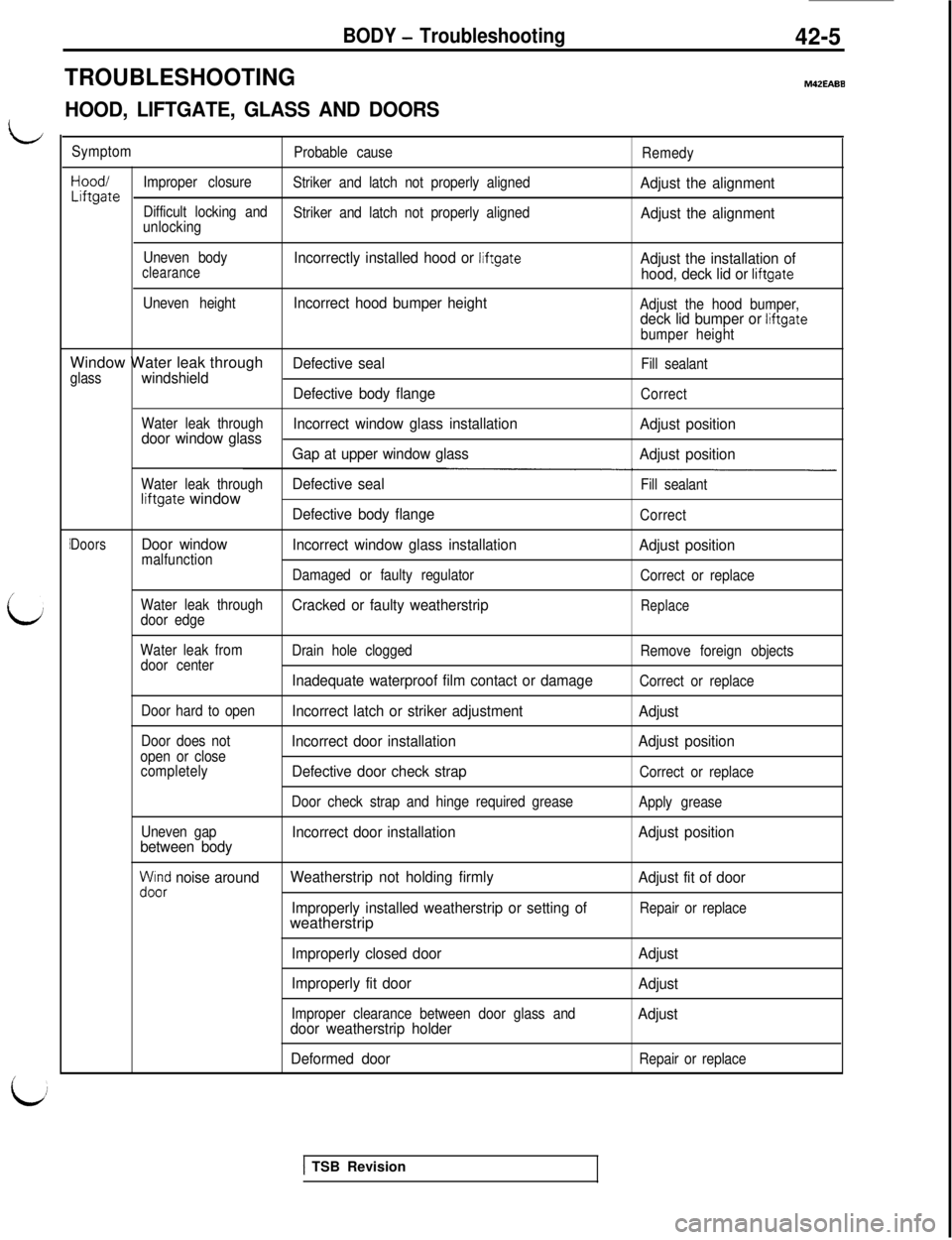

TROUBLESHOOTING

BODY - Troubleshooting42-5

M42EABE

HOOD, LIFTGATE, GLASS AND DOORS

LSymptom

Probable cause

Remedy

Hood/

Improper closureLiftgateStriker and latch not properly alignedAdjust the alignment

Difficult locking and

unlockingStriker and latch not properly alignedAdjust the alignment

Uneven bodyclearanceIncorrectly installed hood or liftgateAdjust the installation of

hood, deck lid or liftgate

Uneven height

Incorrect hood bumper heightAdjust the hood bumper,deck lid bumper or liftgate

bumper heightWindow Water leak through

Defective sealFill sealant

glasswindshield

Defective body flange

Correct

Water leak through

door window glassIncorrect window glass installation

Adjust position

Gap at upper window glass

Adjust position

Water leak throughDefective sealFill sealantliftgate windowDefective body flangeCorrect

DoorsDoor windowmalfunctionIncorrect window glass installation

Adjust position

Damaged or faulty regulator

Correct or replace

Water leak through

Cracked or faulty weatherstripdoor edgeReplace

Water leak from

door centerDrain hole clogged

Remove foreign objects

Inadequate waterproof film contact or damageCorrect or replace

Door hard to open

Incorrect latch or striker adjustment

Adjust

Door does notIncorrect door installationopen or closeAdjust position

completelyDefective door check strapCorrect or replace

Door check strap and hinge required grease

Apply grease

Uneven gap

Incorrect door installation

between bodyAdjust position

yoi$ noise aroundWeatherstrip not holding firmly

Adjust fit of door

Improperly installed weatherstrip or setting of

Repair or replaceweatherstrip

Improperly closed door

Improperly fit door

Improper clearance between door glass anddoor weatherstrip holder

Deformed doorAdjust

Adjust

Adjust

Repair or replace

1 TSB Revision

Page 886 of 1146

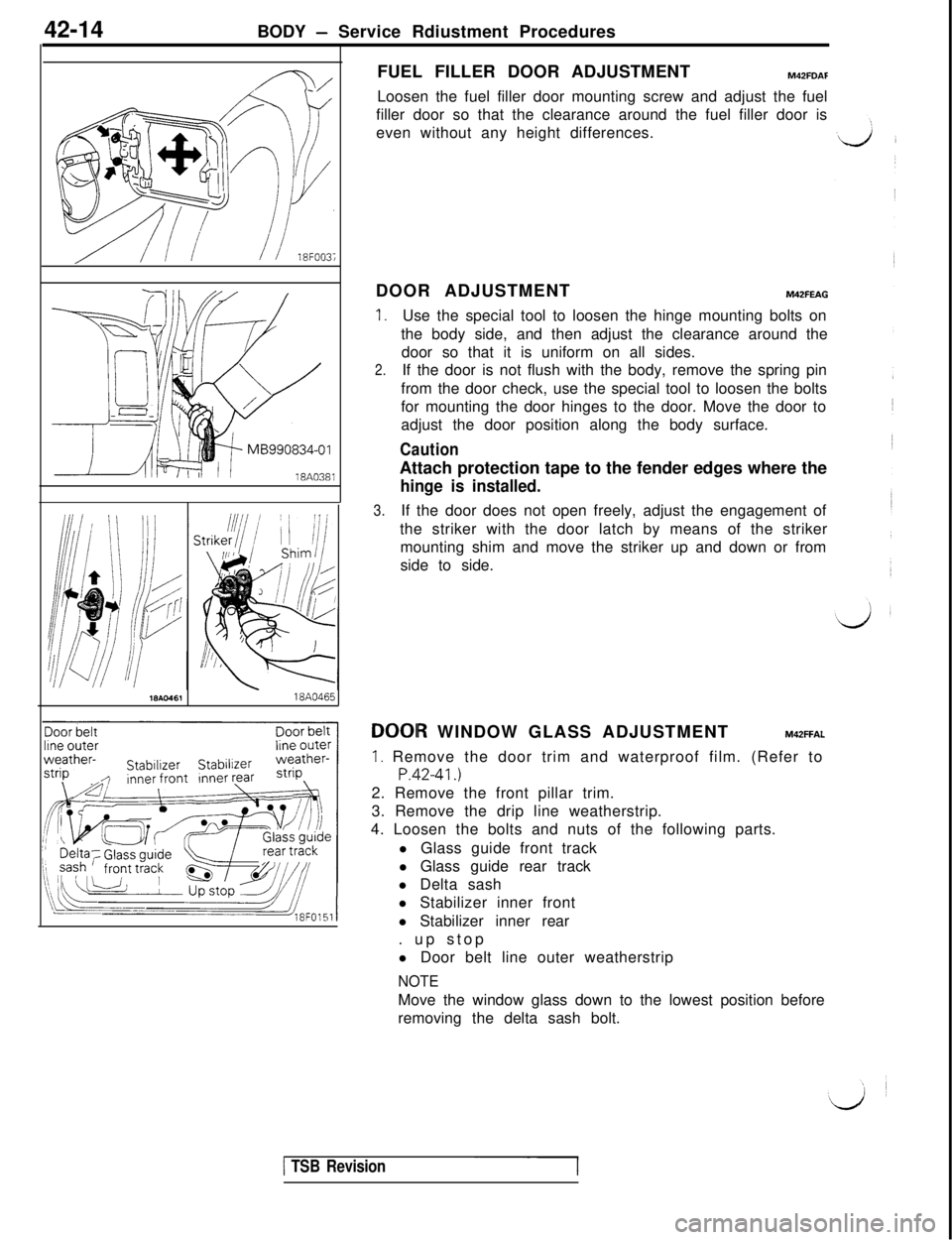

42-14BODY - Service Rdiustment ProceduresMB990834-0118A0381

18Ac-46118A0465FUEL FILLER DOOR ADJUSTMENT

M42FDAFLoosen the fuel filler door mounting screw and adjust the fuel

filler door so that the clearance around the fuel filler door is

even without any height differences.

DOOR ADJUSTMENT

M42FEAG

1.Use the special tool to loosen the hinge mounting bolts on

the body side, and then adjust the clearance around the

door so that it is uniform on all sides.

2.If the door is not flush with the body, remove the spring pin

from the door check, use the special tool to loosen the bolts

for mounting the door hinges to the door. Move the door to

adjust the door position along the body surface.

CautionAttach protection tape to the fender edges where the

hinge is installed.

3.If the door does not open freely, adjust the engagement of

the striker with the door latch by means of the striker

mounting shim and move the striker up and down or from

side to side.DOOIR WINDOW GLASS ADJUSTMENT

M42FFAL

1. Remove the door trim and waterproof film. (Refer to

P.42-41.)2. Remove the front pillar trim.

3. Remove the drip line weatherstrip.

4. Loosen the bolts and nuts of the following parts.

l Glass guide front track

l Glass guide rear track

l Delta sash

l Stabilizer inner front

l Stabilizer inner rear

. up stop

l Door belt line outer weatherstrip

NOTEMove the window glass down to the lowest position before

removing the delta sash bolt.

1 TSB Revision-1

Page 888 of 1146

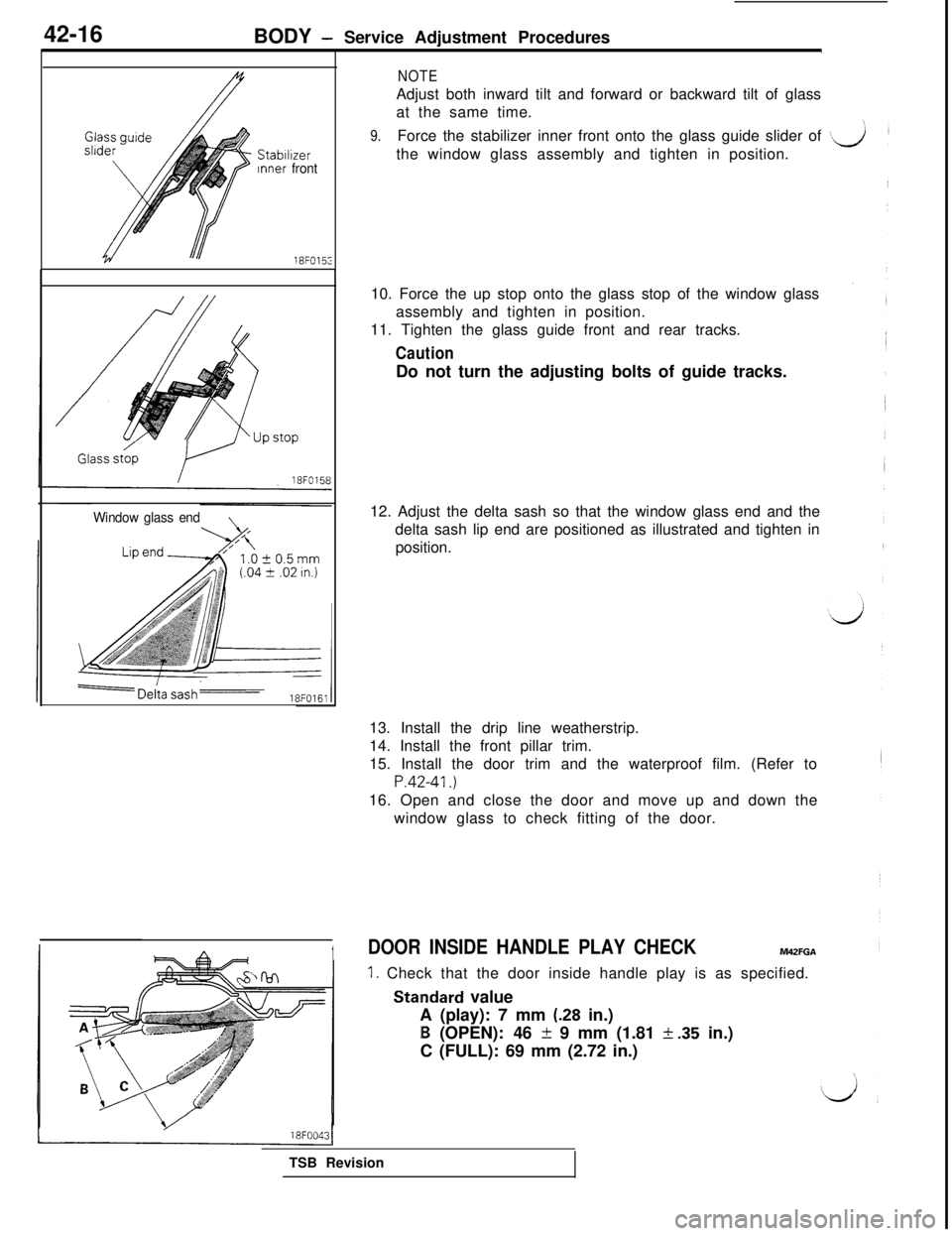

42-16

BODY - Service Adjustment Procedures

StabtlizerInner front18FO15:

Window glass end

NOTEAdjust both inward tilt and forward or backward tilt of glass

at the same time.

9.Force the stabilizer inner front onto the glass guide slider of

the window glass assembly and tighten in position.

10. Force the up stop onto the glass stop of the window glass

assembly and tighten in position.

11. Tighten the glass guide front and rear tracks.

CautionDo not turn the adjusting bolts of guide tracks.

12. Adjust the delta sash so that the window glass end and the

delta sash lip end are positioned as illustrated and tighten in

position.

13. Install the drip line weatherstrip.

14. Install the front pillar trim.

15. Install the door trim and the waterproof film. (Refer to

P.42-41.)16. Open and close the door and move up and down the

window glass to check fitting of the door.

1DOOR INSIDE HANDLE PLAY CHECKM42FGA

1. Check that the door inside handle play is as specified.

Staindard value

A (play): 7 mm

(.28 in.)

B (OPEN): 46 & 9 mm (1.81 i .35 in.)

C (FULL): 69 mm (2.72 in.)

TSB Revision

Page 914 of 1146

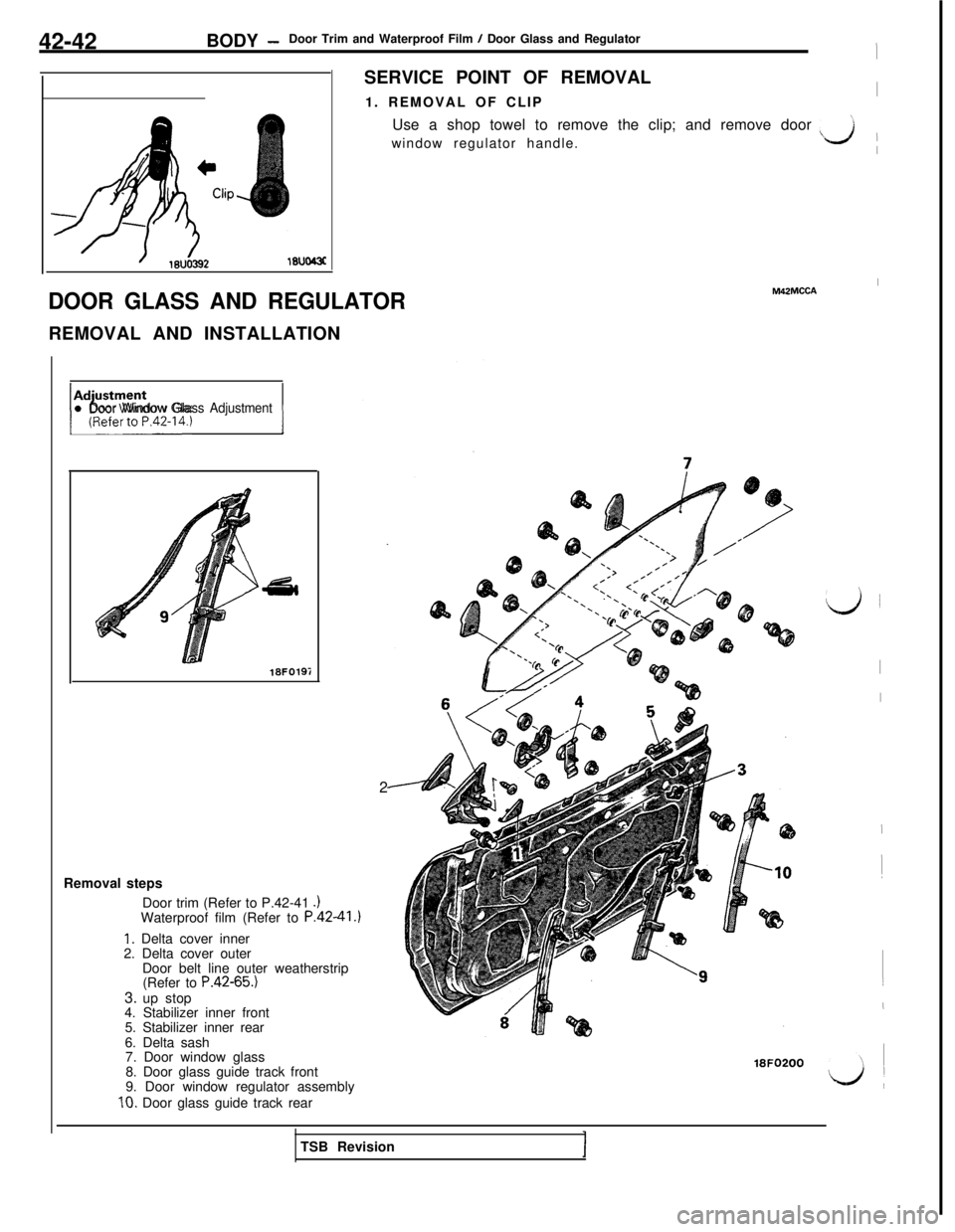

42-42BODY -Door Trim and Waterproof Film / Door Glass and Regulator

ISERVICE POINT OF REMOVAL

1. REMOVAL OF CLIP

IUse a shop towel to remove the clip; and remove door

window regulator handle.

\L.J II

DOOR GLASS AND REGULATORREMOVAL AND INSTALLATION

~;:;zL4., 1l Door Window Glass Adjustment

18FOlQi2

Removal steps

Door trim (Refer to P.42-41

.IWaterproof film (Refer to P.42-41 .I

1. Delta cover inner

2. Delta cover outer

Door belt line outer weatherstrip

(Refer to

P.42-65.)3. up stop

4. Stabilizer inner front

5. Stabilizer inner rear

6. Delta sash

7. Door window glass

8. Door glass guide track front

9. Door window regulator assemblyIO. Door glass guide track rear

IM42MCCA

18FO200

d

I

I

I

!

(

I

L&lTSB Revision

Page 923 of 1146

L

/

idBODY

- Power Window

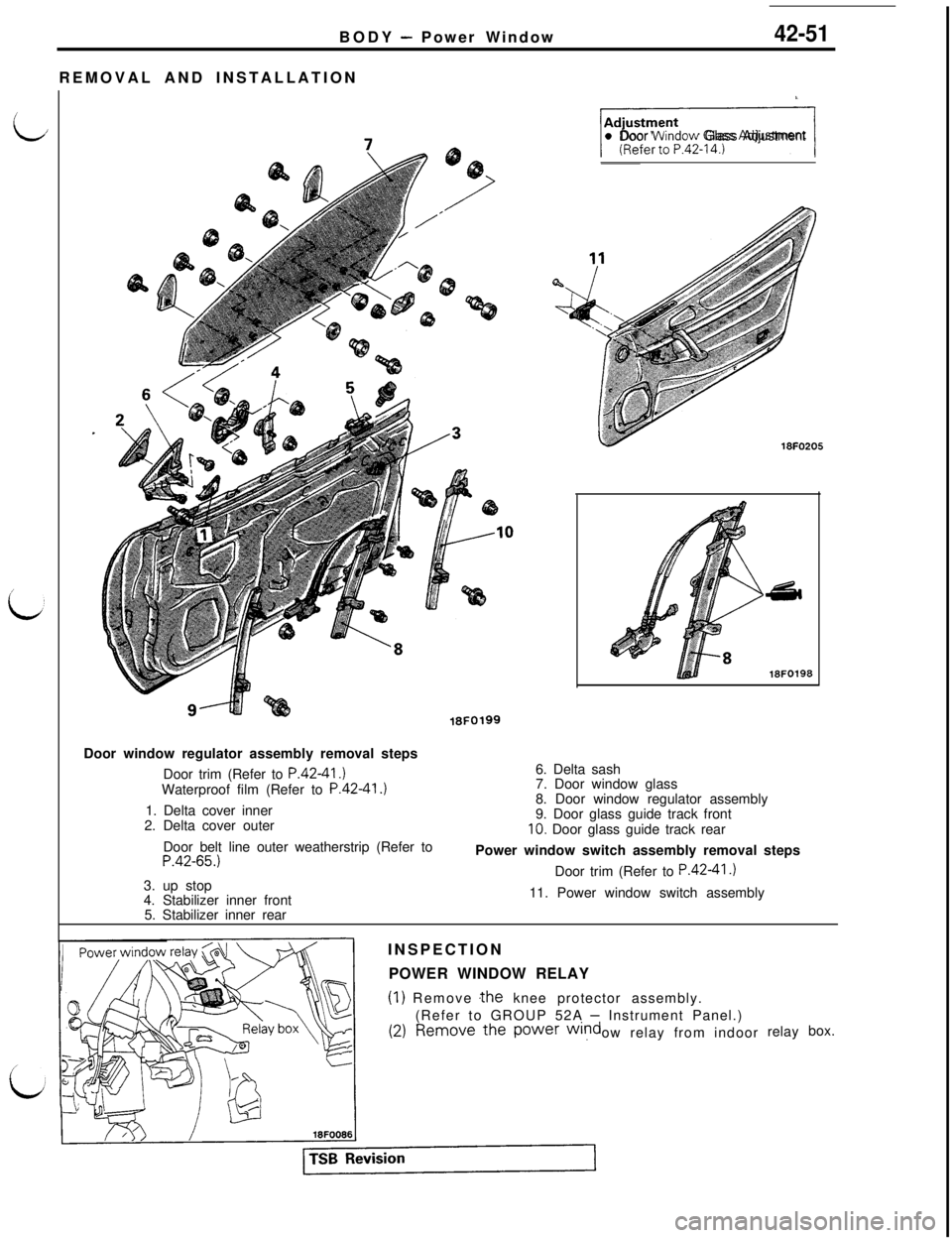

REMOVAL AND INSTALLATION42-51

Cll Door Wlndow Glass Adjustment

18FO205

18FO198Door window regulator assembly removal steps

Door trim (Refer to

P.4241.)Waterproof film (Refer to P.42-41.)1. Delta cover inner

2. Delta cover outer

18FO1996. Delta sash

7. Door window glass

8. Door window regulator assembly

9. Door glass guide track front

10. Door glass guide track rear

Door belt line outer weatherstrip (Refer to

P.42-65.)3. up stop

4. Stabilizer inner frontPower window switch assembly removal steps

Door trim (Refer to P.42-41.)11. Power window switch assembly

5. Stabilizer inner rear

INSPECTION

POWER WINDOW RELAY

(1) Remove .the knee protector assembly.

(Refer to GROUP 52A

- Instrument Panel.)

ow relay from indoorrelaybox.

Page 991 of 1146

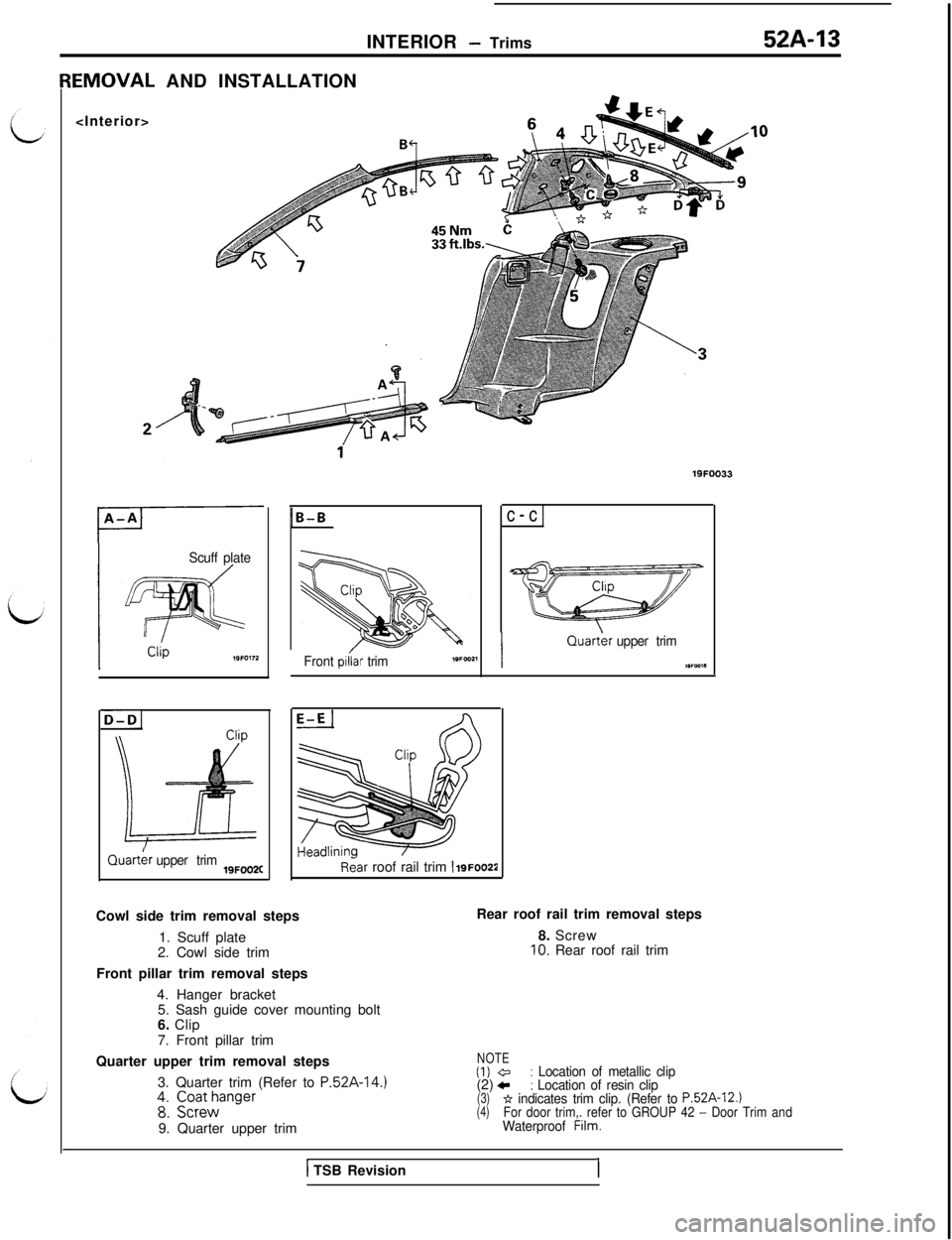

INTERIOR - Trims52A-13EMOVAL AND INSTALLATION

Scuff plate

D-D1Quart&

upper trim19FOO2C

1B-B

Front piiar trimc-cIQuart&

upper trim

,wca*

Rear roof rail trim 1 igFoo22Cowl side trim removal steps

1. Scuff plate

2. Cowl side trim

Front pillar trim removal steps

4. Hanger bracket

5. Sash guide cover mounting bolt

6. Clip

7. Front pillar trimRear roof rail trim removal steps

8. Screw

10. Rear roof rail trim

Quarter upper trim removal steps

3. Quarter trim (Refer to

P.52A-14.)48: ;;;;anger9. Quarter upper trim

1 TSB Revision

NOTE(1) @: Location of metallic clip(2) c: Location of resin clip(3)* indicates trim clip. (Refer to P.52A-12.)(4)For door trim,. refer to GROUP 42 - Door TrimandWaterproof Film.

I

Page 995 of 1146

L

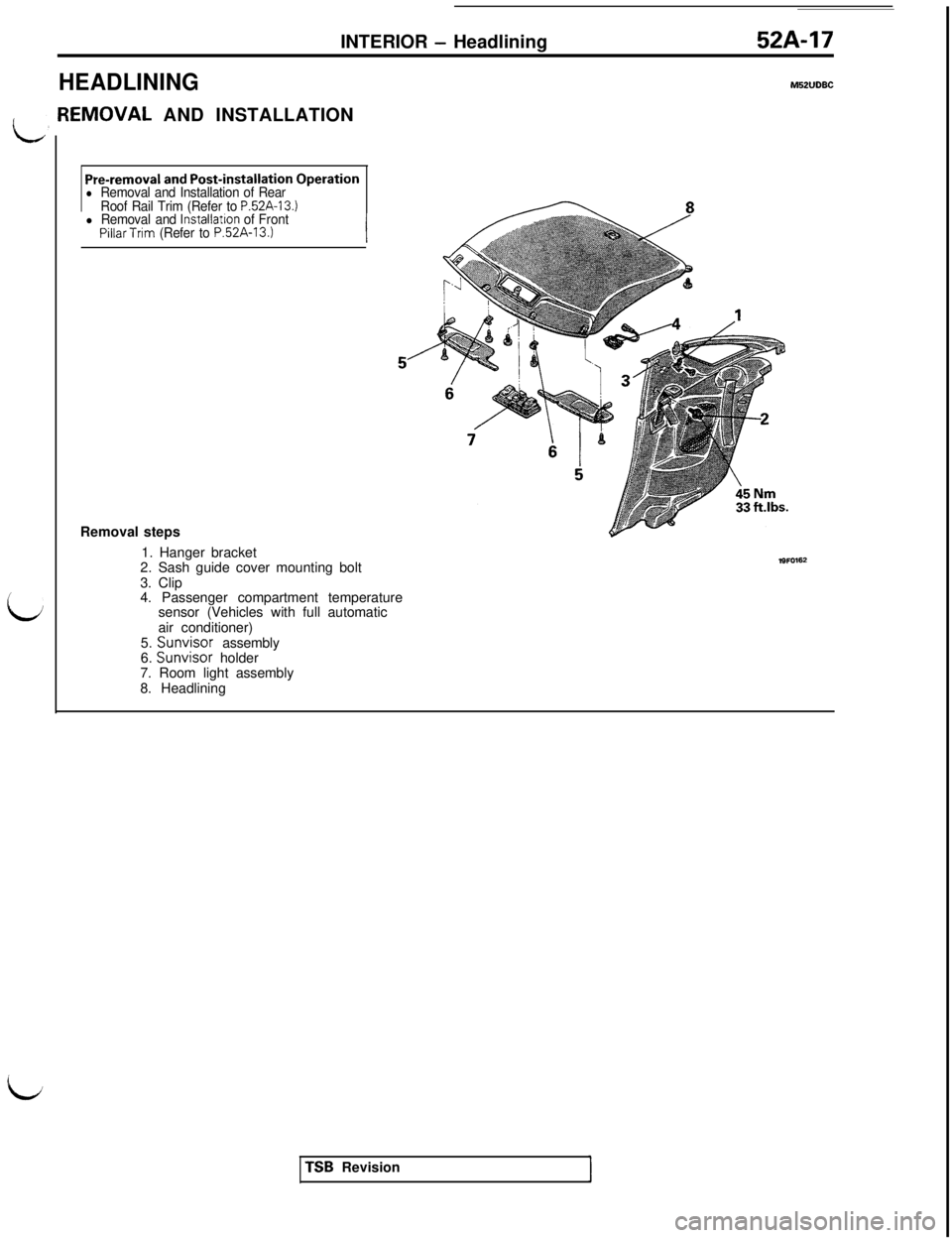

LINTERIOR

- Headlining52A-17

HEADLININGM52lJDBC[EMOVAL AND INSTALLATION

Pre-removal and Post-installation Operationl Removal and Installation of Rear

Roof Rail Trim (Refer to P52A-13.)l Removal and lnstallatron of FrontPillarTrim (Refer to P.52A-13.)Removal steps

1. Hanger bracket

2. Sash guide cover mounting bolt

3. Clip

4. Passenger compartment temperature

sensor (Vehicles with full automatic

air conditioner)

5. Sunvisor assembly

6. Sunvisor holder

7. Room light assembly

8. HeadliningTSB Revision