check engine MITSUBISHI 3000GT 1991 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 108 of 1146

13-2

Boost Meter

Components Location........................................................36

Crank Angle Sensor

............................................................72Detonation Sensor................................................................84EGR Control Solenoid Valve

EGR Temperature Sensor

Fuel Pump Operation Check................................................137Fuel Pump Relay No. 2........................................................53Fuel Pump Resistor............................................................53

Idle Position Switch............................................................68Idle Speed Control Servo (Stepper Motor Type)............1 IOIgnition Coil and Power Transistor....................................115Ignition Switch-ST and Inhibitor Switch ................76Ignition Switch-ST

Injectors

94

Oxygen Sensor

Power Steering Oil Pressure Switch................................80Power Supply and Ignition Switch-IG................................41

Purge Control Solenord Valve............................................1 19Release of Residual Pressure from High

Pressure Fuel Hose............................................................137Throttle Position Sensor....................................................65Top Dead Center Sensor....................................................70Variable Induction Control Servo (DC Motor)

SERVICE ADJUSTMENT PROCEDURES............................31

Adjustment of Fixed SAS....................................................35Adjustment of Idle Position Switch and

Throttle Position Sensor (TPS)............................................33Basic Idle Speed Adjustment............................................31Throttle Body (Throttle Valve Area) Cleaning....................33

SPECIAL TOOLS........................................................................8

SPECIFICATIONS

....................................................................6

General Specifications........................................................6Sealant....................................................................................7Service Specifications........................................................7

THROlTLE BODY....................................................................143

TROUBLESHOOTING............................................................9

Check Chart Classified by Problem Symptoms................16Circuit Diagram....................................................................18Engine Warning Light (Malfunction Indicator Light)........11Explanation and Cautions about Harness Check............10Explanation of Troubleshooting Procedures....................9Fuel Tank and Fuel Line........................................................30

Problem Symptoms Table (For Your Information)............17Self-diagnosis........................................................................12)

I

Page 115 of 1146

FUEL SYSTEM - Troubleshooting13-9

START1

1. Verification of trouble symptomI

2. Reading of self-diagnosis code

3. Estimation of the causes of trouble and

setting of check items

\1

4. Inspection of engine control unit input/

output signals

\1

5. Inspection of MPI system component

LL

6. Inspection of individual MPI system

components

7. Re-inspection and repair of trouble

symptom

8. Verification and prevention of

reoccur-

TROUBLESHO.OTlNGMlBEBBS

EXPLANATION OF TROUBLESHOOTING PROCE-

DURES

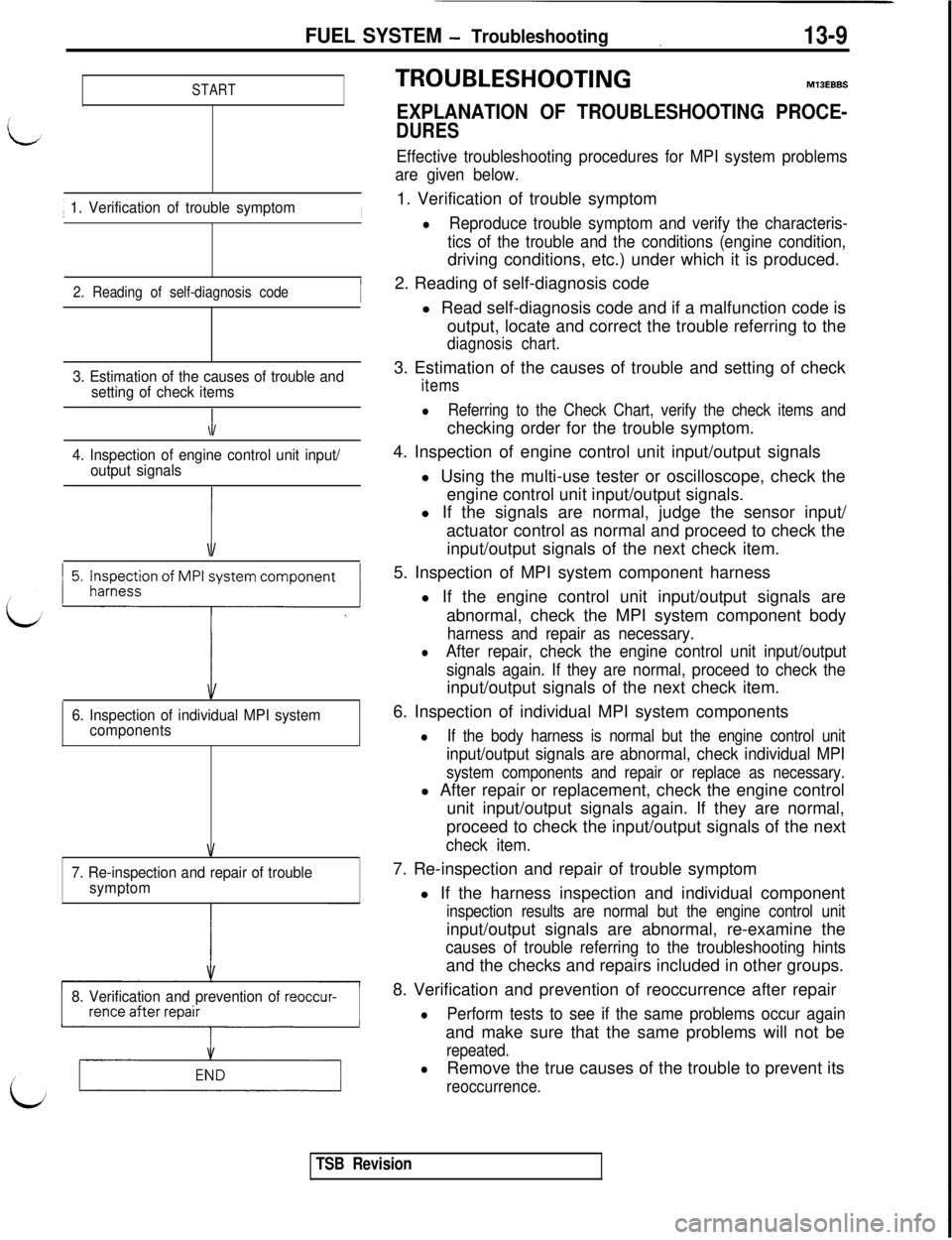

Effective troubleshooting procedures for MPI system problems

are given below.1. Verification of trouble symptom

lReproduce trouble symptom and verify the characteris-

tics of the trouble and the conditions (engine condition,driving conditions, etc.) under which it is produced.

2. Reading of self-diagnosis code

l Read self-diagnosis code and if a malfunction code is

output, locate and correct the trouble referring to the

diagnosis chart.3. Estimation of the causes of trouble and setting of check

items

lReferring to the Check Chart, verify the check items andchecking order for the trouble symptom.

4. Inspection of engine control unit input/output signals

l Using the multi-use tester or oscilloscope, check the

engine control unit input/output signals.

l If the signals are normal, judge the sensor input/

actuator control as normal and proceed to check the

input/output signals of the next check item.

5. Inspection of MPI system component harness

l If the engine control unit input/output signals are

abnormal, check the MPI system component body

harness and repair as necessary.

lAfter repair, check the engine control unit input/output

signals again. If they are normal, proceed to check theinput/output signals of the next check item.

6. Inspection of individual MPI system components

lIf the body harness is normal but the engine control unit

input/output signals are abnormal, check individual MPI

system components and repair or replace as necessary.l After repair or replacement, check the engine control

unit input/output signals again. If they are normal,

proceed to check the input/output signals of the next

check item.7. Re-inspection and repair of trouble symptom

l If the harness inspection and individual component

inspection results are normal but the engine control unitinput/output signals are abnormal, re-examine the

causes of trouble referring to the troubleshooting hintsand the checks and repairs included in other groups.

8. Verification and prevention of reoccurrence after repair

lPerform tests to see if the same problems occur againand make sure that the same problems will not be

repeated.

lRemove the true causes of the trouble to prevent its

reoccurrence.

TSB Revision

Page 117 of 1146

FUEL SYSTEM - Troubleshooting13-11

L

L

Sensor side6FU1215

Malfunctionl

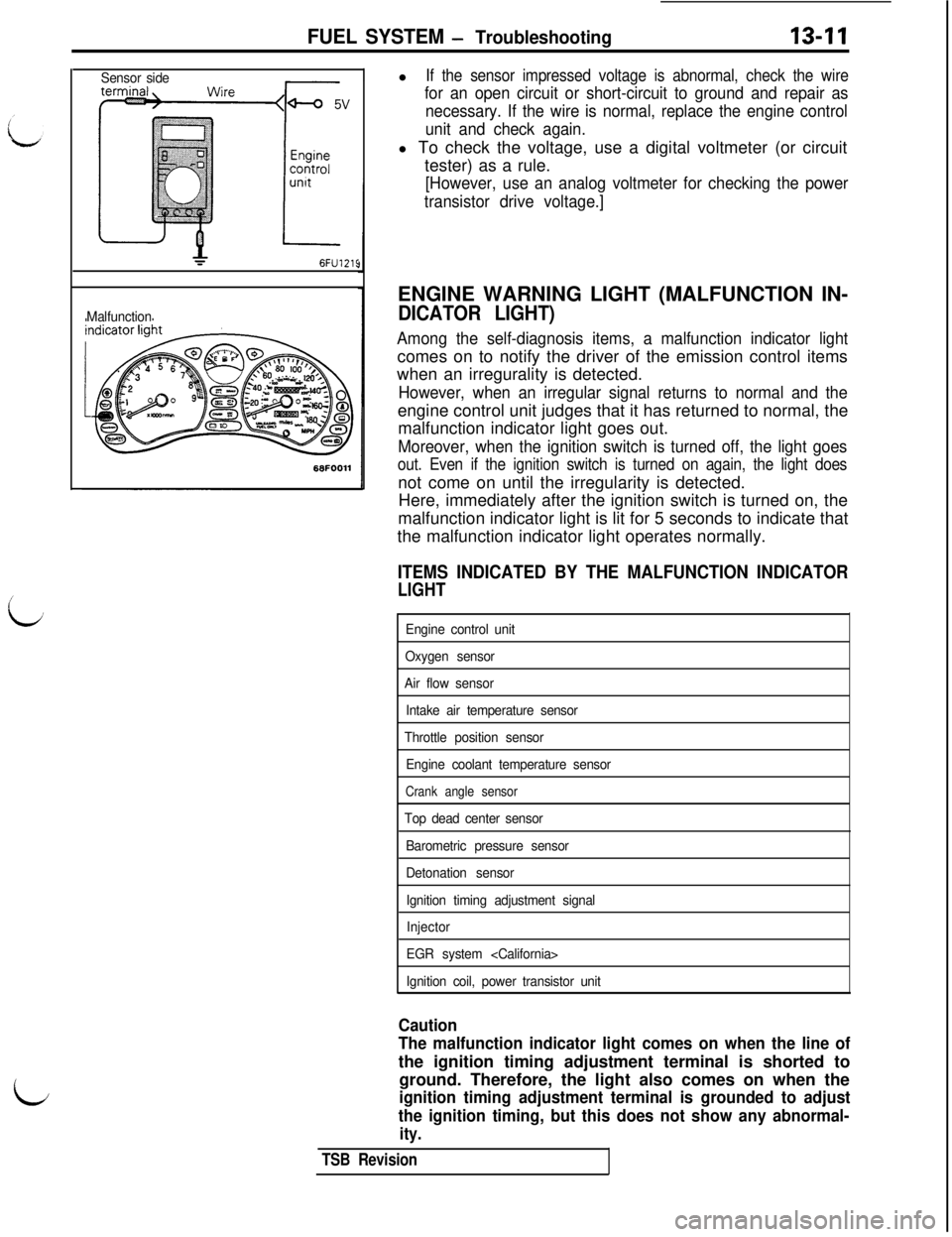

If the sensor impressed voltage is abnormal, check the wire

for an open circuit or short-circuit to ground and repair as

necessary. If the wire is normal, replace the engine control

unit and check again.l To check the voltage, use a digital voltmeter (or circuit

tester) as a rule.

[However, use an analog voltmeter for checking the power

transistor drive voltage.]ENGINE WARNING LIGHT (MALFUNCTION IN-

DICATOR LIGHT)

Among the self-diagnosis items, a malfunction indicator lightcomes on to notify the driver of the emission control items

when an irregurality is detected.

However, when an irregular signal returns to normal and theengine control unit judges that it has returned to normal, the

malfunction indicator light goes out.

Moreover, when the ignition switch is turned off, the light goes

out. Even if the ignition switch is turned on again, the light doesnot come on until the irregularity is detected.

Here, immediately after the ignition switch is turned on, the

malfunction indicator light is lit for 5 seconds to indicate that

the malfunction indicator light operates normally.

ITEMS INDICATED BY THE MALFUNCTION INDICATOR

LIGHT

Engine control unit

Oxygen sensor

Air flow sensor

Intake air temperature sensor

Throttle position sensor

Engine coolant temperature sensor

Crank angle sensor

Top dead center sensor

Barometric pressure sensor

Detonation sensor

Ignition timing adjustment signal

Injector

EGR system

Ignition coil, power transistor unit

Caution

The malfunction indicator light comes on when the line ofthe ignition timing adjustment terminal is shorted to

ground. Therefore, the light also comes on when the

ignition timing adjustment terminal is grounded to adjust

the ignition timing, but this does not show any abnormal-

ity.

TSB Revision

Page 118 of 1146

13-12FUEL SYSTEM - Troubleshooting

MALFUNCTION INDICATOR LIGHT INSPECTION

(1) Check that when the ignition switch is turned on, the lightilluminates for about 5 seconds and then goes out.

(2) If the light does not illuminate, check for open circuit in

dharness, blown fuse and blown bulb.

SELF-DIAGNOSIS

The engine control unit monitors the input/output signals (some

signals at all times and the others under specified conditions) ofthe engine control unit.

When it is noticed that an irregularity has continued for a

specified time or longer from when the irregular signal is

initially monitored, passing a certain number, the engine controlunit judges that an irregularity has occurred, memorizes the

malfunction code, and outputs the signal to the self-diagnosis

output terminal.

There are 21 diagnosis items, including the normal state, andthe diagnosis results can be read out with a voltmeter or

multi-use tester.Moreover, since memorization of the malfunction codes is

backed up directly by the battery, the diagnosis results are

memorized even if the ignition key is turned off. The malfunc-

tion codes will, however, be erased when the battery terminalor the engine control unit connector is disconnected.

The malfunction code can also be erased by turning on the

ignition switch and sending the malfunction code erase signalfrom the multi-use tester to the engine control unit.

CautionIf the sensor connector is disconnected with the ignition

_ _switch turned on, the malfunction code is memorized. Ind

this case, send the malfunction code erase signal from themulti-use tester to the engine control unit or disconnect

the battery terminal

(-) for 10 seconds or more, and the

diagnosis memory will be erased.

The 21 diagnosis items are provided as follows, and if plural

items are activated, they are all indicated sequentially from the

smallest code number.

CautionThe malfunction code for the ignition timing adjustment

signal is output when the line of the ignition timing

adjustment terminal is shorted to ground. Therefore, the

malfunction code is also output when the ignition timing

adjustment terminal is grounded to adjust the ignition

timing, but this does not show any abnormality.

TSB Revision

Page 119 of 1146

FUEL SYSTEM - Troubleshootinn

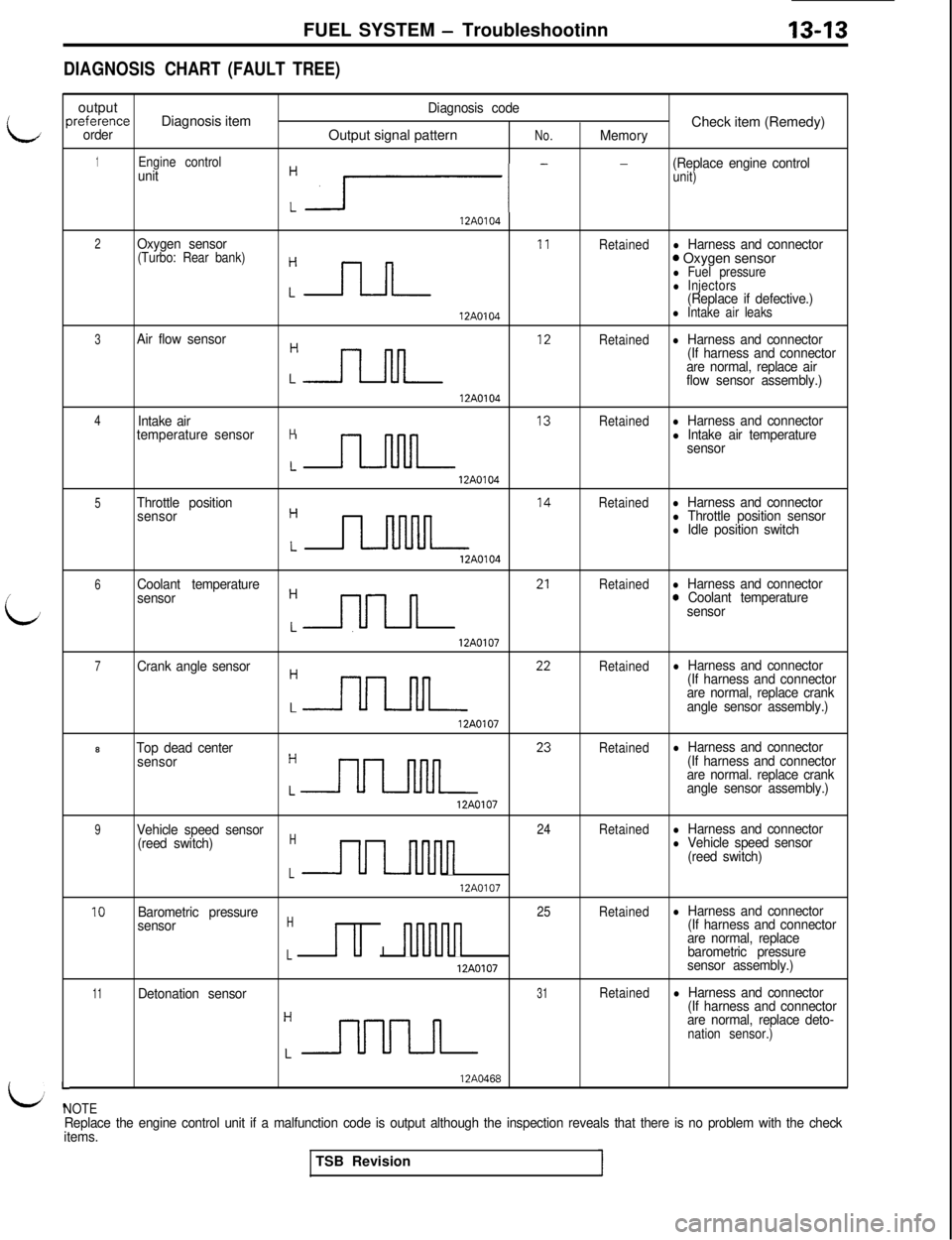

DIAGNOSISCHART (FAULT TREE)

i

L

Foutput

Diagnosis codeIreferenceDiagnosis item

Check item (Remedy)orderOutput signal patternNo.Memory

1Engine controlunit

:r- -

(Replace engine controlunit)

12A0104

2Oxygen sensorRetainedl Harness and connector(Turbo: Rear bank)

Cnn I’

0 Oxygen sensorl Fuel pressurel Injectors(Replace if defective.)

12A0104l Intake air leaks

3Air flow sensor

:n ‘*

Retainedl Harness and connector

(If harness and connector

are normal, replace air

flow sensor assembly.)

12A0104

4Intake airRetainedl Harness and connector

temperature sensorH

Ln I3

l Intake air temperature

sensor

12A0104

5Throttle position

sensor

:n I4

Retainedl Harness and connectorl Throttle position sensorl Idle position switch

12AO104

6Coolant temperature

:nn 21

Retainedl Harness and connector

sensor0 Coolant temperature

sensor12A0107

7Crank angle sensor

:nn 22

Retainedl Harness and connector

(If harness and connector

are normal, replace crank

angle sensor assembly.)

12A01078

Top dead centerRetainedl Harness and connector

sensor

:nn 23

(If harness and connector

are normal. replace crank

angle sensor assembly.)

12A0107

9Vehicle speed sensor24Retainedl Harness and connector

(reed switch)H

UInnnn

l Vehicle speed sensor

(reed switch)

L12A0107

10Barometric pressure25Retainedl Harness and connector

sensorHu I

nnluln

(If harness and connector

are normal, replace

Lbarometric pressure

12A0107sensor assembly.)

11Detonation sensor31Retainedl Harness and connector

:-r-uuuL

(If harness and connector

are normal, replace deto-

nation sensor.)

L-NOTE

12A0468

Replace the engine control unit if a malfunction code is output although the inspection reveals that there is no problem with the check

items.TSB Revision

Page 120 of 1146

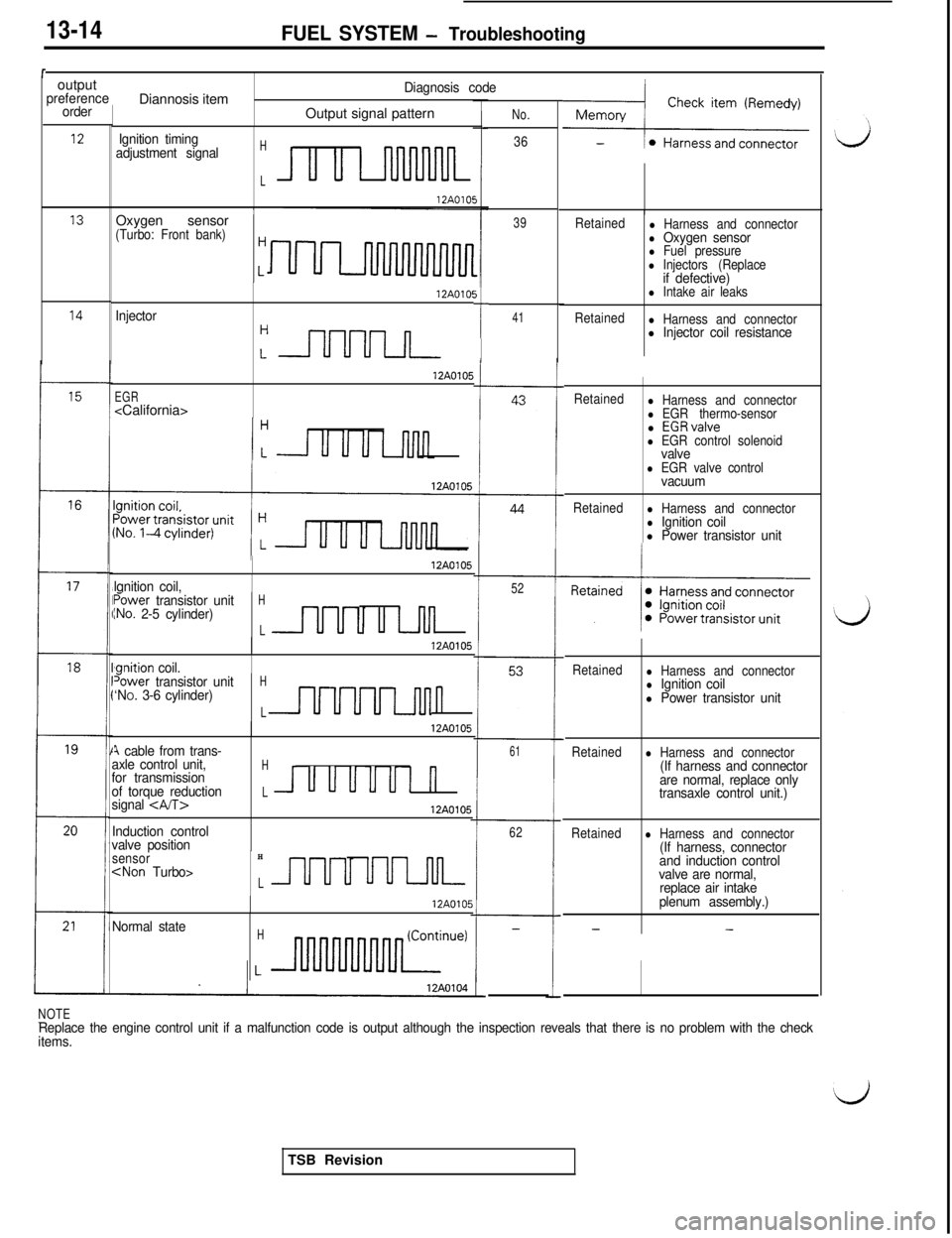

13-14FUEL SYSTEM - Troubleshooting

routput

preference

order

7Diannosis item

Diagnosis code

IOutput signal patternNo.

36

39

121 Ignition timing

adjustment signalH

L

13Oxygen sensor ’(Turbo: Front bank)HRetainedl Harness and connectorl Oxygen sensorl Fuel pressurel Injectors (Replaceif defective)l Intake air leaks

Retained

l Harness and connectorl Injector coil resistance

5

I--

Injector12AOlO!

:nnnn

EGR

12A0105

14

41

Retainedl Harness and connectorl EGR thermo-sensorl EGRvalvel EGR control solenoidvalvel EGR valve controlvacuum

Retainedl Harness and connectorl Ignition coill Power transistor unit

16

lqnition coil,

12A0105

52power transistor unitINO. 2-5 cylinder)H

Lu Lnll

‘qnition coil.

12AO105

18Retainedl Harness and connectorl Ignition coill Power transistor unit

Retainedl Harness and connector(If harness and connector

are normal, replace only

transaxle control unit.)

Retainedl Harness and connector(If harness, connector

and induction control

valve are normal,

replace air intake

plenum assembly.)

--

Tower transistor unitH‘NO. 3-6 cylinder)

Ln

12A0105

A cable from trans-

axle control unit,Hfor transmission

of torque reductionLUUUUUI n

signal 12A0105

Induction control

valve position

61

62

sensorH

12A0105

Normal stateH-

NOTE-Replace the engine control unit if a malfunction code is output although the inspection reveals that there is no problem with the check

items.TSB Revision

Page 121 of 1146

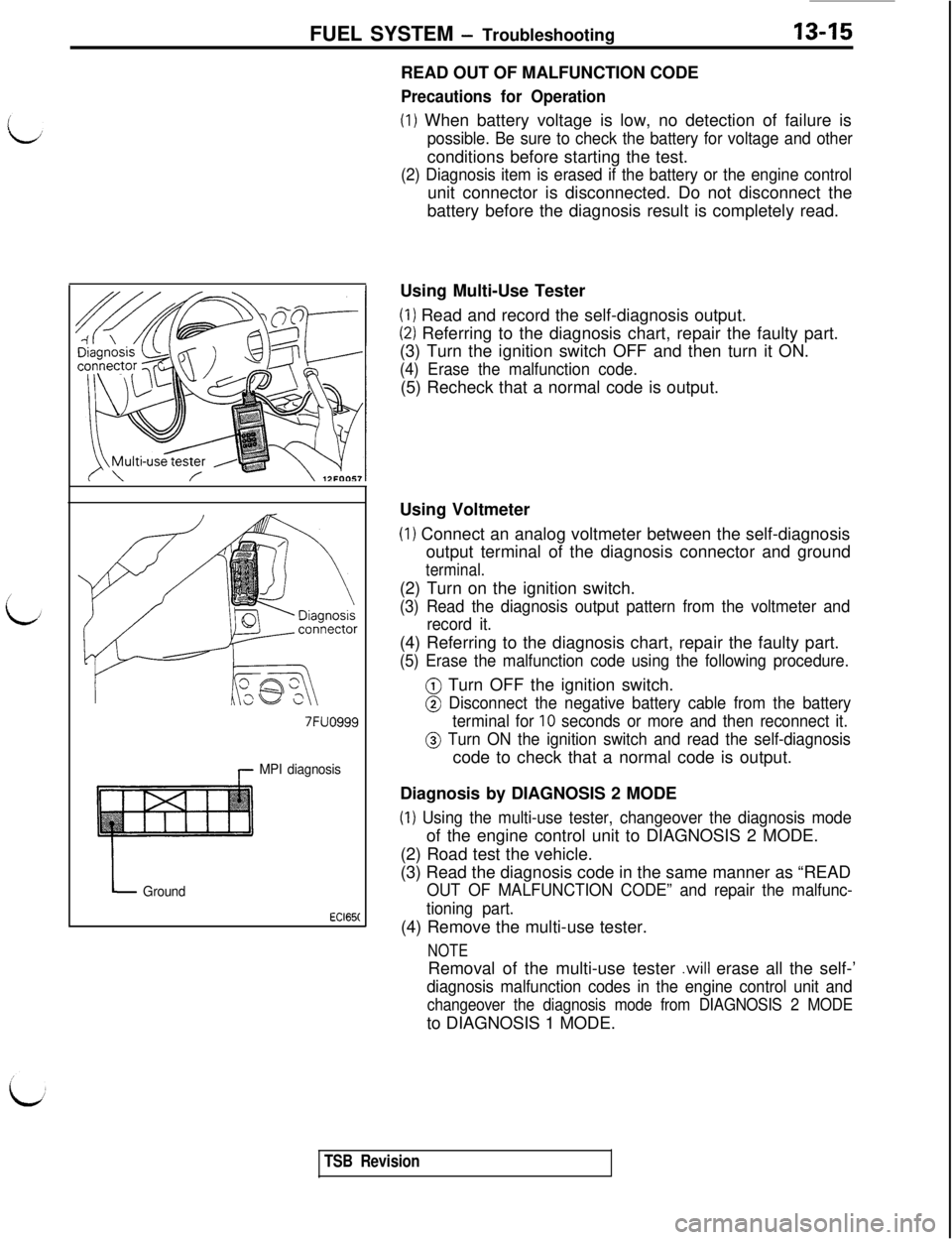

FUEL SYSTEM - Troubleshooting13-15READ OUT OF MALFUNCTION CODE

Precautions for Operation

(1) When battery voltage is low, no detection of failure is

possible. Be sure to check the battery for voltage and otherconditions before starting the test.

(2) Diagnosis item is erased if the battery or the engine controlunit connector is disconnected. Do not disconnect the

battery before the diagnosis result is completely read.

Using Multi-Use Tester

(I) Read and record the self-diagnosis output.

(2) Referring to the diagnosis chart, repair the faulty part.

(3) Turn the ignition switch OFF and then turn it ON.

(4) Erase the malfunction code.(5) Recheck that a normal code is output.

7FUO999

r MPI diagnosis

L Ground

EC165(Using Voltmeter(I) Connect an analog voltmeter between the self-diagnosis

output terminal of the diagnosis connector and ground

terminal.(2) Turn on the ignition switch.

(3) Read the diagnosis output pattern from the voltmeter and

record it.(4) Referring to the diagnosis chart, repair the faulty part.

(5) Erase the malfunction code using the following procedure.

@ Turn OFF the ignition switch.

@ Disconnect the negative battery cable from the battery

terminal for

10 seconds or more and then reconnect it.

@ Turn ON the ignition switch and read the self-diagnosiscode to check that a normal code is output.

Diagnosis by DIAGNOSIS 2 MODE

(1) Using the multi-use tester, changeover the diagnosis modeof the engine control unit to DIAGNOSIS 2 MODE.

(2) Road test the vehicle.

(3) Read the diagnosis code in the same manner as “READ

OUT OF MALFUNCTION CODE” and repair the malfunc-

tioning part.(4) Remove the multi-use tester.

NOTERemoval of the multi-use tester

.will erase all the self-’

diagnosis malfunction codes in the engine control unit and

changeover the diagnosis mode from DIAGNOSIS 2 MODEto DIAGNOSIS 1 MODE.

TSB Revision

Page 122 of 1146

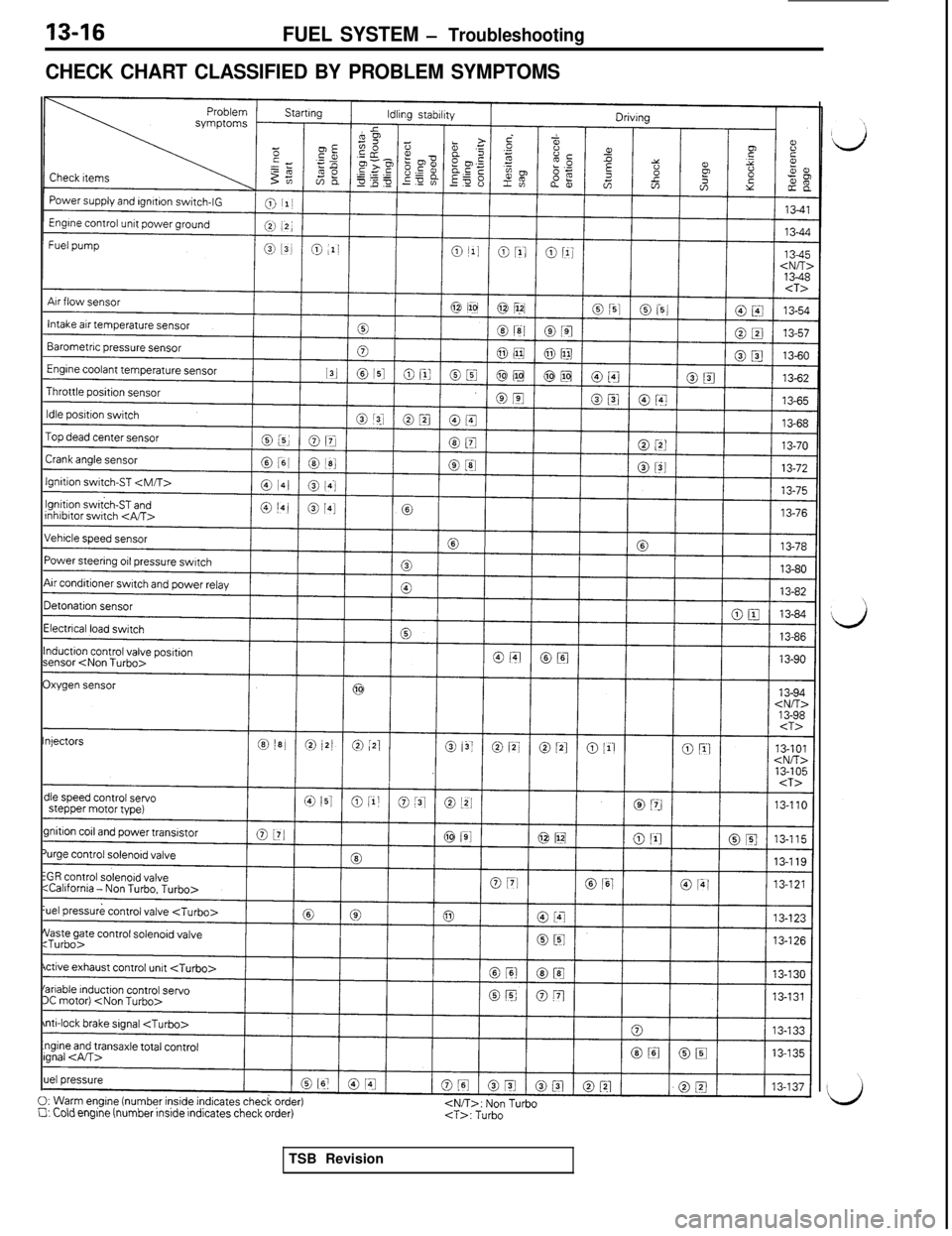

13-16FUEL SYSTEM - Troubleshooting

CHECK CHART CLASSIFIED BY PROBLEM SYMPTOMSstepper motor type)

0:Warmen,gine (number inside indicates check order)Cl: Cold engine (number inside indicates check order)

Page 137 of 1146

SERVICE ADJUSTMENT PROCEDURES

MlBFHSU

BASIC IDLE SPEED ADJUSTMENT

NOTE(1) The basic idle speed has been factory-adjusted with the

speed adjusting screw (SAS) and does not normally require

adjustment.(2) If the adjustment is required, first check that the ignition

plug, injector,

ISC servo, and compression pressure are

normal.

(1) Before starting the inspection and adjustment procedures,set the vehicle in the following conditions:

l

Engine coolant temperature: 80 to 95°C (176 to 205°F)l Lights, electric cooling fan, accessories: OFF

lTransaxle: Neutral (P range on vehicles with automatic

transaxle)l Steering wheel: Straightforward position

(2) When using the multi-use tester, connect it to the diagnosis

connector.

NOTEThe connection of the multi-use tester grounds the

self-

diagnosis/data transmission selector terminal.

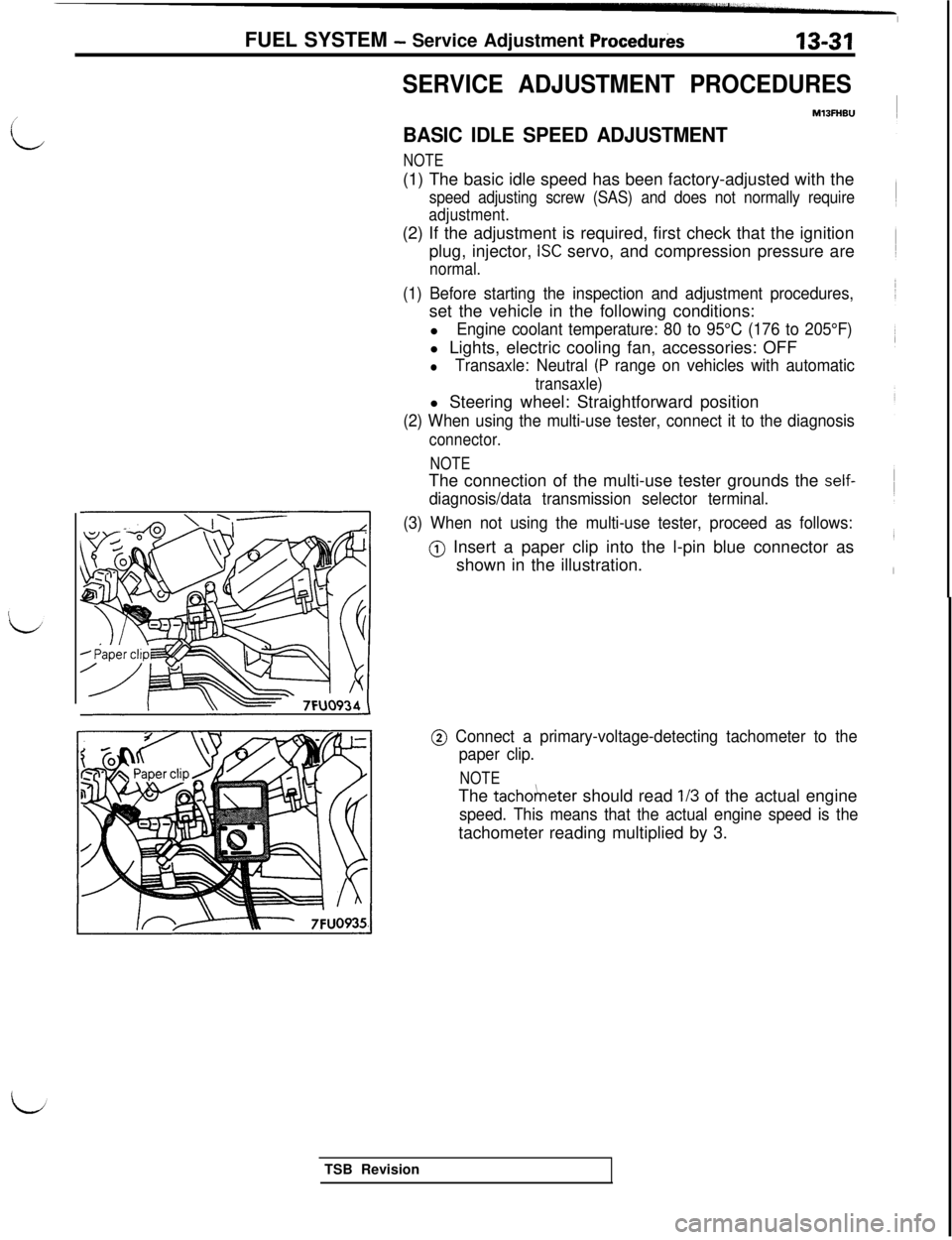

(3) When not using the multi-use tester, proceed as follows:

@) Insert a paper clip into the l-pin blue connector as

shown in the illustration. FUEL SYSTEM

- Service Adjustment Procedurks13-31

i

@ Connect a primary-voltage-detecting tachometer to the

paper clip.

NOTEThe

tacho/neter should read l/3 of the actual engine

speed. This means that the actual engine speed is thetachometer reading multiplied by 3.

TSB Revision

Page 138 of 1146

13-32FUEL SYSTEM - Service Adjustment Procedures

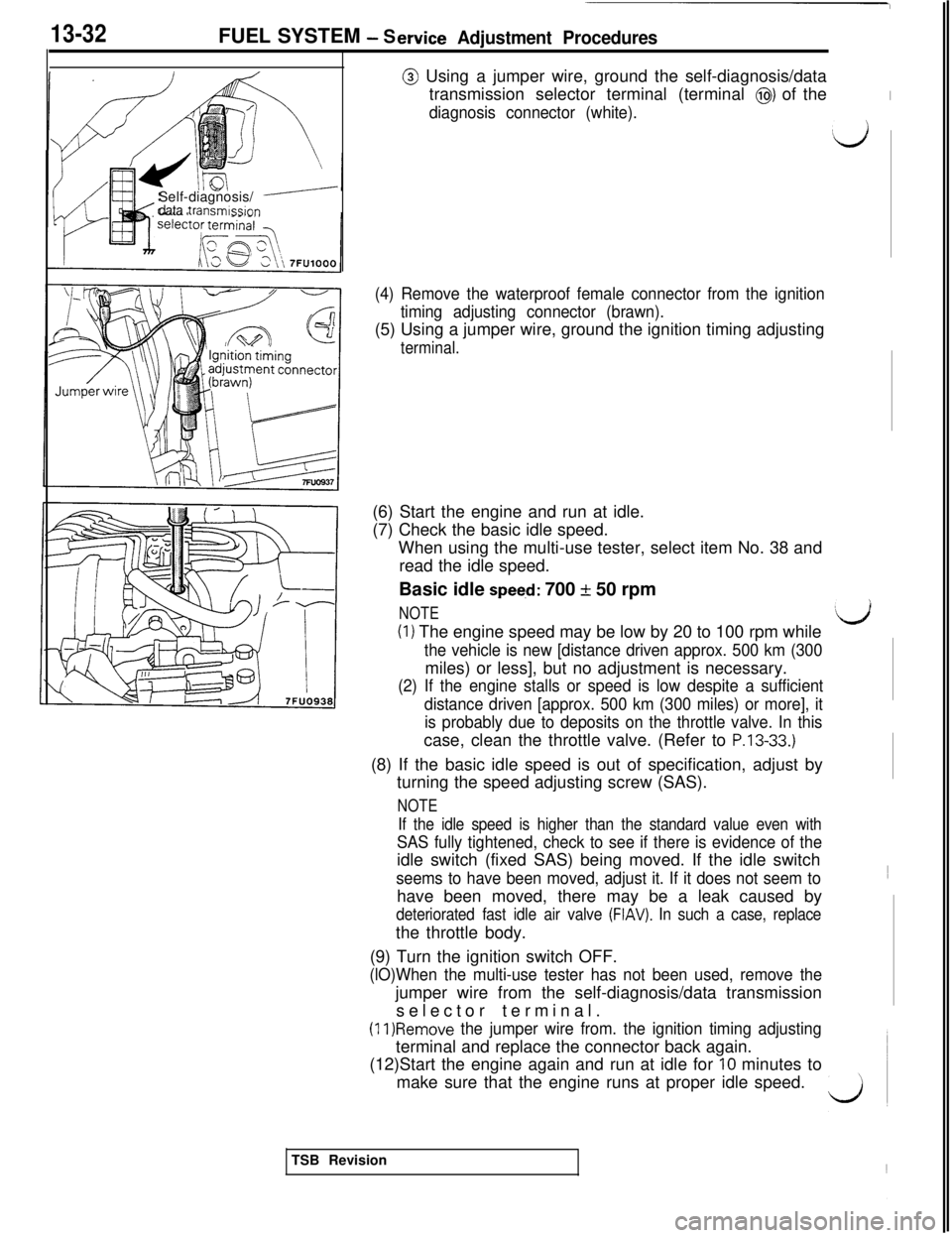

@ Using a jumper wire, ground the self-diagnosis/data

transmission selector terminal (terminal

@) of theI

diagnosis connector (white).

dSelf-diagnosis/

ydata transmission

(4) Remove the waterproof female connector from the ignition

timing adjusting connector (brawn).(5) Using a jumper wire, ground the ignition timing adjusting

terminal.(6) Start the engine and run at idle.

(7) Check the basic idle speed.

When using the multi-use tester, select item No. 38 and

read the idle speed.

Basic idle

speeci: 700 + 50 rpm

NOTE(I) The engine speed may be low by 20 to 100 rpm while

the vehicle is new [distance driven approx. 500 km (300miles) or less], but no adjustment is necessary.

(2) If the engine stalls or speed is low despite a sufficient

distance driven [approx. 500 km (300 miles) or more], it

is probably due to deposits on the throttle valve. In thiscase, clean the throttle valve. (Refer to

P.13-33.)(8) If the basic idle speed is out of specification, adjust by

turning the speed adjusting screw (SAS).

NOTE

If the idle speed is higher than the standard value even with

SAS fully tightened, check to see if there is evidence of theidle switch (fixed SAS) being moved. If the idle switch

seems to have been moved, adjust it. If it does not seem tohave been moved, there may be a leak caused by

deteriorated fast idle air valve (FIAV). In such a case, replacethe throttle body.

(9) Turn the ignition switch OFF.

(lO)When the multi-use tester has not been used, remove thejumper wire from the self-diagnosis/data transmission

selector terminal.

(11)Remove the jumper wire from. the ignition timing adjustingterminal and replace the connector back again.

(12)Start the engine again and run at idle for

10 minutes to

make sure that the engine runs at proper idle speed.

‘dTSB Revision