check engine MITSUBISHI 3000GT 1991 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 158 of 1146

13-52FUEL SYSTEM - 0

n-vehicle Inspection of MPI Components

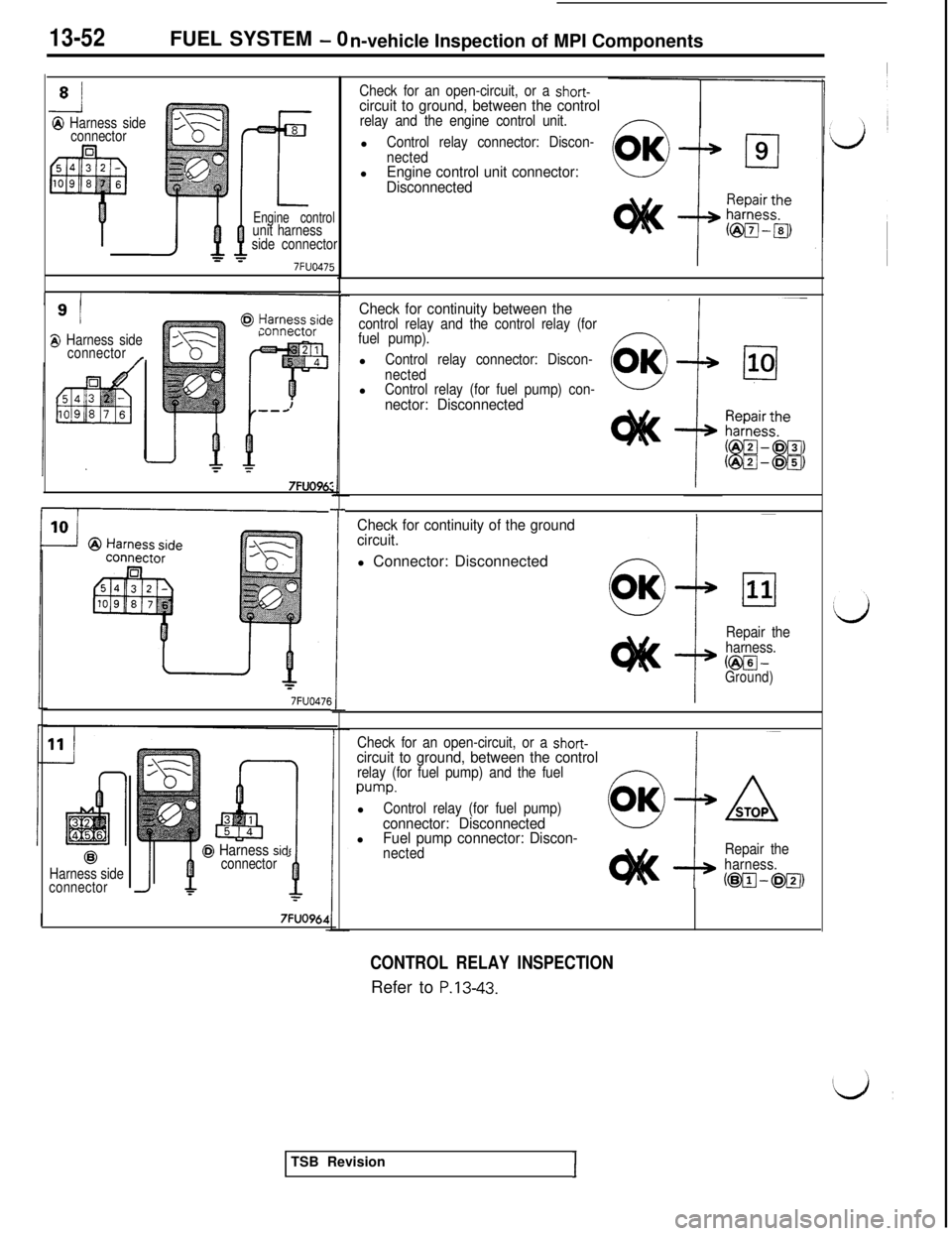

-i8

@ Harness side

connector

Check for an open-circuit, or a short-circuit to ground, between the controlrelay and the engine control unit.l

Control relay connector: Discon-

nectedl

Engine control unit connector:

Disconnected

Engine controlunit harness

side connector

7FUO475g

/Check for continuity between thecontrol relay and the control relay (for

fuel pump).l

Control relay connector: Discon-

nectedl

Control relay (for fuel pump) con-nector: Disconnected

zonnector8 Harness side

connector

/

7FUO96:

T

Check for continuity of the ground

circuit.l Connector: Disconnected

!

Repair the

harness.

@pJ-Ground)

7FUO476

Check for an open-circuit, or a short-circuit to ground, between the controlrelay (for fuel pump) and the fuel

pump.l

Control relay (for fuel pump)connector: DisconnectedlFuel pump connector: Discon-nectedRepair the

harness.

(@@-@lTJ)

@I Harness sidtconnector@Harness side

connector

I7FUO964

CONTROL RELAY INSPECTIONRefer to

P.13-43.TSB Revision

1

Page 161 of 1146

FUEL SYSTEM - On-vehicle Inspection of MPI Components13-55

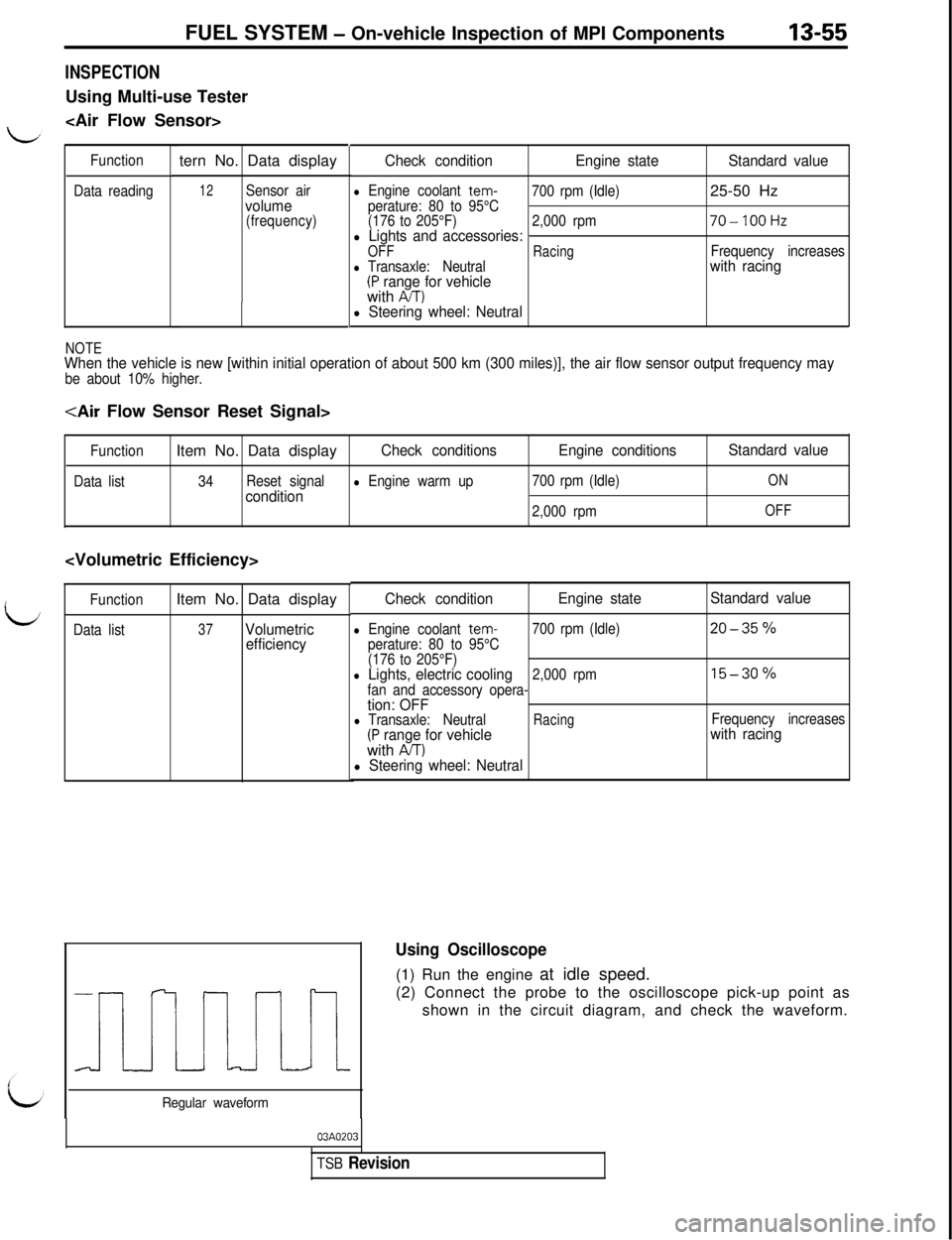

INSPECTIONUsing Multi-use Tester

Function

Data readingtern No. Data display

12Sensor airvolume(frequency)

Check conditionEngine stateStandard value

l Engine coolant tem-

700 rpm (Idle)25-50 Hzperature: 80 to 95°C

(176 to 205°F)2,000 rpm70-IOOHzl Lights and accessories:OFFRacingFrequency increasesl Transaxle: Neutralwith racing(P range for vehiclewith AIT)l Steering wheel: Neutral

NOTEWhen the vehicle is new [within initial operation of about 500 km (300 miles)], the air flow sensor output frequency maybe about 10% higher.

Function

Data listItem No. Data displayCheck conditionsEngine conditionsStandard value

34Reset signall Engine warm up700 rpm (Idle)ON

condition2,000 rpmOFF

L;

FunctionItem No. Data display

Data list37Volumetric

efficiencyCheck conditionEngine stateStandard valuel Engine coolant tem-700 rpm (Idle)20-35%

perature: 80 to 95°C

(176 to 205°F)

l Lights, electric cooling2,000 rpm15-30%

fan and accessory opera-tion: OFFl Transaxle: NeutralRacingFrequency increases

(P range for vehiclewith racingwith &T)

l Steering wheel: Neutral

Using Oscilloscope(1) Run the engine at idle speed.

(2) Connect the probe to the oscilloscope pick-up point as

shown in the circuit diagram, and check the waveform.

Regular waveform

03A0203

TSB Revision

Page 162 of 1146

13-56FUEL SYSTEM - 0

n-vehicle Inspection of MPI Components

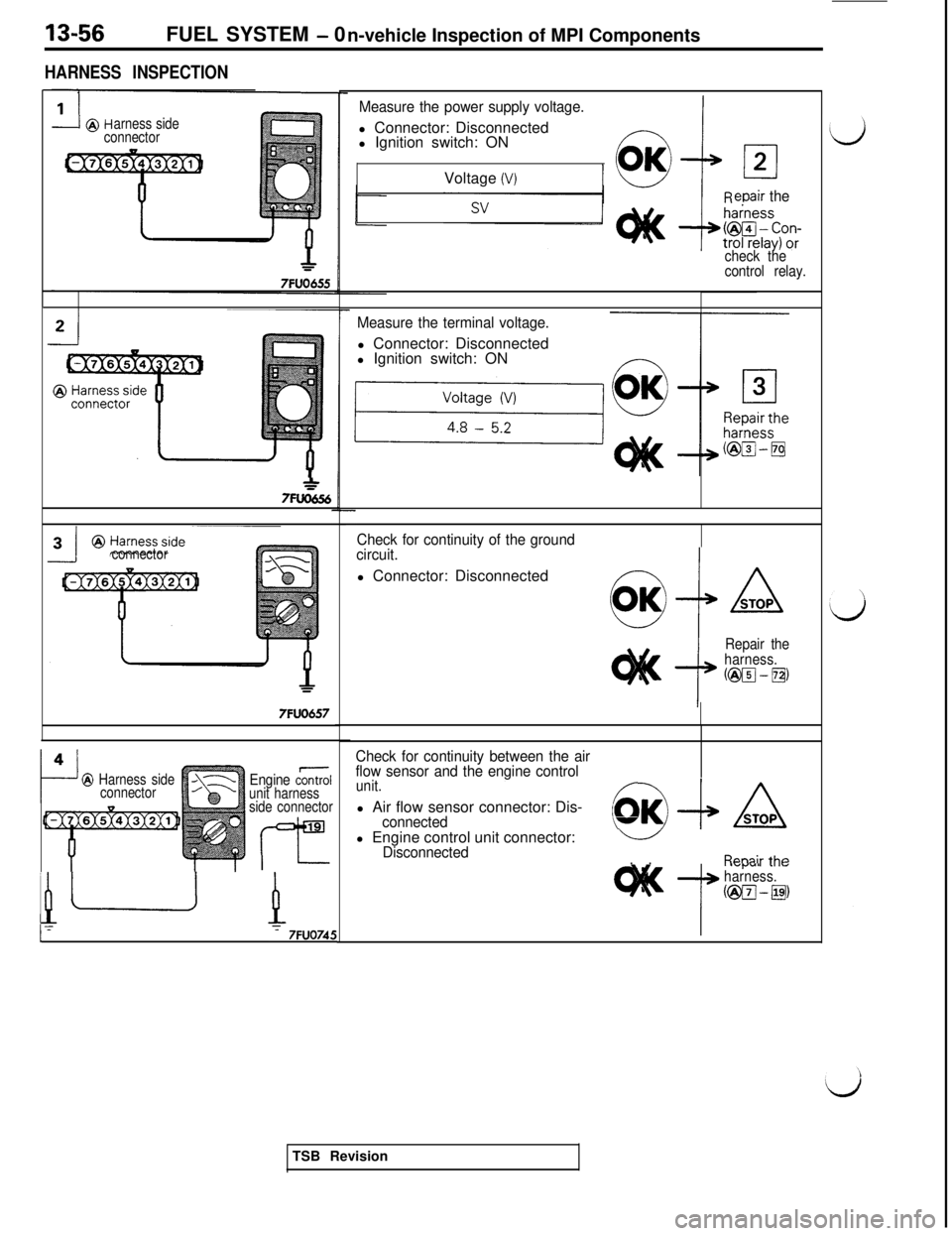

HARNESS INSPECTION

--barness side

connector

*7FUO656

connector

7FUO6574

?

@ Harness sideEngine c&lconnector

unit harness

side connector

I -

1

m

!h 4.7Fuo745u

Measure the power supply voltage.l Connector: Disconnected

l Ignition switch: ON

Voltage

(V)

eoair the

check the

control relay.

Measure the terminal voltage.l Connector: Disconnected

l Ignition switch: ON

Check for continuity of the ground

circuit.l Connector: Disconnected

Repair the

harness.

@El - I@)

Check for continuity between the air

flow sensor and the engine control

unit.l Air flow sensor connector: Dis-f

connected10l Engine control unit connector:

‘L-/Disconnected. .Rr.annir th(

t

I ‘“yu’3harness.

TSB Revision

Page 164 of 1146

13-58FUEL SYSTEM - On-vehicle Inspection of MPI Components

INSPECTION

Using Multi-use Tester

FunctionItem No. Data displayCheck conditionIntake air temperatureStandard valued

Data reading13Sensorignition switch: ON orAt -20°C (-4°F)-20°C

temperatureengine running

At 0°C (32°F)0°C

At 20°C (68°F)20°C

At 40°C (104°F)40°C

At 80°C (176°F)80°C

HARNESS INSPECTION7FUO657

I

connector

7FUO6607FUO661

ITSB I

Check for continuity of the groundcircuit.l Connector: Disconnected

Repair the

harness.,

(@I3 - q ,

Measure the power supply voltage.l Connector: Disconnected

l Ignition switch: ON

Voltage

(V)4.5

- 4.9Repair the

harness.

@@J-@)

SENSOR INSPECTION

(1) Disconnect the air flow sensor connectors.

(2) Measure resistance between terminals @ and

@.

ITemperature [“C (“F)]IResistance (kfl)

I0 (32)I6.0

I20 (681I2.7

wisionI

d

Page 167 of 1146

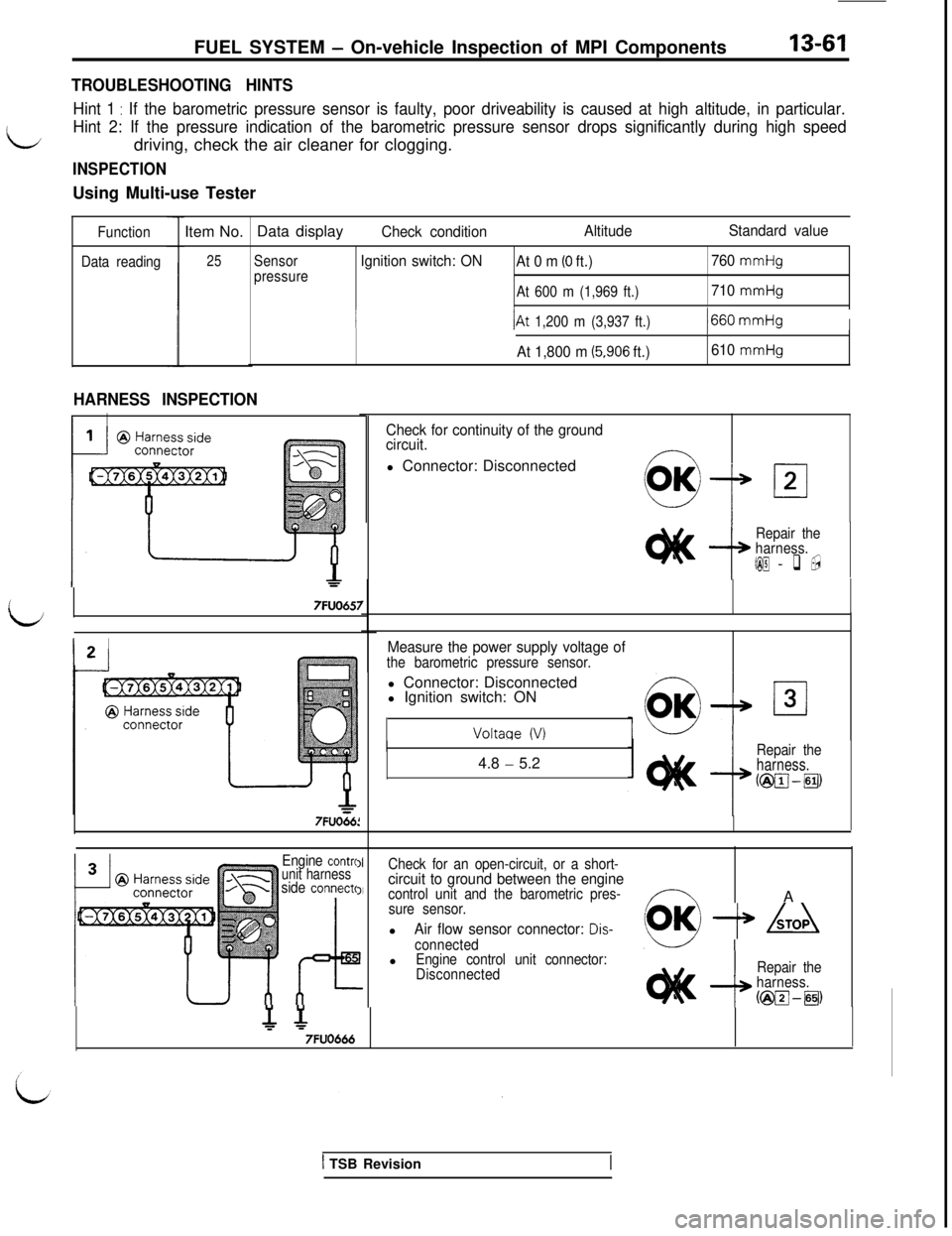

FUEL SYSTEM - On-vehicle Inspection of MPI Components13-61

TROUBLESHOOTING HINTS

Hint 1 : If the barometric pressure sensor is faulty, poor driveability is caused at high altitude, in particular.

L

Hint 2: If the pressure indication of the barometric pressure sensor drops significantly during high speeddriving, check the air cleaner for clogging.

INSPECTIONUsing Multi-use Tester

Function

Data readingItem No.’ Data display

25

Check conditionAltitudeStandard value

Sensor

pressureIgnition switch: ON

At 0 m (0 ft.)760 mmHg

At 600 m (1,969 ft.)

710 mmHg

I/At 1,200 m (3,937 ft.)1660 mmHgI

At 1,800 m (5.906 ft.)610 mmHg

HARNESS INSPECTION

II

L

7FUO657

7FUO66:

Check for continuity of the ground

circuit.l Connector: Disconnected

Repair the

harness.

&@I - q ,

Measure the power supply voltage ofthe barometric pressure sensor.l Connector: Disconnected

l Ignition switch: ON

Voltaqe (V)4.8

- 5.2Repair theharness.

KgpJ-pJ,

Engine contraunit harnessside connects

Check for an open-circuit, or a short-circuit to ground between the enginecontrol unit and the barometric pres-,Y---,A

sure sensor.l

Air flow sensor connector: Dis-(OK) -+ kTOA

connectedlEngine control unit connector:

Disconnected

--I

Repair the

harness.

Jg

7FUO666

1 TSB Revision

Page 169 of 1146

id

LFUEL SYSTEM

- On-vehicle Inspection of MPI Components13-63

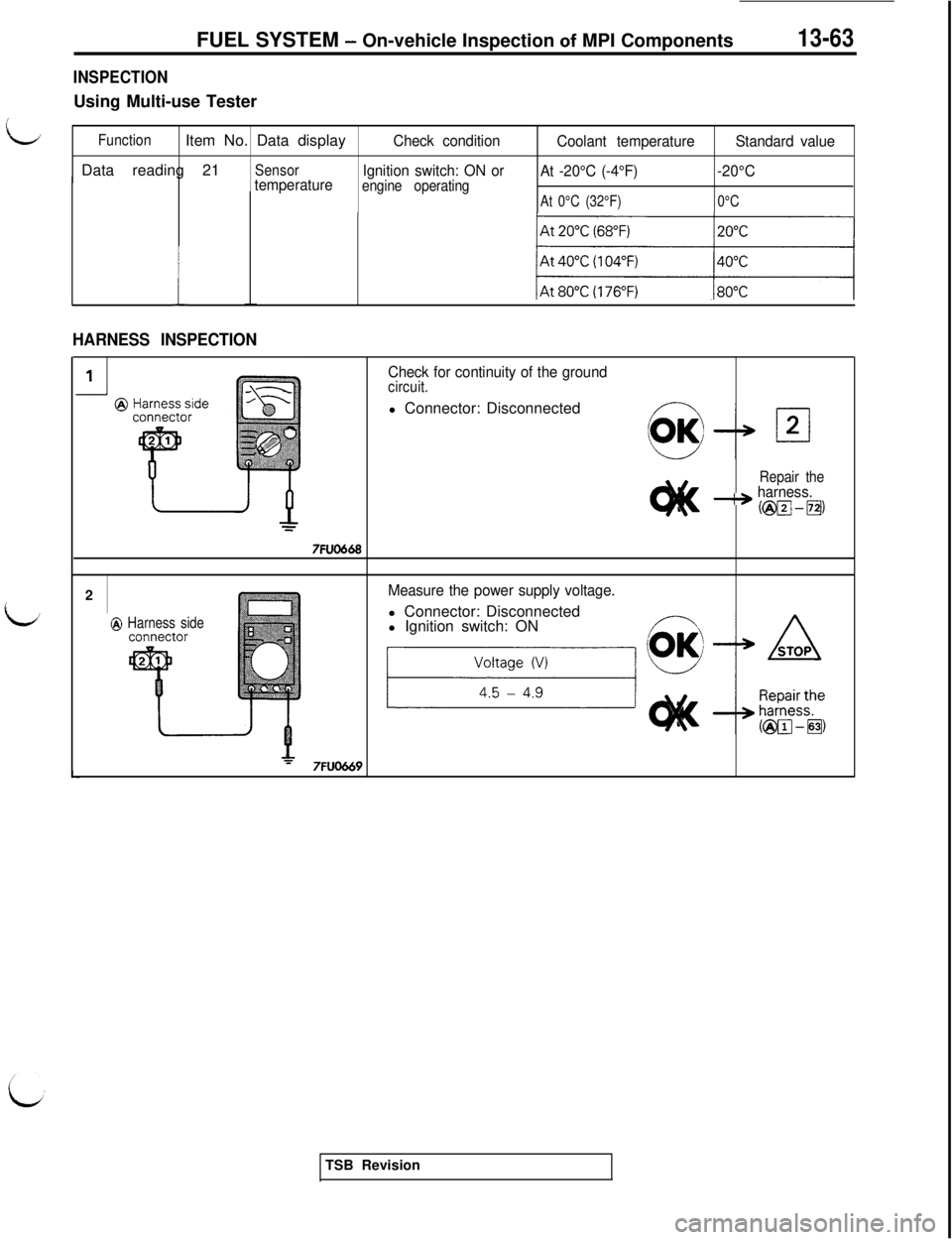

INSPECTIONUsing Multi-use Tester

LFunctionItem No. Data displayCheck condition

Coolant temperatureStandard valueData reading 21

SensorIgnition switch: ON or

At -20°C (-4°F)-20°C

temperatureengine operatingAt 0°C (32°F)0°C

HARNESS INSPECTION

Check for continuity of the groundcircuit.l Connector: Disconnected

Repair the---+ harness.

7FUO6682

Measure the power supply voltage.l Connector: Disconnected

@ Harness sidel Ignition switch: ON

7FUO669TSB Revision

Page 170 of 1146

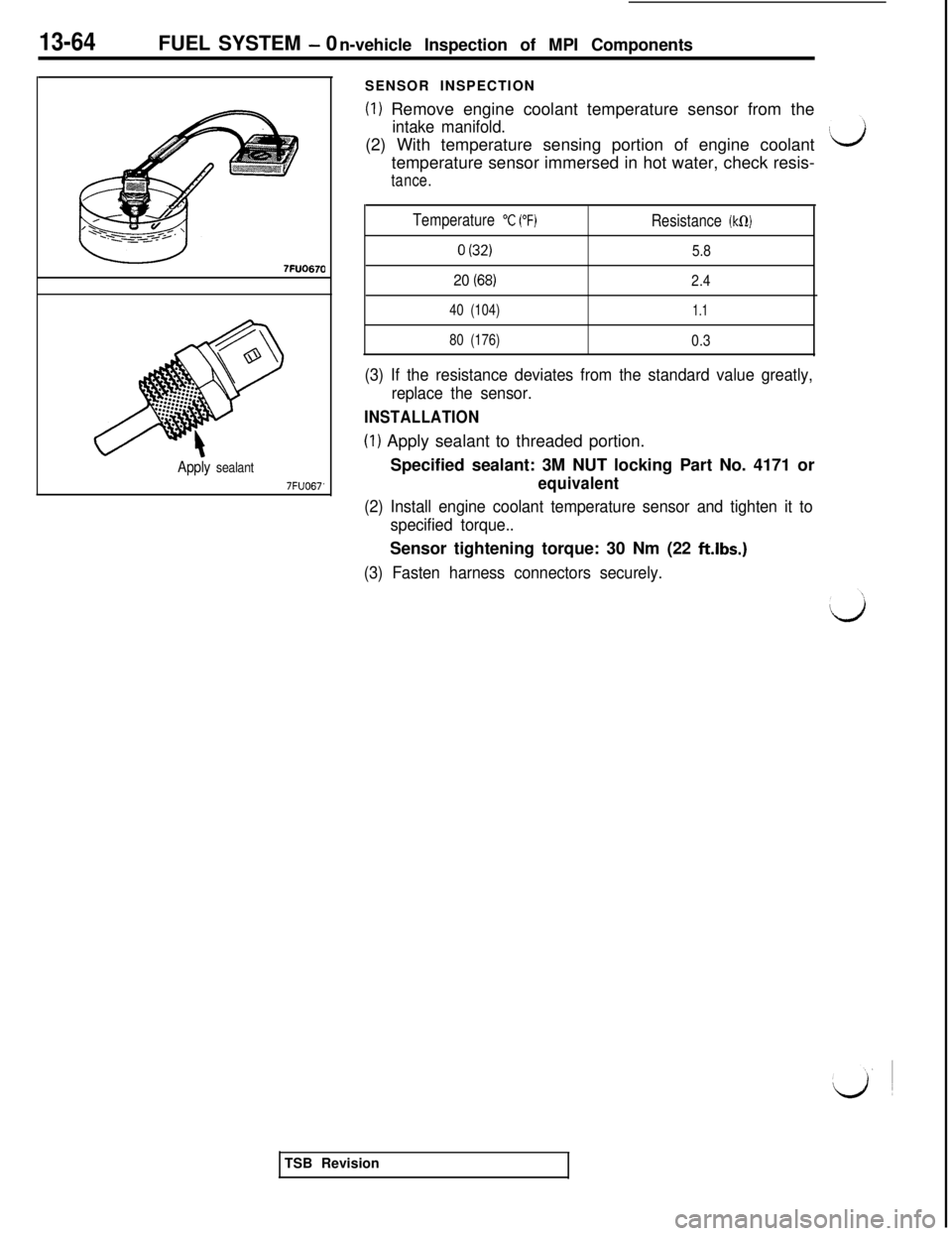

13-64FUEL SYSTEM - 0

n-vehicle Inspection of MPI Components

7FUO670

Apply sealant

7FUO67’SENSOR INSPECTION

(1) Remove engine coolant temperature sensor from the

intake manifold.(2) With temperature sensing portion of engine coolant

temperature sensor immersed in hot water, check resis-

tance.

Temperature

“C (“F)Resistance (kCI)

0 (32)5.8

20 (68)2.4

40 (104)1.1

80 (176)0.3

(3) If the resistance deviates from the standard value greatly,

replace the sensor.

INSTALLATION

(1) Apply sealant to threaded portion.

Specified sealant: 3M NUT locking Part No. 4171 or

equivalent

(2) Install engine coolant temperature sensor and tighten it to

specified torque..Sensor tightening torque: 30 Nm (22

ft.lbs.)

(3) Fasten harness connectors securely.TSB Revision

Page 171 of 1146

FUEL SYSTEM - On-vehicle Inspection of MPI Components13-65

i

1

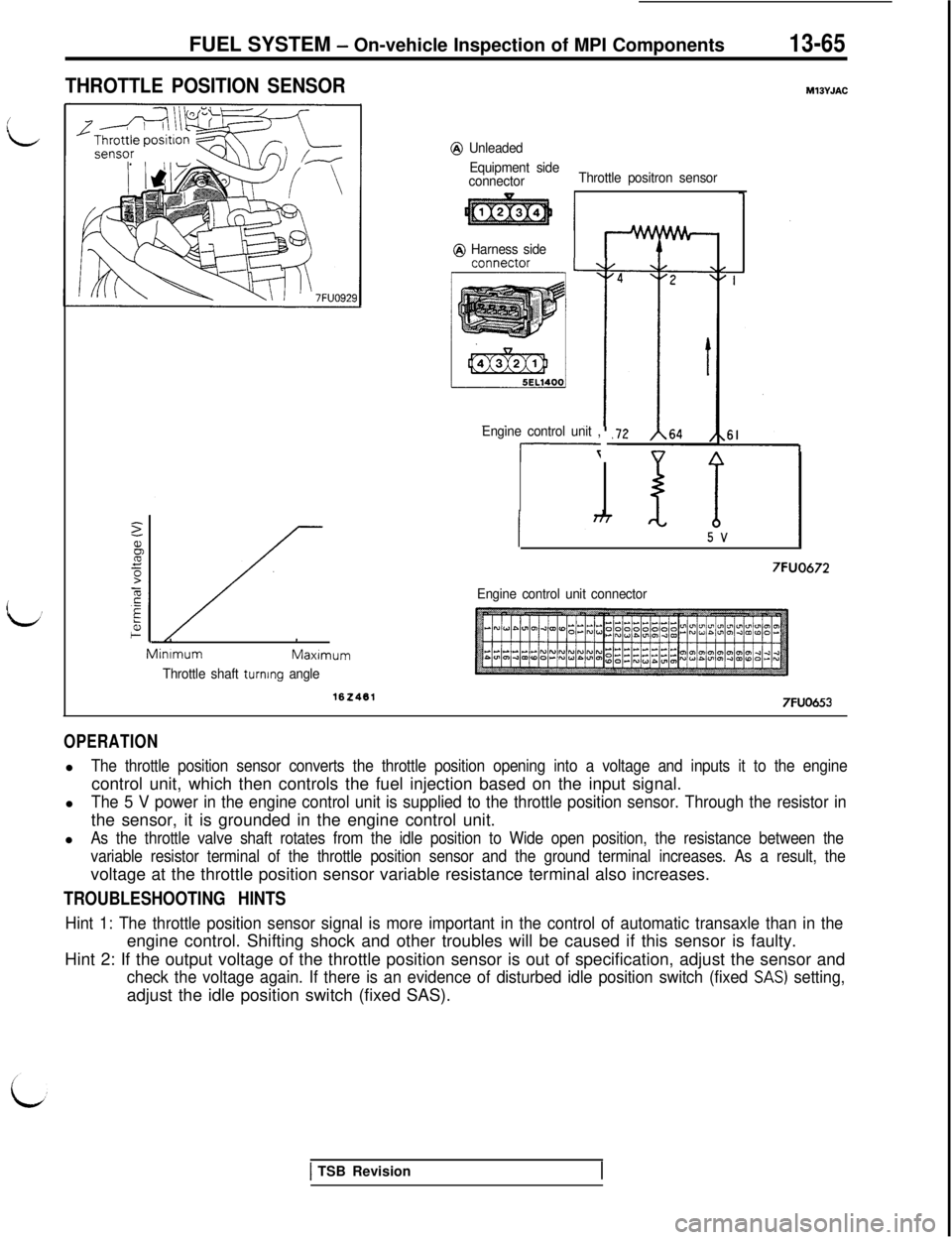

THROTTLE POSITION SENSORM13YJAC

Maximum

Throttle shaft

turning angle

162481

Minlmum

@ Unleaded

Equipment side

connectorThrottle positron sensor

I

@ Harness side

connector

Ii

SEL14001

Engine control unit ,

I

Engine control unit connector

7FUO672

7FUO653

OPERATIONl

The throttle position sensor converts the throttle position opening into a voltage and inputs it to the enginecontrol unit, which then controls the fuel injection based on the input signal.

l

The 5 V power in the engine control unit is supplied to the throttle position sensor. Through the resistor inthe sensor, it is grounded in the engine control unit.

l

As the throttle valve shaft rotates from the idle position to Wide open position, the resistance between the

variable resistor terminal of the throttle position sensor and the ground terminal increases. As a result, thevoltage at the throttle position sensor variable resistance terminal also increases.

TROUBLESHOOTING HINTS

Hint 1: The throttle position sensor signal is more important in the control of automatic transaxle than in theengine control. Shifting shock and other troubles will be caused if this sensor is faulty.

Hint 2: If the output voltage of the throttle position sensor is out of specification, adjust the sensor and

check the voltage again. If there is an evidence of disturbed idle position switch (fixed SAS) setting,adjust the idle position switch (fixed SAS).

1 TSB Revision

Page 172 of 1146

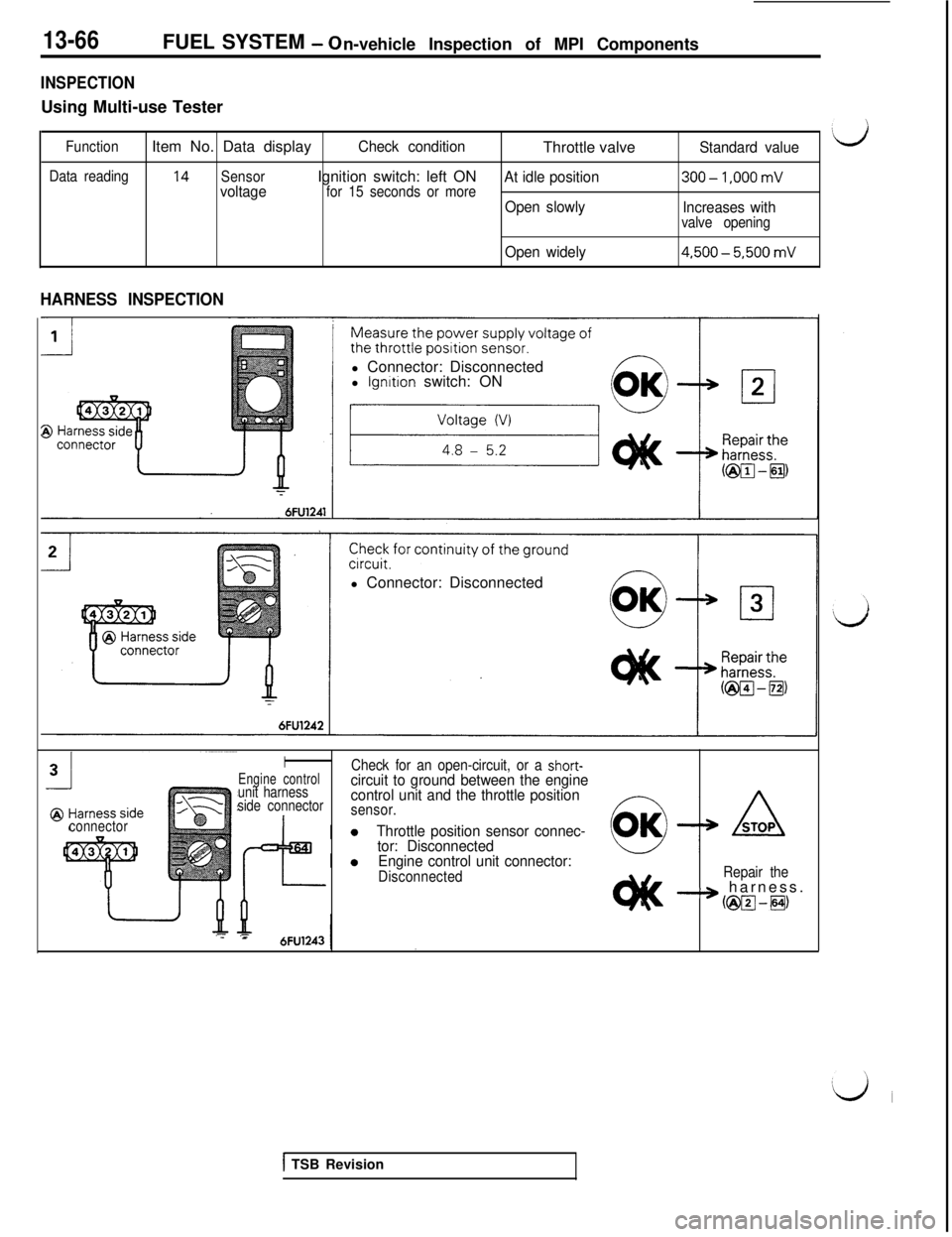

13-66FUEL SYSTEM - 0n-vehicle Inspection of MPI Components

INSPECTIONUsing Multi-use Tester

FunctionItem No. Data displayCheck conditionThrottle valveStandard value‘d

Data reading14SensorIgnition switch: left ONvoltagefor 15 seconds or moreAt idle position300-1.000 mV

Open slowly

Increases withvalve opening

Open widely4.500-5.500 mV

HARNESS INSPECTIONl Connector: Disconnected

l

lgnrtion switch: ON

l Connector: Disconnected

connector

I

Engine controlCheck for an open-circuit, or a short-

unit harnesscircuit to ground between the engine

side connectorcontrol unit and the throttle positionsensor.

Throttle position sensor connec-

tor: Disconnected

Engine control unit connector:

DisconnectedRepair theB-3 harness.

km-8)

-z =6FU1243

[ TSB Revision

Page 174 of 1146

13-68FUEL SYSTEM - On-vehicle Inspection of MPI Components

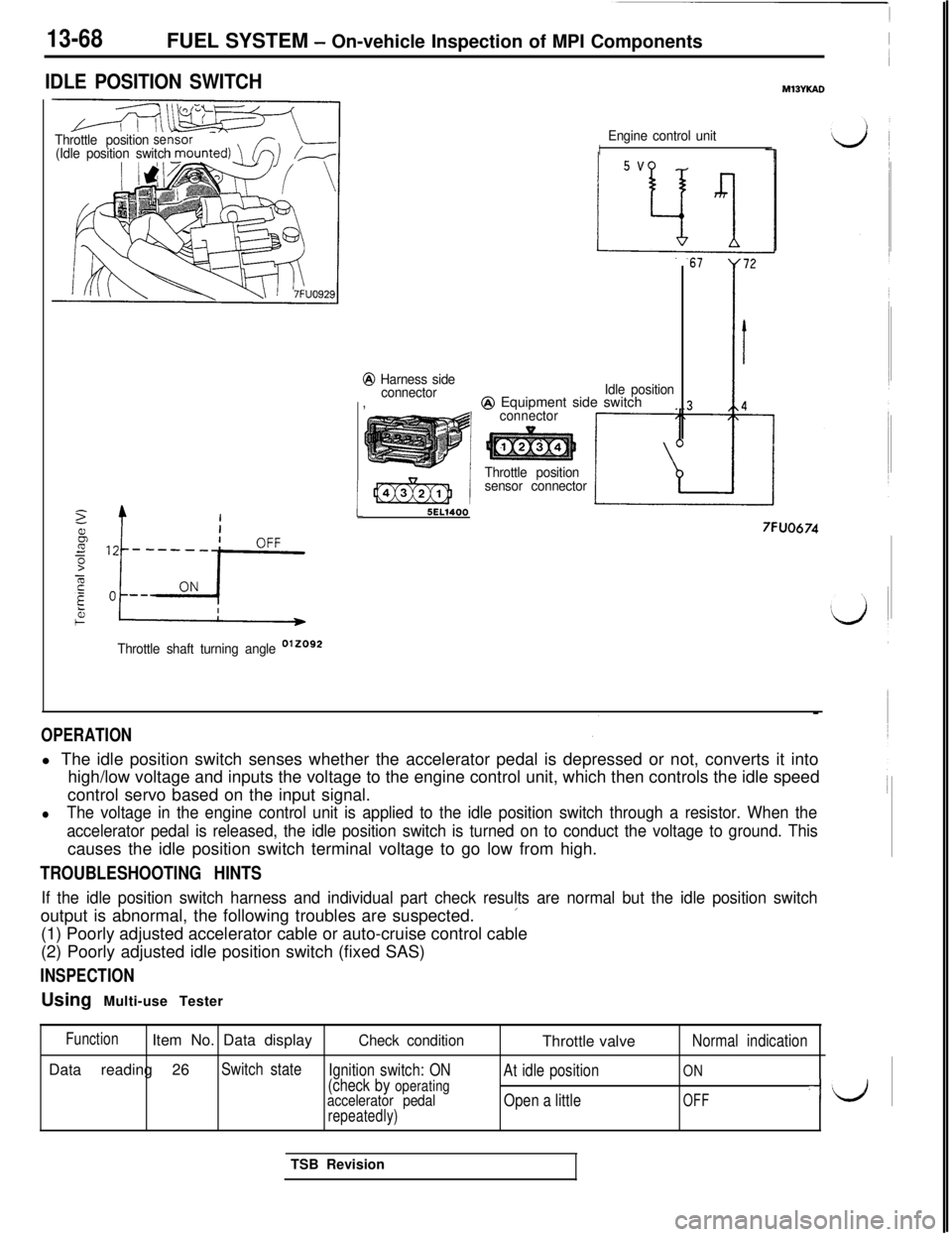

IDLE POSITION SWITCHMlBYKAD

Throttle positionse(Idle position switch

2

/bz----;-p

b+i

Throttle shaft turning angle D’20g2

i

Engine control unitI

@ Harness side

connectorIdle position,

@ Equipment side switchconnector

Throttle position

sensor connector

5EL1400

7FUO674

OPERATIONl The idle position switch senses whether the accelerator pedal is depressed or not, converts it into

high/low voltage and inputs the voltage to the engine control unit, which then controls the idle speed

control servo based on the input signal.

lThe voltage in the engine control unit is applied to the idle position switch through a resistor. When the

accelerator pedal is released, the idle position switch is turned on to conduct the voltage to ground. Thiscauses the idle position switch terminal voltage to go low from high.

TROUBLESHOOTING HINTS

If the idle position switch harness and individual part check results are normal but the idle position switchoutput is abnormal, the following troubles are suspected.

’(1) Poorly adjusted accelerator cable or auto-cruise control cable

(2) Poorly adjusted idle position switch (fixed SAS)

INSPECTIONUsing Multi-use Tester

FunctionItem No. Data displayCheck conditionThrottle valveNormal indicationData reading 26

Switch state

Ignition switch: ONON(check by operatingAt idle position

accelerator pedalOpen a littleOFF-J

repeatedly)TSB Revision