check engine MITSUBISHI 3000GT 1991 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 86 of 1146

11-36ENGINE - Cylinder Head and Valve

SquarenssVALVE SPRINGS

(1) Check free length of each valve spring and replace if

necessary.

!

FreelengthStandard value: 46.9 mm

(1.846 in.)\bJLimit: 45.9 mm

(1.807 in.)

(2) Using a square, test squareness of each valve spring. If

spring is excessively out of square, replace it.

Standard value: Less than 2”

Limit: 4

1 EN035

VALVE GUIDES

1 EN29ECheck the valve stem-to-guide clearance. If the clearance

exceeds the service limit, replace the valve guide with new

oversize part.

Standard value:

Intake

Exhaust0.02 - 0.05 mm (0008 - .0020 in.)

Limit:0.05

- 0.09 mm (.0020 - .0035 in.)

Intake

Exhaust0.10 mm (0039 in.)

0.12 mm (0047

in.)6EN043

1AVALVE SEAT RECONDITIONING PROCEDURES

(I 1 Before valve seat reconditioning, check valve stem to guide

clearance.

(2)Recondition the valve seat with a seat grinder or cutter. The

valve seat width should be the specified value at the center

of the valve face.

Inspect the valve seat with prussian blue to determine

LJwhere the valve contacts the seat. To do this, coat valve

seat lightly with prussian blue, and then set valve in place.

Rotate the valve with light pressure. If the blue is

transferred to the center of valve face, contact is satisfac-

tory.

If the blue is transferred to top edge of the valve face, lower

valve seat with a 30 degrees stone or cutter. If the blue is

transferred to the bottom edge of valve face, raise valve

seat with a 65 degrees stone or cutter.

Valve seat diameter:

Intake34 mm (I .34 in.)

ExhaustSeat width: 0.9

29.5 mm (1.16 in.)

- 1.3 mm (035 - .051 in.)

(3) The valve and valve seat should be lapped with a lapping

compound.

VALVE SEAT REPLACEMENT PROCEDURE

(1) Grind the valve seat to be replaced from the inside to thin

the wall thickness. Then, remove the valve seat.

1 ENOE18

TSB Revision

Page 91 of 1146

ENGINE - Oil Pan and Oil Pump

Removal steps

1. Transaxle stay (front)

2. Transaxle stay (rear)

3. Oil pressure switch4.

Z:

;:9.10.l+11.l*12.** l * 13.

Oil pressure gauge unitOil filterOil cooler by-pass valve

Oil filter bracket stay

Oil filter bracket

Oil filter bracket gasket

Drain plugDrain plug gasket0; y; boltI

16. Relief plug17. Relief spring18. Relief plunger** 19. Crankshaft front oil seal

20. Oil pump case

21. Oil pump gasket

22. Oil pump cover

23. Oil pump outer rotor

24. Oil pump inner rotor

14. Oil screen

15. Oil screen gasket

Side

clearance

BodyclearanceSERVICE POINTS OF REMOVALMllRBBB

13. REMOVAL OF OIL PAN

(1) Knock the special tool in deeply between the oil pan and

cylinder block.

(2) Hitting the side of the special tool, slide and remove the

oil pan.

INSPECTION

OIL PUMPMllRKAB

Assemble the rotor on the oil pump and check the clearance

with a feeler gauge.

Standard value:

Body clearanceO.lOO- 0.181 mm (.0039 - .0071 in.)

Side clearance0.040 - 0.095 mm (.0016 - .0037 in.)

TSB Revision

Page 95 of 1146

ENGINE - Piston and. Connectina RodII-45

LJ

Front mark

-

MD998764

lEN0113

lEN0114

v5EN057

,, Push in by thepiston.

IPiston ringPistonring gap6EN0379. REMOVAL OF PISTON PIN

(1) Insert the special tool,

Pushrod from the front mark side

of the piston top and install the guide B.

(2) With the piston top facing the front mark side of the

special tool, Piston Pin Setting Base and the piston front

mark facing up, set the piston and connecting rod

assembly.

(3) Using a press, remove the piston pin.

NOTEAfter the piston pin is removed, store the piston, piston

pin and connecting rod as grouped for each cylinder

number.

INSPECTION

PISTON RING

MllTCEA

(1) Check the clearance between the piston ring and the ring

groove. When it exceeds the limit, replace the rings, the

piston, or both.

Standard value:

No.10.03 - 0.07 mm (.0012 - .0028 in.)

No.20.02

- 0.06 mm (.OOOS - ‘0024 in.)

Limit: No.10.1 mm (.004 in.)

No.20.1 mm

(.004 in.)(2) Insert the piston ring into the cylinder bore putting it against

the top of the piston head and pressing it in.

When it makes a right angle, measure the piston ring gap

with a feeler gauge. When the gap is too large, replace the

piston ring.

Standard value:

No.10.30-0.45 mm (.0118- .0177 in.)

No.20.45- 0.60 mm (.0177 - .0236 in.)

Oil ring side rail0.20 - 0.60 mmLimit: No.1

(.0079 - .0236 in.)

0.8 mm

(.031 in.)

No.20.8 mm

(.031 in.)

Oil ring side rail1 .O mm (.039 in.)

I

LJ

TSB Revision1

Page 97 of 1146

ENGINE - Piston and Connecting RodII-47

6EN0223

Side rail

Side rail end

7EN249

7EN250

ldentiftcation mark embossed

No. 1

7Barrel

weldenthcation mark

Tapered

we7EN013i

LI(7) Check that the piston moves smoothly.

8. INSTALLATION OF OIL RING

(1) Fit the oil ring spacer into the piston ring groove.

NOTEOn the side rail and the spacer, no difference exists

between the upper and the lower surfaces.

(2) Attach the side rail on the upper side. When attaching

the side rail, engage one side of the side rail with the

piston groove. If pressed with a finger, as shown in the

illustration, it should enter easily.

NOTEThe side rail may be broken like other piston rings if the

gap is opened by the ring expander.

(3) In the same procedure as Step

(2), position the side rail

on the lower side.

(4) Check that the side rail smoothly rotates in both

directions.

7.INSTALLATION OF PISTON RING No. 2 / 6. PISTON

RING No.1

(1) Using a piston ring expander, position the No.2 and

No.1 piston rings.

Identification mark: No.1

No.2

NOTE

T

T2(1) Keep in mind that Nos.1 and 2 are different in shape.

(2) Assemble the Nos.1 and 2 piston rings with the

manufacturer and size marks stamped on the side

facing upward (toward the piston top).

TSB Revision

Page 98 of 1146

11-48ENGINE - Piston and Connecting Rod

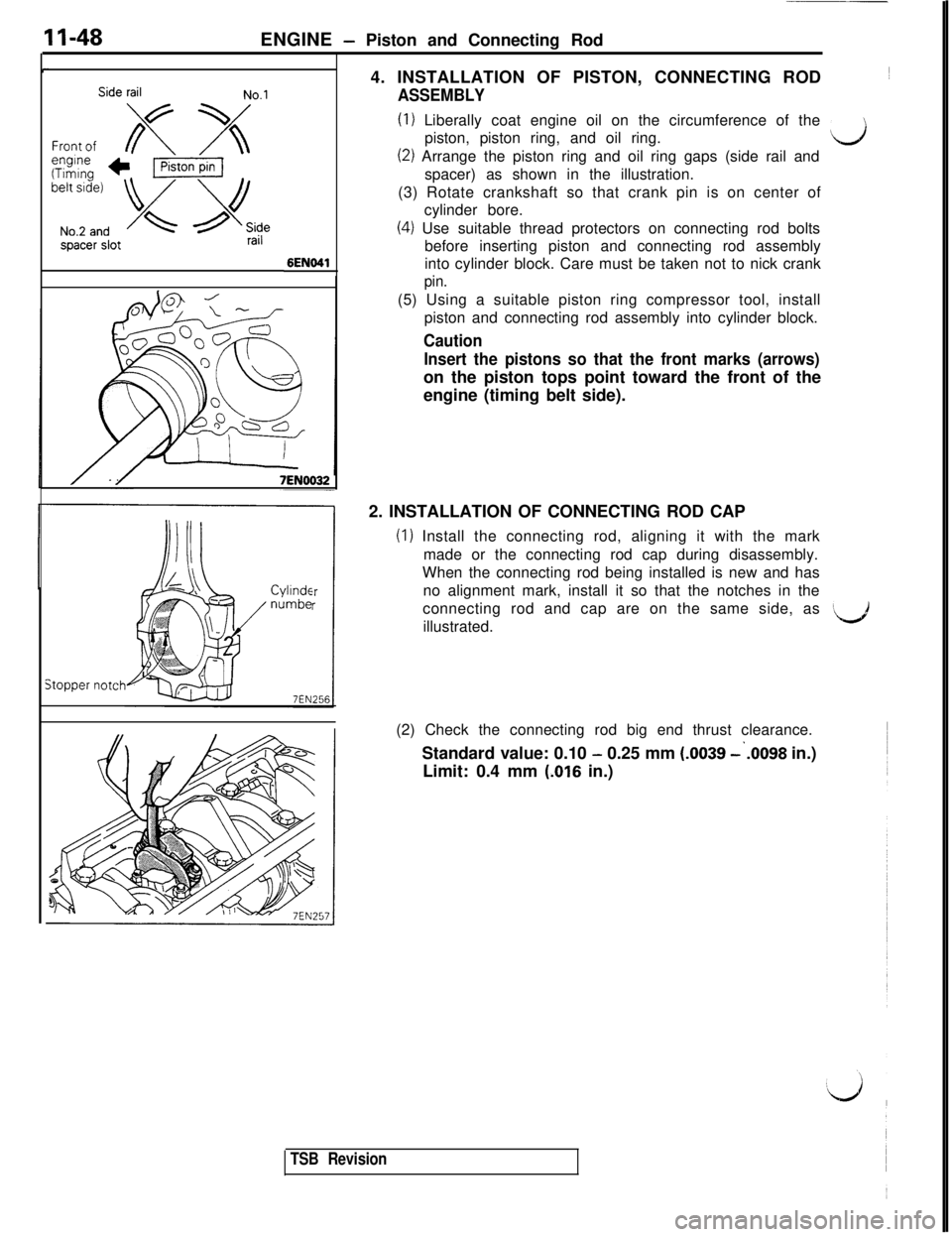

Side railNo.1

spacer slotrail

6ENO41

7EN0032

Cylindcnumbe

Stopper notch4. INSTALLATION OF PISTON, CONNECTING ROD~

ASSEMBLY

(1) Liberally coat engine oil on the circumference of the

piston, piston ring, and oil ring.

d

(2) Arrange the piston ring and oil ring gaps (side rail and

spacer) as shown in the illustration.

(3) Rotate crankshaft so that crank pin is on center of

cylinder bore.

(4) Use suitable thread protectors on connecting rod bolts

before inserting piston and connecting rod assembly

into cylinder block. Care must be taken not to nick crank

pin.(5) Using a suitable piston ring compressor tool, install

piston and connecting rod assembly into cylinder block.

Caution

Insert the pistons so that the front marks (arrows)on the piston tops point toward the front of the

engine (timing belt side).

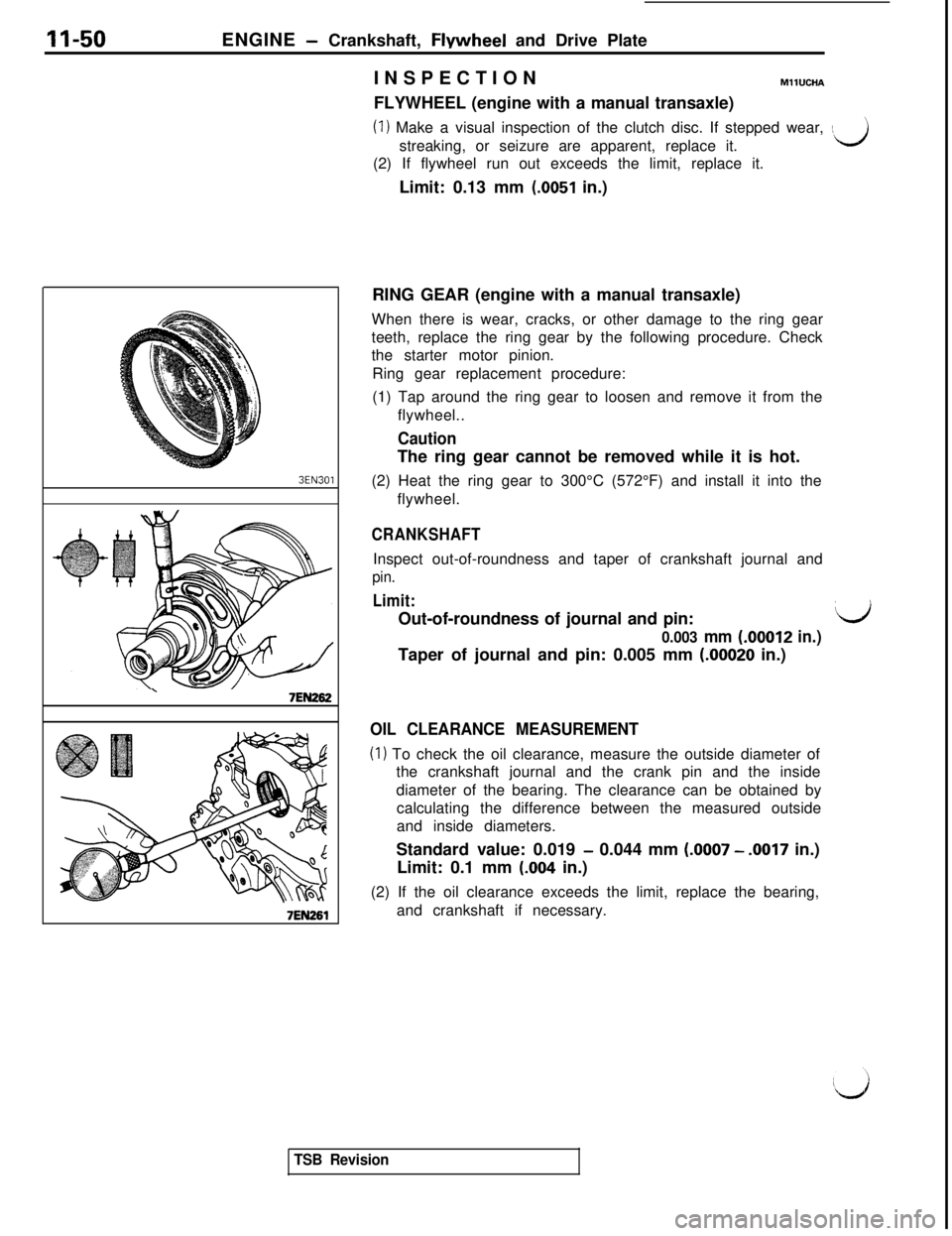

2. INSTALLATION OF CONNECTING ROD CAP

(1) Install the connecting rod, aligning it with the mark

made or the connecting rod cap during disassembly.

When the connecting rod being installed is new and has

no alignment mark, install it so that the notches in the

connecting rod and cap are on the same side, as

illustrated.

‘d(2) Check the connecting rod big end thrust clearance.

Standard value: 0.10

- 0.25 mm (.0039 -‘.0098 in.)

Limit: 0.4 mm

(-016 in.)

TSB Revision

Page 100 of 1146

II-50ENGINE - Crankshaft, FlYwheel and Drive Plate

\7EN262

7EN261INSPECTION

MllUCHAFLYWHEEL (engine with a manual transaxle)

(I) Make a visual inspection of the clutch disc. If stepped wear, :streaking, or seizure are apparent, replace it.\J(2) If flywheel run out exceeds the limit, replace it.

Limit: 0.13 mm

t.0051 in.)

RING GEAR (engine with a manual transaxle)

When there is wear, cracks, or other damage to the ring gear

teeth, replace the ring gear by the following procedure. Check

the starter motor pinion.

Ring gear replacement procedure:

(1) Tap around the ring gear to loosen and remove it from the

flywheel..

CautionThe ring gear cannot be removed while it is hot.

(2) Heat the ring gear to 300°C (572°F) and install it into the

flywheel.

CRANKSHAFTInspect out-of-roundness and taper of crankshaft journal and

pin.

Limit:Out-of-roundness of journal and pin:

LJ

0.003 mm (.00012 in.)Taper of journal and pin: 0.005 mm

(.00020 in.)

OIL CLEARANCE MEASUREMENT

(I) To check the oil clearance, measure the outside diameter of

the crankshaft journal and the crank pin and the inside

diameter of the bearing. The clearance can be obtained by

calculating the difference between the measured outside

and inside diameters.

Standard value: 0.019

- 0.044 mm i.0007 - .0017 in.)

Limit: 0.1 mm

(.004 in.)

(2) If the oil clearance exceeds the limit, replace the bearing,

and crankshaft if necessary.

TSB Revision

Page 102 of 1146

11-52ENGINE - Crankshaft, Flywheel and Drive Plate

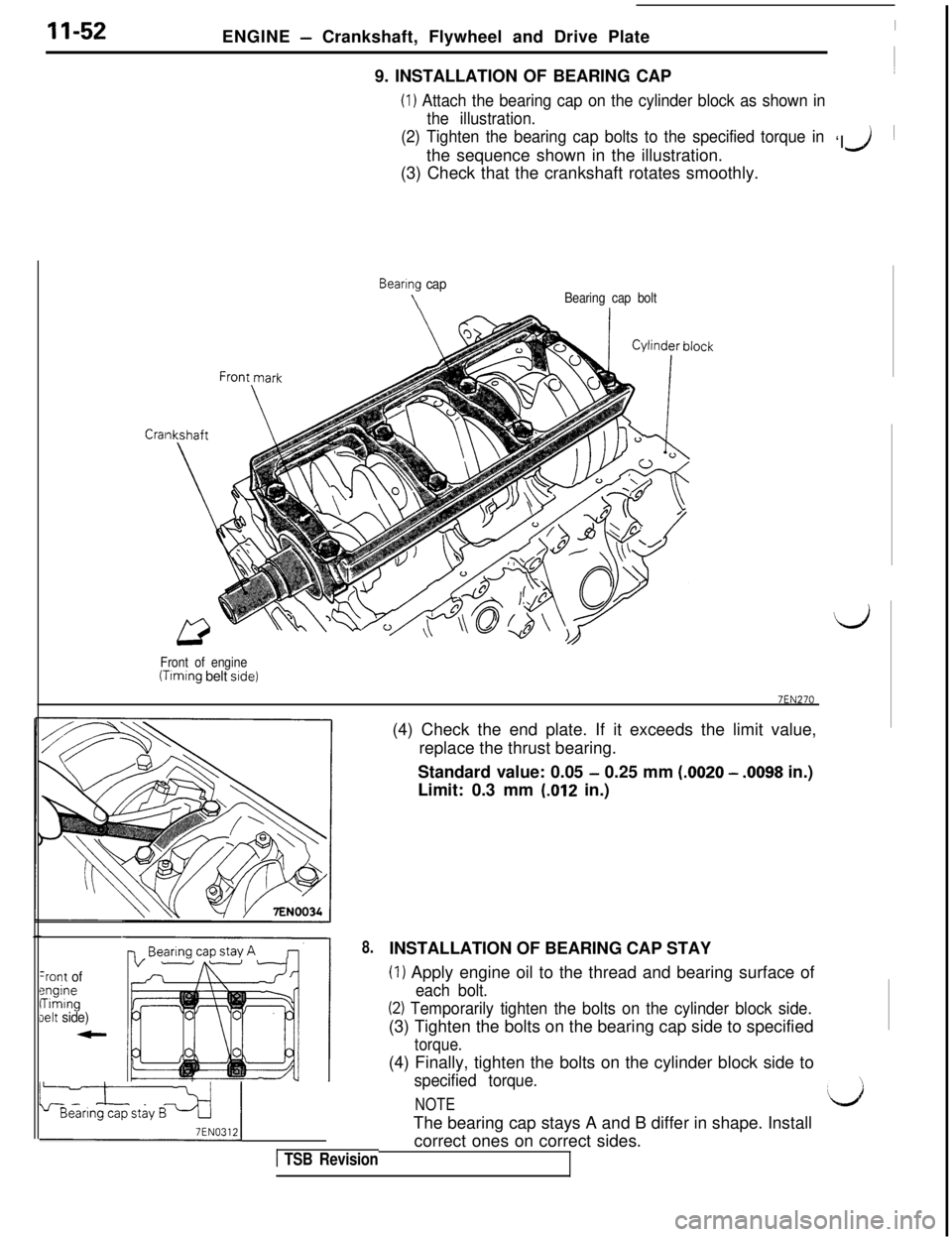

9. INSTALLATION OF BEARING CAP

(1) Attach the bearing cap on the cylinder block as shown in

the illustration.

(2) Tighten the bearing cap bolts to the specified torque in‘I

the sequence shown in the illustration.

J ~

(3) Check that the crankshaft rotates smoothly.

Cral

Bearing cap

\Bearing cap bolt

Front of engine

(Timing belt side)

7EN270(4) Check the end plate. If it exceeds the limit value,

replace the thrust bearing.

Standard value: 0.05

- 0.25 mm (.0020 - .0098 in.)

Limit: 0.3 mm

(.012 in.)

-rent ofengineTimingIelt side)

8.

LLiN03,ij

1 TSB RevisionINSTALLATION OF BEARING CAP STAY

(1) Apply engine oil to the thread and bearing surface of

each bolt.

(2) Temporarily tighten the bolts on the cylinder block side.(3) Tighten the bolts on the bearing cap side to specified

torque.(4) Finally, tighten the bolts on the cylinder block side to

specified torque.

NOTEThe bearing cap stays A and B differ in shape. Install

correct ones on correct sides.d

Page 104 of 1146

11-54ENGINE - Cylinder Block

I

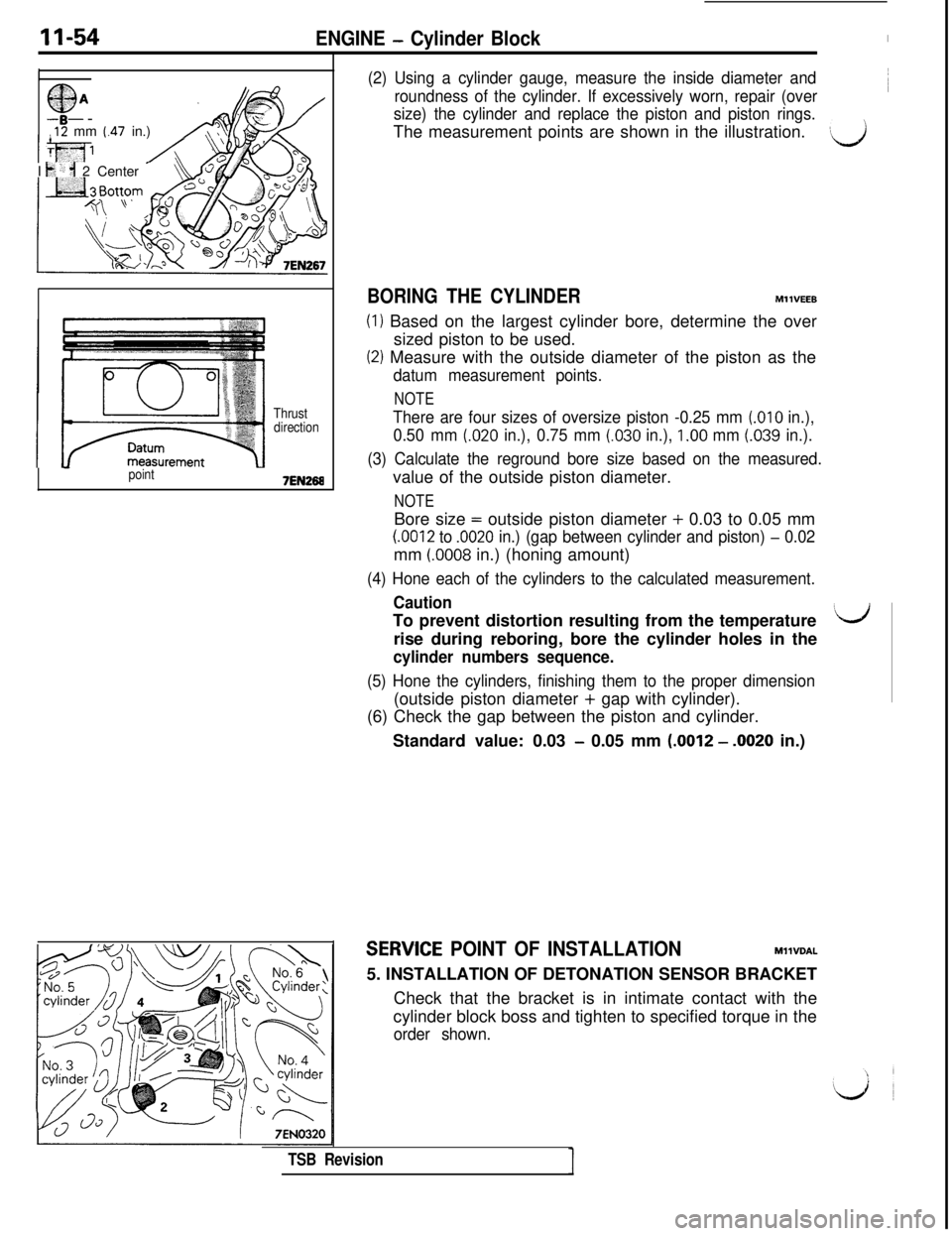

$jA A@/

,12 mm (.47 in.)

I

t+ ‘: ;I 2 Center -

Thrust

direction

-point7EN268

(2) Using a cylinder gauge, measure the inside diameter and

roundness of the cylinder. If excessively worn, repair (over~

size) the cylinder and replace the piston and piston rings.The measurement points are shown in the illustration.

)d

BORING THE CYLINDERMllVEEB

(1) Based on the largest cylinder bore, determine the over

sized piston to be used.

(2) Measure with the outside diameter of the piston as the

datum measurement points.

NOTE

There are four sizes of oversize piston -0.25 mm (.OlO in.),

0.50 mm

(.020 in.), 0.75 mm (.030 in.), 1.00 mm (.039 in.).

(3) Calculate the reground bore size based on the measured.value of the outside piston diameter.

NOTEBore size = outside piston diameter + 0.03 to 0.05 mm

(.0012 to .0020 in.) (gap between cylinder and piston) - 0.02mm (0008 in.) (honing amount)

(4) Hone each of the cylinders to the calculated measurement.

CautionTo prevent distortion resulting from the temperature‘drise during reboring, bore the cylinder holes in the

cylinder numbers sequence.

(5) Hone the cylinders, finishing them to the proper dimension(outside piston diameter + gap with cylinder).

(6) Check the gap between the piston and cylinder.

Standard value: 0.03

- 0.05 mm (.0012 - .0020 in.)

SERWCE POINT OF INSTALLATIONMllVDAL

5. INSTALLATION OF DETONATION SENSOR BRACKET

Check that the bracket is in intimate contact with the

cylinder block boss and tighten to specified torque in the

order shown.

TSB Revision

Page 105 of 1146

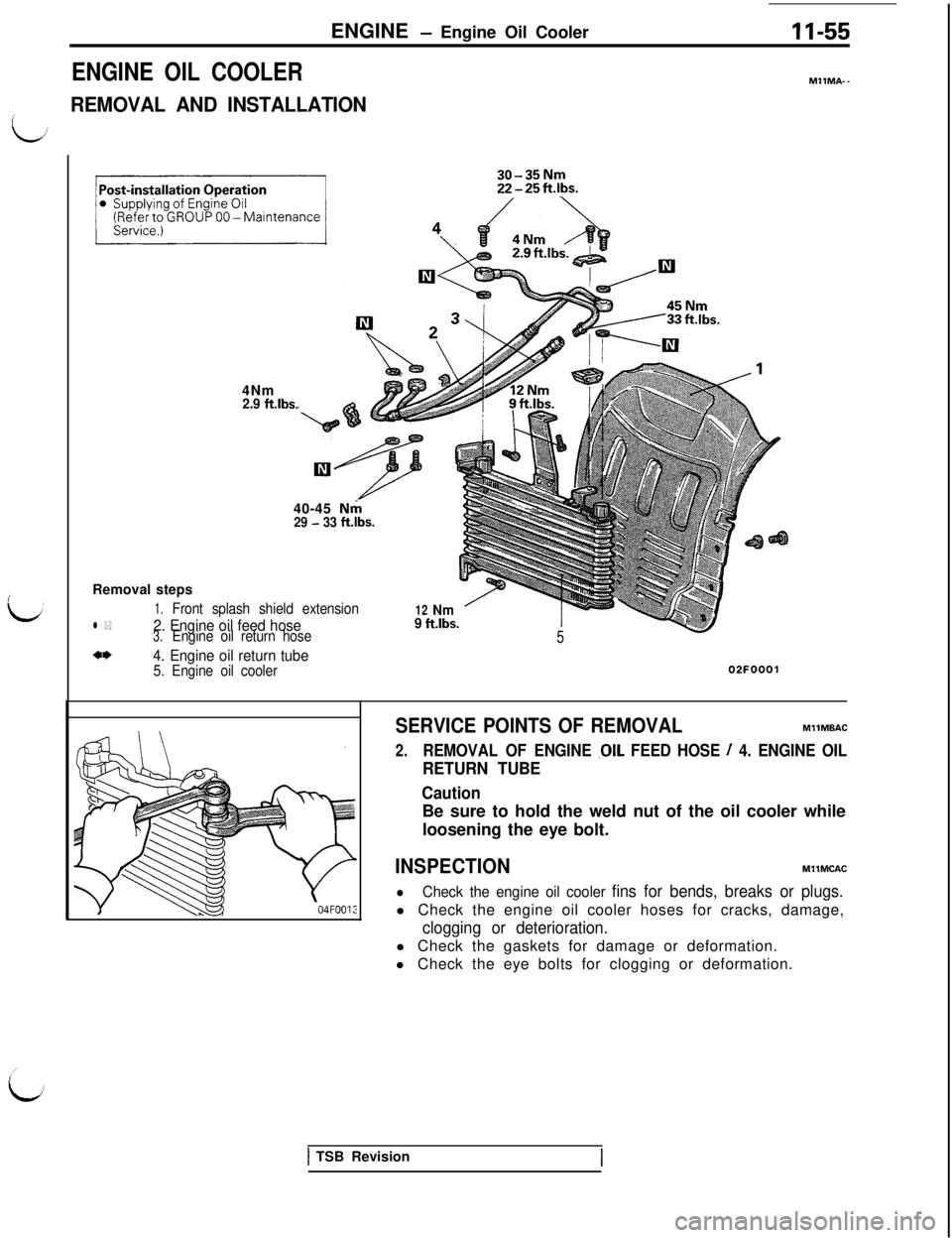

ENGINE - Engine Oil Cooler

ENGINE OIL COOLER

REMOVAL AND INSTALLATION

11-55

MllMA-.4Nm

2.9 ft.lbs.40-45

Nrh

29 - 33 ft.lbs.Removal steps

1.Front splash shield extensionl *2. Engine oil feed hose3.Engine oil return hose

4*4. Engine oil return tube5. Engine oil cooler

12Nm

9 ft.lbs.5

02FOOOi

SERVICE POINTS OF REMOVALMllMBAC

2.REMOVAL OF ENGINE .OIL FEED HOSE / 4. ENGINE OIL

RETURN TUBE

CautionBe sure to hold the weld nut of the oil cooler while

loosening the eye bolt.

INSPECTIONMllMCAC

l

Check the engine oil cooler fins for bends, breaks or plugs.l Check the engine oil cooler hoses for cracks, damage,

clogging or deterioration.l Check the gaskets for damage or deformation.

l Check the eye bolts for clogging or deformation.

1 TSB Revision

Page 107 of 1146

FUEL

SYSTEM

CONTENTSM13AA- _

CRUISE CONTROL SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . .158SPECIFICATIONS. . . . . . . .._._....................................................155

CRUISE CONTROL SYSTEM*................................................185

SERVICE ADJUSTMENT PROCEDURES............................178

Cruise Control Cables Inspection and Adjustment........178Cruise Control SystemInspection....................................179individual Parts Inspection....................................................181

SPECIAL TOOLS........................................................................159

SPECIFICATIONS....................................................................158

General Specifications........................................................158Service Specifications........................................................158

TROUBLESHOOTING............................................................159

Check Chart............................................................................163Harness and Components Layout....................................176Preliminary Inspection........................................................159Self-diagnosis Checking........................................................172Troubleshooting Quick Reference Chart............................159

ENGINE CONTROL............................................155

ENGINE CONTROL................................................................157

SERVICE ADJUSTMENT PROCEDURES............................156

Accelerator Cable Inspection and Adjustment................156Accelerator Switch Inspection and Adjustment................156

Service Specifications........................................................

155

TROUBLESHOOTING............................................................

155

Accelerator Cable and Accelerator Pedal........................155

FUEL SYSTEM....................................................3

DETONATION SENSOR........................................................154

FUEL FILTER............................................................................

153

FUEL LINE AND VAPOR LINE................................................151

FUEL PUMP AND FUEL GAUGE UNIT ASSEMBLYAND OVERFILL LIMITER (TWO-WAY VALVE)................149

FUEL TANK.................................................................................146

GENERAL INFORMATION

....................................................

3

MPI System Diagram............................................................3

INJECTOR................................................................................141

ON-VEHICLE INSPECTION OF MPI COMPONENTS........36

Active Exhaust Control Unit

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

(1)A Supplemental Restraint System (SRS), which uses a driver-side air bag, has been installed in the 3000GT.(2)The SRS includes the following components: impact sensors, SRS diagnosis unit: SRS warning light, air bagmodule, clock spring, interconnecting wiring. Other SRS-related components (that may have to be

removed/installed in connection with SRS service or maintenance) are indicated in the table of contents byan asterisk (*).

WARNING!(I)Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inadvertent firing of the air bag) or to the driver (from

rendering the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at anauthorized MITSUBISHI dealer.

(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP

528 -Supplemental Restraint System (SRS), before beginning any service or maintenance of any component of theSRS or any SRS-related component.