brake sensor MITSUBISHI 3000GT 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 4 of 1146

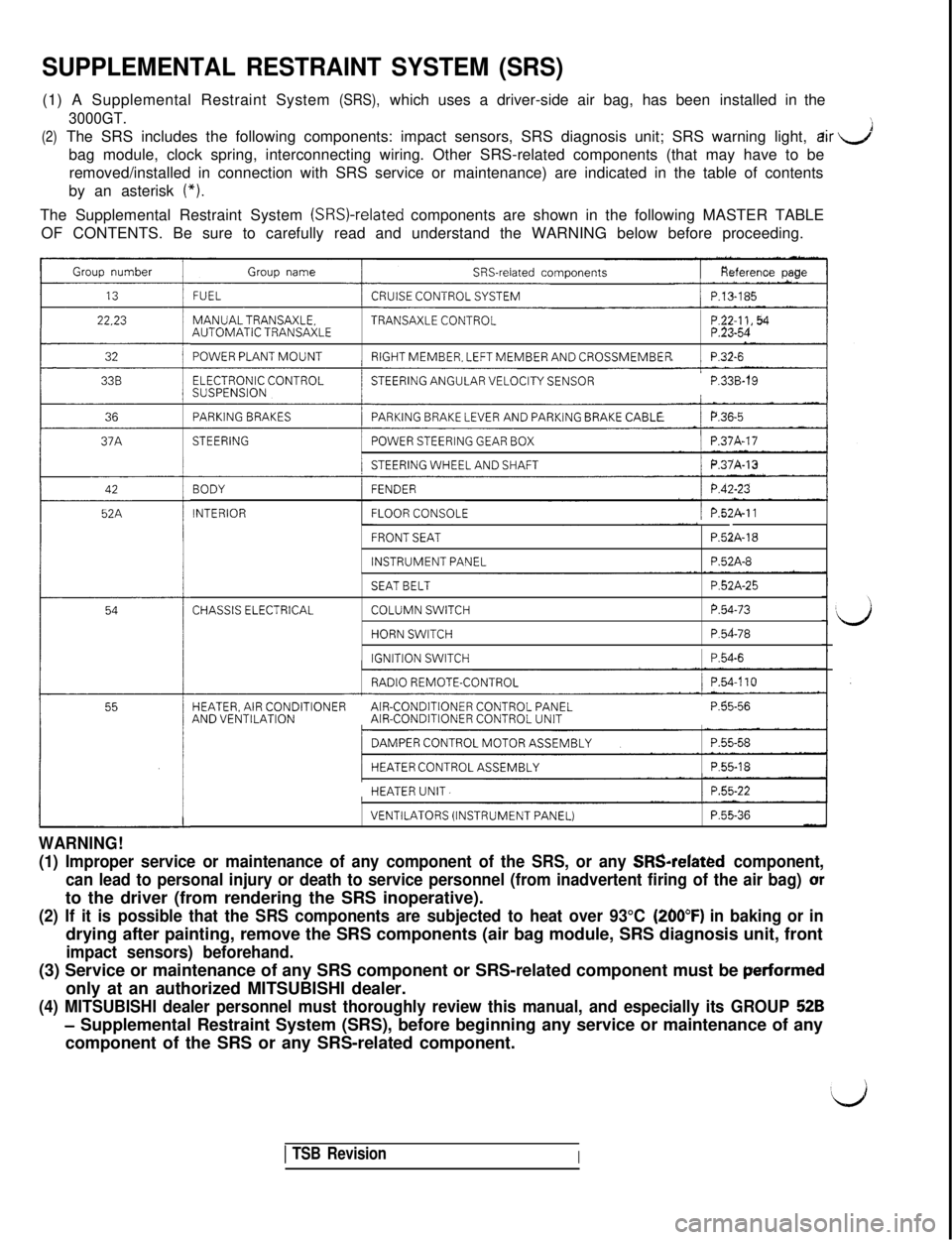

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

dir J

bag module, clock spring, interconnecting wiring. Other SRS-related comp\

onents (that may have to be

(*).

The Supplemental Restraint System (SRSI-related components are shown in the following MASTER TABLE

OF CONTENTS. Be sure to carefully read and understand the WARNING below \

before proceeding.

Group number

22.23

32

36

42

52A

Group nameSRS-related components

FUELCRUISE CONTROL SYSTEM/ P.13-185

MANUALTRANSAXLE.TRANSAXLE CONTROLAUTOMATIC TRANSAXLE

POWER PLANT MOUNTRIGHT MEMBER, LEFT MEMBER AND CROSSMEMBERP.32-6

ELECTRONIC CONTROLSUSPENSION’STEERING ANGULAR VELOCITY SENSORP.33B-19

PARKING BRAKESPARKING BRAKE LEVER AND PARKiNG BRAKE CABLE/ P.36~5I

STEERING/POWER STEERING GEAR BOX/ P.37A-17

/STEERING WHEEL AND SHAFTj P.37A-13

BODY

INTERIOR

FENDER

FLOOR CONSOLE/ P.52A-11

FRONT SEAT

INSTRUMENT PANEL

P52A-18

P.52A-8

CHASSIS ELECTRICAL

SEAT BELT

COLUMN SWITCH

HORN SWITCH

IGNITION SWITCH

P.52A-25

P.54-73

P.54-78

1 P.54-6

RADIO REMOTE-CONTROL/ P.54.110

HEATER, AIR CONDITIONERAIR-CONDITIONER CONTROL PANELAND VENTILATIONAIR-CONDITIONER CONTROL UNITP.55-56

/DAMPER CONTROL MOTOR ASSEMBLYI

/HEATER CONTROL ASSEMBLY1 P.55-18I

HEATER UNIT.1 P.55-22

WARNING!

VENTILATORS (INSTRUMENT PANEL)P.55-36

(1) Improper service or maintenance of any component of the SRS, or an\

y SRSrelated component,

can lead to personal injury or death to service personnel (from inadver\

tent firing of the air bag) or

to the driver (from rendering the SRS inoperative).

(260°F) in baking or in

drying after painting, remove the SRS components (air bag module, SRS d\

iagnosis unit, front

perfarmed

only at an authorized MITSUBISHI dealer.

52B

- Supplemental Restraint System (SRS), before beginning any service or m\

aintenance of any

component of the SRS or any SRS-related component.

1 TSB RevisionI

Page 48 of 1146

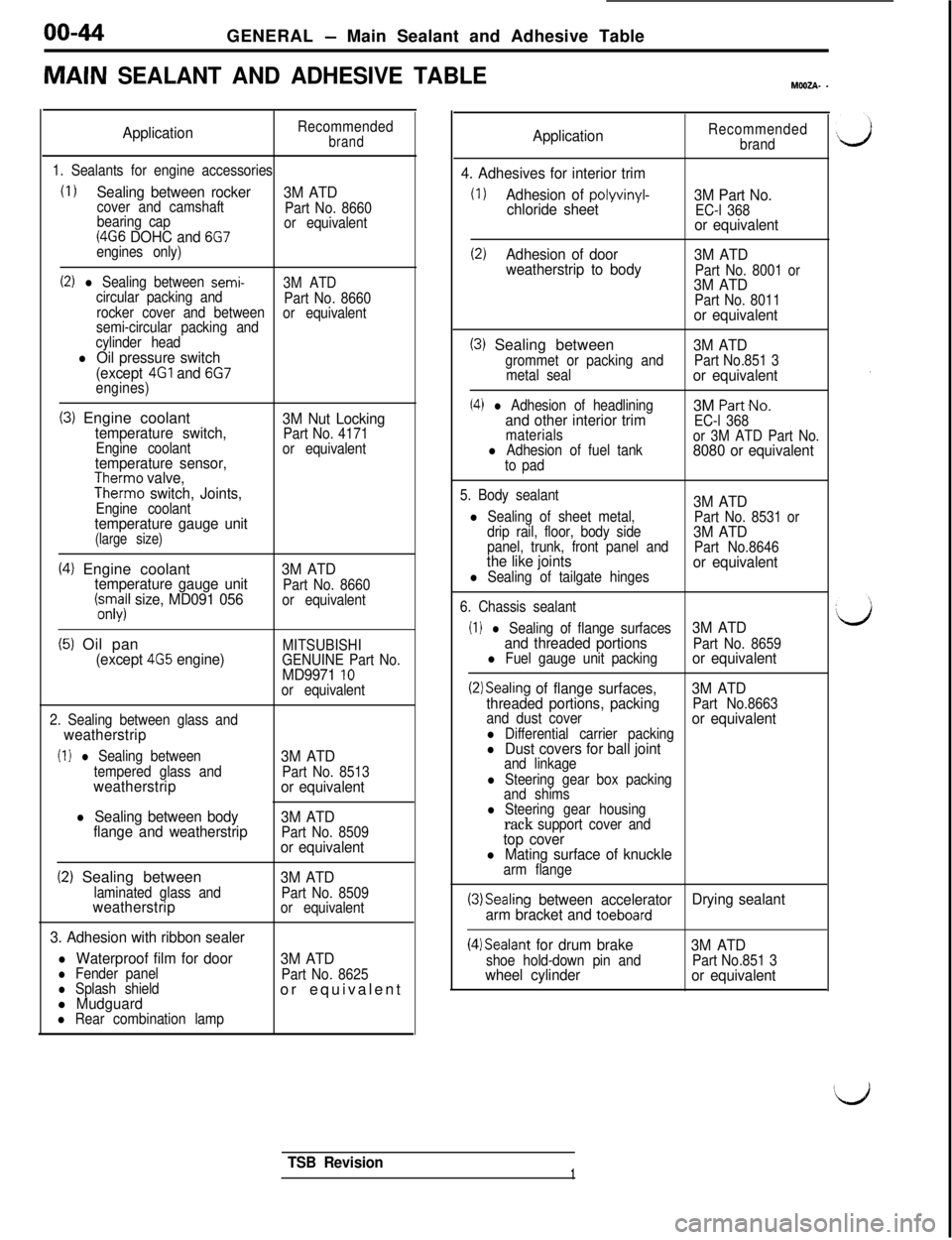

00-44

GENERAL - Main Sealant and Adhesive Table

MAIN SEALANT AND ADHESIVE TABLEMWZA- -

ApplicationRecommendedbrand

1. Sealants for engine accessories

(I 1Sealing between rocker

3M ATDcover and camshaft

Part No. 8660

bearing cap

(4G6 DOHC and 6G7or equivalent

engines only)

(2) l Sealing between semi-3M ATD

circular packing and

Part No. 8660

rocker cover and between

semi-circular packing andor equivalent

cylinder head

l Oil pressure switch

(except 4Gl and 6G7engines)

(3) Engine coolanttemperature switch,Engine coolanttemperature sensor,Therm0 valve,Therm0 switch, Joints,Engine coolanttemperature gauge unit(large size)

3M Nut LockingPart No. 4171

or equivalent

(4) Engine coolanttemperature gauge unit(;.s;il size, MD091 0563M ATDPart No. 8660

or equivalent

(5) Oil pan(except 4G5 engine)MITSUBISHI

GENUINE Part No.

MD9971 10or equivalent

2. Sealing between glass and

weatherstrip

(I 1 l Sealing between

tempered glass and

weatherstrip

l Sealing between body

flange and weatherstrip3M ATD

Part No. 8513or equivalent

3M ATD

Part No. 8509or equivalent

(2) Sealing betweenlaminated glass andweatherstrip

3. Adhesion with ribbon sealer

l Waterproof film for doorl Fender panell Splash shieldl Mudguardl Rear combination lamp

3M ATDPart No. 8509

or equivalent

3M ATDPart No. 8625or equivalent

ApplicationRecommended

brand

4. Adhesives for interior trim

(1)Adhesion of polyvinyl-chloride sheet3M Part No.EC-l 368or equivalent

(2)Adhesion of door

3M ATD

weatherstrip to body

Part No. 8001 or3M ATDPart No. 8011or equivalent

(3) Sealing betweengrommet or packing and

metal seal

(4) l Adhesion of headliningand other interior trimmaterialsl Adhesion of fuel tank

to pad

3M ATDPart No.851 3or equivalent3M

Part-No.

EC-l 368

or 3M ATD Part No.

8080 or equivalent

5. Body sealant3M ATDl Sealing of sheet metal,

Part No. 8531 or

drip rail, floor, body side3M ATDpanel, trunk, front panel and

Part No.8646the like jointsl Sealing of tailgate hingesor equivalent

6. Chassis sealant

(I 1 l Sealing of flange surfaces3M ATD

and threaded portions

Part No. 8659l Fuel gauge unit packingor equivalent

(2)Sealing of flange surfaces,3M ATD

threaded portions, packingPart No.8663

and dust cover

l Differential carrier packingor equivalent

l Dust covers for ball jointand linkage

l Steering gear box packing

and shims

l Steering gear housingrack support cover andtop coverl Mating surface of knucklearm flange

(3)Sealing between accelerator

arm bracket and toeboardDrying sealant

(4)Sealant for drum brakeshoe hold-down pin andwheel cylinder3M ATDPart No.851 3or equivalent

TSB Revision1

Page 67 of 1146

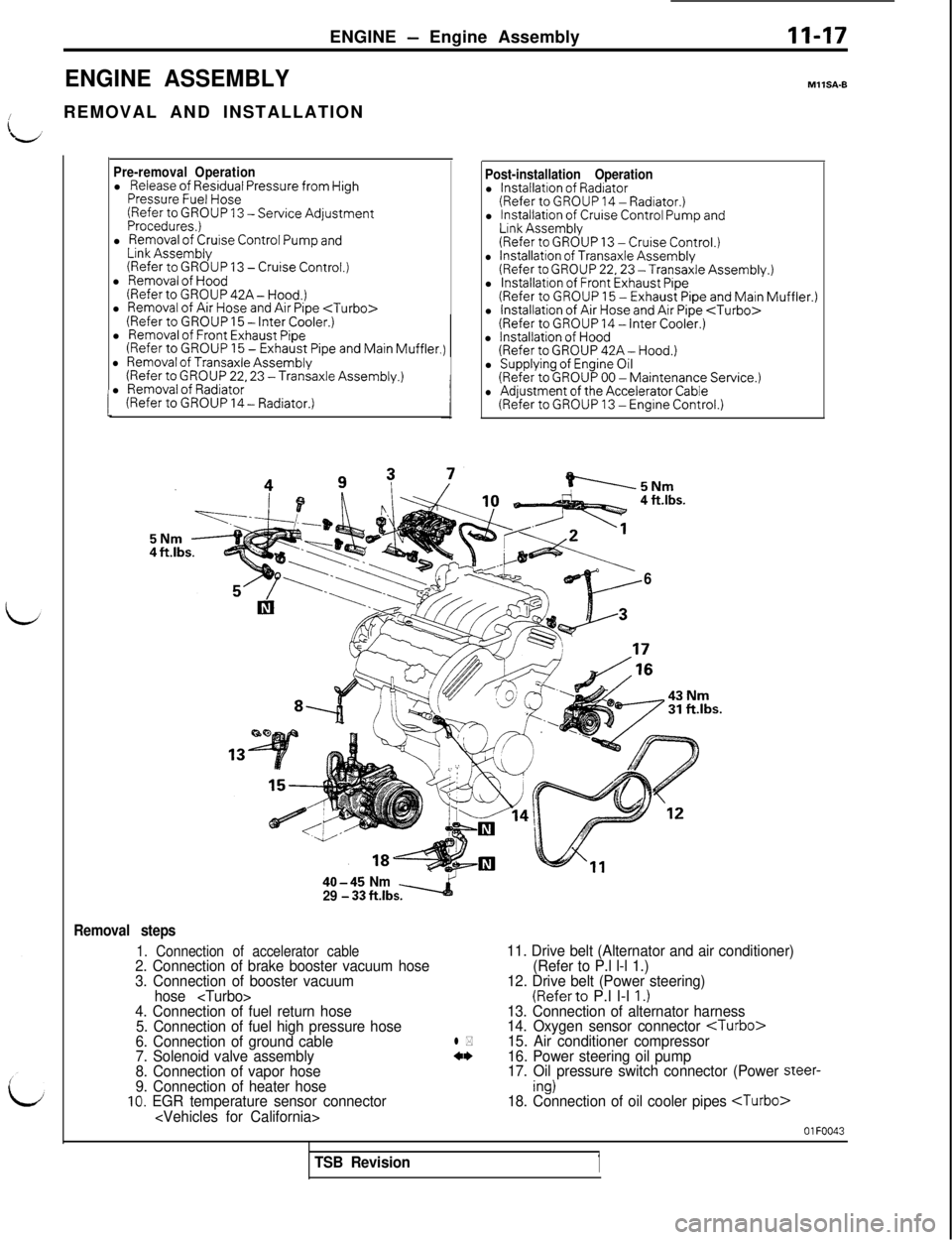

ENGINE - Engine AssemblyII-17

ENGINE ASSEMBLY

/REMOVAL AND INSTALLATION

I

Pre-removal Operationl Release of Residual Pressure from HighPressure Fuel Hose(Refer to GROUP 13 -Service AdjustmentProcedures,)l Removal of Cruise Control Pump andLink Assembly(Refer to GROUP 13 - Cruise Control.)l Removal of Hood(RefertoGROUP42A-Hood.)

l

Removal of Air Hose and Air Pipe

Post-installation Operationl Installation of Radiator(Refer to GROUP 14 - Radiator.)l Installation of Cruise Control Pump andLink Assembly(Refer to GROUP 13 -Cruise Control.)l Installation of Transaxle Assembly(Refer to GROUP 22,23 -Transaxle Assembly.)l lnstallatron of Front Exhaust Pipe(Refer to GROUP 15 - Exhaust Pipe and Main Muffler.)l Installation of Air Hose and Air Pipe

MllSA-B

4 ft.lbs.

6

40-45 Nm

29 - 33 fklbs.

Removal steps

1. Connection of accelerator cable11. Drive belt (Alternator and air conditioner)

2. Connection of brake booster vacuum hose(Refer to P.l l-l 1.)

3. Connection of booster vacuum12. Drive belt (Power steering)

hose

(Referto P.l l-l I.)4. Connection of fuel return hose13. Connection of alternator harness

5. Connection of fuel high pressure hose14. Oxygen sensor connector

6. Connection of ground cablel *15. Air conditioner compressor

7. Solenoid valve assembly4w

16. Power steering oil pump

8. Connection of vapor hose17. Oil pressure switch connector (Power steer-9. Connection of heater hoseing)10. EGR temperature sensor connector18. Connection of oil cooler pipes

OlFOO43

TSB Revision1

Page 76 of 1146

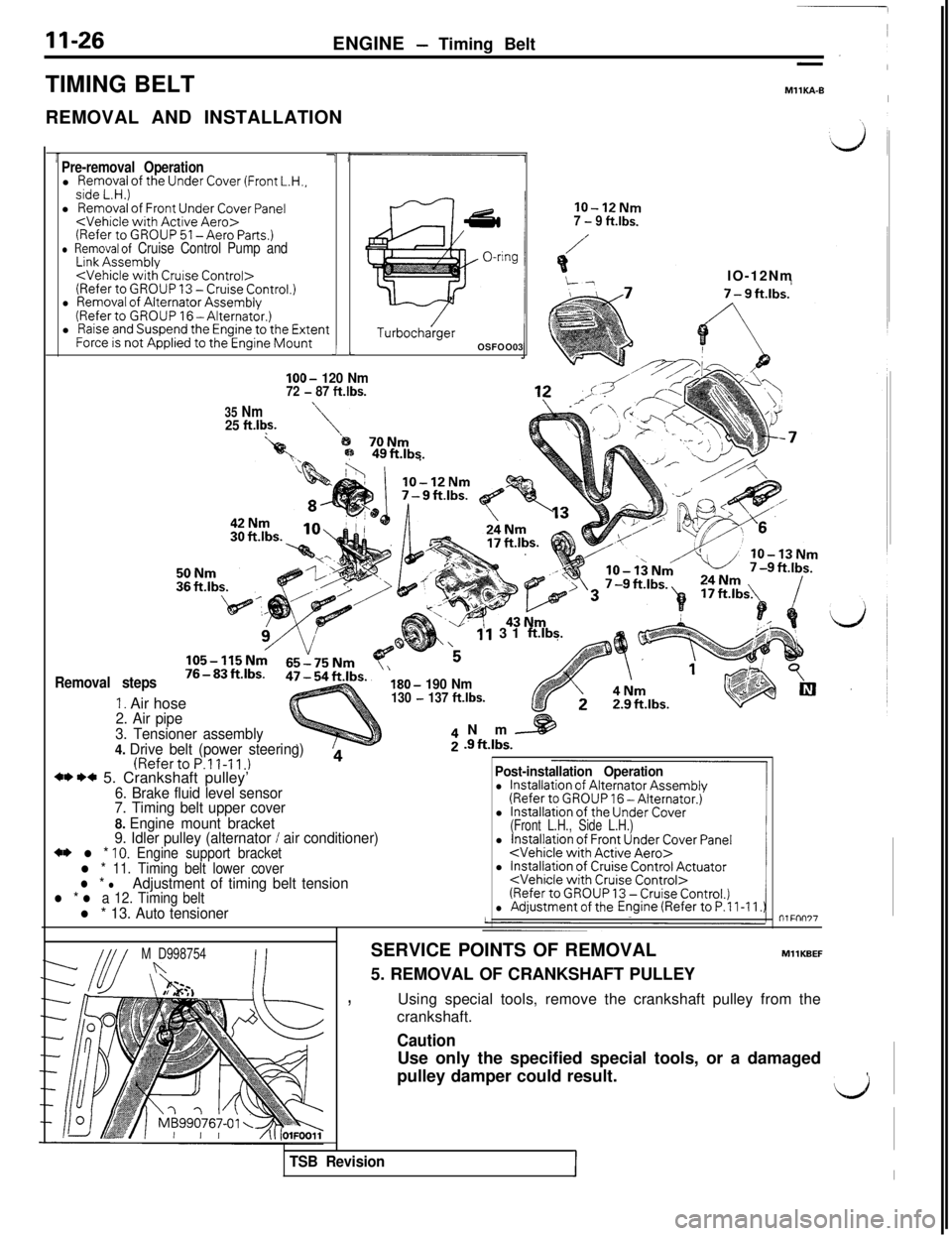

11-26ENGINE - Timing Belt

TIMING BELT

REMOVAL AND INSTALLATION

MllKA-BI

Pre-removal Operationl Removal of the Under Cover (Front L.H.,side L.H.)l Removal of Front Under Cover Panel

l Raise and Suspend the Engine to the ExtentForce is not Applied to the Engine Mounti LIOO-

120 Nm72 - 87 ft.lbs.

35 Nm25 ft.l$.

TurbochargerOSFOO03

lo-12Nm7 - 9 ft.lbs.

Removal steps

1. Air hose

11 31 ftlbs.

‘5IO-12Nm

B;p 49ftJbs.

\

180- 190 Nm130 - 137 ft.lbs.

2. Air pipe

3. Tensioner assembly

4. Drive belt (power steering)

(RefertoP.ll-11.)4** I)* 5. Crankshaft pulley’6. Brake fluid level sensor

7. Timing belt upper cover

8. Engine mount bracket

9. Idler pulley (alternator

/ air conditioner)+* l * 10. Engine support bracketl * 11. Timing belt lower coverl * lAdjustment of timing belt tensionl * l a 12. Timing beltl * 13. Auto tensionerNm

[email protected].

Post-installation Operation

l Installation of Alternator Assembly(Refer to GROUP 16 -Alternator.)

l Installation of the Under Cover(Front L.H., Side L.H.)l Installation of Front Under Cover Panel

l Installation of Cruise Control Actuator

M D998754nSERVICE POINTS OF REMOVAL

5. REMOVAL OF CRANKSHAFT PULLEYMllKBEF

,Using special tools, remove the crankshaft pulley from the

crankshaft.

TSB RevisionII

CautionUse only the specified special tools, or a damaged

pulley damper could result.

,

LJ

Page 107 of 1146

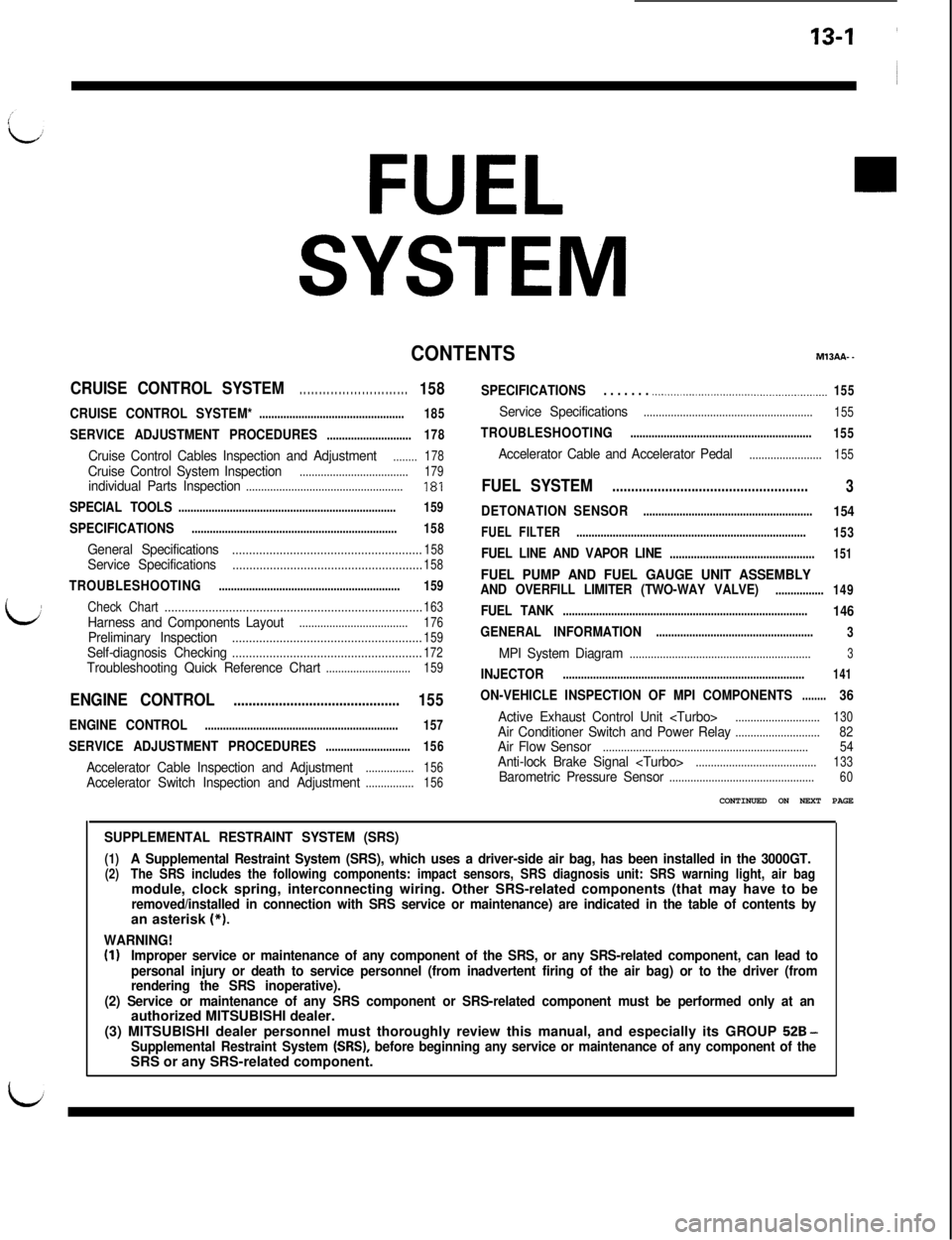

FUEL

SYSTEM

CONTENTSM13AA- _

CRUISE CONTROL SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . .158SPECIFICATIONS. . . . . . . .._._....................................................155

CRUISE CONTROL SYSTEM*................................................185

SERVICE ADJUSTMENT PROCEDURES............................178

Cruise Control Cables Inspection and Adjustment........178Cruise Control SystemInspection....................................179individual Parts Inspection....................................................181

SPECIAL TOOLS........................................................................159

SPECIFICATIONS....................................................................158

General Specifications........................................................158Service Specifications........................................................158

TROUBLESHOOTING............................................................159

Check Chart............................................................................163Harness and Components Layout....................................176Preliminary Inspection........................................................159Self-diagnosis Checking........................................................172Troubleshooting Quick Reference Chart............................159

ENGINE CONTROL............................................155

ENGINE CONTROL................................................................157

SERVICE ADJUSTMENT PROCEDURES............................156

Accelerator Cable Inspection and Adjustment................156Accelerator Switch Inspection and Adjustment................156

Service Specifications........................................................

155

TROUBLESHOOTING............................................................

155

Accelerator Cable and Accelerator Pedal........................155

FUEL SYSTEM....................................................3

DETONATION SENSOR........................................................154

FUEL FILTER............................................................................

153

FUEL LINE AND VAPOR LINE................................................151

FUEL PUMP AND FUEL GAUGE UNIT ASSEMBLYAND OVERFILL LIMITER (TWO-WAY VALVE)................149

FUEL TANK.................................................................................146

GENERAL INFORMATION

....................................................

3

MPI System Diagram............................................................3

INJECTOR................................................................................141

ON-VEHICLE INSPECTION OF MPI COMPONENTS........36

Active Exhaust Control Unit

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

(1)A Supplemental Restraint System (SRS), which uses a driver-side air bag, has been installed in the 3000GT.(2)The SRS includes the following components: impact sensors, SRS diagnosis unit: SRS warning light, air bagmodule, clock spring, interconnecting wiring. Other SRS-related components (that may have to be

removed/installed in connection with SRS service or maintenance) are indicated in the table of contents byan asterisk (*).

WARNING!(I)Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inadvertent firing of the air bag) or to the driver (from

rendering the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at anauthorized MITSUBISHI dealer.

(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP

528 -Supplemental Restraint System (SRS), before beginning any service or maintenance of any component of theSRS or any SRS-related component.

Page 267 of 1146

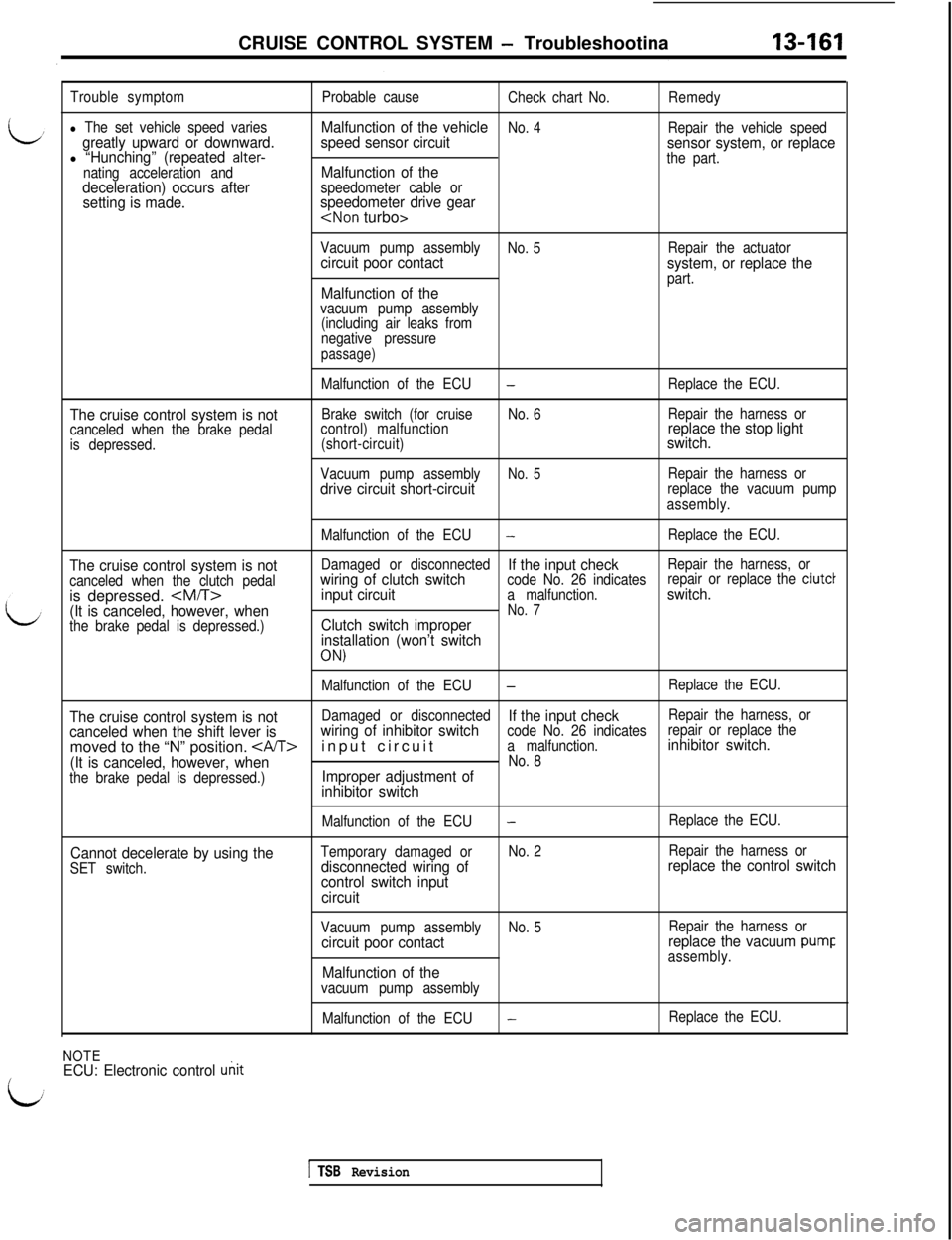

CRUISE CONTROL SYSTEM - Troubleshootina13461

Trouble symptom

l The set vehicle speed variesgreatly upward or downward.l “Hunching” (repeated alter-

nating acceleration and

deceleration) occurs after

setting is made.

Probable cause

Check chart No.Remedy

Malfunction of the vehicleNo. 4Repair the vehicle speedspeed sensor circuit

sensor system, or replacethe part.Malfunction of thespeedometer cable orspeedometer drive gear

Vacuum pump assembly

No. 5Repair the actuatorcircuit poor contact

system, or replace thepart.Malfunction of thevacuum pump assembly

(including air leaks from

negative pressure

passage)

The cruise control system is notcanceled when the brake pedal

is depressed.Malfunction of the ECU

-Replace the ECU.

Brake switch (for cruiseNo. 6Repair the harness or

control) malfunction

replace the stop light

(short-circuit)switch.

Vacuum pump assemblyNo. 5Repair the harness ordrive circuit short-circuitreplace the vacuum pump

assembly.

The cruise control system is notcanceled when the clutch pedalis depressed.

-Replace the ECU.

Damaged or disconnected

If the input checkRepair the harness, orwiring of clutch switchcode No. 26 indicatesrepair or replace the clutch

input circuita malfunction.switch.No. 7Clutch switch improper

installation (won’t switch

ON)

Malfunction of the ECU-Replace the ECU.

The cruise control system is notDamaged or disconnectedIf the input checkRepair the harness, or

canceled when the shift lever iswiring of inhibitor switchcode No. 26 indicatesrepair or replace themoved to the “N” position.

input circuita malfunction.inhibitor switch.

(It is canceled, however, when

No. 8

the brake pedal is depressed.)Improper adjustment of

inhibitor switch

Cannot decelerate by using the

SET switch.Malfunction of the ECU

Temporary damaged ordisconnected wiring of

control switch input

circuit

-

No. 2Replace the ECU.

Repair the harness orreplace the control switch

Vacuum pump assemblyNo. 5Repair the harness orcircuit poor contactreplace the vacuum puml:assembly.

Malfunction of thevacuum pump assembly

Malfunction of the ECU

-Replace the ECU.

NOTEECU: Electronic control unit

1 TSB Revision

Page 268 of 1146

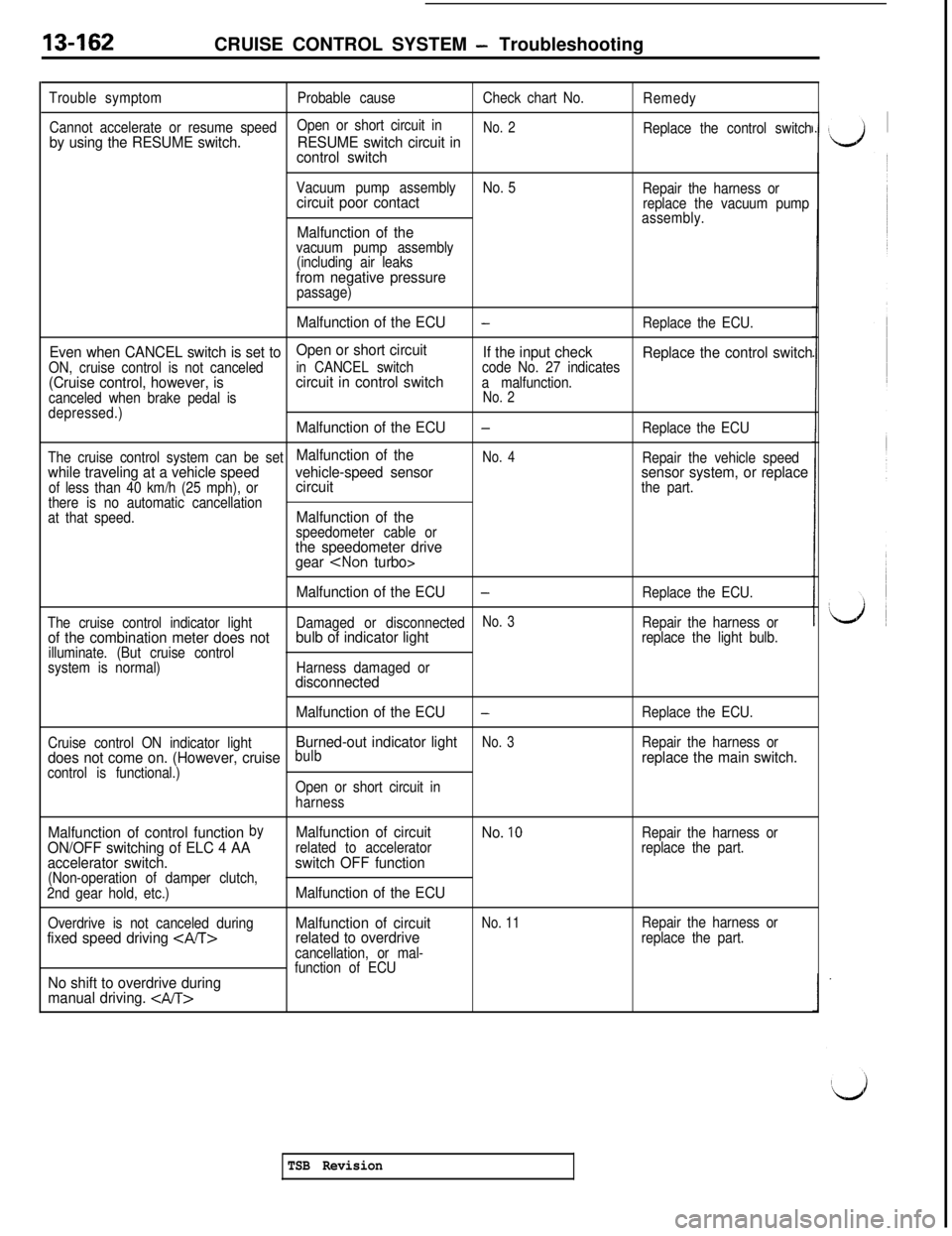

13-162CRUISE CONTROL SYSTEM - Troubleshooting

Trouble symptomProbable causeCheck chart No.

Remedy

Cannot accelerate or resume speedOpen or short circuit in

No. 2by using the RESUME switch.RESUME switch circuit inReplace the control switch

control switch

Vacuum pump assemblyNo. 5circuit poor contactRepair the harness or

replace the vacuum pump

Malfunction of thevacuum pump assembly

(including air leaks

from negative pressurepassage)assembly.

Malfunction of the ECU-Replace the ECU.

Even when CANCEL switch is set toON, cruise control is not canceled

Open or short circuit

in CANCEL switchIf the input check

Replace the control switch

(Cruise control, however, iscode No. 27 indicatescircuit in control switch

canceled when brake pedal isa malfunction.

depressed.)No. 2

Malfunction of the ECU-Replace the ECU

The cruise control system can be set

Malfunction of theNo. 4while traveling at a vehicle speedvehicle-speed sensorRepair the vehicle speed

of less than 40 km/h (25 mph), or

circuitsensor system, or replace

there is no automatic cancellationthe part.

at that speed.Malfunction of thespeedometer cable orthe speedometer drive

gear

Malfunction of the ECU

-Replace the ECU.

The cruise control indicator light

No. 3

of the combination meter does notDamaged or disconnectedbulb of indicator lightRepair the harness or

illuminate. (But cruise controlreplace the light bulb.

system is normal)Harness damaged or

disconnected

Malfunction of the ECU

-Replace the ECU.

Cruise control ON indicator light

No. 3

does not come on. (However, cruiseBurned-out indicator lightbulbRepair the harness or

control is functional.)replace the main switch.

Open or short circuit in

harness

Malfunction of control functionby

ON/OFF switching of ELC 4 AA

accelerator switch.

(Non-operation of damper clutch,

2nd gear hold, etc.)

Overdrive is not canceled during

fixed speed driving

No shift to overdrive during

manual driving.

Malfunction of circuitrelated to acceleratorswitch OFF function

Malfunction of the ECU

Malfunction of circuit

related to overdrive

cancellation, or mal-

function of ECU

No. IO

No. 11Repair the harness or

replace the part.

Repair the harness or

replace the part.

TSB Revision

Page 281 of 1146

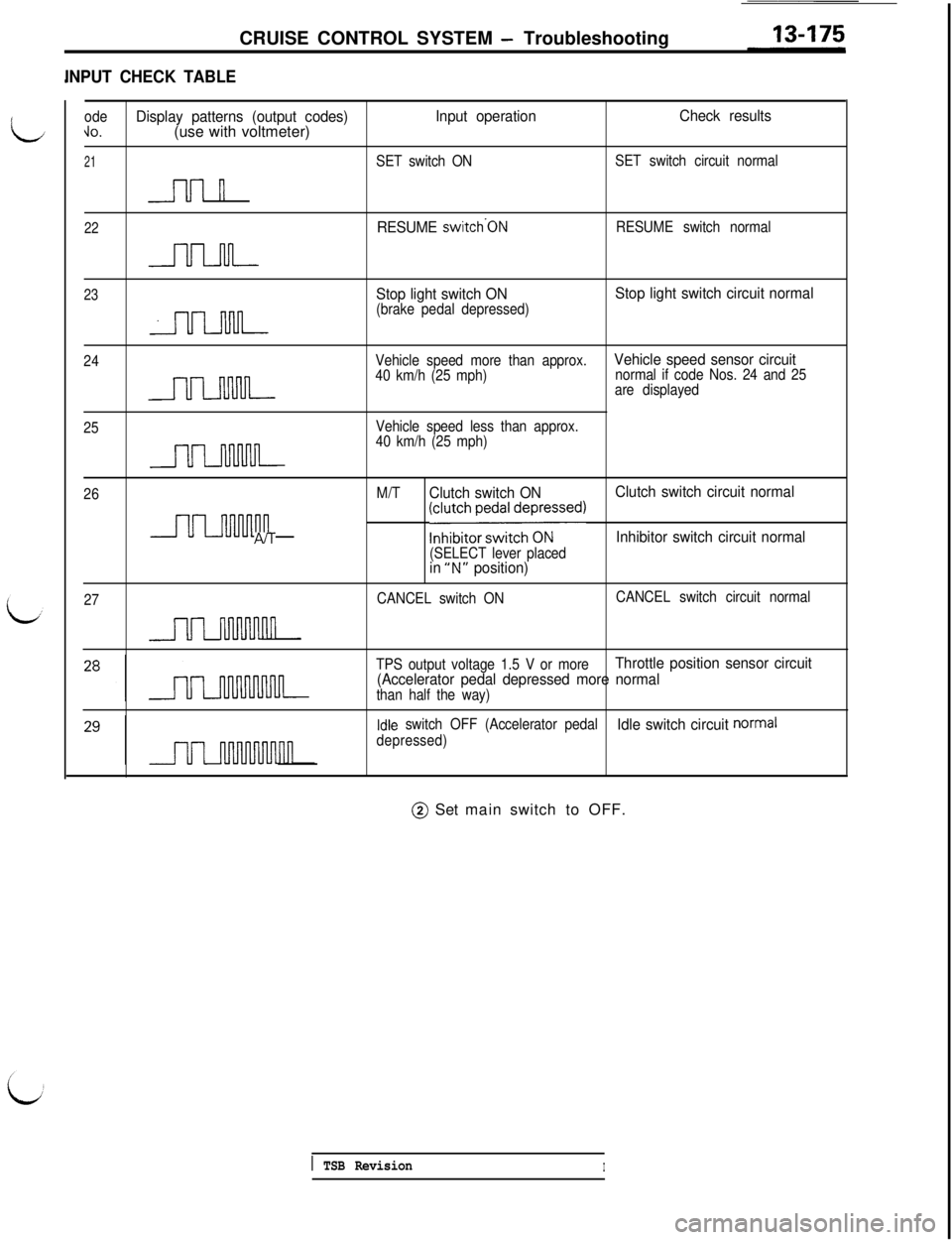

CRUISE CONTROL SYSTEM - Troubleshooting

INPUT CHECK TABLE

odeDisplay patterns (output codes)Input operationCheck results40.(use with voltmeter)

21SET switch ONSET switch circuit normal

n

22RESUME switch.ONRESUME switch normal

23

nn

Stop light switch ON(brake pedal depressed)

Stop light switch circuit normal

24Vehicle speed more than approx.

40 km/h (25 mph)Vehicle speed sensor circuitnormal if code Nos. 24 and 25

are displayed

25Vehicle speed less than approx.

40 km/h (25 mph)

26M/T

Clutch switch ON

-1~ ~~;~~o~~i~~~~;sed’

(SELECT lever placedin “N” position)Clutch switch circuit normal

Inhibitor switch circuit normal

27CANCEL switch ONCANCEL switch circuit normal

TPS output voltage 1.5 V or more

Throttle position sensor circuit

(Accelerator pedal depressed more normal

than half the way)

Idle switch OFF (Accelerator pedalIdle switch circuit normal

depressed)@ Set main switch to OFF.

1 TSB RevisionI

Page 289 of 1146

CRUISE CONTROL SYSTEM - Service Adjustment Procedures13-183

onoo5J16LO285

141014;

TFA0359

16FO13LResistance

3--1Okl2

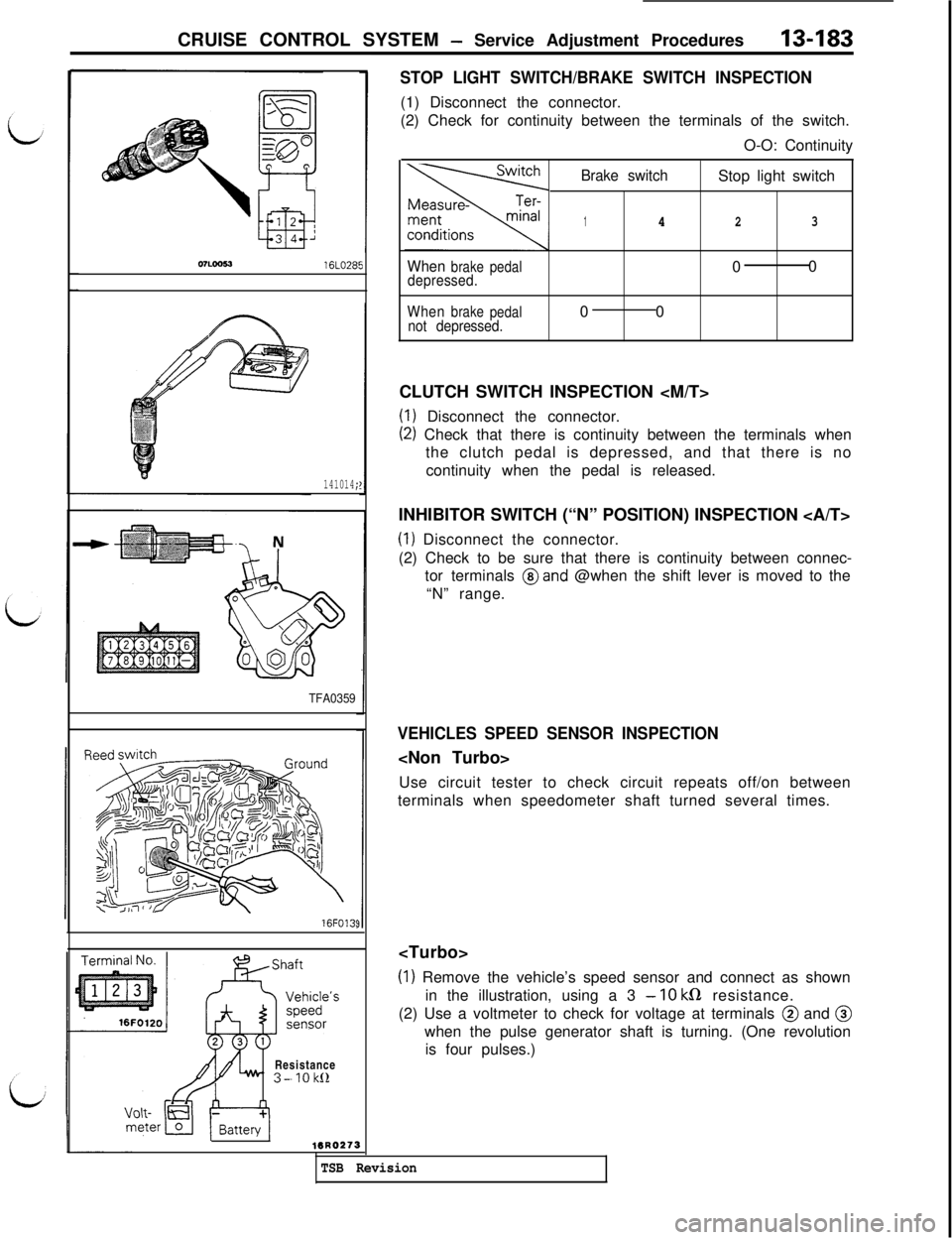

STOP LIGHT SWITCH/BRAKE SWITCH INSPECTION(1) Disconnect the connector.

(2) Check for continuity between the terminals of the switch.

O-O: Continuity

Brake switchStop light switch

1423

Whenbrakepedal00depressed.

When

brake

pedal00not depressed.CLUTCH SWITCH INSPECTION

(I) Disconnect the connector.

(2) Check that there is continuity between the terminals when

the clutch pedal is depressed, and that there is no

continuity when the pedal is released.

INHIBITOR SWITCH (“N” POSITION) INSPECTION

(1) Disconnect the connector.

(2) Check to be sure that there is continuity between connec-

tor terminals

@and @when the shift lever is moved to the

“N” range.

VEHICLES SPEED SENSOR INSPECTION

Use circuit tester to check circuit repeats off/on between

terminals when speedometer shaft turned several times.

(1) Remove the vehicle’s speed sensor and connect as shown

in the illustration, using a 3

- 10 kQ resistance.

(2) Use a voltmeter to check for voltage at terminals @ and @

when the pulse generator shaft is turning. (One revolution

is four pulses.)

16R0273

TSB Revision

Page 323 of 1146

INTAKE AND EXHAUST - Air Intake Plenum

AIR INTAKE PLENUM

/REMOVAL AND INSTALLATIQNMlWA-B

L/

i

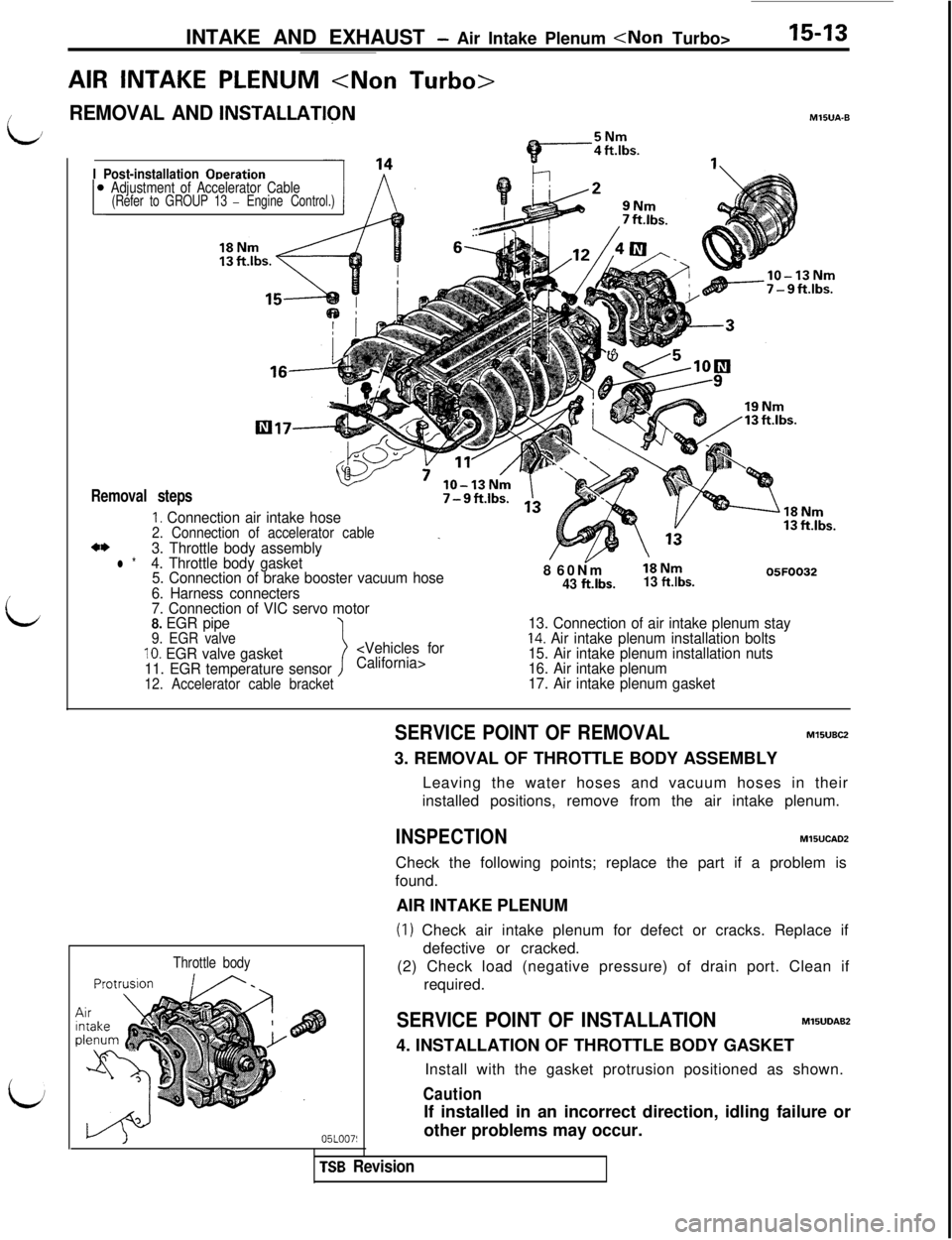

I Post-installation ODeration

Adjustment of Accelerator Cable

(Refer to GROUP 13 - Engine Control.)

Removal steps7-9ft.lbs.

I. Connection air intake hose2. Connection of accelerator cable_*I)3. Throttle body assemblyl *4. Throttle body gasket

5. Connection of brake booster vacuum hose

6. Harness connecters8 60Nm;6Nm05FOO32

43 ft.lbs.13 ft.lbs.

7. Connection of VIC servo motor

8. EGR pipe

9. EGR valve

11. EGR temperature sensor

12. Accelerator cable bracket

13. Connection of air intake plenum stay14. Air intake plenum installation bolts

15. Air intake plenum installation nuts

16. Air intake plenum

17. Air intake plenum gasket

Throttle body

SERVICE POINT OF REMOVALM15UBC23. REMOVAL OF THROTTLE BODY ASSEMBLY

Leaving the water hoses and vacuum hoses in their

installed positions, remove from the air intake plenum.

INSPECTIONM15UCAD2

Check the following points; replace the part if a problem is

found.

AIR INTAKE PLENUM

(1) Check air intake plenum for defect or cracks. Replace if

defective or cracked.

(2) Check load (negative pressure) of drain port. Clean if

required.

SERVICE POINT OF INSTALLATIONMl5UDAB2

4. INSTALLATION OF THROTTLE BODY GASKET

Install with the gasket protrusion positioned as shown.

CautionIf installed in an incorrect direction, idling failure or

other problems may occur.

TSB Revision