coolant level MITSUBISHI 3000GT 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 38 of 1146

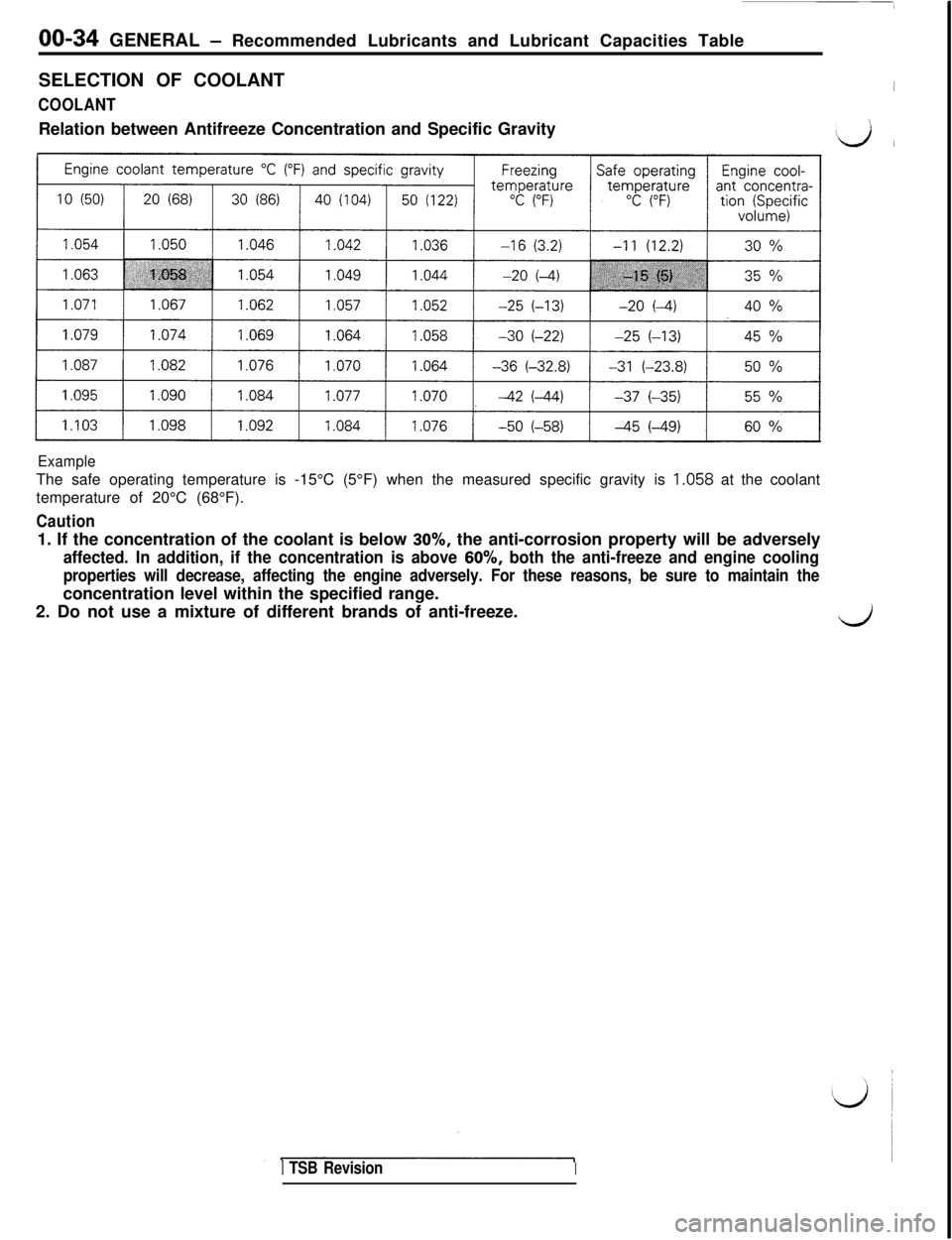

00-34 GENERAL - Recommended Lubricants and Lubricant Capacities Table

SELECTION OF COOLANT

COOLANTRelation between Antifreeze Concentration and Specific Gravity

I

\

‘d I

ExampleThe safe operating temperature is -15°C (5°F) when the measured specific gravity is 1.058 at the coolant

temperature of 20°C (68°F).

Caution1. If the concentration of the coolant is below 30%, the anti-corrosion property will be adversely

affected. In addition, if the concentration is above 60%, both the anti-freeze and engine cooling

properties will decrease, affecting the engine adversely. For these reasons, be sure to maintain theconcentration level within the specified range.

2. Do not use a mixture of different brands of anti-freeze.

-/‘.

1 TSB RevisionI

Page 42 of 1146

00-38GENERAL - Maintenance Service

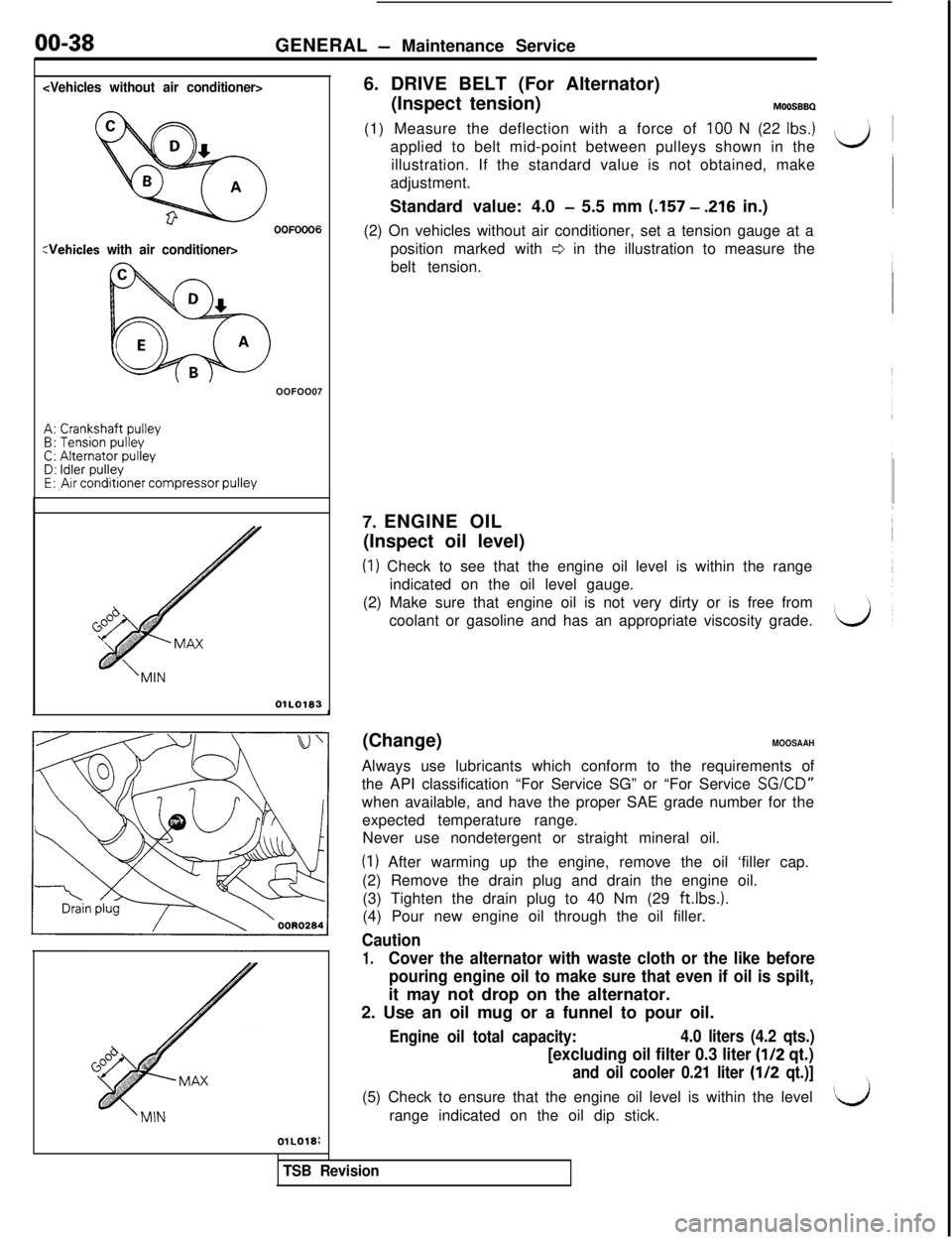

00F0006

:Vehicles with air conditioner>OOFOO07

A: Crankshaft pulleyB: Tension pulleyC: Alternator pulleyD: Idler pulleyE: ,Air conditioner compressor pulley

OlLO183

OlLO18:(Inspect tension)

MOOS88(1(1) Measure the deflection with a force of

100 N (22 Ibs.)applied to belt mid-point between pulleys shown in the

illustration. If the standard value is not obtained, make

adjustment.

Standard value: 4.0

- 5.5 mm (.157 - 216 in.)

(2) On vehicles without air conditioner, set a tension gauge at a

position marked with

r3 in the illustration to measure the

belt tension.

7. ENGINE OIL

(Inspect oil level)

(I) Check to see that the engine oil level is within the range

indicated on the oil level gauge.

(2) Make sure that engine oil is not very dirty or is free from

coolant or gasoline and has an appropriate viscosity grade.J

(Change)

MOOSAAHAlways use lubricants which conform to the requirements of

the API classification “For Service SG” or “For Service

SGKD”when available, and have the proper SAE grade number for the

expected temperature range.

Never use nondetergent or straight mineral oil.

(1) After warming up the engine, remove the oil ‘filler cap.

(2) Remove the drain plug and drain the engine oil.

(3) Tighten the drain plug to 40 Nm (29 ft.lbs.).

(4) Pour new engine oil through the oil filler.

Caution

1.Cover the alternator with waste cloth or the like before

pouring engine oil to make sure that even if oil is spilt,it may not drop on the alternator.

2. Use an oil mug or a funnel to pour oil.

Engine oil total capacity:4.0 liters (4.2 qts.)

[excluding oil filter 0.3 liter (l/2 qt.)

and oil cooler 0.21 liter (l/2 qt.)](5) Check to ensure that the engine oil level is within the level

range indicated on the oil dip stick.

TSB Revision

Page 45 of 1146

GENERAL - Maintenance Service00-41

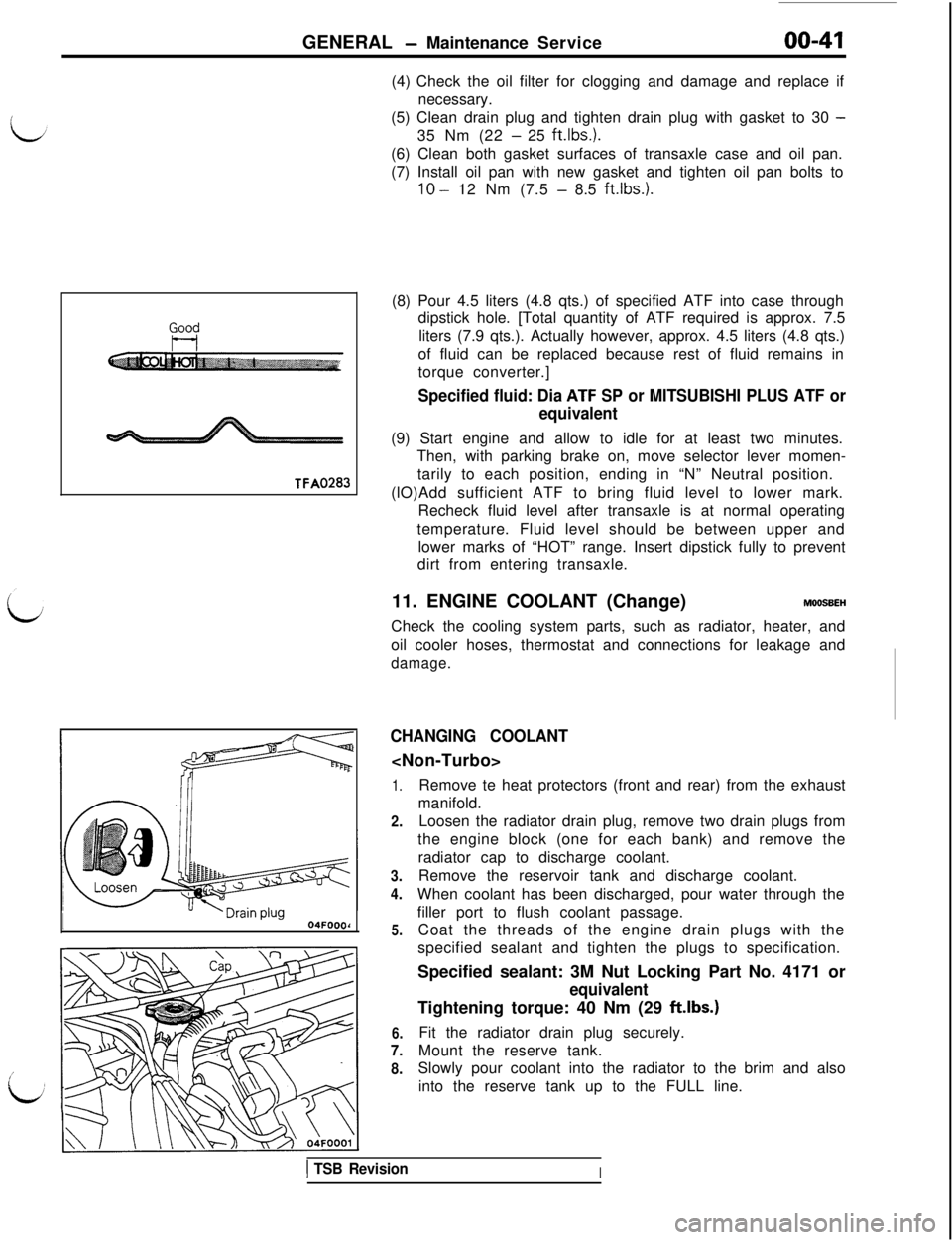

Good

t-lVA0283

I04FOOOd(4) Check the oil filter for clogging and damage and replace if

necessary.

(5) Clean drain plug and tighten drain plug with gasket to 30

-35 Nm (22

- 25 ft.lbs.).

(6) Clean both gasket surfaces of transaxle case and oil pan.

(7) Install oil pan with new gasket and tighten oil pan bolts to

10 - 12 Nm (7.5 - 8.5 ft.lbs.).

(8) Pour 4.5 liters (4.8 qts.) of specified ATF into case through

dipstick hole. [Total quantity of ATF required is approx. 7.5

liters (7.9 qts.). Actually however, approx. 4.5 liters (4.8 qts.)

of fluid can be replaced because rest of fluid remains in

torque converter.]

Specified fluid: Dia ATF SP or MITSUBISHI PLUS ATF or

equivalent(9) Start engine and allow to idle for at least two minutes.

Then, with parking brake on, move selector lever momen-

tarily to each position, ending in “N” Neutral position.

(lO)Add sufficient ATF to bring fluid level to lower mark.

Recheck fluid level after transaxle is at normal operating

temperature. Fluid level should be between upper and

lower marks of “HOT” range. Insert dipstick fully to prevent

dirt from entering transaxle.

11. ENGINE COOLANT (Change)

MOOSBEHCheck the cooling system parts, such as radiator, heater, and

oil cooler hoses, thermostat and connections for leakage and

damage.

CHANGING COOLANT

1.

2.

3.

4.

5.

6.

7.

8.Remove te heat protectors (front and rear) from the exhaust

manifold.

Loosen the radiator drain plug, remove two drain plugs from

the engine block (one for each bank) and remove the

radiator cap to discharge coolant.

Remove the reservoir tank and discharge coolant.

When coolant has been discharged, pour water through the

filler port to flush coolant passage.

Coat the threads of the engine drain plugs with the

specified sealant and tighten the plugs to specification.

Specified sealant: 3M Nut Locking Part No. 4171 or

equivalentTightening torque: 40 Nm (29

ftlbs.)Fit the radiator drain plug securely.

Mount the reserve tank.

Slowly pour coolant into the radiator to the brim and also

into the reserve tank up to the FULL line.

1 TSB RevisionI

Page 301 of 1146

COOLING - Service Adiustment Procedures.14-7

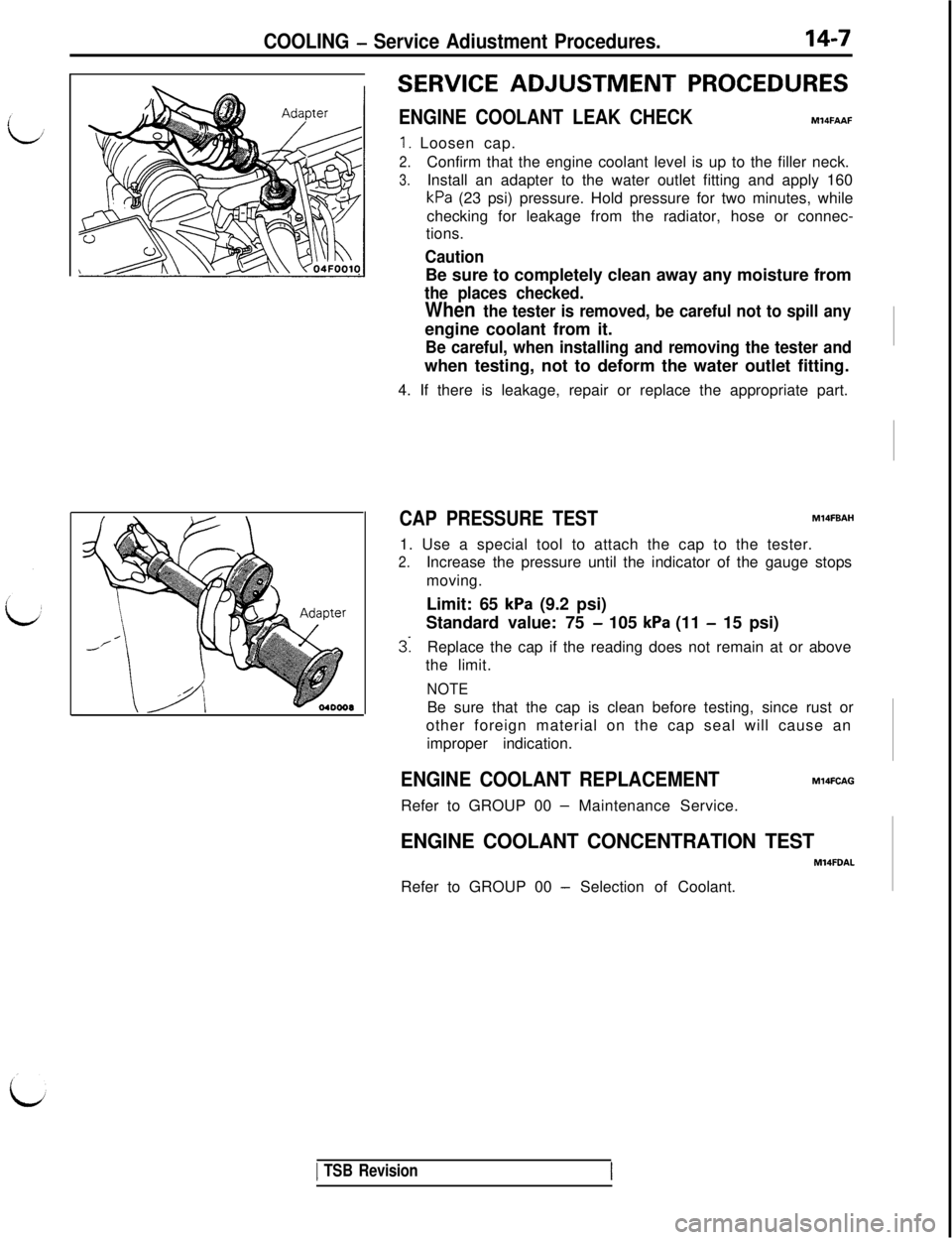

SERVICE ADJUSTMENT PROCEDURES

ENGINE COOLANT LEAK CHECKMl4FAAF

1. Loosen cap.

2.Confirm that the engine coolant level is up to the filler neck.

3.Install an adapter to the water outlet fitting and apply 160

kPa (23 psi) pressure. Hold pressure for two minutes, while

checking for leakage from the radiator, hose or connec-

tions.

CautionBe sure to completely clean away any moisture from

the places checked.

When the tester is removed, be careful not to spill anyengine coolant from it.

Be careful, when installing and removing the tester andwhen testing, not to deform the water outlet fitting.

4. If there is leakage, repair or replace the appropriate part.

CAP PRESSURE TESTM14FBAH1. Use a special tool to attach the cap to the tester.

2.Increase the pressure until the indicator of the gauge stops

moving.

Limit: 65

kPa (9.2 psi)

Standard value: 75

- 105 kPa (11 - 15 psi)

3:Replace the cap if the reading does not remain at or above

the limit.

NOTEBe sure that the cap is clean before testing, since rust or

other foreign material on the cap seal will cause an

improper indication.

ENGINE COOLANT REPLACEMENTM14FCAGRefer to GROUP 00

- Maintenance Service.

ENGINE COOLANT CONCENTRATION TEST

M14FDALRefer to GROUP 00

- Selection of Coolant.

1 TSB Revision

Page 495 of 1146

AUTOMATIC TRANSAXLE - Troubleshootinn23-43

CONVERTER STALL TESTStall test consist of determining maximum engine

speed obtained at full throttle in “D” and

“I?”positions. This test checks torque converter

statoroverrunning clutch operation, and holding ability of

transaxle clutches and low-reverse brake.

Caution

During this test, make sure that no one stand in

front of or behind vehicle.

1. Check transaxle fluid level. Fluid should be at

normal operating temperature

[70 - 80°C (160 -

18O”F)I. Engine coolant should also be at normal

operating temperature

[80 - 90°C (180 - 19O”F)l.2. Apply chocks to both rear wheels.

3. Attach engine tachometer.

4. Apply parking and service brakes fully.

5. Start engine.

6. With selector lever in “D” position, depress

accelerator pedal fully to read engine maximum

rpm. Do not hold throttle wide open any longer

than is necessary to obtain maximum engine

rpm reading, and never longer than 5 seconds at

a time. If more than one stall test is required,

operate engine at approximately 1,000 rpm in

neutral for 2 minutes to cool transaxle fluid

between tests.

Stall speed: 2,200

- 3,200 rpm

7.Place selector lever to “R” position and perform

stall test by the same procedure as in foregoing

item.

Stall Speed Above Specification in “D”

If stall speed is higher than specification, rear clutch

or overrunning clutch of transaxle is slipping. In this

case, perform hydraulic test to locate cause of

slippage.

Stall Speed Above Specification in “R”

If stall speed is higher than specification, front

clutch of transaxle or low-reverse brake is slipping.

In this case, perform hydraulic test to locate cause

of slippage.

Stall Speed Below Specification in “D” and “R”

If stall speed is lower than specification, insufficient

engine output or faulty torque converter is sus-

pected. Check for engine misfiring, ignition timing,

valve clearance, etc. If these are good, torque

converter is faulty.

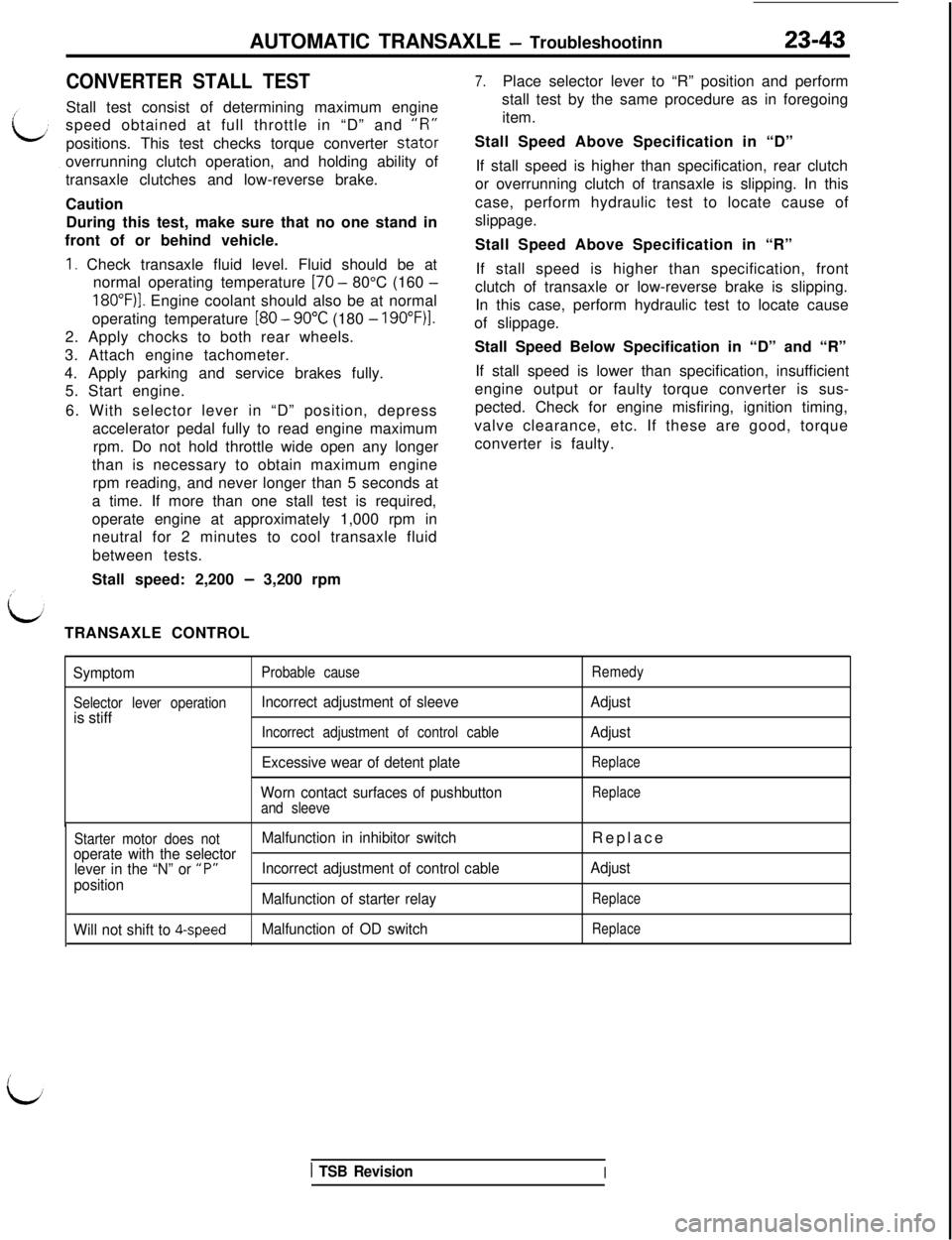

TRANSAXLE CONTROL

Symptom

Selector lever operationis stiff

Probable cause

Incorrect adjustment of sleeve

Remedy

Adjust

Incorrect adjustment of control cable

Excessive wear of detent plate

Worn contact surfaces of pushbutton

and sleeve

Adjust

Replace

Replace

Starter motor does notMalfunction in inhibitor switchReplace

operate with the selector

lever in the “N” or “P”Incorrect adjustment of control cableAdjust

position

Will not shift to

4-speed

Malfunction of starter relay

Malfunction of OD switchReplace

Replace

1 TSB RevisionI