fuel pump MITSUBISHI 3000GT 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 67 of 1146

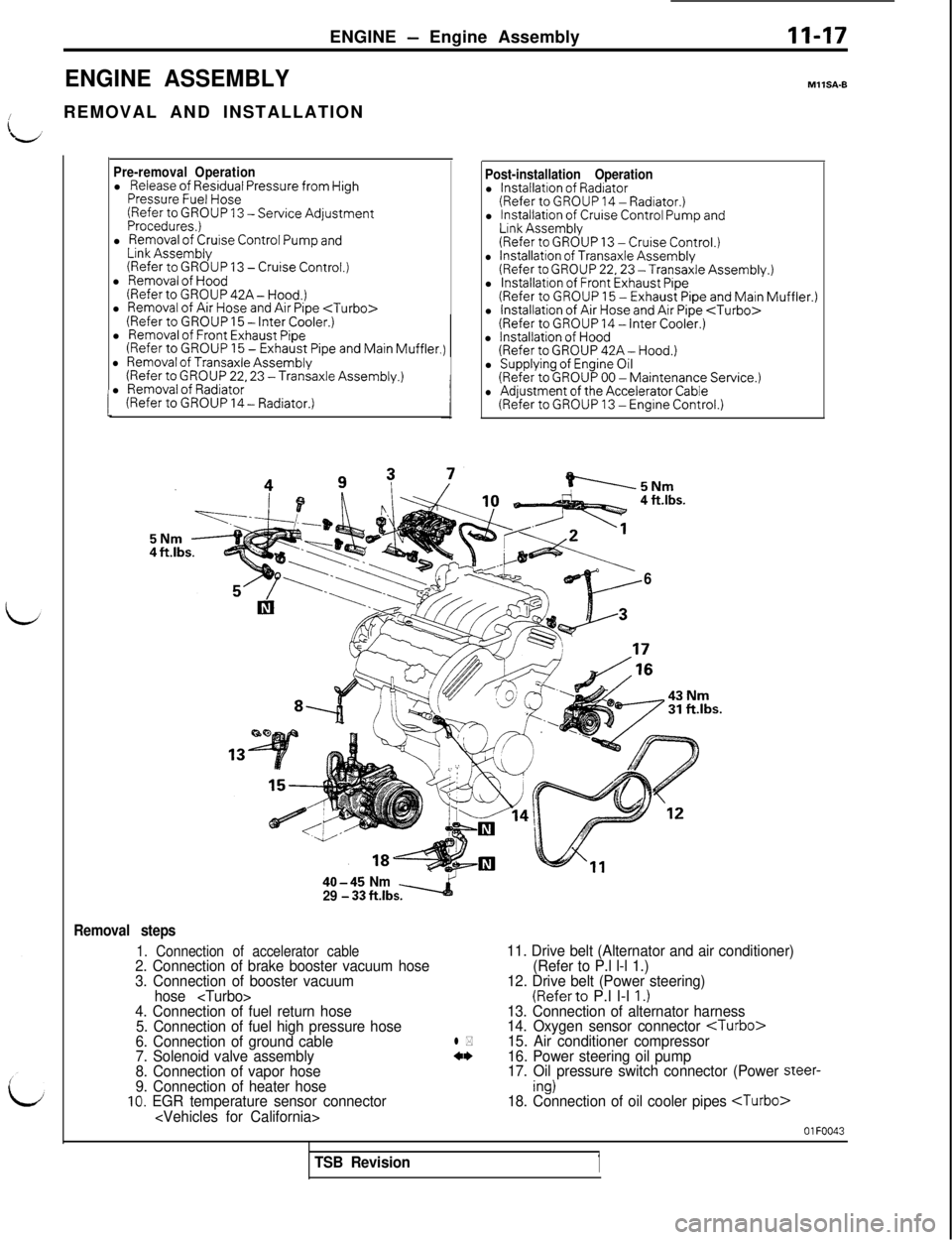

ENGINE - Engine AssemblyII-17

ENGINE ASSEMBLY

/REMOVAL AND INSTALLATION

I

Pre-removal Operationl Release of Residual Pressure from HighPressure Fuel Hose(Refer to GROUP 13 -Service AdjustmentProcedures,)l Removal of Cruise Control Pump andLink Assembly(Refer to GROUP 13 - Cruise Control.)l Removal of Hood(RefertoGROUP42A-Hood.)

l

Removal of Air Hose and Air Pipe

Post-installation Operationl Installation of Radiator(Refer to GROUP 14 - Radiator.)l Installation of Cruise Control Pump andLink Assembly(Refer to GROUP 13 -Cruise Control.)l Installation of Transaxle Assembly(Refer to GROUP 22,23 -Transaxle Assembly.)l lnstallatron of Front Exhaust Pipe(Refer to GROUP 15 - Exhaust Pipe and Main Muffler.)l Installation of Air Hose and Air Pipe

MllSA-B

4 ft.lbs.

6

40-45 Nm

29 - 33 fklbs.

Removal steps

1. Connection of accelerator cable11. Drive belt (Alternator and air conditioner)

2. Connection of brake booster vacuum hose(Refer to P.l l-l 1.)

3. Connection of booster vacuum12. Drive belt (Power steering)

hose

(Referto P.l l-l I.)4. Connection of fuel return hose13. Connection of alternator harness

5. Connection of fuel high pressure hose14. Oxygen sensor connector

6. Connection of ground cablel *15. Air conditioner compressor

7. Solenoid valve assembly4w

16. Power steering oil pump

8. Connection of vapor hose17. Oil pressure switch connector (Power steer-9. Connection of heater hoseing)10. EGR temperature sensor connector18. Connection of oil cooler pipes

OlFOO43

TSB Revision1

Page 107 of 1146

FUEL

SYSTEM

CONTENTSM13AA- _

CRUISE CONTROL SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . .158SPECIFICATIONS. . . . . . . .._._....................................................155

CRUISE CONTROL SYSTEM*................................................185

SERVICE ADJUSTMENT PROCEDURES............................178

Cruise Control Cables Inspection and Adjustment........178Cruise Control SystemInspection....................................179individual Parts Inspection....................................................181

SPECIAL TOOLS........................................................................159

SPECIFICATIONS....................................................................158

General Specifications........................................................158Service Specifications........................................................158

TROUBLESHOOTING............................................................159

Check Chart............................................................................163Harness and Components Layout....................................176Preliminary Inspection........................................................159Self-diagnosis Checking........................................................172Troubleshooting Quick Reference Chart............................159

ENGINE CONTROL............................................155

ENGINE CONTROL................................................................157

SERVICE ADJUSTMENT PROCEDURES............................156

Accelerator Cable Inspection and Adjustment................156Accelerator Switch Inspection and Adjustment................156

Service Specifications........................................................

155

TROUBLESHOOTING............................................................

155

Accelerator Cable and Accelerator Pedal........................155

FUEL SYSTEM....................................................3

DETONATION SENSOR........................................................154

FUEL FILTER............................................................................

153

FUEL LINE AND VAPOR LINE................................................151

FUEL PUMP AND FUEL GAUGE UNIT ASSEMBLYAND OVERFILL LIMITER (TWO-WAY VALVE)................149

FUEL TANK.................................................................................146

GENERAL INFORMATION

....................................................

3

MPI System Diagram............................................................3

INJECTOR................................................................................141

ON-VEHICLE INSPECTION OF MPI COMPONENTS........36

Active Exhaust Control Unit

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

(1)A Supplemental Restraint System (SRS), which uses a driver-side air bag, has been installed in the 3000GT.(2)The SRS includes the following components: impact sensors, SRS diagnosis unit: SRS warning light, air bagmodule, clock spring, interconnecting wiring. Other SRS-related components (that may have to be

removed/installed in connection with SRS service or maintenance) are indicated in the table of contents byan asterisk (*).

WARNING!(I)Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inadvertent firing of the air bag) or to the driver (from

rendering the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at anauthorized MITSUBISHI dealer.

(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP

528 -Supplemental Restraint System (SRS), before beginning any service or maintenance of any component of theSRS or any SRS-related component.

Page 108 of 1146

13-2

Boost Meter

Components Location........................................................36

Crank Angle Sensor

............................................................72Detonation Sensor................................................................84EGR Control Solenoid Valve

EGR Temperature Sensor

Fuel Pump Operation Check................................................137Fuel Pump Relay No. 2........................................................53Fuel Pump Resistor............................................................53

Idle Position Switch............................................................68Idle Speed Control Servo (Stepper Motor Type)............1 IOIgnition Coil and Power Transistor....................................115Ignition Switch-ST and Inhibitor Switch ................76Ignition Switch-ST

Injectors

94

Oxygen Sensor

Power Steering Oil Pressure Switch................................80Power Supply and Ignition Switch-IG................................41

Purge Control Solenord Valve............................................1 19Release of Residual Pressure from High

Pressure Fuel Hose............................................................137Throttle Position Sensor....................................................65Top Dead Center Sensor....................................................70Variable Induction Control Servo (DC Motor)

SERVICE ADJUSTMENT PROCEDURES............................31

Adjustment of Fixed SAS....................................................35Adjustment of Idle Position Switch and

Throttle Position Sensor (TPS)............................................33Basic Idle Speed Adjustment............................................31Throttle Body (Throttle Valve Area) Cleaning....................33

SPECIAL TOOLS........................................................................8

SPECIFICATIONS

....................................................................6

General Specifications........................................................6Sealant....................................................................................7Service Specifications........................................................7

THROlTLE BODY....................................................................143

TROUBLESHOOTING............................................................9

Check Chart Classified by Problem Symptoms................16Circuit Diagram....................................................................18Engine Warning Light (Malfunction Indicator Light)........11Explanation and Cautions about Harness Check............10Explanation of Troubleshooting Procedures....................9Fuel Tank and Fuel Line........................................................30

Problem Symptoms Table (For Your Information)............17Self-diagnosis........................................................................12)

I

Page 125 of 1146

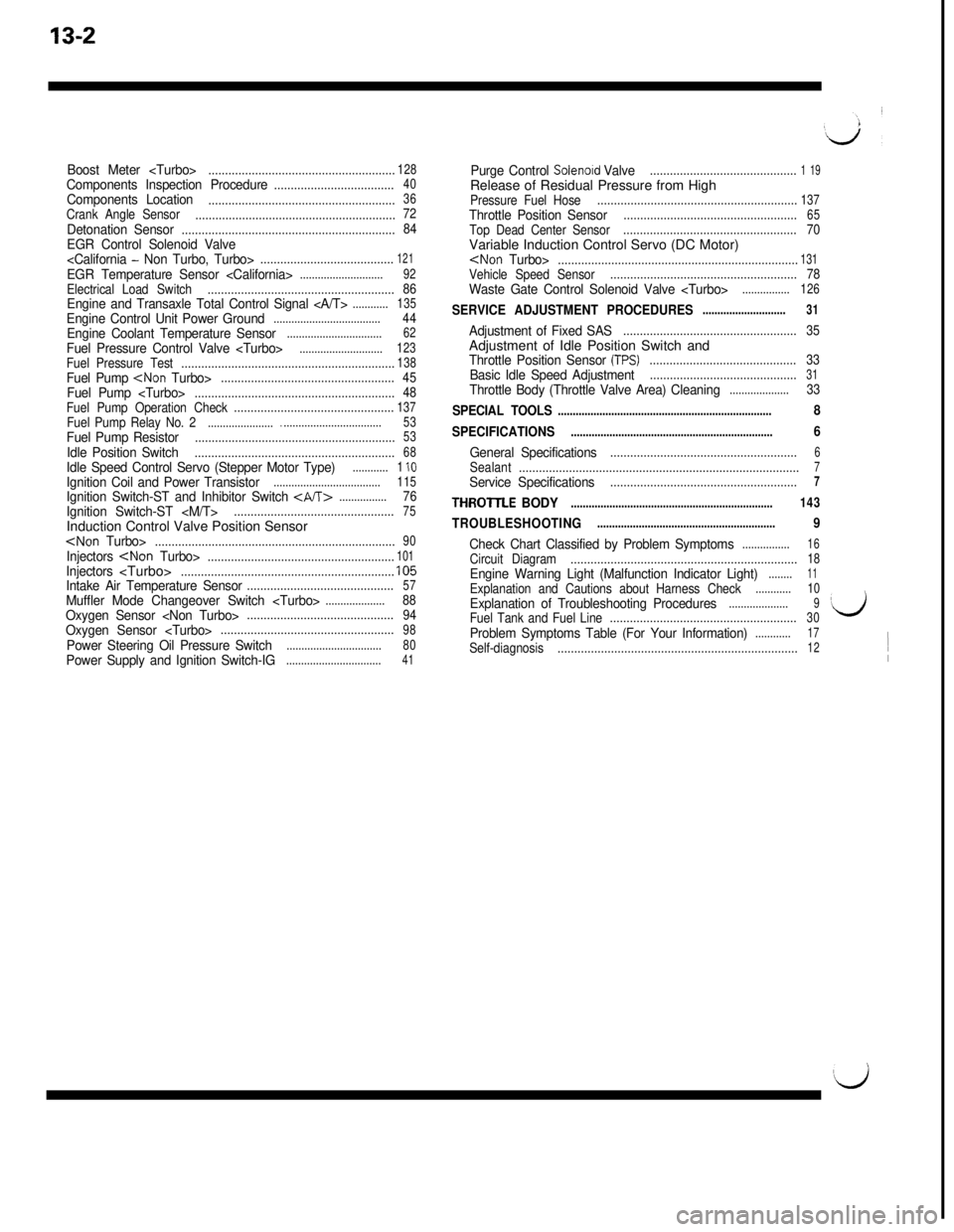

FUEL SYSTEM - Troubleshooting

IGNITISWITCf

3

%:\77@

015AAL\I3: II

:;a1

C;

I\g3

IuI

/\7iD-04

D-03

,.c

ALI

J

IY

197G1,

L1231

a36676

7 C-62

J/B

6 C-71

-14

c-30

123

IElI456

r

!YI

R

r---

JI

FEcuG

[4z

.G

L.---E;w

9 c-34p/iaazj

6

*1

I

FUELj PUMPF-16

2

5F-14

I2m3456

6 D-44

pYilasq

A-17 [Alhzb

L%KPWCONNECTOR

59-

)COMBINATION

METER

n1121314t51617181 8 (10~11~12~13~1~1~16~17L

:NSOR

ITCH)3;

s c-14

-13

>t

106&Ij6

1

ENGINE

CONTROL

UNIT

PTSB Revision

Page 131 of 1146

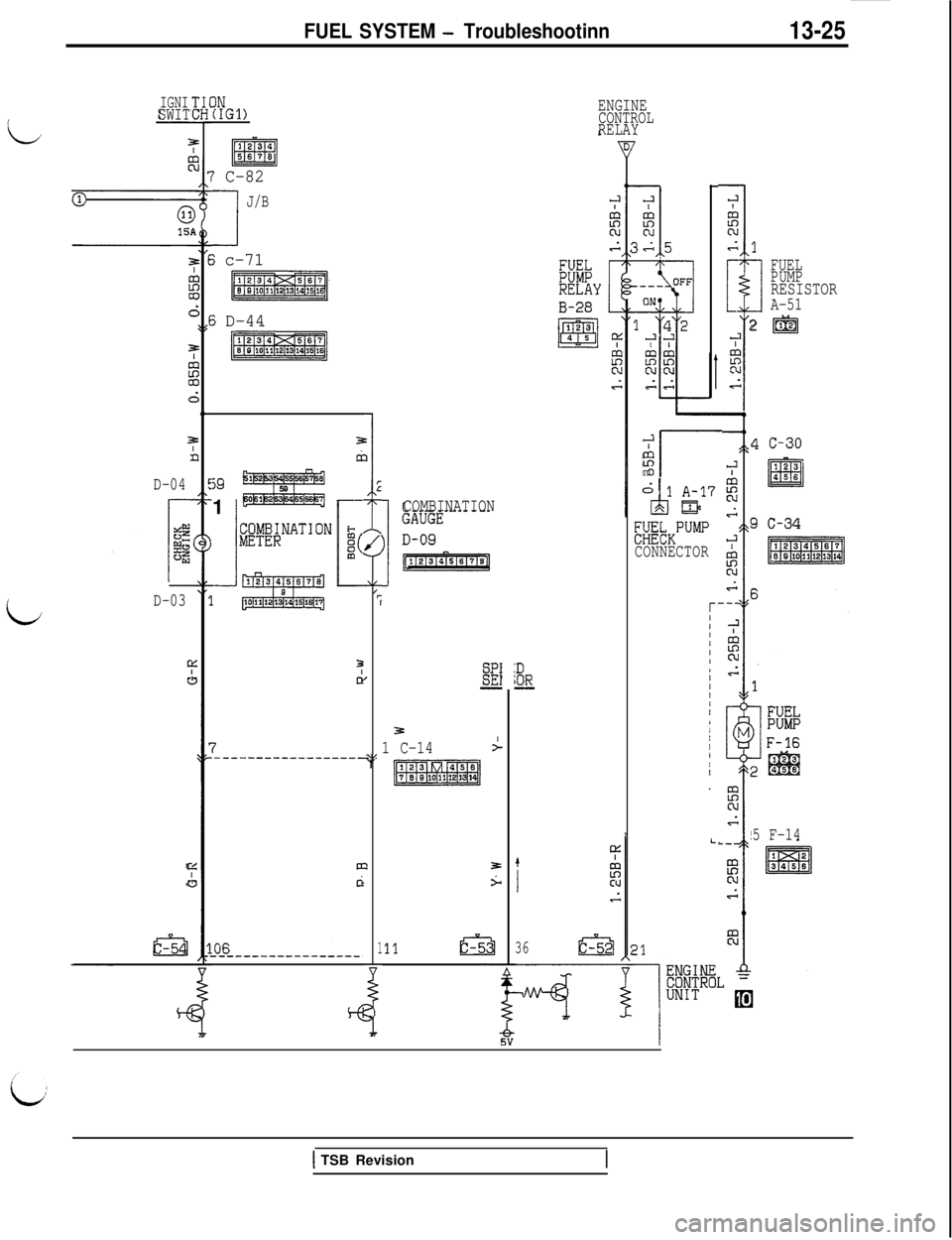

FUEL SYSTEM - Troubleshootinn13-25

ENGINE

CONTROL

RELAYIGNISWITIN(IGl)

1234

liEI5676

7 C-82

I

J/B

: c-71

-1

5 D-44

i

4

E

A 1

:

2-2k

Ns

I

FUEL

PUMP

RESISTORA-51

@%J

E1

i

;

J

A.LIi

,

\I

I

1-

f

J

!I2rm

c-303

n

D-04591

COMBINATION

EEKPUMPCONNECTOR

L

D-03

c

c

3

dWI:DSE!;OR--

1 C-14>

3[ml

3

j.

36

5 F-14L.

c

c

II

d

ti

1 TSB Revision

Page 151 of 1146

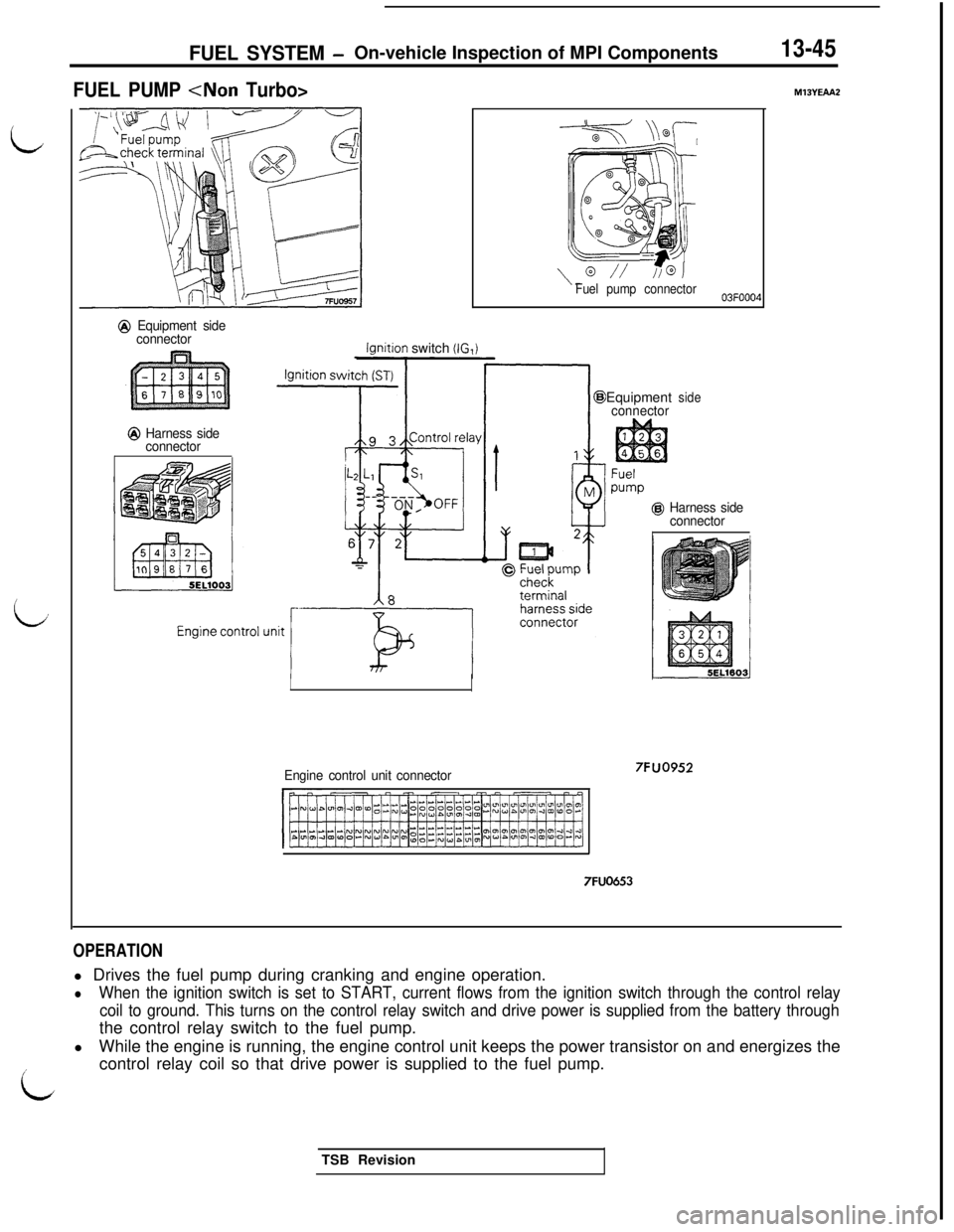

FUEL SYSTEM -On-vehicle Inspection of MPI Components13-45

FUEL PUMP

@ Equipment side

connector

@ Harness side

connector

lqnition switch (IG,i

LL--- /A&

\“// //@JFuel pump connector

Engine control unit connectorEquipment

connectorside

@ Harness side

connector

7FUO653

7FUO952

M13YEAA2

OPERATIONl Drives the fuel pump during cranking and engine operation.

lWhen the ignition switch is set to START, current flows from the ignition switch through the control relay

coil to ground. This turns on the control relay switch and drive power is supplied from the battery throughthe control relay switch to the fuel pump.

lWhile the engine is running, the engine control unit keeps the power transistor on and energizes the

icontrol relay coil so that drive power is supplied to the fuel pump.

LTSB Revision

Page 152 of 1146

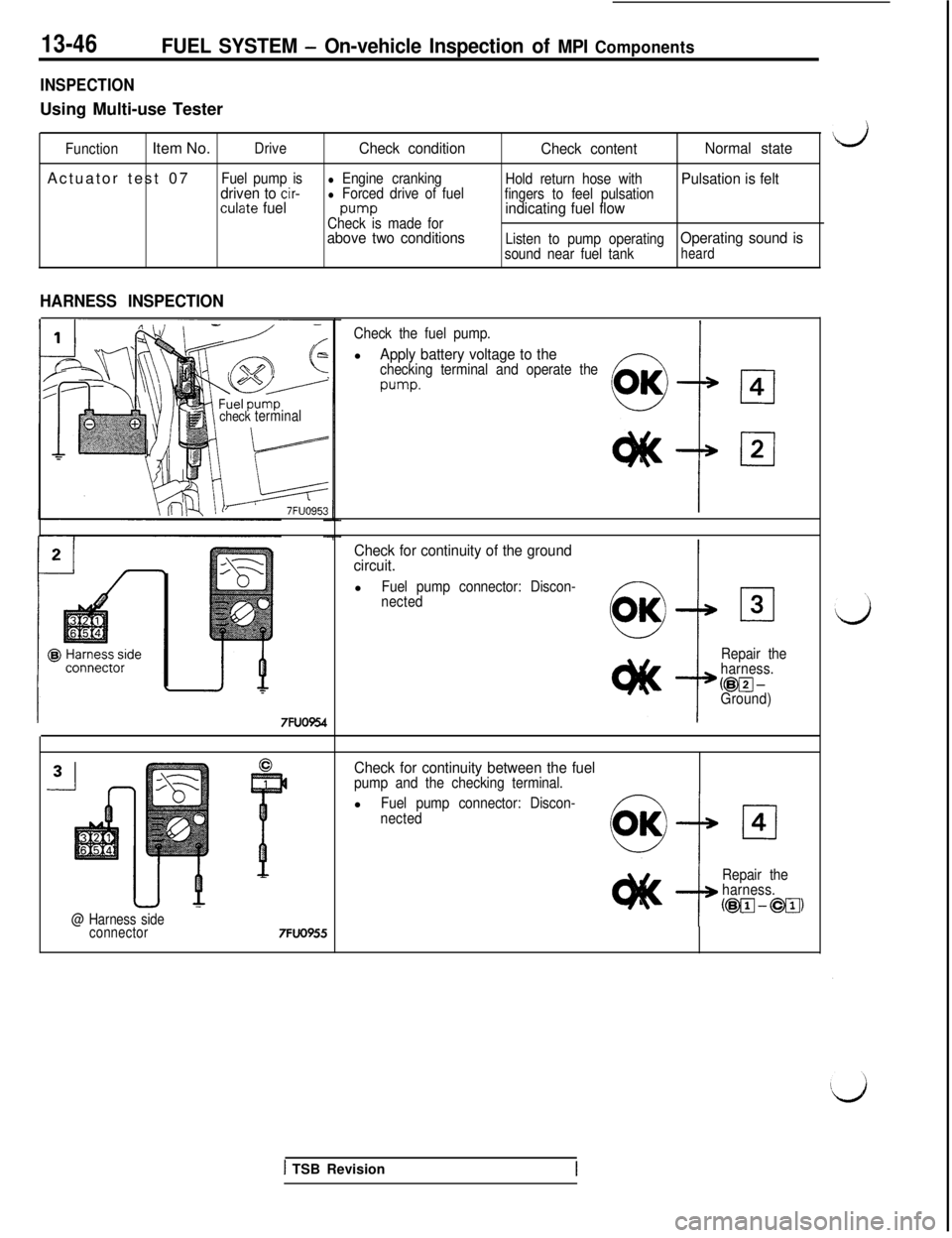

13-46FUEL SYSTEM - On-vehicle Inspection of MPI Components

INSPECTIONUsing Multi-use Tester

FunctionItem No.DriveCheck condition

Check contentNormal statedActuator test 07

Fuel pump isl Engine cranking

Hold return hose withPulsation is felt

driven to cir-l Forced drive of fuelculate fuelfingers to feel pulsation

pump

Check is made forindicating fuel flow

above two conditions

Listen to pump operating

sound near fuel tankOperating sound isheard

HARNESS INSPECTION

check terminal

7FUO954

@ Harness side

connector7FUO955

Check the fuel pump.l

Apply battery voltage to thechecking terminal and operate the

w-w

Check for continuity of the ground

circuit.l

Fuel pump connector: Discon-

nected

Repair the

harness.

@FJ-Ground)

Check for continuity between the fuelpump and the checking terminal.l

Fuel pump connector: Discon-

nectedcl4

Repair the

harness.

@vJ-@g)

1 TSB Revision

Page 153 of 1146

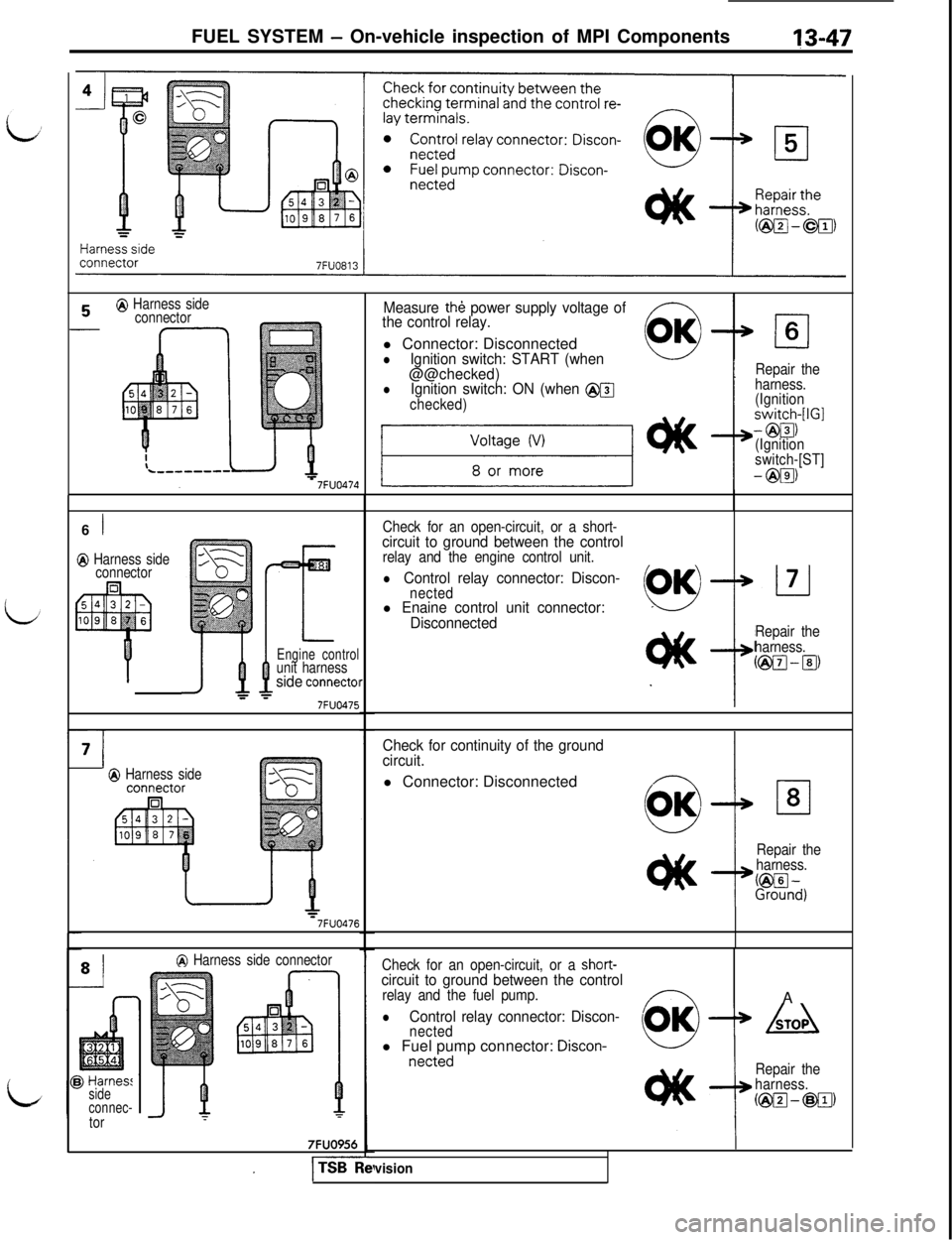

FUEL SYSTEM - On-vehicle inspection of MPI Components

@ Harness side

connector6

1

@ Harness side

connector

77FUO475

-

Engine controlunit harnessside connector

Q Harness side

-1

=7FUO476

9 Harnessside

connec-

tor

@ Harness side connector

7FUO956

Measure th& power supply voltage of

the control relay.l Connector: Disconnected

OK

lIgnition switch: START (when0

@@checked)lIgnition switch: ON (when @@

checked)

cl6

t

Repair the

harness.

(Ignition

switch-[IGI

- @El)

(Ignition

switch-[ST]

- @El)

Check for an open-circuit, or a short-

circuit to ground between the controlrelay and the engine control unit.

lControl relay connector: Discon-nectedl Enaine control unit connector:

Disconnected

Repair the

harness.

@El-lg

Check for continuity of the ground

circuit.l Connector: Disconnected

Repair the

harness.

L%n~)

Check for an open-circuit, or a short-circuit to ground between the controlrelay and the fuel pump.A

lControl relay connector: Discon-nected(OK)+ Adl Fuel pump connector:

Discon-netted

Repair the

harness.

@I@-@g)

I

vision

Page 154 of 1146

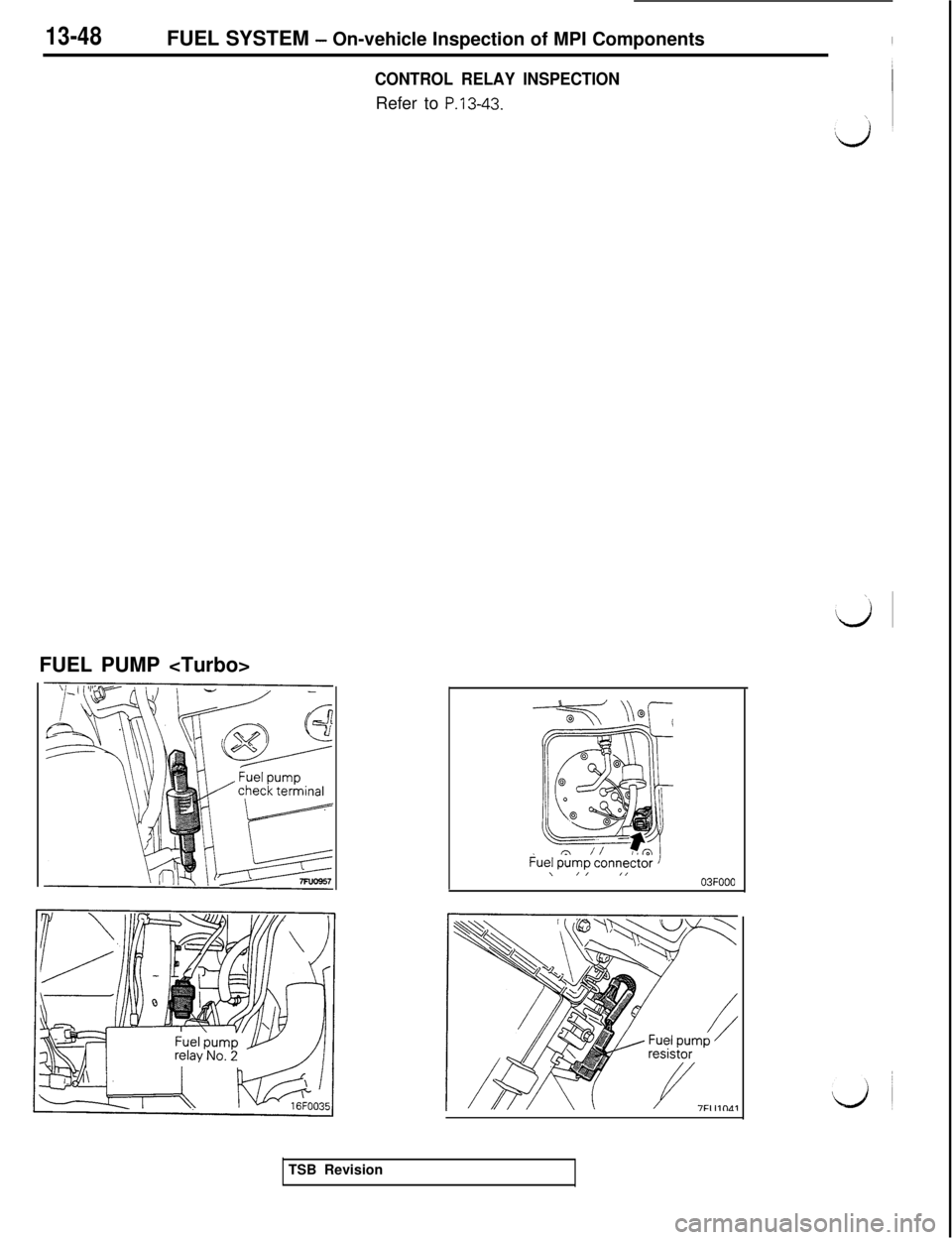

13-48FUEL SYSTEM - On-vehicle Inspection of MPI Components

CONTROL RELAY INSPECTIONRefer to

P.13-43.FUEL PUMP

\/I ,,03FOOO

TSB Revision

Page 155 of 1146

![MITSUBISHI 3000GT 1991 Service Manual FUEL SYSTEM - On-vehicle Inspection of MPI Components

13-49 i

Ignition switch [IG]

Ignition switch [ST]

@ Equipment side

connector9 3Control reta)

;i.

L Ll

@ Harness side

connector

Enaine control unit MITSUBISHI 3000GT 1991 Service Manual FUEL SYSTEM - On-vehicle Inspection of MPI Components

13-49 i

Ignition switch [IG]

Ignition switch [ST]

@ Equipment side

connector9 3Control reta)

;i.

L Ll

@ Harness side

connector

Enaine control unit](/img/19/57085/w960_57085-154.png)

FUEL SYSTEM - On-vehicle Inspection of MPI Components

13-49 i

Ignition switch [IG]

Ignition switch [ST]

@ Equipment side

connector9 3Control reta)

;i.

L Ll

@ Harness side

connector

Enaine control unitEquipment side

connector

M-ii

Resistorw(for fuel pump)

Equipment side

connector

II &A

8 A21

@ Equipment

side@I Harness side

connector

connector

M

‘r

Y

2

7

Y

Fuelpump

-JFuel pumpcheck terminal

7FUO959Engine control unit connector

7FUO653

idTSB Revision