key MITSUBISHI 3000GT 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 20 of 1146

00-16GENERAL - Towina and Hoistina

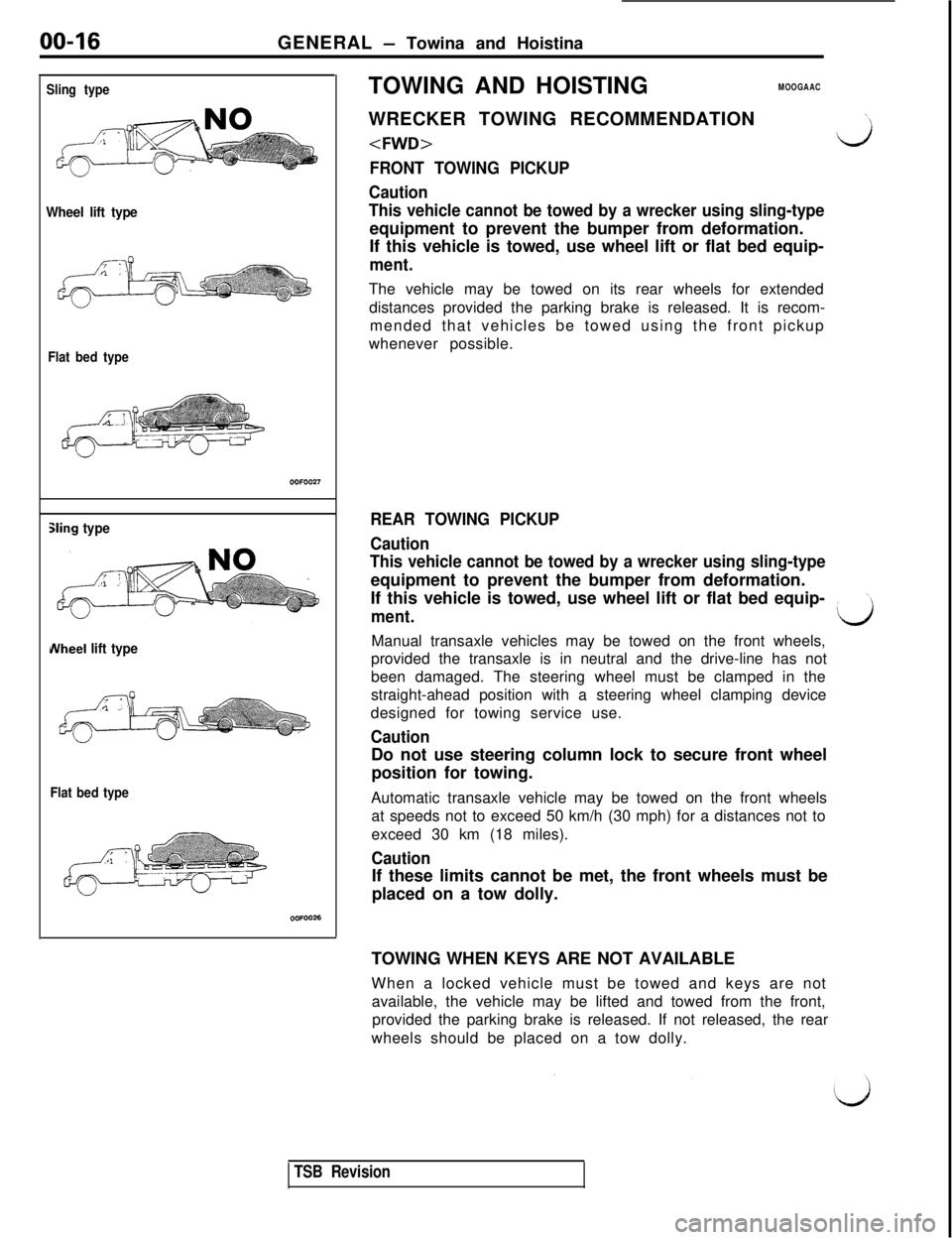

Sling type

Wheel lift type

Flat bed type

Sling type

Wheel lift type

Flat bed typeTOWING AND HOISTING

MOOGAACWRECKER TOWING RECOMMENDATION

FRONT TOWING PICKUP

Caution

\‘i

d

This vehicle cannot be towed by a wrecker using sling-typeequipment to prevent the bumper from deformation.

If this vehicle is towed, use wheel lift or flat bed equip-

ment.The vehicle may be towed on its rear wheels for extended

distances provided the parking brake is released. It is recom-

mended that vehicles be towed using the front pickup

whenever possible.

REAR TOWING PICKUP

Caution

This vehicle cannot be towed by a wrecker using sling-typeequipment to prevent the bumper from deformation.

If this vehicle is towed, use wheel lift or flat bed equip-

\

ment.‘L*3Manual transaxle vehicles may be towed on the front wheels,

provided the transaxle is in neutral and the drive-line has not

been damaged. The steering wheel must be clamped in the

straight-ahead position with a steering wheel clamping device

designed for towing service use.

CautionDo not use steering column lock to secure front wheel

position for towing.

Automatic transaxle vehicle may be towed on the front wheels

at speeds not to exceed 50 km/h (30 mph) for a distances not to

exceed 30 km (18 miles).

CautionIf these limits cannot be met, the front wheels must be

placed on a tow dolly.

TOWING WHEN KEYS ARE NOT AVAILABLE

When a locked vehicle must be towed and keys are not

available, the vehicle may be lifted and towed from the front,

provided the parking brake is released. If not released, the rear

wheels should be placed on a tow dolly.

TSB Revision

Page 118 of 1146

13-12FUEL SYSTEM - Troubleshooting

MALFUNCTION INDICATOR LIGHT INSPECTION

(1) Check that when the ignition switch is turned on, the lightilluminates for about 5 seconds and then goes out.

(2) If the light does not illuminate, check for open circuit in

dharness, blown fuse and blown bulb.

SELF-DIAGNOSIS

The engine control unit monitors the input/output signals (some

signals at all times and the others under specified conditions) ofthe engine control unit.

When it is noticed that an irregularity has continued for a

specified time or longer from when the irregular signal is

initially monitored, passing a certain number, the engine controlunit judges that an irregularity has occurred, memorizes the

malfunction code, and outputs the signal to the self-diagnosis

output terminal.

There are 21 diagnosis items, including the normal state, andthe diagnosis results can be read out with a voltmeter or

multi-use tester.Moreover, since memorization of the malfunction codes is

backed up directly by the battery, the diagnosis results are

memorized even if the ignition key is turned off. The malfunc-

tion codes will, however, be erased when the battery terminalor the engine control unit connector is disconnected.

The malfunction code can also be erased by turning on the

ignition switch and sending the malfunction code erase signalfrom the multi-use tester to the engine control unit.

CautionIf the sensor connector is disconnected with the ignition

_ _switch turned on, the malfunction code is memorized. Ind

this case, send the malfunction code erase signal from themulti-use tester to the engine control unit or disconnect

the battery terminal

(-) for 10 seconds or more, and the

diagnosis memory will be erased.

The 21 diagnosis items are provided as follows, and if plural

items are activated, they are all indicated sequentially from the

smallest code number.

CautionThe malfunction code for the ignition timing adjustment

signal is output when the line of the ignition timing

adjustment terminal is shorted to ground. Therefore, the

malfunction code is also output when the ignition timing

adjustment terminal is grounded to adjust the ignition

timing, but this does not show any abnormality.

TSB Revision

Page 278 of 1146

13-172CRUISE CONTROL SYSTEM - Troubleshooting

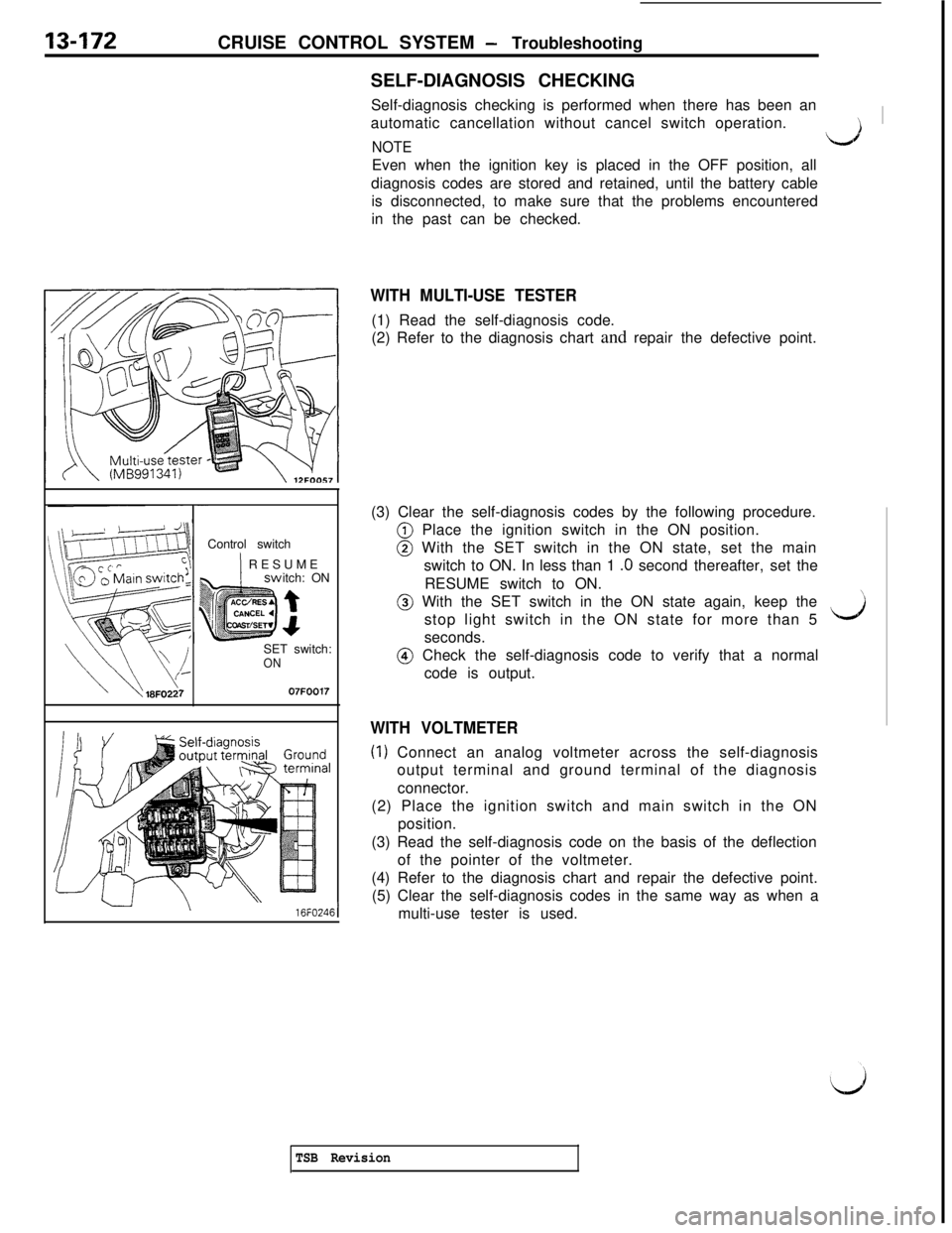

SELF-DIAGNOSIS CHECKING

Self-diagnosis checking is performed when there has been an

automatic cancellation without cancel switch operation.

‘1 ’

NOTE‘LAEven when the ignition key is placed in the OFF position, all

diagnosis codes are stored and retained, until the battery cable

is disconnected, to make sure that the problems encountered

in the past can be checked.

Control switch

1 RESUME

itch: ON

t

4SET switch:

ON

07FOO17

-\16FO2461

WITH MULTI-USE TESTER(1) Read the self-diagnosis code.

(2) Refer to the diagnosis chart and repair the defective point.

(3) Clear the self-diagnosis codes by the following procedure.@ Place the ignition switch in the ON position.@ With the SET switch in the ON state, set the main

switch to ON. In less than 1

.O second thereafter, set the

RESUME switch to ON.@ With the SET switch in the ON state again, keep the

’stop light switch in the ON state for more than 5dseconds.@ Check the self-diagnosis code to verify that a normal

code is output.

WITH VOLTMETER

(1) Connect an analog voltmeter across the self-diagnosis

output terminal and ground terminal of the diagnosis

connector.

(2) Place the ignition switch and main switch in the ON

position.

(3) Read the self-diagnosis code on the basis of the deflection

of the pointer of the voltmeter.

(4) Refer to the diagnosis chart and repair the defective point.

(5) Clear the self-diagnosis codes in the same way as when a

multi-use tester is used.

TSB Revision

Page 285 of 1146

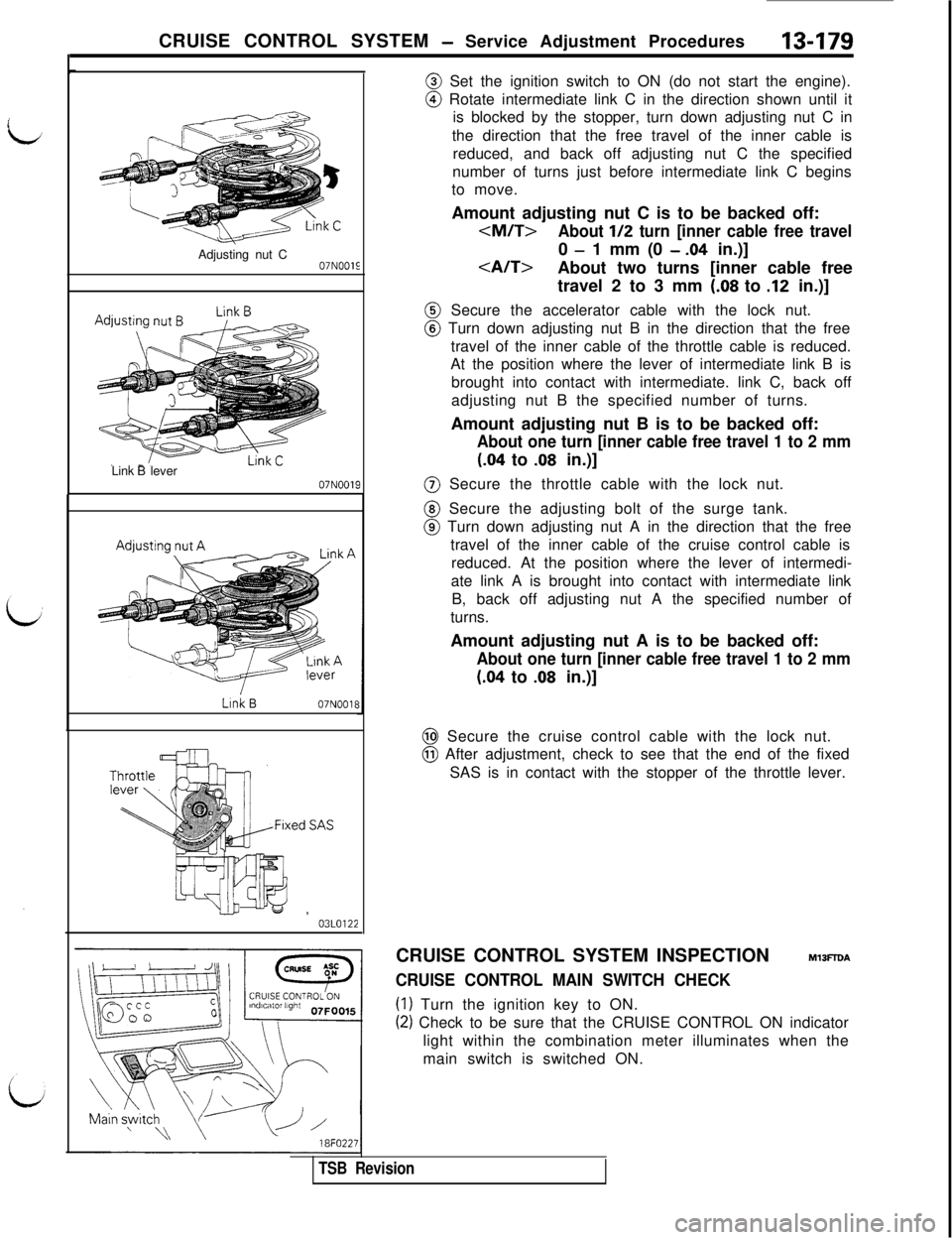

CRUISE CONTROL SYSTEM - Service Adjustment Procedures13-179Adjusting nut C

07NOOlELink Blever

07N0019Link

B07NOOlE

y,jj--ww ,03LO122

\\ \18FO2.2'@ Set the ignition switch to ON (do not start the engine).@ Rotate intermediate link C in the direction shown until it

is blocked by the stopper, turn down adjusting nut C in

the direction that the free travel of the inner cable is

reduced, and back off adjusting nut C the specified

number of turns just before intermediate link C begins

to move.

Amount adjusting nut C is to be backed off:

- 1 mm (0 - .04 in.)]

About two turns [inner cable free

travel 2 to 3 mm

(.08 to .12 in.)]@ Secure the accelerator cable with the lock nut.@ Turn down adjusting nut B in the direction that the free

travel of the inner cable of the throttle cable is reduced.

At the position where the lever of intermediate link B is

brought into contact with intermediate. link C, back off

adjusting nut B the specified number of turns.

Amount adjusting nut B is to be backed off:

About one turn [inner cable free travel 1 to 2 mm

(.04 to .08 in.)]@ Secure the throttle cable with the lock nut.@ Secure the adjusting bolt of the surge tank.@ Turn down adjusting nut A in the direction that the free

travel of the inner cable of the cruise control cable is

reduced. At the position where the lever of intermedi-

ate link A is brought into contact with intermediate link

B, back off adjusting nut A the specified number of

turns.

Amount adjusting nut A is to be backed off:

About one turn [inner cable free travel 1 to 2 mm

(.04 to .08 in.)]@ Secure the cruise control cable with the lock nut.@ After adjustment, check to see that the end of the fixed

SAS is in contact with the stopper of the throttle lever.

CRUISE CONTROL SYSTEM INSPECTION

MlBFlDA

CRUISE CONTROL MAIN SWITCH CHECK

(1) Turn the ignition key to ON.

(2) Check to be sure that the CRUISE CONTROL ON indicator

light within the combination meter illuminates when the

main switch is switched ON.

TSB Revision

Page 389 of 1146

MANUAL TRANSAXLE

110*u011009FO12

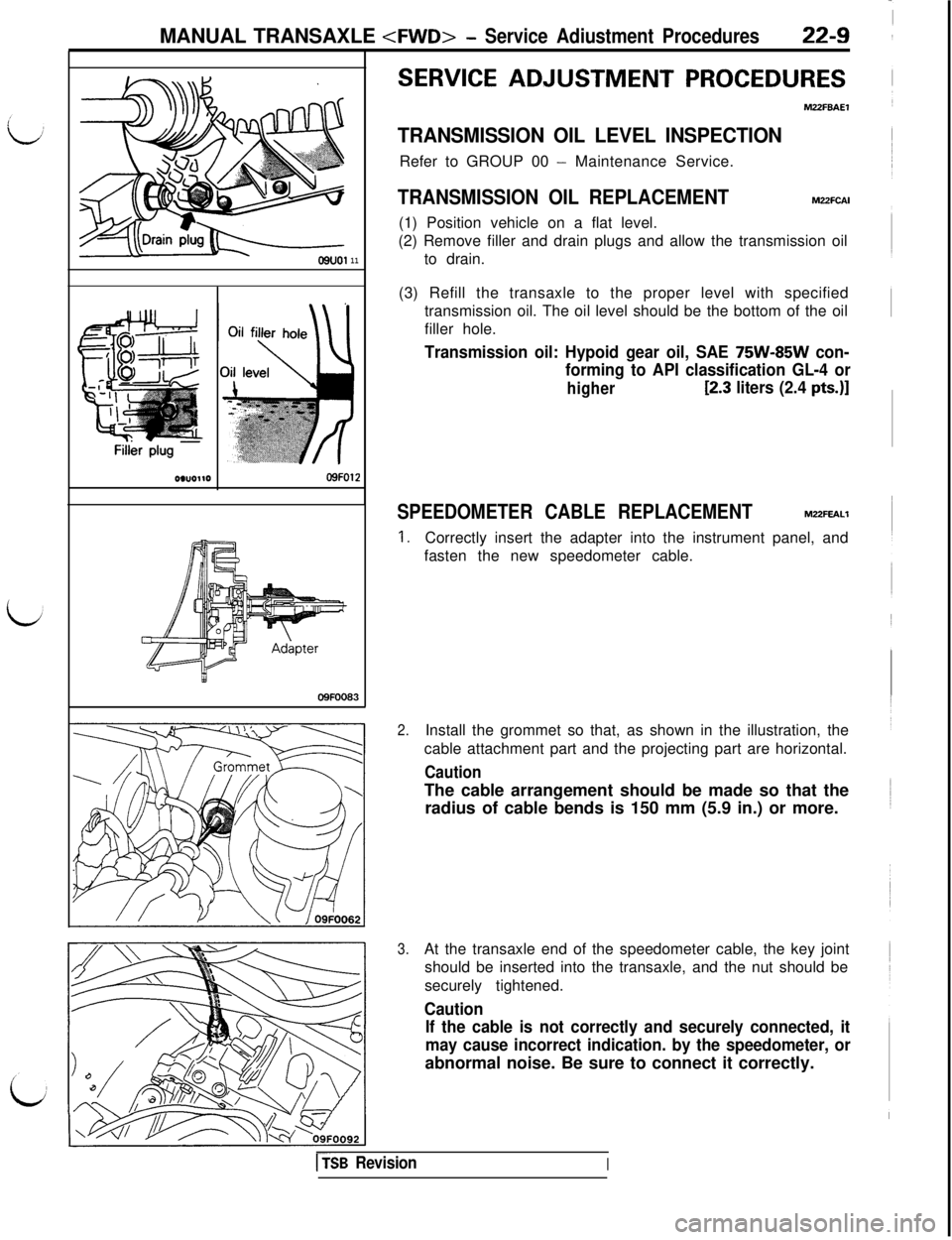

SERVICE ADJUSTMENT PROCEDURES

MZZFBAEl

TRANSMISSION OIL LEVEL INSPECTIONRefer to GROUP 00

- Maintenance Service.

TRANSMISSION OIL REPLACEMENTM22FCAI(1) Position vehicle on a flat level.

(2) Remove filler and drain plugs and allow the transmission oil

to drain.

(3) Refill the transaxle to the proper level with specified

transmission oil. The oil level should be the bottom of the oil

filler hole.

Transmission oil: Hypoid gear oil, SAE 75W-85W con-

forming to API classification GL-4 or

higherC2.3 liters (2.4 pts.)]

SPEEDOMETER CABLE REPLACEMENTMUFEALl

1.Correctly insert the adapter into the instrument panel, and

fasten the new speedometer cable.

2.Install the grommet so that, as shown in the illustration, the

cable attachment part and the projecting part are horizontal.

CautionThe cable arrangement should be made so that the

radius of cable bends is 150 mm (5.9 in.) or more.

3.At the transaxle end of the speedometer cable, the key joint

should be inserted into the transaxle, and the nut should be

securely tightened.

Caution

If the cable is not correctly and securely connected, it

may cause incorrect indication. by the speedometer, orabnormal noise. Be sure to connect it correctly.

DSB RevisionI

Page 408 of 1146

22-28

MANUAL TRANSAXLE

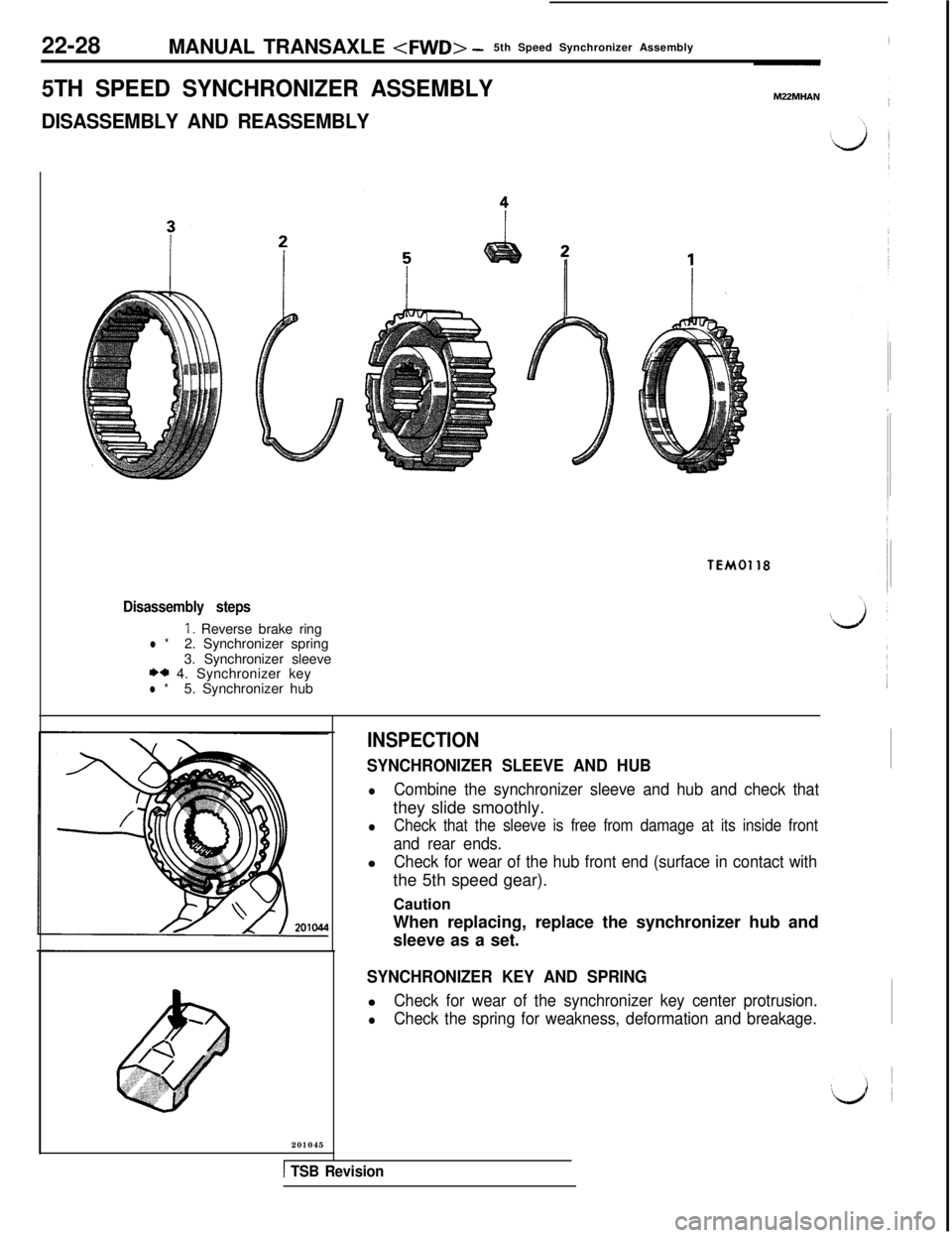

5TH SPEED SYNCHRONIZER ASSEMBLY

DISASSEMBLY AND REASSEMBLY

TEMOl18

Disassembly steps

1. Reverse brake ringl *2. Synchronizer spring

3. Synchronizer sleeve

** 4. Synchronizer keyl *5. Synchronizer hub

@

/r /

JI,::. ‘..-‘. .\:’201045

INSPECTION

SYNCHRONIZER SLEEVE AND HUB

lCombine the synchronizer sleeve and hub and check thatthey slide smoothly.

lCheck that the sleeve is free from damage at its inside front

and rear ends.l

Check for wear of the hub front end (surface in contact withthe 5th speed gear).

Caution

When replacing, replace the synchronizer hub and

sleeve as a set.

SYNCHRONIZER KEY AND SPRINGl

Check for wear of the synchronizer key center protrusion.

lCheck the spring for weakness, deformation and breakage.

1 TSB Revision

Page 409 of 1146

MANUAL TRANSAXLE

22-29

i

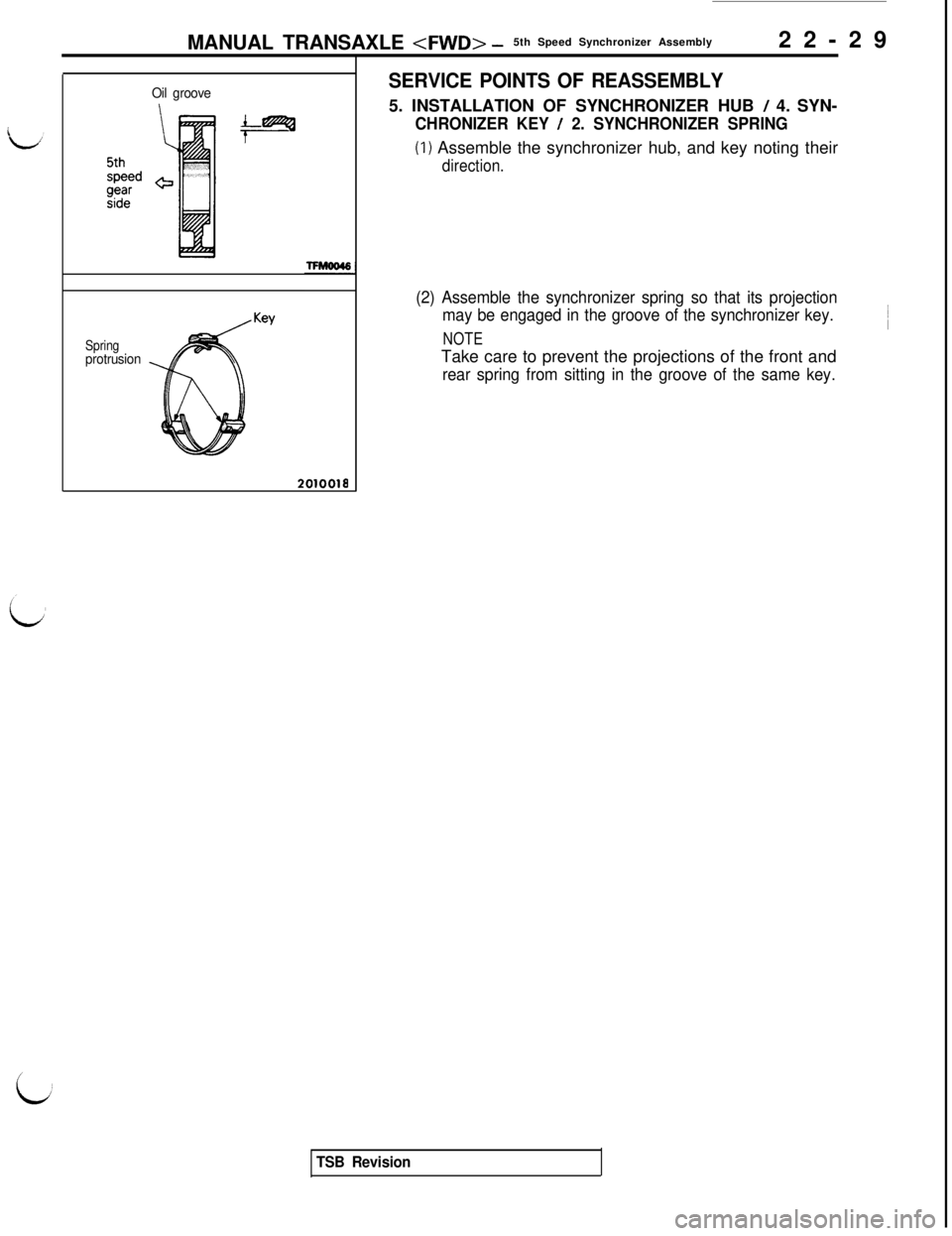

Oil groove

Springprotrusion

201001a

SERVICE POINTS OF REASSEMBLY5. INSTALLATION OF SYNCHRONIZER HUB

/ 4. SYN-

CHRONIZER KEY / 2. SYNCHRONIZER SPRING

(1) Assemble the synchronizer hub, and key noting their

direction.

(2) Assemble the synchronizer spring so that its projection

may be engaged in the groove of the synchronizer key.

NOTETake care to prevent the projections of the front and

rear spring from sitting in the groove of the same key.

TSB Revision

Page 410 of 1146

22-30

MANUAL TRANSAXLE

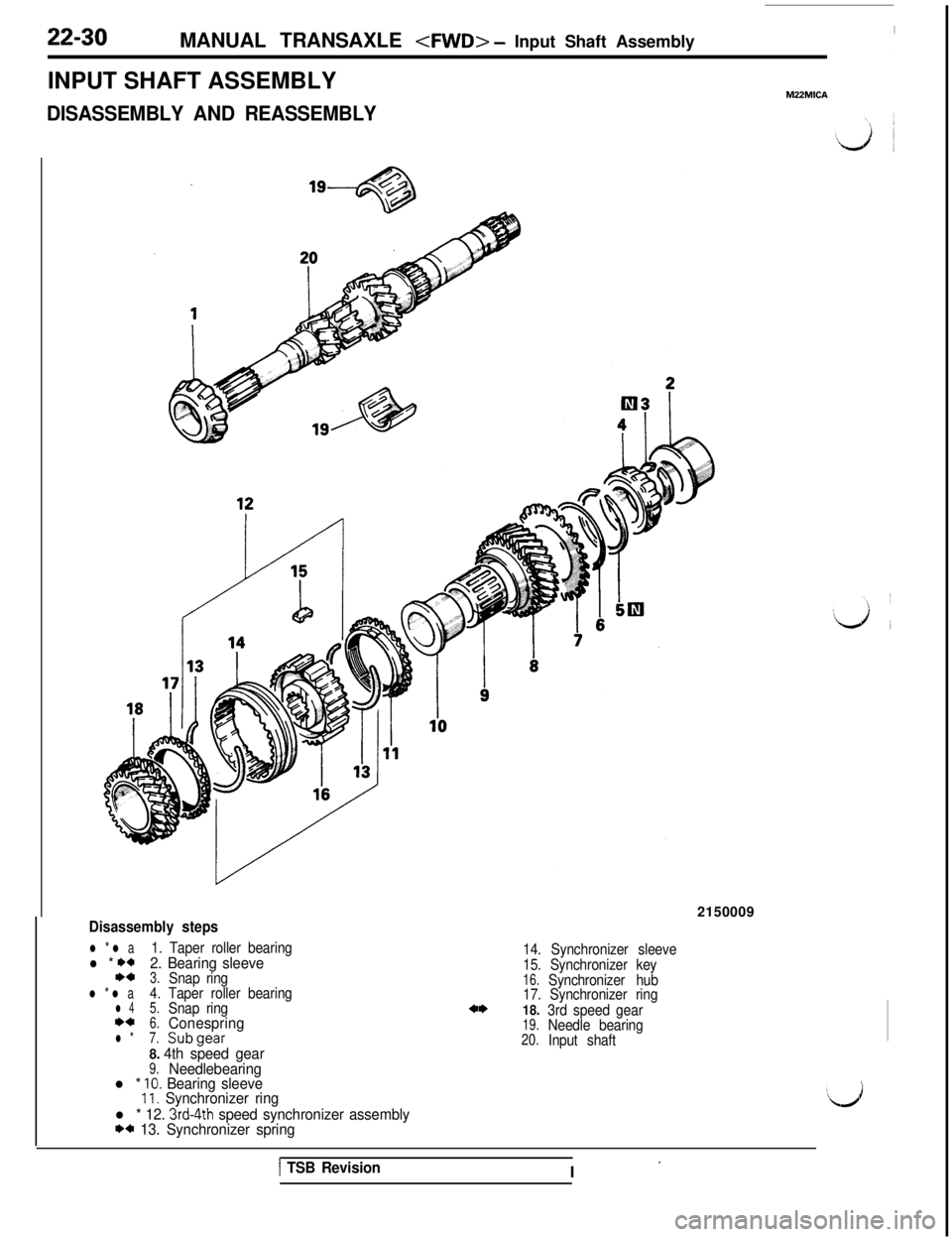

INPUT SHAFT ASSEMBLY

MZZMICA

DISASSEMBLY AND REASSEMBLY2150009

Disassembly steps

l * l a1. Taper roller bearingl * *a2. Bearing sleeveI)+3.Snap ringl * l a4. Taper roller bearingl 45.Snap ring**6.Conespringl *7.Subgear

8. 4th speed gear

9.Needlebearingl * 10. Bearing sleeveII. Synchronizer ring

l * 12. 3rd-4th speed synchronizer assembly** 13. Synchronizer spring

14. Synchronizer sleeve

15. Synchronizer key

16.Synchronizer hub

17. Synchronizer ring

18.

3rd speed gear

19.Needle bearing20.Input shaft

1 TSB RevisionI ’

Page 412 of 1146

22-32MANUAL TRANSAXLE

20105'

Damage, breakage

Damage, wearTFMOll!

Synchnizer ringGLar

TFMOll201044

/

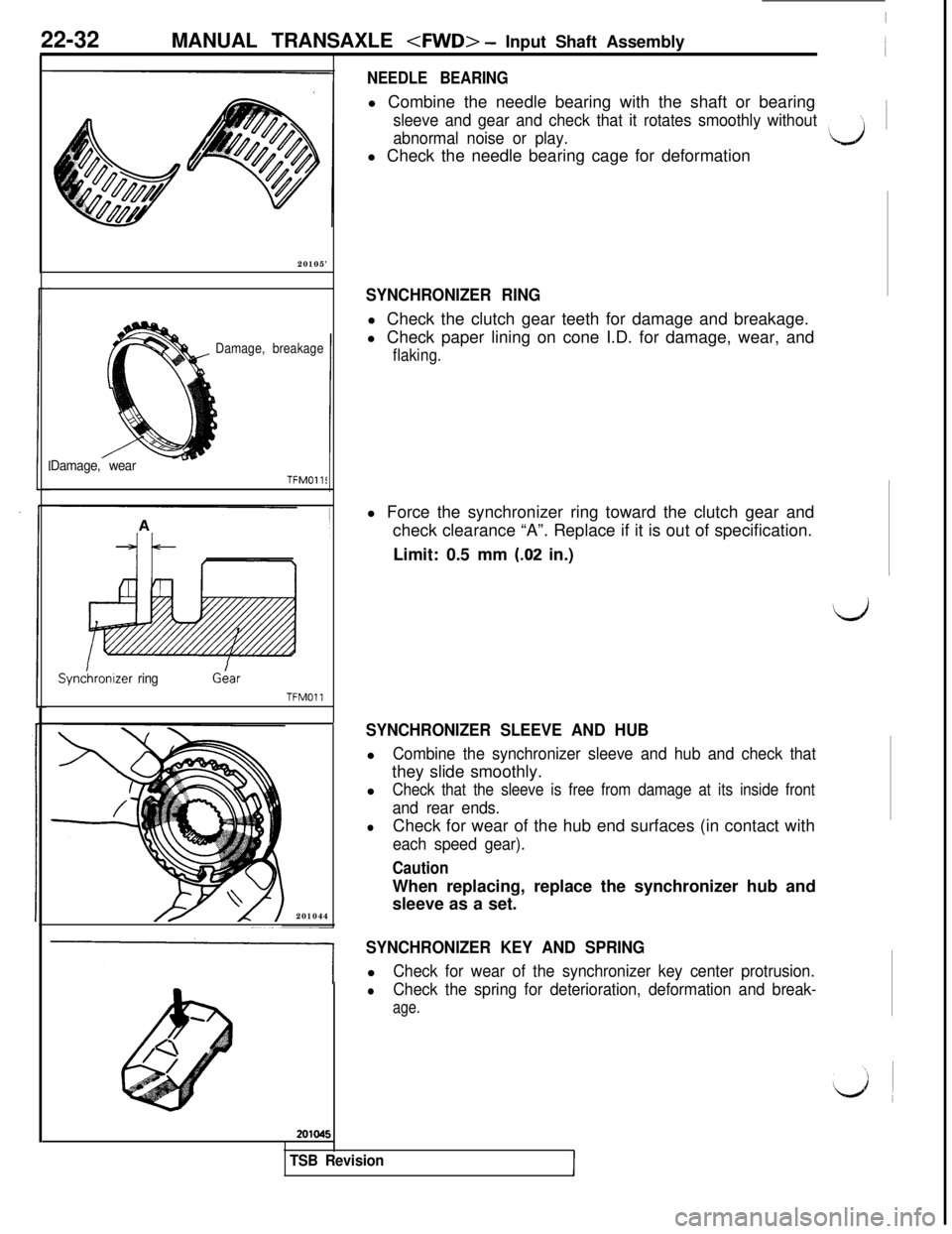

NEEDLE BEARINGl Combine the needle bearing with the shaft or bearing

sleeve and gear and check that it rotates smoothly without

abnormal noise or play.l Check the needle bearing cage for deformation

SYNCHRONIZER RINGl Check the clutch gear teeth for damage and breakage.

l Check paper lining on cone I.D. for damage, wear, and

flaking.l Force the synchronizer ring toward the clutch gear and

check clearance “A”. Replace if it is out of specification.

Limit: 0.5 mm

(.02 in.)

SYNCHRONIZER SLEEVE AND HUBl

Combine the synchronizer sleeve and hub and check thatthey slide smoothly.

l

Check that the sleeve is free from damage at its inside front

and rear ends.

lCheck for wear of the hub end surfaces (in contact with

each speed gear).

CautionWhen replacing, replace the synchronizer hub and

sleeve as a set.

SYNCHRONIZER KEY AND SPRINGl

Check for wear of the synchronizer key center protrusion.

lCheck the spring for deterioration, deformation and break-

age.

TSB Revision

Page 413 of 1146

MANUAL TRANSAXLE

SpriprotKey2010018

MD998348-01

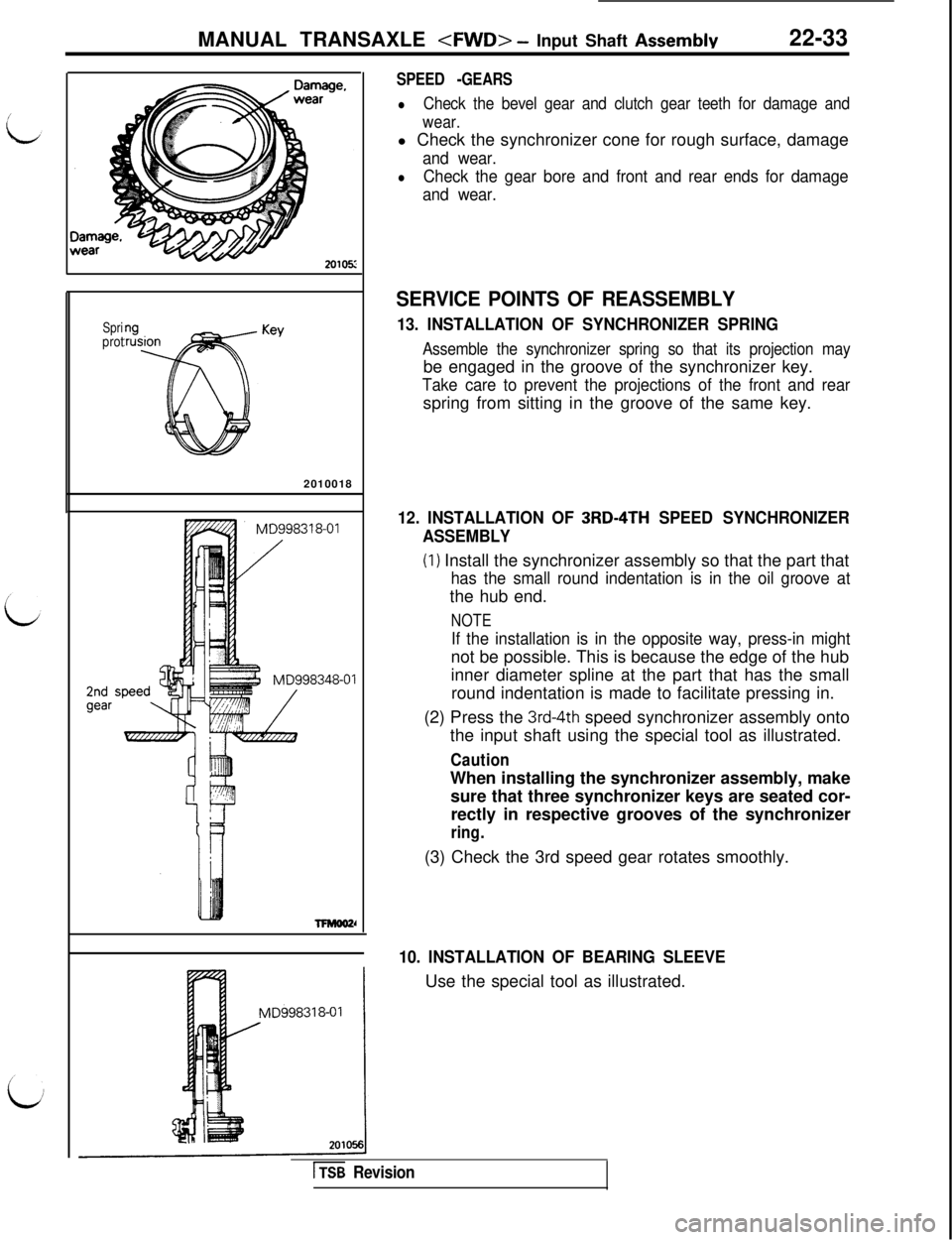

SPEED -GEARS

lCheck the bevel gear and clutch gear teeth for damage and

wear.l Check the synchronizer cone for rough surface, damage

and wear.

lCheck the gear bore and front and rear ends for damage

and wear.

SERVICE POINTS OF REASSEMBLY

13. INSTALLATION OF SYNCHRONIZER SPRING

Assemble the synchronizer spring so that its projection maybe engaged in the groove of the synchronizer key.

Take care to prevent the projections of the front and rearspring from sitting in the groove of the same key.

12. INSTALLATION OF 3RD-4TH SPEED SYNCHRONIZER

ASSEMBLY

(I) Install the synchronizer assembly so that the part that

has the small round indentation is in the oil groove atthe hub end.

NOTE

If the installation is in the opposite way, press-in mightnot be possible. This is because the edge of the hub

inner diameter spline at the part that has the small

round indentation is made to facilitate pressing in.

(2) Press the

3rd-4th speed synchronizer assembly onto

the input shaft using the special tool as illustrated.

CautionWhen installing the synchronizer assembly, make

sure that three synchronizer keys are seated cor-

rectly in respective grooves of the synchronizer

ring.(3) Check the 3rd speed gear rotates smoothly.

10. INSTALLATION OF BEARING SLEEVEUse the special tool as illustrated.

rTSB Revision