switch MITSUBISHI 3000GT 1995 2.G Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1995, Model line: 3000GT, Model: MITSUBISHI 3000GT 1995 2.GPages: 738, PDF Size: 35.06 MB

Page 590 of 738

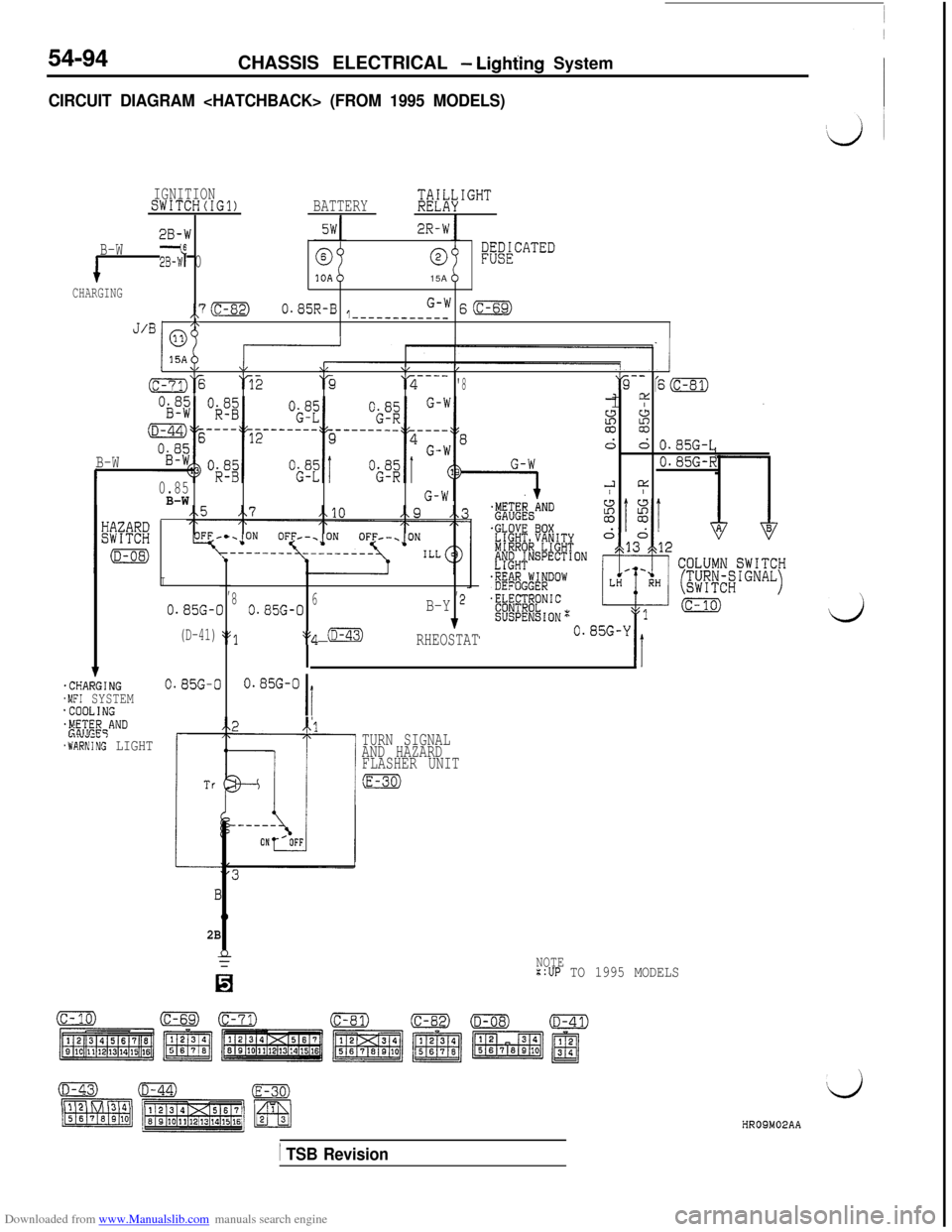

Downloaded from www.Manualslib.com manuals search engine 54-94CHASSIS ELECTRICAL - Lighting System

CIRCUIT DIAGRAM

IGNITIONSWITCH(IG1)BATTERY;di\IGHT

28-W2R-W

B-W2B-W6 00l;akCATED15A

CHARGING

,,7(c-82)0.85R-B1G-WS(c-69)-----------_/\J’BI no

1.CHARGING.MFI SYSTEM'COOLING$F!;E$qAND

.WARNIiG LIGHT

I,,

0.85G-C810.85G-06B-Y 2

(D-41)::q (D-43)1

‘$1RHEOSTAT

0.85G-00.85G-0

Ii

I \"w\/\/b/---- -------- --------a‘% ‘52‘3---_‘2'8"9-- '6m2 DiI I2

si

d: O.BSG-L

B-W0.85G-R

0.852 L1:

B-W/ I

2B

TURN SIGNAL

AND HAZARD

FLASHER UNIT

:E-30)

NOTE::UP TO 1995 MODELS

dHROSM02AA

/ TSB Revision

Page 591 of 738

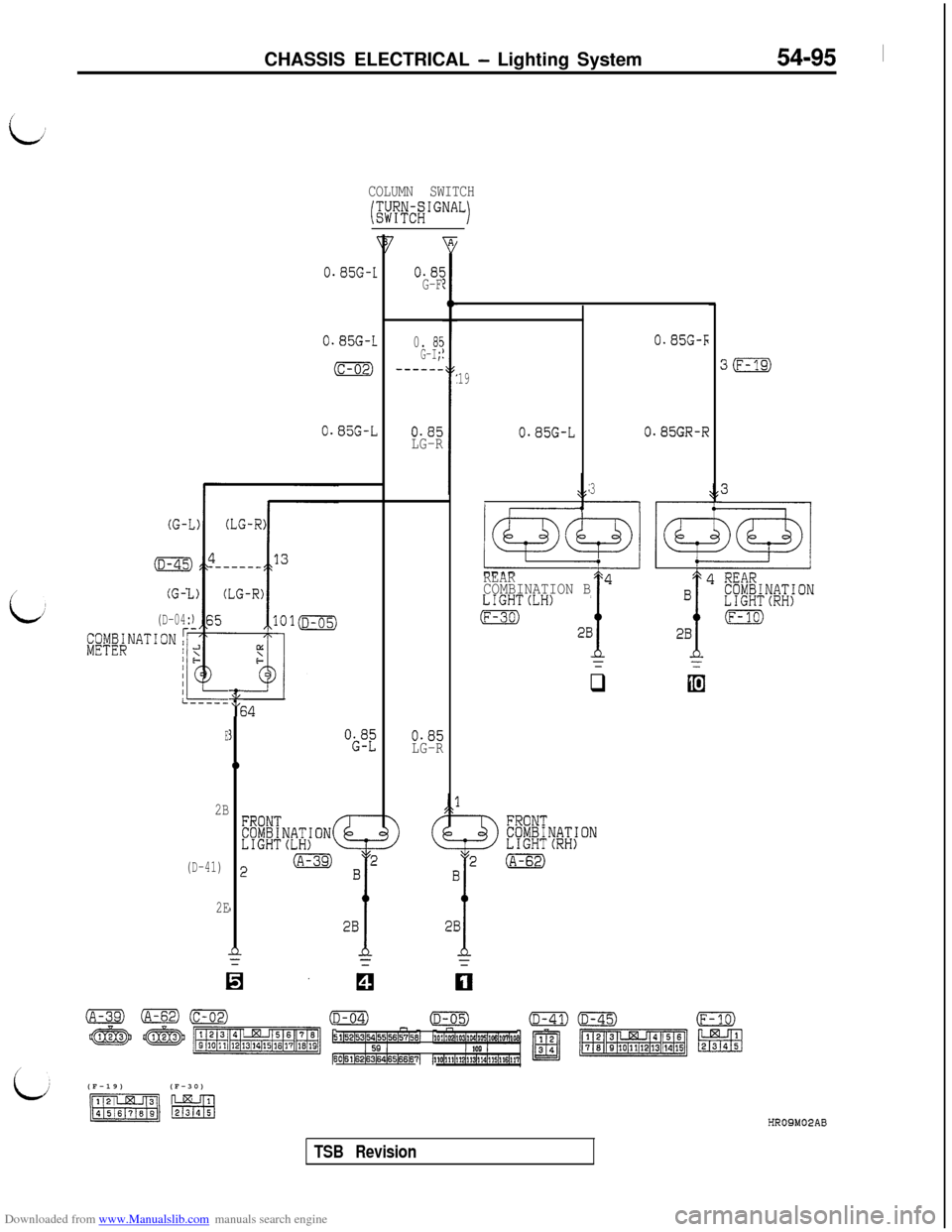

Downloaded from www.Manualslib.com manuals search engine CHASSIS ELECTRICAL - Lighting System54-95 1

COLUMN SWITCH

!$;fyi$IGNALi

(G-l

iD-45)

(G-Z

(D-04:

0.85G-1

0.85G-L

(c-02)

0.85G-L

E

2B

(D-41)

-cAL

“‘t

I

0

I

f

;

,

nz

2E

;4

"i;!,5-

0.8:

G-F

0.

8FG-I;-_-___

0.85

LG-R

0.85LG-R

19

0.85G-L

I-

3

=A

wREARCOMBINATION B4LIGHTCLH)

(F-30) 2B

d=

q

0.85G-F

0.85GR-R

30(F-19)(F-30)HROSM02AB

TSB Revision

Page 592 of 738

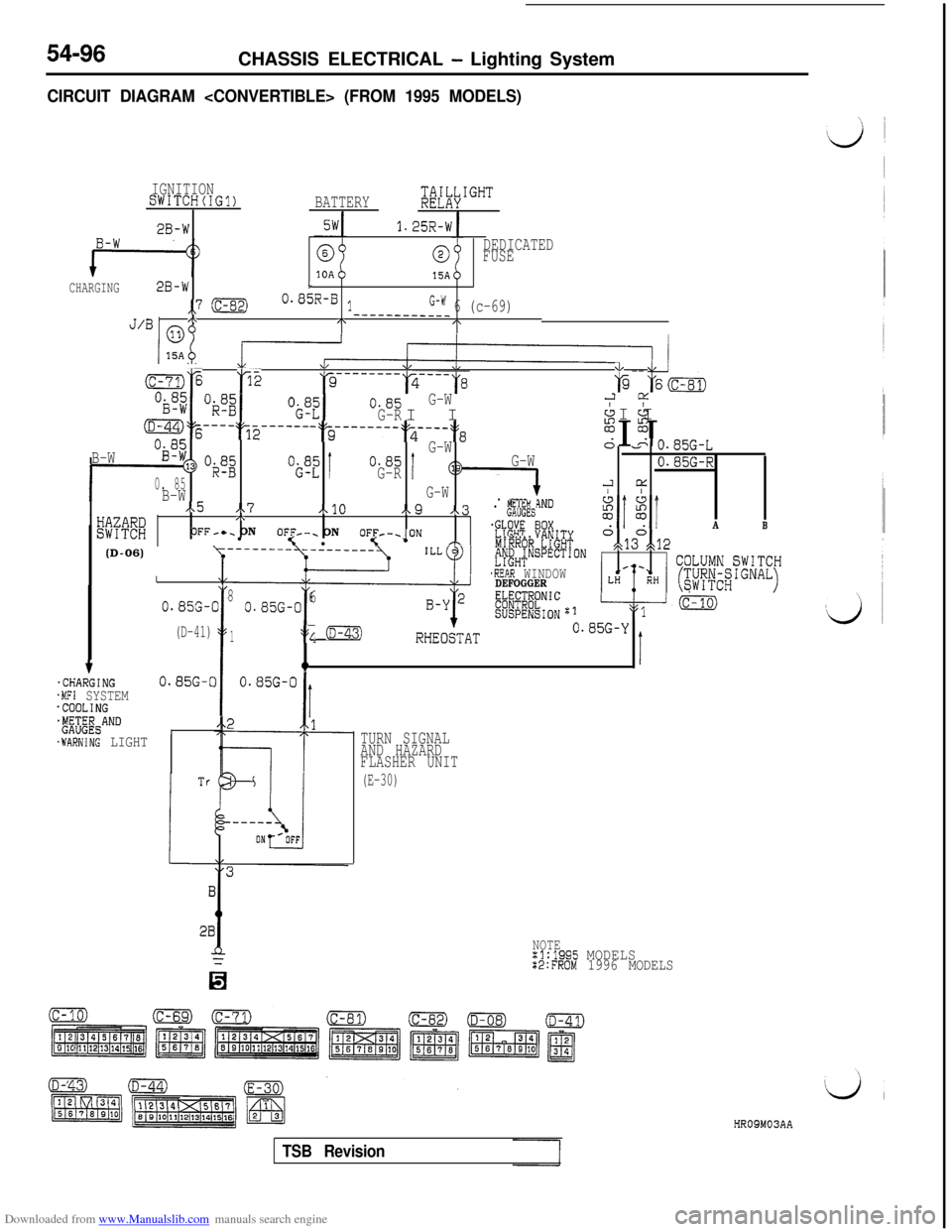

Downloaded from www.Manualslib.com manuals search engine 54-96CHASSIS ELECTRICAL - Lighting System

CIRCUIT DIAGRAM

IGNITIONSWITCH(IG?)BATTERY;&IGHT

2B-W1.25R-W

0DEDICATED

FUSE

15ACHARGING2B-wL

,,7 :c-82)0.85R-B lG-W 6 (c-69)/\J’BI mo

-___----____/\I\

B-W

f-

D-44)% ---- :T2 ------ -$~e---m--.~s---:~8%I I&

Og;G-WA&n

*3> “$2“i;“=!0.85

0. 85G-RI

B-WG-W

I/x5 .\7A10e9 x.3wmj,\. p!&'

OFF-c. ON

lOFF--. ON5 loF1;F-~oN m'R% thnrnnnb

G-W

1. .----iND

- - v.85G-L

0.85G-R

2 cc/ I.

E(D-06)IOX

'E%T'~~~J~~SPECTION

.REAR WINDOWDEFOGGERE#@;.NIC

SUSPENSIONzl

A

o,d3°gt12

B

\y---- --------

:c-?:,jE p2w

*\L &I--

a-7j% 166

“$ZI0.85G-W

G-RI I2 CL

& &I I

I

0.8%-(

(D-41)

38

I

0.85G-06

1:s; (D-43)RHEObAT0.85G-Y

qIt.CHARGING0.85G-C.MFI SYSTEM.COOLING+&$&ANDI.WARNING LIGHT

28

TURN SIGNAL

AND HAZARD

FLASHER UNIT

(E-30)

NOTEx1:1995 MODELSX2:FROM 1996 MODELS

HR09M03AA

TSB Revision

Page 593 of 738

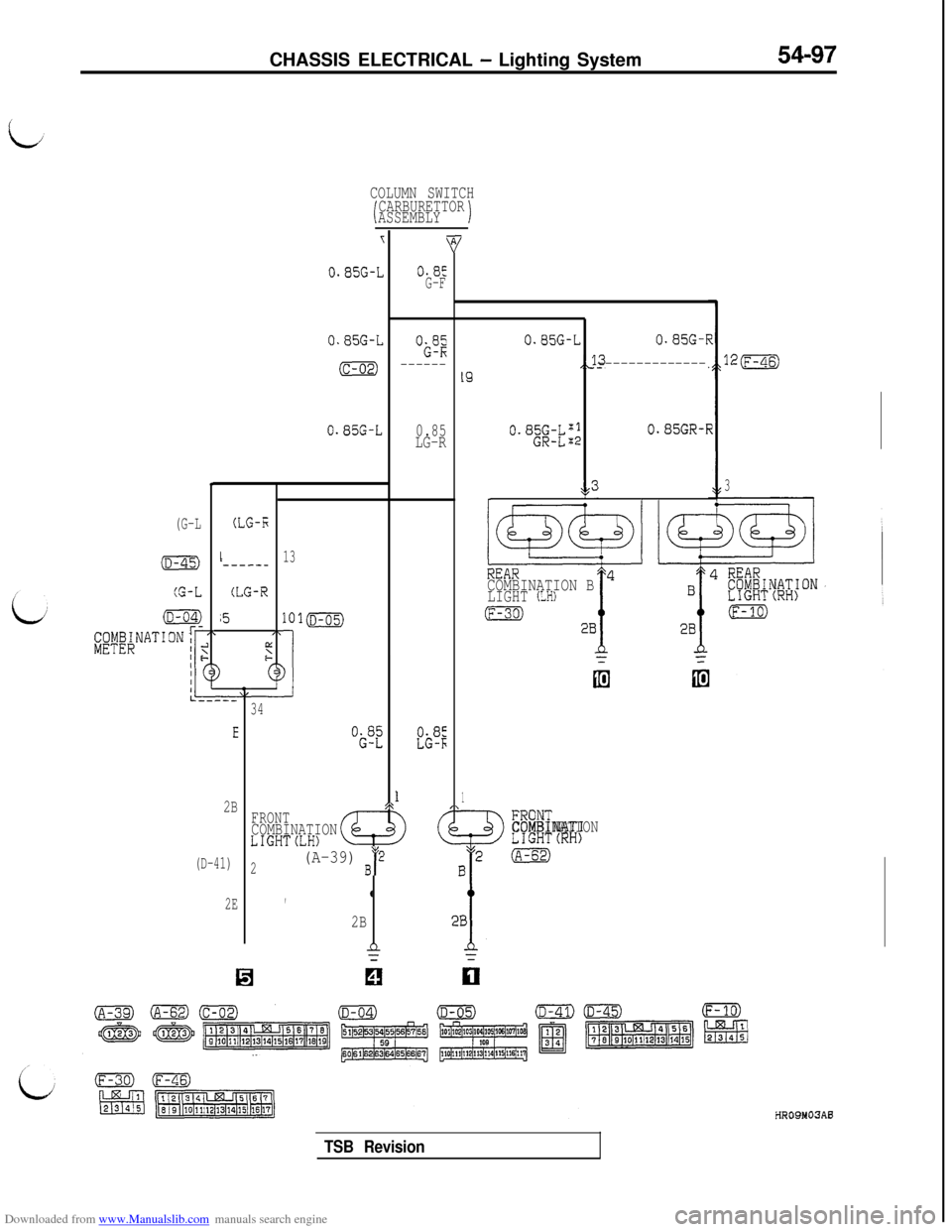

Downloaded from www.Manualslib.com manuals search engine CHASSIS ELECTRICAL - Lighting System54-97

COLUMN SWITCH

iCARBURETTOR

ASSEMBLY1

(G-L(LG-E

0.85G-L

0.85G-L

(c-02)

0.85G-L

L-----_

(LG-R

;5

2B

(D-41)

2E13

101m

I)

34

1.

,4

2B

nz

0.8EG-F

0.85G-R

------

0.85

LG-R

0.85G-L0.85G-f

,J3--------------19

0.85G-Lx10.85GR-IGR-L*2

r-y3I /

wCOMBINATION B4LIGHT (LH)

(F-30) 2B

!

1

COMBINATION

12m

3

TSB Revision

Page 596 of 738

Downloaded from www.Manualslib.com manuals search engine 54-100CHASSIS ELECTRICAL - Lighting System

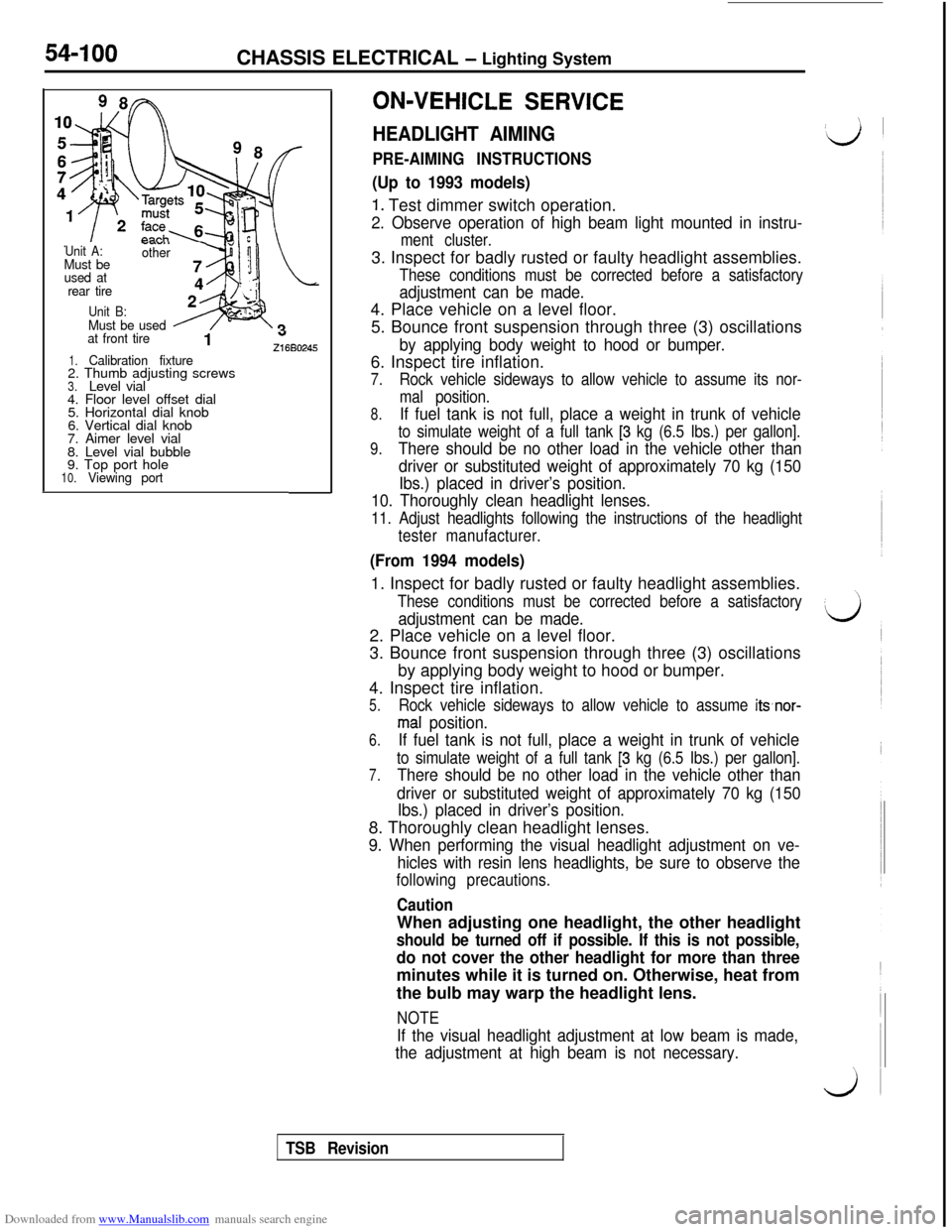

Unit A:Must be

used at

rear tire

“..“I. .other

Unit B:Must be used

at front tire1 -216802451.Calibration fixture2. Thumb adjusting screws

3.Level vial

4. Floor level offset dial

5. Horizontal dial knob

6. Vertical dial knob

7. Aimer level vial

8. Level vial bubble

9. Top port hole

10.Viewing portON-VEHICLE

SERVICE

HEADLIGHT AIMING

PRE-AIMING INSTRUCTIONS

(Up to 1993 models)

1. Test dimmer switch operation.

2. Observe operation of high beam light mounted in instru-

ment cluster.3. Inspect for badly rusted or faulty headlight assemblies.

These conditions must be corrected before a satisfactory

adjustment can be made.4. Place vehicle on a level floor.

5. Bounce front suspension through three (3) oscillations

by applying body weight to hood or bumper.6. Inspect tire inflation.

7.Rock vehicle sideways to allow vehicle to assume its nor-

mal position.

8.If fuel tank is not full, place a weight in trunk of vehicle

9.

to simulate weight of a full tank [3 kg (6.5 Ibs.) per gallon].

There should be no other load in the vehicle other than

driver or substituted weight of approximately 70 kg (150

Ibs.) placed in driver’s position.

10. Thoroughly clean headlight lenses.

11. Adjust headlights following the instructions of the headlight

tester manufacturer.

(From 1994 models)1. Inspect for badly rusted or faulty headlight assemblies.

These conditions must be corrected before a satisfactory

adjustment can be made.2. Place vehicle on a level floor.

3. Bounce front suspension through three (3) oscillations

by applying body weight to hood or bumper.

4. Inspect tire inflation.

5.Rock vehicle sideways to allow vehicle to assume it.snor-

mal position.

6.If fuel tank is not full, place a weight in trunk of vehicle

7.

to simulate weight of a full tank [3 kg (6.5 Ibs.) per gallon].

There should be no other load in the vehicle other than

driver or substituted weight of approximately 70 kg (150

Ibs.) placed in driver’s position.8. Thoroughly clean headlight lenses.

9. When performing the visual headlight adjustment on ve-

hicles with resin lens headlights, be sure to observe the

following precautions.

CautionWhen adjusting one headlight, the other headlight

should be turned off if possible. If this is not possible,

do not cover the other headlight for more than threeminutes while it is turned on. Otherwise, heat from

the bulb may warp the headlight lens.

NOTE

If the visual headlight adjustment at low beam is made,

the adjustment at high beam is not necessary.

TSB Revision

Page 599 of 738

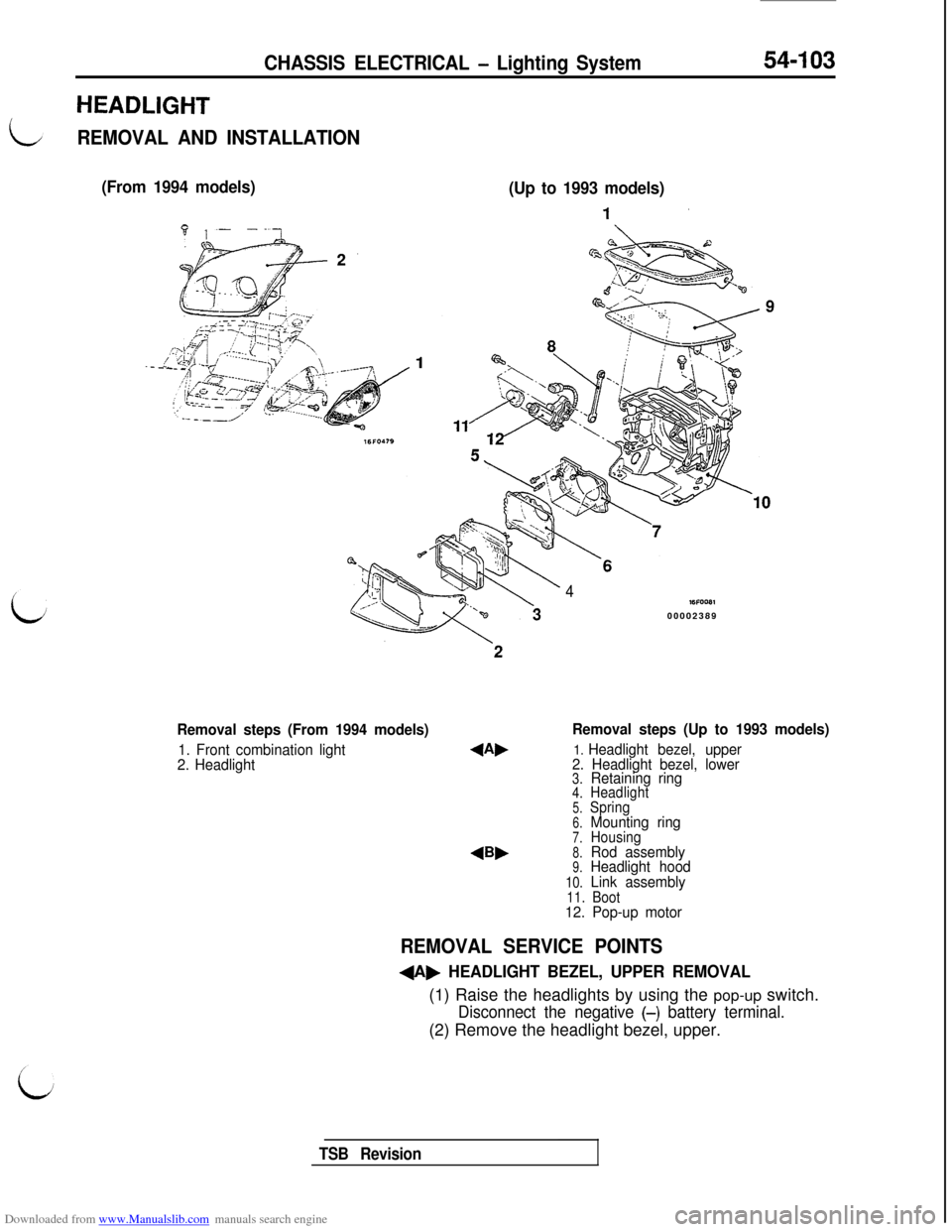

Downloaded from www.Manualslib.com manuals search engine HEADLIGHT

CHASSIS ELECTRICAL - Lighting System54-103

REMOVAL AND INSTALLATION

(From 1994 models)

(Up to 1993 models)

Removal steps (From 1994 models)

1. Front combination light

2. Headlight

4Bb

4WFOOB100002389

Removal steps (Up to 1993 models)

1. Headlight bezel, upper

2. Headlight bezel, lower

3.Retaining ring4.Headlight5.Spring6.Mounting ring7.Housing8.Rod assembly9.Headlight hood

10.Link assembly11. Boot12. Pop-up motor

REMOVAL SERVICE POINTS

+A, HEADLIGHT BEZEL, UPPER REMOVAL(1) Raise the headlights by using the pop-up switch.

Disconnect the negative (-) battery terminal.(2) Remove the headlight bezel, upper.

TSB Revision

Page 605 of 738

Downloaded from www.Manualslib.com manuals search engine CHASSIS ELECTRICAL - Lighting System54-109

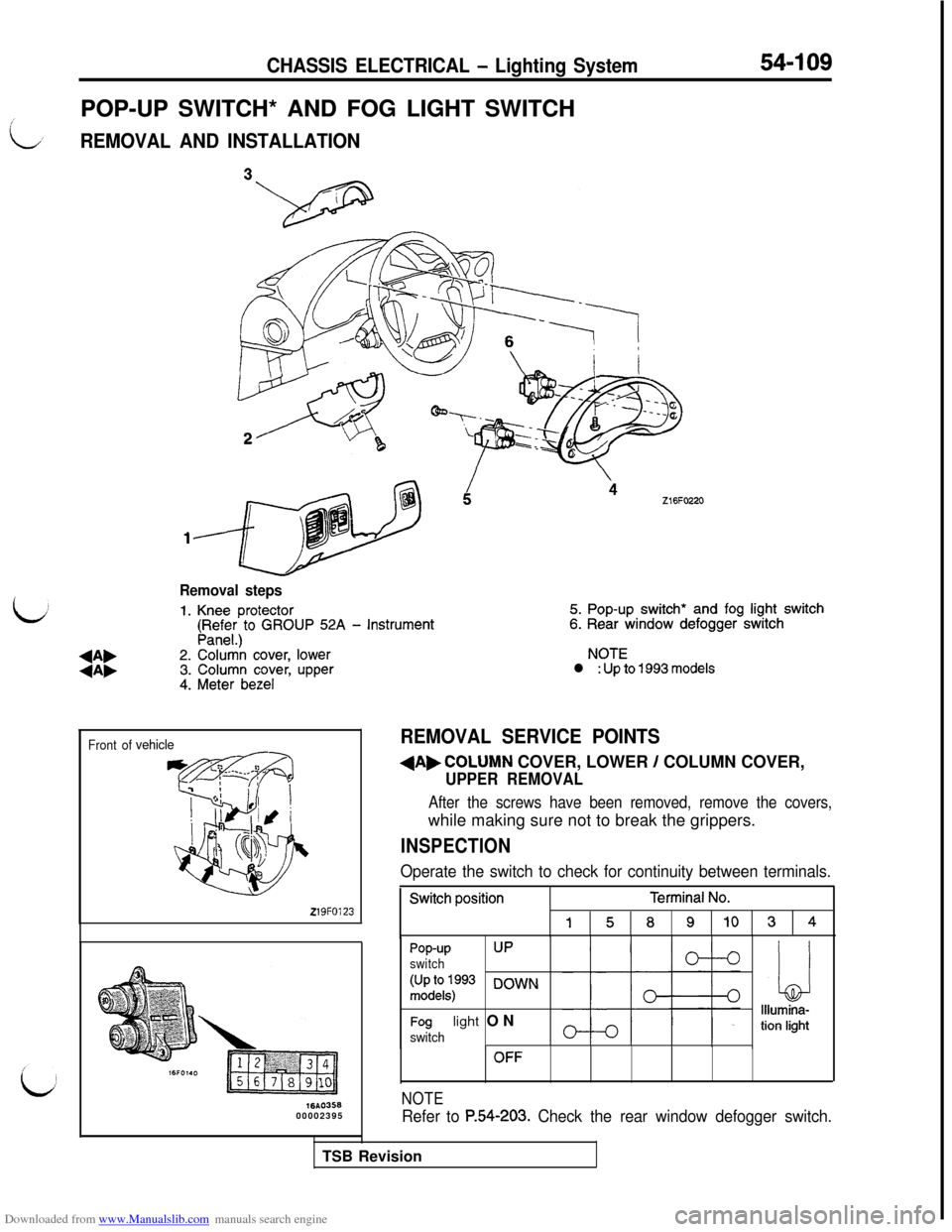

POP-UP SWITCH* AND FOG LIGHT SWITCH

i

LREMOVAL AND INSTALLATION

bZ16FO220

b

Removal steps

1. Knee protector5. Pop-up switch* and fog light switch

(pR,;$)to GROUP 52A - Instrument6. Rear window defogger switch

+A,2. Colur& cover, lowerNOTE

+A,3. Column cover, upperl : Up to 1993 models

4. Meter bezel

Front ofvehicle

219FO123

lbA035600002395

REMOVAL SERVICE POINTS

dAbCOLUMN COVER, LOWER / COLUMN COVER,

UPPER REMOVAL

After the screws have been removed, remove the covers,while making sure not to break the grippers.

INSPECTION

Operate the switch to check for continuity between terminals.

Switch positionTerminal No.

15891034

Pop-upUP

switch

:;;1kq:p93 DOWN

Foglight ONswitch

OFF

NOTE

Refer to P.54-203. Check the rear window defogger switch.TSB Revision

Page 606 of 738

Downloaded from www.Manualslib.com manuals search engine 54-110CHASSIS ELECTRICAL - Lighting System

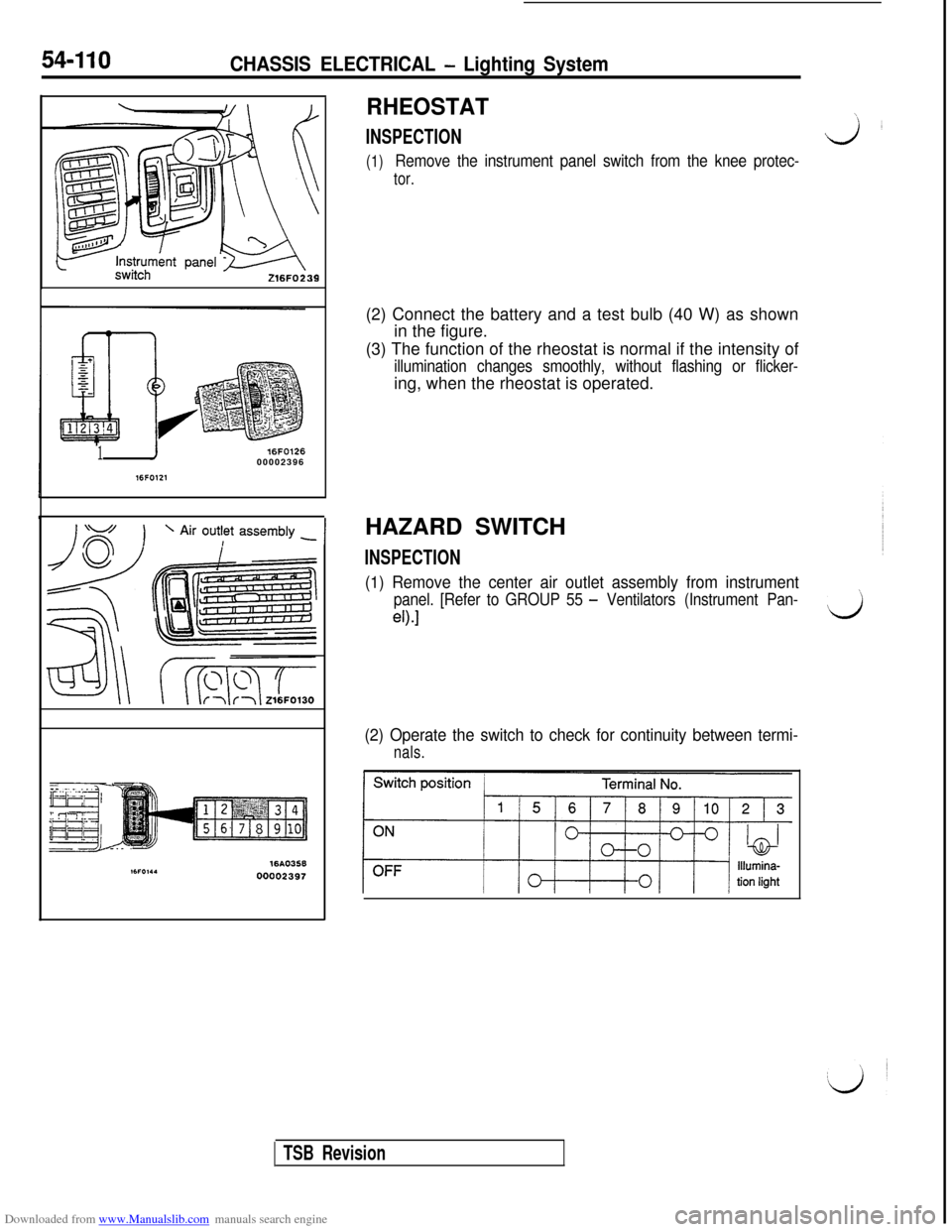

1

16FO121

16FO12600002396

I‘VA1 I\ Air outlet assembly _I

RHEOSTAT\

INSPECTIONJL

(1)Remove the instrument panel switch from the knee protec-

tor.(2) Connect the battery and a test bulb (40 W) as shown

in the figure.

(3) The function of the rheostat is normal if the intensity of

illumination changes smoothly, without flashing or flicker-ing, when the rheostat is operated.

HAZARD SWITCH

INSPECTION

(1) Remove the center air outlet assembly from instrument

panel. [Refer to GROUP 55 - Ventilators (Instrument Pan-’

eO.1d

(2) Operate the switch to check for continuity between termi-

nals.

TSB Revision

Page 607 of 738

Downloaded from www.Manualslib.com manuals search engine CHASSIS ELECTRICAL - Column Switch

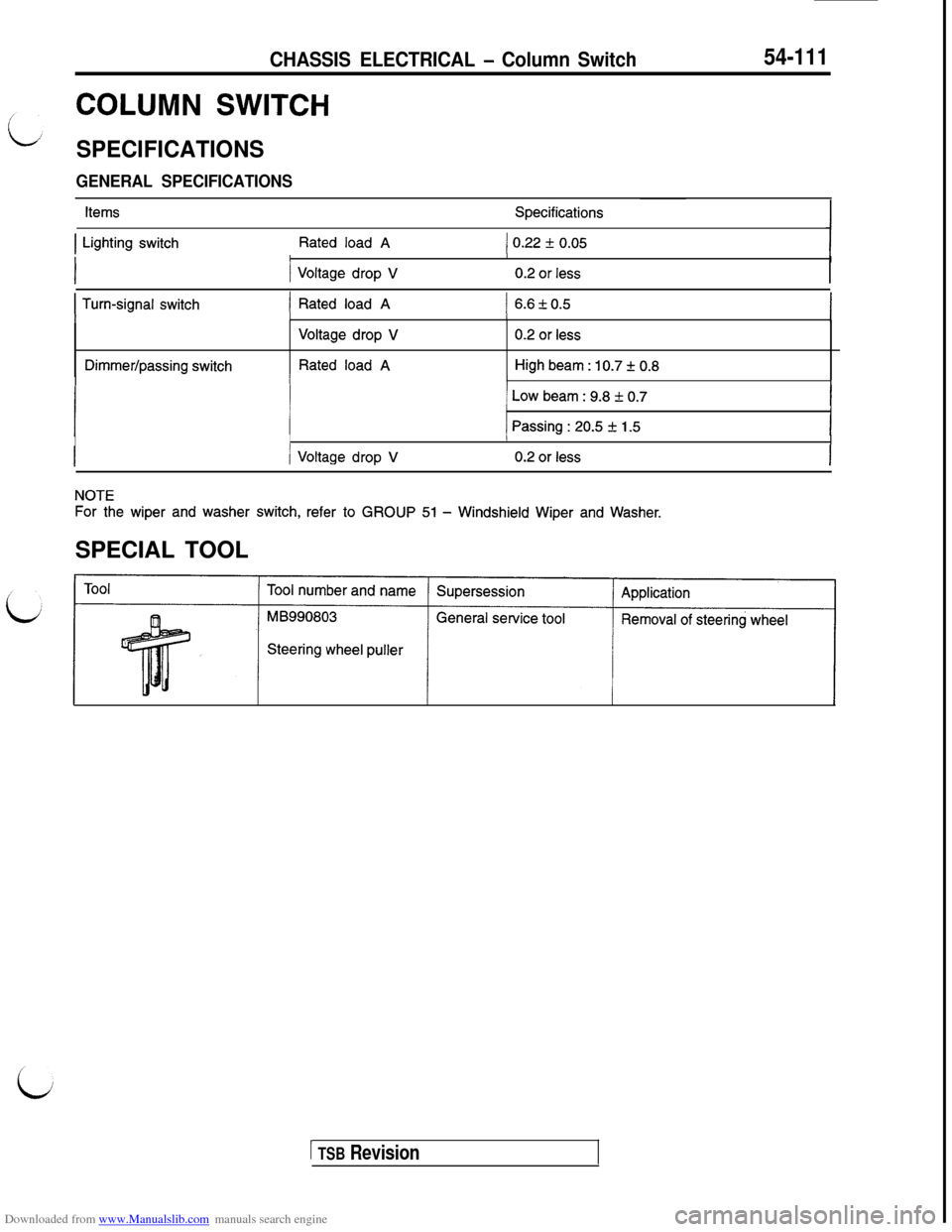

COLUMN SWITCH

SPECIFICATIONS

GENERAL SPECIFICATIONS

54-111

ItemsSpecifications

1 Lighting switchRated load A1 0.22 f 0.05IIII

1 Voltage drop V0.2 or less

I Turn-signal switch) Rated load A1 6.6kO.5III/I

Dimmer/passing switch

Voltage drop V

Rated load A

0.2 or less

High beam : 10.7 + 0.8IIII

1 Low beam : 9.8 f 0.7IIII

j Passing : 20.5 + 1.5IIII

/ Voltage drop V0.2 or less

NOTE

For the wiper and washer switch, refer to GROUP 51 - Windshield Wiper and Washer.SPECIAL TOOL

Steering wheel puller

1 TSB Revision

Page 608 of 738

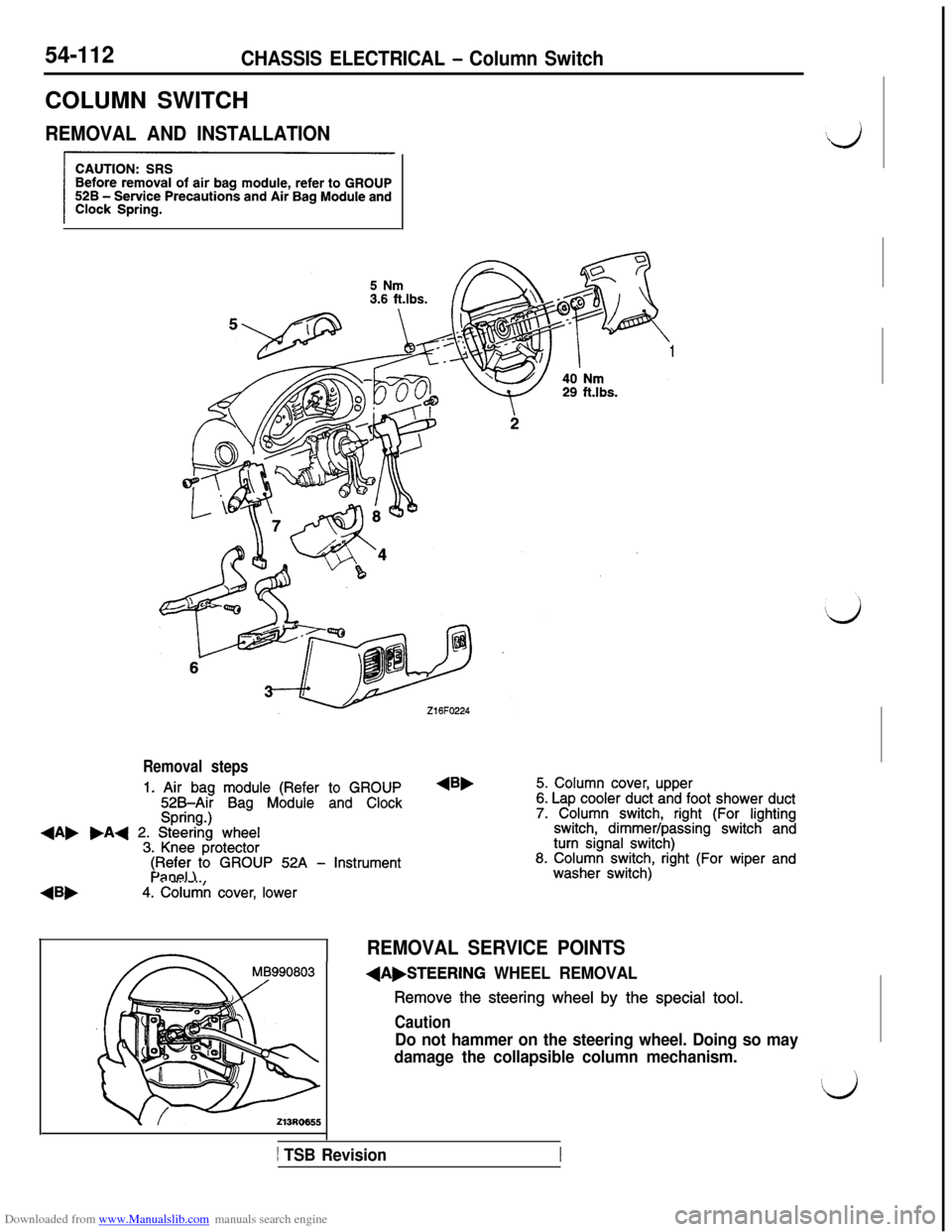

Downloaded from www.Manualslib.com manuals search engine 54-112CHASSIS ELECTRICAL - Column SwitchCOLUMN SWITCH

REMOVAL AND INSTALLATION

1

Removal steps

1. Air bag module (Refer to GROUP525Air Bag Module and ClockSpring.)+A, .A+ 2. Steering wheel3. Knee protector

4Bb

$F$i;)to GROUP 52A - Instrument

4. Column cover, lower

4B,5. Column cover, upper6. Lap cooler duct and foot shower duct7. Column switch, right (For lightingswitch, dimmer/passing switch andturn signal switch)8. Column switch, right (For wiper andwasher switch)

REMOVAL SERVICE POINTS

(A,STEERING WHEEL REMOVAL

Remove the steering wheel by the special tool.

Caution

Do not hammer on the steering wheel. Doing so may

damage the collapsible column mechanism.

1 TSB Revision