diagram MITSUBISHI 380 2005 Owners Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 446 of 1500

INPUT SIGNAL PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-446

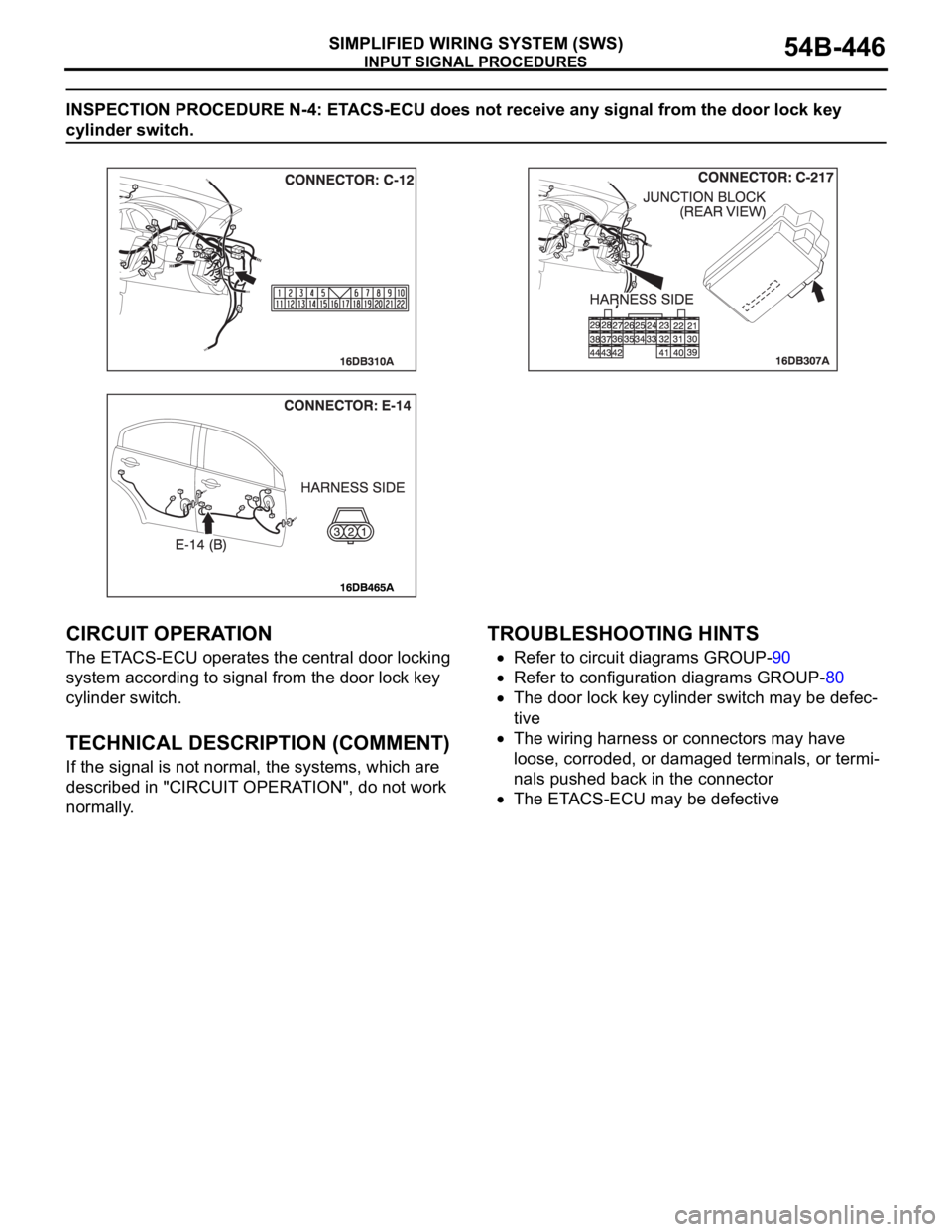

INSPECTION PROCEDURE N-4: ETACS-ECU does not receive any signal from the door lock key

cylinder switch.

.

CIRCUIT OPERATION

The ETACS-ECU operates the central door locking

system according to signal from the door lock key

cylinder switch.

.

TECHNICAL DESCRIPTION (COMMENT)

If the signal is not normal, the systems, which are

described in "CIRCUIT OPERATION", do not work

normally.

.

TROUBLESHOOTING HINTS

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

The door lock key cylinder switch may be defec-

tive

The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector

The ETACS-ECU may be defective

Page 451 of 1500

INPUT SIGNAL PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-451

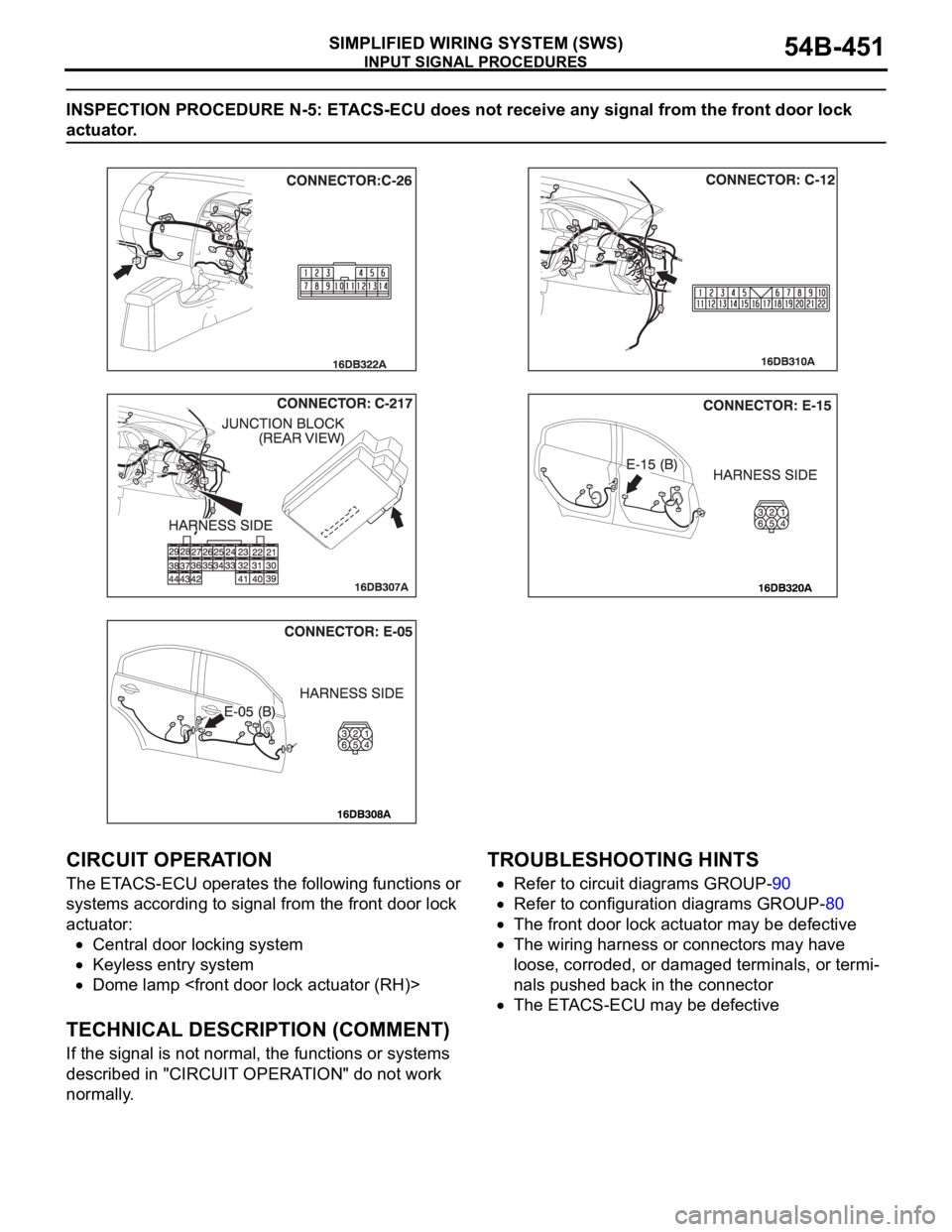

INSPECTION PROCEDURE N-5: ETACS-ECU does not receive any signal from the front door lock

actuator.

.

CIRCUIT OPERATION

The ETACS-ECU operates the following functions or

systems according to signal from the front door lock

actuator:

Central door locking system

Keyless entry system

Dome lamp

.

TECHNICAL DESCRIPTION (COMMENT)

If the signal is not normal, the functions or systems

described in "CIRCUIT OPERATION" do not work

normally.

.

TROUBLESHOOTING HINTS

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

The front door lock actuator may be defective

The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector

The ETACS-ECU may be defective

Page 460 of 1500

INPUT SIGNAL PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-460

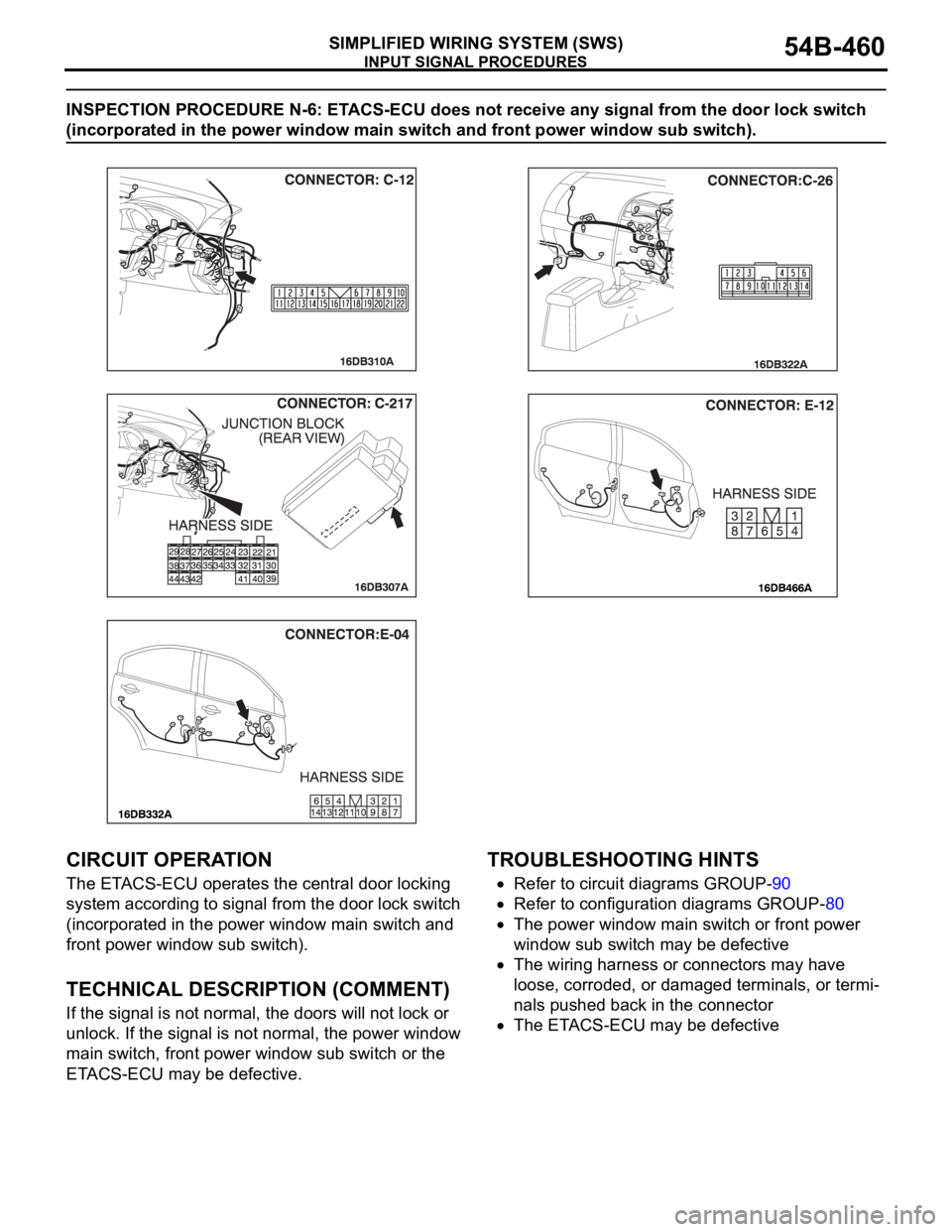

INSPECTION PROCEDURE N-6: ETACS-ECU does not receive any signal from the door lock switch

(incorporated in the power window main switch and front power window sub switch).

.

CIRCUIT OPERATION

The ETACS-ECU operates the central door locking

system according to signal from the door lock switch

(incorporated in the power window main switch and

front power window sub switch).

.

TECHNICAL DESCRIPTION (COMMENT)

If the signal is not normal, the doors will not lock or

unlock. If the signal is not normal, the power window

main switch, front power window sub switch or the

ETACS-ECU may be defective.

.

TROUBLESHOOTING HINTS

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

The power window main switch or front power

window sub switch may be defective

The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector

The ETACS-ECU may be defective

Page 469 of 1500

INPUT SIGNAL PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-469

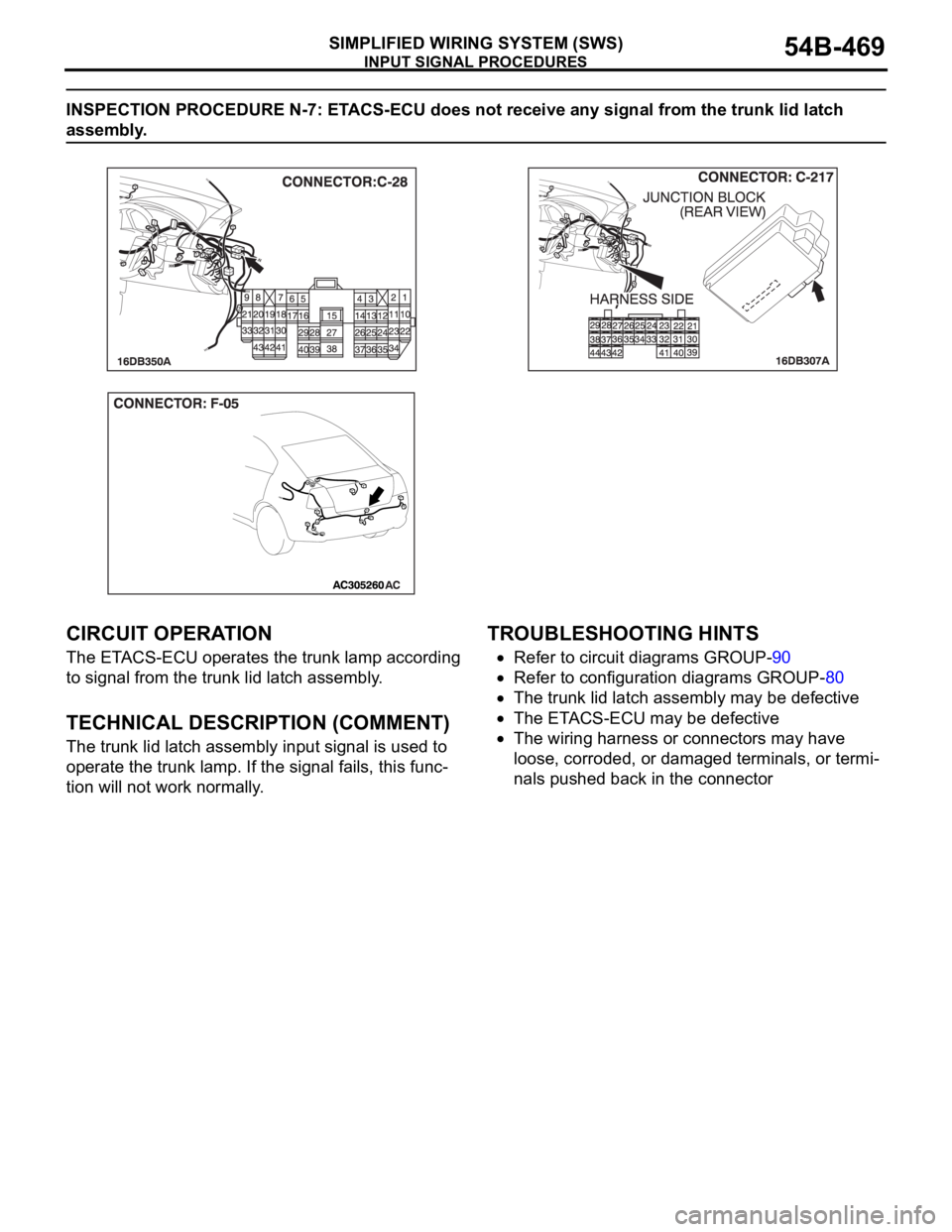

INSPECTION PROCEDURE N-7: ETACS-ECU does not receive any signal from the trunk lid latch

assembly.

.

CIRCUIT OPERATION

The ETACS-ECU operates the trunk lamp according

to signal from the trunk lid latch assembly.

.

TECHNICAL DESCRIPTION (COMMENT)

The trunk lid latch assembly input signal is used to

operate the trunk lamp. If the signal fails, this func-

tion will not work normally.

.

TROUBLESHOOTING HINTS

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

The trunk lid latch assembly may be defective

The ETACS-ECU may be defective

The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector

Page 472 of 1500

INPUT SIGNAL PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-472

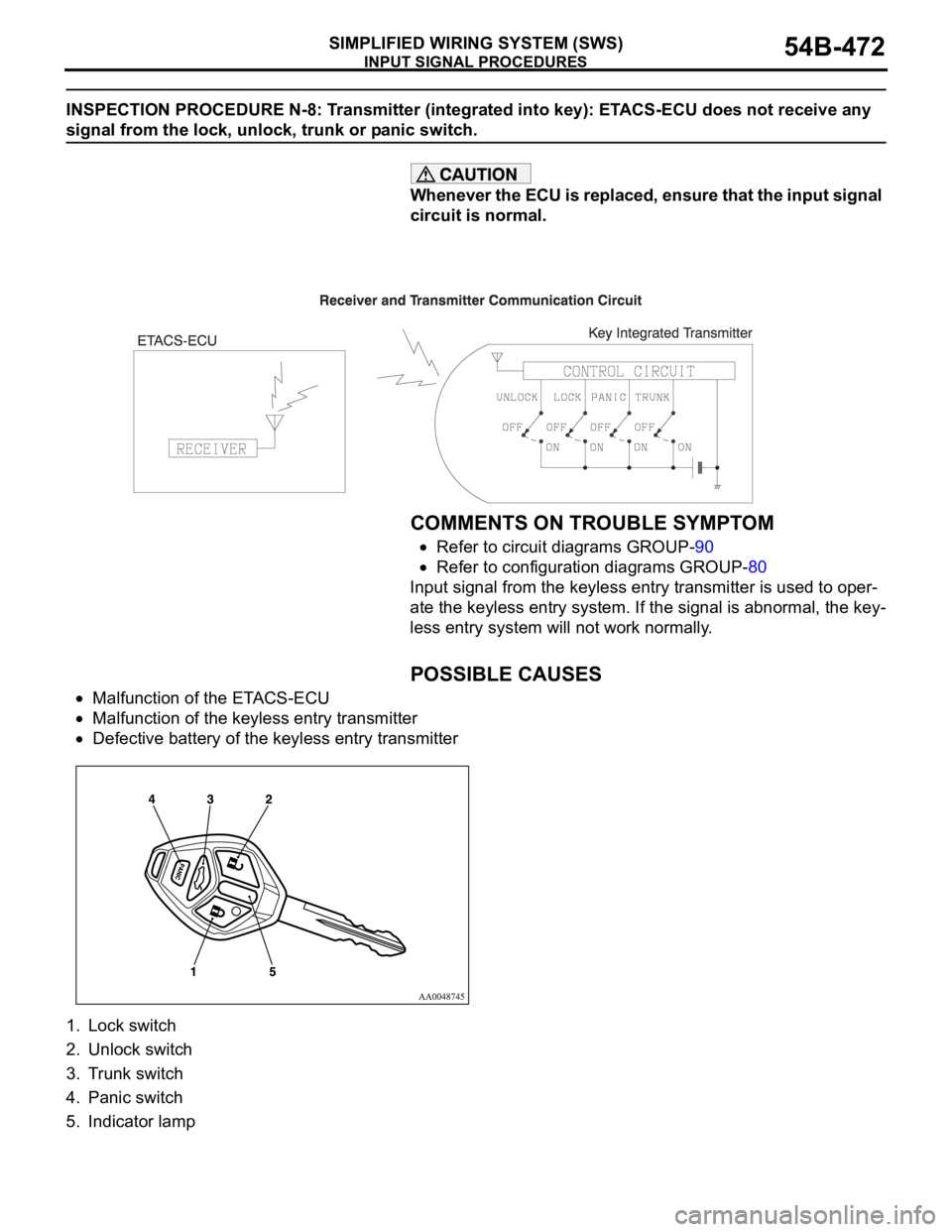

INSPECTION PROCEDURE N-8: Transmitter (integrated into key): ETACS-ECU does not receive any

signal from the lock, unlock, trunk or panic switch.

Whenever the ECU is replaced, ensure that the input signal

circuit is normal.

.

COMMENTS ON TROUBLE SYMPTOM

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

Input signal from the keyless entry transmitter is used to oper-

ate the keyless entry system. If the signal is abnormal, the key-

less entry system will not work normally.

.

POSSIBLE CAUSES

Malfunction of the ETACS-ECU

Malfunction of the keyless entry transmitter

Defective battery of the keyless entry transmitter

1. Lock switch

2. Unlock switch

3. Trunk switch

4. Panic switch

5. Indicator lamp

Page 474 of 1500

INPUT SIGNAL PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)54B-474

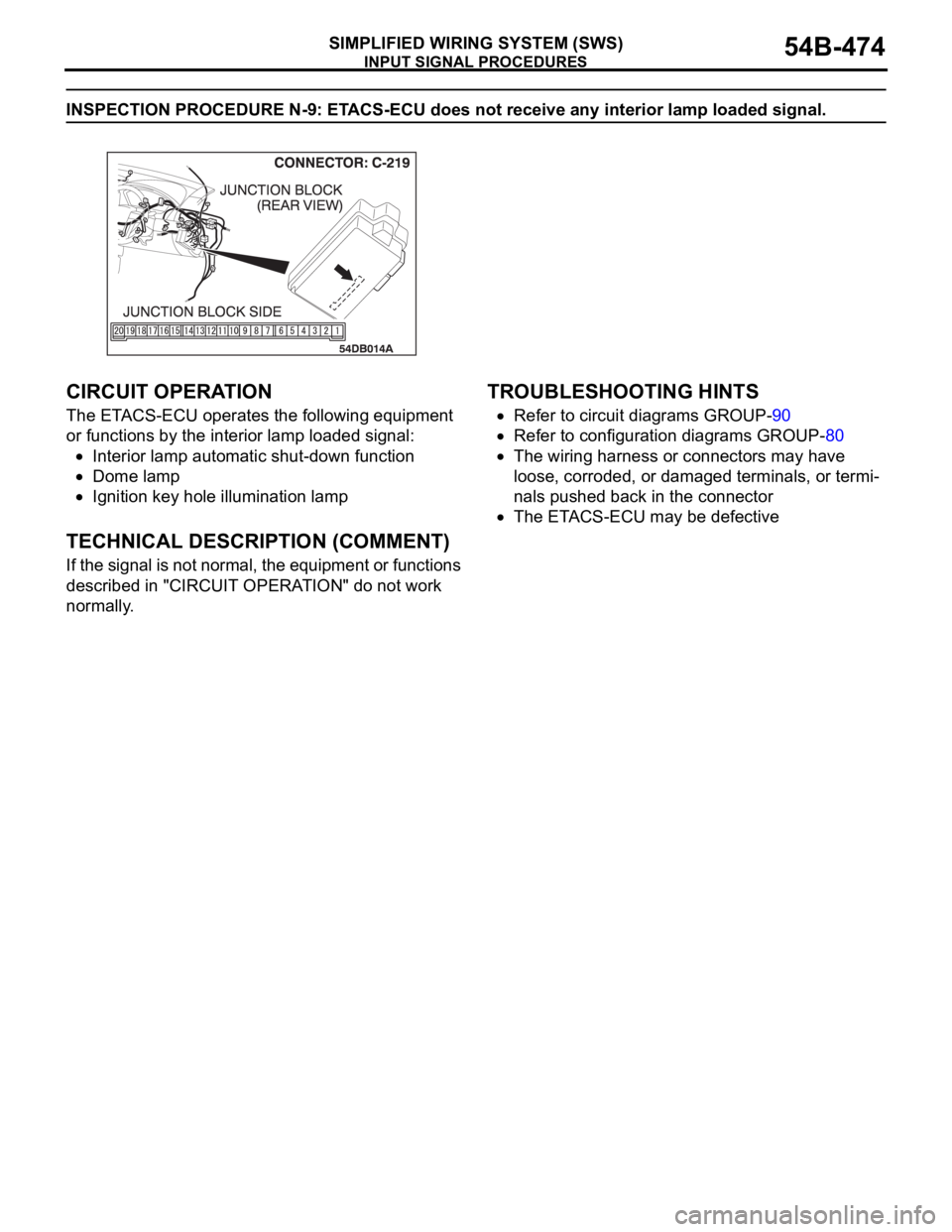

INSPECTION PROCEDURE N-9: ETACS-ECU does not receive any interior lamp loaded signal.

.

CIRCUIT OPERATION

The ETACS-ECU operates the following equipment

or functions by the interior lamp loaded signal:

Interior lamp automatic shut-down function

Dome lamp

Ignition key hole illumination lamp

.

TECHNICAL DESCRIPTION (COMMENT)

If the signal is not normal, the equipment or functions

described in "CIRCUIT OPERATION" do not work

normally.

.

TROUBLESHOOTING HINTS

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector

The ETACS-ECU may be defective

Page 512 of 1500

FRONT SEAT ASSEMBLY

INTERIOR52A-23

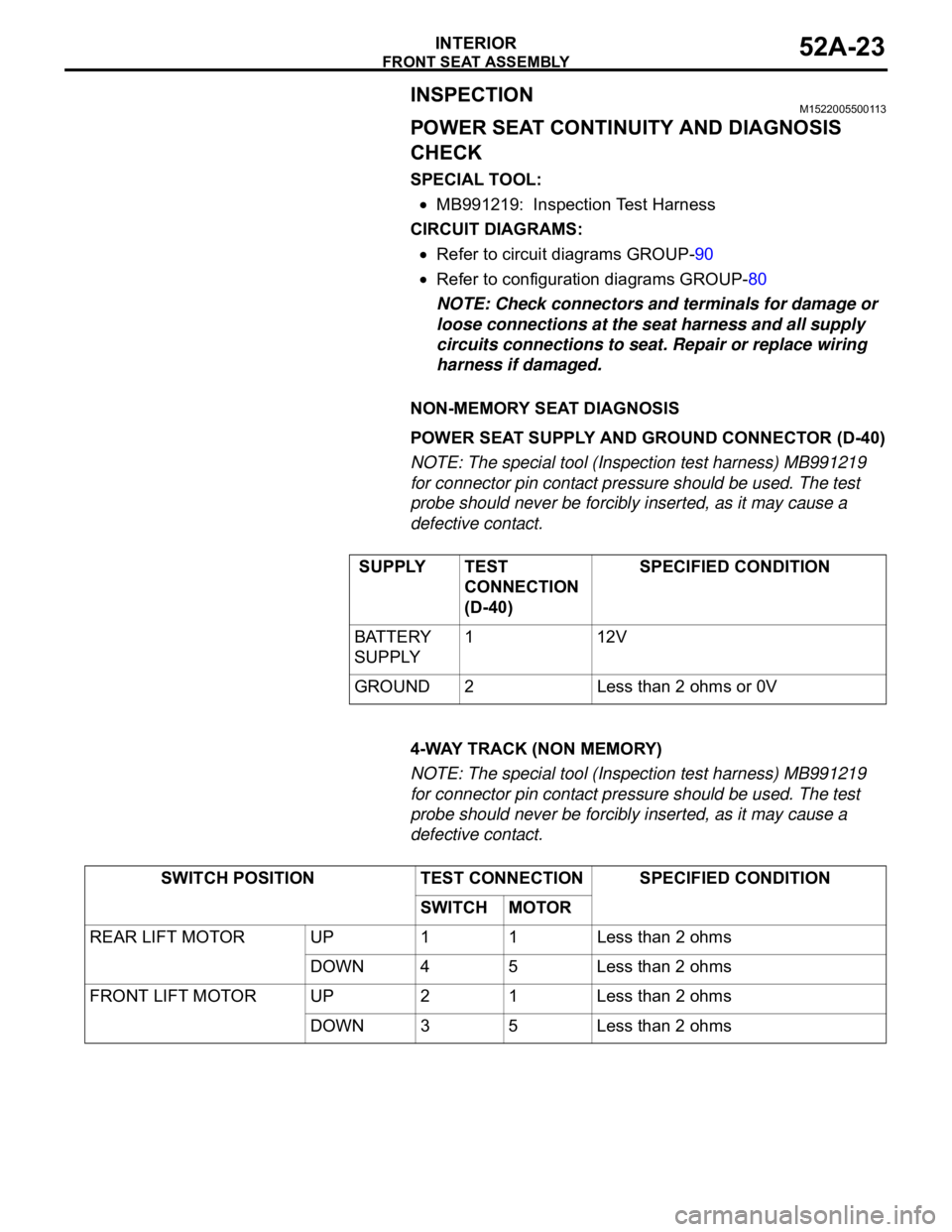

INSPECTIONM1522005500113

POWER SEAT CONTINUITY AND DIAGNOSIS

CHECK

SPECIAL TOOL:

MB991219: Inspection Test Harness

CIRCUIT DIAGRAMS:

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

NOTE: Check connectors and terminals for damage or

loose connections at the seat harness and all supply

circuits connections to seat. Repair or replace wiring

harness if damaged.

NON-MEMORY SEAT DIAGNOSIS

POWER SEAT SUPPLY AND GROUND CONNECTOR (D-40)

NOTE: The special tool (Inspection test harness) MB991219

for connector pin contact pressure should be used. The test

probe should never be forcibly inserted, as it may cause a

defective contact.

4-WAY TRACK (NON MEMORY)

NOTE: The special tool (Inspection test harness) MB991219

for connector pin contact pressure should be used. The test

probe should never be forcibly inserted, as it may cause a

defective contact. SUPPLY TEST

CONNECTION

(D-40) SPECIFIED CONDITION

BATTERY

SUPPLY112V

GROUND 2 Less than 2 ohms or 0V

SWITCH POSITION TEST CONNECTION SPECIFIED CONDITION

SWITCH MOTOR

REAR LIFT MOTOR UP 1 1 Less than 2 ohms

DOWN 4 5 Less than 2 ohms

FRONT LIFT MOTOR UP 2 1 Less than 2 ohms

DOWN 3 5 Less than 2 ohms

Page 514 of 1500

FRONT SEAT ASSEMBLY

INTERIOR52A-25

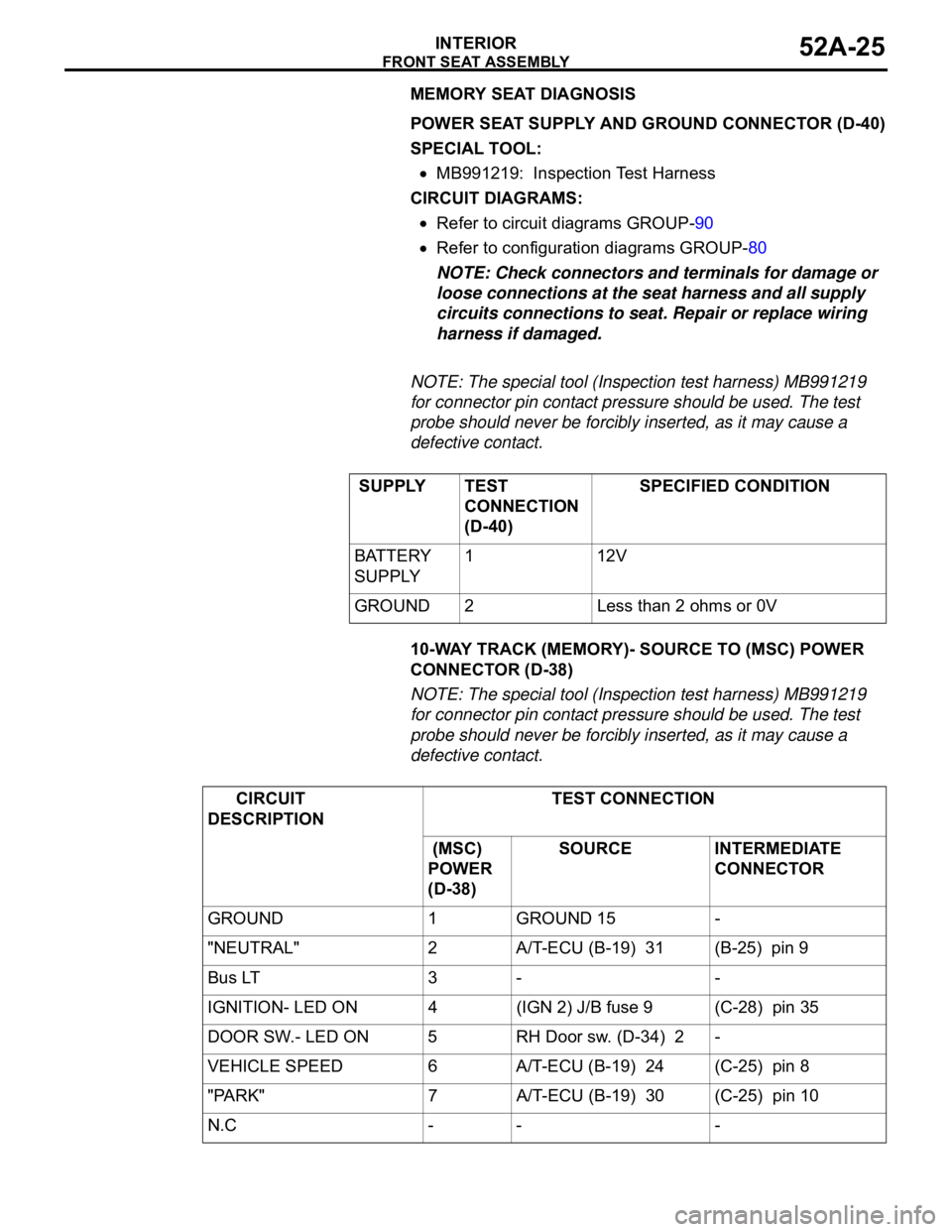

MEMORY SEAT DIAGNOSIS

POWER SEAT SUPPLY AND GROUND CONNECTOR (D-40)

SPECIAL TOOL:

MB991219: Inspection Test Harness

CIRCUIT DIAGRAMS:

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

NOTE: Check connectors and terminals for damage or

loose connections at the seat harness and all supply

circuits connections to seat. Repair or replace wiring

harness if damaged.

NOTE: The special tool (Inspection test harness) MB991219

for connector pin contact pressure should be used. The test

probe should never be forcibly inserted, as it may cause a

defective contact.

10-WAY TRACK (MEMORY)- SOURCE TO (MSC) POWER

CONNECTOR (D-38)

NOTE: The special tool (Inspection test harness) MB991219

for connector pin contact pressure should be used. The test

probe should never be forcibly inserted, as it may cause a

defective contact. SUPPLY TEST

CONNECTION

(D-40) SPECIFIED CONDITION

BATTERY

SUPPLY112V

GROUND 2 Less than 2 ohms or 0V

CIRCUIT

DESCRIPTION TEST CONNECTION

(MSC)

POWER

(D-38) SOURCE INTERMEDIATE

CONNECTOR

GROUND 1 GROUND 15 -

"NEUTRAL" 2 A/T-ECU (B-19) 31 (B-25) pin 9

Bus LT 3 - -

IGNITION- LED ON 4 (IGN 2) J/B fuse 9 (C-28) pin 35

DOOR SW.- LED ON 5 RH Door sw. (D-34) 2 -

VEHICLE SPEED 6 A/T-ECU (B-19) 24 (C-25) pin 8

"PARK" 7 A/T-ECU (B-19) 30 (C-25) pin 10

N.C - - -

Page 515 of 1500

FRONT SEAT ASSEMBLY

INTERIOR52A-26

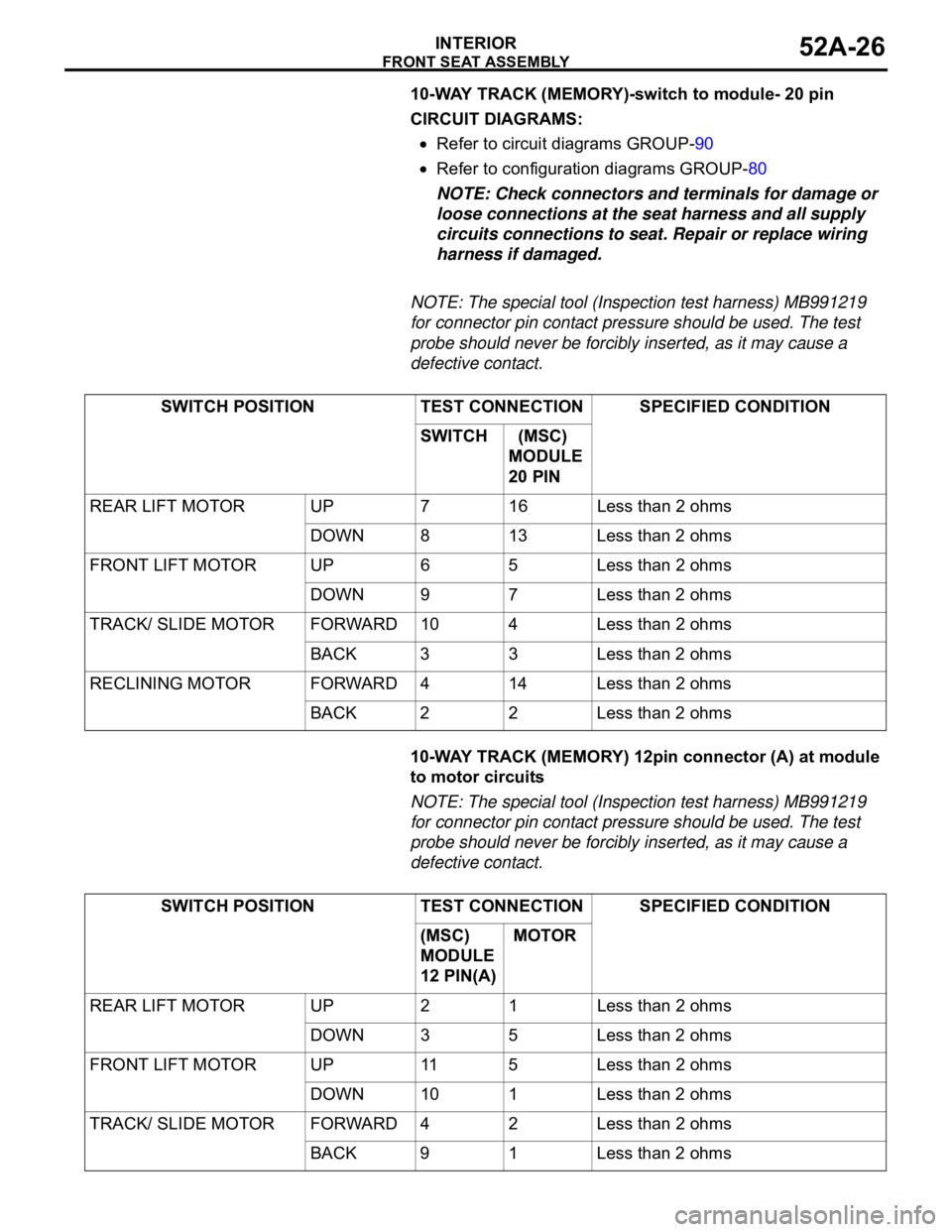

10-WAY TRACK (MEMORY)-switch to module- 20 pin

CIRCUIT DIAGRAMS:

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

NOTE: Check connectors and terminals for damage or

loose connections at the seat harness and all supply

circuits connections to seat. Repair or replace wiring

harness if damaged.

NOTE: The special tool (Inspection test harness) MB991219

for connector pin contact pressure should be used. The test

probe should never be forcibly inserted, as it may cause a

defective contact.

10-WAY TRACK (MEMORY) 12pin connector (A) at module

to motor circuits

NOTE: The special tool (Inspection test harness) MB991219

for connector pin contact pressure should be used. The test

probe should never be forcibly inserted, as it may cause a

defective contact. SWITCH POSITION TEST CONNECTION SPECIFIED CONDITION

SWITCH (MSC)

MODULE

20 PIN

REAR LIFT MOTOR UP 7 16 Less than 2 ohms

DOWN 8 13 Less than 2 ohms

FRONT LIFT MOTOR UP 6 5 Less than 2 ohms

DOWN 9 7 Less than 2 ohms

TRACK/ SLIDE MOTOR FORWARD 10 4 Less than 2 ohms

BACK 3 3 Less than 2 ohms

RECLINING MOTOR FORWARD 4 14 Less than 2 ohms

BACK 2 2 Less than 2 ohms

SWITCH POSITION TEST CONNECTION SPECIFIED CONDITION

(MSC)

MODULE

12 PIN(A) MOTOR

REAR LIFT MOTOR UP 2 1 Less than 2 ohms

DOWN 3 5 Less than 2 ohms

FRONT LIFT MOTOR UP 11 5 Less than 2 ohms

DOWN 10 1 Less than 2 ohms

TRACK/ SLIDE MOTOR FORWARD 4 2 Less than 2 ohms

BACK 9 1 Less than 2 ohms

Page 516 of 1500

FRONT SEAT ASSEMBLY

INTERIOR52A-27

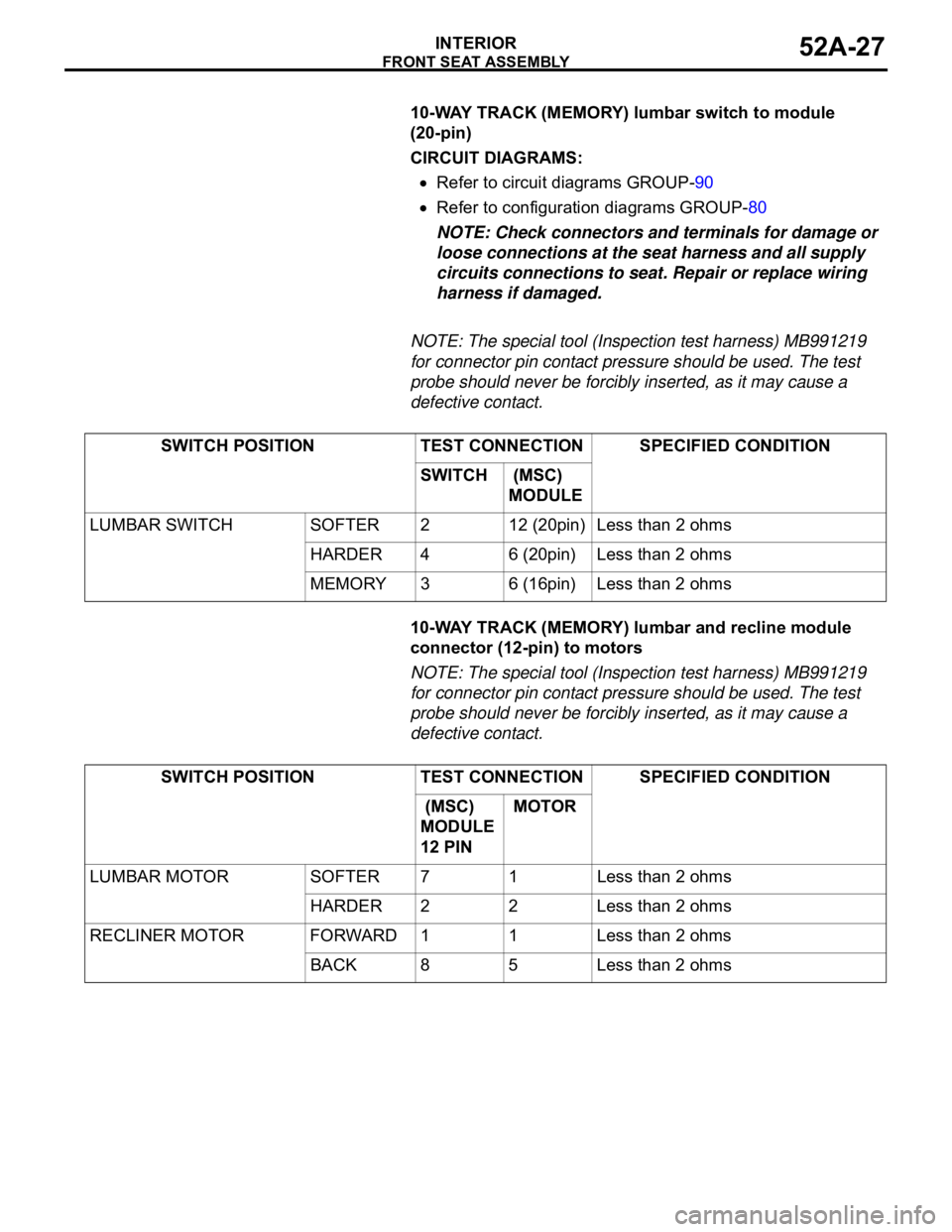

10-WAY TRACK (MEMORY) lumbar switch to module

(20-pin)

CIRCUIT DIAGRAMS:

Refer to circuit diagrams GROUP-90

Refer to configuration diagrams GROUP-80

NOTE: Check connectors and terminals for damage or

loose connections at the seat harness and all supply

circuits connections to seat. Repair or replace wiring

harness if damaged.

NOTE: The special tool (Inspection test harness) MB991219

for connector pin contact pressure should be used. The test

probe should never be forcibly inserted, as it may cause a

defective contact.

10-WAY TRACK (MEMORY) lumbar and recline module

connector (12-pin) to motors

NOTE: The special tool (Inspection test harness) MB991219

for connector pin contact pressure should be used. The test

probe should never be forcibly inserted, as it may cause a

defective contact. SWITCH POSITION TEST CONNECTION SPECIFIED CONDITION

SWITCH (MSC)

MODULE

LUMBAR SWITCH SOFTER 2 12 (20pin) Less than 2 ohms

HARDER 4 6 (20pin) Less than 2 ohms

MEMORY 3 6 (16pin) Less than 2 ohms

SWITCH POSITION TEST CONNECTION SPECIFIED CONDITION

(MSC)

MODULE

12 PIN MOTOR

LUMBAR MOTOR SOFTER 7 1 Less than 2 ohms

HARDER 2 2 Less than 2 ohms

RECLINER MOTOR FORWARD 1 1 Less than 2 ohms

BACK 8 5 Less than 2 ohms